Patents

Literature

78results about How to "There will be no stuck" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

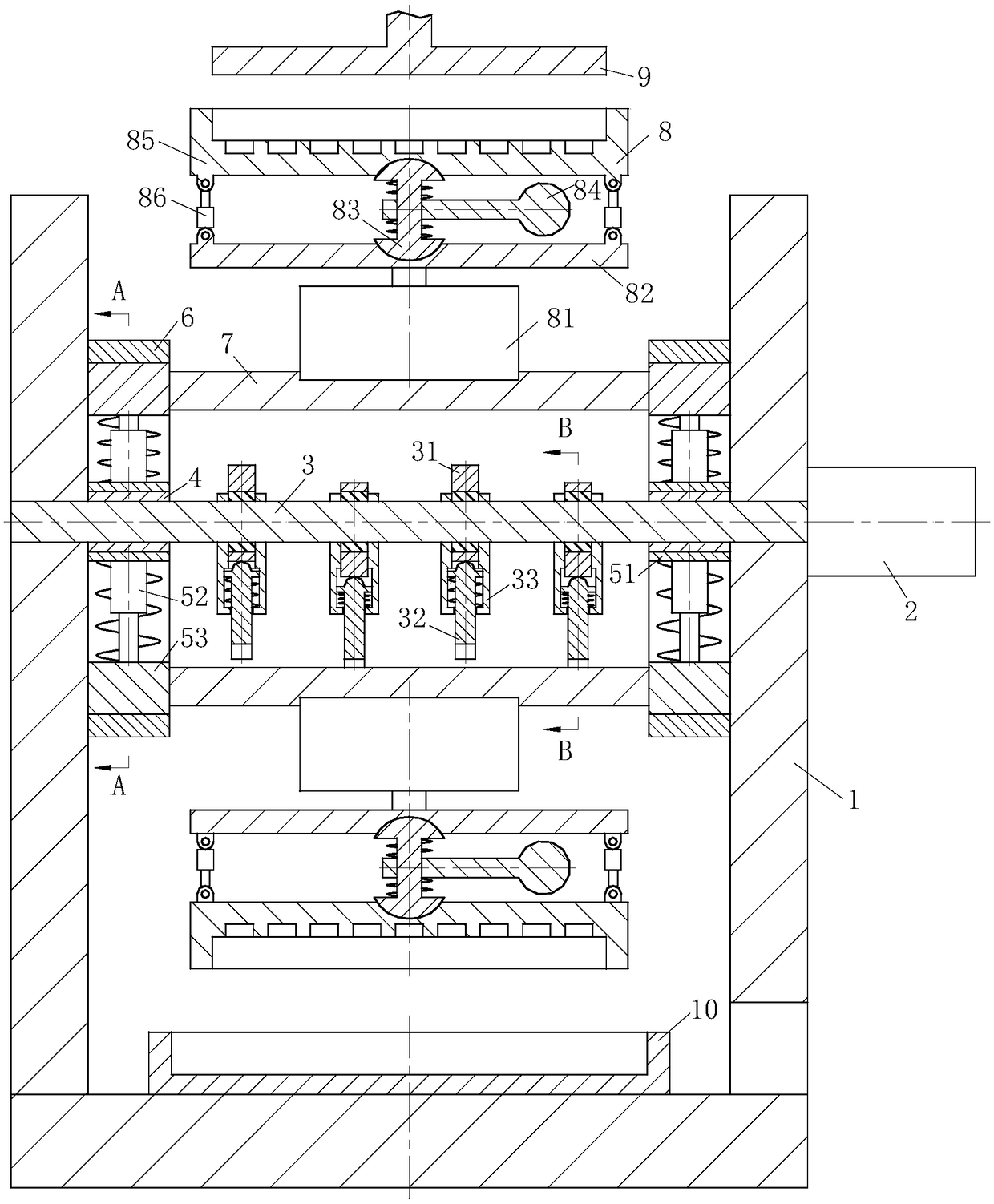

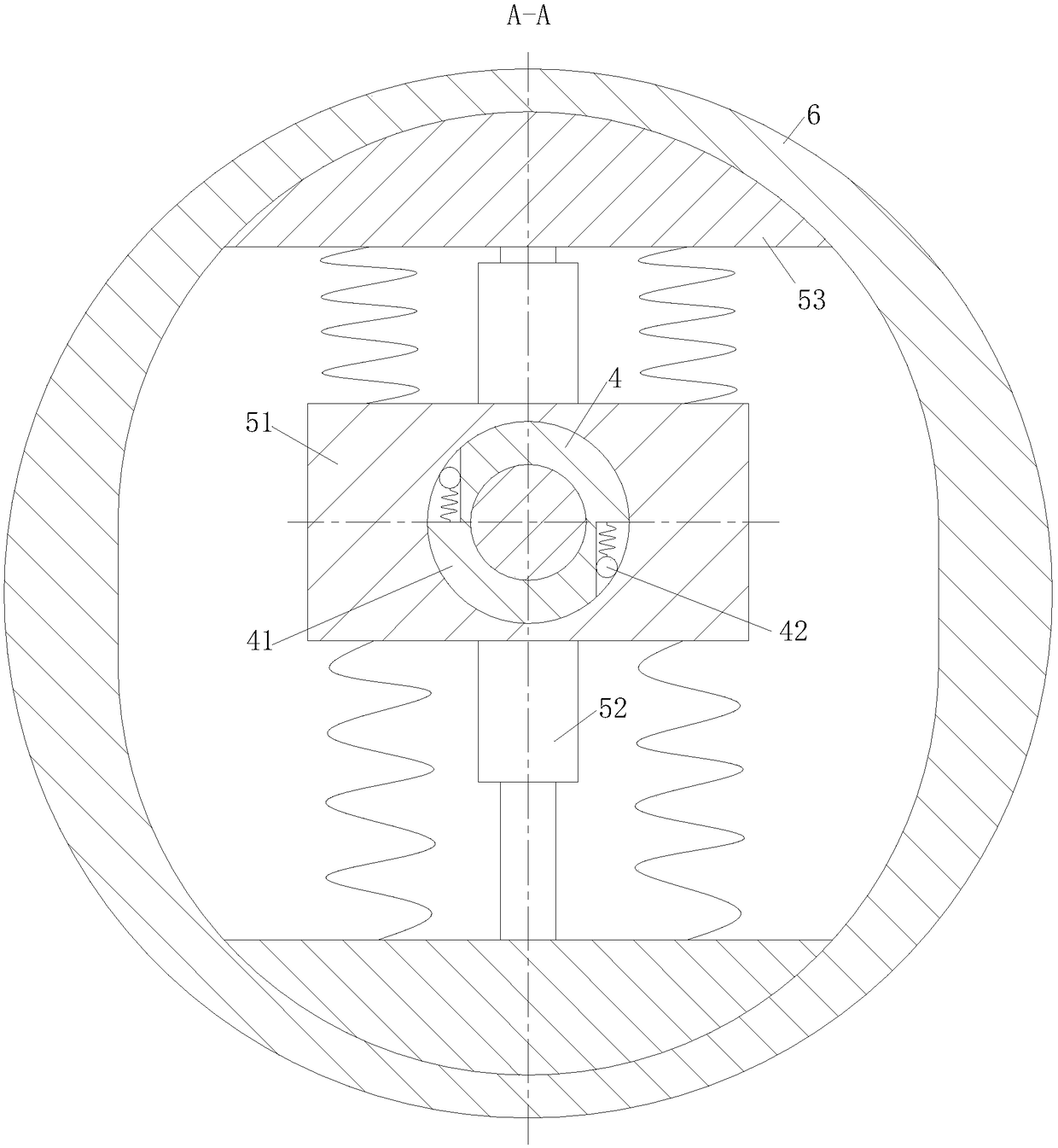

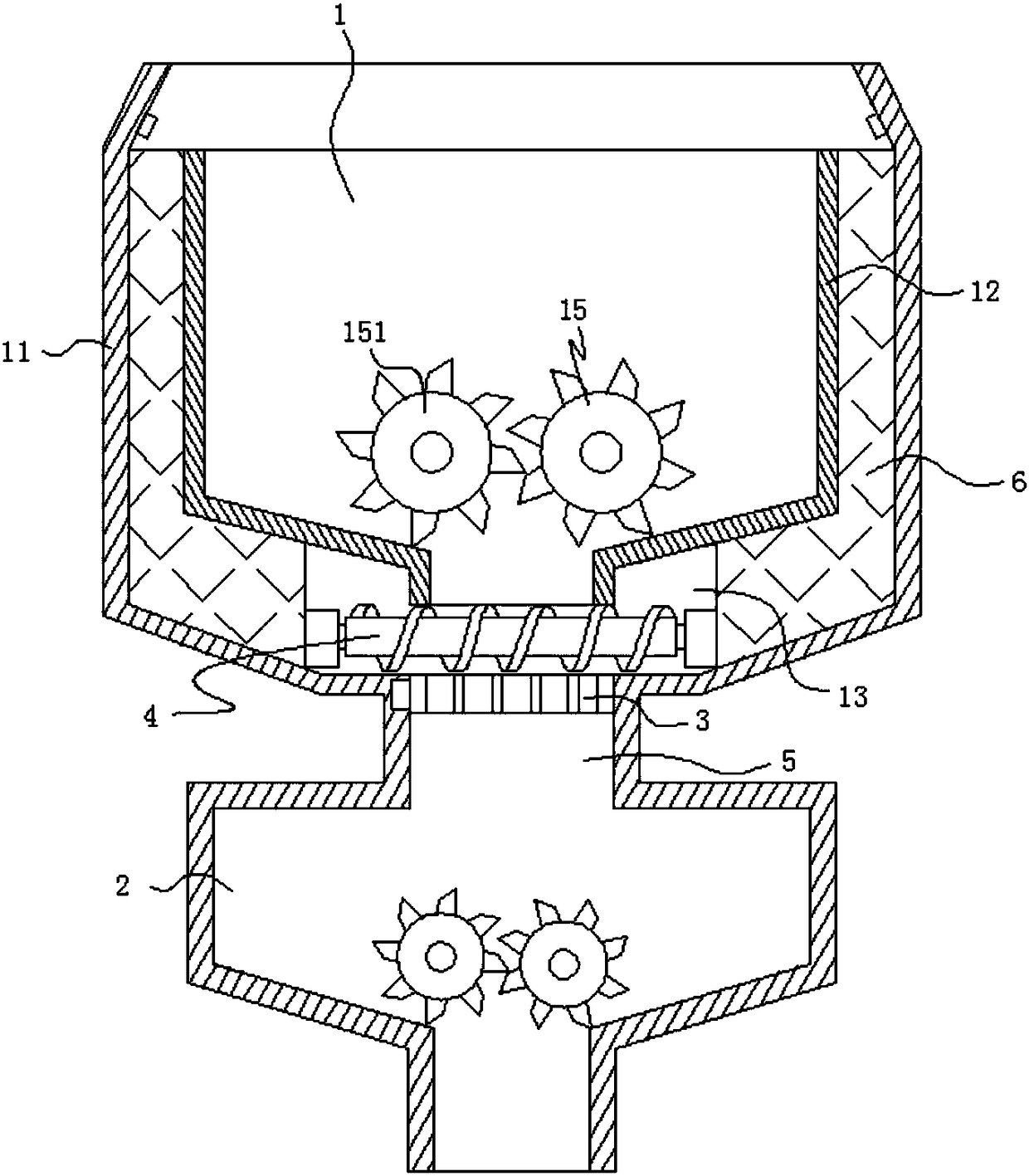

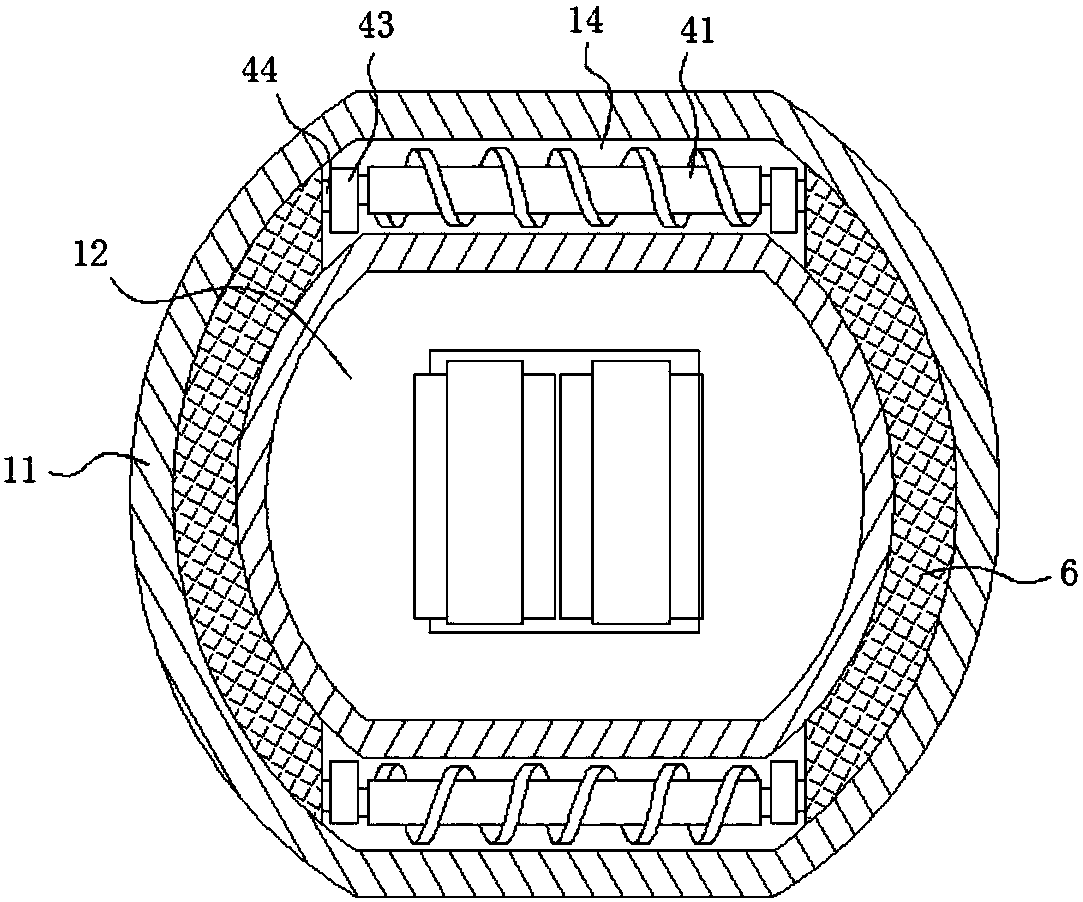

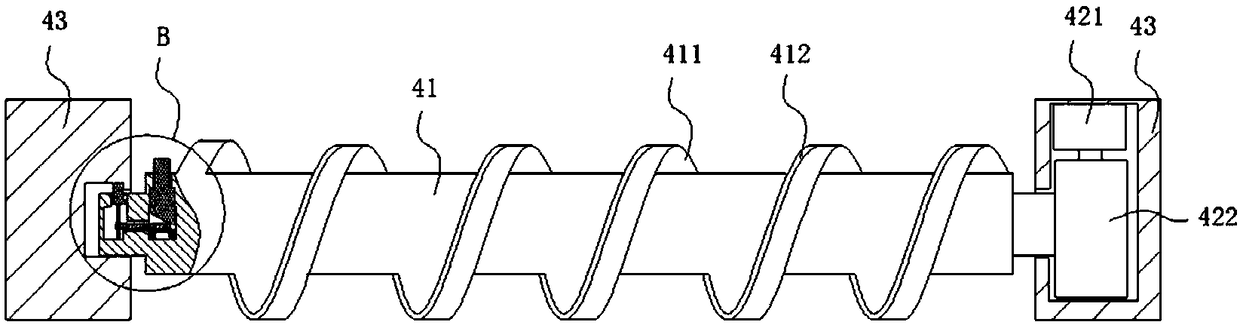

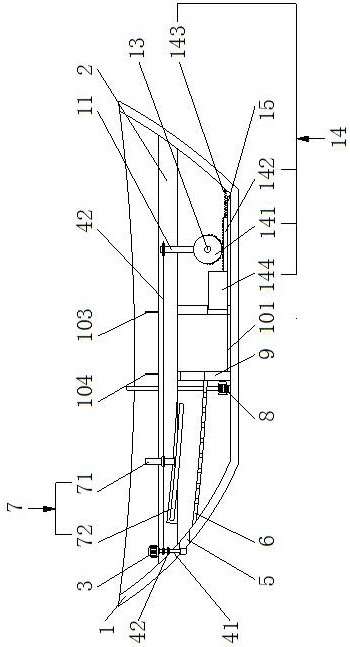

Household garbage crushing sorting system

ActiveCN104874582AThere will be no stuckStuck situation solvedSolid waste disposalGrain treatmentsSocial benefitsLitter

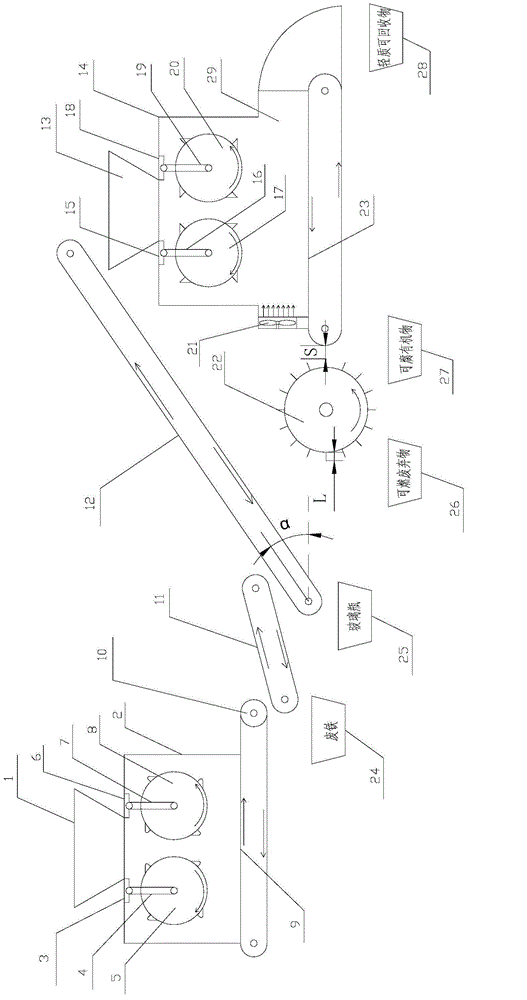

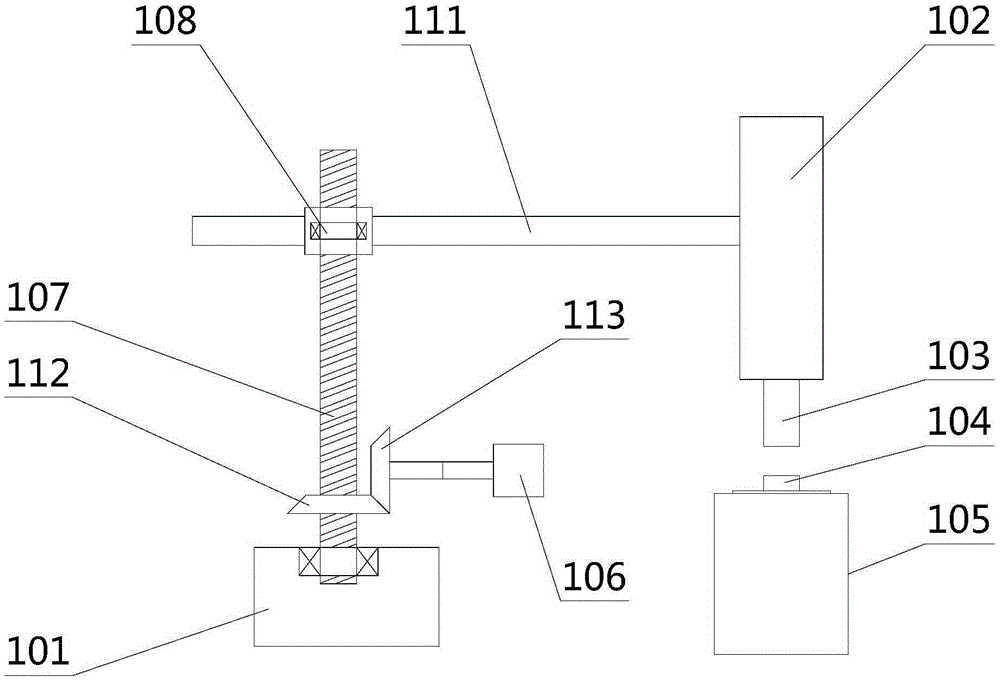

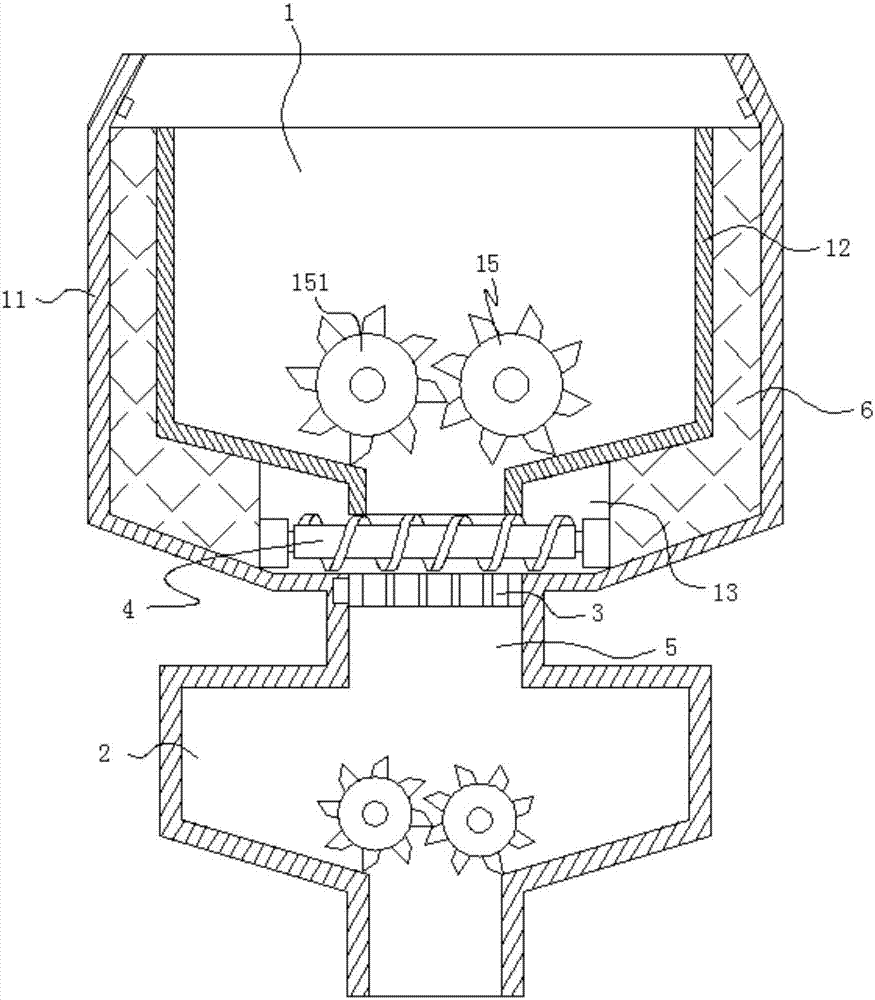

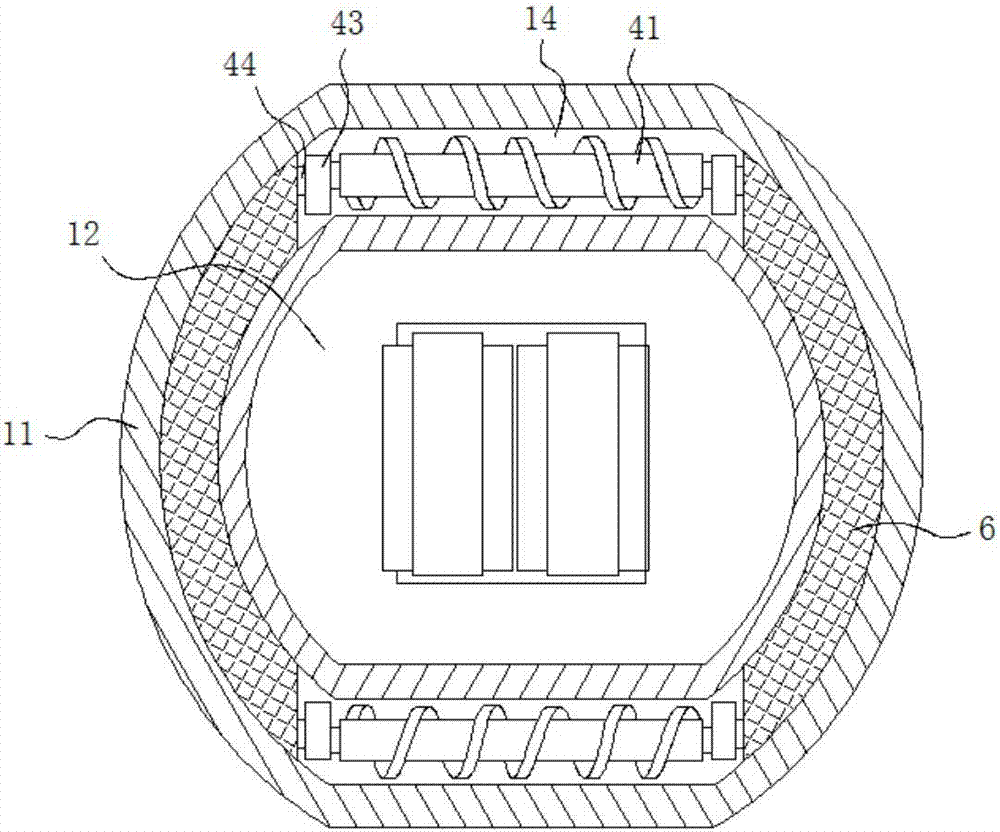

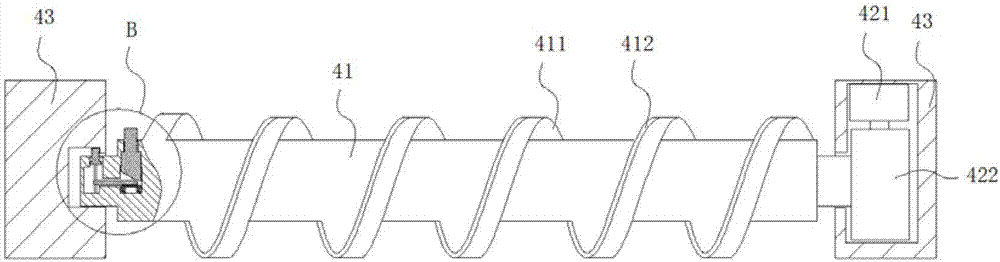

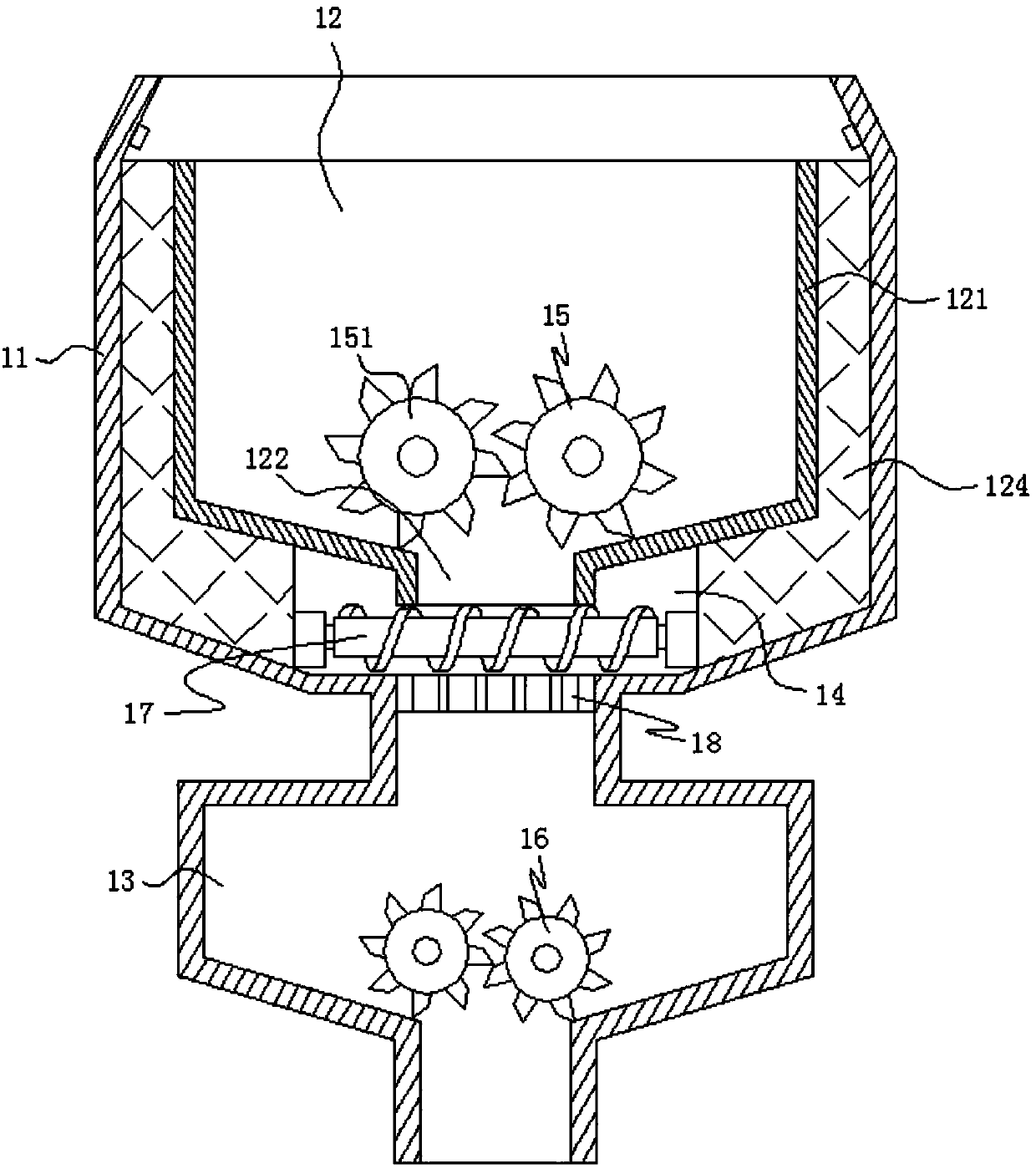

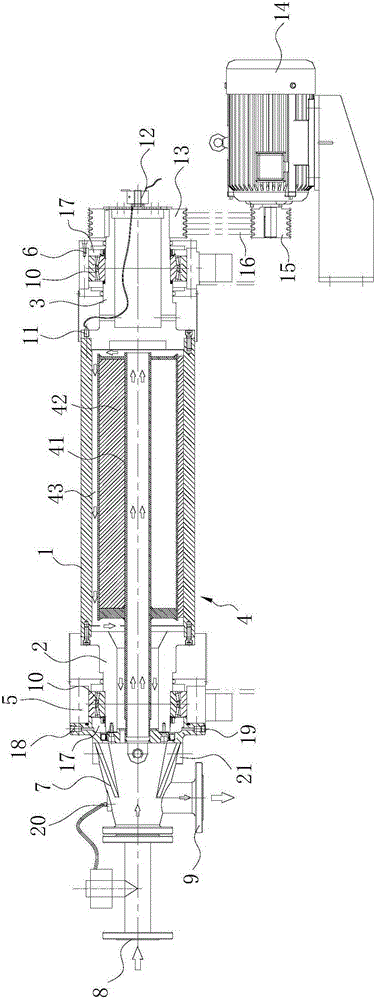

The invention discloses a household garbage crushing sorting system. The sorting system consists of a quantitative feeding device, a magnetic separation device, a gravity gradient sorting device, a pendulum type crushing device, an air separation device, a needle selection device and a material conveying device. The sorting system is compact in structure, can achieve continuous production, is high in production efficiency, simple to operate, safe and reliable, and can divide urban household garbage into decayable organic matter, combustible wastes, metal, glass and light recoverable matter, so that the urban household garbage can be sufficiently utilized as a resource, and the sorting system has very high environmental benefit and social benefit simultaneously.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Cutting machine with guiding function for gauze element production and processing

ActiveCN110861132AAvoid creasesAvoid offsetMetal working apparatusWebs handlingMechanical engineeringIndustrial engineering

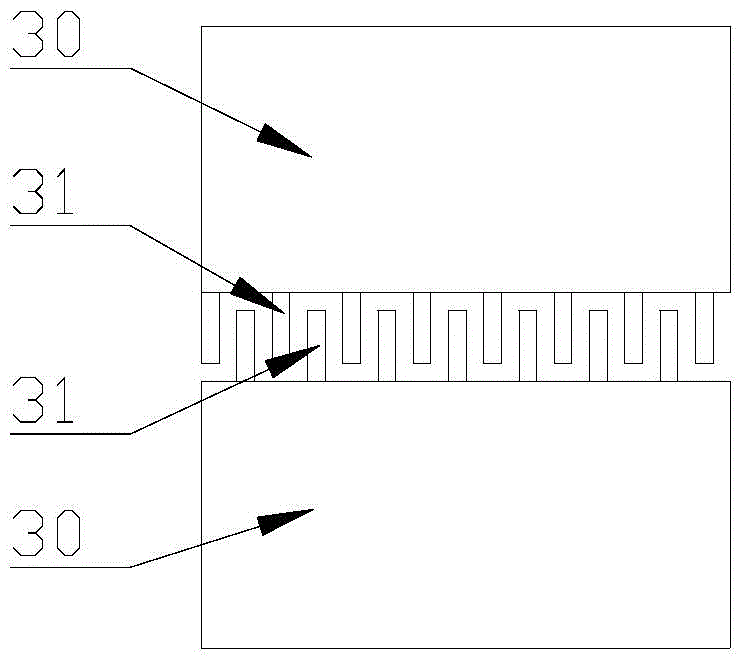

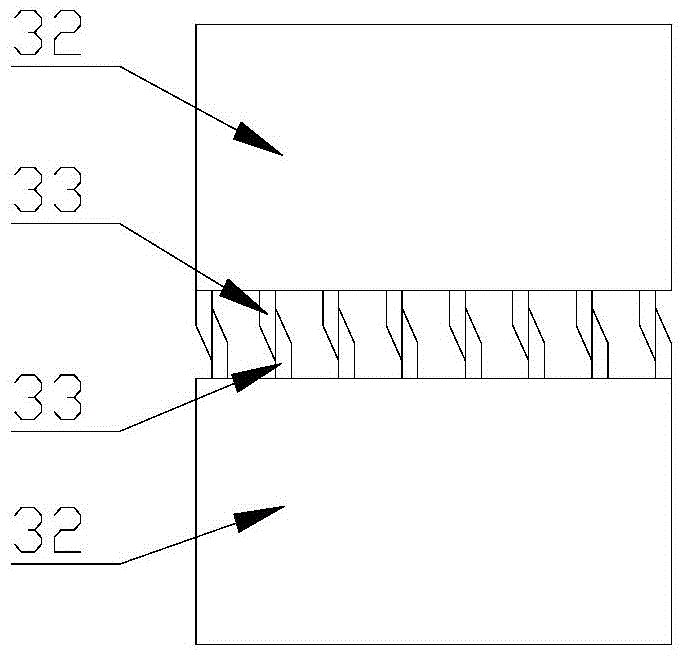

The invention relates to the field of gauze element production and processing devices, in particular to a cutting machine with a guiding function for gauze element production and processing. The cutting machine comprises a base, supporting legs, a discharge sleeve, a cutting structure, a feeding structure, a guiding structure and a discharging structure; the cutting structure can synchronously drive the feeding structure to work while the cutting structure is working, through the setting of the feeding structure, the feeding operation can be automatically conducted on a gauze element, the workintensity of manual feeding is reduced, the cut gauze element can further be leveled and limited, namely the wrinkle of the gauze element during cutting is avoided, the deviation of the gauze elementcaused by difficult fixation of the gauze element during cutting is also avoided, the guiding structure is arrange at the top end, close to one end of the feeding structure, of the base, the gauze element entering the feeding structure can be guided, the gauze element of the feeding structure is prevented from wrinkling and deviating, the guiding structure can be adjusted, and thus gauze elementswith different width can further be guided.

Owner:LIXIN FUYA GAUZE CO LTD

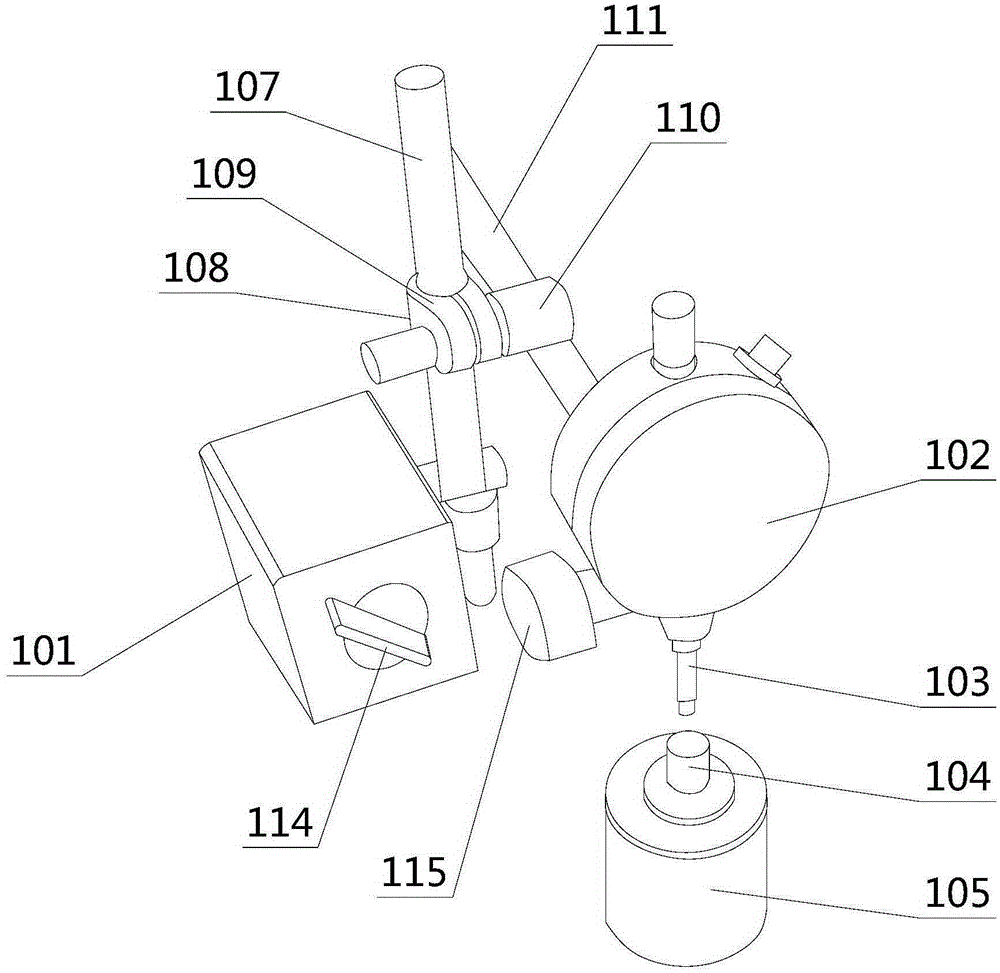

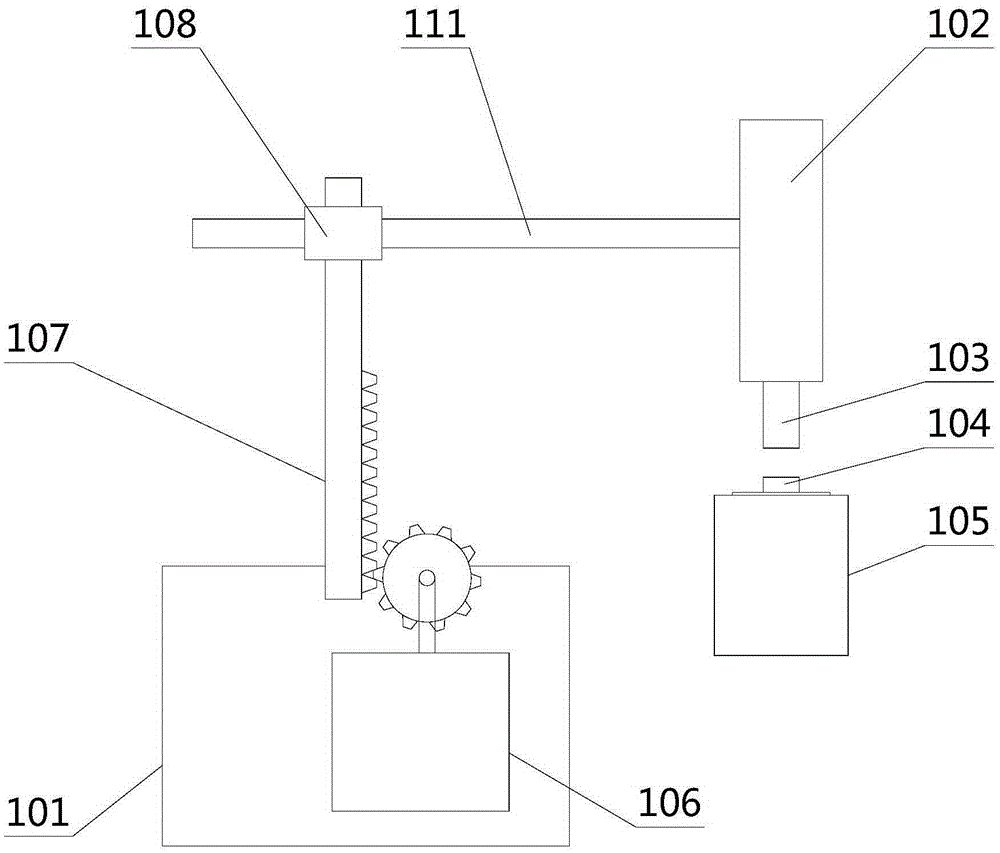

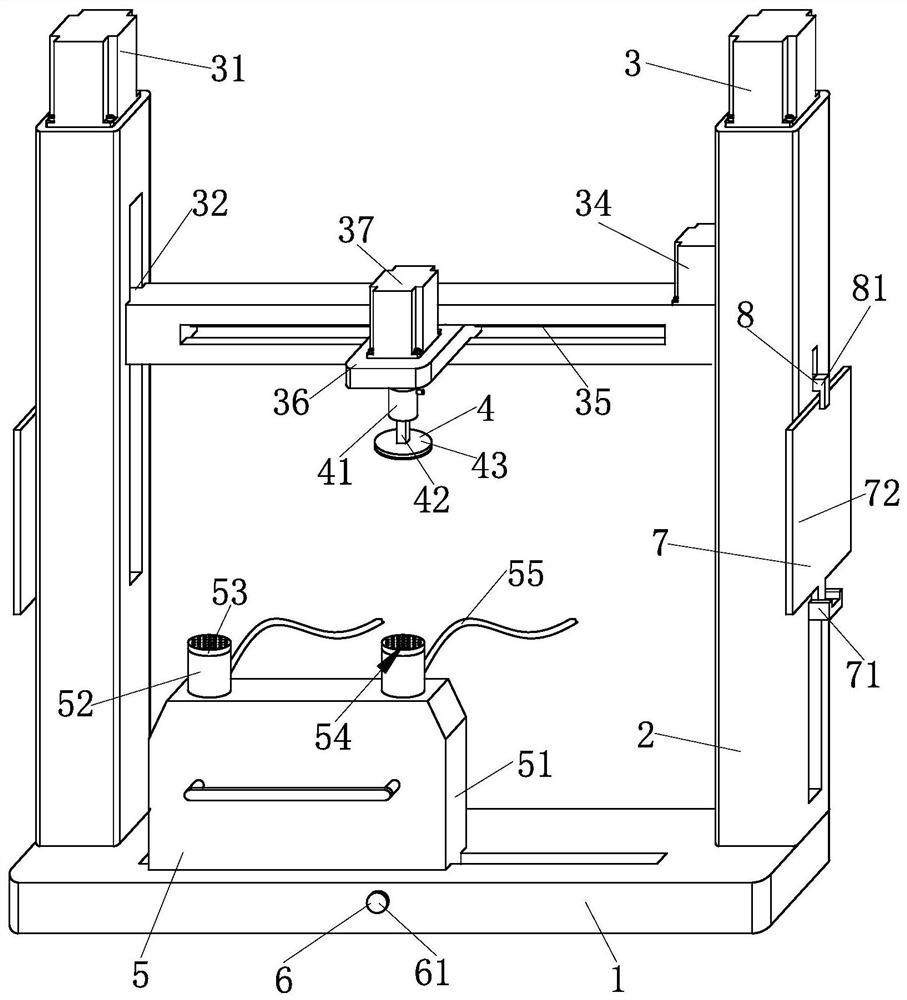

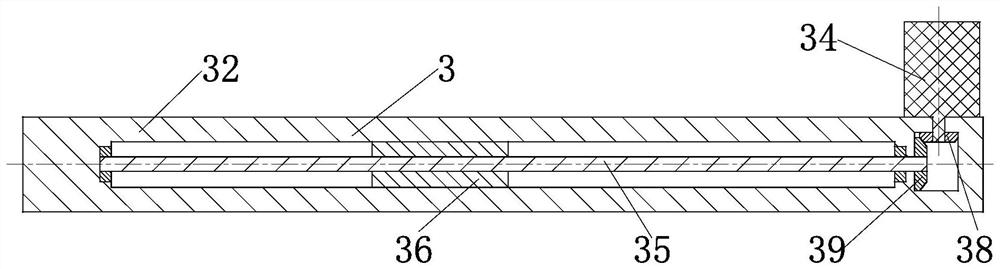

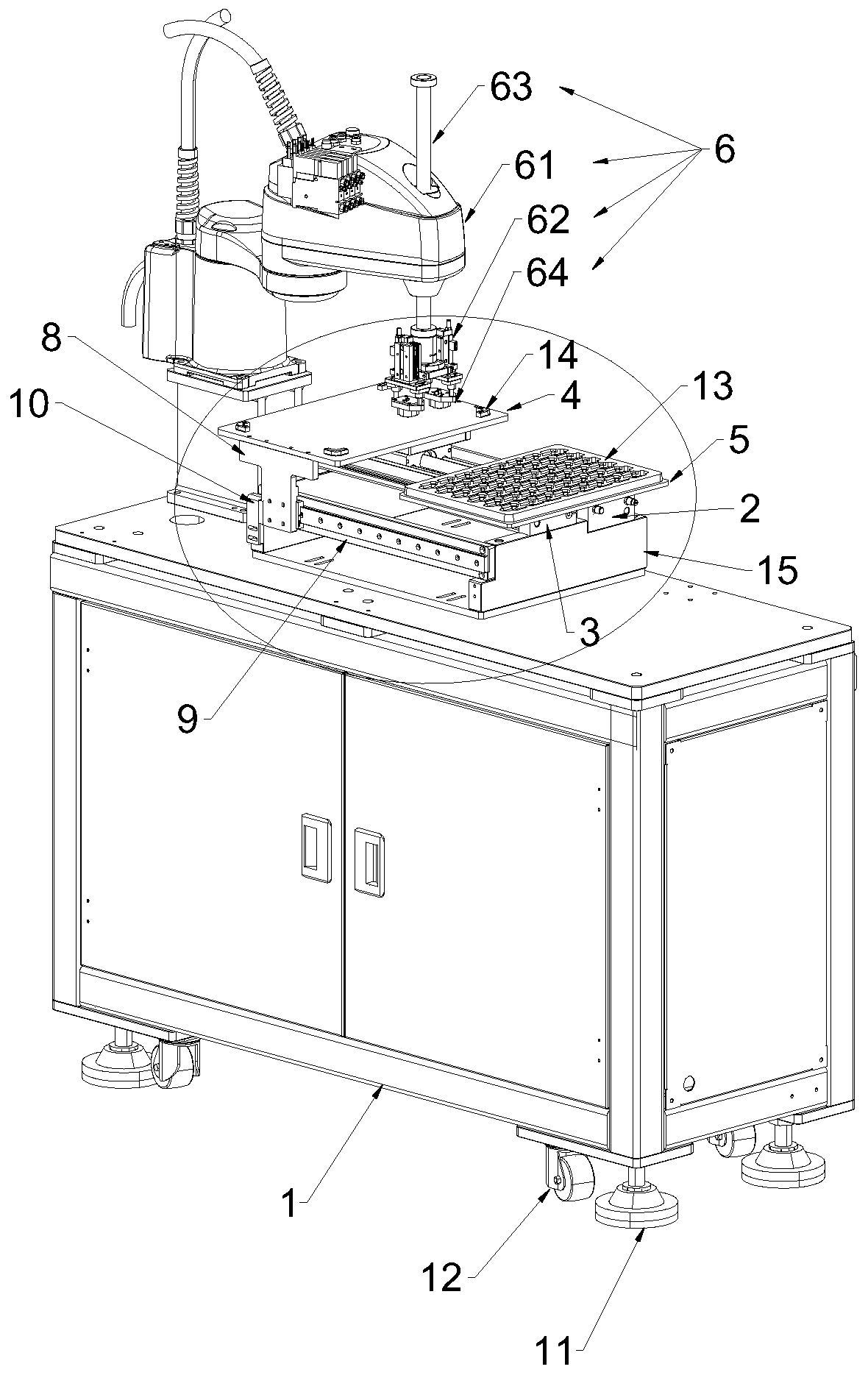

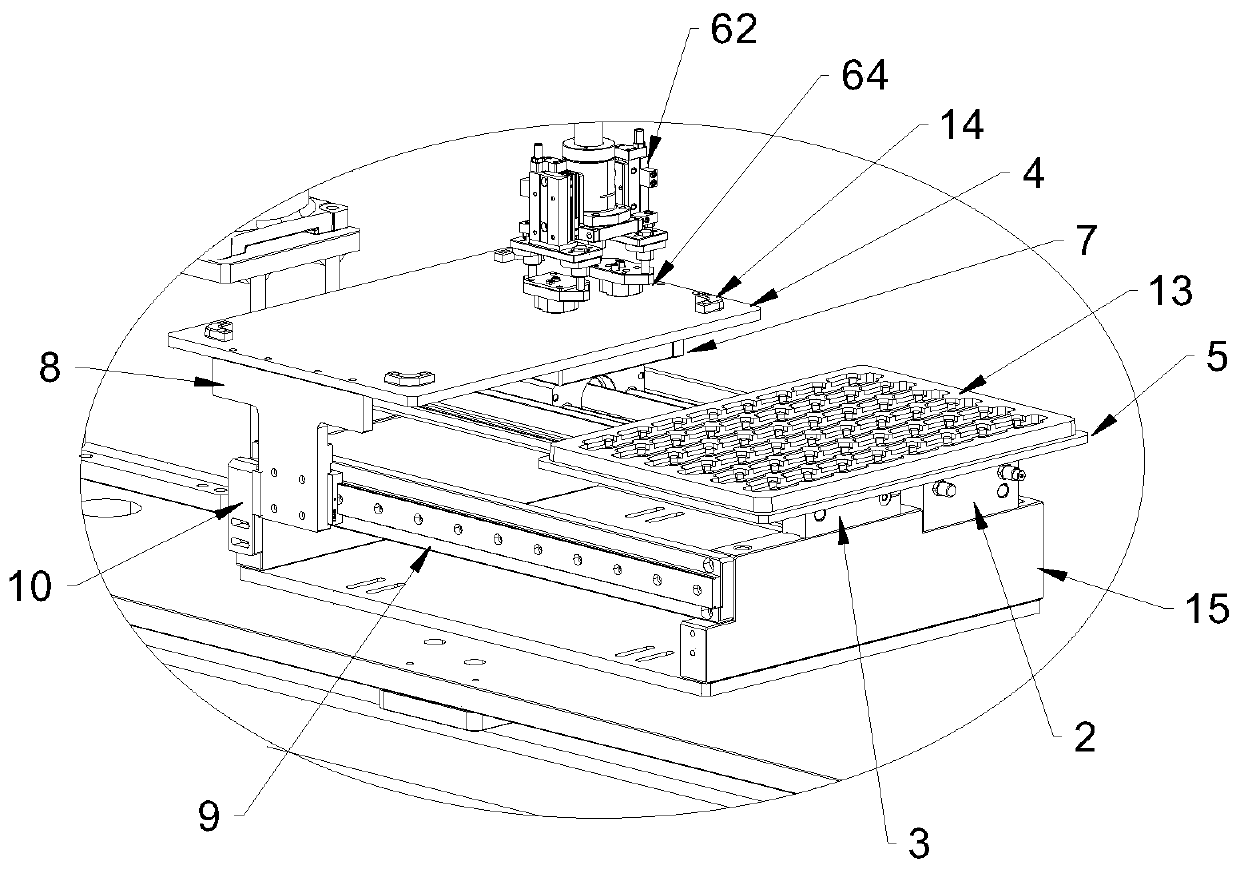

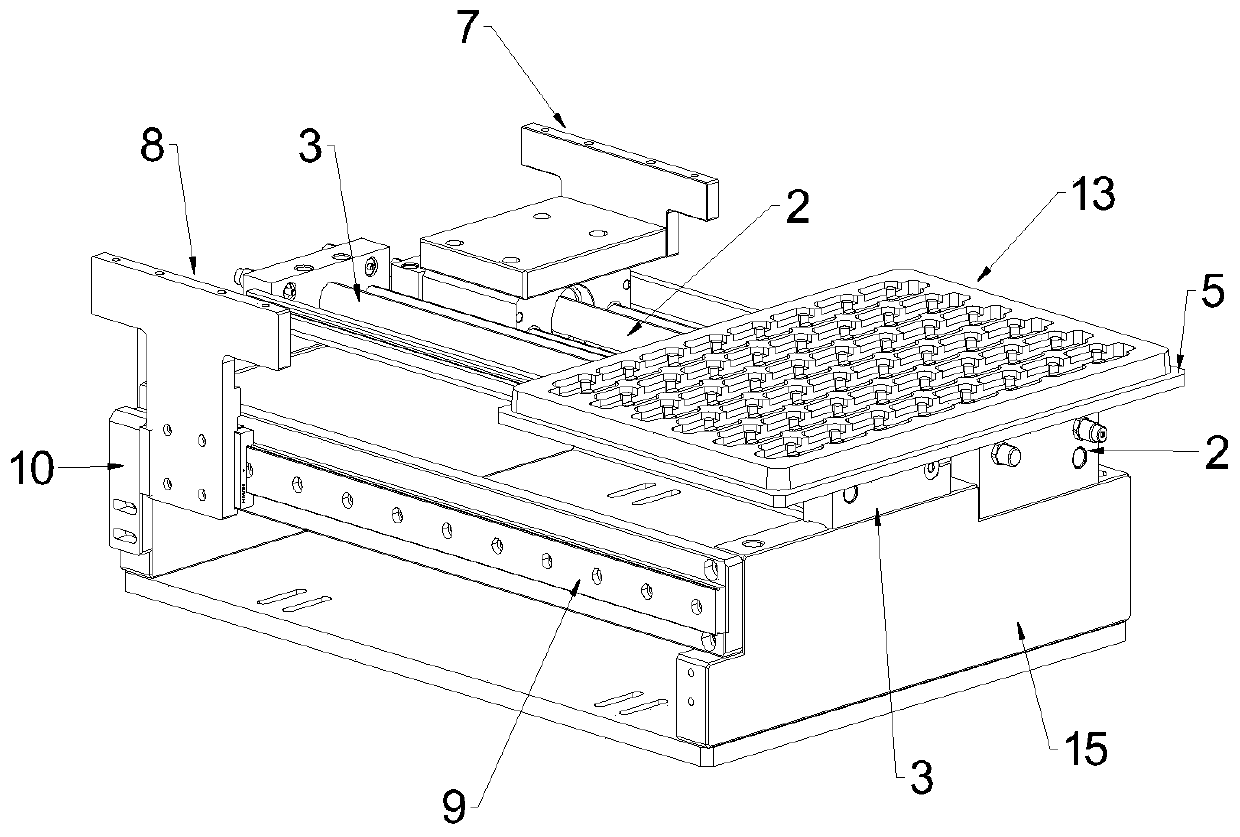

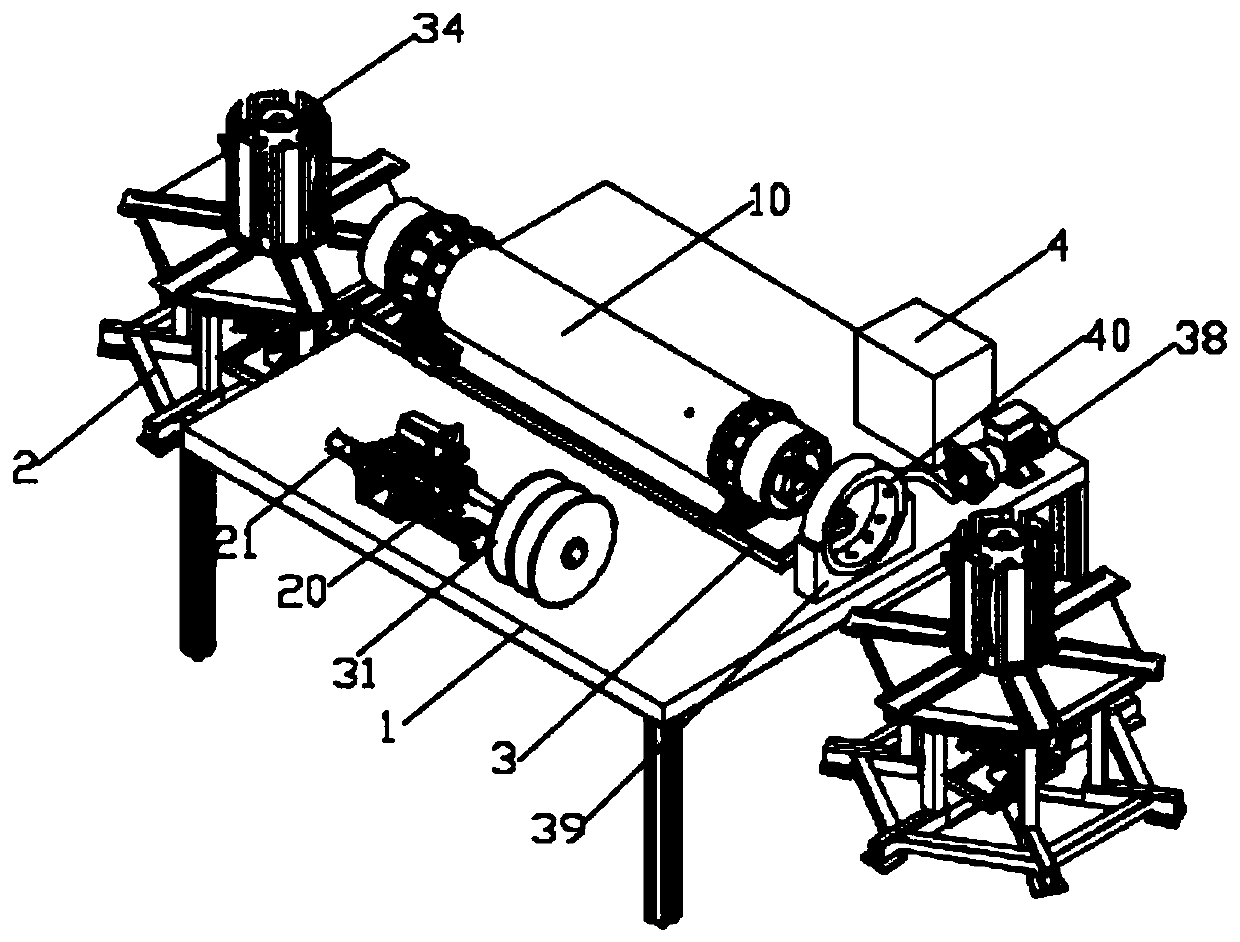

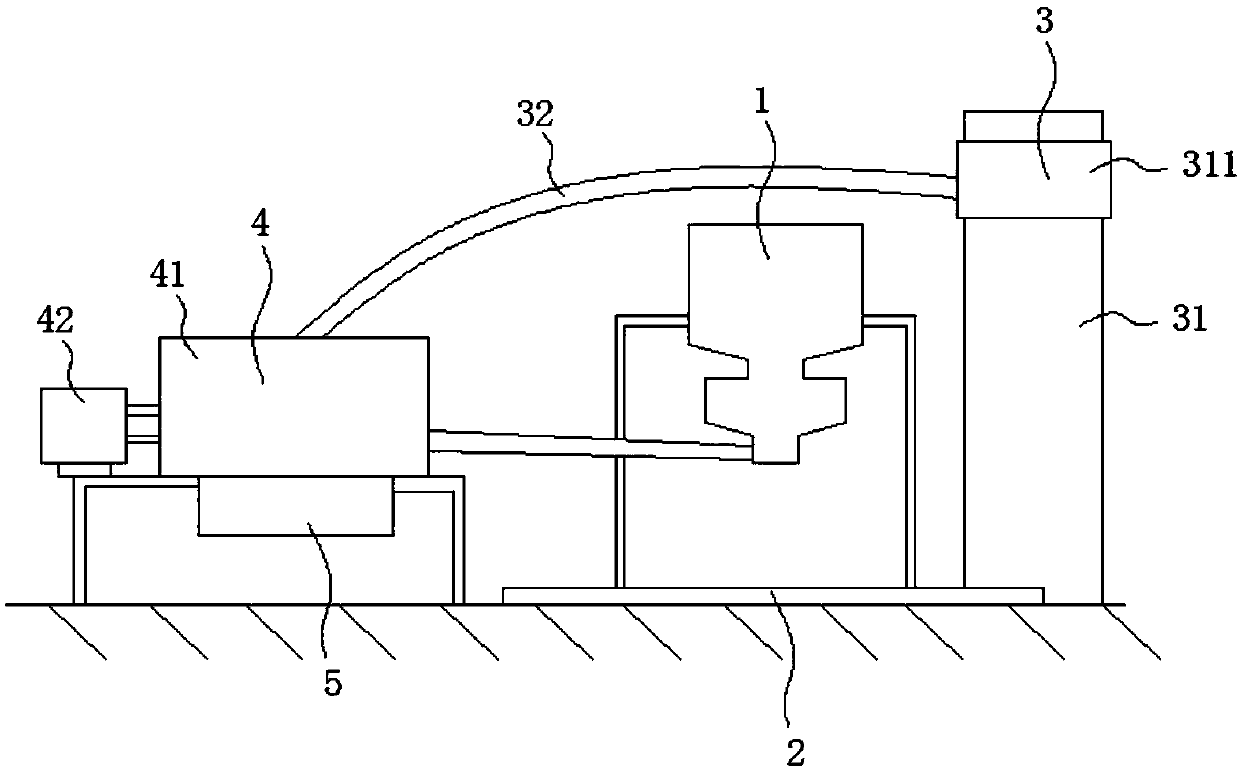

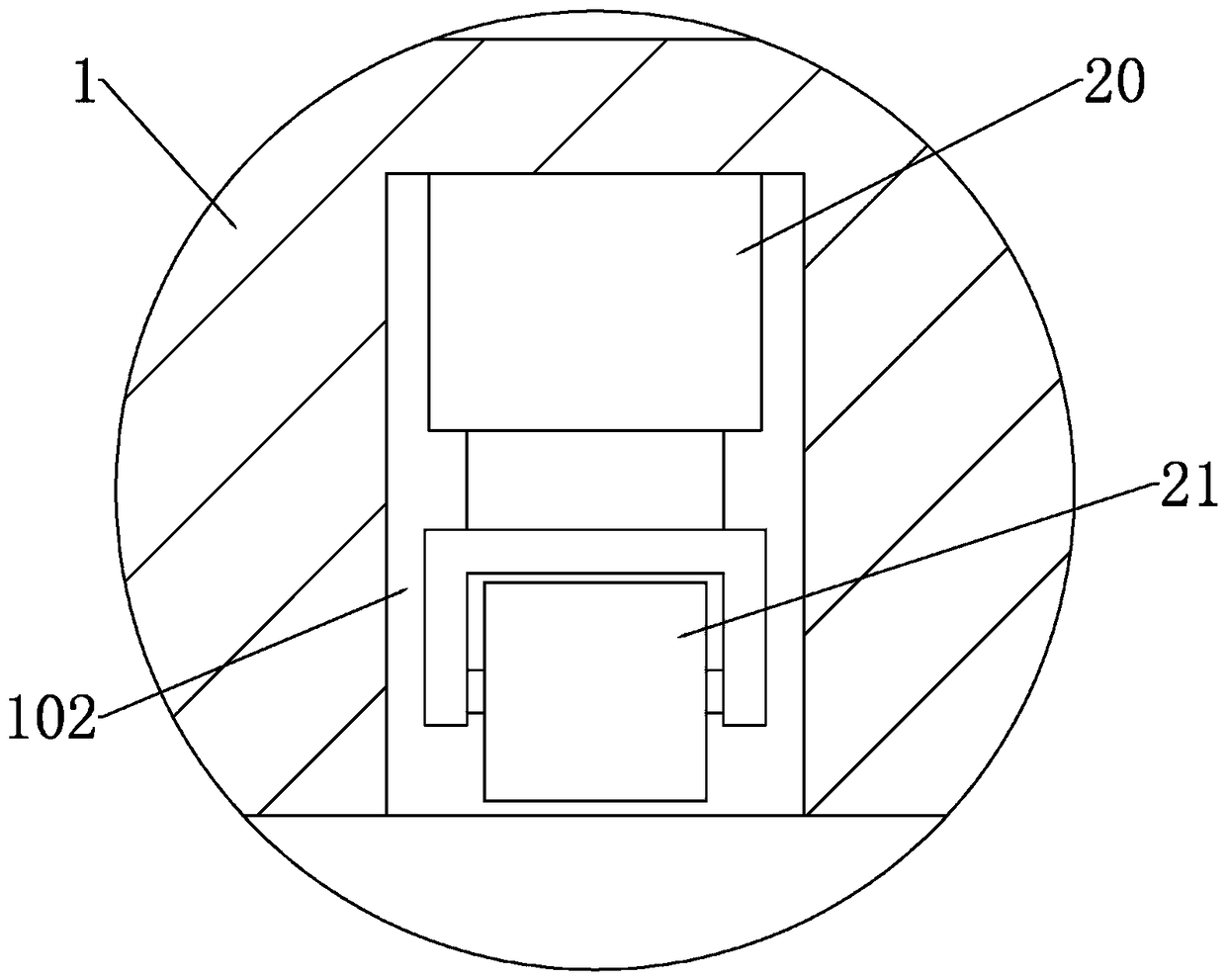

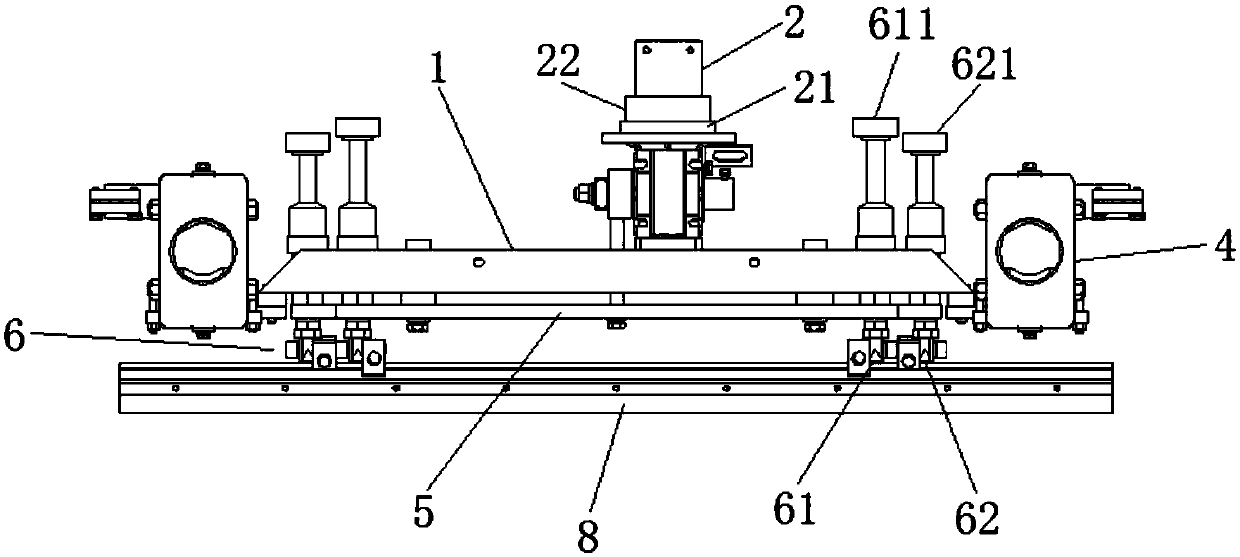

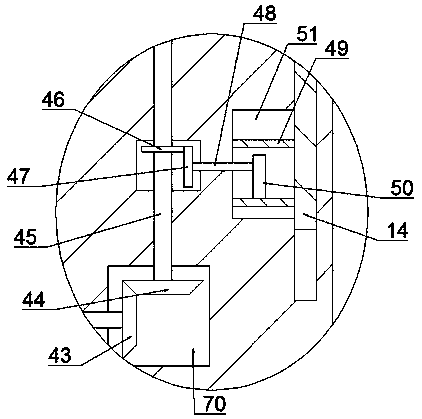

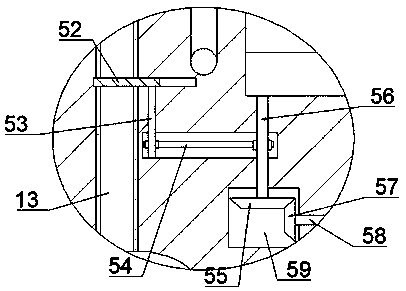

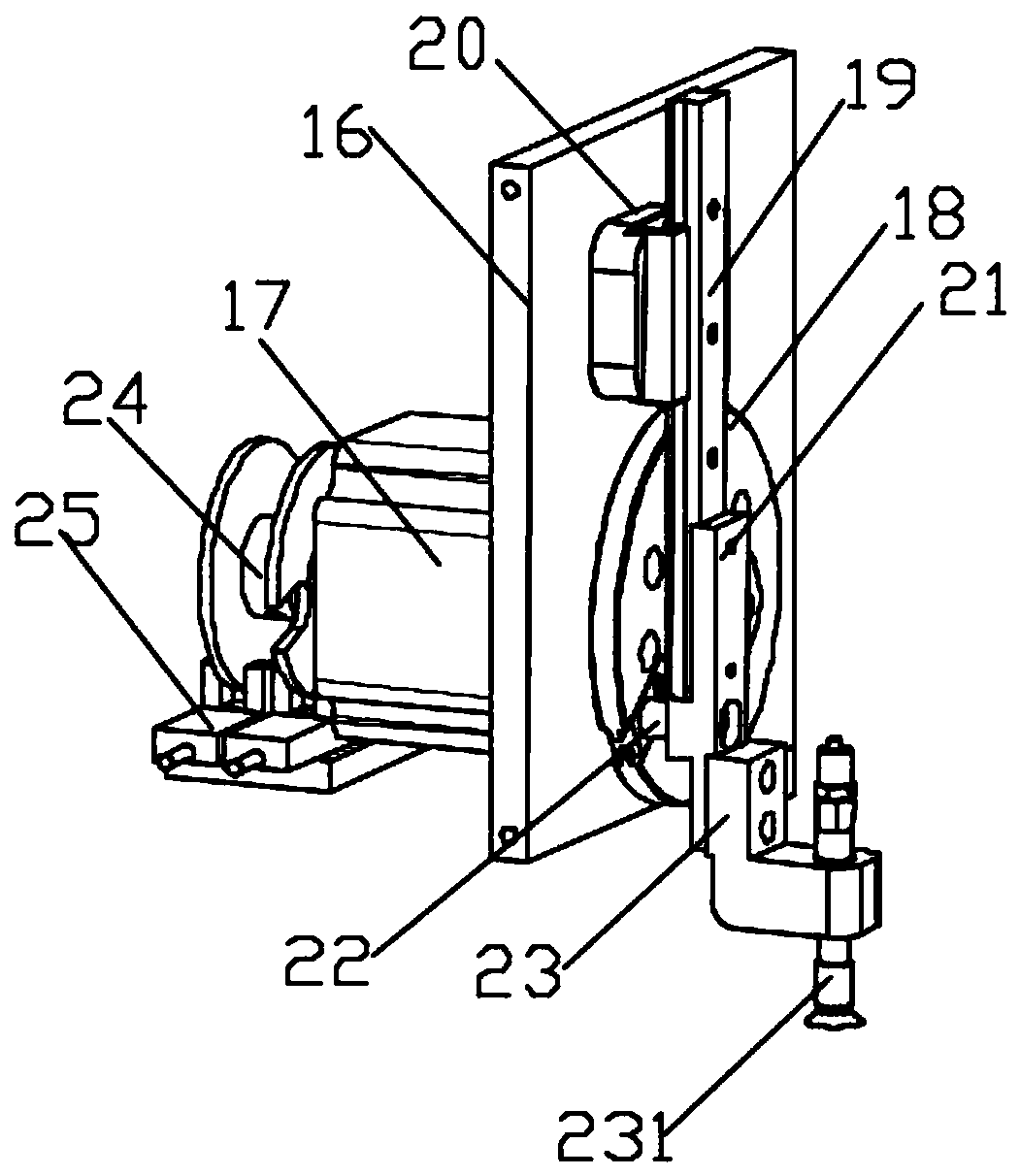

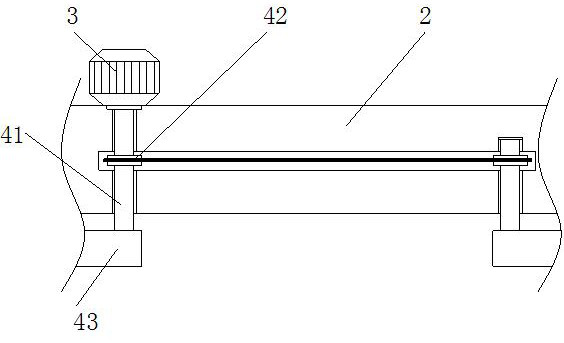

Pressure testing device of tappet body

ActiveCN105259037ATo achieve the purpose of testingHigh power transmission efficiencyForce measurementMaterial strength using tensile/compressive forcesTest efficiencyHead pressing

The invention provides a pressure testing device of a tappet body and belongs to the field of detection devices of the tappet bodies. The pressure testing device comprises a base and a dynamometer, wherein the base is provided with a lifting device which is fixedly connected with the dynamometer; the dynamometer is provided with a testing head. The pressure testing device also comprises a fixed sleeve which can be matched with the tappet body, wherein the fixed sleeve is arranged under the testing head; when the lifting device drives the dynamometer to move downwards, the testing head presses the tappet body. The pressure testing device provided by the invention has the advantages that the performance of pressure bearing of the tappet body can be well tested, the structure is simple, the operation is simple and convenient, the testing efficiency is improved, and the price is low, so that the production cost is greatly reduced.

Owner:CHONGQING RUIJIA MACHINERY CO LTD

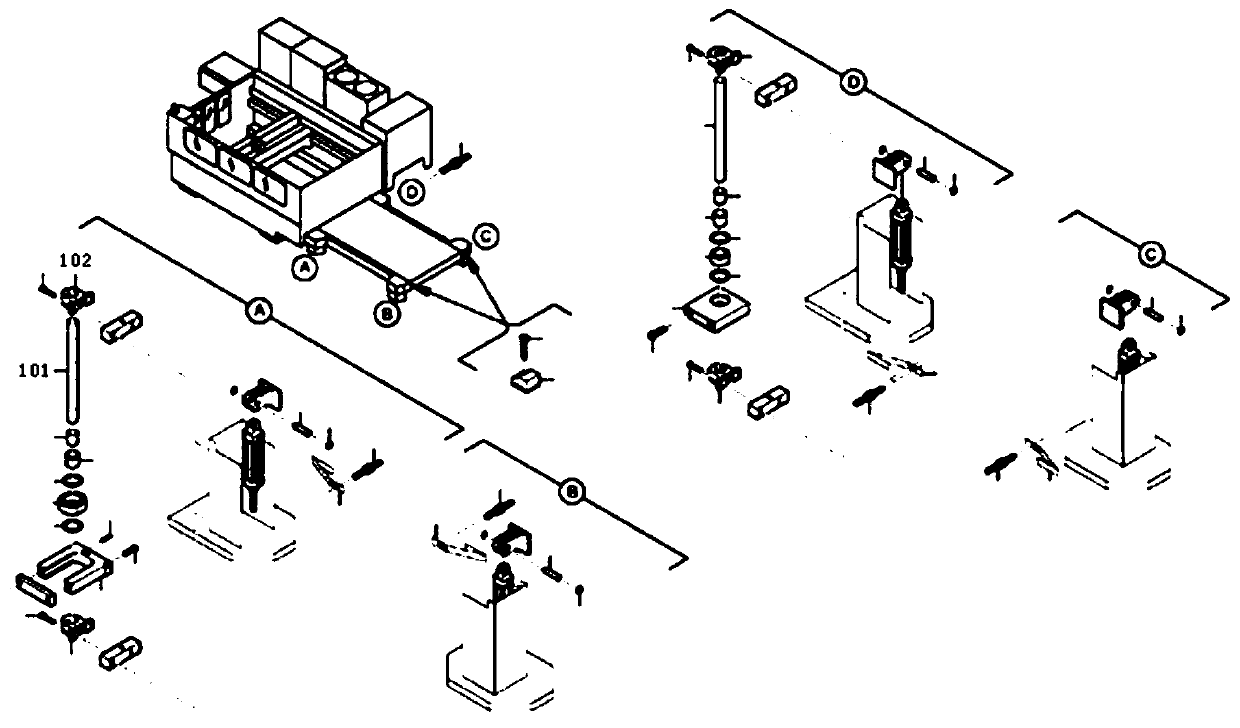

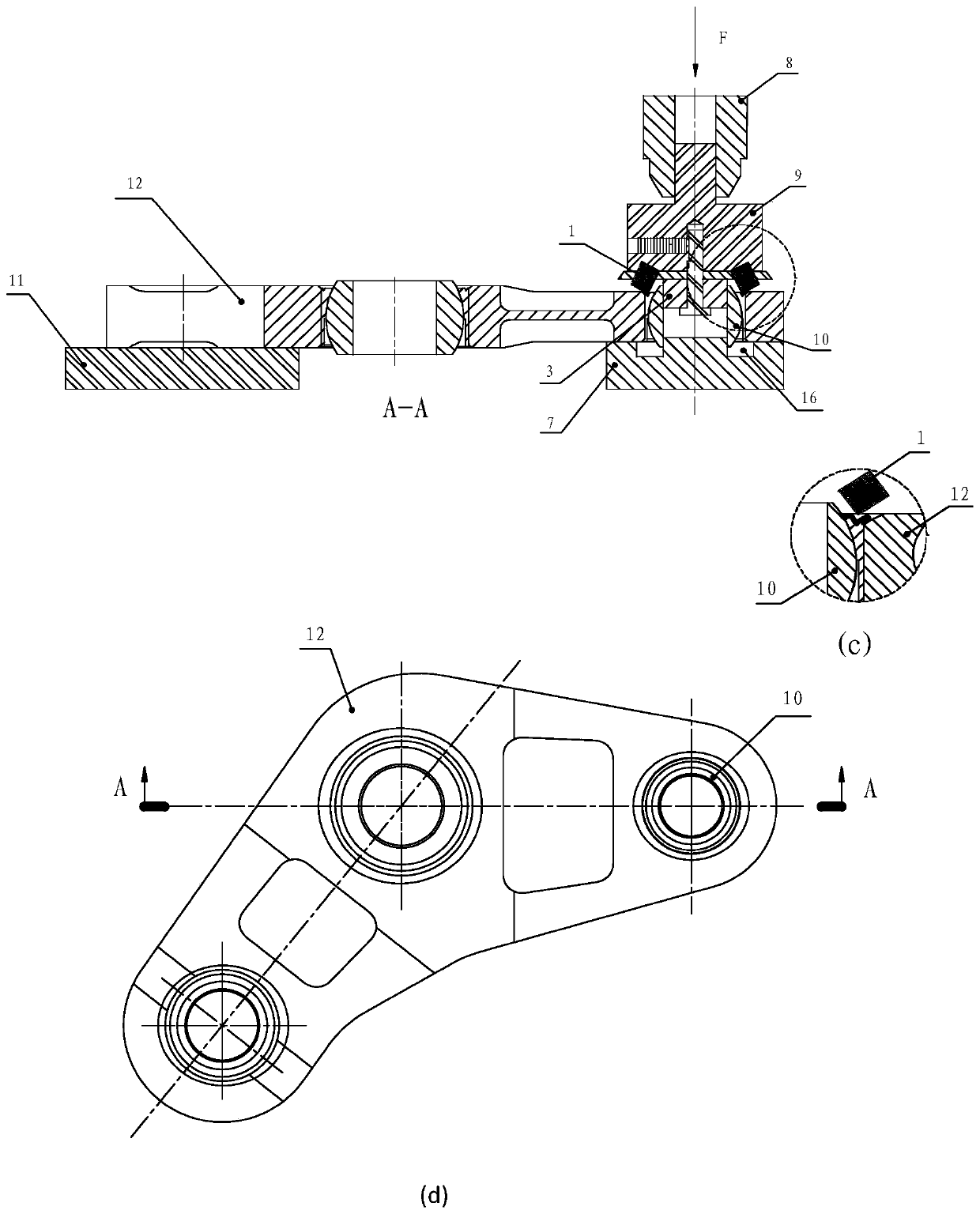

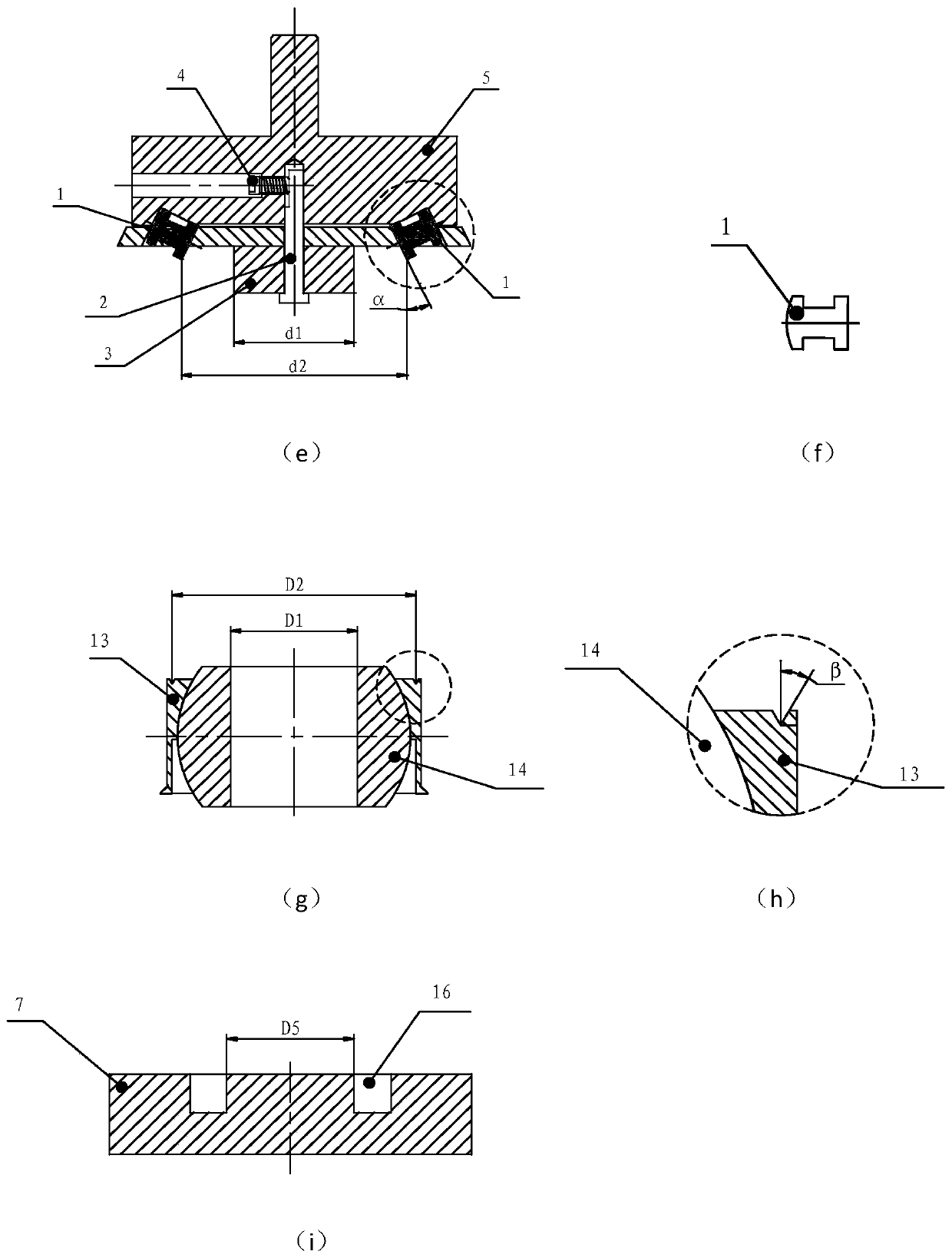

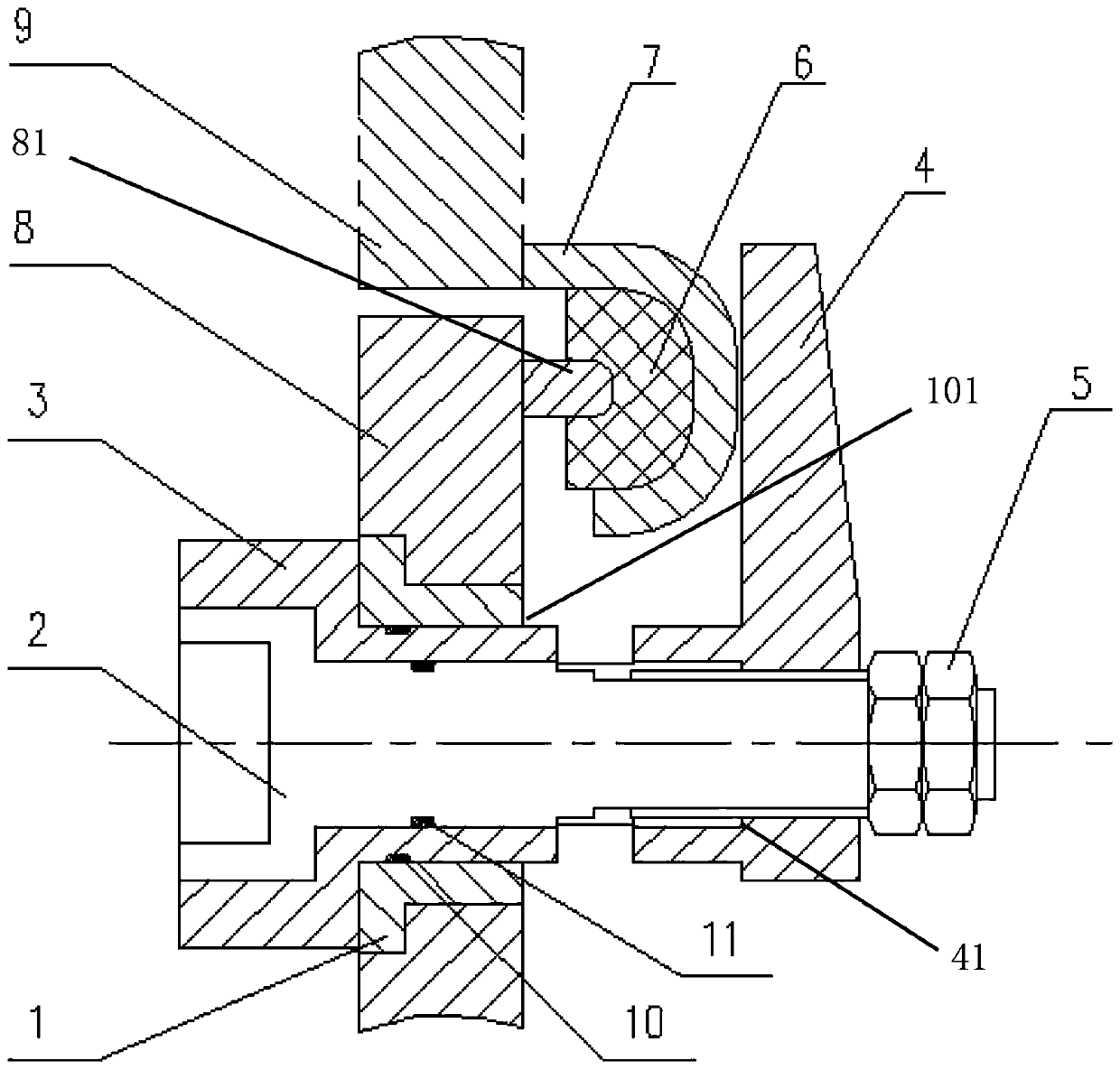

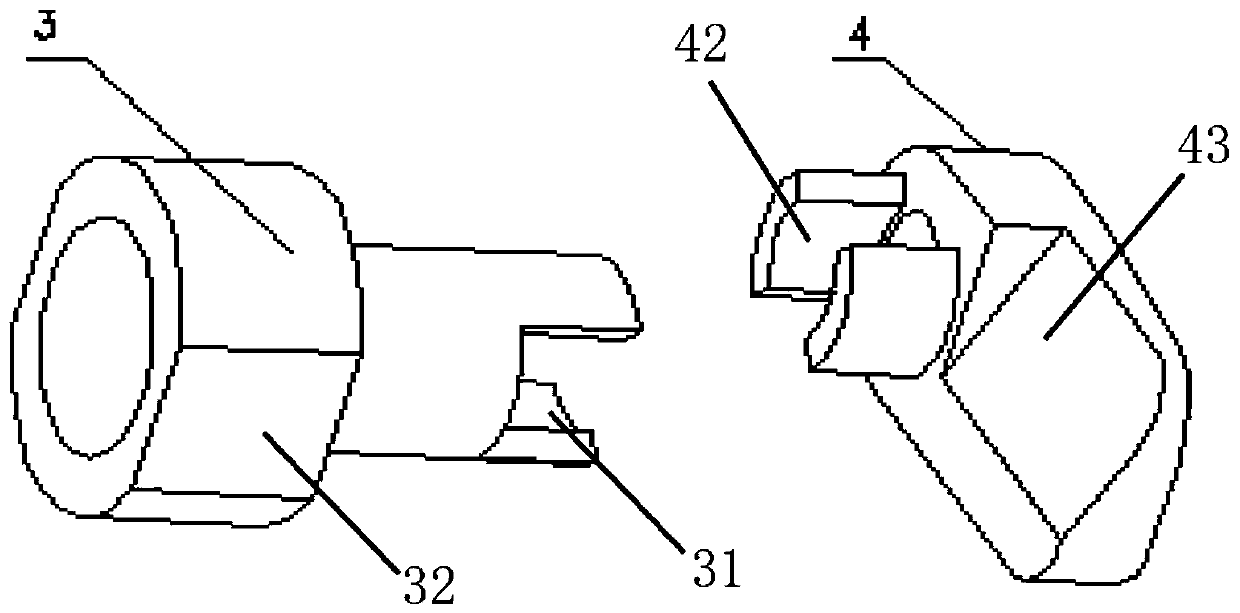

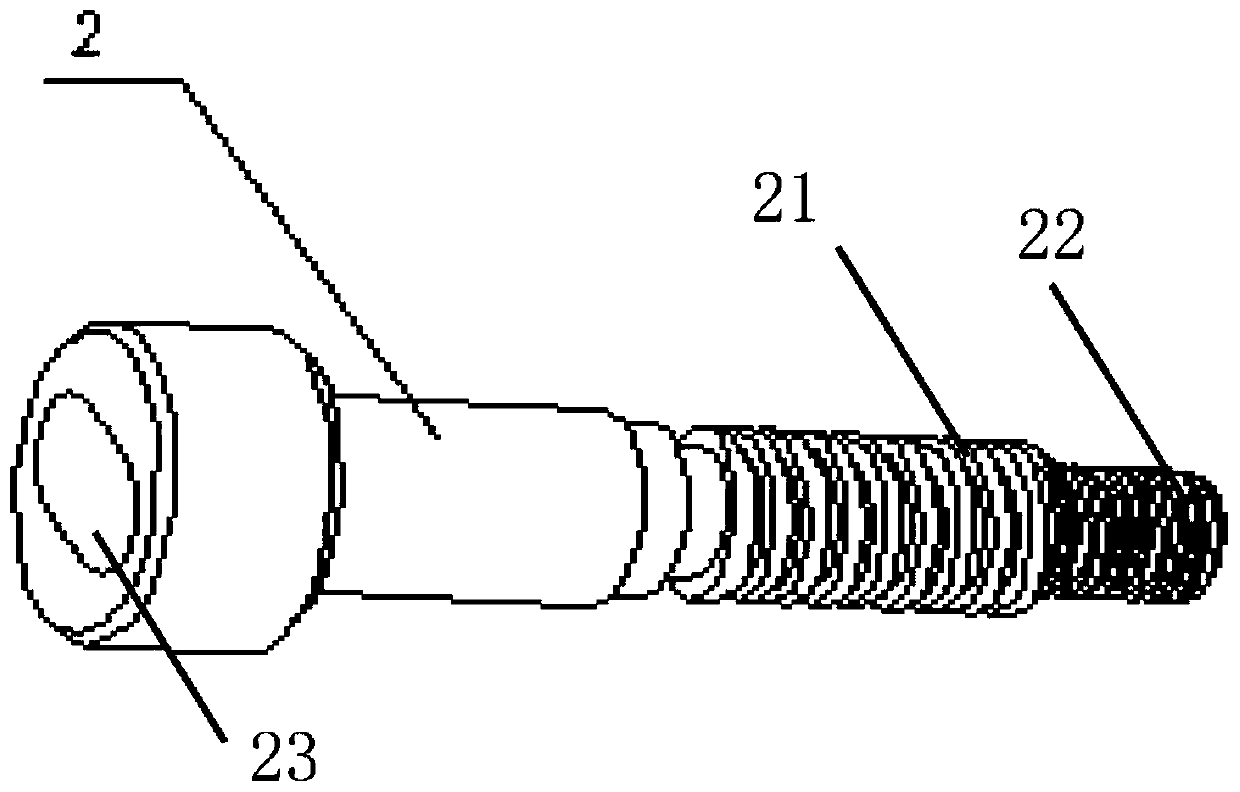

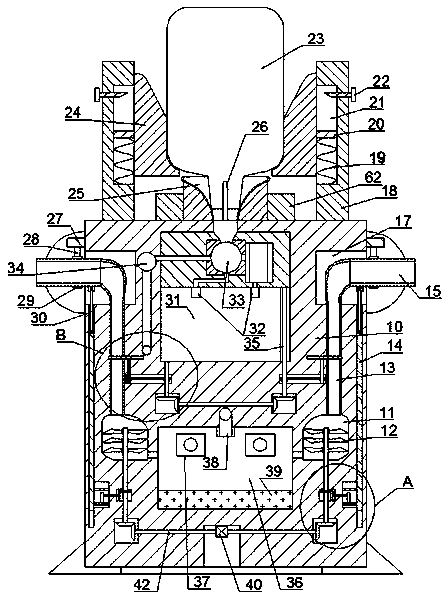

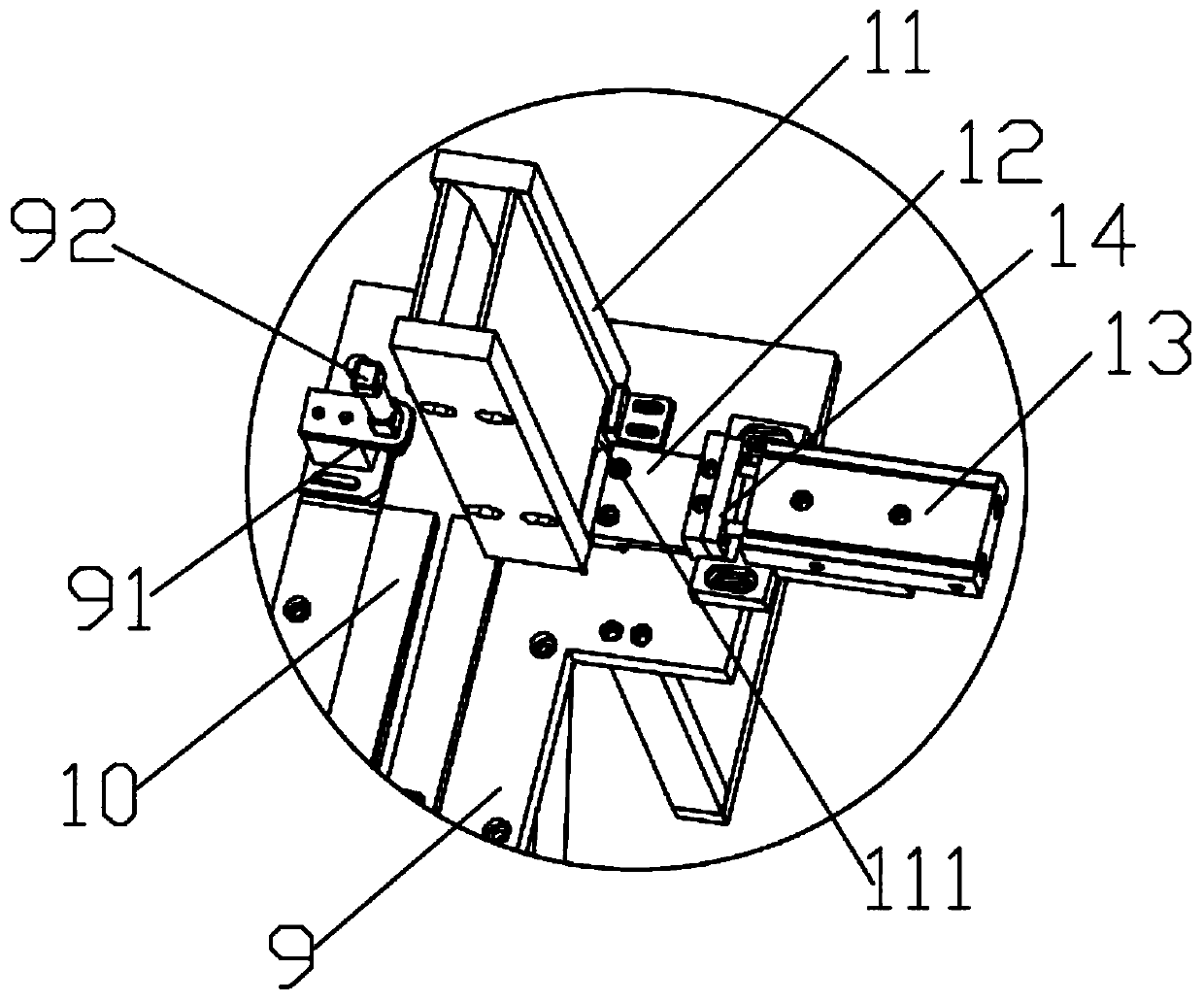

Joint bearing flanging tool and process of using same for joint bearing flanging

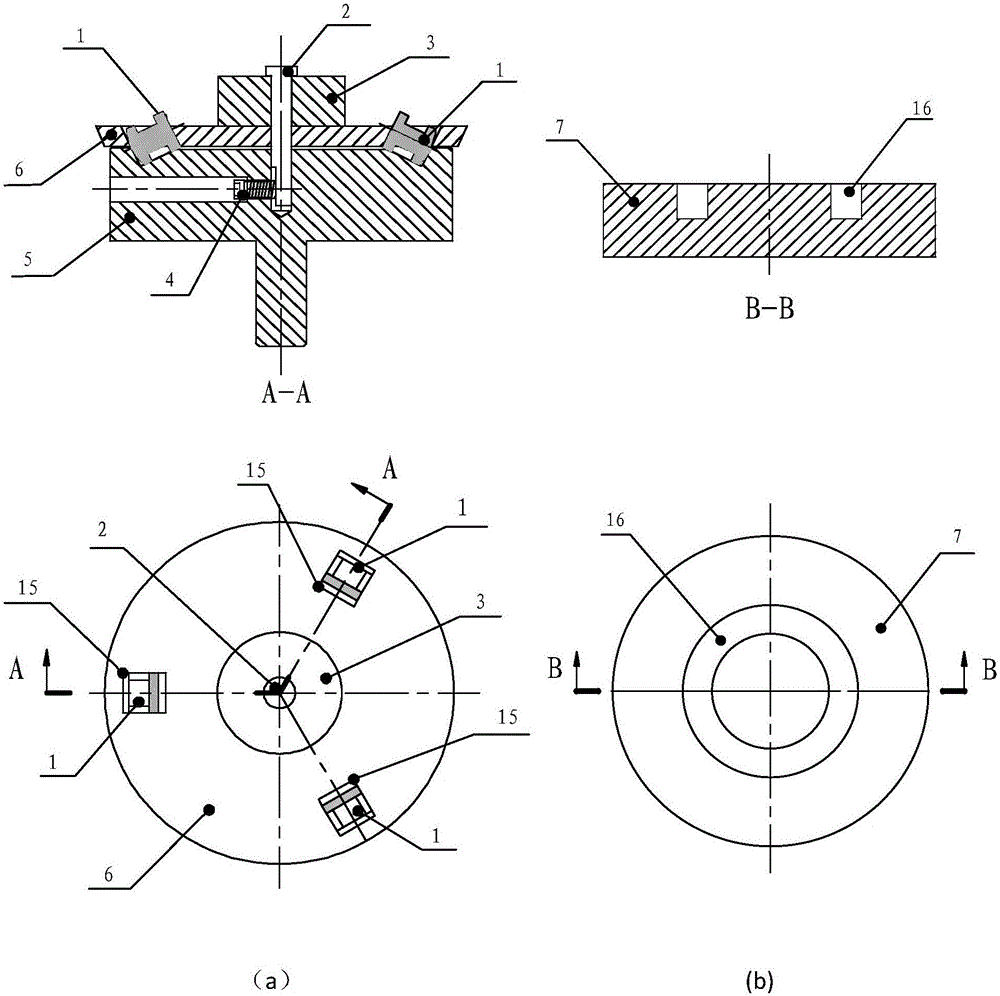

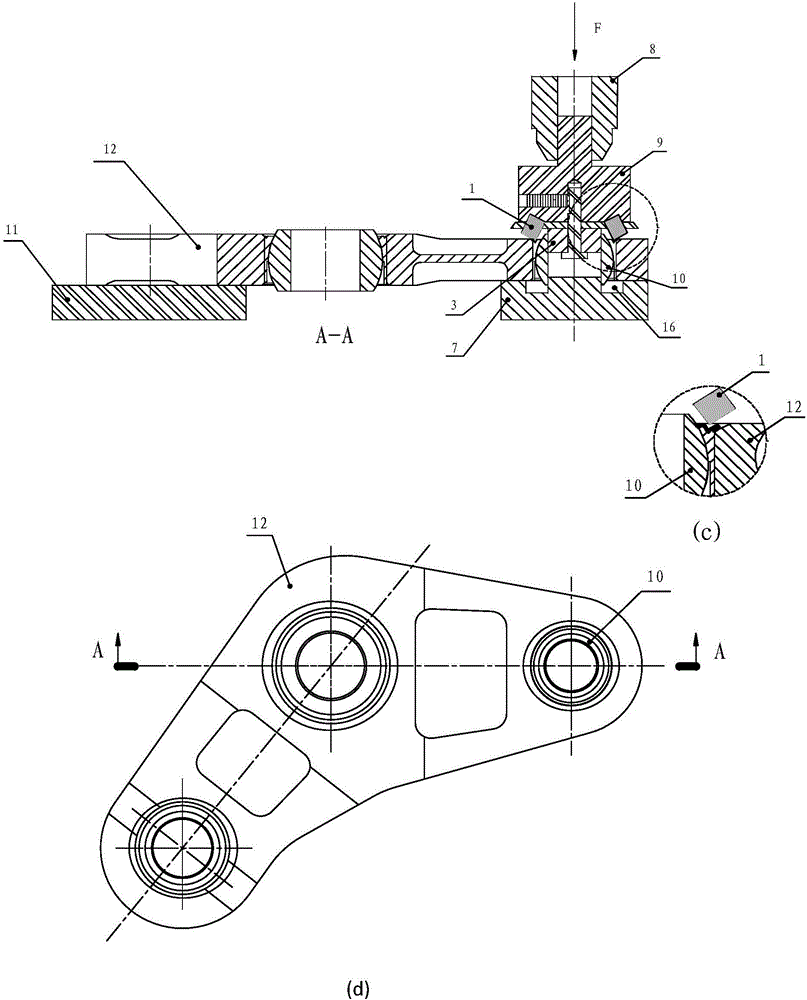

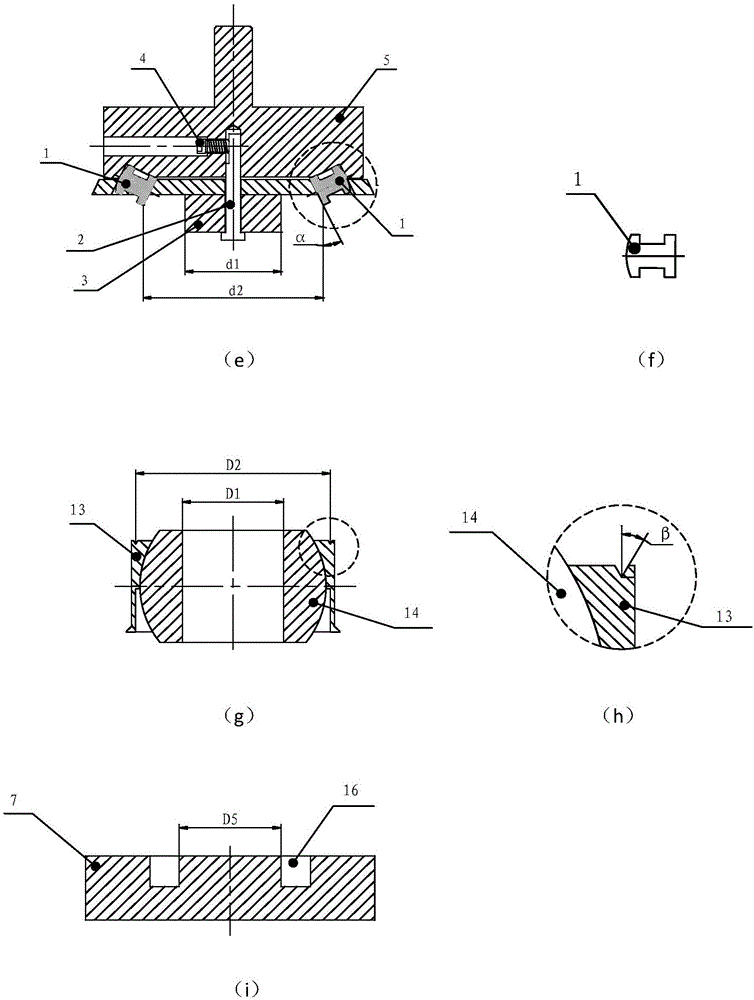

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

PCB double-sided board grinding device for electronic product and working method thereof

ActiveCN110900335ASanding effectReduce contact areaGrinding carriagesGrinding drivesPiston rodWheel drive

The invention discloses a PCB double-sided board grinding device for an electronic product and a working method thereof. The device comprises a machine table, wherein a clamping seat and a grinding table are arranged on the machine table, a chip collecting box is mounted on the grinding table, the clamping seat is of a rectangular box body structure, a fixing plate is mounted in the clamping seat,a first air cylinder is further arranged in the clamping seat, and a piston rod of the first air cylinder is connected with a connecting strip. According to the device, the first cylinder piston rodis contracted, so that one mounting plate is driven to move through the connecting strip, the mounting plate drives a rod sleeve to slide on a fixing rod, then a clamping strip drives a rotating wheeland a limiting rolling wheel to rotated, the rotating wheel drives the other clamping strip to move, the two clamping strips are driven to move towards each other, and then two moving side columns are driven to move towards each other through the two mounting plates, so that the technical problem that the PCB board grinding device is prone to be stuck due to the conventional screw rod adjusting clamping in the prior art is solved.

Owner:江苏百维能源科技有限公司

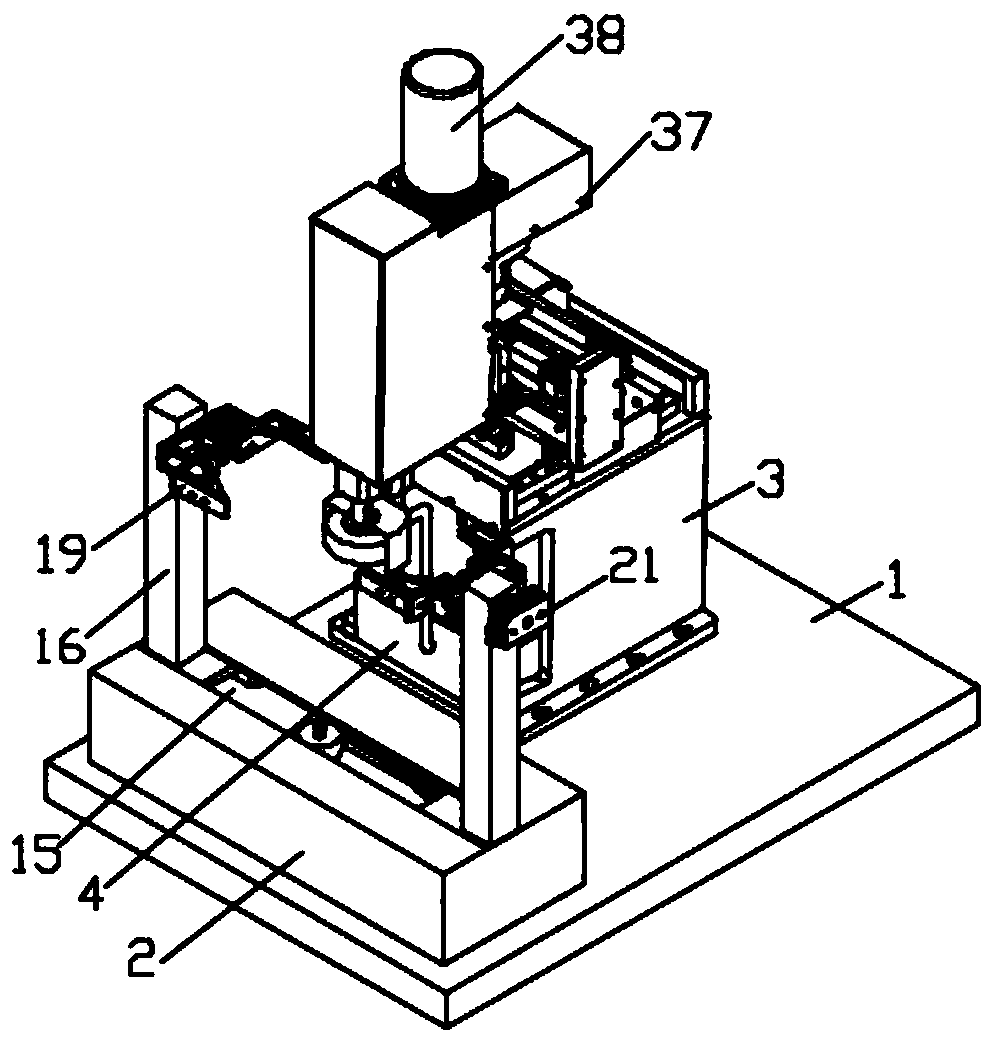

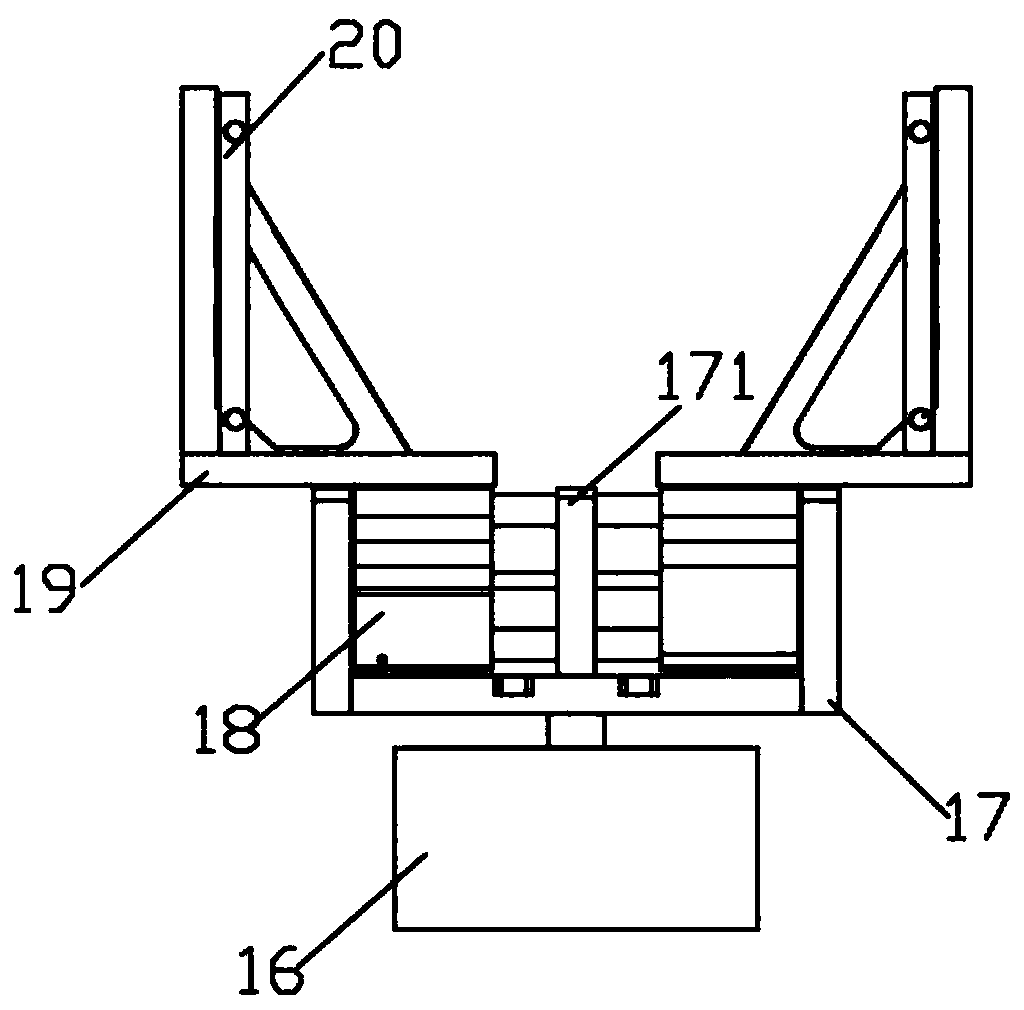

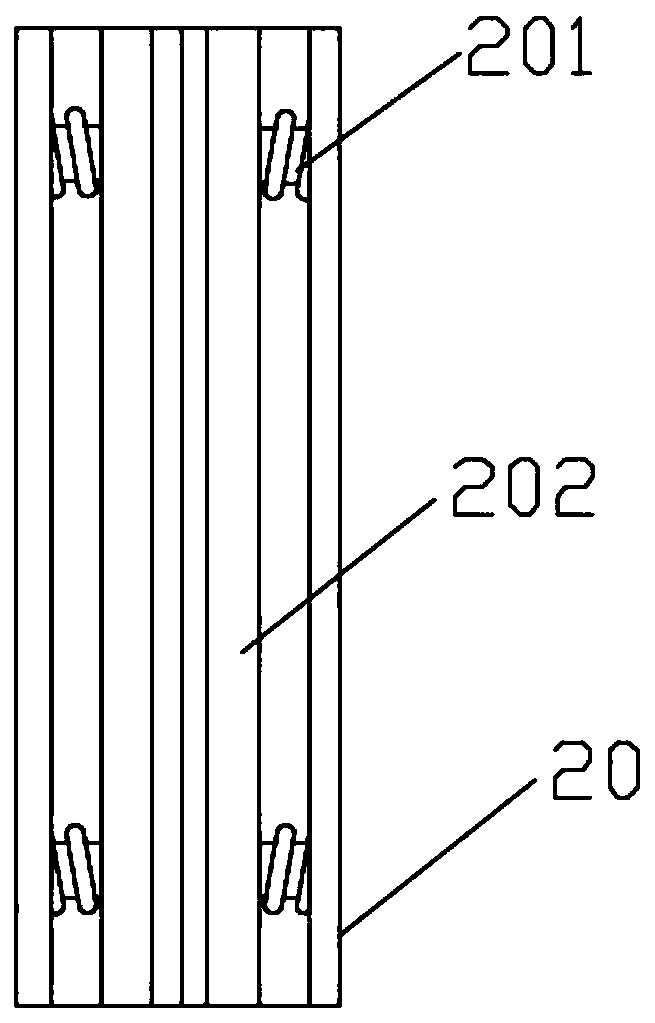

Automatic unmanned aerial vehicle wing production device

ActiveCN112658898AEasy to replaceQuick changeGrinding wheel securing apparatusGrinding drivesUncrewed vehicleStructural engineering

The invention relates to the technical field of unmanned aerial vehicle wing production and processing, in particular to an automatic unmanned aerial vehicle wing production device which comprises a base, stand columns, moving structures, a replacing structure, a fixing structure, a limiting structure, a containing structure and an anti-rotation structure. The moving structures are arranged at one ends of the two stand columns, a polishing assembly can be automatically adjusted to be close to a to-be-polished wing and away from the to-be-polished wing, so that the to-be-polished wing is conveniently and automatically polished, the polishing assembly can be rapidly installed and replaced in cooperation with the arrangement of the replacing structure, and therefore the damaged polishing assembly can be conveniently replaced in the later period; and by installing the fixing structure at the top end of the base, the wing can be adsorbed and fixed according to the vacuum adsorption principle, so that the surface of the wing is comprehensively polished conveniently, polishing and discharging can be conducted independently, namely, when one wing is polished, the other wing can be discharged or charged, and therefore the discharging and charging time is shortened, and accordingly, the polishing efficiency can be improved.

Owner:江苏惠新知识产权服务有限公司

Suspension type self-balancing hydraulic lifting device

PendingCN110405364AIncrease the carrying loadReduce frictionLaser beam welding apparatusHydraulic cylinderSynchronous motor

The invention discloses a suspension type self-balancing hydraulic lifting device which comprises a bracket, a synchronous motor, lifting devices and a hydraulic station; the center of the bracket extends in a length direction and extends in a width direction to form an X axis and a Y axis respectively; and the four lifting devices are symmetrically arranged in the X axis and the Y axis; each lifting device comprises a hydraulic cylinder, a supporting block and a positioning block; a supporting block is connected to a moving rod of each hydraulic cylinder; the positioning blocks and the supporting blocks are arranged on the lower surface of the bracket in a one-to-one correspondence manner; the positioning blocks is separably tangent and abutted to the surfaces of the corresponding supporting blocks; and the synchronous motor is arranged at an intersection of the X axis and the Y axis. The lifting device disclosed by the invention does not have the deadlocking phenomenon in the liftingprocess; the perpendicularity of the lifting device is not strictly required, and the production cost is low; by adopting hydraulic power, the bearing load is high, lifting is stable, and a stop position is accurate; and the overall structure is stable.

Owner:FOSHAN HONGSHI LASER TECH CO LTD

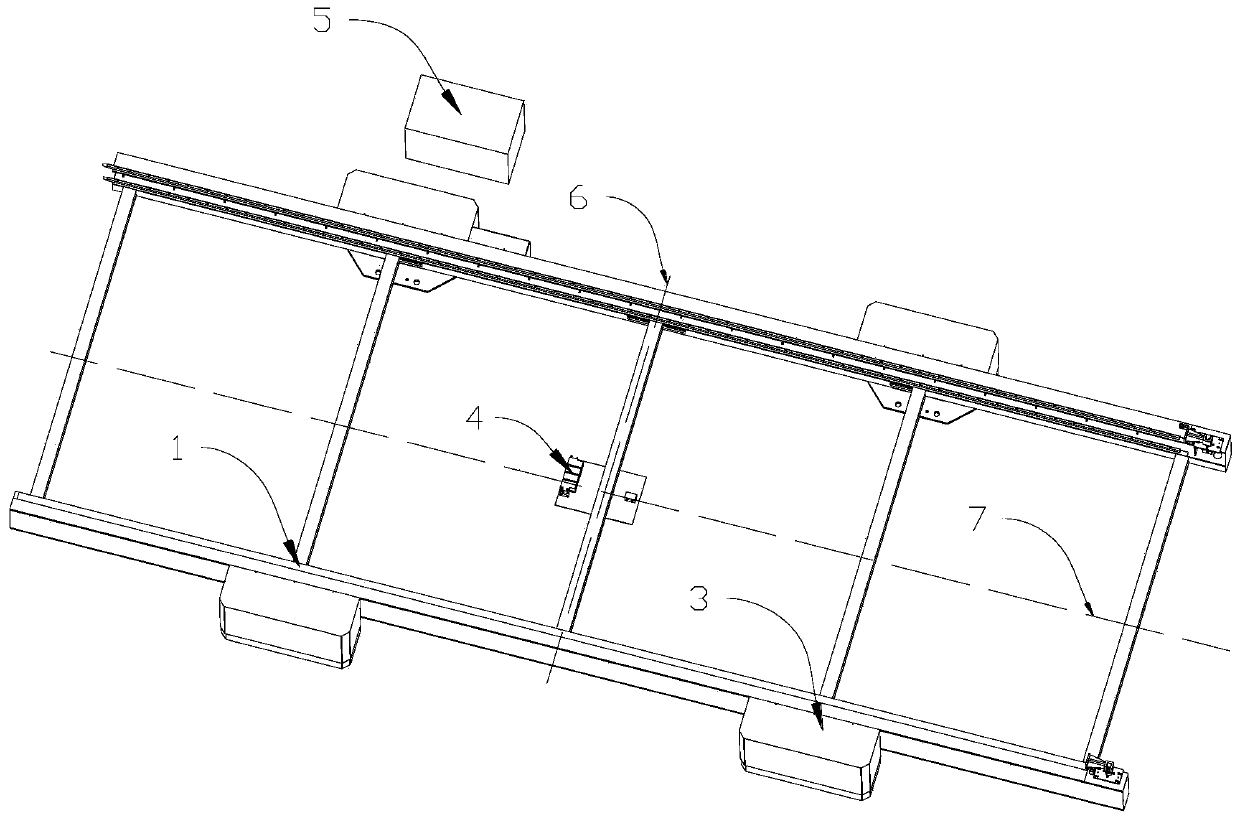

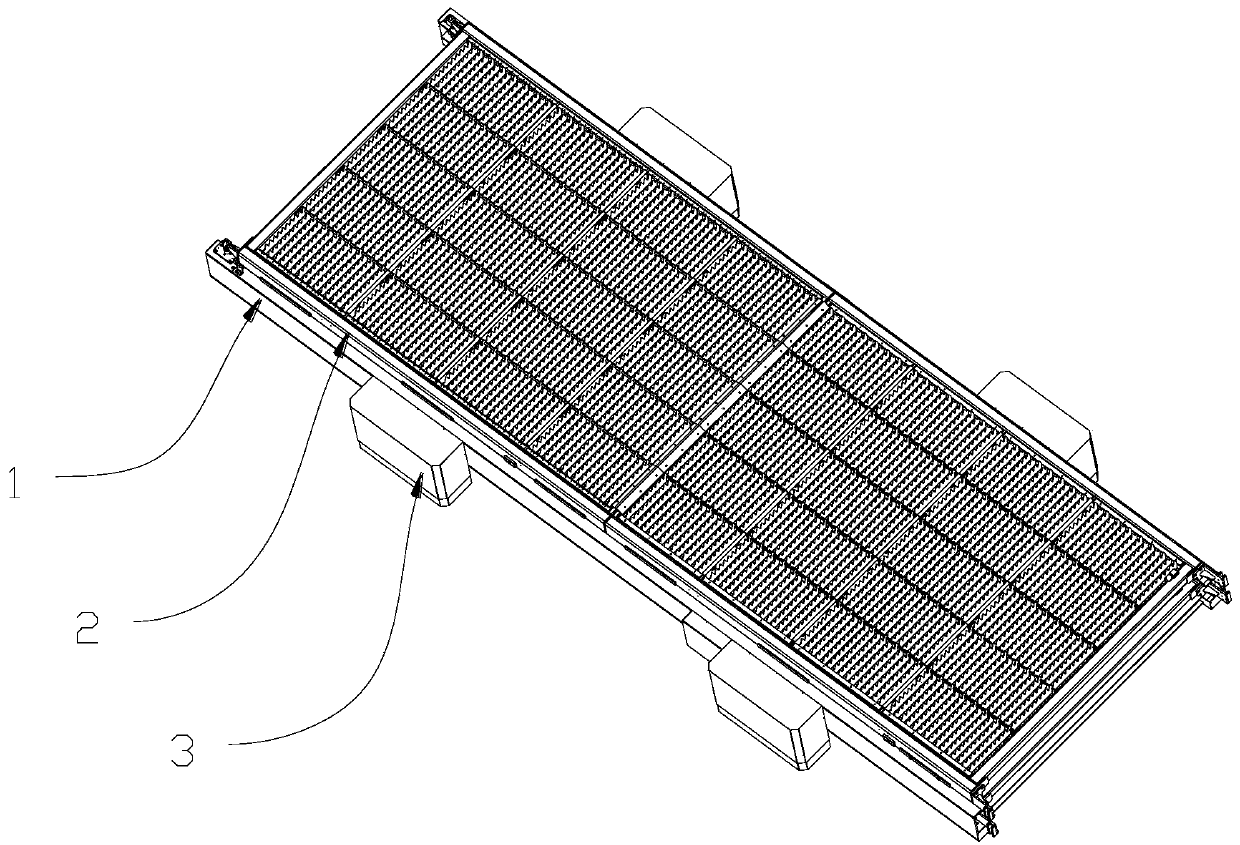

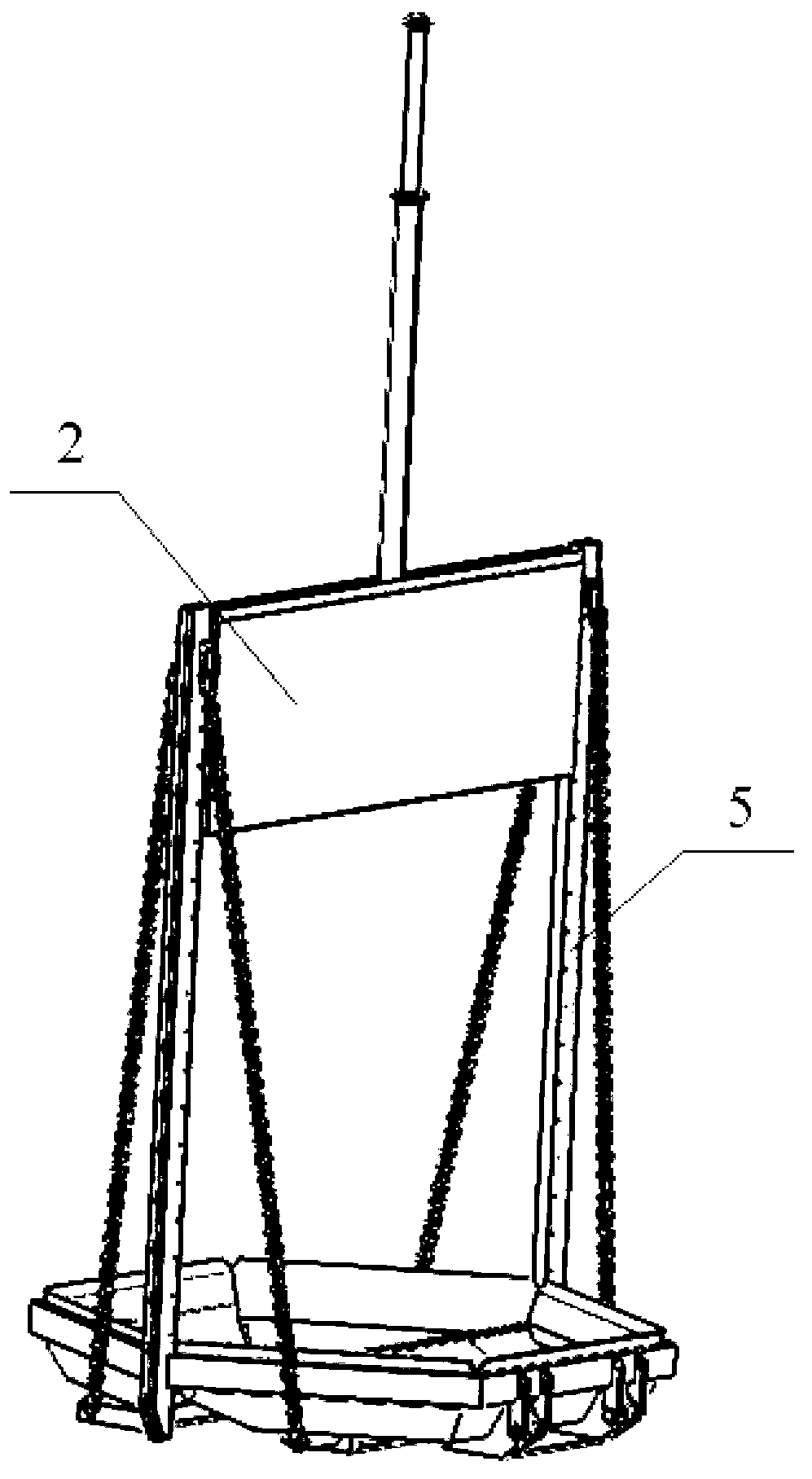

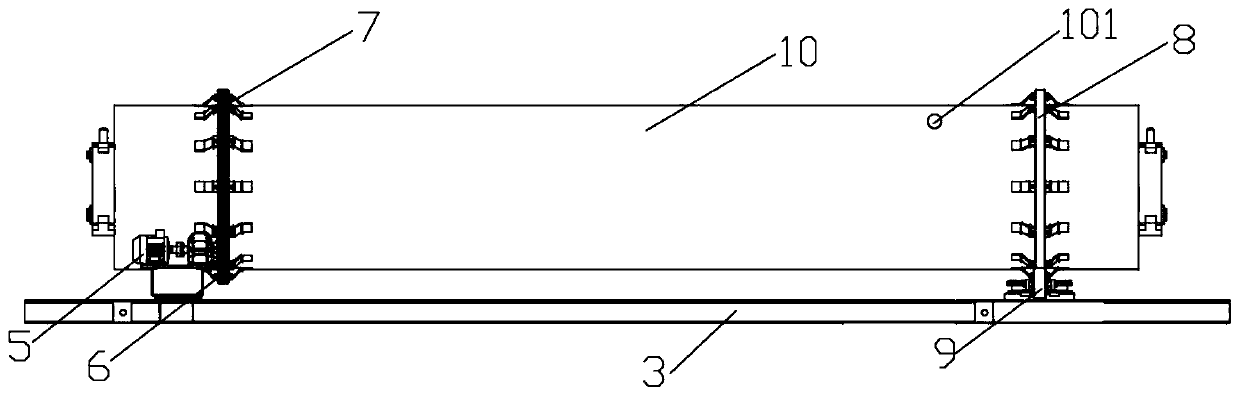

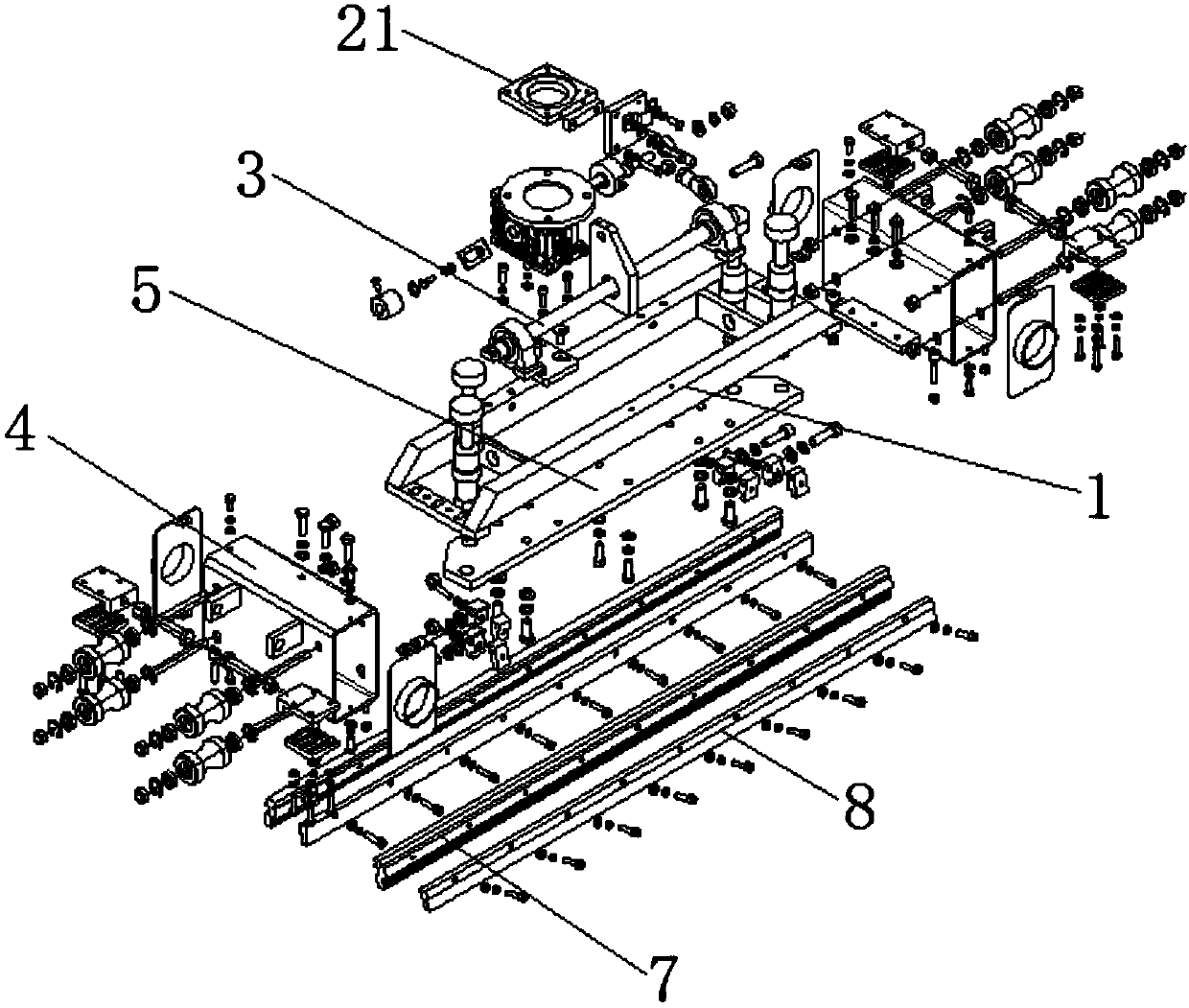

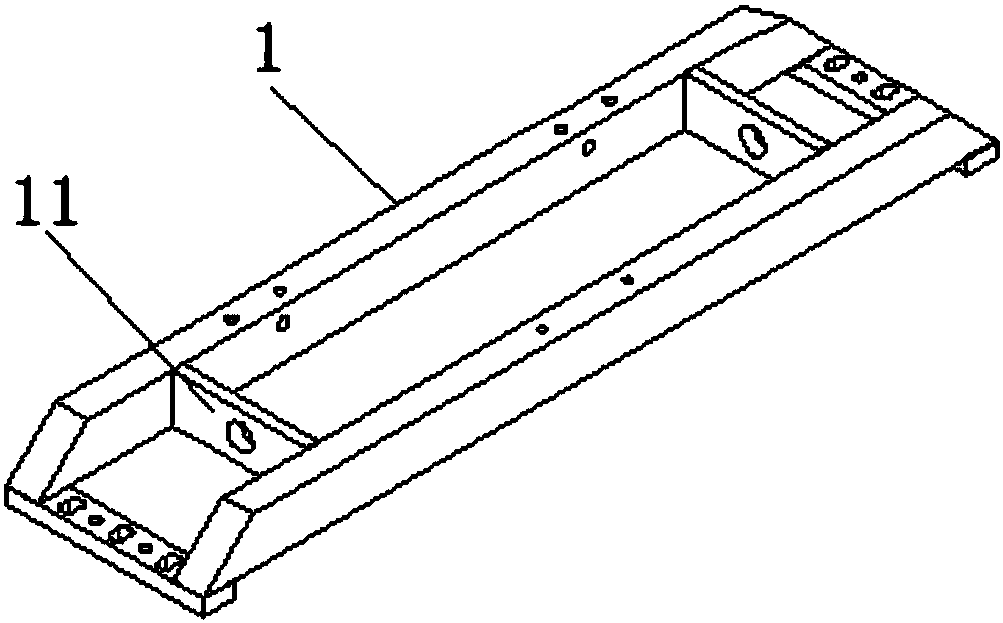

Large material plate replacing device

PendingCN111017555AImplement automatic replacementReduce workloadConveyorsConveyor partsSoft materialsIndustrial engineering

The invention discloses a large material plate replacing device. The large material plate replacing device comprises a rack, a feeding mechanism, a first air cylinder, a second air cylinder, a first pallet and a second pallet; and the feeding mechanism, the first air cylinder and the second air cylinder are all arranged on the rack, the first pallet is connected with the output end of the first air cylinder, the second pallet is connected with the output end of the second air cylinder, and the first pallet and the second pallet can alternately move to a feeding area. According to the large material plate replacing device, the first air cylinder can drive a material plate on the first pallet to move, the second air cylinder can drive a material plate on the second pallet to move, the firstair cylinder and the second air cylinder can alternately convey the material plates responsible respectively to the feeding area, and the two material plates can be automatically replaced. The large material plate replacing device is suitable for large material plates, especially large blister plates, and is also suitable for soft material plates; and according to the large material plate replacing device, the structure is simple and practical, the space is saved, the manufacturing cost is low, the plates are not clamped, sticking is avoided, operation is smooth and stable, and labor and the workload of starting personnel are reduced.

Owner:SUZHOU LINGYU ELECTRONICS TECH CO LTD

Building construction method for wall

InactiveCN108005256AAvoid processing powerAvoid the situationSludge treatmentCovering/liningsEcological environmentBrick

The invention discloses a building construction method for a wall. The building construction method comprises the following steps that (1) wall building is conducted, specifically, steel bars are erected in the positions, corresponding to the indoor wall, of a construction site, and a brick wall is built through piling outside the steel bars; (2) a wall blank is formed, specifically, concrete is poured in the brick wall and the steel bars, and the wall blank is formed after the concrete is solidified; and (3) plastering is conducted, specifically, plastering operation is conducted on the wallthrough mortar, wherein the preparation method of the mortar comprises the following steps that after building waste is crushed by a crushing device, crushed stone is obtained, then the crushed stoneis made into sand through a sand-making machine and thus the sand is obtained, the sand, cement and water are mixed and stirred, and thus the mortar is prepared. The sand and stone are manufactured directly by the building waste, so that waste of the non-renewable resources is avoided effectively; besides, pollution of the building waste to the ecological environment can be also avoided directly,and protection of the ecological environment is improved further; and various investments in treatment of the building waste are saved, the engineering cost is reduced effectively, and meanwhile the municipal expenditure can be also reduced to a great extent.

Owner:常成友

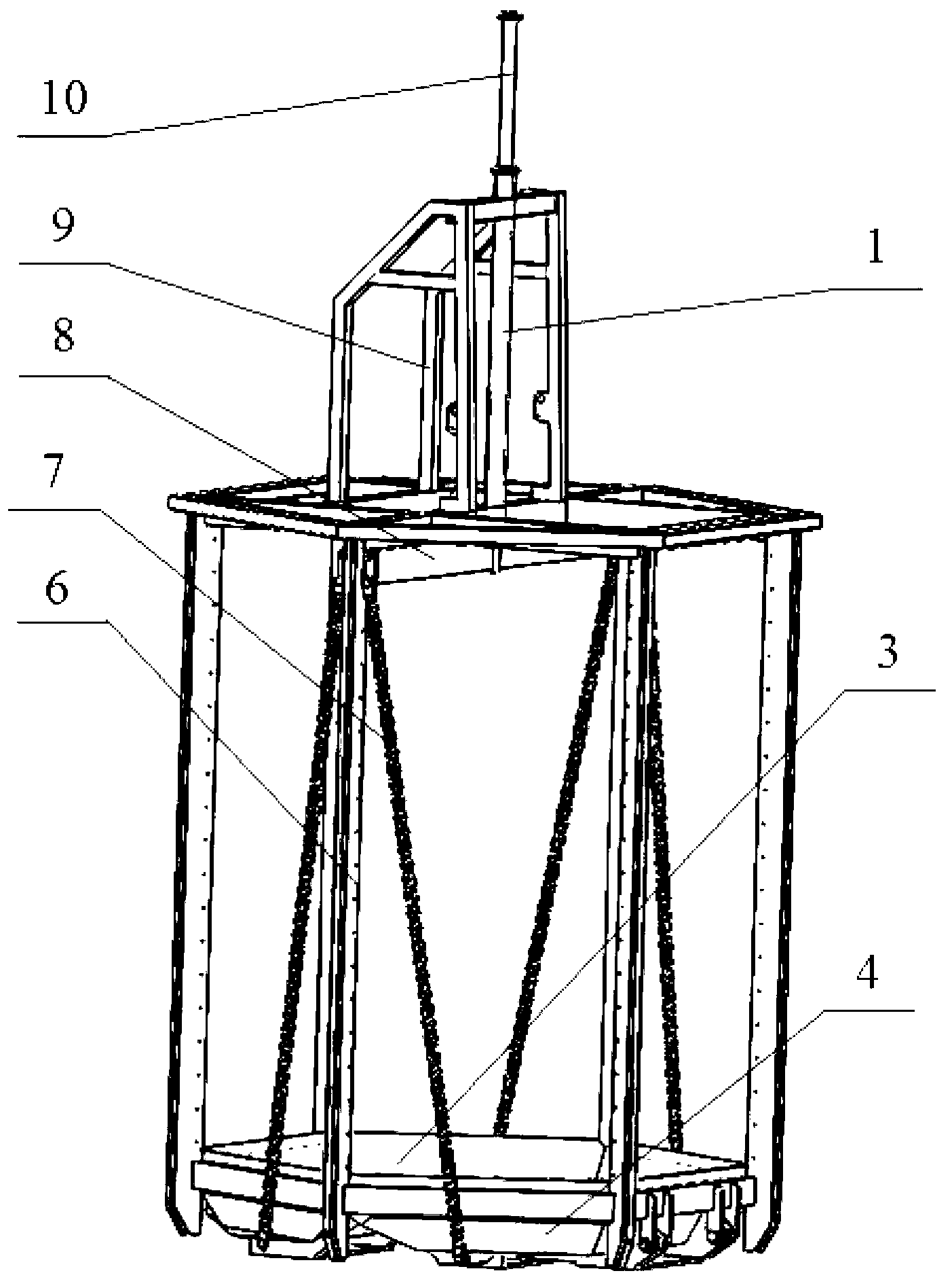

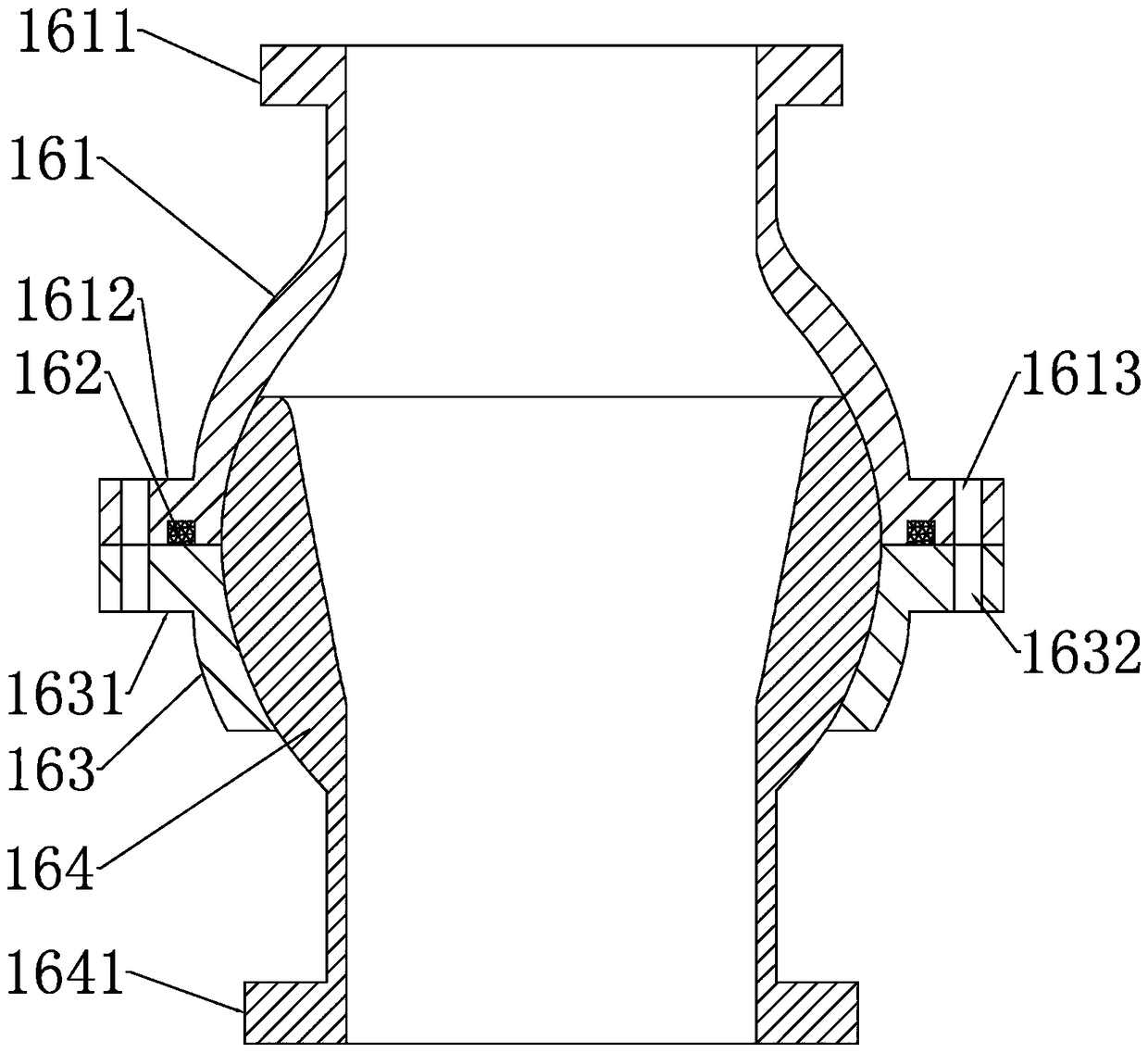

Bottom cover opening and closing mechanism of garbage collection device

A bottom cover opening and closing mechanism of a garbage collection device comprises an inner hanging rod, an outer hanging rod, an inner hanging rod beam, a first vertical rod, a second vertical rod, hoisting chains, a left bottom cover and a right bottom cover. The outer hanging rod is fixed on the garbage collection device, the inner hanging rod is nested in the outer hanging rod and forms a moving pair and is fixed on the inner hanging rod beam. Two ends of the inner hanging rod beam form moving pairs together with the first vertical rod and the second vertical rod respectively, and the first vertical rod and the second vertical rod are parallel with each other and are fixed on the garbage collection device. The inner hanging rod beam is connected with the left bottom cover and the right bottom cover respectively through the hoisting chains, and the left bottom cover is hinged to the right bottom cover. The bottom cover opening and closing mechanism is simplified in structure and reduces cost.

Owner:一清环境管理浙江有限公司

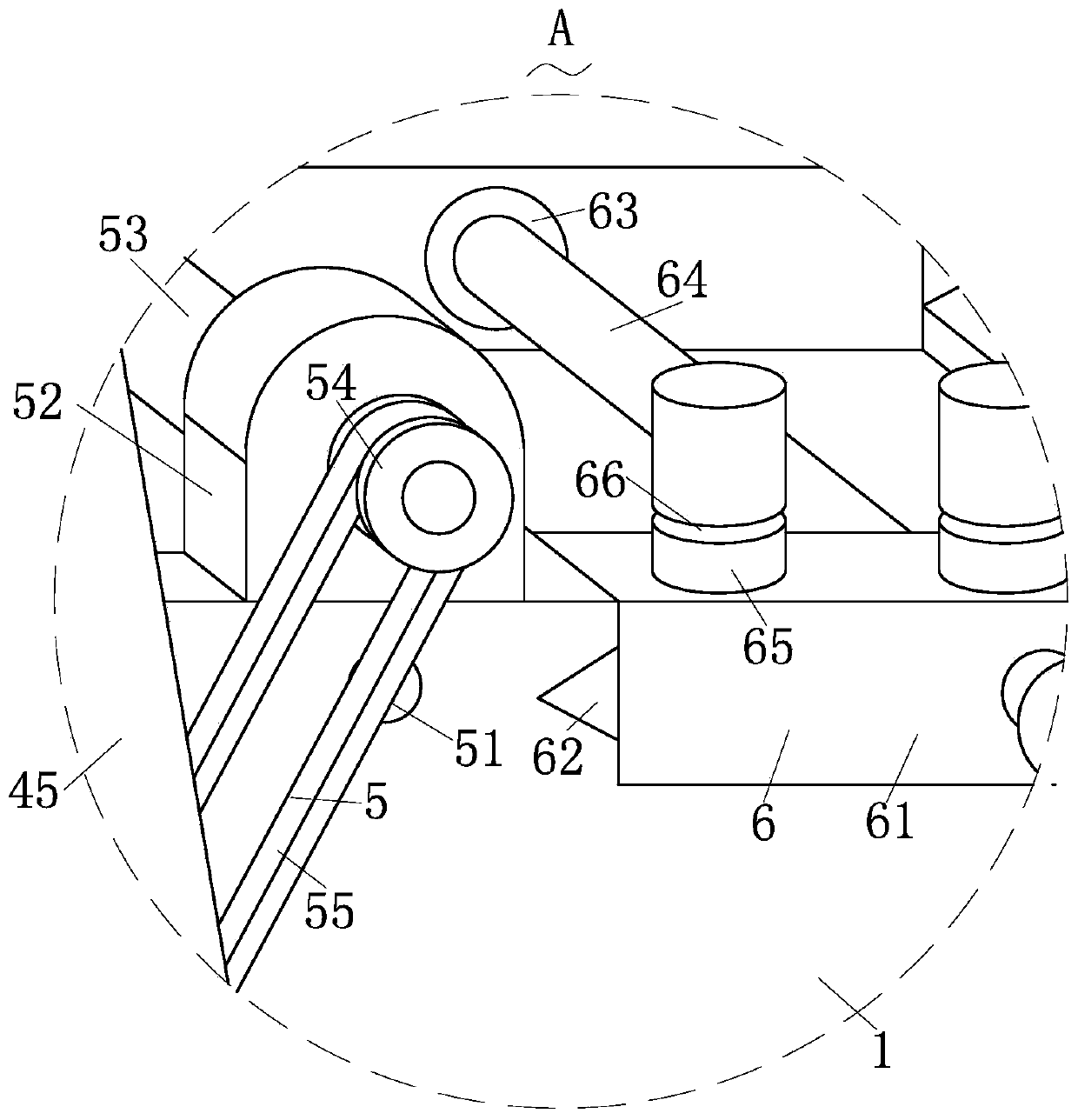

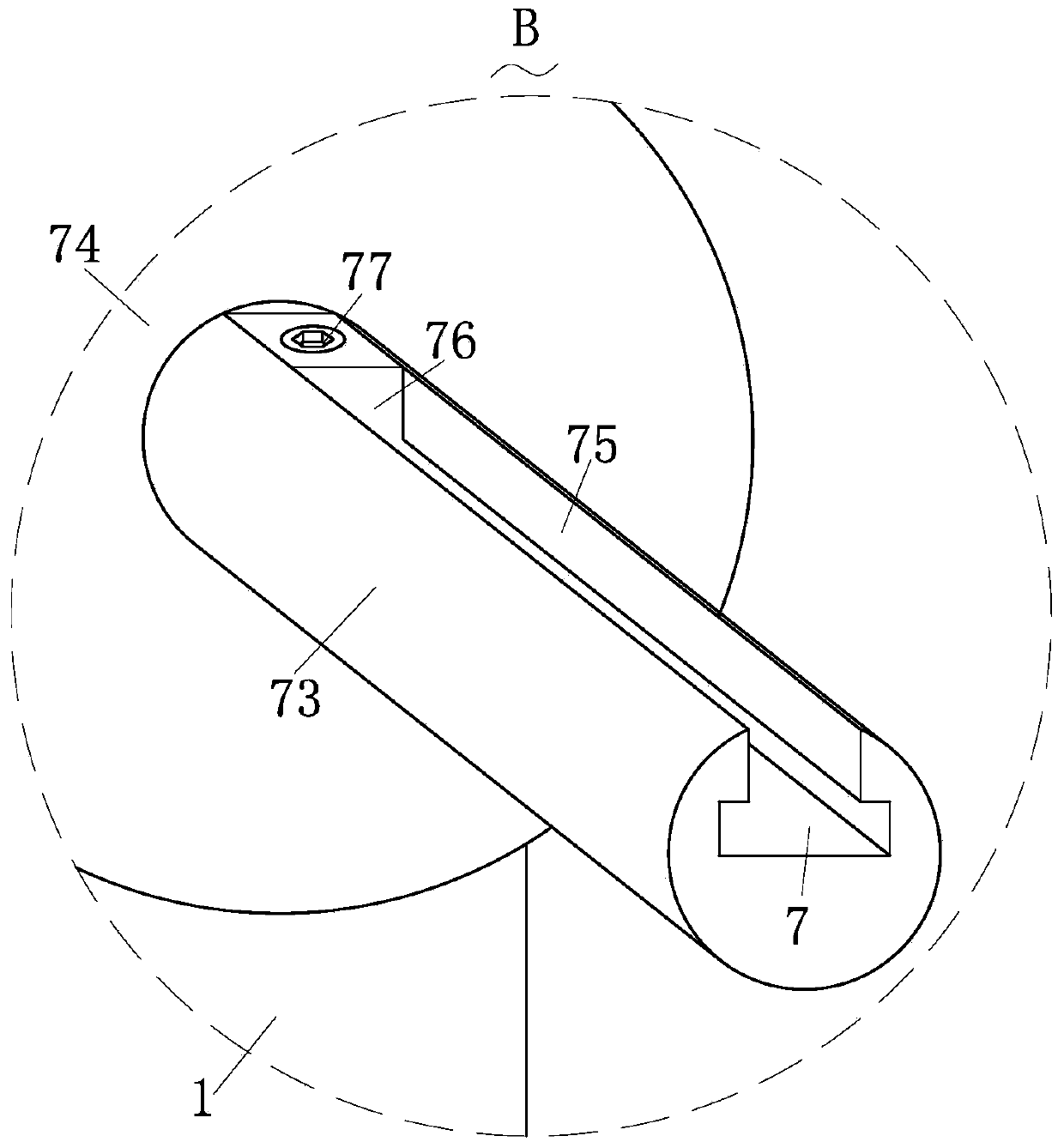

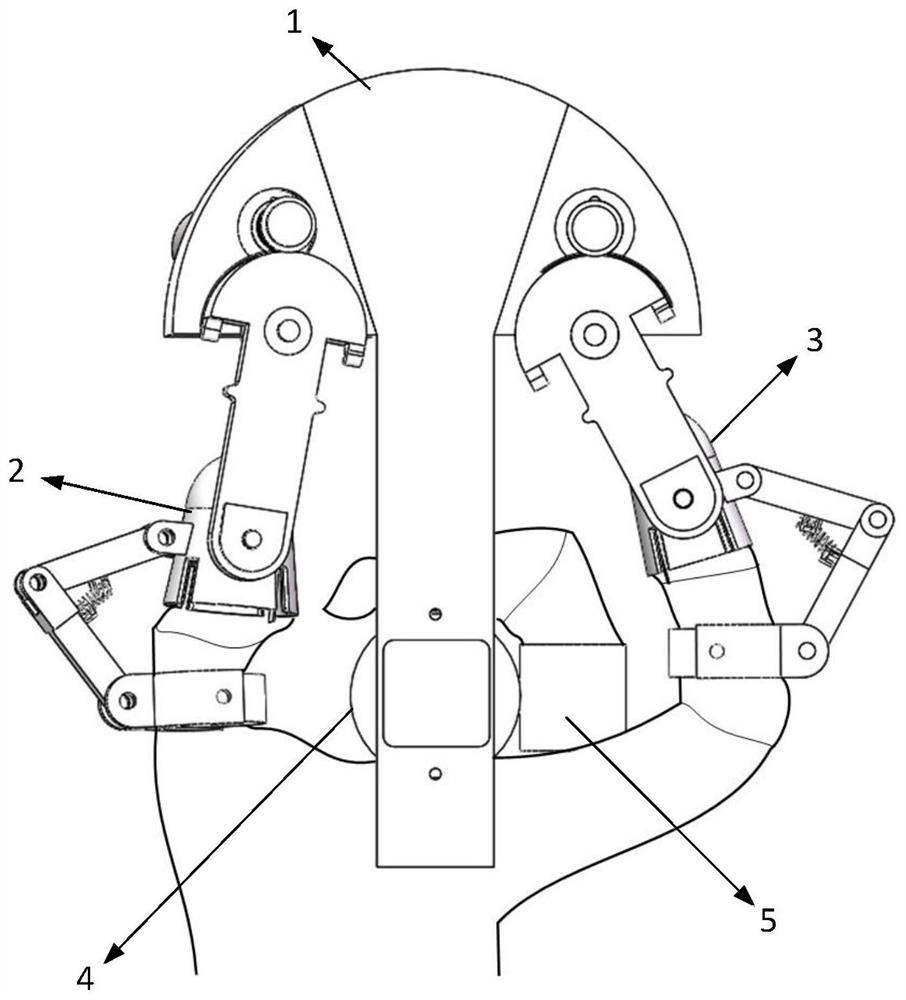

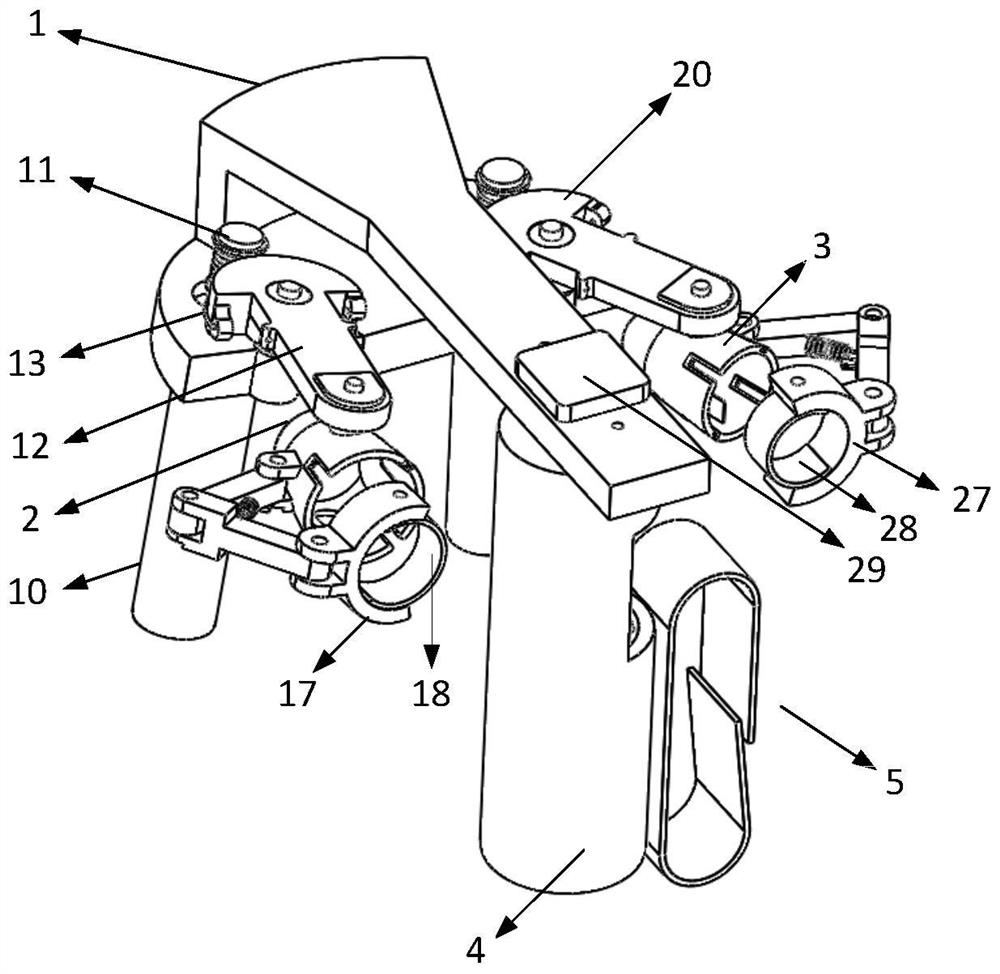

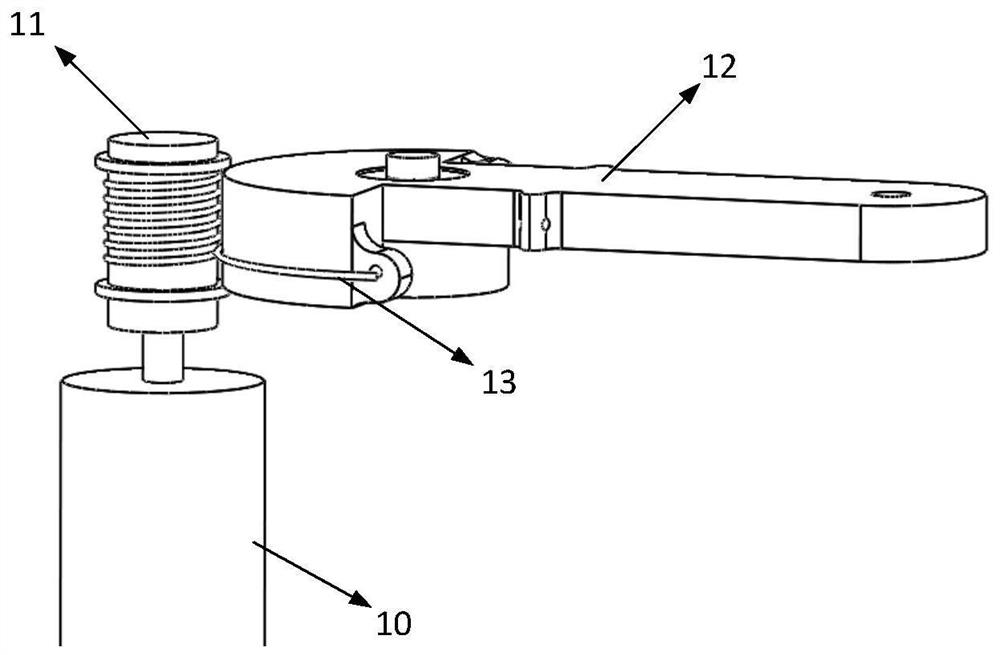

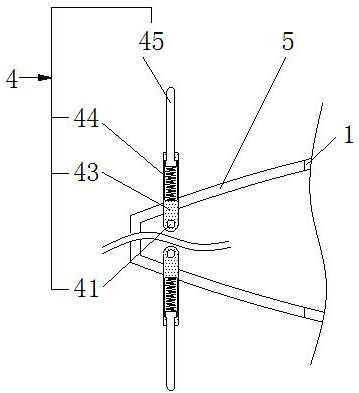

Two-degree-of-freedom rope transmission type finger force feedback device

ActiveCN112621790AThere will be no stuckImprove human-computer interactionAdditive manufacturing apparatusGripping headsHand partsIndex finger

The invention provides a two-degree-of-freedom rope transmission type finger force feedback device. The two-degree-of-freedom rope transmission type finger force feedback device comprises a hand support mechanism, a thumb movement mechanism, an index finger movement mechanism and a handle mechanism. The hand support mechanism comprises a motor, a motor shaft sleeve, a sliding rail and an IMU sensor. The thumb movement mechanism comprises a long rotating disc, a torque sensor, an angle sensor, a thumb sleeve, a pressure sensor, a two-bar linkage, a thumb bracket and a thumb fixing ring. The handle mechanism comprises a cylindrical grab handle, a pressure sensor, a flexible fixing band and a sliding block. Torque is transmitted between the rotating disc and the motor through a rope. The handle mechanism can move back and forth and self-reset. According to the two-degree-of-freedom rope transmission type finger force feedback device, the problems that traditional finger force feedback is high in cost and cannot be adjusted are solved, wearing is compact, and the self-adaptive freedom degree is achieved; rope transmission ensures that feedback force is smooth and real; and through the carried sensor, information such as hand postures, thumb and index finger rotating angles, grabbing force and middle finger contact force can be transmitted in real time.

Owner:SOUTHEAST UNIV

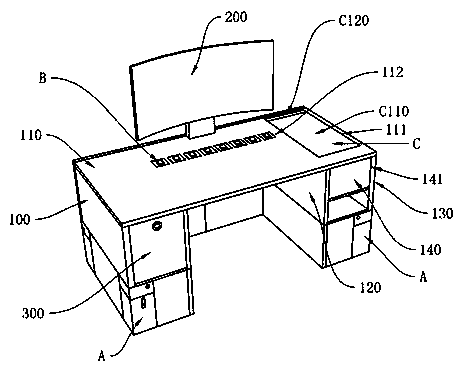

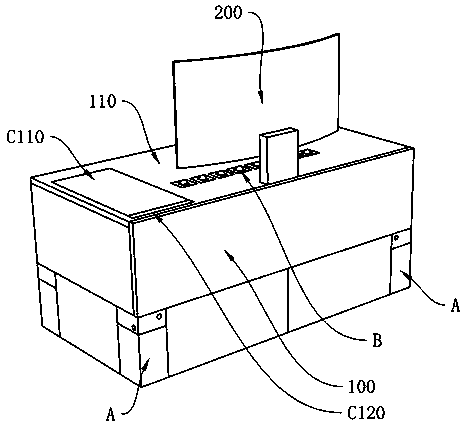

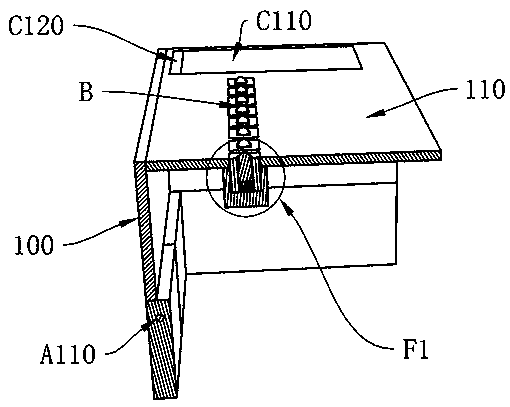

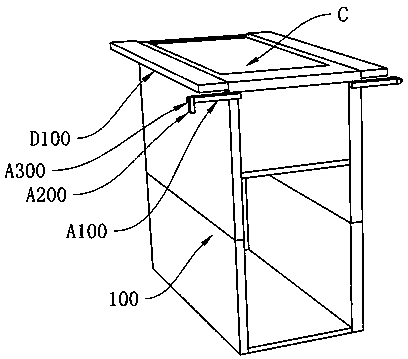

Intelligent building operation and maintenance management platform

ActiveCN109330189APrevent dereliction of dutyEffective warningAlarmsVariable height tablesMaintenance managementEngineering

The invention discloses an intelligent building operation and maintenance management platform. The platform includes a table body, the top surface of the table body is a table top. An alarm groove anda panel groove are formed in the table top. The alarm groove is internally provided with the alarm component. The right side of the table body is provided with a panel cavity, the panel cavity is internally provided with a panel component, and the bottom of the table body is installed on a support component; the open end of the panel cavity is sealed through a safety gate. According to the existing ergonomics theory, the support component, the alarm component and the panel component are designed and conform to the operation and observation habits of people, and thus a better monitoring and control effect is achieved. The alarm component gives an alarm through ascending and lighting and is designed in a key observation area, thereby having an effective alarm effect on users. The panel component integrates a control button which can be substantially controlled, direct control over all devices can be achieved, and thus the situation is avoided that the control is difficult and slow and cannot be achieved when something is wrong with the system.

Owner:ZHEJIANG SUBO TECH CO LTD

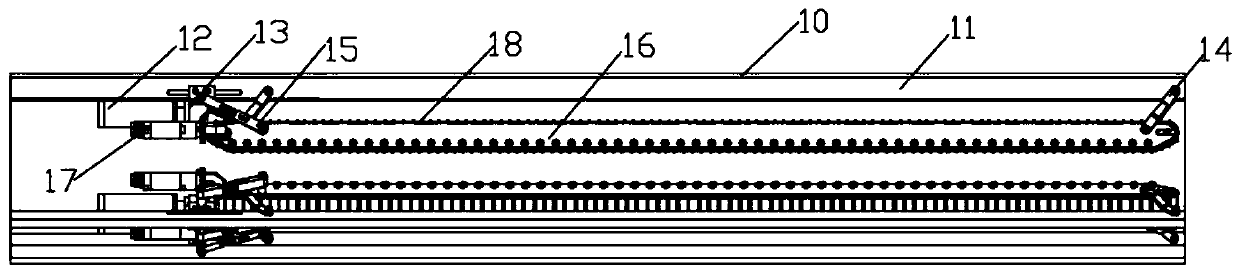

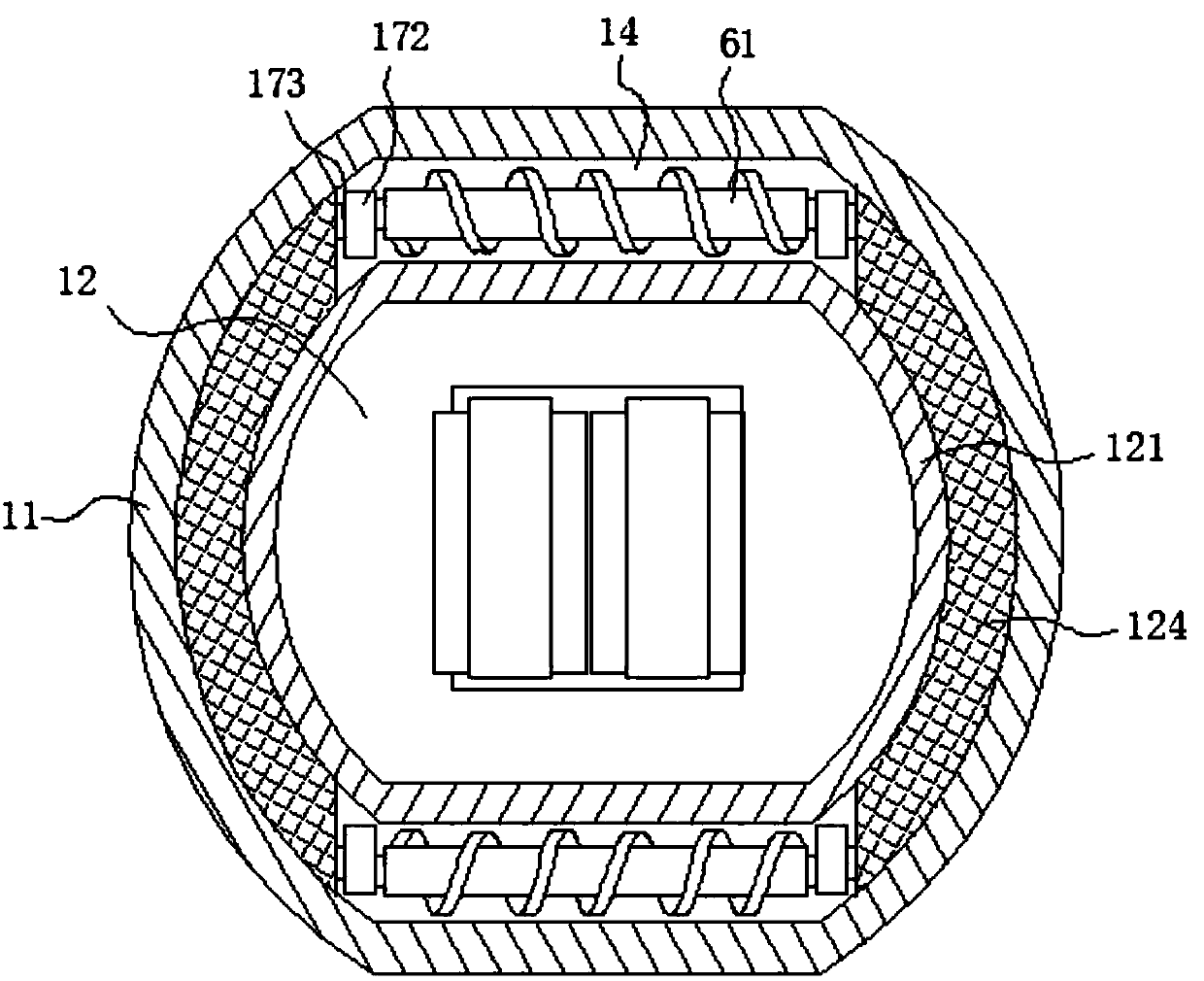

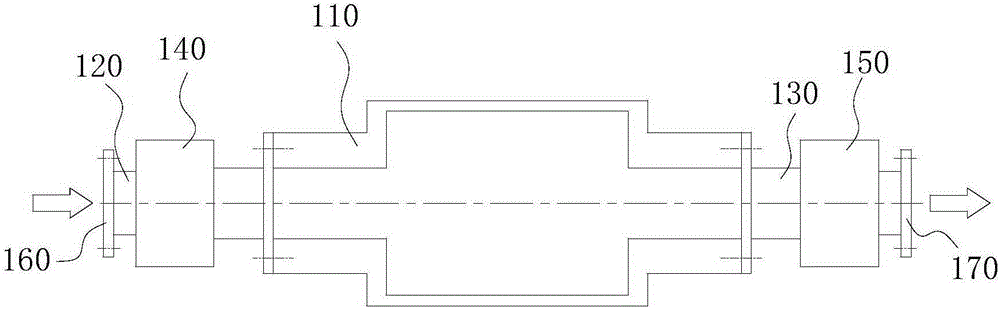

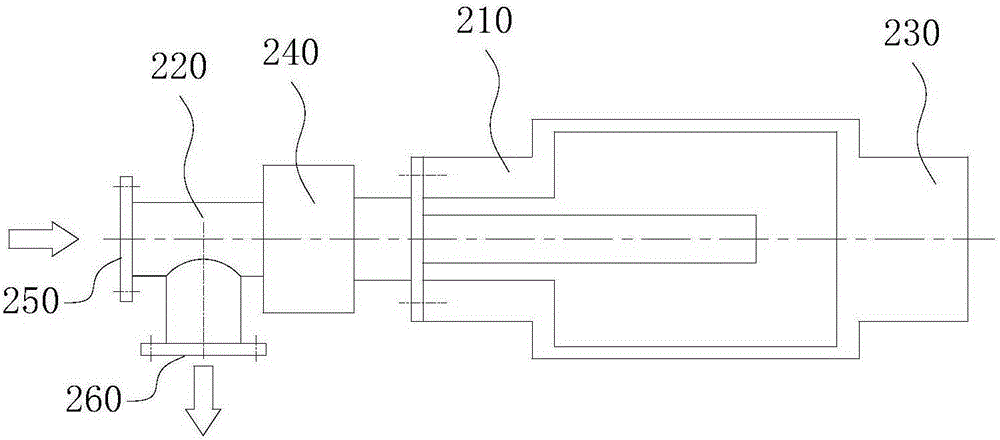

Tight winding equipment for RTP composite tubes

The invention discloses tight winding equipment for RTP composite tubes. The tight winding equipment comprises a rack and two winding and unwinding frames; the two winding and unwinding frames are symmetrically arranged on the two sides of the rack; a rectangular base is mounted at the top of the rack; and a tube feeding barrel is arranged above the rectangular base. According to the tight windingequipment, connecting blocks are driven by piston rods of telescopic air cylinders to slide on kidney-shaped holes in raised lines, the connecting blocks cooperate with spring pins and rotating pinsto drive side connecting plates to move towards the RTP composite tubes, then three conveying tracks are driven to make contact with the outer walls of the RTP composite tubes, the conveying tracks are driven by second motors through driving wheels to rotate and begins to convey the RTP composite tubes, through inner structure arrangement of the tube feeding barrel, the equipment can be used for conveying the RTP composite tubes in different outer diameters, meanwhile, the three conveying tracks make contact with and convey the RTP composite tubes simultaneously, the condition of slipping of the RTP composite tubes during conveying is avoided effectively, and the conveying efficiency of the RTP composite tubes is higher through cooperation with winding and unwinding on the two sides.

Owner:ANHUI JIELANTE NEW MATERIAL CO LTD

Joint bearing flanging tool and flanging process

The invention relates to a joint bearing flanging tool for aviation hanging parts, and a process of using the same for joint bearing flanging. The joint bearing flanging tool mainly comprises a roll, a retainer, a guide pin, a force-bearing support seat and a location support seat, wherein clearance fit is formed among the components; and the bearing flanging tool needs to be used in a manner of being matched with the flanged joint bearings in the hanging parts in specification and dimension during use. The joint bearing flanging tool is simple in structure, uniform in stress, capable of being automatically centred, stable in performance, reliable in quality, and capable of ensuring stability and smoothness during joint bearing flanging. According to the process of using the joint bearing flanging tool for bearing flanging, which is disclosed by the invention, the joint bearing flanging tool is installed on a spindle of a radial drilling machine, each flanged bearing is rotated and extruded to the required flanging dimensions through enabling the roll to contact with the groove surface of the flanged bearing. The process is stable in machining, simple to operate, short in alignment time, high in efficiency, stable in quality, and convenient for batch production.

Owner:CHENGDU ENGINE GROUP

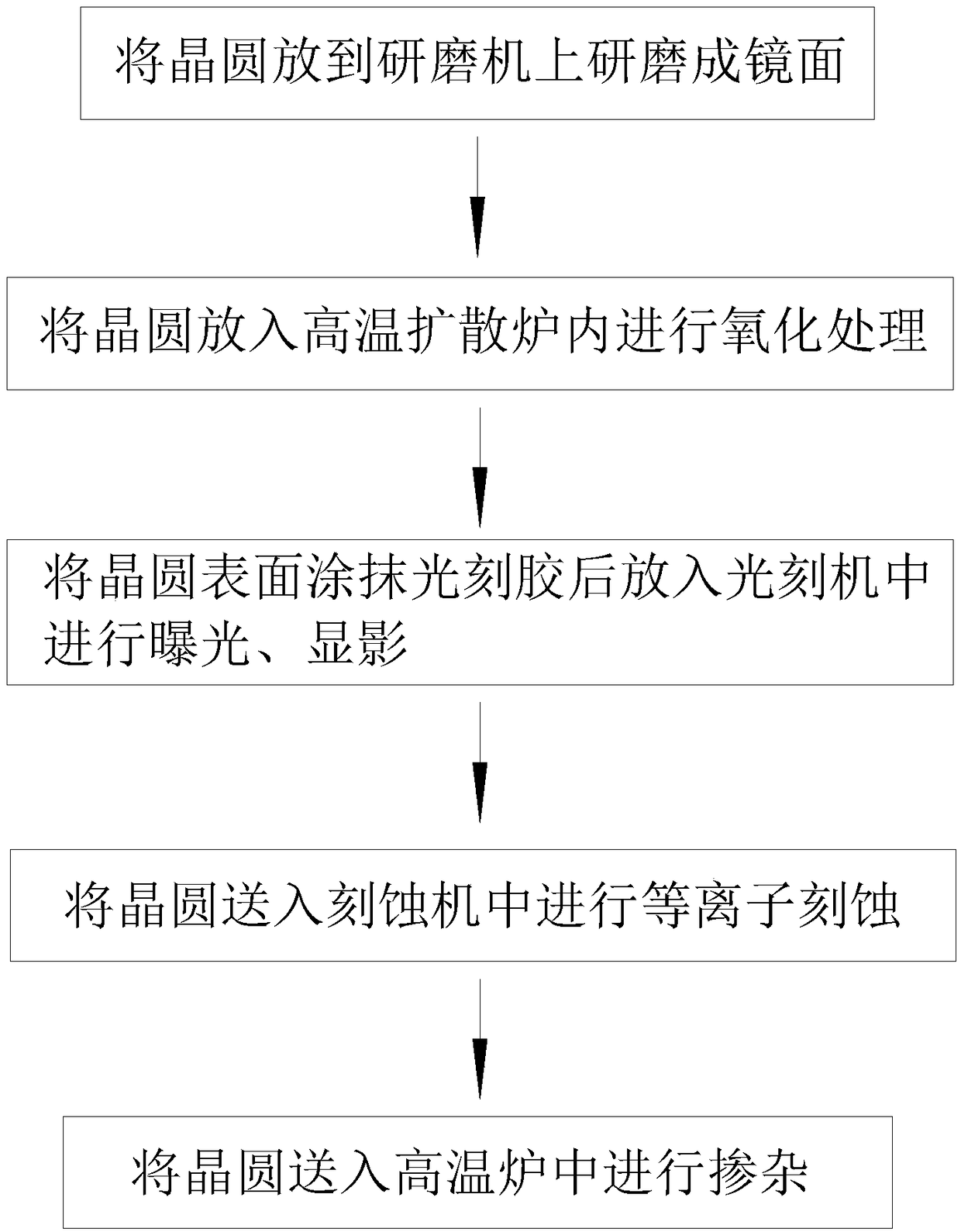

Semiconductor chip production technology

ActiveCN108807228AAchieve cleanupGood for fallingSemiconductor/solid-state device manufacturingSemiconductor chipEngineering

The invention belongs to the technical field of semiconductor manufacturing, and particularly discloses a semiconductor chip production technology. The technology comprises the following steps: putting wafers onto a grinding machine to be ground into mirror surfaces; putting the wafers into a high temperature diffusion furnace for oxidation treatment; after smearing the surfaces of the wafers witha photoresist, putting the wafers into a photoetching machine for exposure and developing; feeding the wafers into an etching machine for plasma etching; and feeding the wafers into the high temperature furnace for doping. In the grinding machine used in the technology, a circular arc-shaped sliding block is arranged on the waist-shaped hole of a fixed disc, a grinding device connected onto the circular arc-shaped sliding block through a connecting rod is in a floating state, and then the falling of silicon wafer particles inside a grinding disc is realized; the vibration of the grinding device at the lower end of the connecting rod is realized by setting cams with different initial angles; a balancing weight is arranged at the middle part of a transmission connecting rod, the rotation ofthe grinding disc in a fixed plane is realized, and then high-precision grinding of the surfaces of the wafers is realized.

Owner:海南千和企业管理有限公司

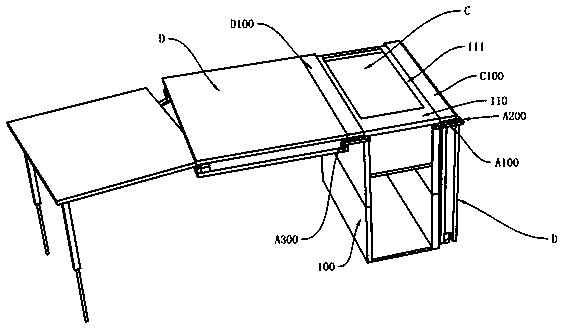

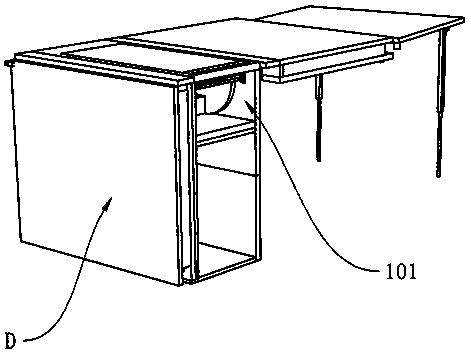

Intelligent platform of safe hospital

ActiveCN109222414AEasy to monitorImprove control effectOffice tablesExtensible tablesArchitectural engineeringMonitoring and control

The invention discloses an intelligent platform of a safe hospital. The platform comprises a table body, wherein the top surface of the table body is a desktop, a panel groove is arranged on the desktop, and a cover plate of a panel component is arranged in the panel groove; a panel assembly mounting cavity is also arranged on the table body, and a panel assembly is installed in the panel assemblymounting cavity; The two sides of the table body are respectively installed with folding and expanding assemblies, and a socket assembly is arranged on the desktop and beside the panel slot. According to the existing ergonomic theory, the invention designs the panel component and the expansion component, which accord with the operation habit and the observation habit of the human, thereby playinga better monitoring and control effect. The platform can expand the larger desktop space through the expansion component, so that the installation of the warning component can be satisfied under thecondition of the later hardware system expansion, and the accommodation performance of the warning component can be increased. The platform can fully exert the function of the platform as a table whenthe panel assembly is not opened through the linkage design of the plug-in assembly and the panel assembly.

Owner:ZHEJIANG SUBO TECH CO LTD

Sand manufacturing system

ActiveCN109833961AThe primary and secondary cooperation effect is goodAchieve recyclingGrain treatmentsManufacturing systemsConstruction waste

The invention discloses a sand manufacturing system. The sand manufacturing system comprises a crushing unit, a piling unit, a charging unit which cooperates with the piling unit, a drying unit and adust removing and discharging unit, wherein the crushing unit comprises a housing, a first crushing cavity arranged in the housing, a second crushing cavity, a recovering chamber, first crushing devices arranged in the first crushing cavity, second crushing devices arranged in the second crushing cavity and a recovering device arranged in the recovering chamber; an outlet of the first crushing cavity communicates with an outlet of the recovering chamber and an inlet of the second crushing cavity; and a filtering device is arranged at an outlet of the recovering chamber. Through adoption of thesand manufacturing system disclosed by the invention, two operations of coarse crushing and fine crushing of construction wastes can be realized on the same equipment, so that the working efficiencyis high; cutters are not liable to damage, so that the service life of the equipment is long; and besides, the filtering device is arranged, so that the situation that the cutters in the second crushing cavity are used for crushing materials which does not conform to the processing specification is further avoided, and the damage ratio is reduced.

Owner:杭州益森实业有限公司

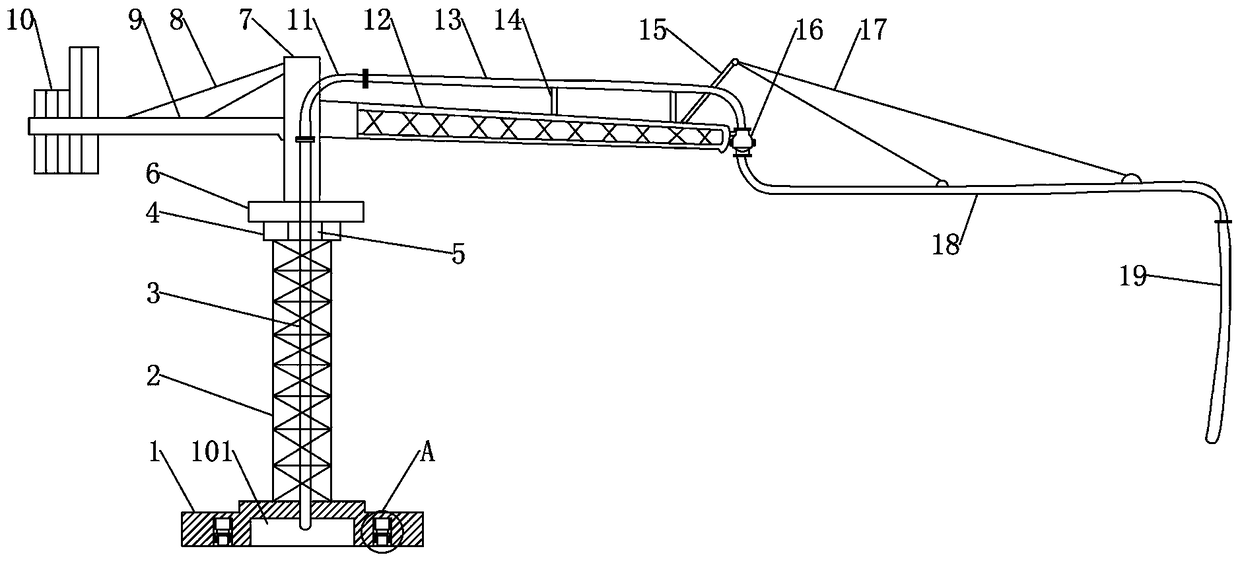

Concrete placing equipment

InactiveCN108442706AEasy to moveSimple structureBuilding material handlingHydraulic cylinderEngineering

The invention discloses concrete placing equipment. The concrete placing equipment comprises a base, a vertical frame is arranged on the upper end surface of the base, a bearing seat is arranged at the upper end of the vertical frame, a pivotal bearing is installed in the bearing seat in a sleeved mode, the lower end of an upper installation seat is installed in the pivotal bearing in a sleeved mode, a balancing arm and a main beam are separately arranged on both sides of the upper installation seat, and a weight box is arranged at the tail end of the balancing arm. A conveying pipe includes avertical pipe, a transverse pipe, a rotary pipe and a discharge hose which are connected in sequence. A roller installing cavity is formed in the lower end surface of the base, roller drive hydrauliccylinders and rolling wheels are arranged in the roller installing cavity, the roller drive hydraulic cylinders are fixedly installed on the top of the roller installing cavity, and the rolling wheels are installed at the lower ends of hydraulic telescopic rods of the roller drive hydraulic cylinders. The roller drive hydraulic cylinders and the rolling wheels are arranged, the rolling wheels aredriven by the roller drive hydraulic cylinders to move up and down, when a placing device needs to move, the rolling wheels are pushed out, when the placing device is not needed, the rolling wheels are installed in the roller installing cavity, the structure is simple, and the use is convenient.

Owner:李晓

Cabin door locking device of special vehicle

The invention discloses a cabin door locking device of a special vehicle. The cabin door locking device comprises a cabin door and a deck; a cabin door through hole is formed in the cabin door, and alock sleeve is arranged in the cabin door through hole; a rotatable lock shaft is arranged in the lock sleeve, and one end of the lock sleeve is in transmission connection with a lock tongue arrangedon the inner side of the cabin door; the lock tongue can move in the axis direction of the lock shaft, and is provided with a lock tongue threaded hole, and a first outer thread matched with the locktongue threaded hole is arranged on the lock shaft; and a sealing part is arranged on the inner side of the deck and internally provided with a flexible sealing piece, and when the cabin door is closed, a flange on the inner side of the cabin door compresses the flexible sealing piece. According to the cabin door locking device of the special vehicle, the pressure of the locking device on the cabin door locking position is adjustable, and the cabin door locking device is small in occupied space, good in airtightness, high in reliability, simple in structure and easy to operate.

Owner:JIANGLU MACHINERY & ELECTRONICS GROUP

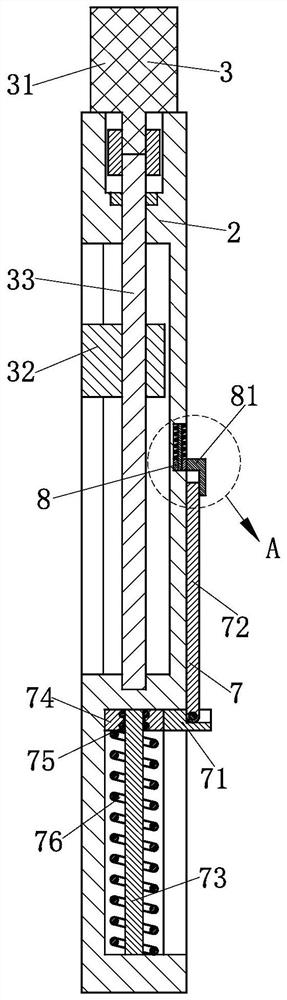

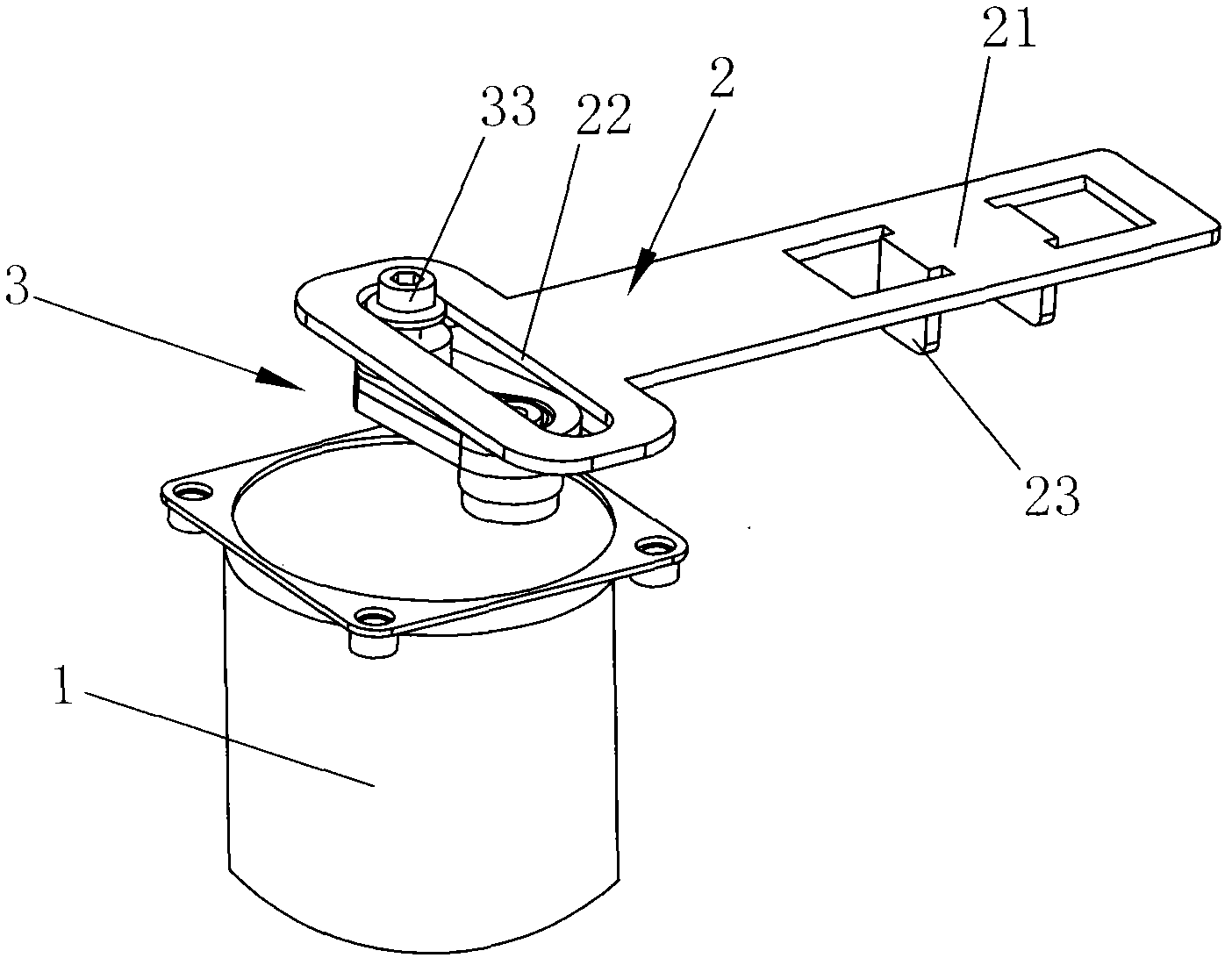

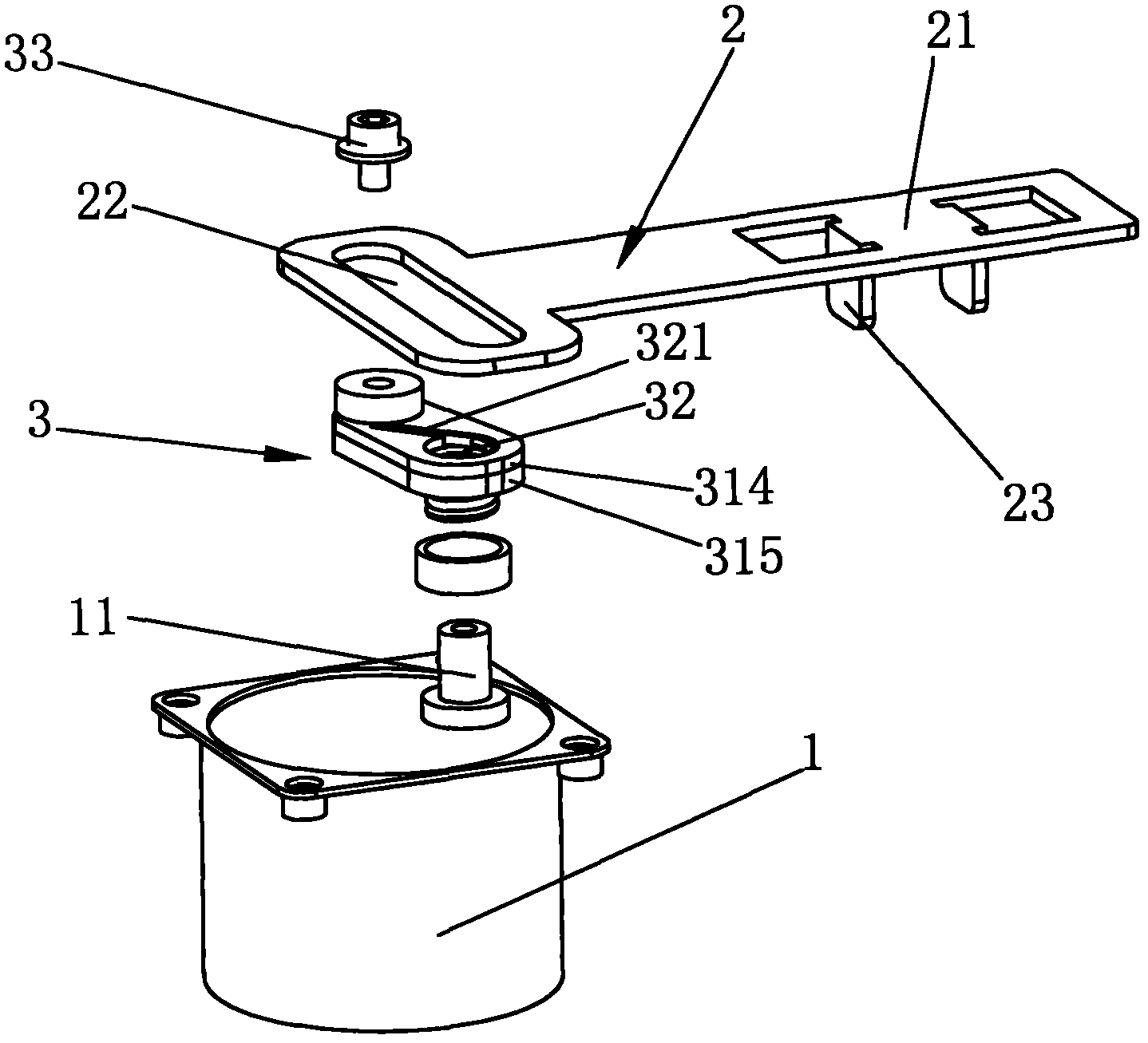

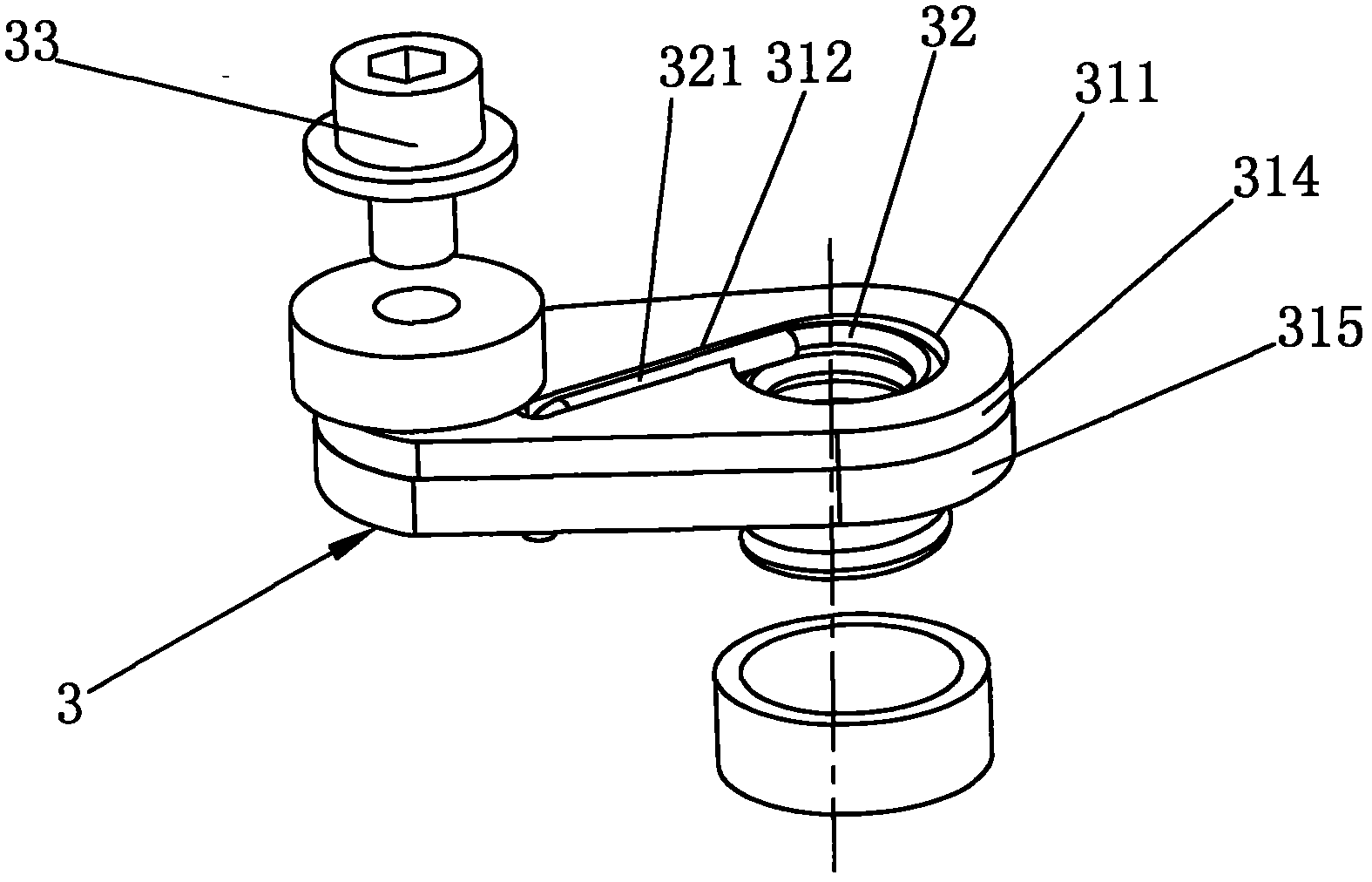

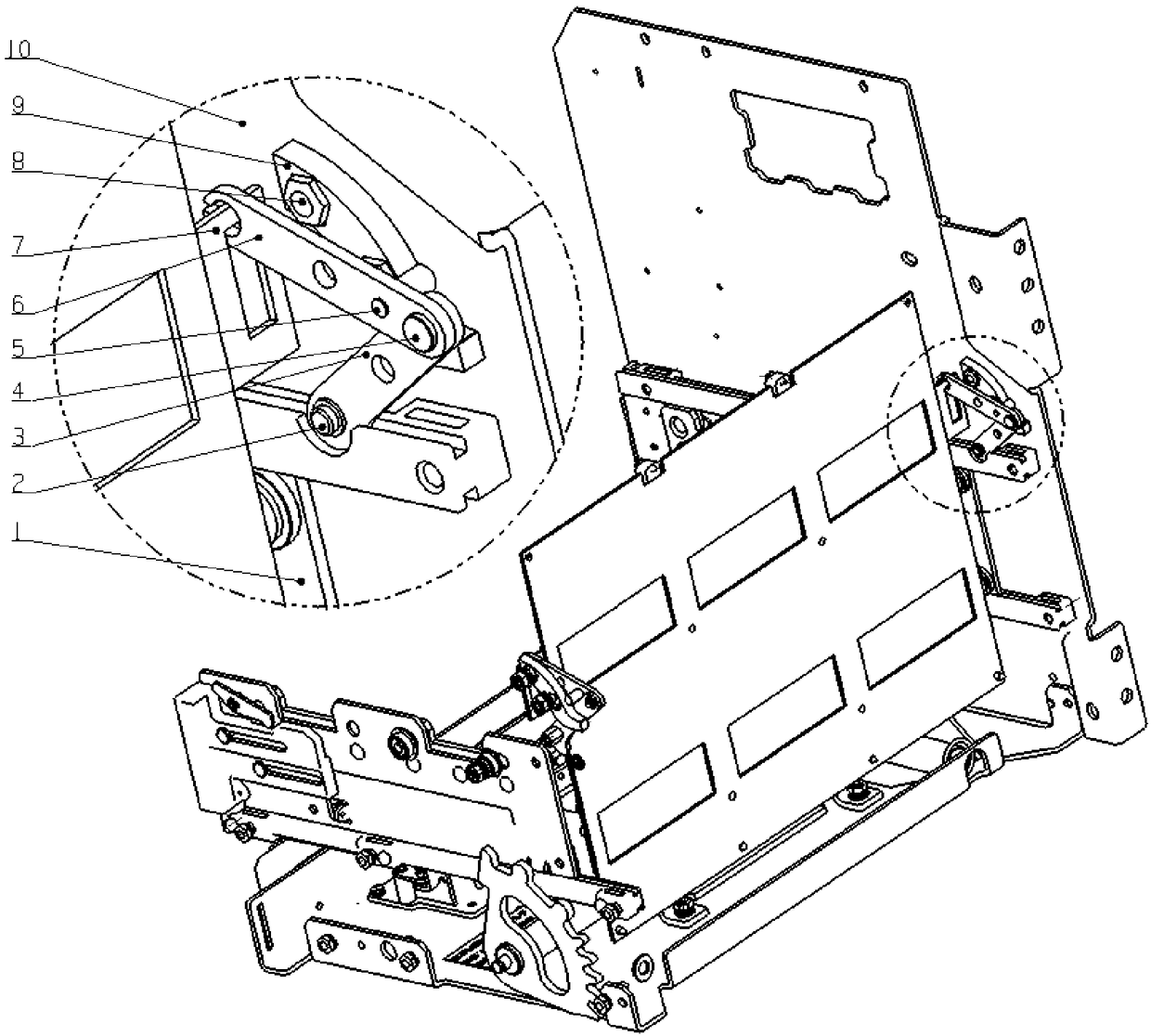

Transmission mechanism of circuit breaker

ActiveCN102054605AThere will be no stuckGuaranteed reliabilitySwitch power arrangementsTorsion springMotor shaft

The invention relates to a transmission mechanism of a circuit breaker, wherein the other end, which is opposite to an operating end, of a lifting lever is provided with a sliding groove; the arranging direction of the sliding groove is vertical to the moving direction of the lifting lever; a link mechanism comprises a crank, a torsion spring and a slide block, and one end of the crank is provided with a spring hole opposite to a motor shaft; the torsion spring is contained in the spring hole and is simultaneously sleeved on the motor shaft; one skintle of the torsion spring is fixedly connected with the crank; the other end of the crank is arranged below the sliding groove of the lifting lever; the upper end of the slide block is arranged in the sliding groove of the lifting lever and isin slide fit with the sliding groove; the lower end of the slide block is fixedly connected with the crank; and the motion of the lifting lever is realized through the sliding of the slide block in the sliding groove under the driven of the positive and negative rotation of the motor. Electromotive switch-on and switch-off are realized through the designed special link mechanism and the designed special lifting lever, the security is improved, the stucking of the lifting lever can not happen, and the reliability of the switch-on and switch-off of the circuit breaker is ensured.

Owner:FULONG ELECTRIC CO LTD

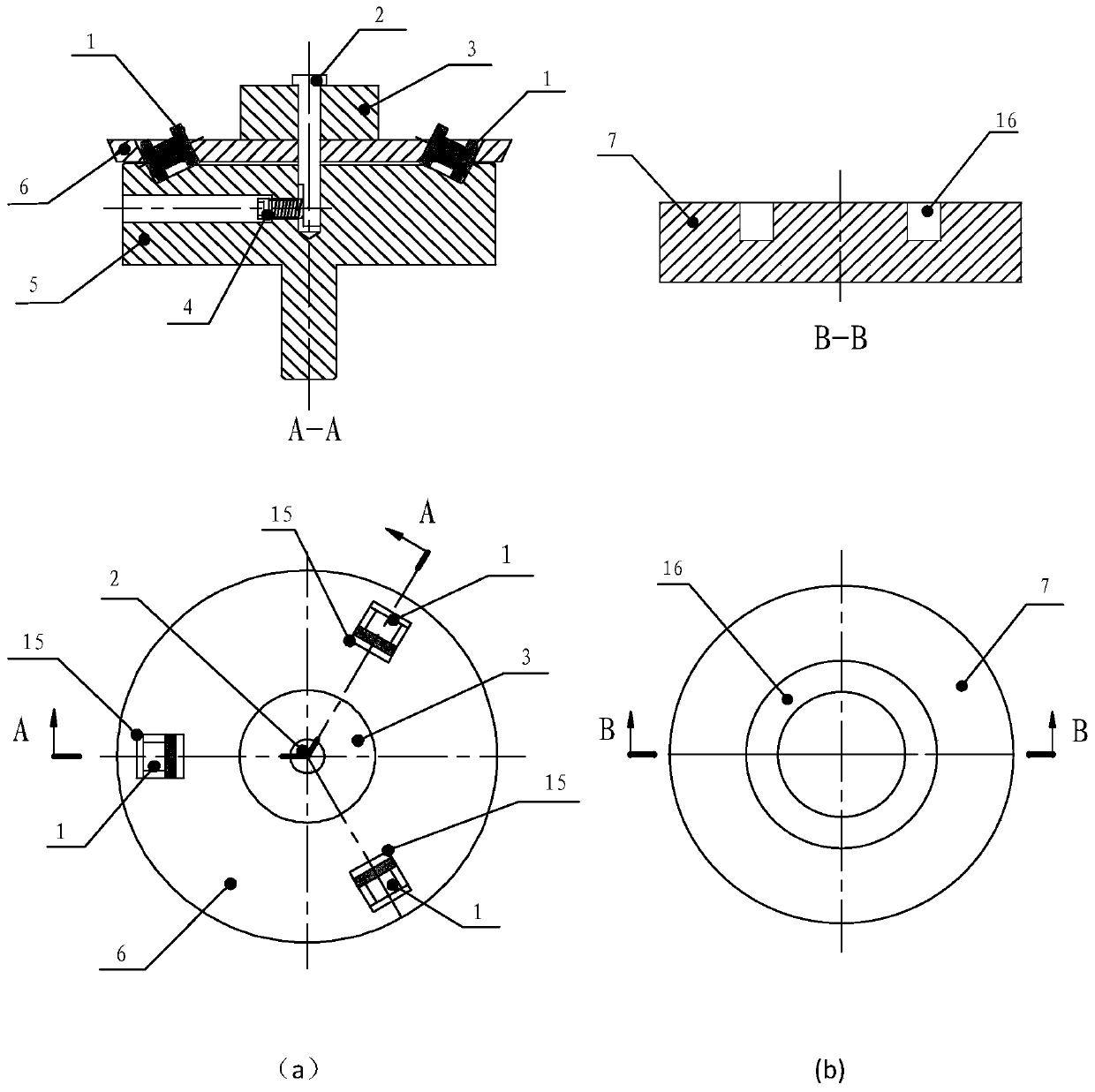

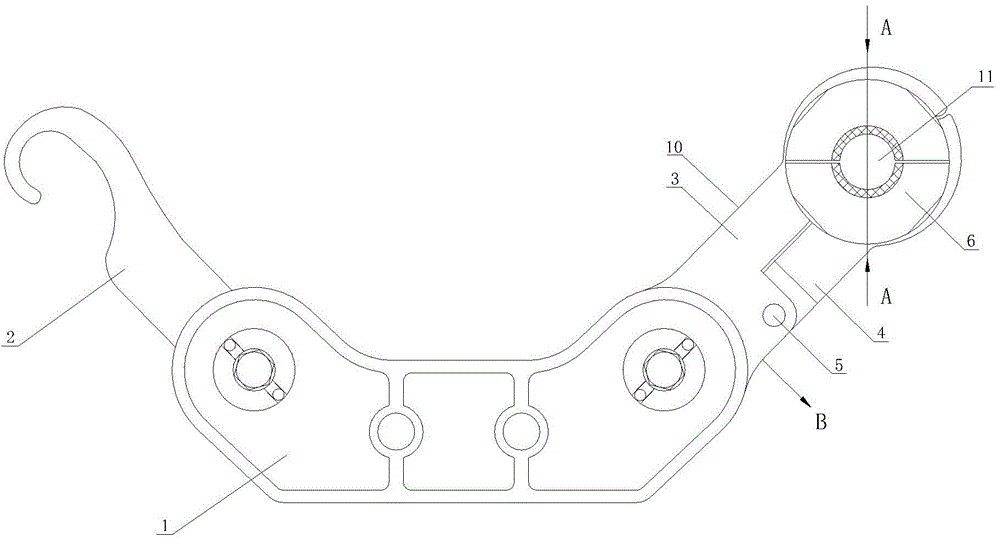

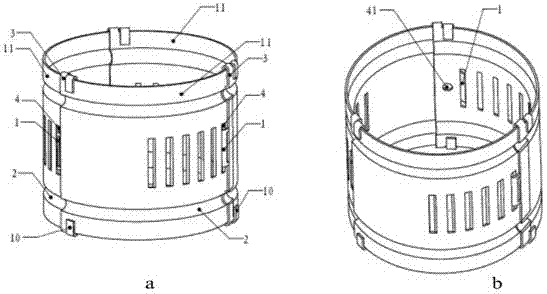

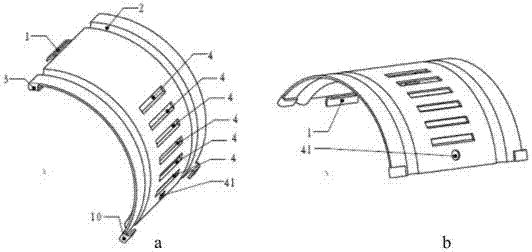

Anti-slip pre-twisted damping type spacer

InactiveCN105024331ASmooth rotationGood wear resistanceMaintaining distance between parallel conductorsPower transmissionMechanical engineering

The invention provides an anti-slip pre-twisted damping type spacer which is good in anti-swing effect, capable of preventing a wire clamp from sliding on a wire and good in rotating effect at the same time. The anti-slip pre-twisted damping type spacer comprises a spacer body, an anti-slip pre-twisted wire clamp and a wire clamp pressing plate, wherein the wire clamp pressing plate comprises a wire clamp pressing plate body and a wire clamp pressing plate cover plate, and a threading hole formed by the wire clamp pressing plate body and the wire clamp pressing plate cover plate is internally provided a rotational damping wire clamp with a center hole. The anti-slip pre-twisted damping type spacer is characterized in that a stainless steel backing plate is arranged between the rotational damping wire clamp and the threading hole. According to the invention, the rotational damping wire clamp and the threading hole are provided with the stainless steel backing plate therebetween, the stainless steel backing plate is of a corrugated shape, so that the cylindrical inner wall and the damping wire clamp are enabled to have a certain elastic space therebetween, a wire clamp blocking condition does not occur when power transmission line swings and drives the rotational damping wire clamp to rotate, thereby enabling the rotational damping wire clamp to rotate smoothly, and thus enabling the power transmission line not to have a twisting phenomenon.

Owner:张伟

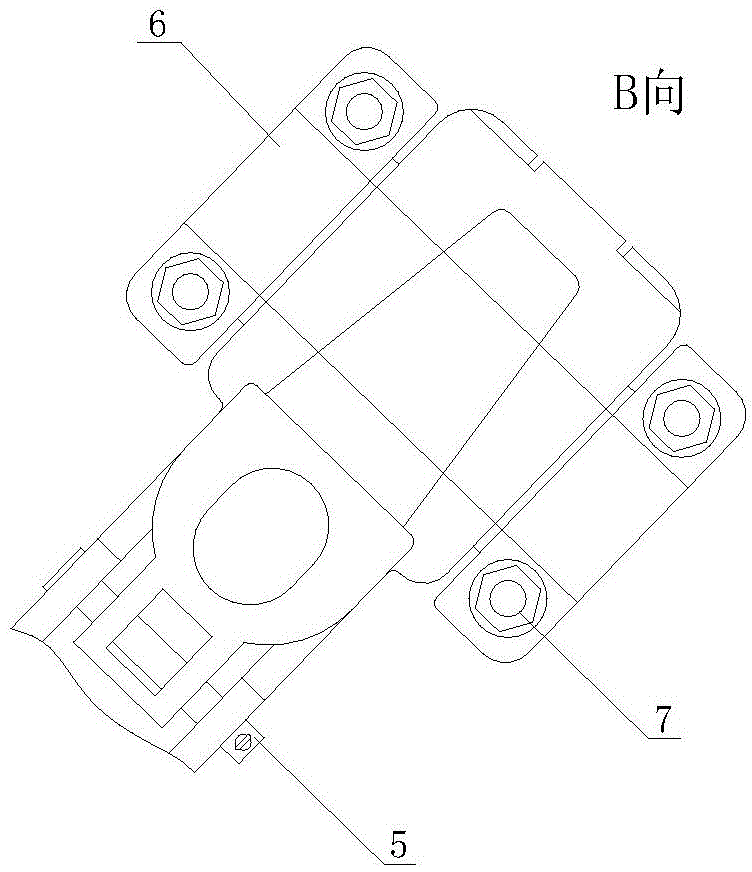

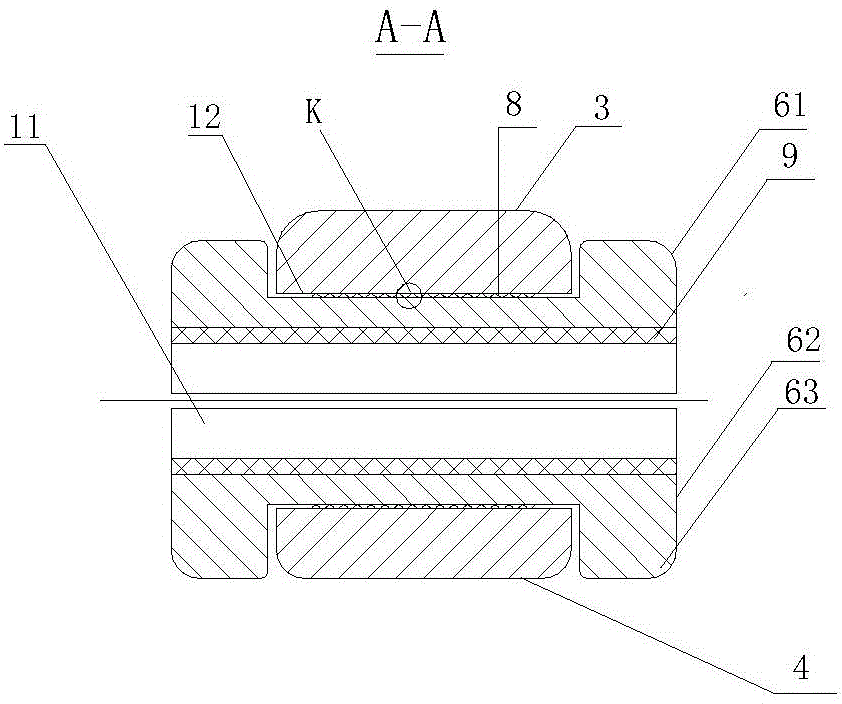

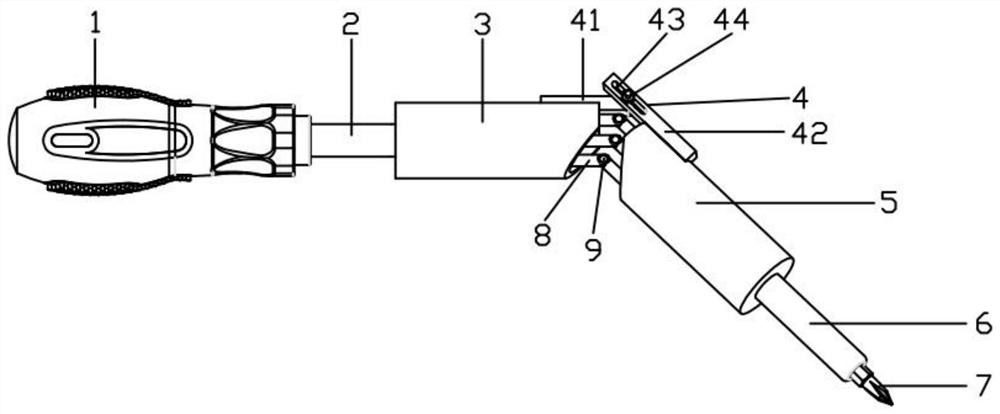

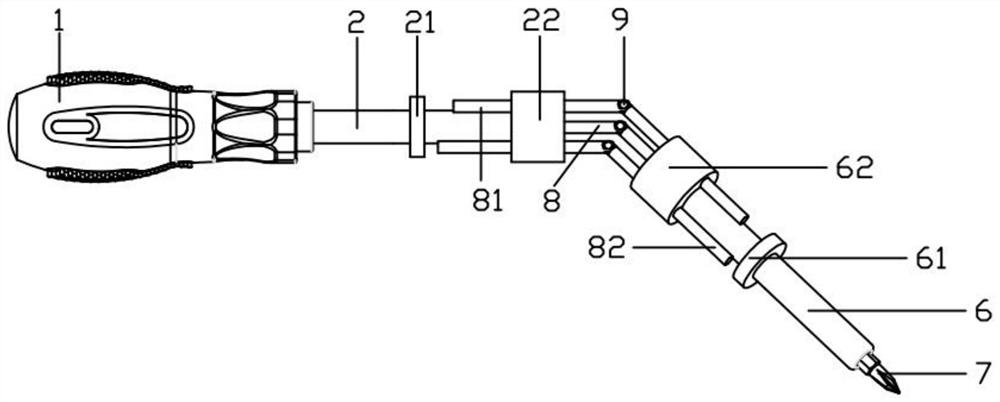

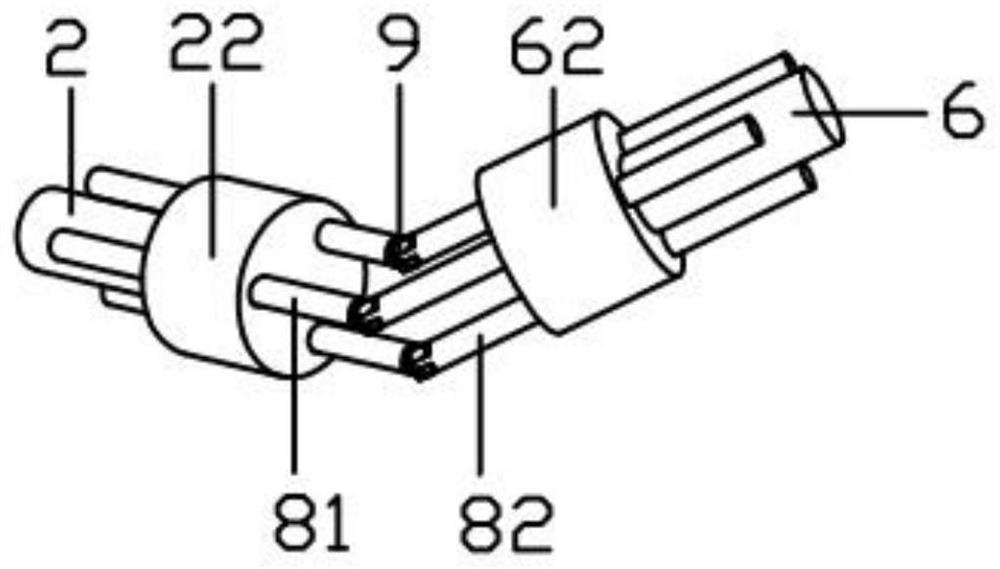

Gearless coupler and multi-angle screwdriver

The invention discloses a gearless coupler and a multi-angle screwdriver. The gearless coupler comprises a first rotor, a second rotor and at least one connecting rod. The end part of the first rotor is fixedly connected with a first rotary disc. The end part of the second rotor is fixedly connected with a second rotary disc. The connecting rod comprises a driving rod and a driven rod. The end parts of the driving rod and the driven rod are not collinear when being connected. The driving rod penetrates into the part, deviating from the axis, of the first rotary disc and is in sliding fit with the first rotary disc. The driven rod penetrates into the part, deviating from the axis, of the second rotary disc and is in sliding fit with the second rotary disc. The multi-angle screwdriver comprises a handle and a movable tool bit connected with the handle, the gearless coupler is connected between the handle and the movable tool bit, and the handle is fixedly connected with the first rotor; and the movable tool bit is coaxially and fixedly connected with the second rotor. By means of the gearless coupler and the multi-angle screwdriver, the angle can be changed to transmit torque, and the screwdriver can fasten a screw in a narrow space.

Owner:中铁建工集团建筑安装有限公司 +1

An auxiliary device for rapid docking of blood vessels during operation

Owner:北京有卓正联医疗科技有限公司

Printing mechanism of ceramic decorating machine

InactiveCN107901594AReduce vibrationNot easy to produce vertical offsetRotary pressesBlade plateFlange

The invention discloses a printing mechanism of a ceramic decorating machine. The printing mechanism is small in noise and high in printing accuracy, and comprises a transverse beam support, a stepping motor, a rotating haft, a scraper installing plate, scrapers, a scraper hanging plate and a scraper clamping plate, the stepping motor and the rotating shaft are arranged above the transverse beam support and are in transmission connection through a stepping motor transition flange, a damping mat is arranged between the stepping motor and the stepping motor transition flange, the two scrapers are arranged on the two sides of the bottom of the scraper installing plate, the scrapers comprise the front scraper and the back scraper, a first adjusting screw is arranged at the top of the front scraper, a second adjusting screw is arranged at the top of the back scraper, the scraper hanging plate and the scraper clamping plate are arranged below the scrapers and are parallel, a gap is reservedbetween the scraper hanging plate and the scraper clamping plate, the scrapers are located in the gap between the scraper hanging plate and the scraper clamping plate, the scraper clamping plate is provided with a clamping plate at the position located on the side face of the gap, and a plurality of compressed springs are arranged between the clamping plate and the scraper clamping plate.

Owner:佛山市嘉印机械设备有限公司

Household small water dispenser with atomization and humidification functions

ActiveCN111265110APrevent splashAvoid burnsLighting and heating apparatusBeverage vesselsStructural engineeringMachine

The invention discloses a household small water dispenser with atomization and humidification functions. The household small water dispenser comprises a main machine body; a fixed base is fixedly arranged on the top surface of the main machine body; a smart base can be fixedly mounted at the top of the fixed base; the smart base comprises an insertion rod fixed to the smart base; two supporting plates which are symmetrical left and right are fixedly arranged on the top surface of the main machine body; bearing blocks are arranged between the two supporting plates in an up-down sliding mode; the side faces, close to each other, of the two bearing blocks are designed to be oblique arc-shaped faces; and a water bucket can be clamped by the bearing blocks. The water bucket can be placed on thebearing blocks, and the problem that the inserting rod is broken off due to misoperation when people place the bucket on the water dispenser is solved; and when the bucket is placed manually, the bucket does not need to be aligned with the smart base, only the opening of the bucket needs to face downwards, and the arc-shaped curved surface of the bearing blocks can automatically align the water outlet of the bucket with the smart base.

Owner:吴瑾

High-speed heat transfer oil roller

ActiveCN103556427BImprove heat transfer efficiencySimple structureTextile shapingHeat transfer efficiencyEngineering

The invention discloses a high-speed heat-transfer oil roller. The high-speed heat-transfer oil roller comprises a roller body, wherein a first roller spindle head and a second roller spindle head for connection with a power source are arranged at the two ends of the roller body, an oil line circulating pipeline for circularly heating the outer surface of the roller body is arranged in the roller body, a first bearing pedestal is arranged on the first roller spindle head, a second bearing pedestal is arranged on the second roller spindle head, bearings enabling the roller body to rotate around the axes of the bearings are arranged between the first bearing pedestal and the first roller spindle head and between the second bearing pedestal and the second roller spindle head, a rotary sealing device for oil inlet and oil outlet is detachably arranged at one side, which is far away from the roller boy, of the first bearing pedestal, and an oil inlet for connection with an inlet end of the oil line circulating pipeline and an oil outlet for connection with an outlet end of the oil line circulating pipeline are formed in the rotary sealing device. The high-speed heat-transfer oil roller disclosed by the invention is simple in structure and high in heat transfer efficiency; the blocking phenomenon and potential safety hazards are avoided in the using process of the high-speed heat-transfer oil roller.

Owner:无锡市艾可密封技术有限公司

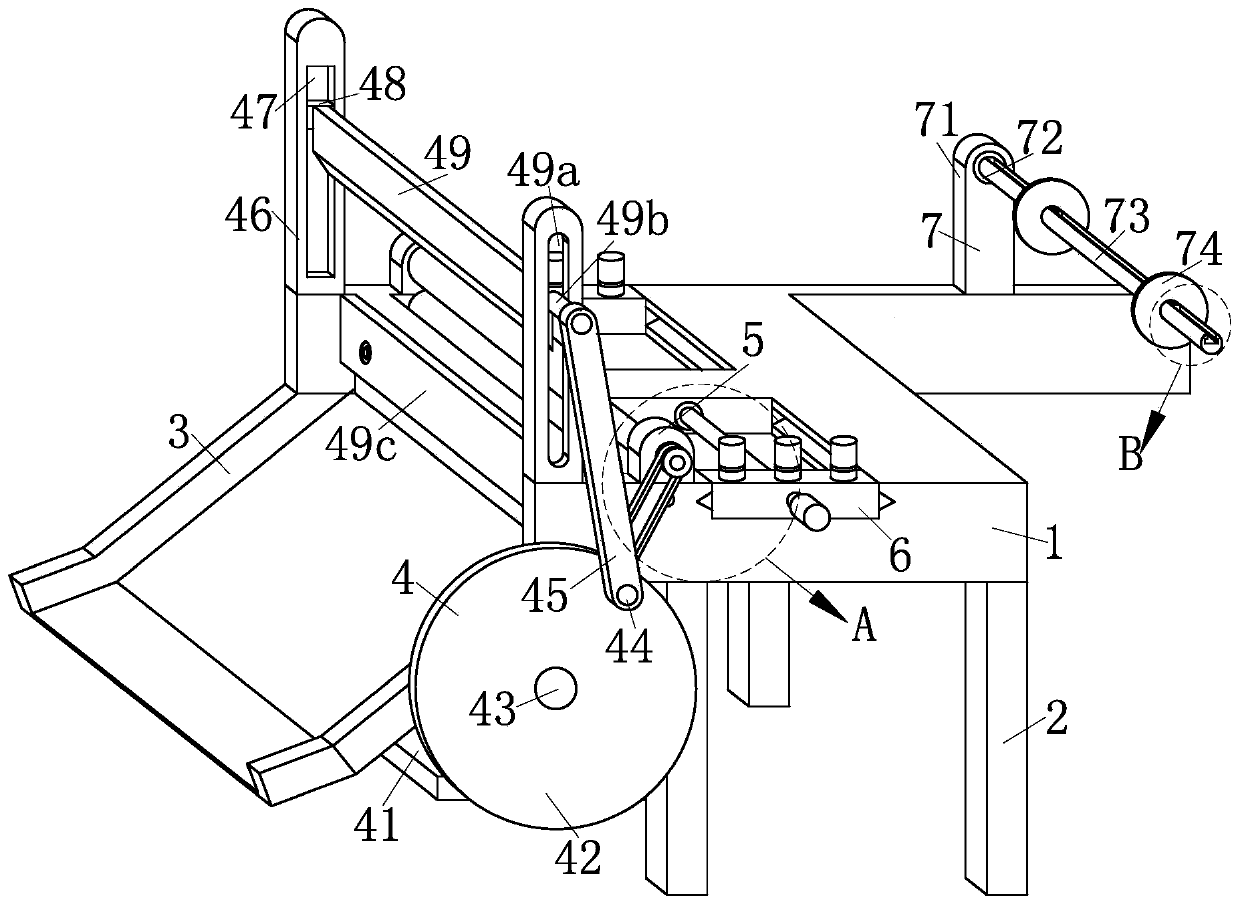

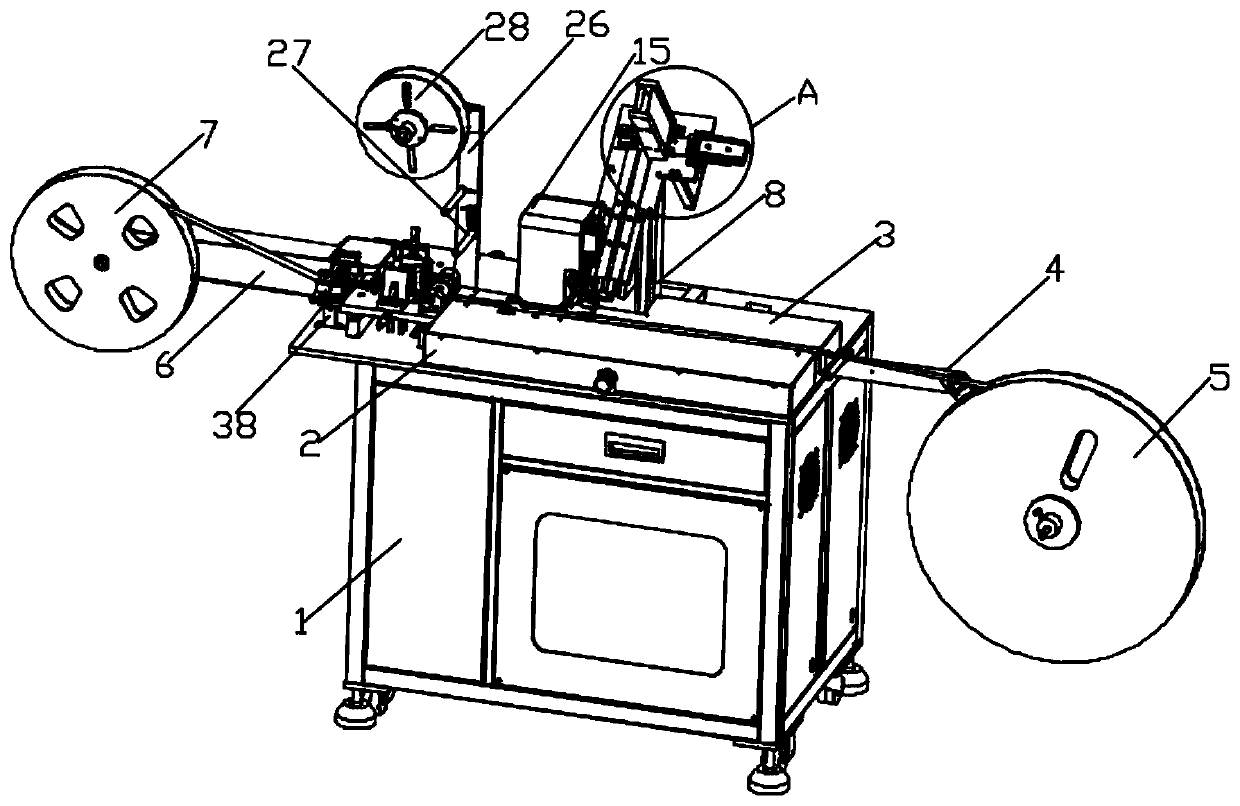

Automatic braiding machine for chip processing and use method of automatic braiding machine

InactiveCN110451002AAvoid misalignmentPracticalWrapping material feeding apparatusPackaging automatic controlMotor driveElectric machinery

The invention discloses an automatic braiding machine for chip processing and a use method of the automatic braiding machine. The automatic braiding machine comprises a cabinet body. A side cover bodyis fixed to one side of the length direction of the top of the cabinet body, a front plate cover and a rear plate cover are arranged on one side of the side cover body, a connecting rod is fixedly mounted on one side of the rear plate cover, and a carrying belt wheel is fixedly mounted at one end of the connecting rod. The output end of a first air cylinder pushes a push plate, the push plate penetrates through a through hole in one side of the bottom of a chip groove, chips at the bottom of the chip groove are pushed out through a through hole in the other side, the chips are guided by a guide groove in a discharging mainboard to slide to a carrying belt between the front plate cover and the rear plate cover, and the technical problem that the chips are prone to staggering in the braiding process in the prior art is solved; and an output shaft of a reset motor drives a rotary disc to rotate, the rotary disc drives a fixing pin to rotate, the fixing pin drives a connecting part to move, the connecting part drives a sliding rod to move on a centering seat downwards, a suction nozzle on a suction nozzle seat sucks the chips, and the technical problem that the suction nozzles are easily jammed in the up-and-down movement process in the prior art is solved.

Owner:ANHUI LONGXINWEI TECH CO LTD

Construction method for building wall

InactiveCN108104470AAvoid processing powerAvoid the situationBuilding material handlingWaste managementScrap

The invention discloses a construction method for a building wall. A breaking unit, a stacking unit, a feeding unit, a drying unit and a dedusting discharging unit are included, wherein the feeding unit is matched with the stacking unit. The breaking unit comprises a shell, a primary processing chamber, a secondary processing chamber, a recovering channel, a first breaking device, a second breaking device and a recovering device, wherein the primary processing chamber is arranged in the shell, the first breaking device is arranged in the primary processing chamber, the second breaking device is arranged in the secondary processing chamber, and the recovering device is arranged in the recovering channel. An outlet of the primary processing chamber communicates with an outlet of the recovering channel and an inlet of the secondary processing chamber, and a filtering piece is arranged at the outlet of the recovering channel. According to the construction method, building waste can be subjected to two operations of coarse breaking and fine breaking on the same equipment, and the working efficiency is high; tools are not prone to being damaged, and the service life of the equipment is long; and meanwhile, the filtering piece is arranged, the situation that the tools in the primary processing chamber break materials not conforming to the processing specifications of the tools is further prevented, and the damage rate is decreased.

Owner:常成友

Floating object cleaning device for surface treatment of rivers and lakes

InactiveCN112813946AComprehensive collectionThere will be no stuckWater cleaningWaterborne vesselsGear wheelFishery

The invention discloses a floating object cleaning device for surface treatment of rivers and lakes. The device comprises a ship body, a deck, a motor and a water pump, the deck is fixedly installed on the inner wall of the ship body, the motor is fixedly installed on the upper surface of the deck, the lower end of the motor is connected with a collecting mechanism, and a containing groove is formed in one end of the ship body. A filtering plate is fixedly installed in the ship body, the water pump is fixedly installed on the inner wall of the lower end of the ship body, meanwhile, a fixing frame is fixedly installed at one end of the ship body, a lifting mechanism is connected into the fixing frame, a driven rod is rotatably connected to one end of the deck, and a bevel gear set is in key connection to the lower end of the driven rod. According to the floating object cleaning device, through movement of a movable block, the movable block extrudes floating objects in the fixing frame, the floating objects are extruded into blocks, the density of the floating objects in the fixing frame is increased, and more floating objects are further contained in the fixing frame.

Owner:崔宝今

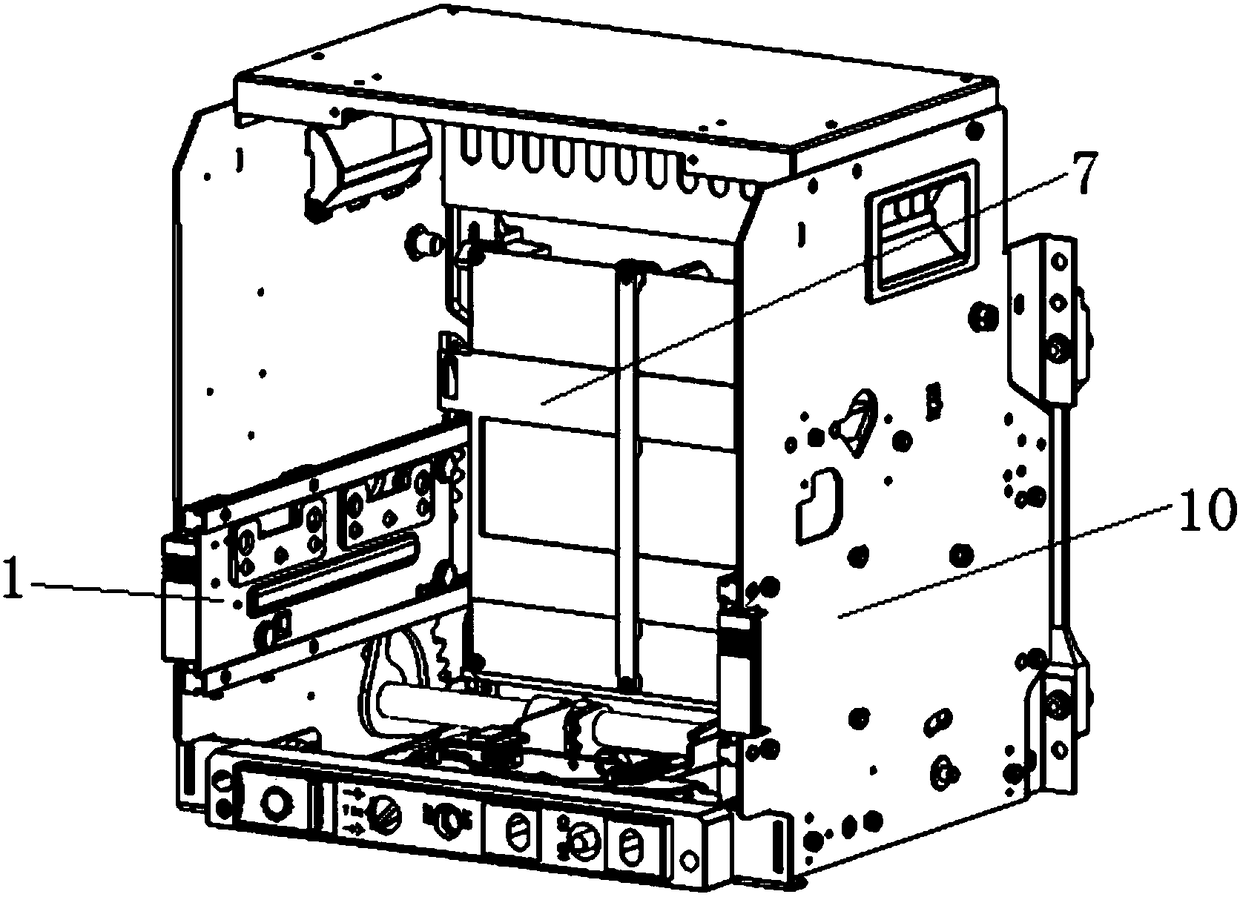

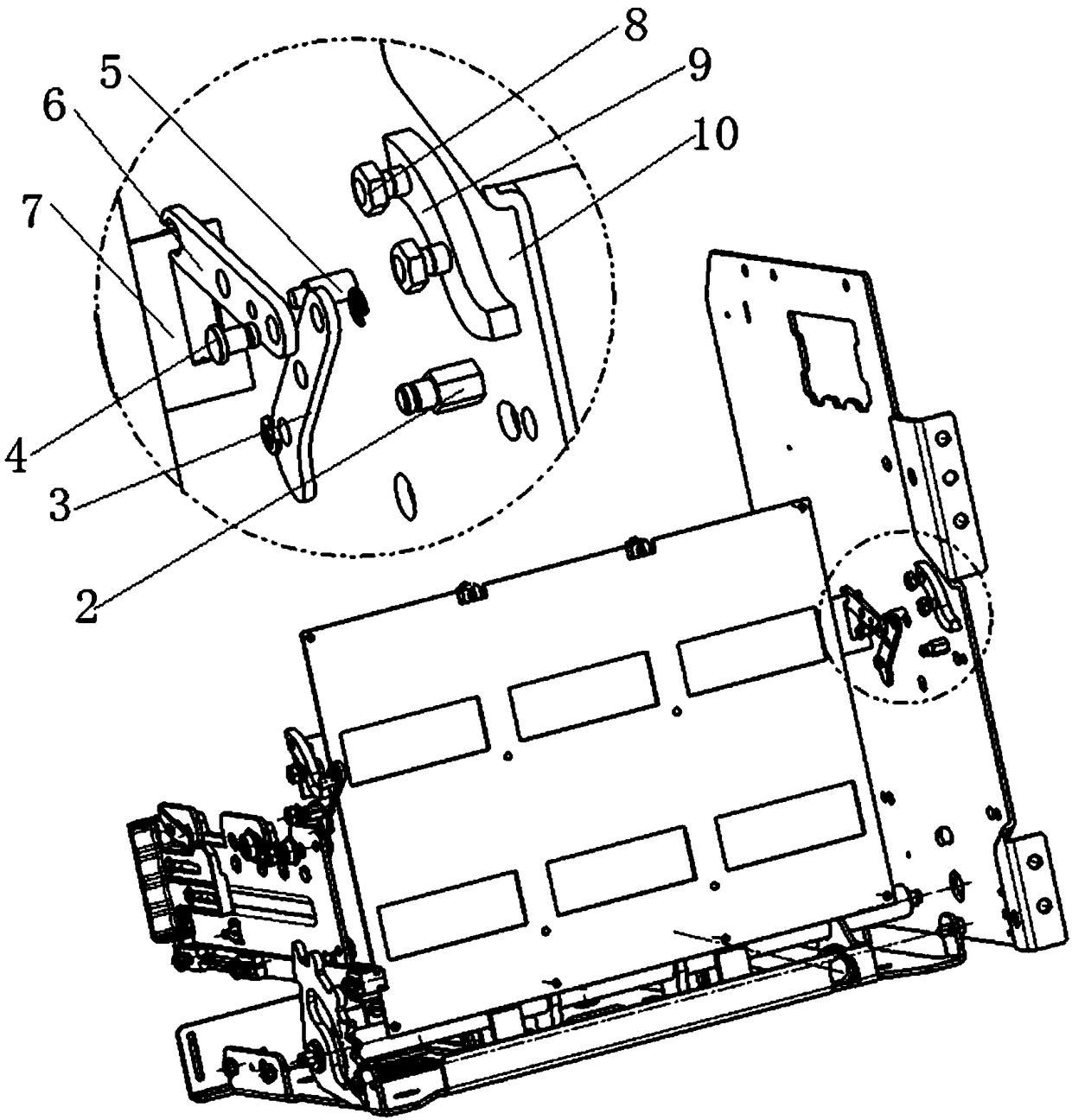

A moving mechanism of the isolation plate in the drawer base of a drawer circuit breaker

ActiveCN106786092BLimit motion angleGuaranteed to move up and downSwitchgear with withdrawable carriageEngineeringCircuit breaker

The invention relates to a movement mechanism of a separation plate in a drawer seat of a drawer type circuit breaker. The mechanism comprises an upper connecting rod, a lower connecting rod, a sliding shaft, a guide rail and a movement side plate, wherein the lower connecting rod is rotatably connected with a side plate of the drawer seat; the upper end of the upper connecting rod is connected with the separation plate and the lower end of the upper connecting rod is hinged to the lower connecting rod; the sliding shaft is arranged on the upper connecting rod and the guide rail is arranged on the side plate of the drawer seat; the guide rail is used as a movement limiting rail of the sliding shaft, so that when the upper connecting rod moves, the vertex at the upper end of the upper connecting rod moves up and down; the movement side plate is parallel to the side plate of the drawer seat; in a horizontal sliding process of the movement side plate, the lower connecting rod is pushed to rotate, so that the upper connecting rod is driven to move; the movement of the upper connecting rod drives the separation plate to move up and down. Compared with the prior art, the upper connecting rod and the lower connecting rod are hinged, a clamping condition does not occur and the stability is high; compared with other mechanisms, door opening movement is more rapid. The movement angle of the connecting rods is limited by the shapes of the connecting rods, so that the mechanism does not pass through a dead point, and the reliability performance of movement is ensured.

Owner:SHANGHAI RENMIN ELECTRICAL APP WORKS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com