Anti-slip pre-twisted damping type spacer

A spacer and damping technology, applied in the field of spacers, can solve the problems of wear, loss, increased friction of the rotary clamp, etc., and achieve the effects of good wear resistance, improved service life and smooth rotation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

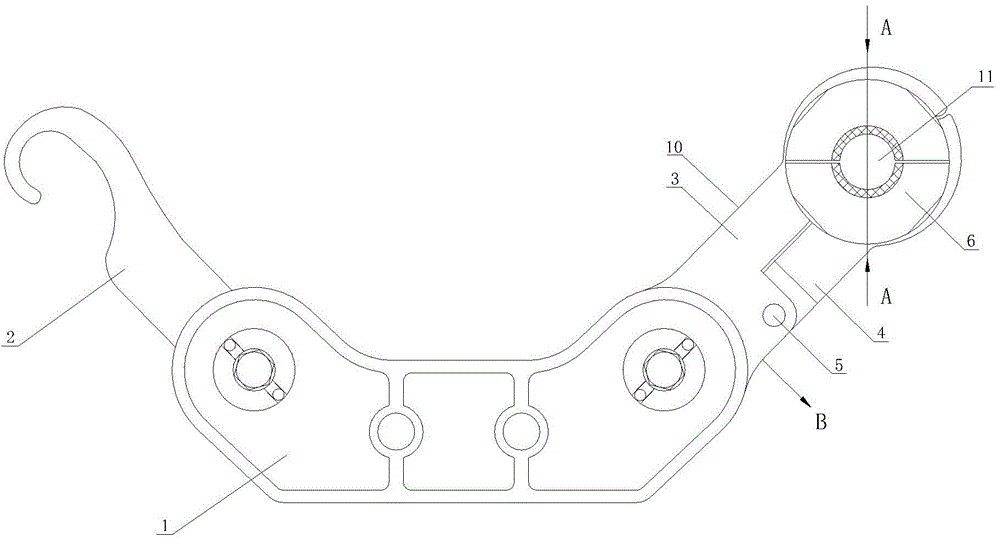

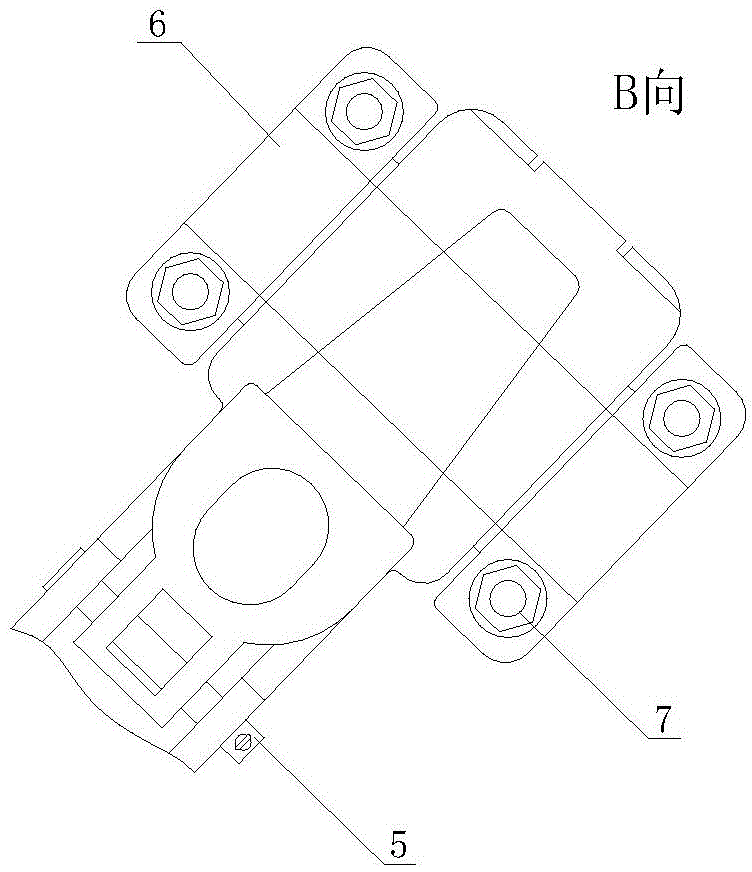

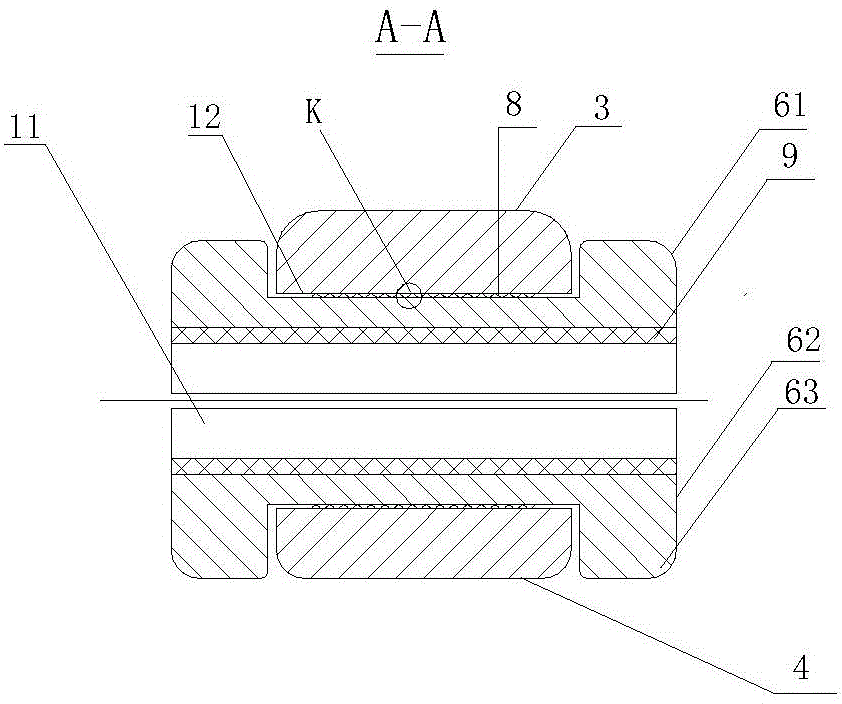

[0017] The present invention as Figure 1-4 As shown, it includes a spacer bar main body 1, an anti-skid pre-twisted wire clamp 2 and a wire clamp pressing plate 10, and the wire clamp pressing plate 10 includes a wire clamp pressing plate main body 3 and a wire clamp pressing plate cover plate 4, and the wire clamp pressing plate main body 3 and The threading hole 12 formed by the cover plate 4 of the cable clamp is provided with a rotating damping cable clamp 6 with a middle hole. It is characterized in that a layer of stainless steel backing plate 8 is provided between the rotating damping cable clamp 6 and the threading hole.

[0018] In use of the present invention, the anti-slip pre-twisted clamp 2 and the rotating damping clamp 6 cooperate with each other, the anti-slip pre-twisting clamp 2 can prevent the axial movement of the spacer on power transmission, and the rotating damping clamp 6 can restrain the power transmission The dance of the lines. Since there is a lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com