Patents

Literature

97results about How to "Guaranteed to move up and down" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

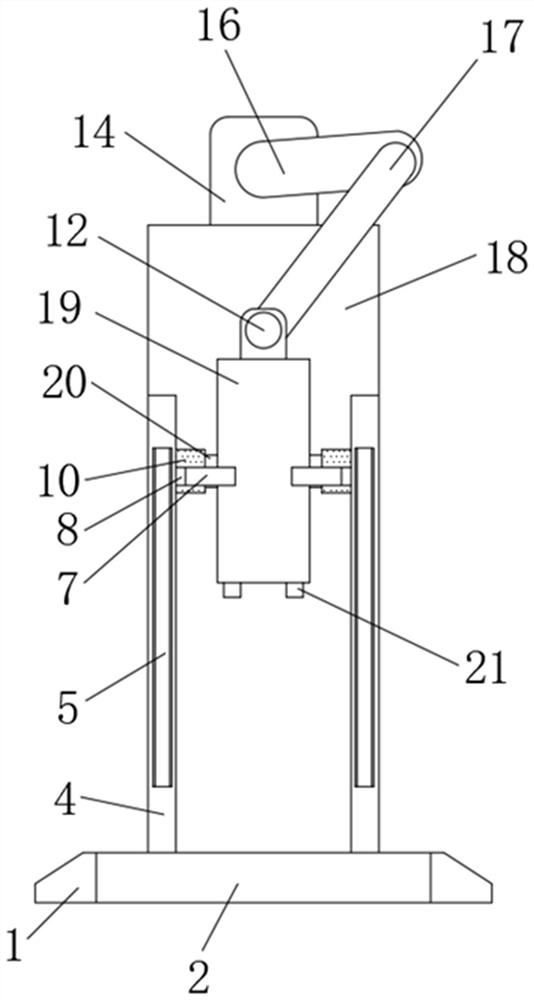

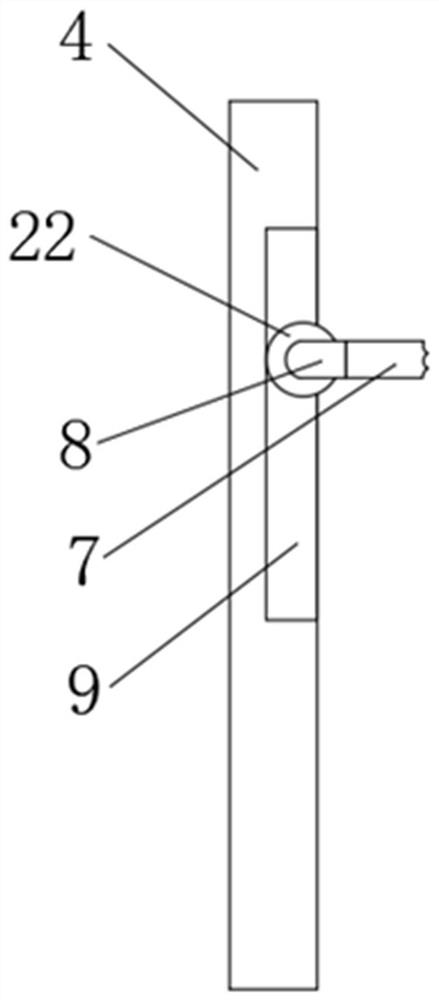

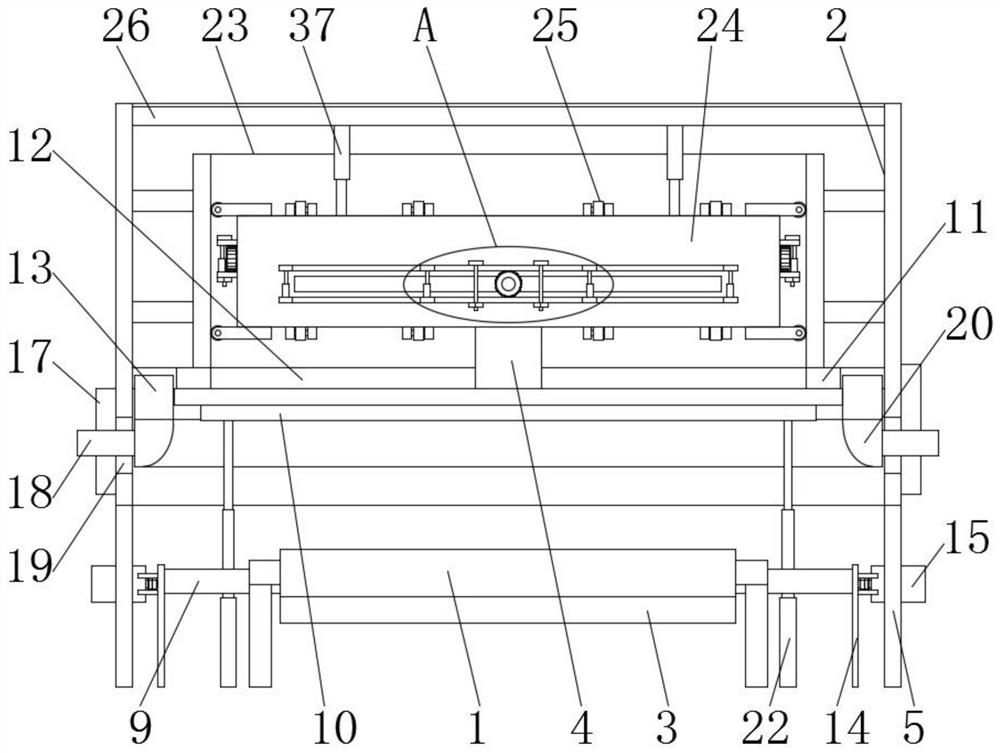

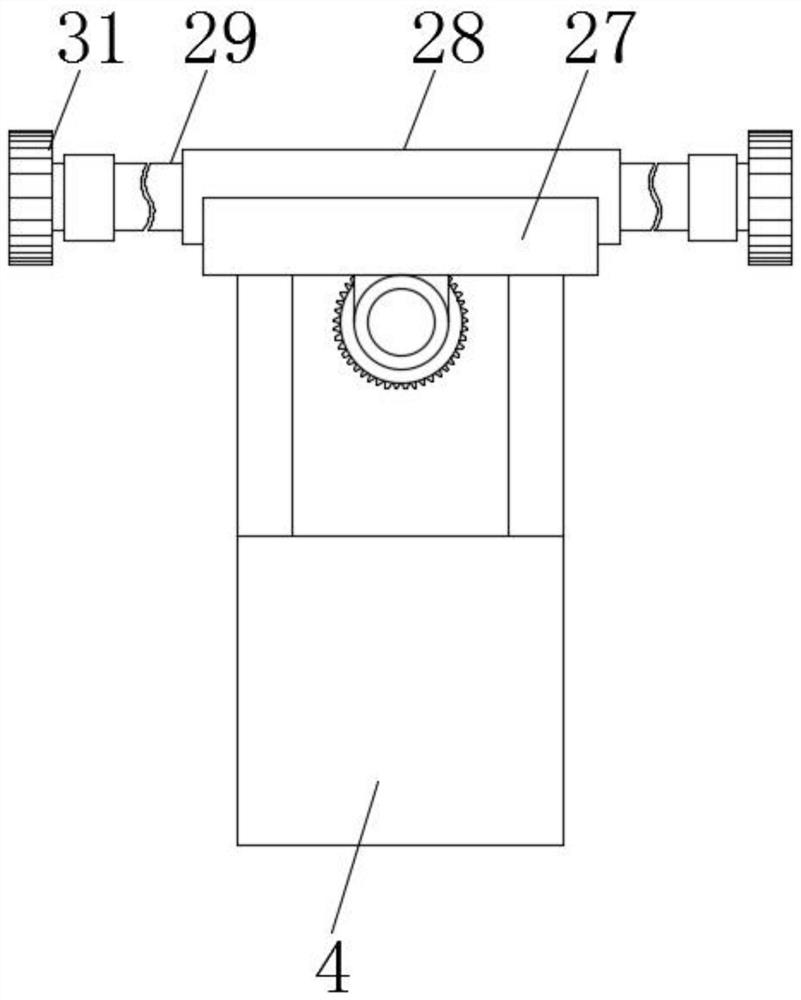

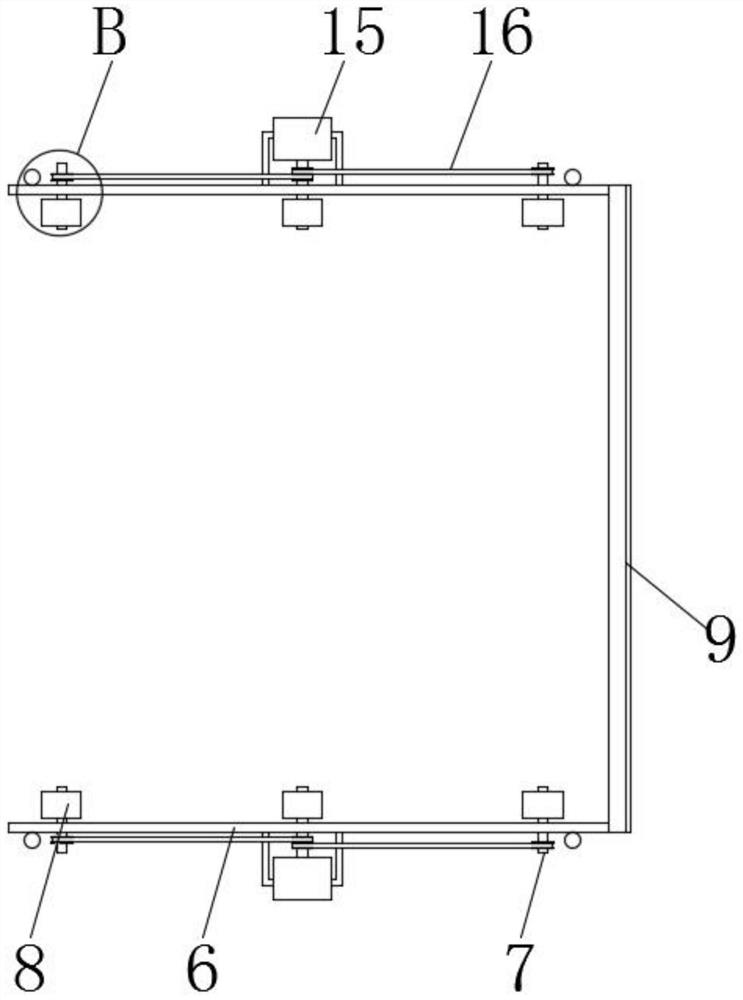

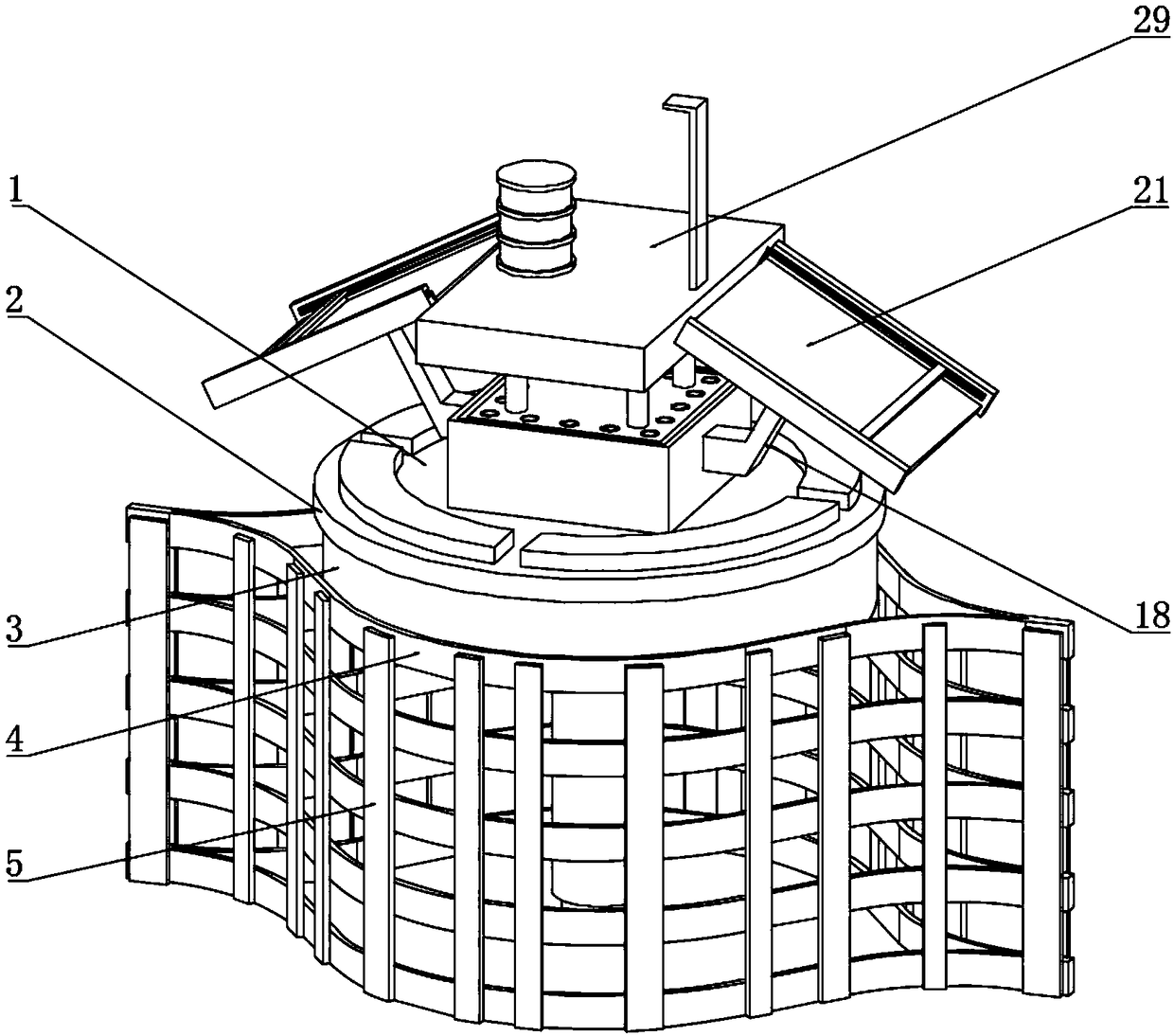

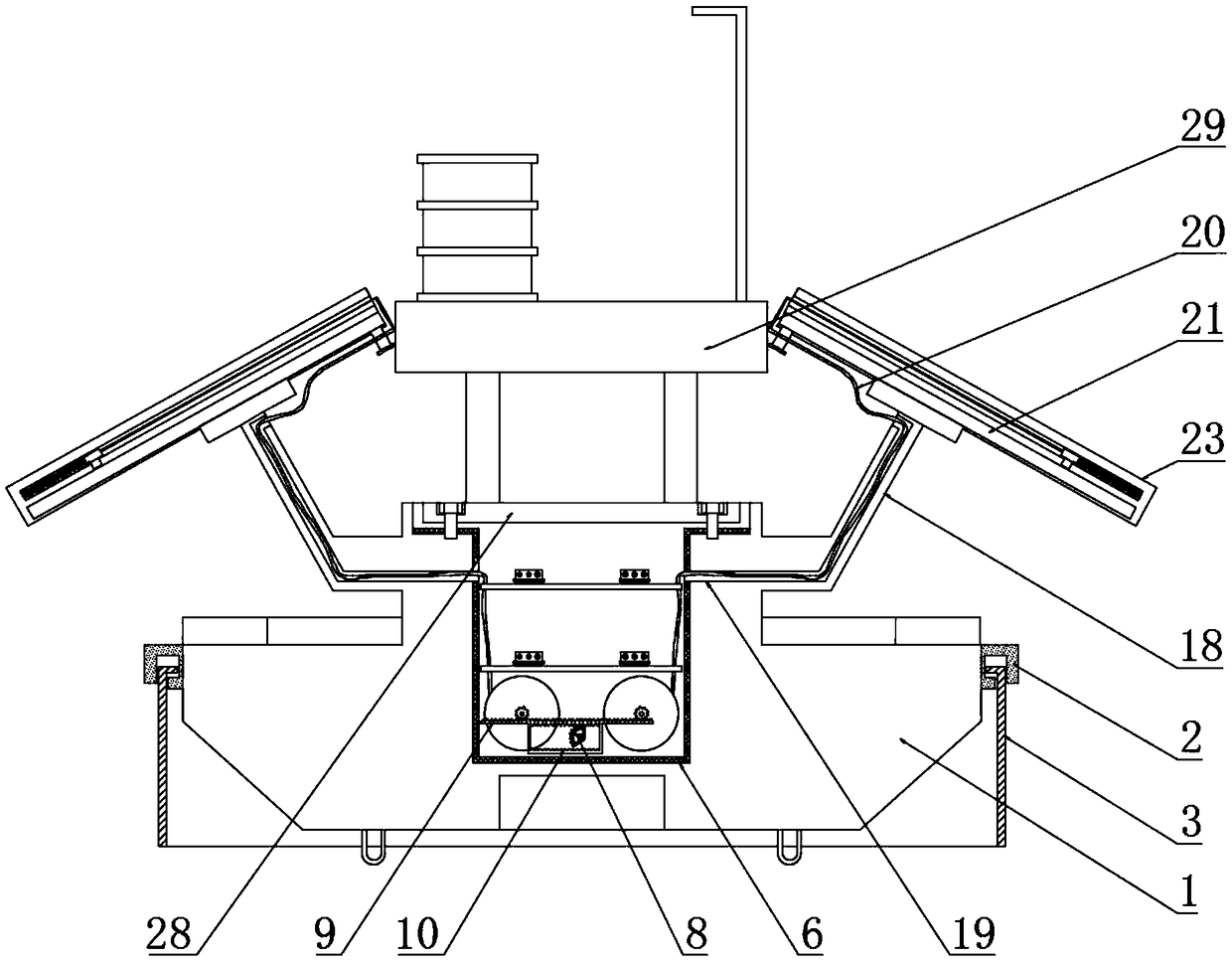

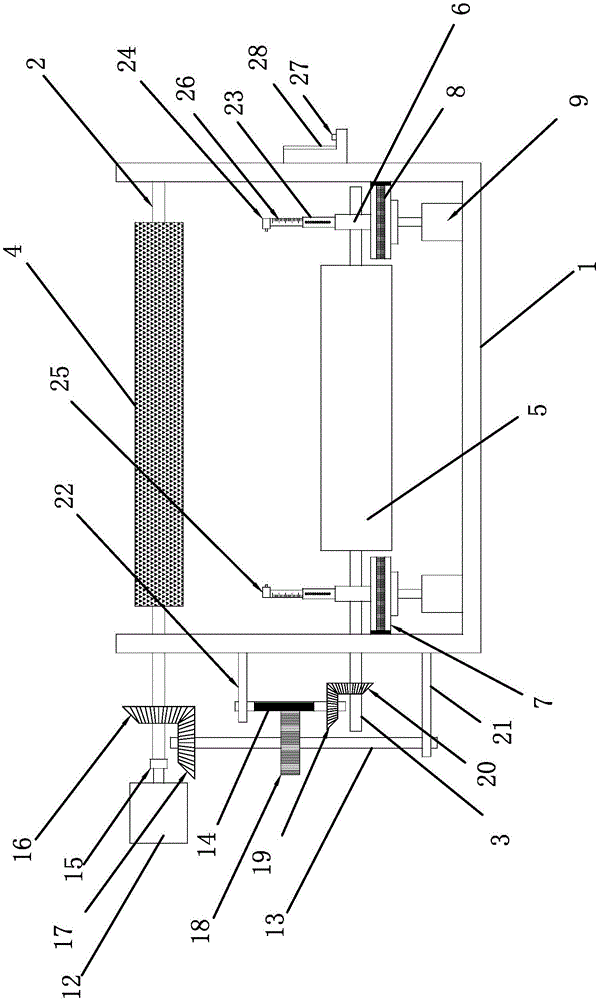

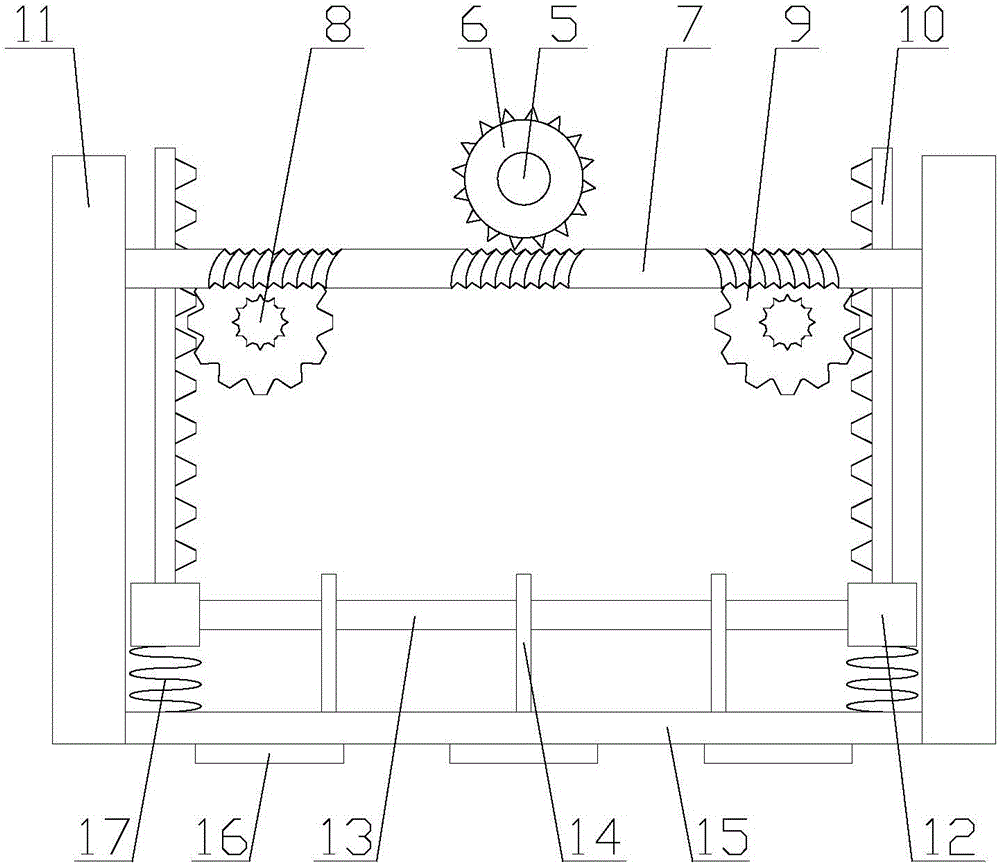

Coal series fault formation simulation test device and forward and reverse fault simulation test method

InactiveCN110006757AAchieve regulationGuaranteed to move up and downMaterial strength using tensile/compressive forcesLifting devicesNormal faultCoal

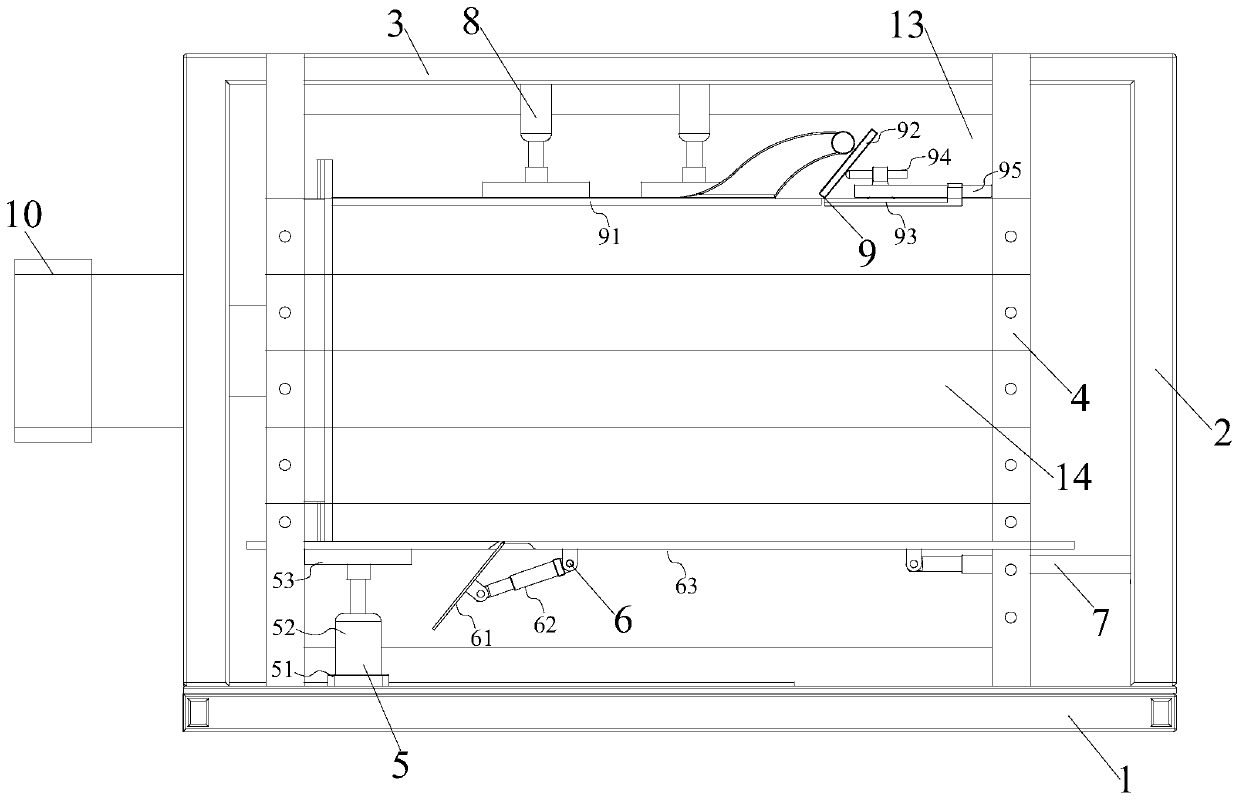

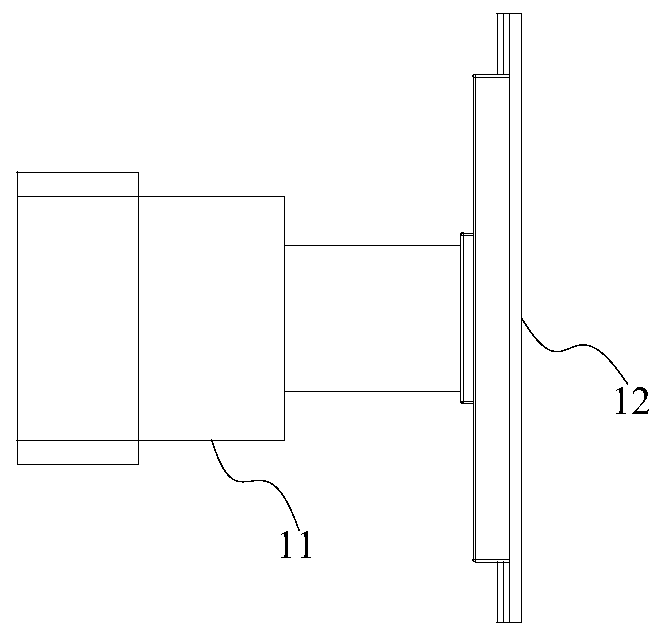

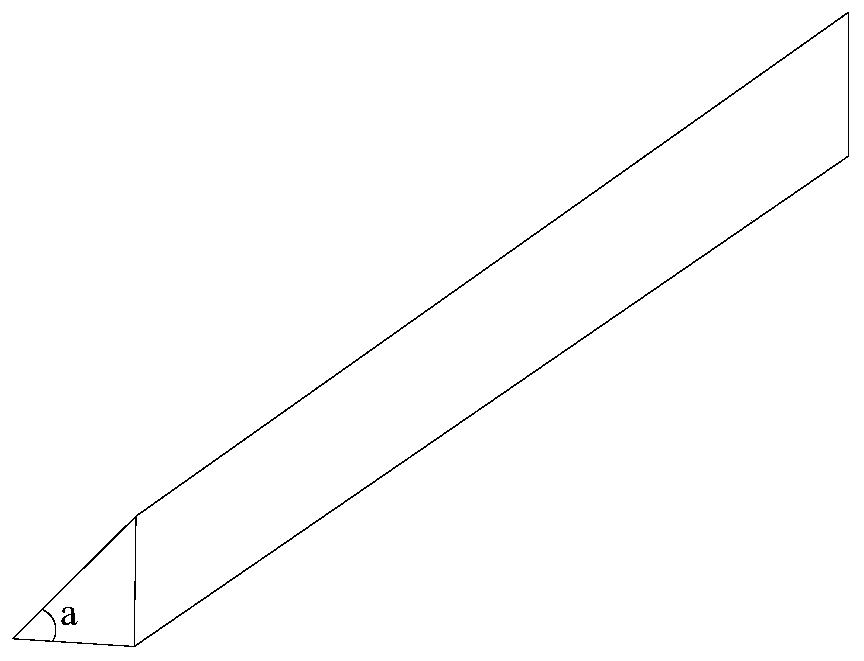

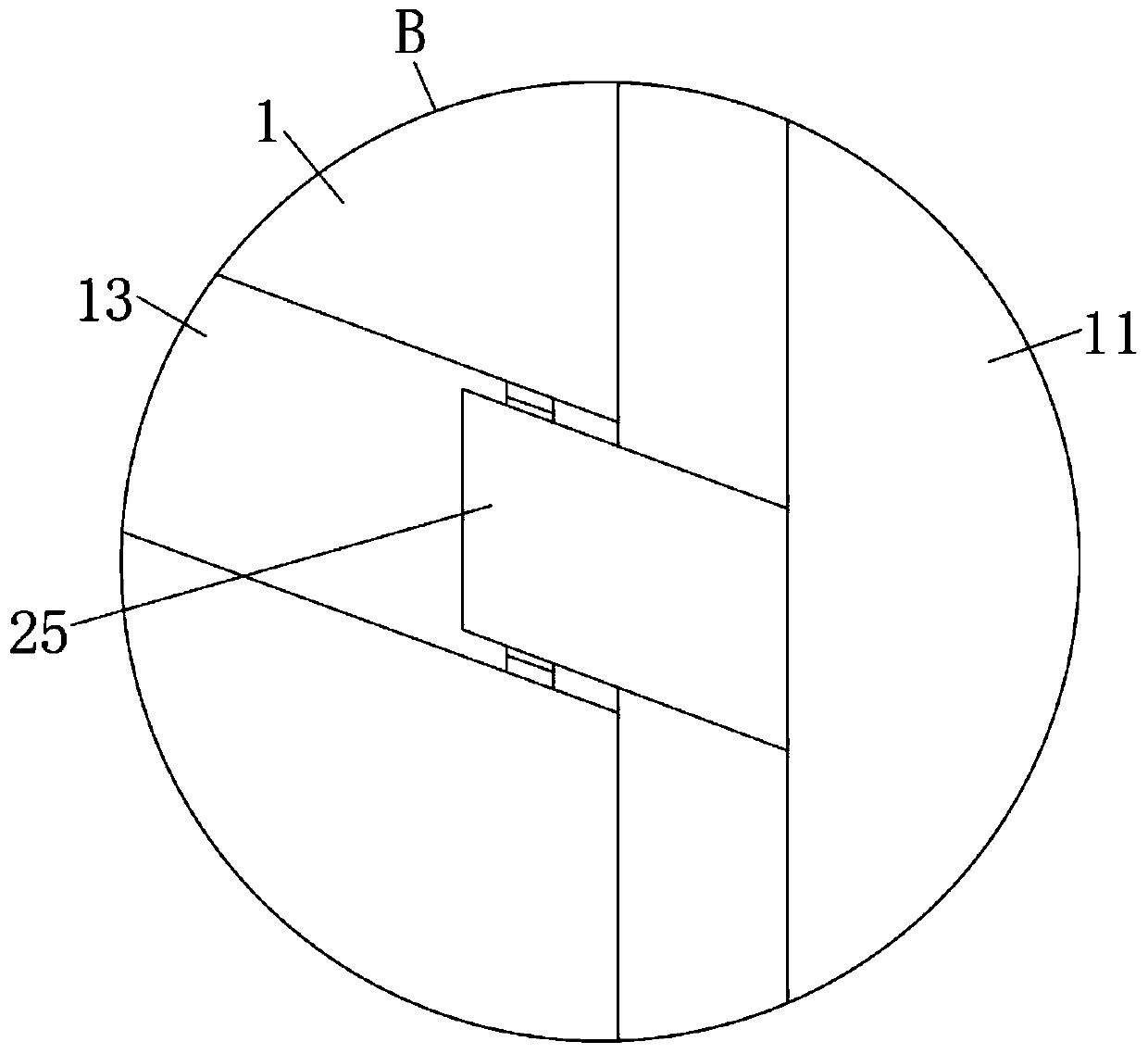

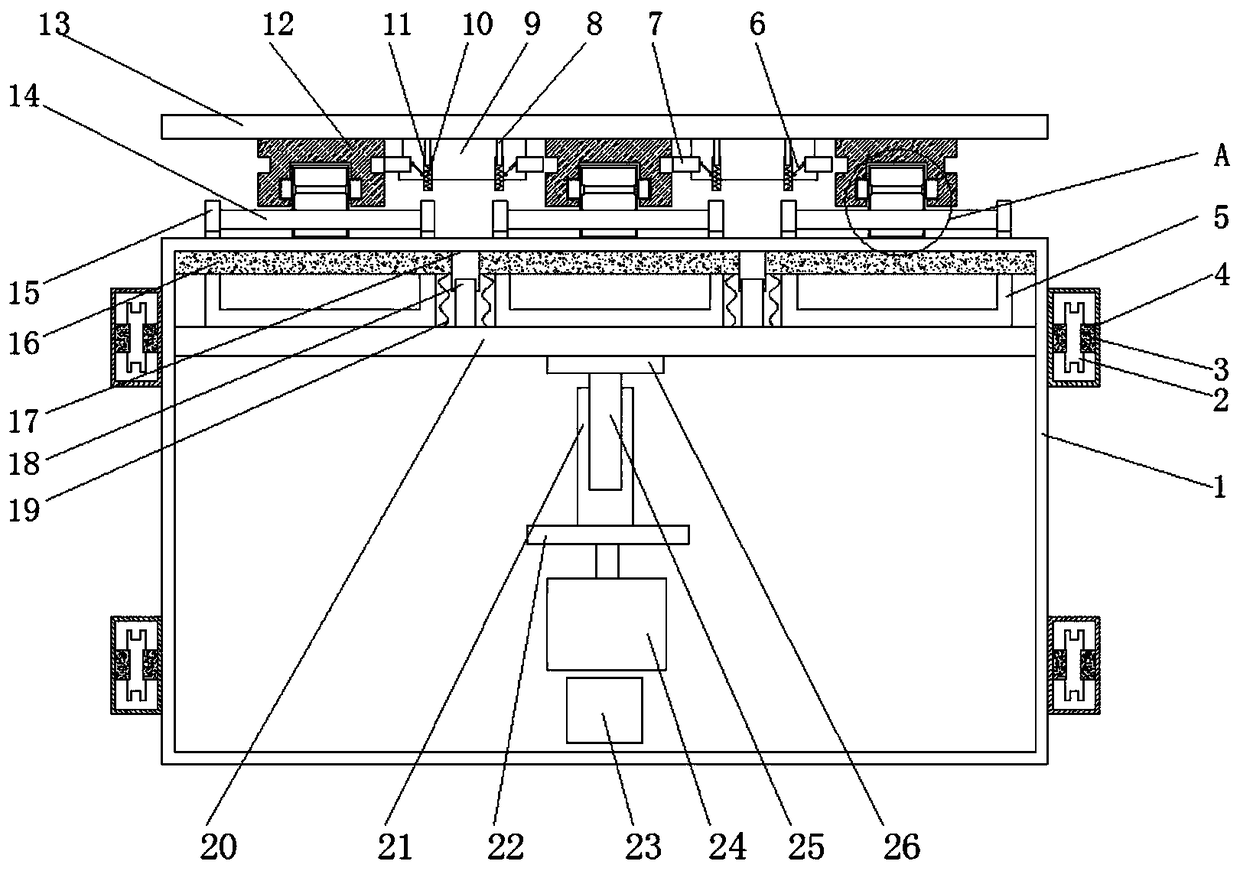

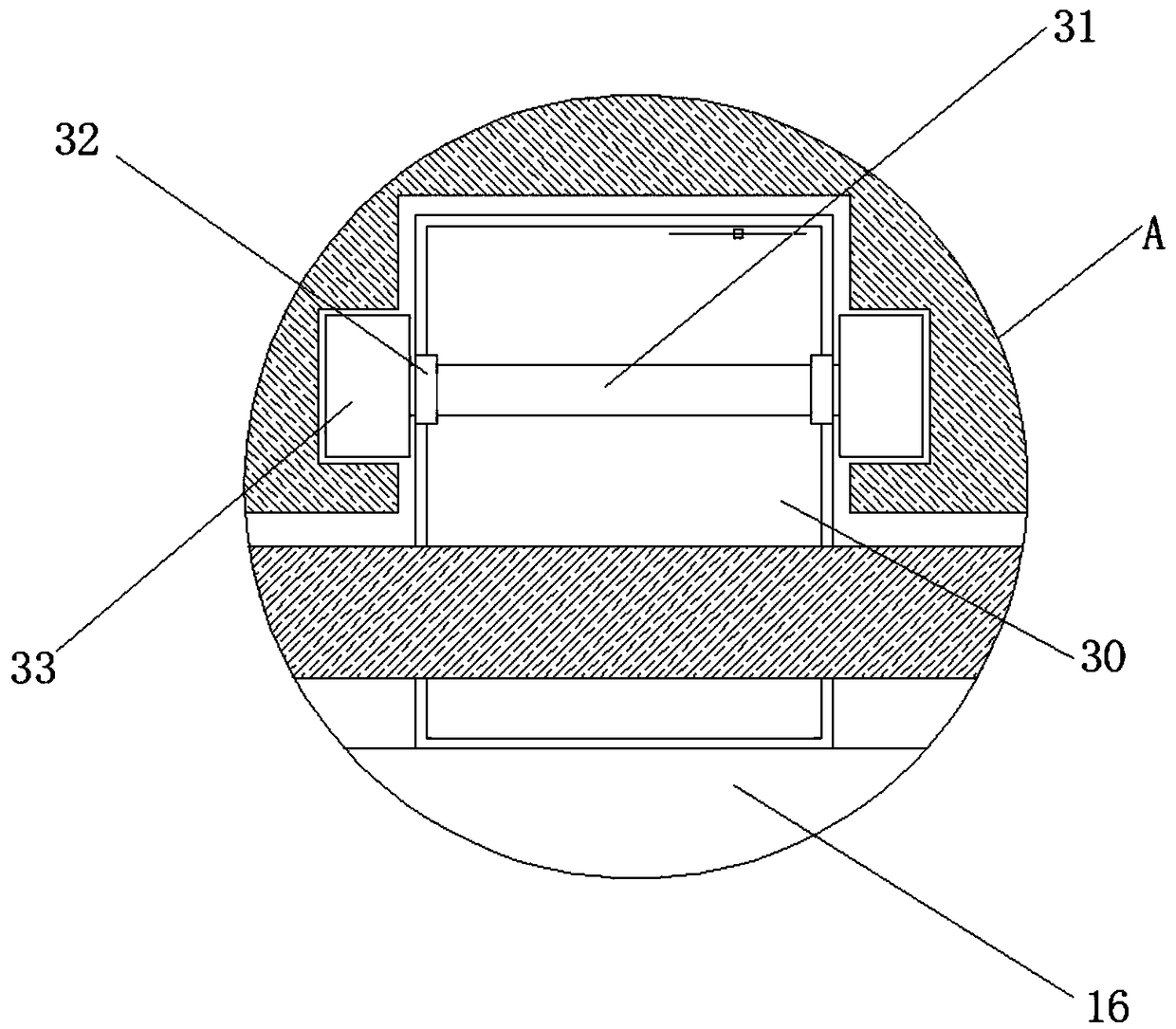

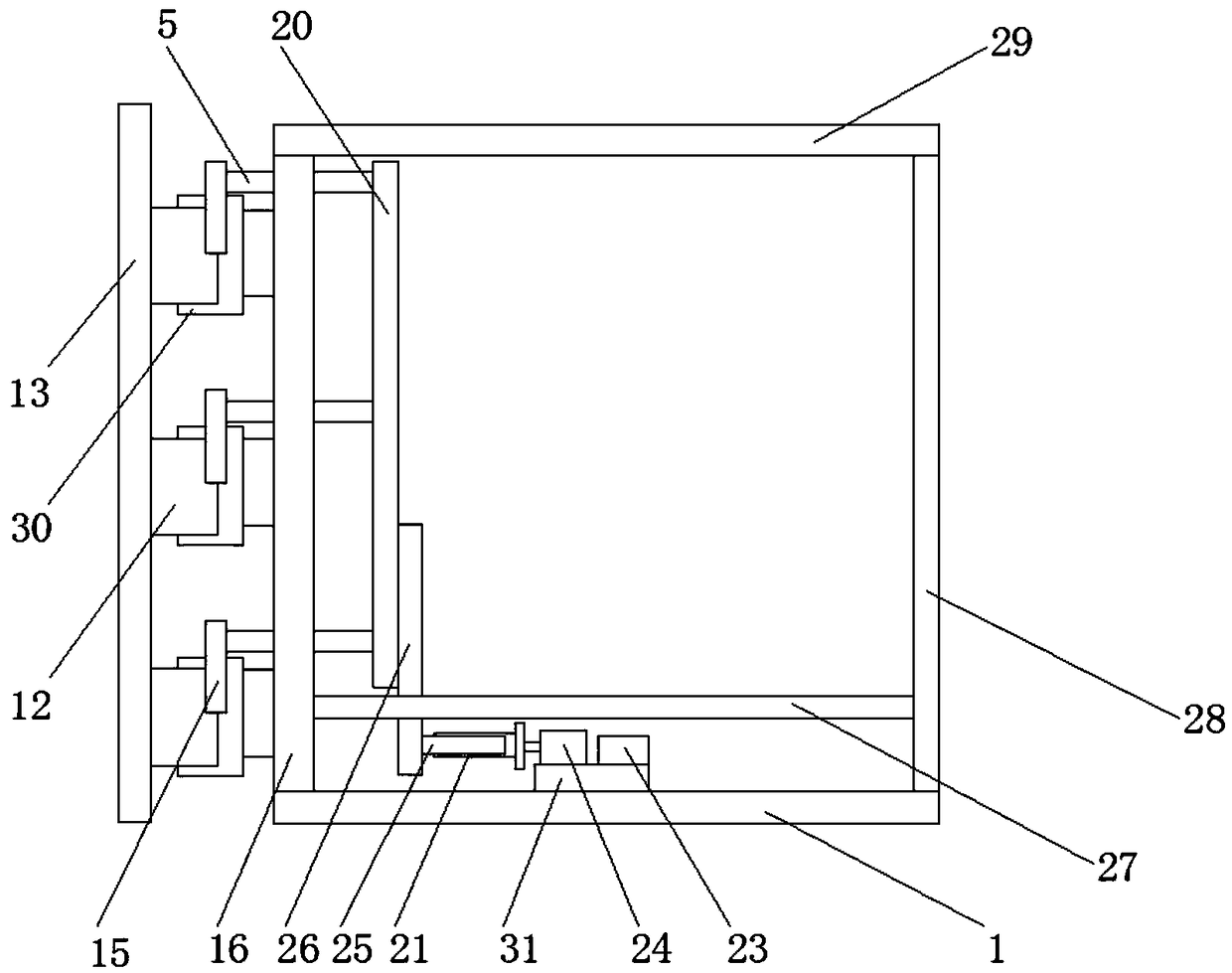

The invention discloses a coal series fault formation simulation test device and a forward and reverse fault simulation test method. The invention relates to the technical field of similar material simulation tests. The device comprises a hydraulic lifting device, a lower angle adjusting device, a push rod device, an upper loading device, an upper angle adjusting device, a lateral loading device and a transparent side plate, the hydraulic lifting device and the angle adjusting mechanism are arranged below the experiment body, the upper loading device and the upper angle adjusting device are arranged above the experiment body, the transparent side plate is arranged on the rear side face of the experiment body, and the lateral loading device is arranged on the end face of the experiment body. When the device is used for simulating the normal fault, the inclination angle of the inclined plate of the lower angle adjusting device is the same as that of the inclined push plate of the upper angle adjusting device, and the upper loading system loads downwards to form the normal fault; when the reverse fault is simulated, a fault inducing device is arranged at the bottom of the experimentalbody, and the reverse fault is formed through loading of a lateral loading device. The technical problem that the fault inclination angle and the crack initiation position of the simulated fault areinconvenient to control is solved.

Owner:SHANDONG UNIV OF SCI & TECH

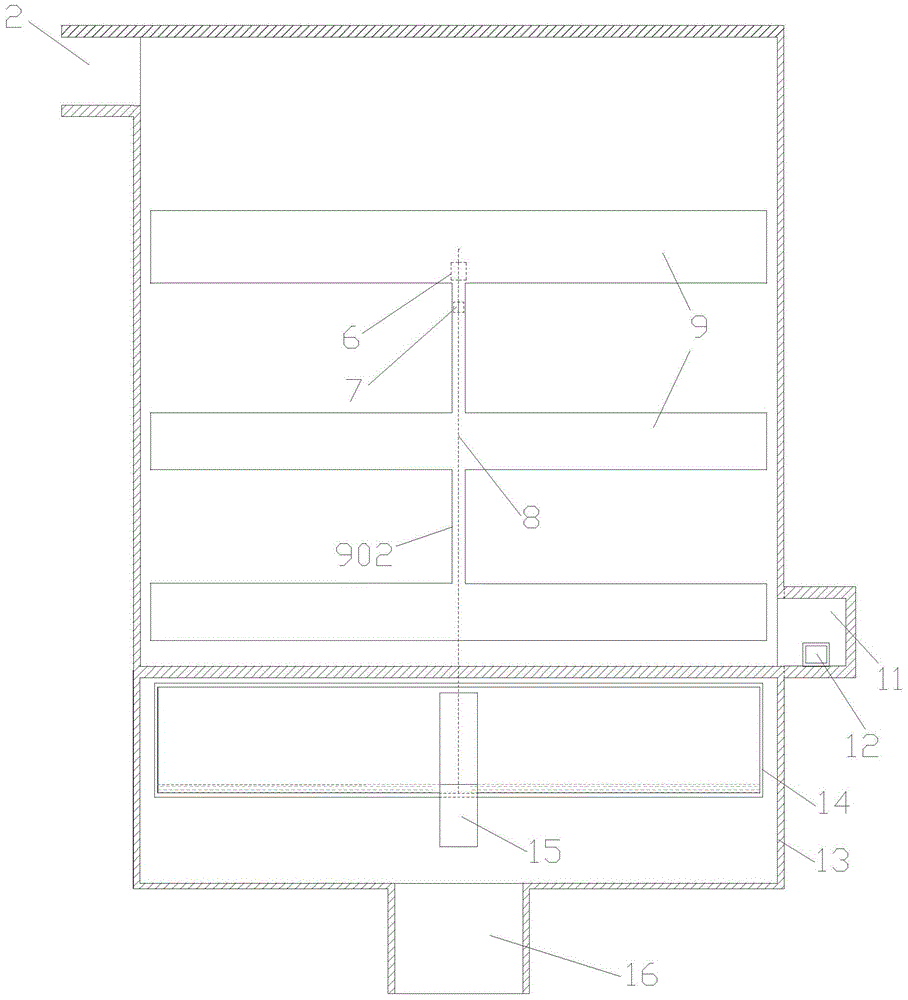

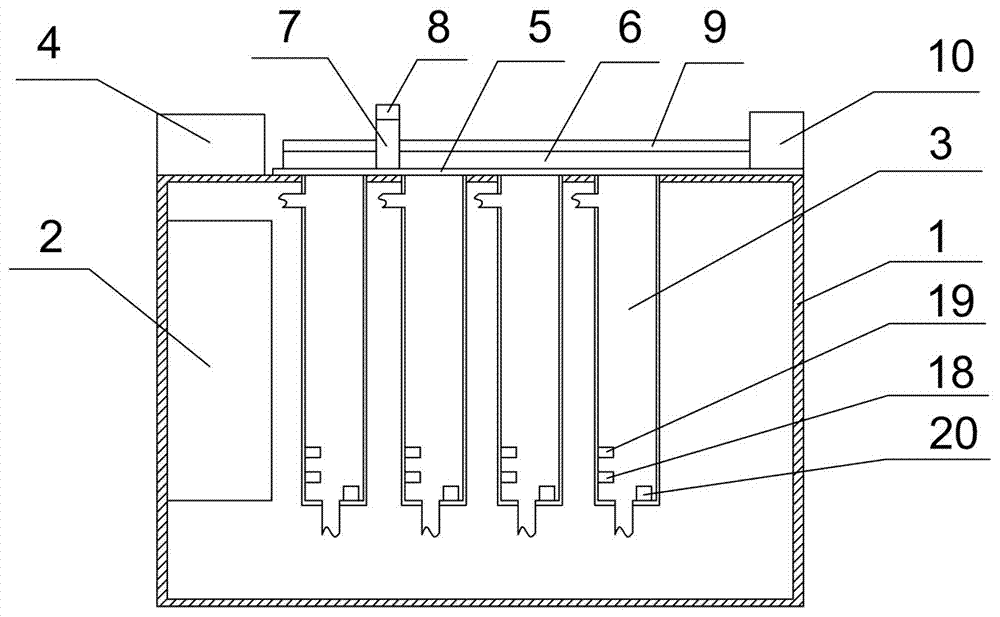

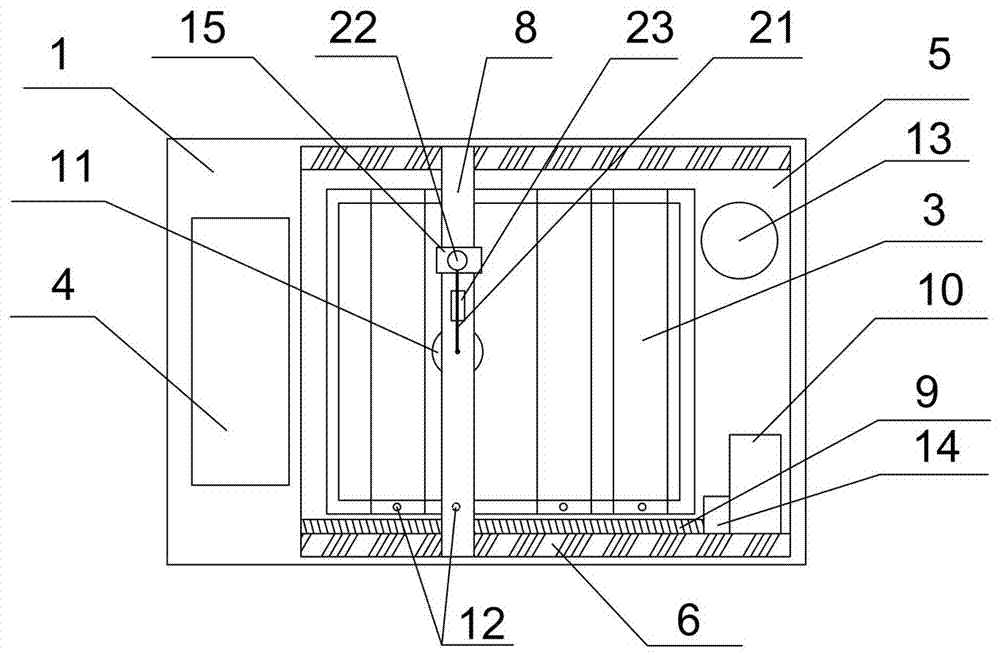

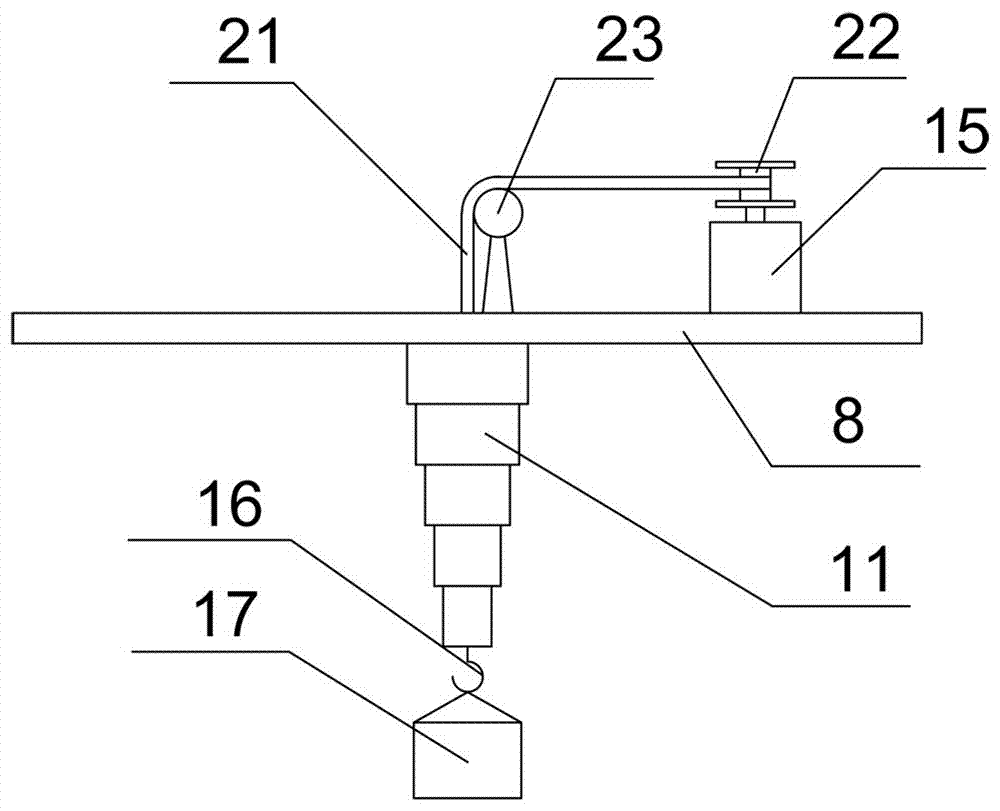

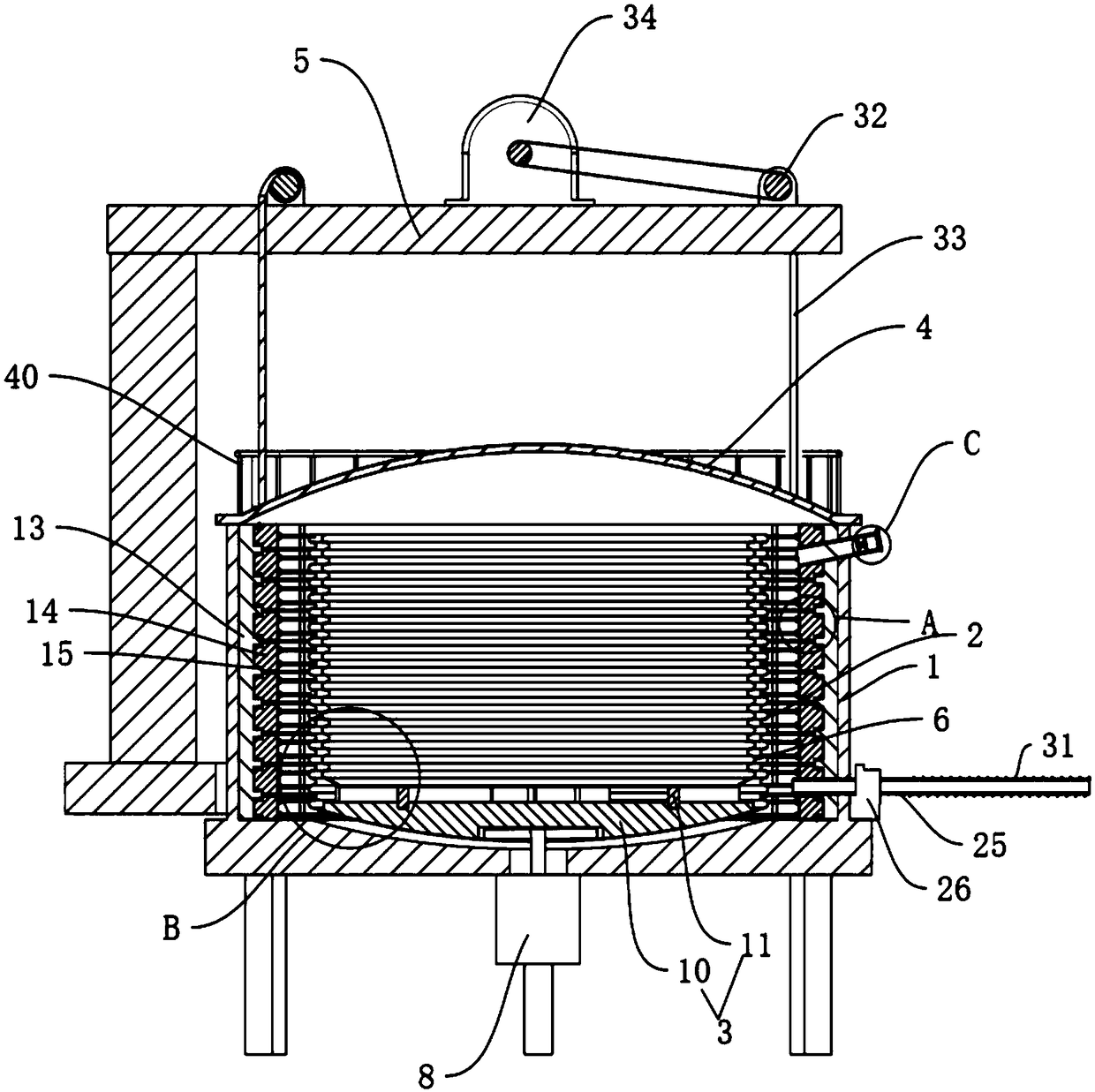

Plate type condenser with automatic liquid removing function

ActiveCN104154769AReduce movement distanceIncrease disturbanceSteam/vapor condensersSiphonHeat transfer efficiency

The invention discloses a plate type condenser with an automatic liquid removing function. The plate type condenser comprises cooling water layers, condensation gas layers, condensation wall faces, liquid scraping devices, pulley blocks, magnets, hanging water collection tanks, siphon pipes and S-shaped plane springs. A condensation gas inlet of the condenser is located in the top of the rear side of the condenser. Condensation gas is condensed into liquid on the wall faces in the condensation gas layers, and the liquid flows into a condensation liquid communication passageway, and then flows out of a condensation liquid outlet. Cooling water enters the condenser from the top and flows downward into the hanging water collection tanks along the cooling water layers. The cooling water of the hanging water collection tanks is periodically collected and drained through the siphons, so that the hanging water collection tanks are made to periodically move up and down, the liquid scraping devices and the S-shaped plane springs are driven by the pulley blocks and the magnets to move up and down in a reciprocating mode so as to scrape away condensation liquid film on condensation wall faces, and therefore heat transfer resistance of condensation plates can be effectively reduced, heat transfer efficiency and condensation efficiency can be improved, impurities in cooling water can be prevented from scaling on the wall faces of the cooling water layers, and the continuous working period of the condenser can be prolonged.

Owner:东南大学常州研究院

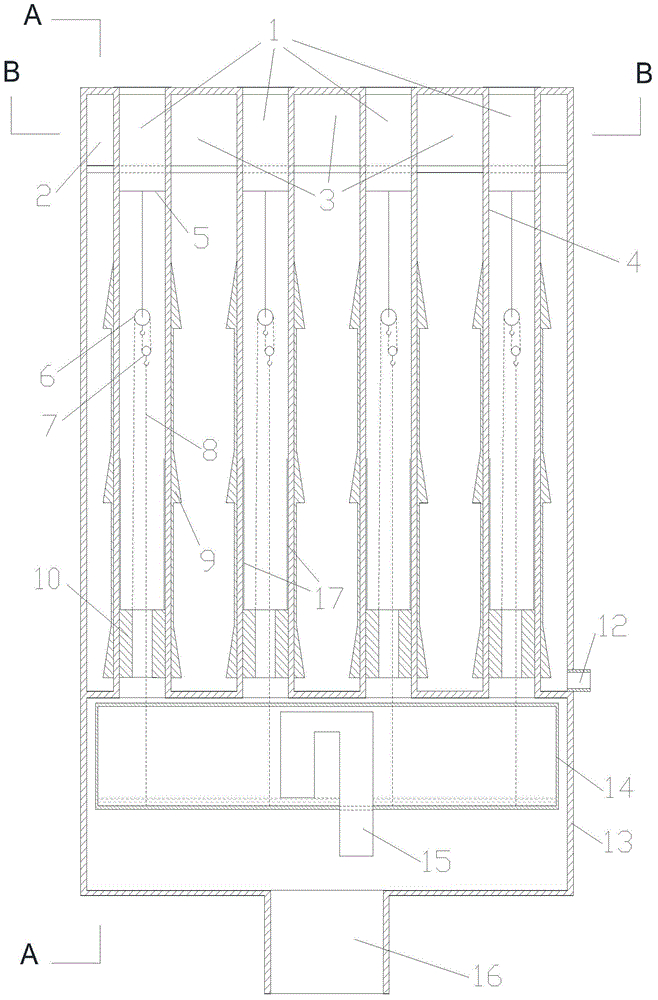

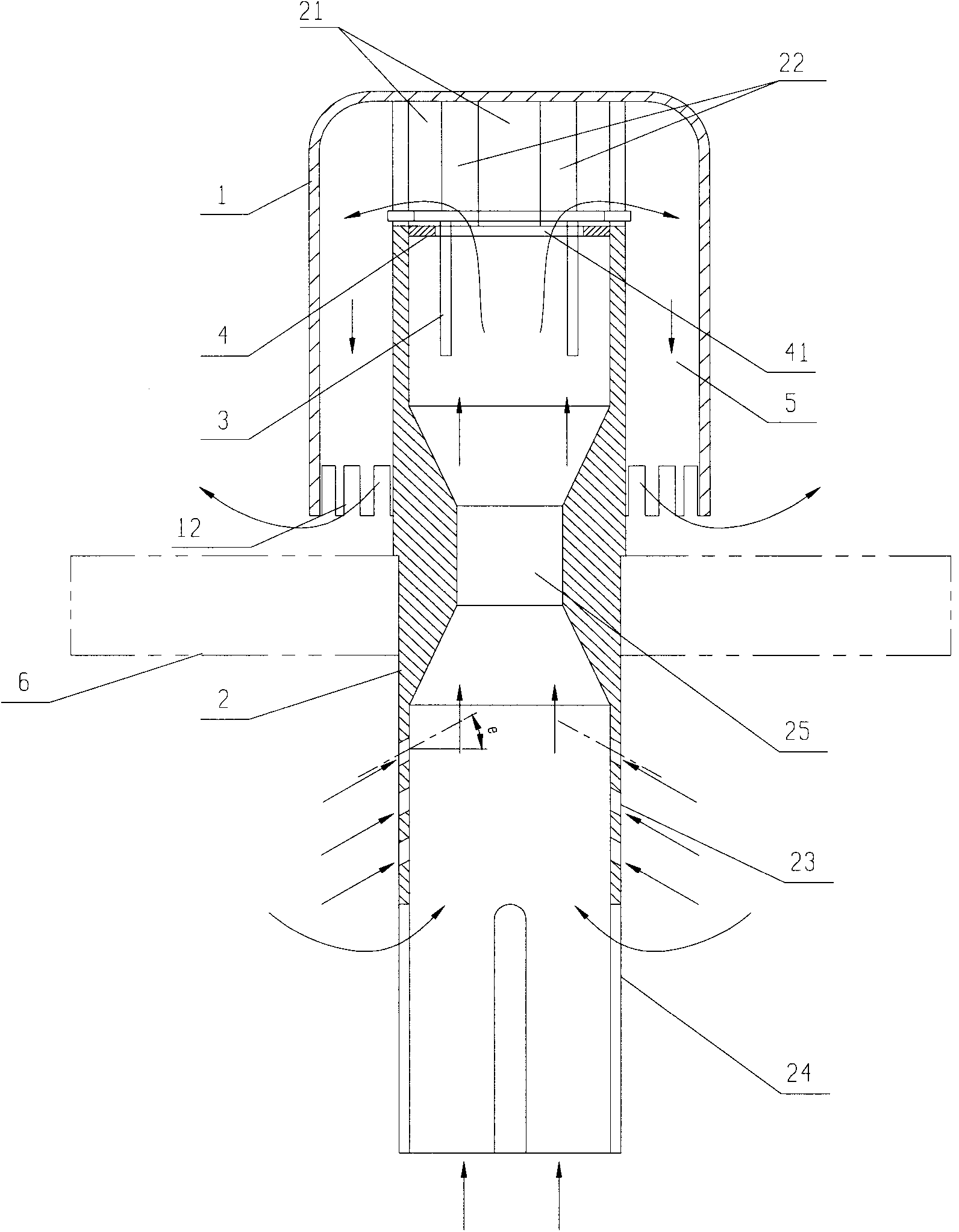

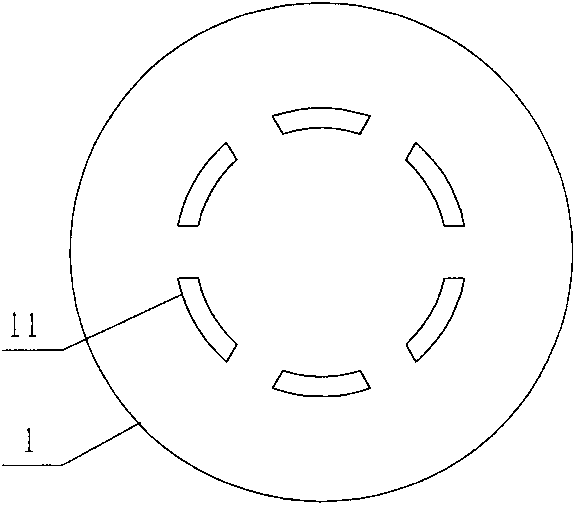

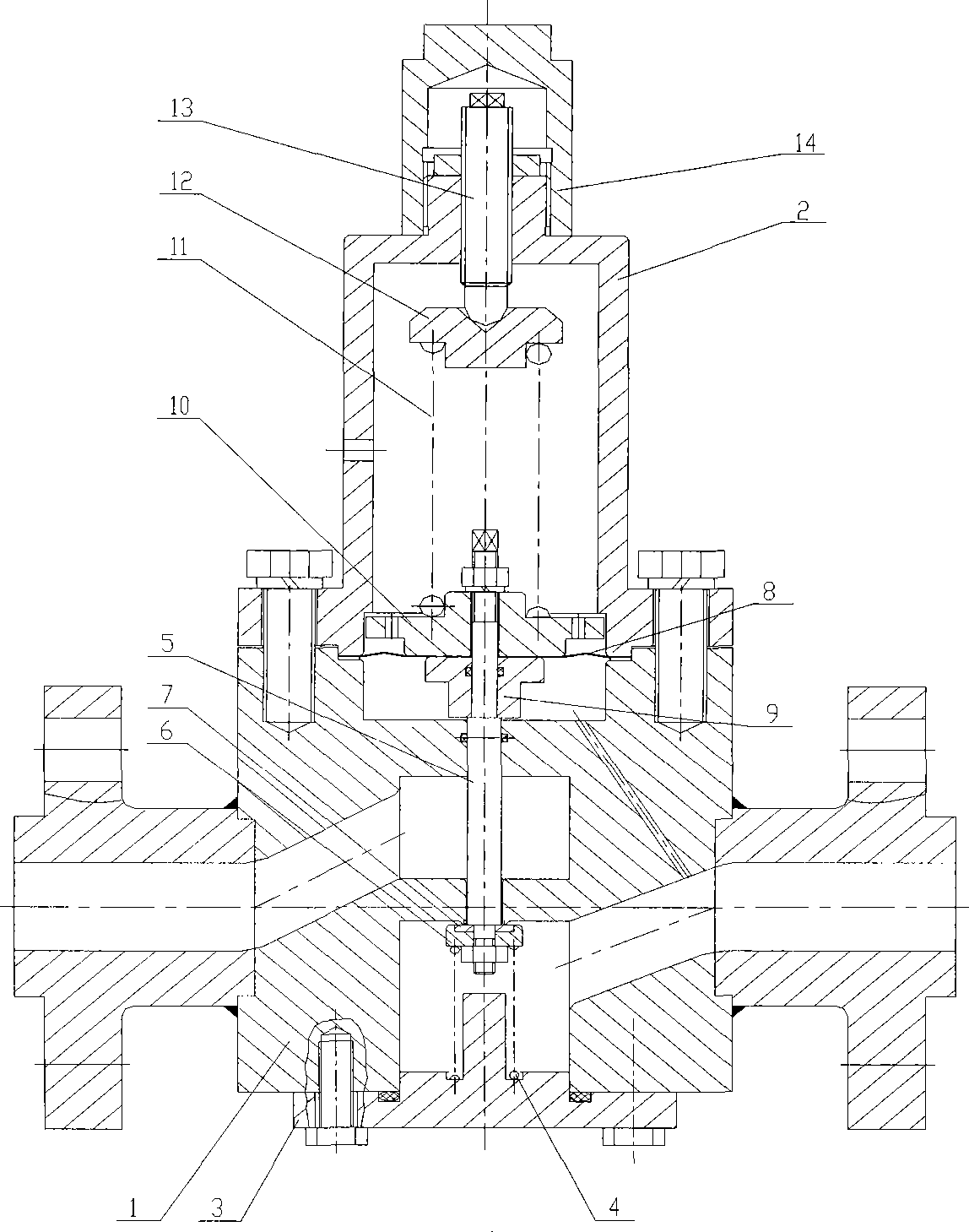

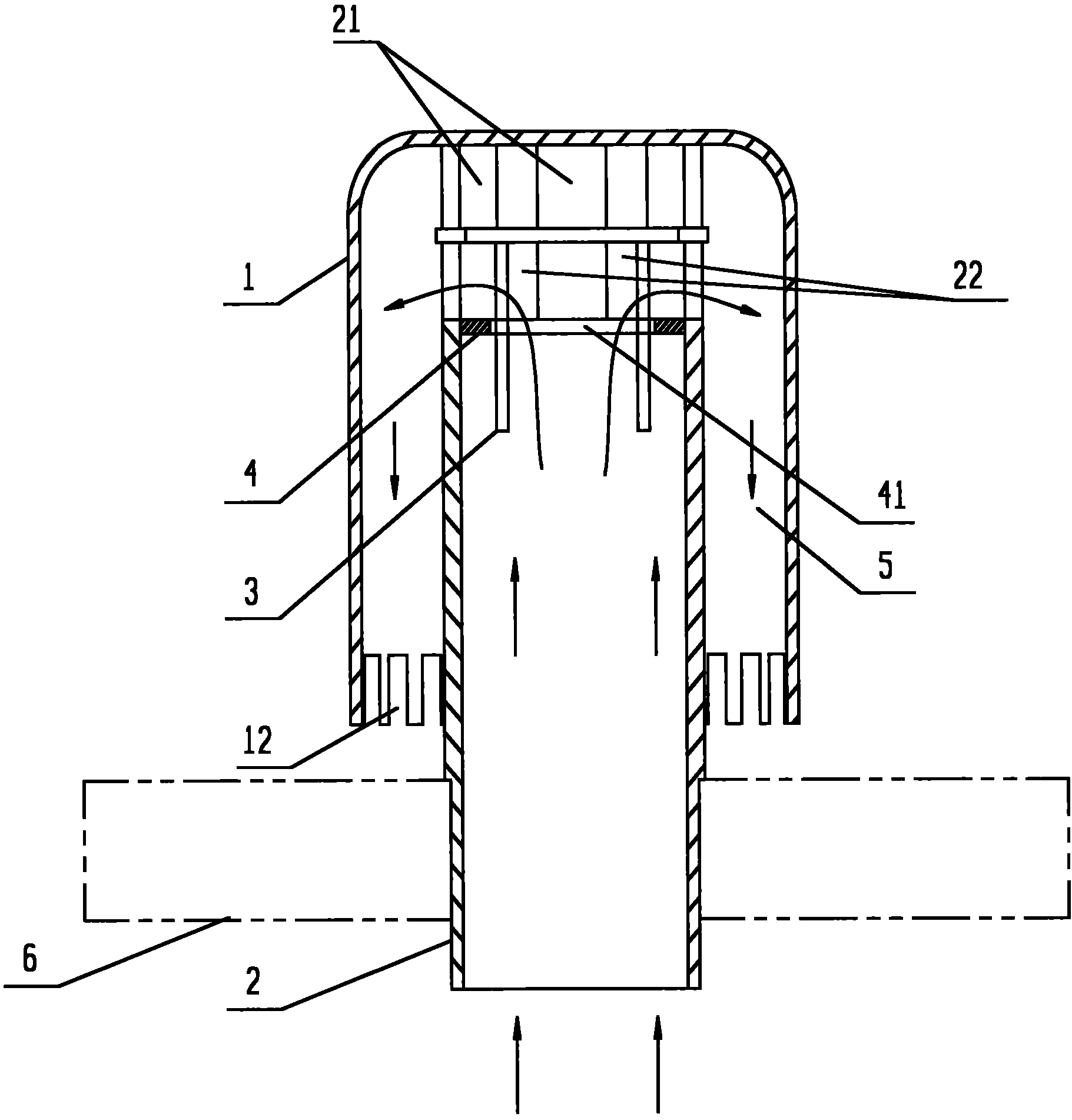

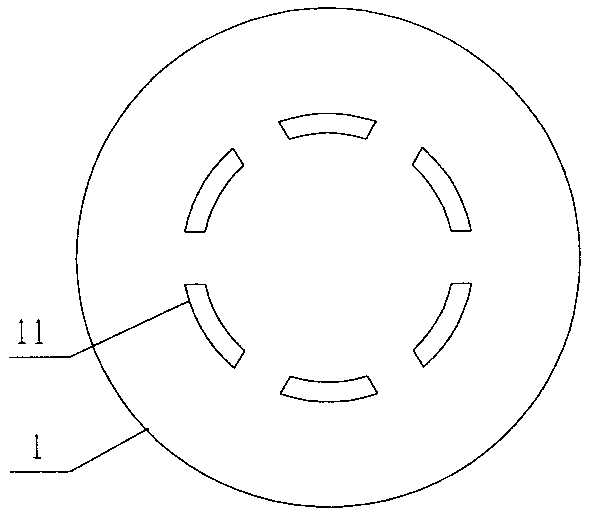

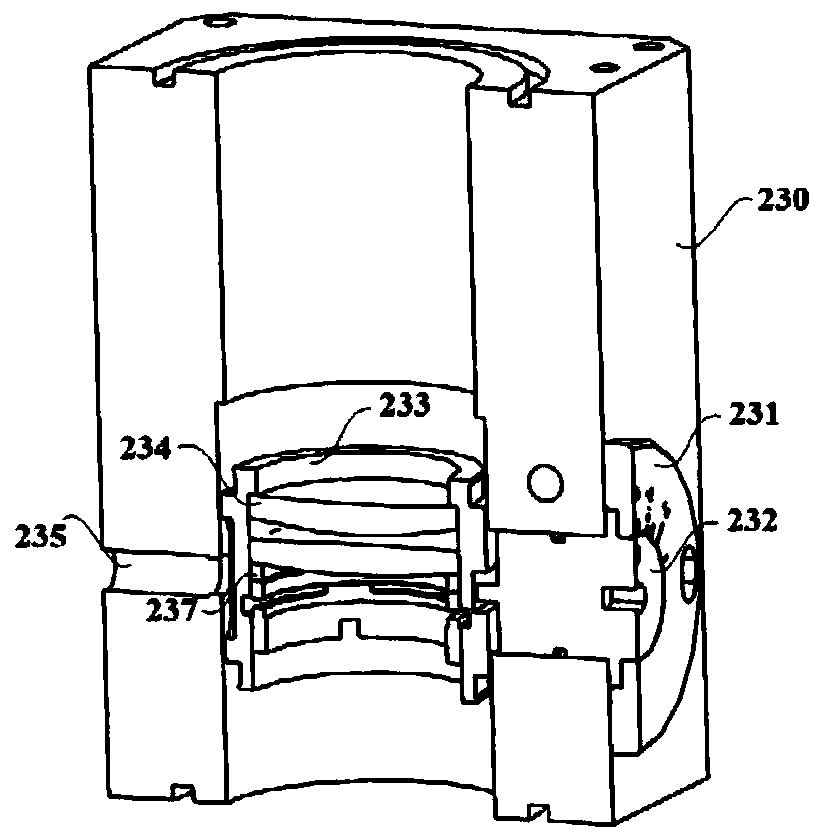

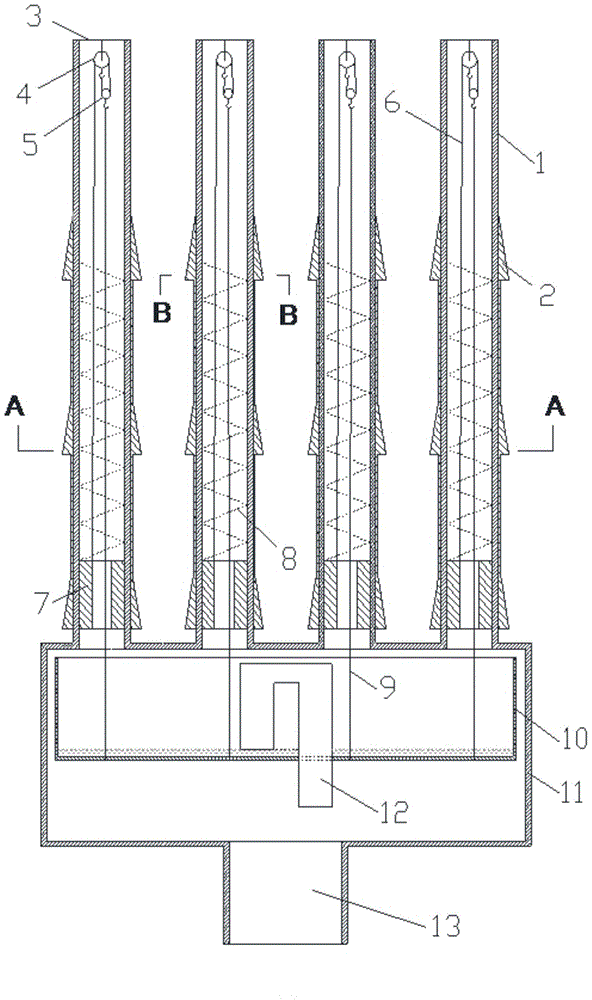

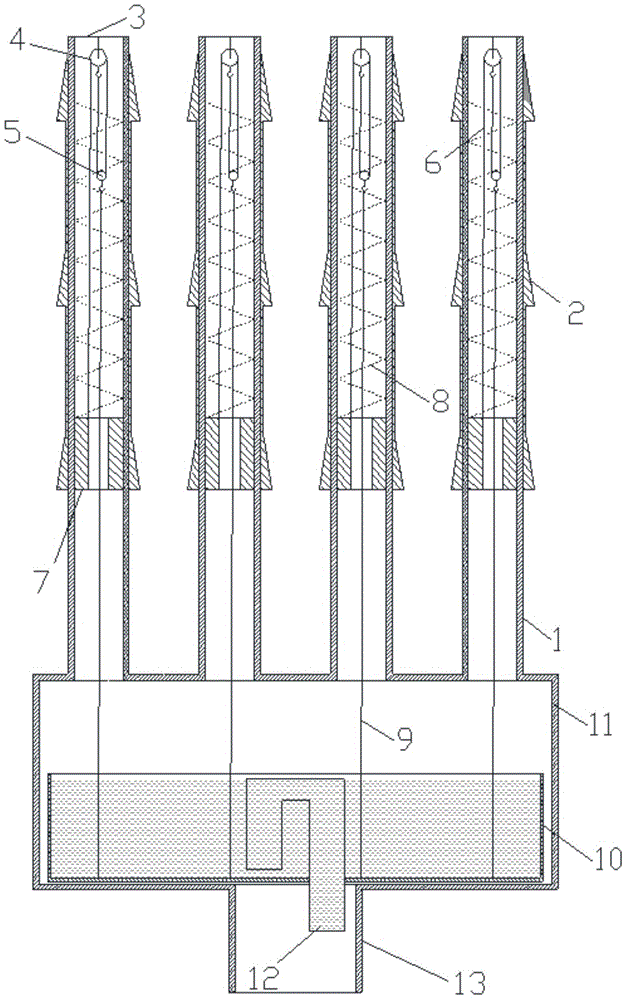

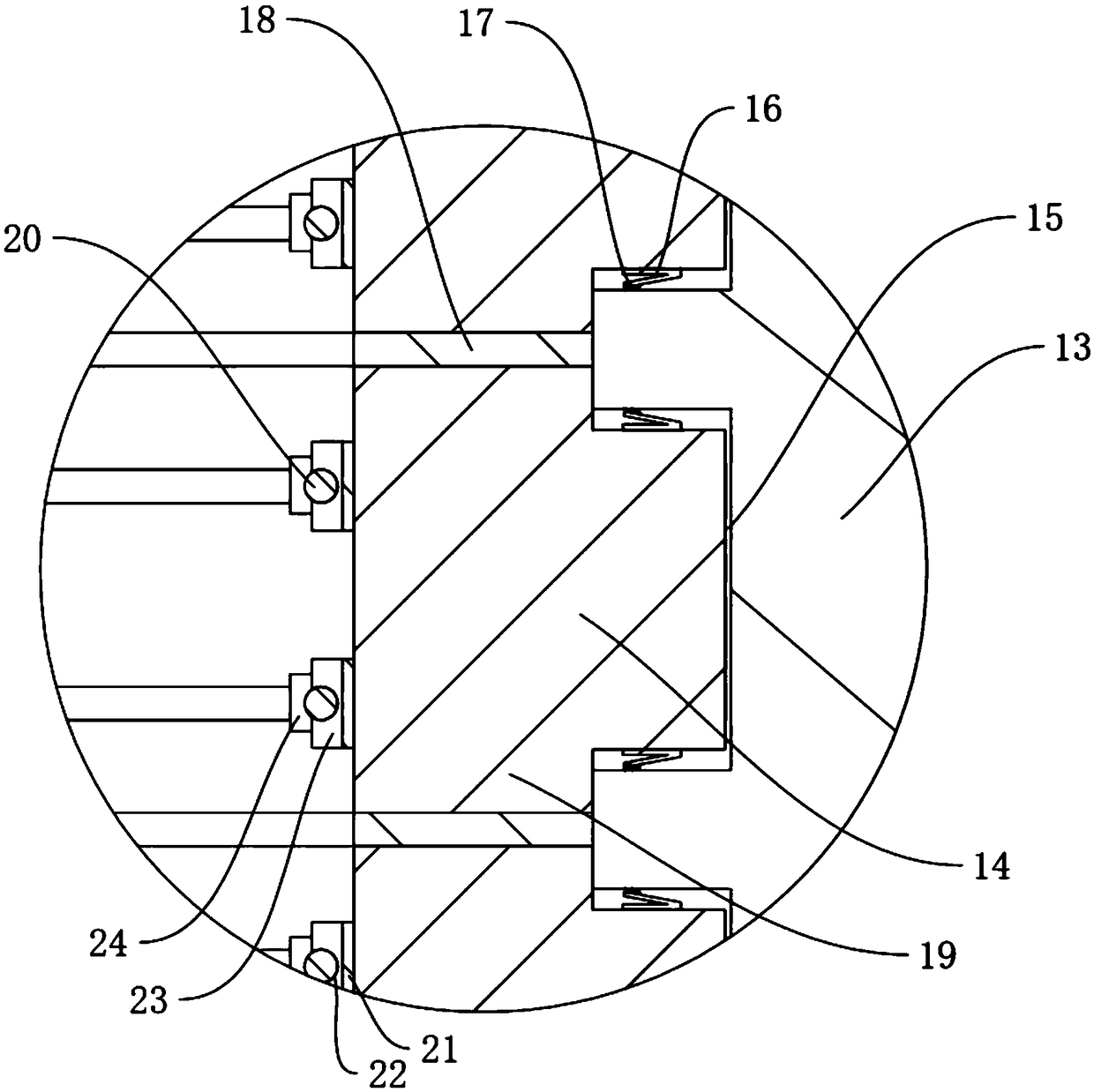

Gas-liquid distributor for fluidized bed reactor

ActiveCN104338493AWell mixedPlay a suction roleChemical/physical processesLiquid pressureProduct gas

The invention discloses a gas-liquid distributor for a fluidized bed reactor. The gas-liquid distributor mainly comprises a center pipe, a bell cap, a floating valve and a valve base, wherein a material outlet is formed in the pipe wall at the end part of the upper section of the center pipe, a material inlet is formed in the lower section of the center pipe, the bell cap is a cover-shaped object which is opened in one end, and covers the end part of the upper section of the center pipe, the blind end of the bell cap is fixedly connected with the end part of the upper section of the center pipe; the valve base is a ring-shaped structure with a valve base hole in the center, the valve base is arranged below the material outlet in the center pipe; the floating valve is of a circular plate-shaped structure, covers above the valve base and can move up and down along the axial direction of the center pipe; a Venturi throat is arranged in the center pipe, which is close to the valve base, at the middle section of the center pipe. The gas-liquid distributor can ensure that gas is crushed into continuous micro-bubbles in a liquid, and can effectively solve or relieve the problem of instable gas-liquid pressure or countercurrent blockage of a material carrying a catalyst when a gas-feed feed is suddenly interrupted; meanwhile, a flowing dead zone inside the distributor is eliminated, and the pressure drop is relatively small.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

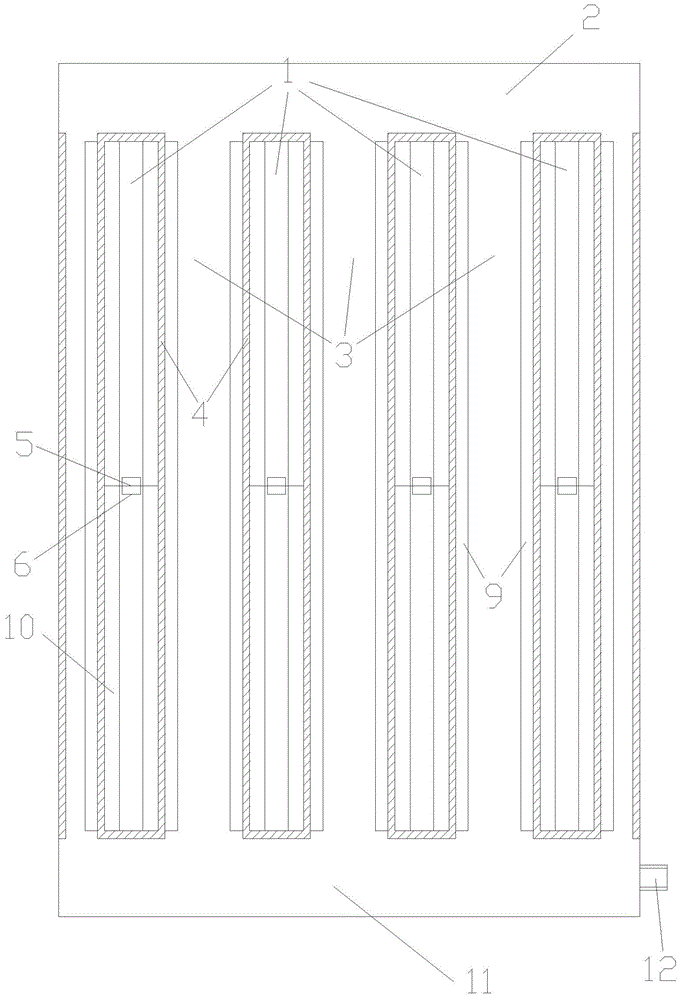

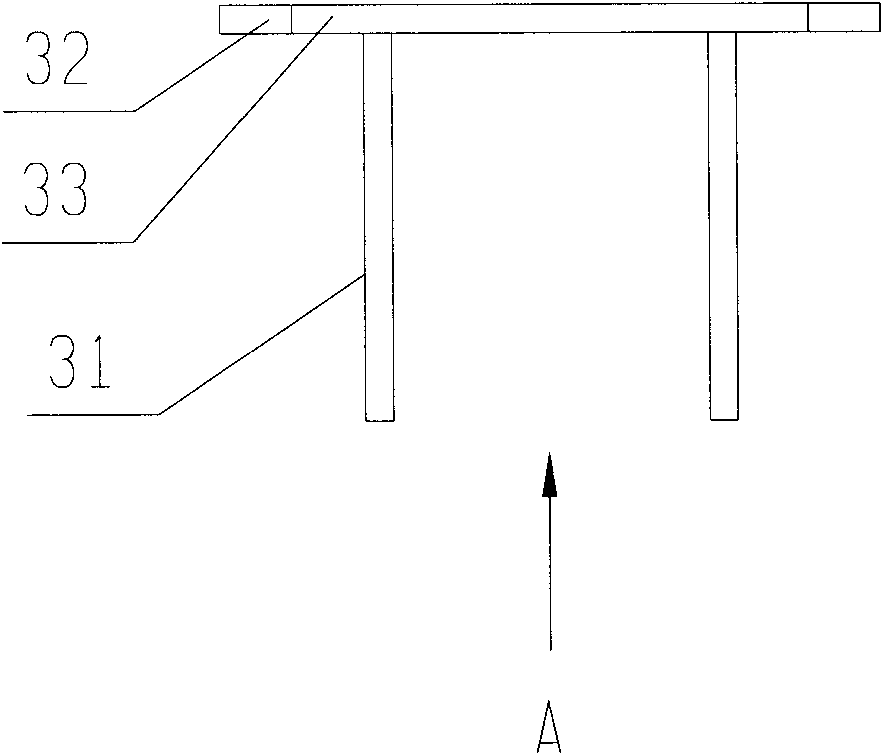

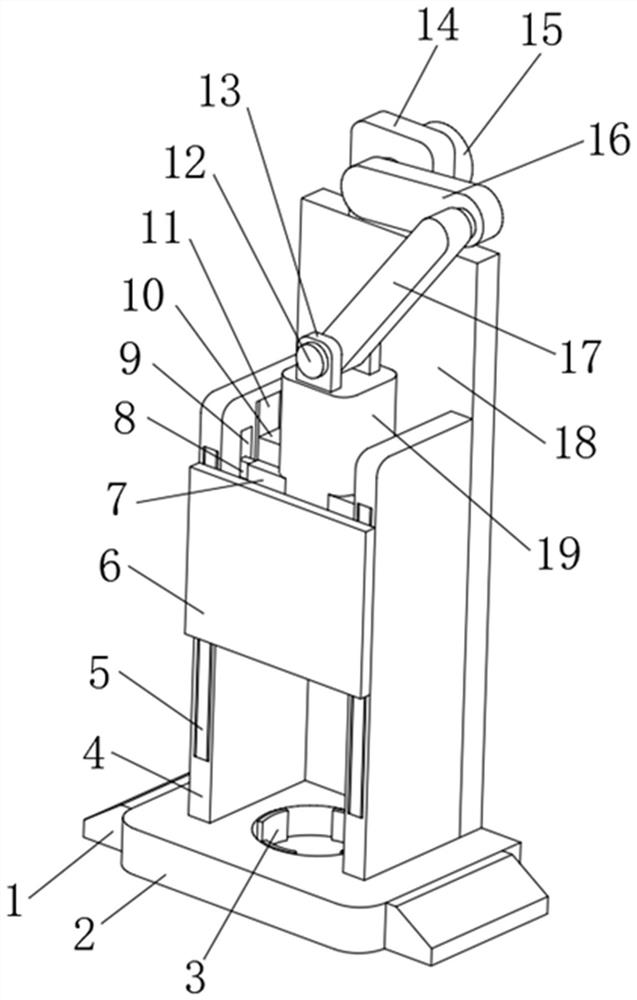

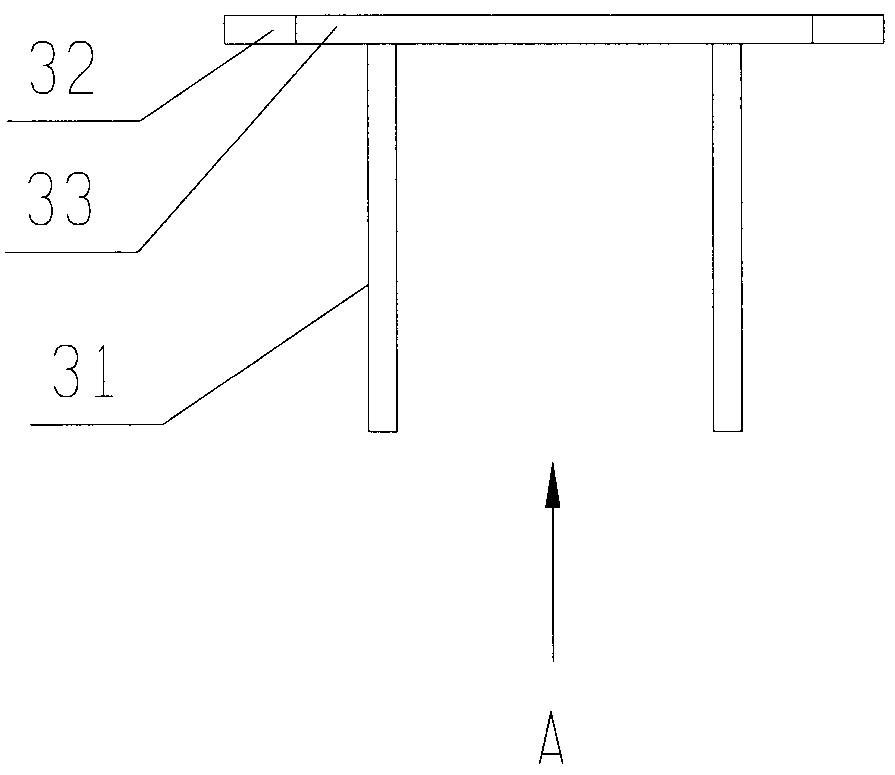

Precise ingredient activation feeder

ActiveCN105417097AStable outputAvoid affecting subsequent processing and productionConveyorsLoading/unloadingAdditive ingredientEngineering

The invention discloses a precise ingredient activation feeder. The precise ingredient activation feeder comprises a frame, a feed excitation bin, a vibration motor and a conveying belt mechanism, and further comprises a buffer bin and a gate plate; the bottom of the feed excitation bin is mounted on the top table surface of the frame through an elastic connecting piece; a vibration end of the vibration motor is connected to the side surface of the feed excitation bin through an elastic connecting piece; a feed port communicated with the internal is formed in the top of the feed excitation bin; a discharge port communicated to the internal of the feed excitation bin is formed in the bottom of the feed excitation bin; a feed channel penetrating through the table surface of the frame up and down is formed in the table surface of the frame; the conveying belt mechanism is transversely arranged below the feed channel; the buffer bin is fixed at the bottom of the table surface of the frame; the bottom of the buffer bin is contacted with a belt; the buffer bin is provided with a discharge gap along the lower end edge of the front side of the advancing direction of the belt; and the gate plate is mounted outside the front side bin wall of the buffer bin. The precise ingredient activation feeder has the advantages of simple structure, convenience for use, capability of activating upper logistics, prevention of arching, capability of adjusting the material discharge quantity, guarantee of the supply quantity of materials in the buffer bin satisfying the requirement and guarantee of stable material conveying.

Owner:WUHAN XIN HUAYUAN ELECTRIC POWER EQUIP

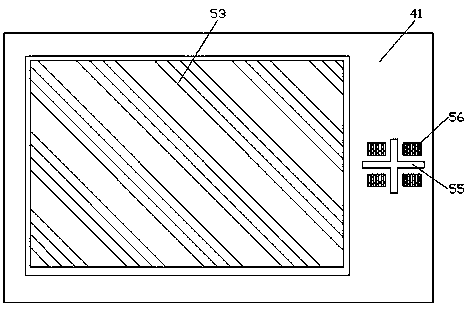

Internet-based solar automatic sun tracking device

ActiveCN108445918AGuaranteed tightnessEnsure consistencyPhotovoltaic supportsControl using feedbackStopped workEngineering

The invention discloses an Internet-based solar automatic sun tracking device which comprises a fixed bottom plate. A storage battery is fixedly arranged inside the fixed bottom plate, four telescopicmoving devices are arranged at four corners of a lower end surface of the fixed bottom plate, and a right end surface of the fixed bottom plate is fixedly connected to an air inflation device. A substrate is arranged in a space above a fixed casing, a photovoltaic panel is embedded and fixedly mounted on an upper end surface of the substrate, a power transmission line is arranged at a lower end of the photovoltaic panel, and a right side of the upper end face of the substrate is provided with a cross mask. Four areas divided by the cross mask are internally and fixedly provided with four photosensitive sensors, and the right end in the substrate is provided with an integrated controller. In the work of the device, sunlight directly irradiates the photosensitive sensors and the photovoltaic panel through different angle adjustments, thereby the utilization efficiency of resources is increased, when a signal received by the integrated controller do not meet the requirements, a control device stops working, and energy is effectively saved.

Owner:晶科电力科技股份有限公司

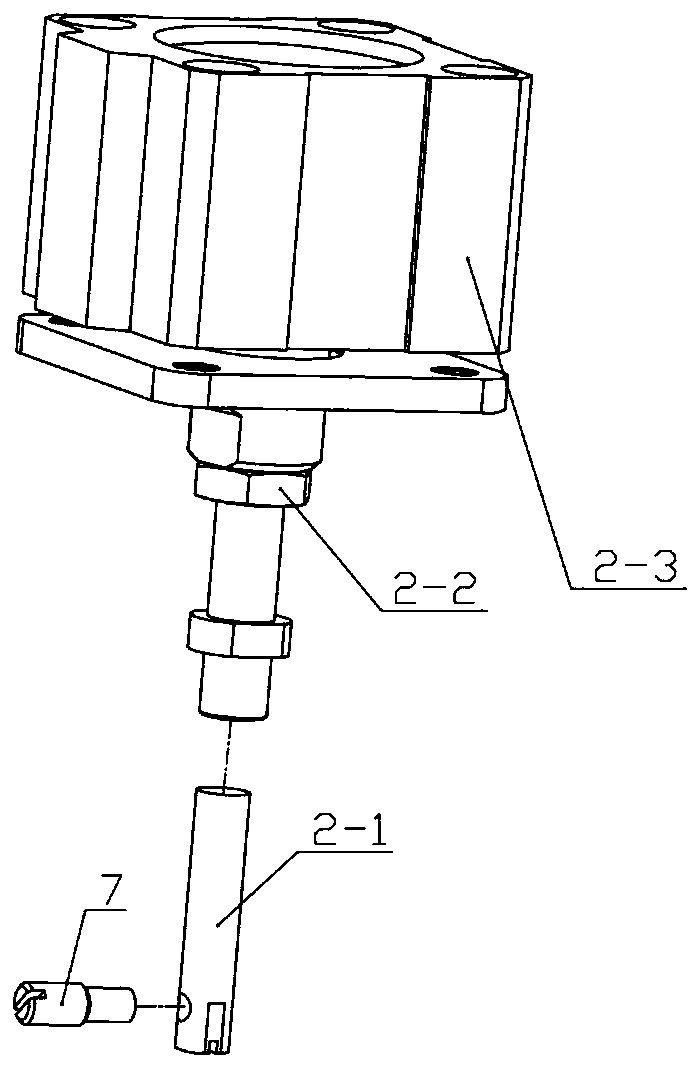

Focusing and zooming system for stage lamps

The invention discloses a focusing and zooming system for stage lamps, comprising a main support and a fixing frame arranged on the main support, wherein the middle part of the fixing frame is hollowed; the side walls of the fixing frame and the main support are defined to form a cavity; a slide guide rail and a guide rod are vertically installed in the cavity; the slide guide rail is sequentially provided with a first slide block and a second slide block from top to bottom; one end of a focusing module is connected to the slide guide rail by the first slide block; the other end of the focusing module is disposed in a corresponding part of the guide rod; one end of a zooming module is connected to the slide guide rail by the second slide block; the other end of the zooming module is placed in a corresponding part of the guide rod; and the focusing module and the zooming module are driven by a first stepper motor device and a second stepper motor device respectively. The system automatically focuses and zooms, so as to be convenient to operate; and an excellent pattern color effect is conveniently obtained to satisfy the requirements for a modern stage.

Owner:GUANGZHOU FINEART LIGHTING

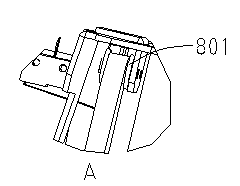

Metallic film type reducing valve

ActiveCN101446363AGuaranteed to move up and downAvoid destructionEqualizing valvesSafety valvesProduct gasValve stem

The invention provides a metallic film type gas reducing valve, which comprises a valve body (1) provided with a flow passage, a main spring box (2) arranged on the valve body (1), a valve stem (5) and a membrane (8), wherein, the valve stem (5) is provided with a first end part arranged in the flow passage of the valve body (1) and a second end part positioned in the main spring box (2); and the membrane (8) is installed on the second end part of the valve stem (5). By adopting the membrane with a special structure, the membrane can be prevented from being damaged caused by excessive pressure in a pipeline system when the valve stem moves up and down and the vale is sealed.

Owner:CHANGZHENG ENG

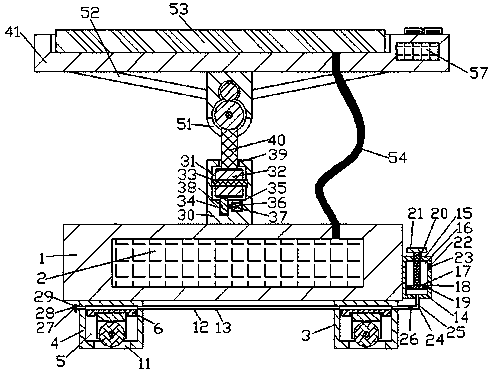

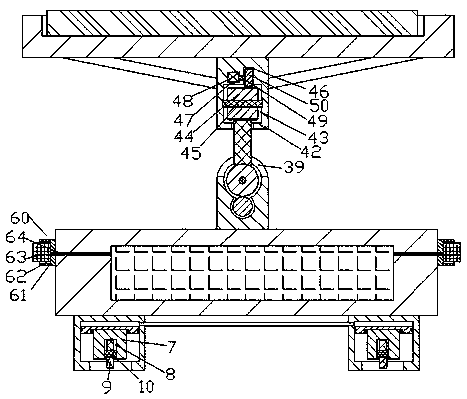

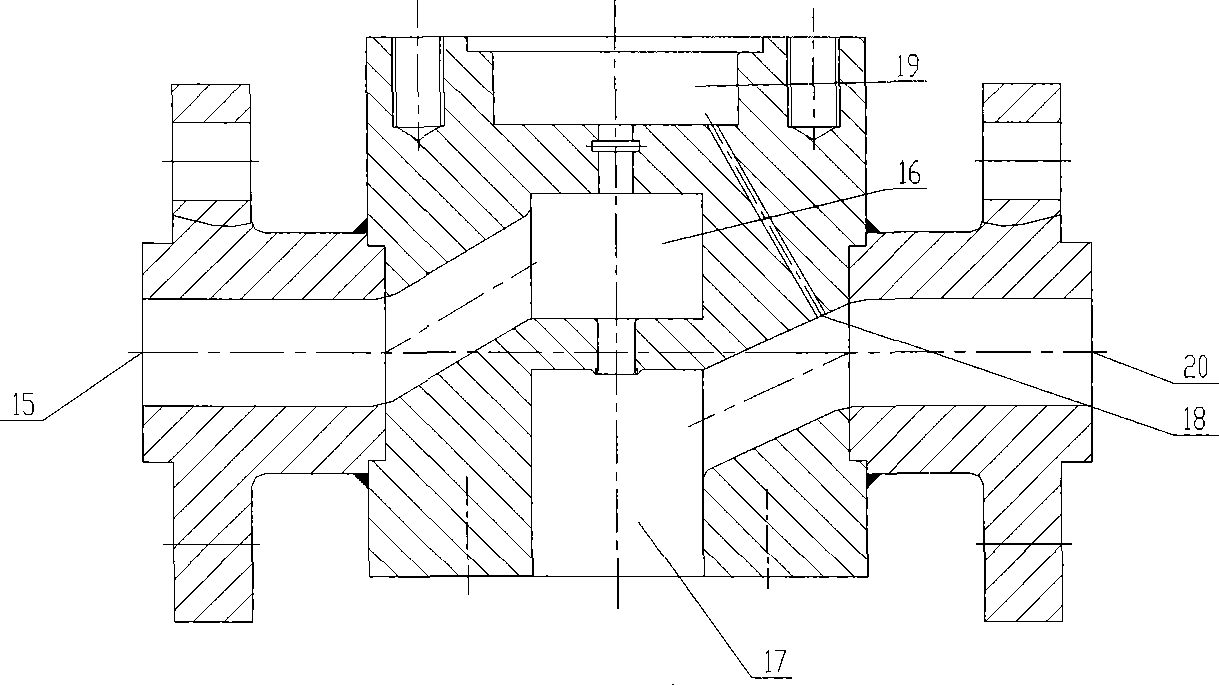

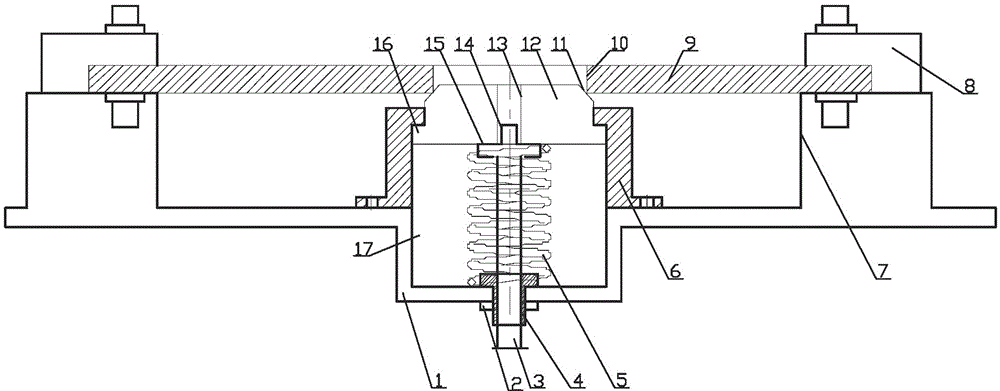

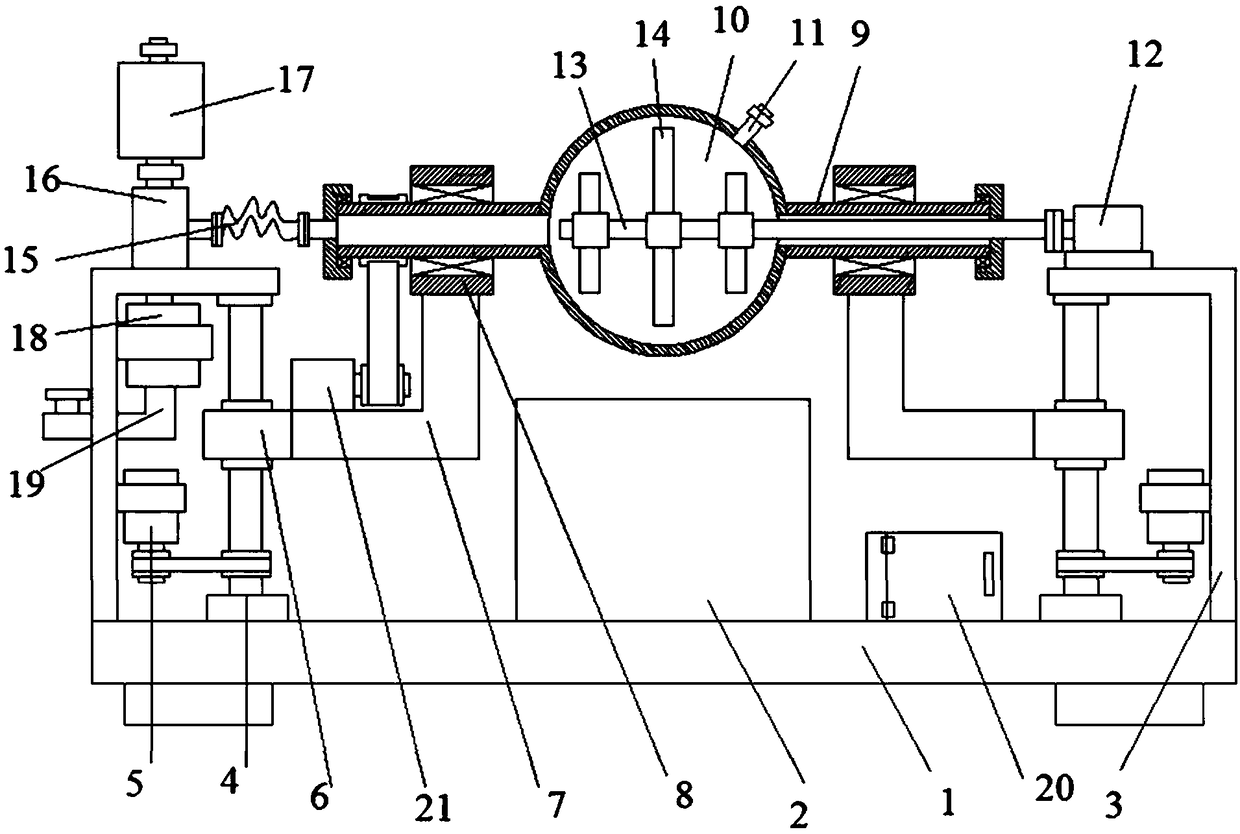

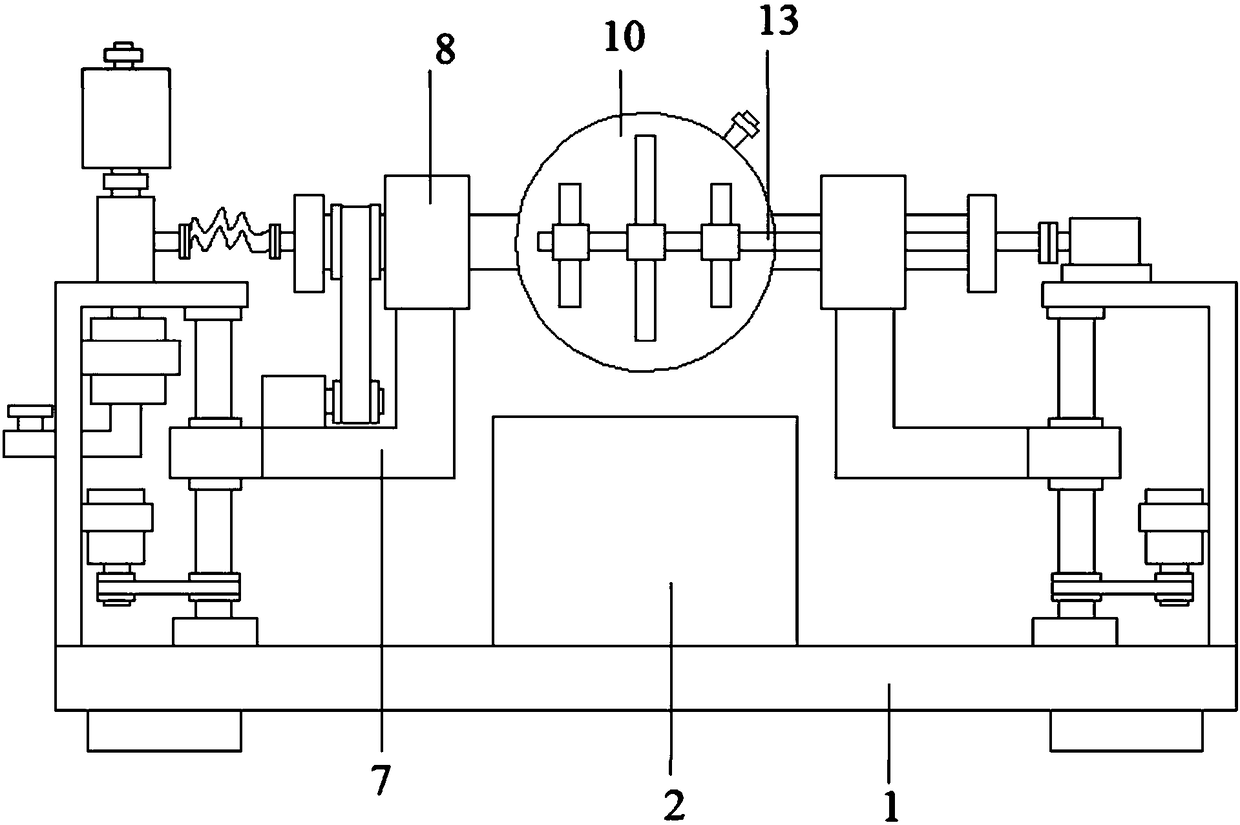

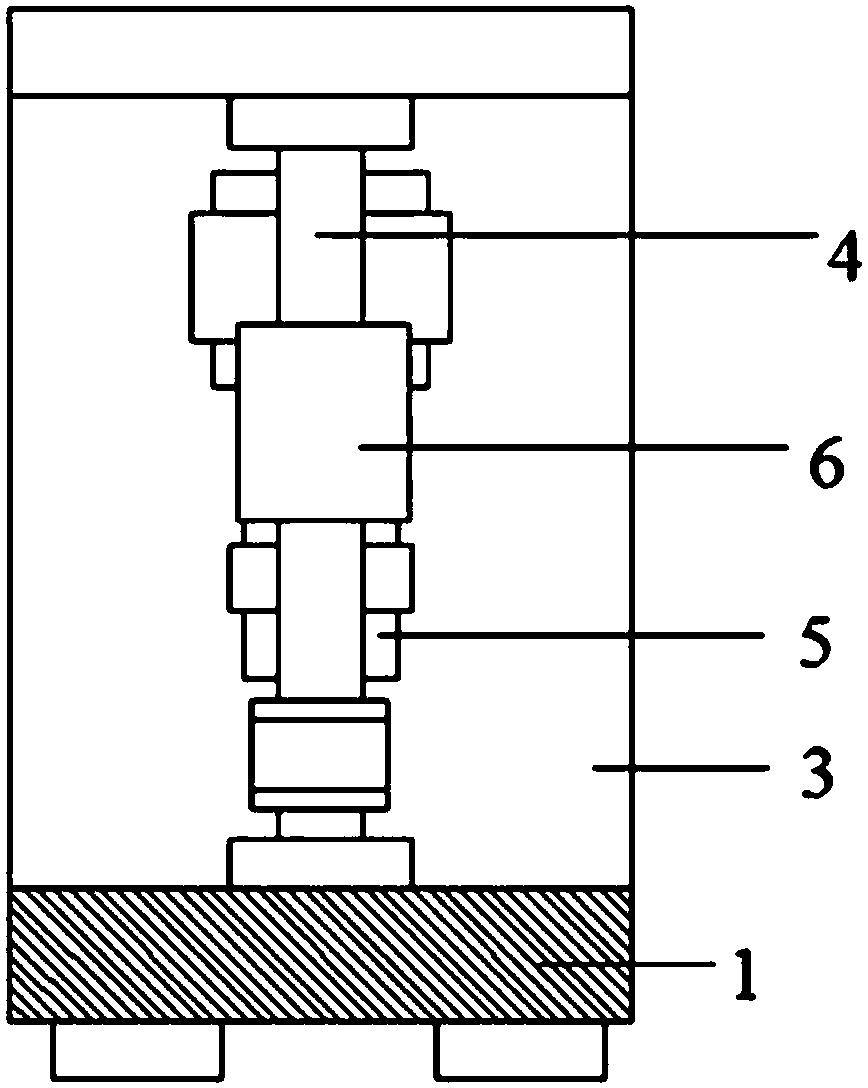

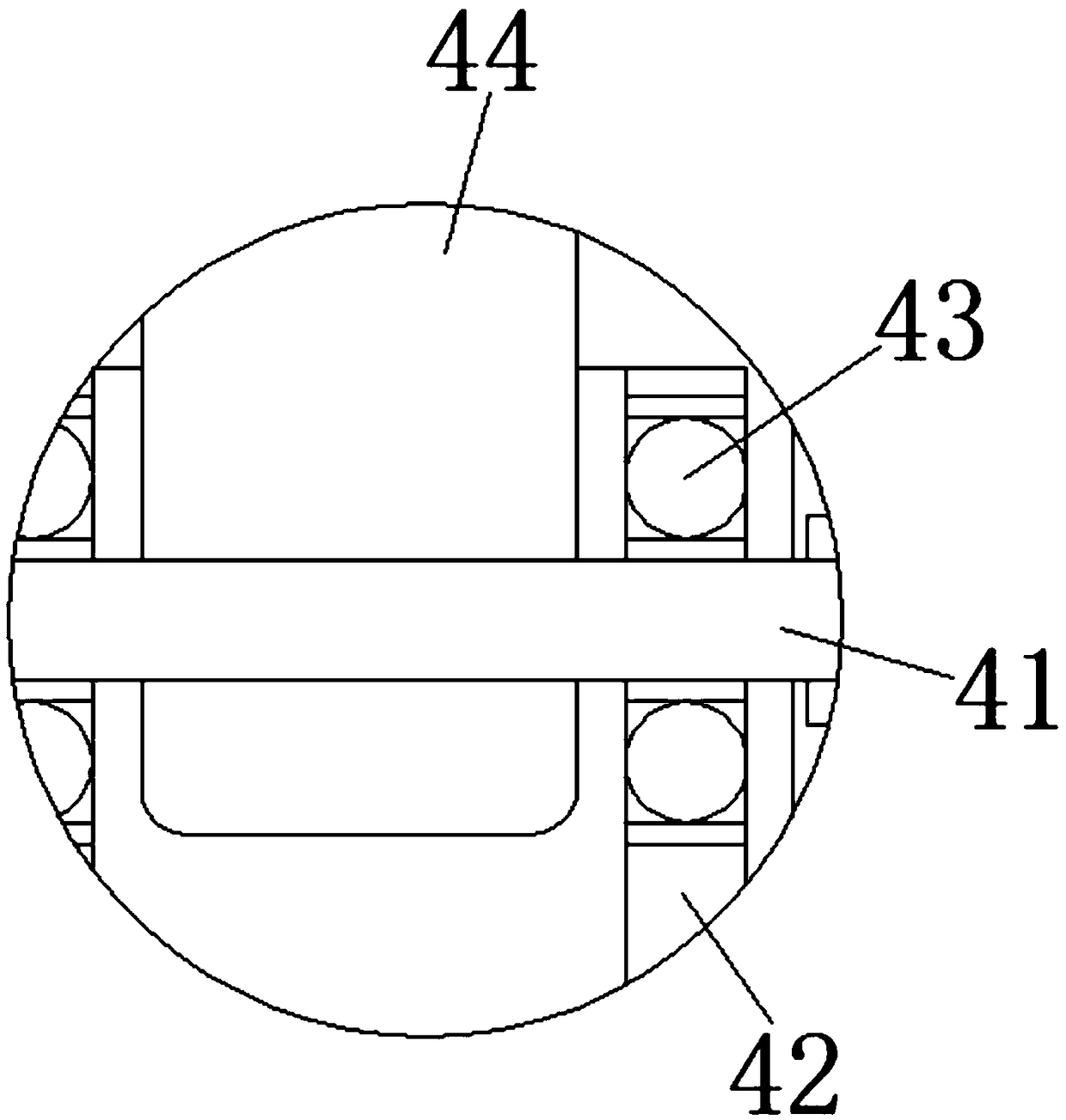

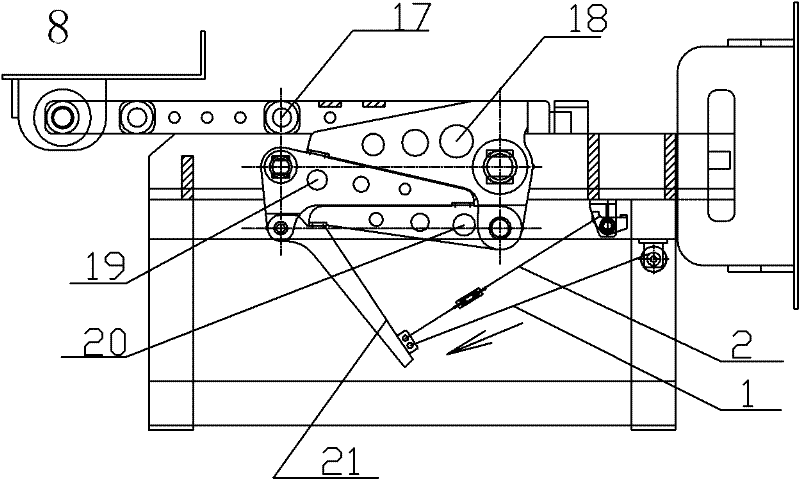

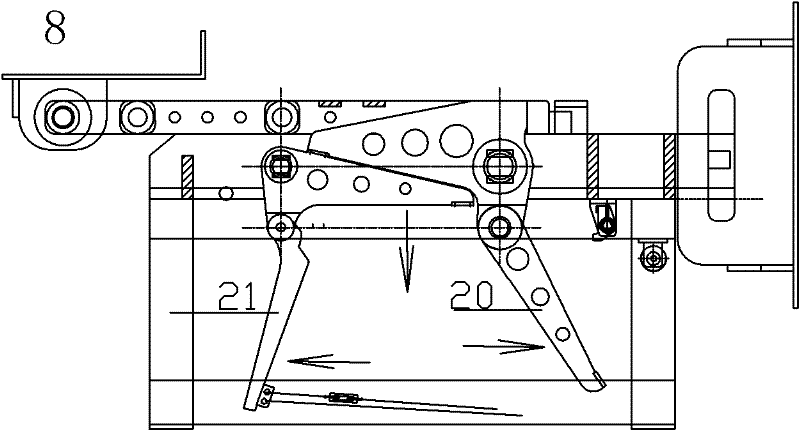

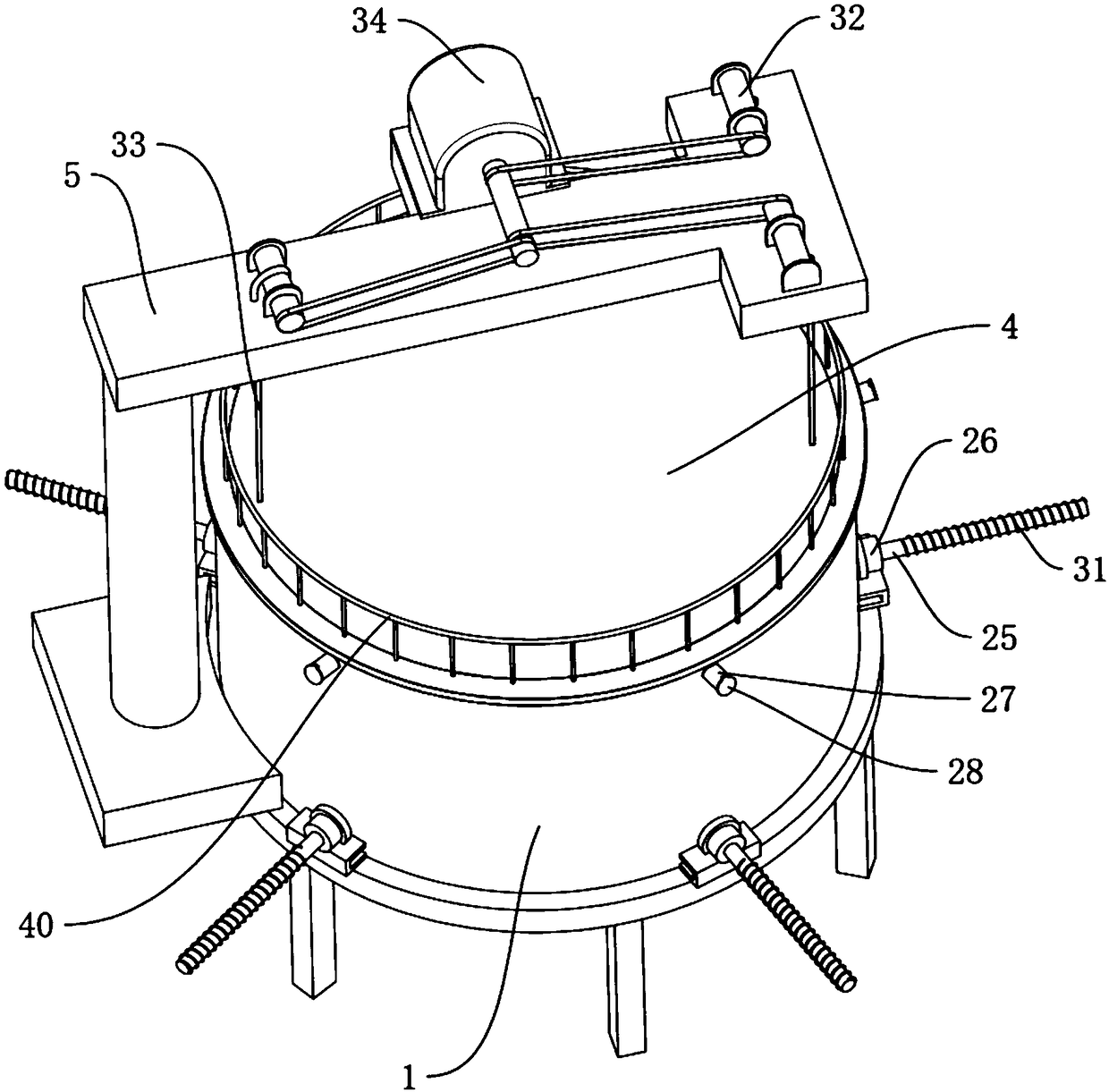

Clamping and positioning device for robot welding positioner of large weldment and spring parameter selection method

ActiveCN105618992AIncrease labor intensityAvoid the cumbersome process of manual operationWelding/cutting auxillary devicesAuxillary welding devicesAuto regulationFile comparison

The invention relates to a clamping and positioning device for a robot welding positioner of a large weldment and a spring parameter selection method. Specific to uncertainty of hole site deviation of a bottom plate of a workpiece, main parameters of a spring are rapidly and conveniently determined through detailed spring stress calculation; and data are recorded and used for data comparison and lookup, and some judgments or conclusions are made. By means of the clamping and positioning device, the spring has an automatic adjusting function and the fixing function of a locking device, accuracy of automatic welding positioning of a robot is ensured, and reliable and fast positioning and clamping of the large weldment and the robot welding positioner are achieved.

Owner:YICHANG JIANGXIA MARINE MACHINERY

Stamping device for new energy automobile brake disc production and application method of stamping device

InactiveCN112296156ARealize partial stamping repair treatmentReduce punching forceShaping toolsMetal-working feeding devicesBrakeNew energy

The invention discloses a stamping device for new energy automobile brake disc production and an application method of the stamping device, and relates to the technical field of new energy automobiles. The stamping device aims to solve the problem that existing stamping equipment cannot repair an element needing to be stamped after stamping is solved. The stamping device specifically comprises a supporting bottom plate, a third supporting plate is in bolted connection to the outer wall of one end of the top of the supporting bottom plate, and first supporting plates are in bolted connection tothe outer walls of the two sides of one end of the third supporting plate. According to the stamping device for new energy automobile brake disc production and the application method of the stampingdevice, first electric guide rails and a protective plate are arranged at one ends of the first supporting plates, the protective plate can be driven by first electric sliding blocks to move up and down, then the stamping position of the bottom of the device is protected by the protective plate, a stamping part is prevented from bursting out accidentally, or outside workers or parts are preventedfrom stretching into the stamping position, and the use safety of the device is improved.

Owner:马鞍山贺辉信息科技有限公司

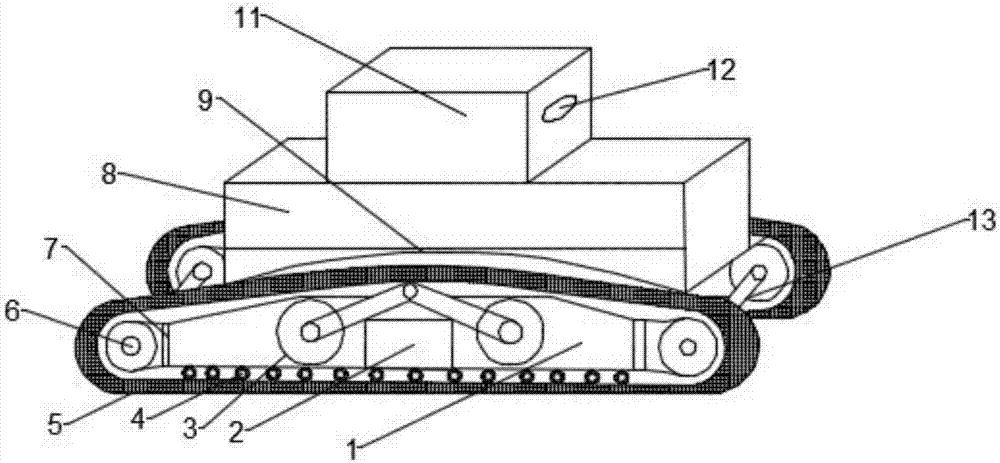

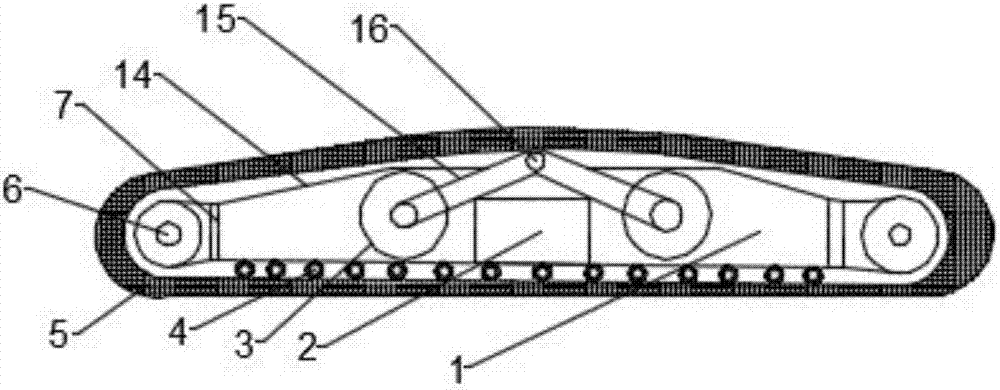

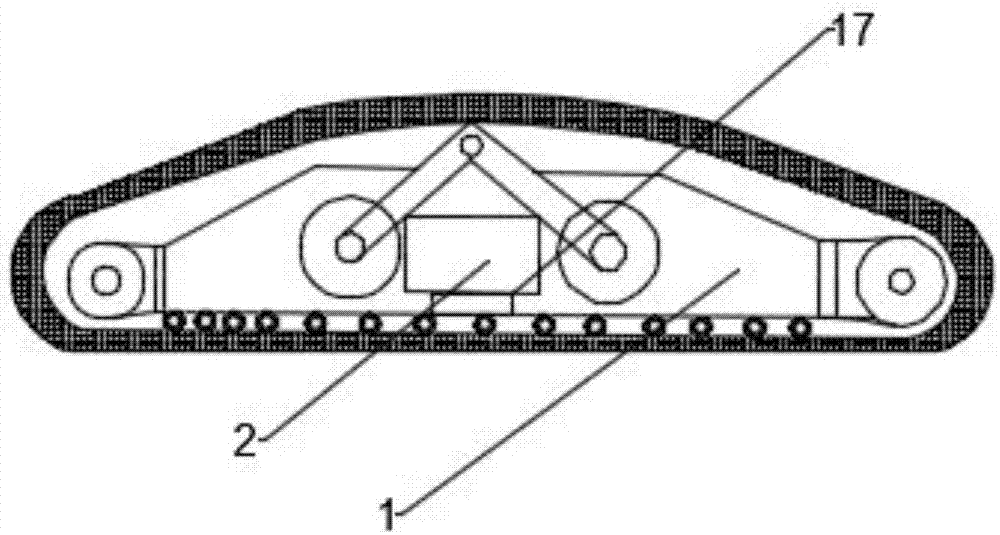

Tracked robot with stretchable chassis

InactiveCN107161227AImprove stabilityGuaranteed normal operationEndless track vehiclesDrive wheelEngineering

The invention discloses a crawler robot with a telescopic chassis, which comprises a telescopic chassis, crawlers are sheathed on both sides of the telescopic chassis, connecting rods are connected between the crawlers, and driving A stretching rod is installed next to the driving wheel, and a rising moving wheel is installed at 20 centimeters of the crawler belt. There are evenly arranged guide pulleys between the crawler belt and the pulling rope. The two lifting moving wheels A telescopic plate is installed between the wheels, a chassis is welded above the telescopic chassis, a drive box and a robot box are sequentially installed above the chassis, and an inductor is welded directly in front of the robot box. The present invention can effectively To prevent the crawler from falling off, the stability of the crawler robot can be improved through the telescopic chassis. The sensor can measure the distance and prevent the crawler robot from colliding when it moves, and its price is cheap, which effectively reduces the manufacturing cost.

Owner:CHANGSHA WUDAO IND DESIGN CO LTD

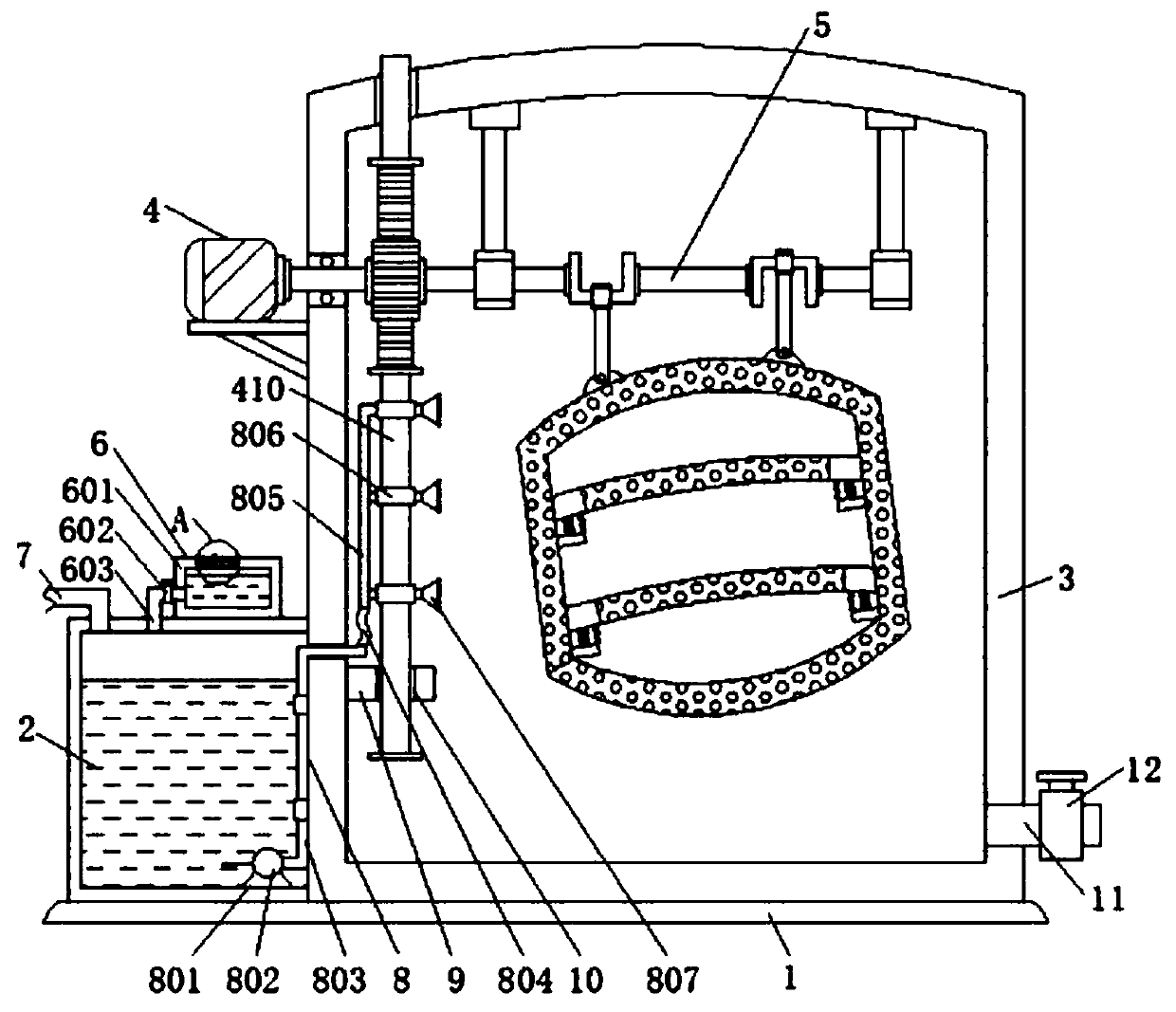

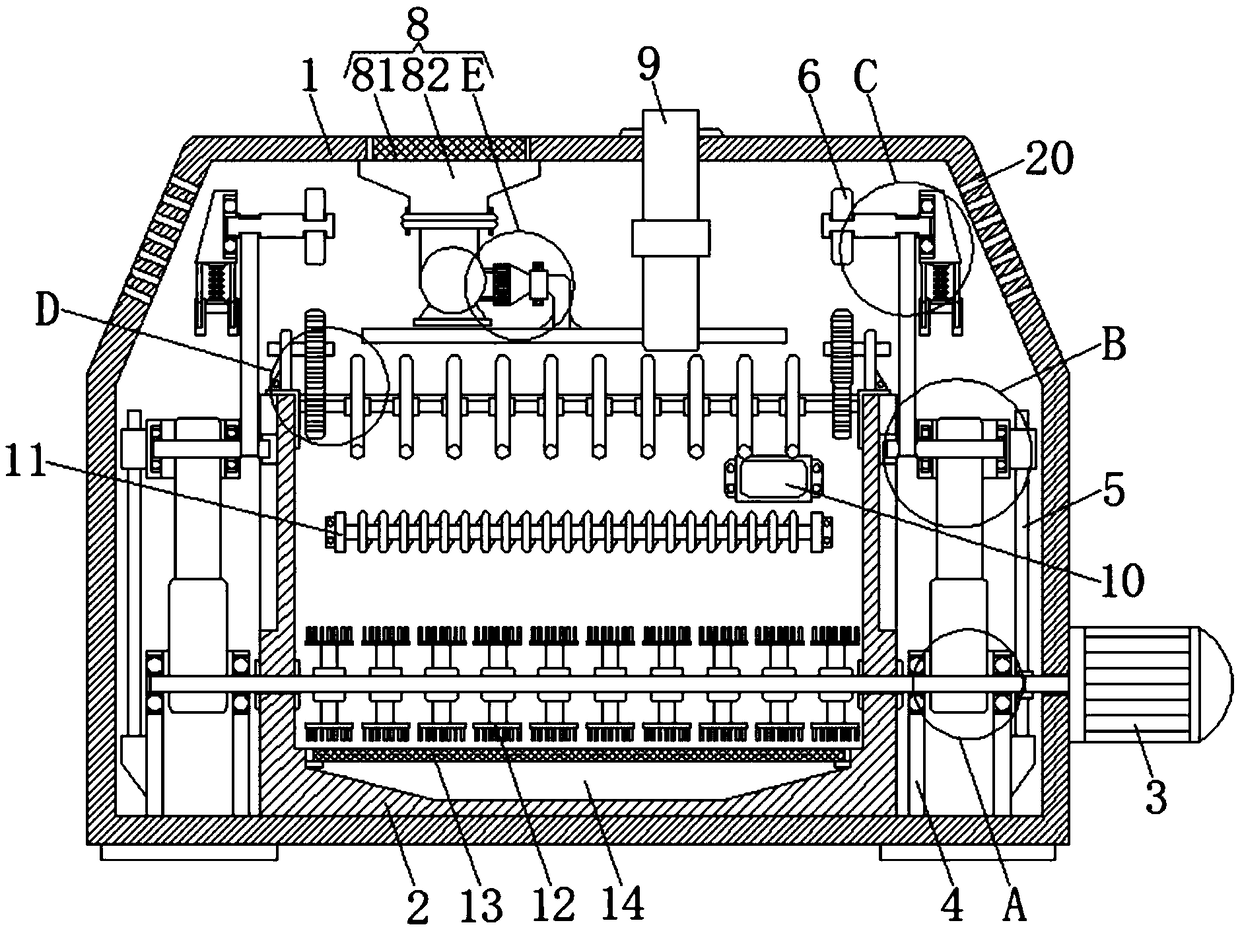

Free swinging device for removing hard yellow mud on surface of codonopsis pilosula and using method

InactiveCN111299263AGood for fallingEffectively eroded and brokenCleaning using liquidsCodonopsis pilosulaMechanical engineering

The invention relates to the technical field of traditional Chinese medicine, in particular to a free swinging device for removing hard yellow mud on the surface of codonopsis pilosula and a using method, and aims to solve the technical problem that after yellow soil is sun-dried, hard blocks are formed and attached to the surface of codonopsis pilosula as well as difficult to simply wash out. Inorder to solve the above technical problem, the free swinging device for removing the hard yellow mud on the surface of codonopsis pilosula is provided. The free swinging device comprises a base, wherein a water tank and a cleaning box are fixedly connected with the top of the base from left to right; a power actuator is fixedly connected with the top of one side of the cleaning box; and the output end of the power actuator penetrates through and extends into the cleaning box. By the adoption of the free swinging device, the hard yellow soil blocks can be effectively eroded and broken; the removal of the hard yellow soil blocks from the surface of codonopsis pilosula can be facilitated; and the problem that after the yellow soil is sun-dried, the hard blocks are formed and attached to thesurface of codonopsis pilosula as well as difficult to simply wash out can be solved.

Owner:杨喜兰

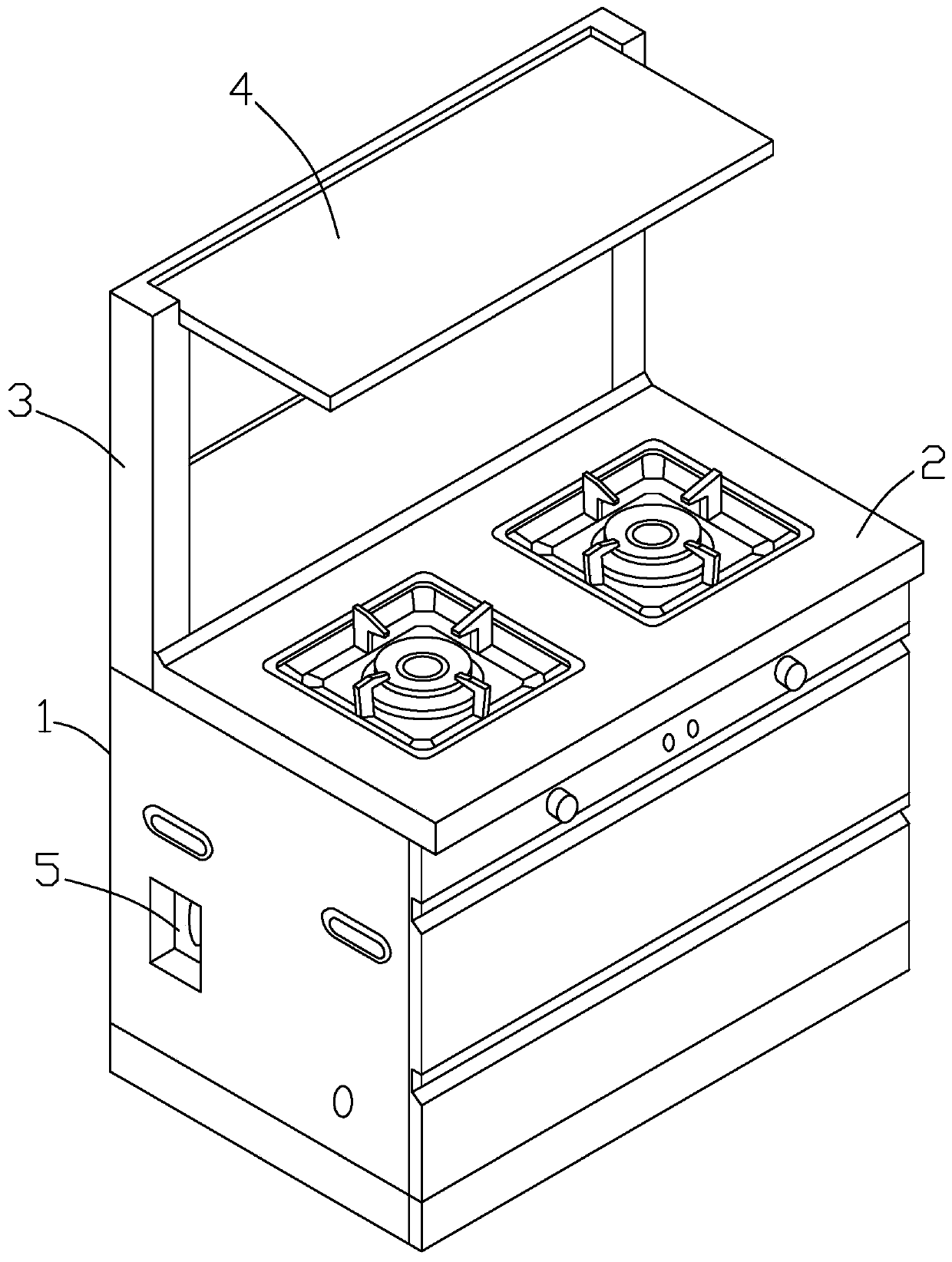

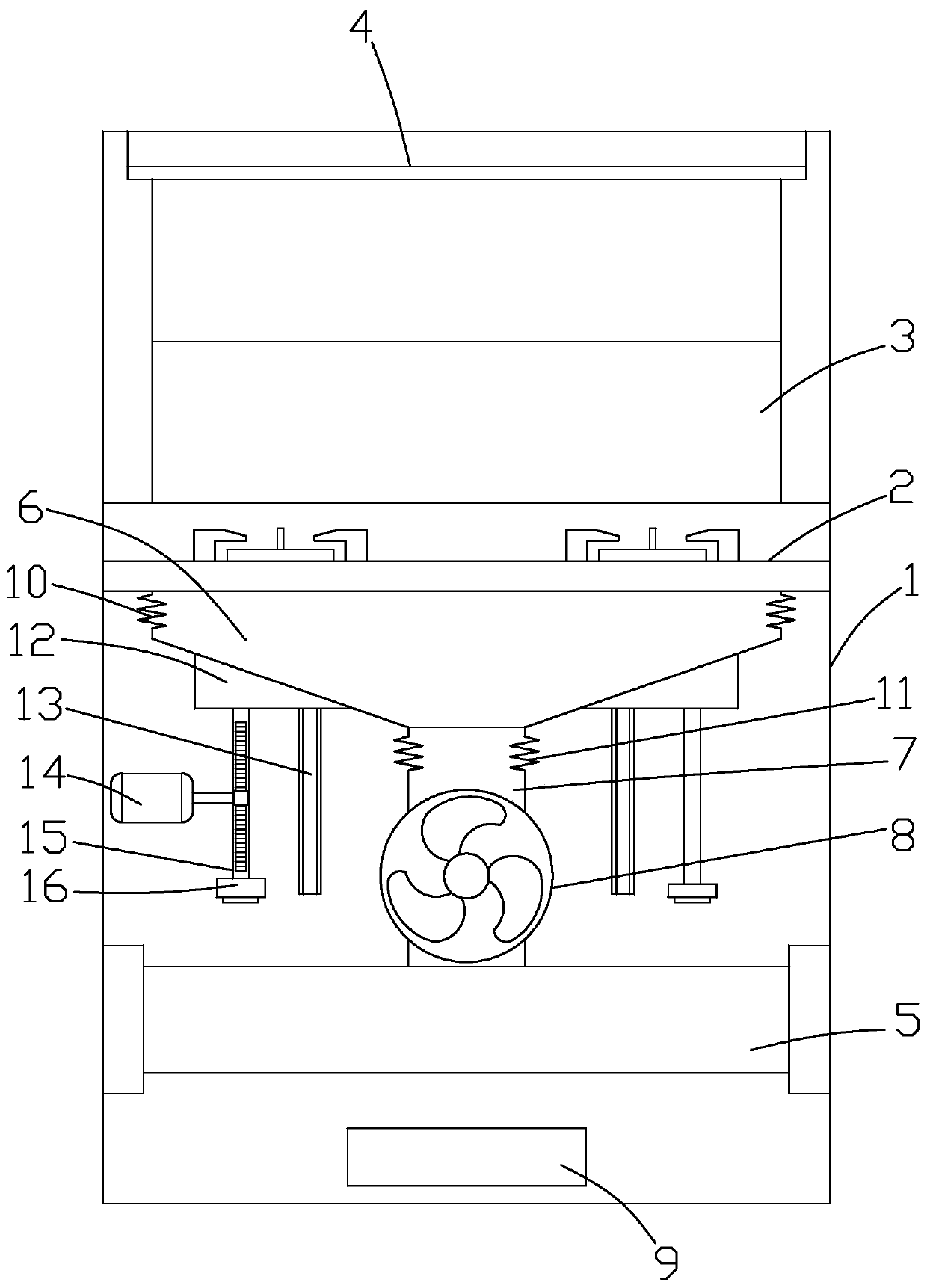

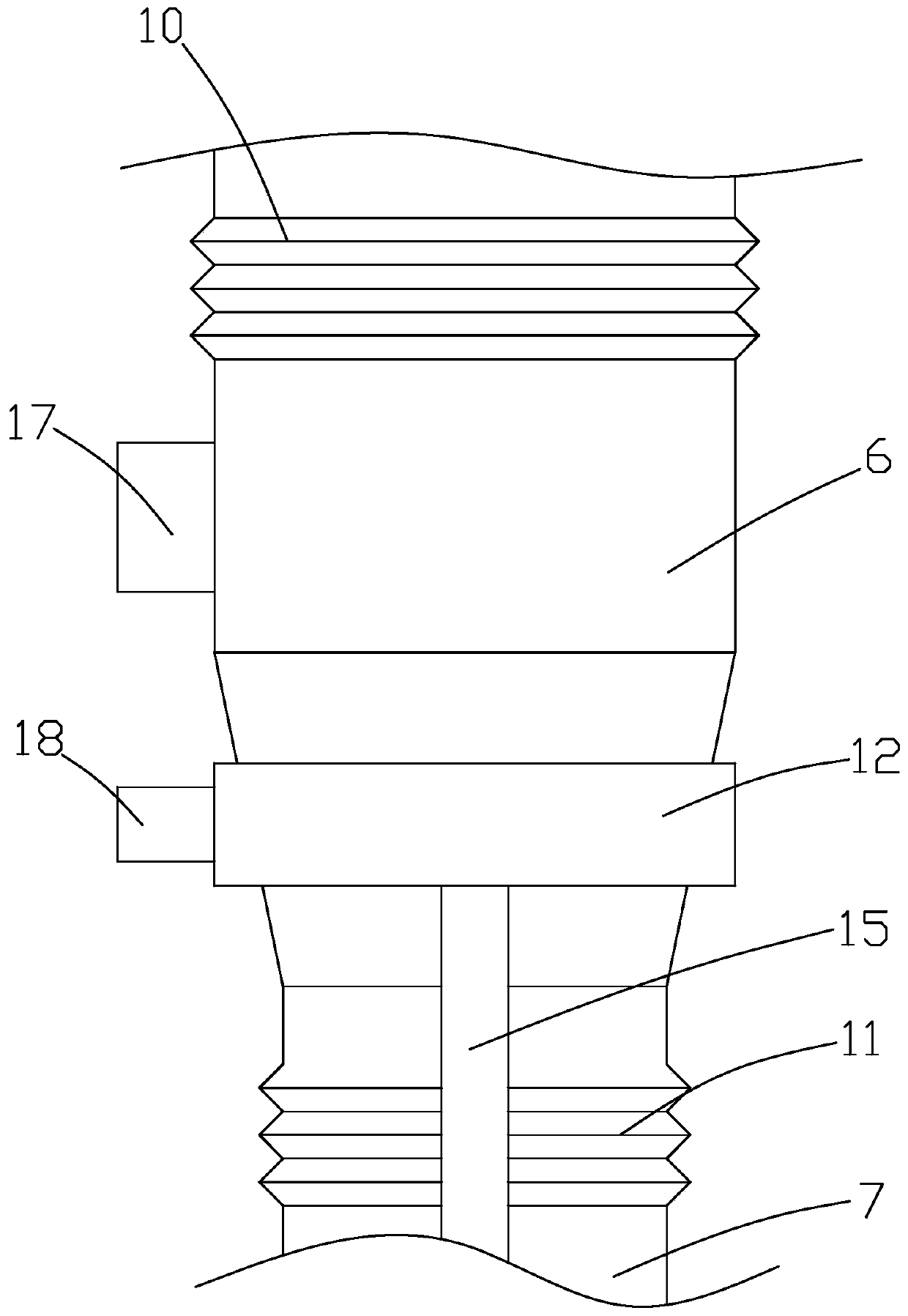

Integration cooker capable of adjusting volume of smoke collection cavity and making method of integration cooker

PendingCN110726164AAdjustable spacingImprove sealingDomestic stoves or rangesPump componentsProcess engineeringWind power

The invention discloses an integration cooker capable of adjusting the volume of a smoke collection cavity and a making method of the integration cooker. The integration cooker comprises an integration cooker body and the adjustable smoke collection cavity, the top of the adjustable smoke collection cavity is communicated with a cooking fume suction groove in the top face of the integration cookerbody, and a supporting mechanism is arranged on the side face of the adjustable smoke collection cavity, and connected with a lifting driving mechanism and a limiting sliding mechanism. The making method of the integration cooker comprises the steps of machining the integration cooker body, machining and installing the adjustable smoke collection cavity, machining and installing the supporting mechanism, installing the lifting driving mechanism, installing the limiting sliding mechanism, and conducting pilot running on the integration cooker. According to the integration cooker, through the design of the adjustable smoke collection cavity, the smoke collection cavity is close to or away from a draught fan, flexible adjustment of wind power in the shifting process of the draught fan is satisfied, and it is avoided that the wind power is suddenly increased or decreased; moreover, up-down floating adjustment on wind power can be made when the draught fan is at different gear positions, the adjustment on the wind power of the integration cooker is diversified, air flow is smoother, and the noise is lowered.

Owner:浙江蓝炬星电器有限公司

Gas distributor for slurry bed reactor

The invention discloses a gas distributor for a slurry bed reactor. The gas distributor for the slurry bed reactor mainly comprises a central pipe, a bubble cap, a floating valve and a valve seat, wherein the pipe wall of the upper end of the central pipe is provided with a gas outlet; a pipe opening in the lower end of the central pipe serves as a gas inlet; the bubble cap is a cover-shaped object with one opened end, and covers the upper end of the central pipe; a blind end of the bubble cap is fixedly connected with the upper end of the central pipe; the valve seat is of circular ring structure with a valve seat holes in the center, and is arranged below the gas outlet and in the central pipe; the floating valve is of a round plate-shaped structure, covers the valve seat and can move vertically along the axial direction of the central pipe. According to the invention, the floating valve acts as a non-return element, and runs stably; the special connection mode between the bubble cap and the central pipe enables a runner to be simple and resistance to be relatively low, thereby greatly weakening a vortex caused by air flow.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

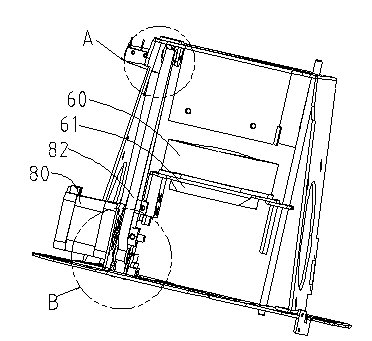

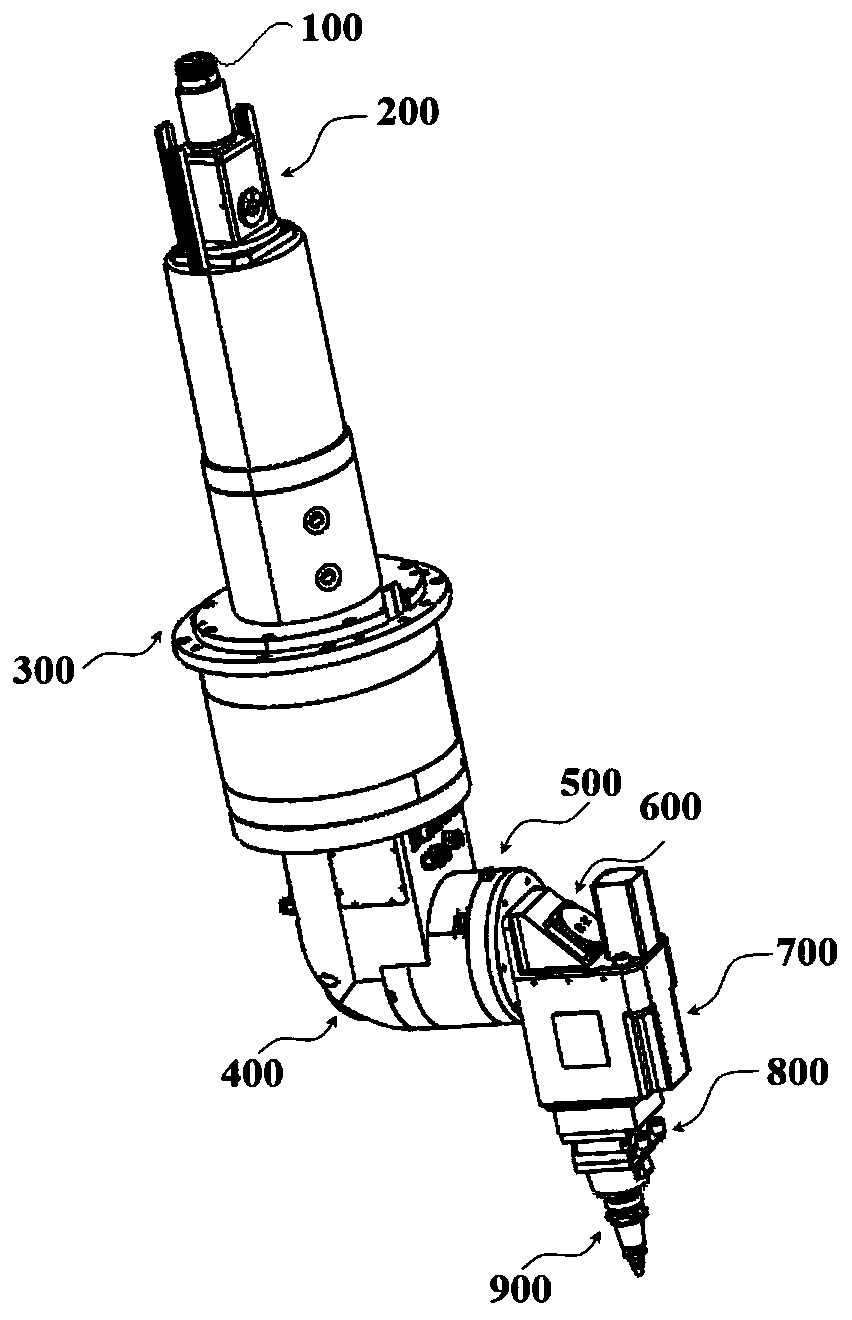

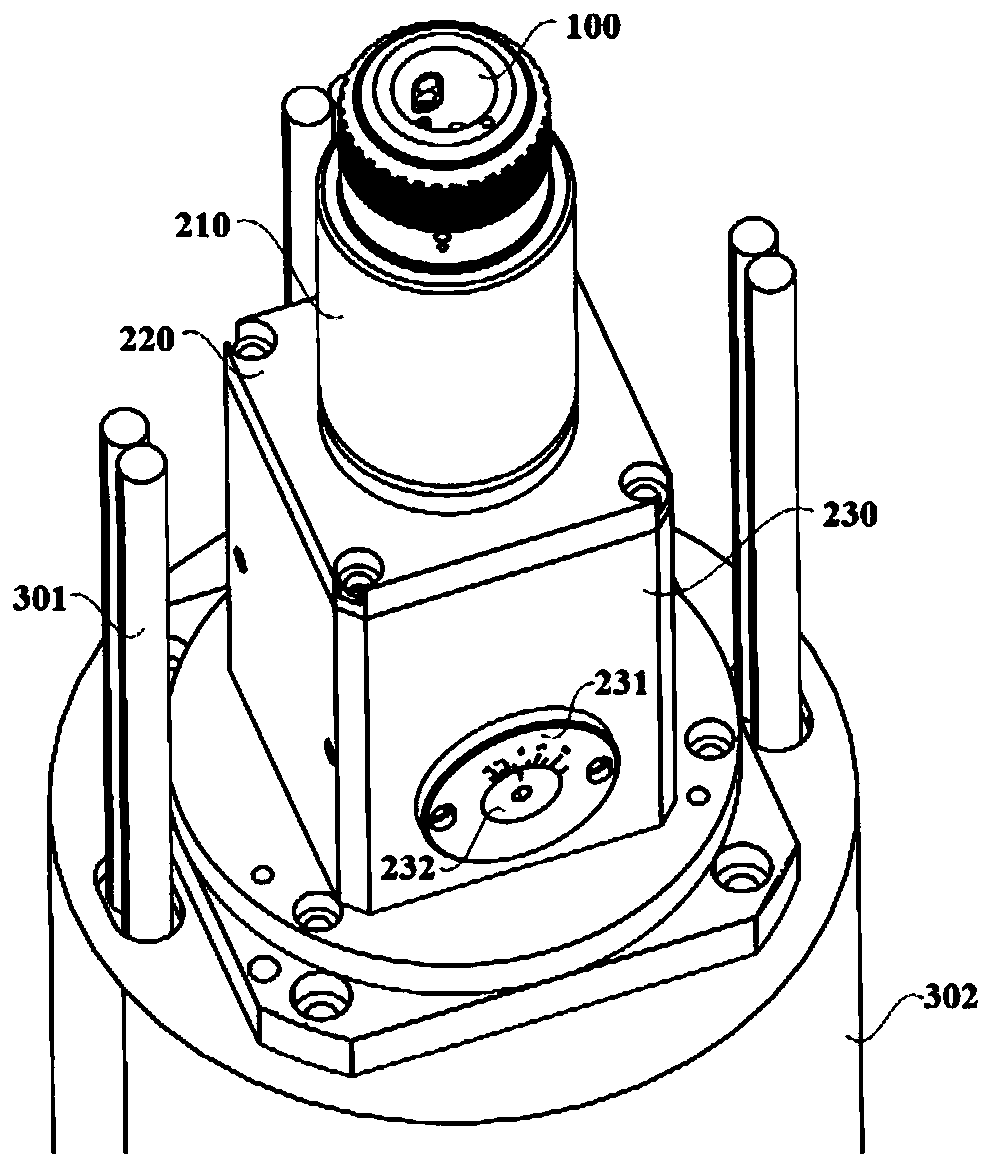

Double-pendulum three-dimensional laser cutting machine

PendingCN110000481AAvoid compromising qualityEasy to laser cutLaser beam welding apparatusLight beamLaser cutting

The invention discloses a double-pendulum three-dimensional laser cutting machine, and belongs to the technical field of laser cutting. The double-pendulum three-dimensional laser cutting machine comprises a focusing mechanism, a first reflection mechanism, a second reflection mechanism and a cutting head. The focusing mechanism is located below a laser inlet, a focusing unit is arranged in the focusing mechanism, a following mechanism and a beam-focusing mechanism are arranged between the second reflection mechanism and the cutting head, the following mechanism is used for driving the beam-focusing mechanism and the cutting head to wholly move up and down, the beam-focusing mechanism is used for adjusting the direction of the light beam, and the laser beam is emitted out of the cutting head. The focusing unit, the following mechanism and the beam-focusing mechanism are arranged, and are matched to jointly adjust the focus point position of the laser beam, it is ensured that the focuspoint position is in the surface of a workpiece to be machined all the time, and the laser cutting is facilitated.

Owner:安徽斯塔克机器人有限公司

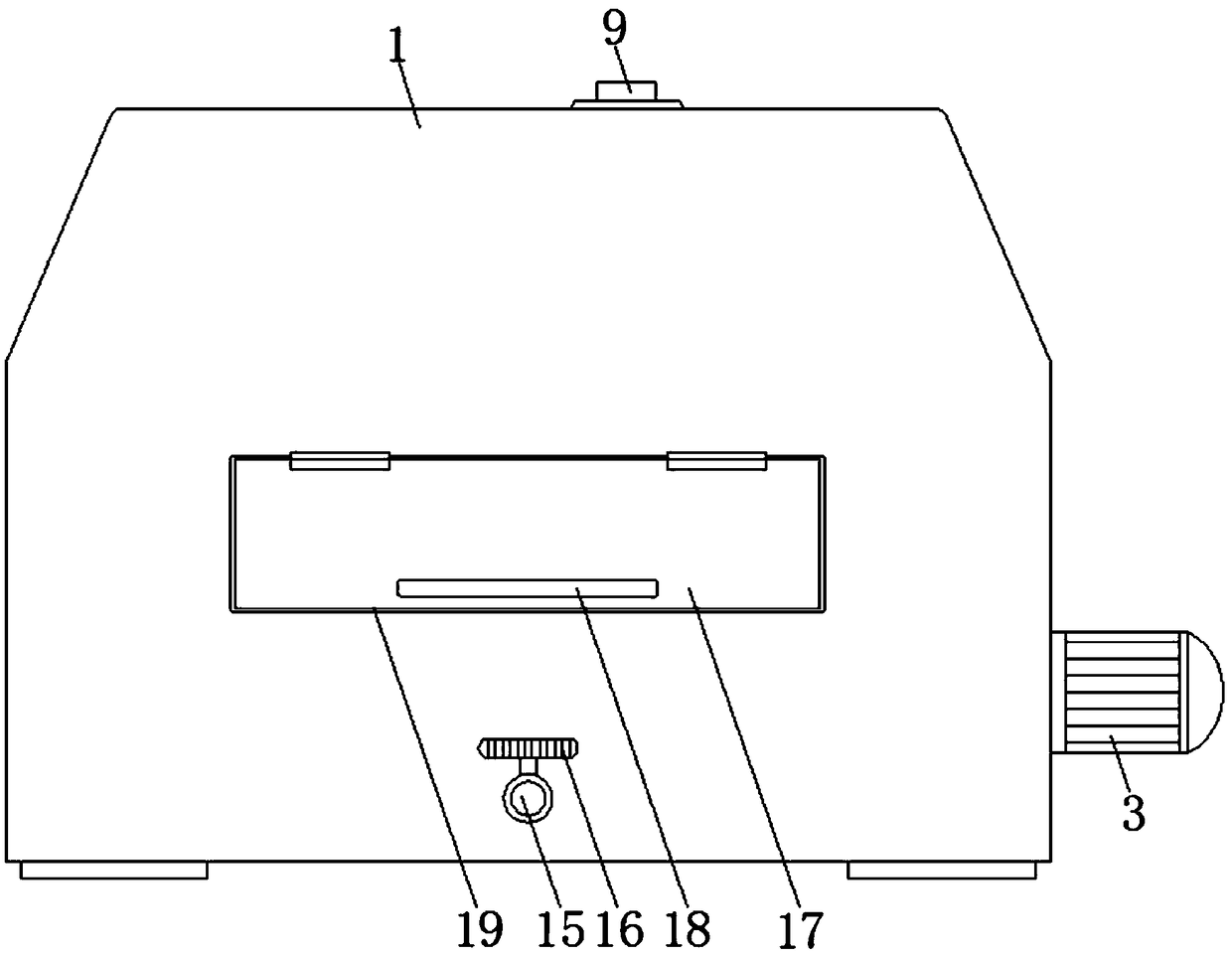

Printing device for paper packaging box production and working method thereof

ActiveCN112208200AGuaranteed to move up and downGuaranteed accuracyPackage recyclingRotary pressesPrint-throughManufacturing engineering

The invention discloses a printing device for paper packaging box production. The printing device comprises a first conveying belt, a printing box, a second conveying belt and a printing machine, wherein the bottom of the printing box is fixedly connected with the ground through supporting rods. The invention relates to the technical field of packaging box printing devices. According to the printing device for paper packaging box production, a packaging box is conveyed through the first conveying belt, the first conveying belt is higher than baffles, the packaging box can cross the baffles tomove to supporting bearings, and after the packaging box is completely located on the supporting bearings, rotating rods and the supporting bearings drive the packaging box to move in the direction close to the baffles until the packaging box makes contact with the baffles, the height and position of the packaging box are adjusted through a lifting plate, the packaging box can be printed through the printing machine, the position of the packaging box does not need to be manually adjusted, and the problems that when an existing printing device works, the position of the packaging box needs to be manually adjusted, efficiency is poor, and a large amount of manpower is wasted are solved.

Owner:舒城县大格包装材料股份有限公司

Novel rotary evaporator

InactiveCN108079604AEvenly heatedEffective rotationEvaporator accessoriesDistillation in rotating vesselsWater bathsRotary evaporator

The invention discloses a novel rotary evaporator. The novel rotary evaporator comprises a base, a water bath kettle is arranged on the upper side of a base plate, an electric control box is arrangedon the right side of the water bath kettle, an L-shaped connecting plate is arranged at the outer end of the upper side of the base, a screw rod is connected with the L-shaped connecting plate, a first motor is arranged outside the screw rod, a sliding block is arranged on the screw rod, an L-shaped connecting rod is arranged on the inner side of the sliding block, a third motor is arranged on theupper side of the L-shaped connecting rod, an upper side of the L-shaped connecting rod is provided with a bearing seat, connecting pipes are arranged inside the bearing seat, a rotary evaporation bottle is arranged between the connecting pipes, a feeding port is arranged on the right side of the upper side of the rotary evaporation bottle, a stirring rod shaft is arranged inside the rotary evaporation bottle, a second motor is arranged on the right side of the stirring shaft, stirring rods are arranged on the upper and lower sides of the stirring shaft, and a connecting hose is arranged on the left side of the connecting pipe on the left end, and a first condensing tube, a second condensing tube, and a liquid storage tube are arranged on the left side of the connecting hose. The novel rotary evaporator can effectively facilitate stirring and moving up and down in a process of rotary evaporation of the evaporator, and can effectively facilitate rotary evaporation of the evaporator.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Cleaning device for plush toys

ActiveCN108914474AAvoid damageEffectively combBrushing washing machinesOther washing machinesEngineeringLinkage concept

The invention discloses a cleaning device for plush toys, and relates to the technical field of plush toys. The cleaning device for the plush toys includes a casing; the central portion of an inner bottom of the casing is fixedly connected to the bottom of a box; a rotation motor is fixedly arranged on the bottom on the right side of the casing; lower transmission mechanisms are arranged on left and right sides of the box respectively, and the two lower transmission mechanisms are fixedly arranged on the left and right sides of the inner bottom of the casing respectively; and upper transmission mechanisms are arranged on the tops of the two lower transmission mechanisms. According to the cleaning device for the plush toys, the rotation motor, the lower transmission mechanisms, the upper transmission mechanisms, joint transmission mechanisms and rubbing linkage mechanisms are arranged to effectively avoid damage to the plush toys due to continuous brushing, and then the problem that theconventional plush toy cleaning devices cannot perform targeted cleaning on the plush toys can be solved.

Owner:海宁佳龙织染有限公司

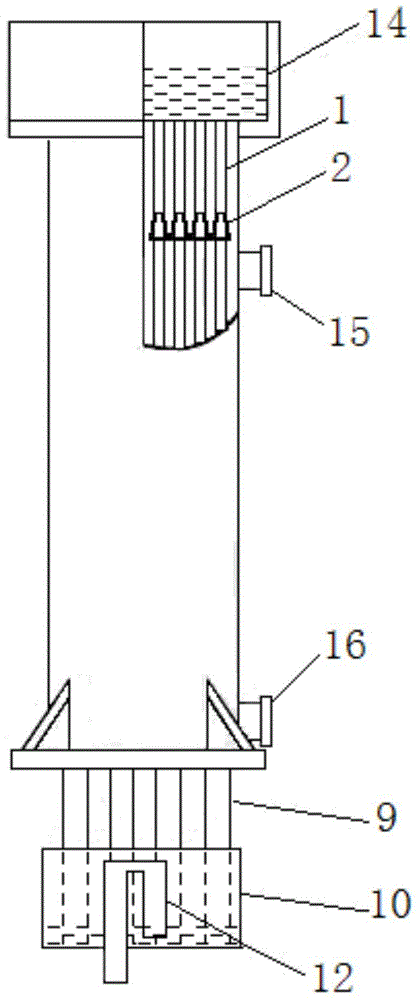

Liquid removing device used outside water cooling type vertical condenser pipes

ActiveCN104154773AIncrease disturbanceExtended working hoursSteam/vapor condensersSiphonReciprocating motion

The invention discloses a liquid removing device used outside water cooling type vertical condenser pipes. The liquid removing device is composed of the condenser pipes, liquid scraping devices, supporting frames, fixed pulleys, moving pulleys, pulley lines, suspension annular magnets, springs, suspension lines, a suspension water collecting basin, a thick pipeline, a siphon and a cooling water outlet. The outer wall faces of the annular magnets are in sliding contact with the inner wall faces of the condenser pipes, the lower ends of the springs are fixedly connected with the upper ends of the annular magnets, and the outer rings of the springs are slightly attached to the inner wall faces of the condenser pipes and are in sliding contact with the inner wall faces of the condenser pipes. The liquid scraping devices are located outside the condenser pipes, the inner wall faces of the liquid scraping devices are in sliding contact with the outer wall faces of the condenser pipes, the suspension water collecting basin is located below the condenser pipes and fixedly connected with hooks arranged at the lower portions of the moving pulleys through the suspension lines, and the siphon is located in the water collecting basin and fixedly connected with the bottom of the water collecting basin. Liquid film and liquid drops on the outer wall faces of the condenser pipes are scraped off through the liquid scraping devices automatically conducting reciprocating movement, and condensation thermal resistance outside the condenser pipes is reduced, so that condensing efficiency is improved.

Owner:东南大学常州研究院

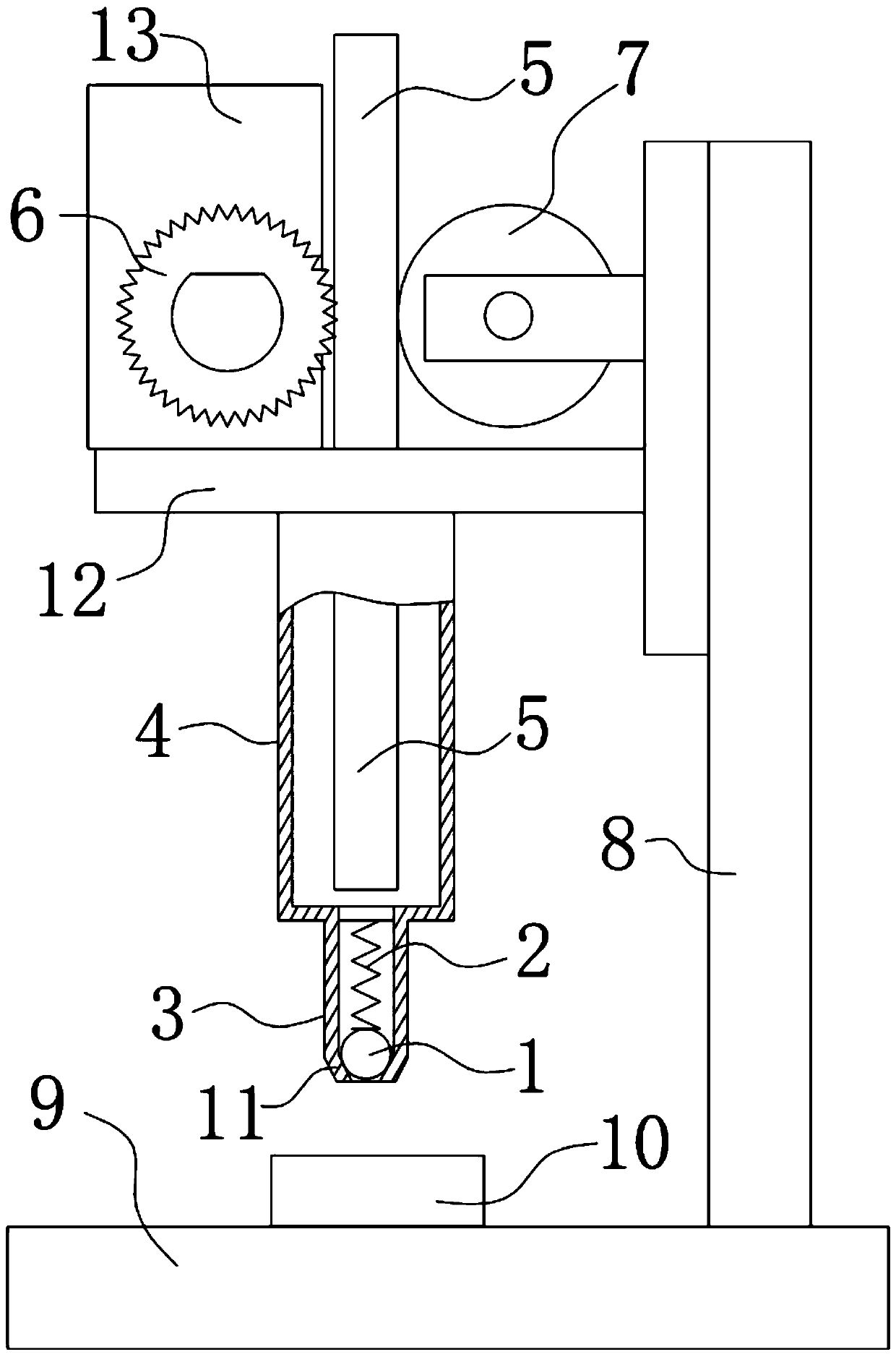

Automatic hot melt adhesive bar glue outlet machine

PendingCN110076049AGuaranteed normal outflowEasy feedingLiquid surface applicatorsCoatingsLiquid stateHot melt

The invention discloses an automatic hot melt adhesive bar glue outlet machine. The automatic hot melt adhesive bar glue outlet machine comprises a glue inlet mechanism, a glue melting mechanism and aglue outlet mechanism; the glue inlet mechanism comprises a gear with rotating power, the axis of the gear is in the horizontal direction, teeth of the gear make contact with a vertical rubber bar, the rubber bar is in a solid bar shape, the glue melting mechanism comprises a heating pipe arranged below the glue inlet mechanism, the top of the heating pipe is provided with an upper opening matched with the rubber bar in a seal manner, the heating pipe melts the rubber bar inserted into the heating pipe into the liquid state, the glue outlet mechanism comprises a glue outlet pipe on the bottomof the glue melting mechanism, the bottom of the glue outlet pipe is provided with a narrowing segment with the inner diameter gradually reduced in the downward direction, a ball body is arranged inthe narrowing segment, the inner diameter of the glue outlet pipe is larger than the diameter of the ball body, the inner diameter of the bottom of the narrowing segment is smaller than the diameter of the ball body, and the ball body is connected with the top of the glue outlet pipe through a pressure spring. Pressure changes brought by glue bar inlet and outlet achieve glue outlet control, the whole equipment is low in cost, simplicity and reliability are achieved, solid glue feeding is facilitated, and outflow of fluid-shaped rubber liquid is ensured.

Owner:昆山兴宝塑料制品有限公司

Buoy station with underwater protection device

ActiveCN108609125AGuaranteed to move up and downAvoid transmissionWaterborne vesselsPhotovoltaicsWater flowWater quality

The invention discloses a buoy station with an underwater protection device. The buoy station comprises a cleaning rod, a cleaning brush, a partition plate, sponge gaskets, an iron sheet frame and a filter gauze, wherein the cleaning brush is arranged on one side of the cleaning rod, the sponge gaskets are attached to the upper surface and the lower surface of the partition plate, and the filter gauze is attached to the outer surface of the iron sheet frame. According to the buoy station, the structure is scientific and reasonable, the use is safe and convenient; the cleaning brush is arranged, the surface of a solar panel is cleaned efficiently, and the situation that the transition efficiency of solar energy is reduced caused by the surface of the solar panel being covered with stains isavoided; a bird repelling agent box is arranged, birds are effectively prevented from nesting or staying on a buoy station body by using a bird repelling agent, so that the birds are prevented from interfering with the transmission of signals to ensure the buoy station to transmit the signals stably; the iron sheet frame and the filter gauze are arranged, and when a river is rushing fast, the impact of the water flow on the buoy station body can be effectively reduced through the iron sheet frame, and meanwhile, water quality acquisition equipment at the bottom of the buoy station can be prevented from being damaged by the impact.

Owner:安徽中疆数字科技有限公司

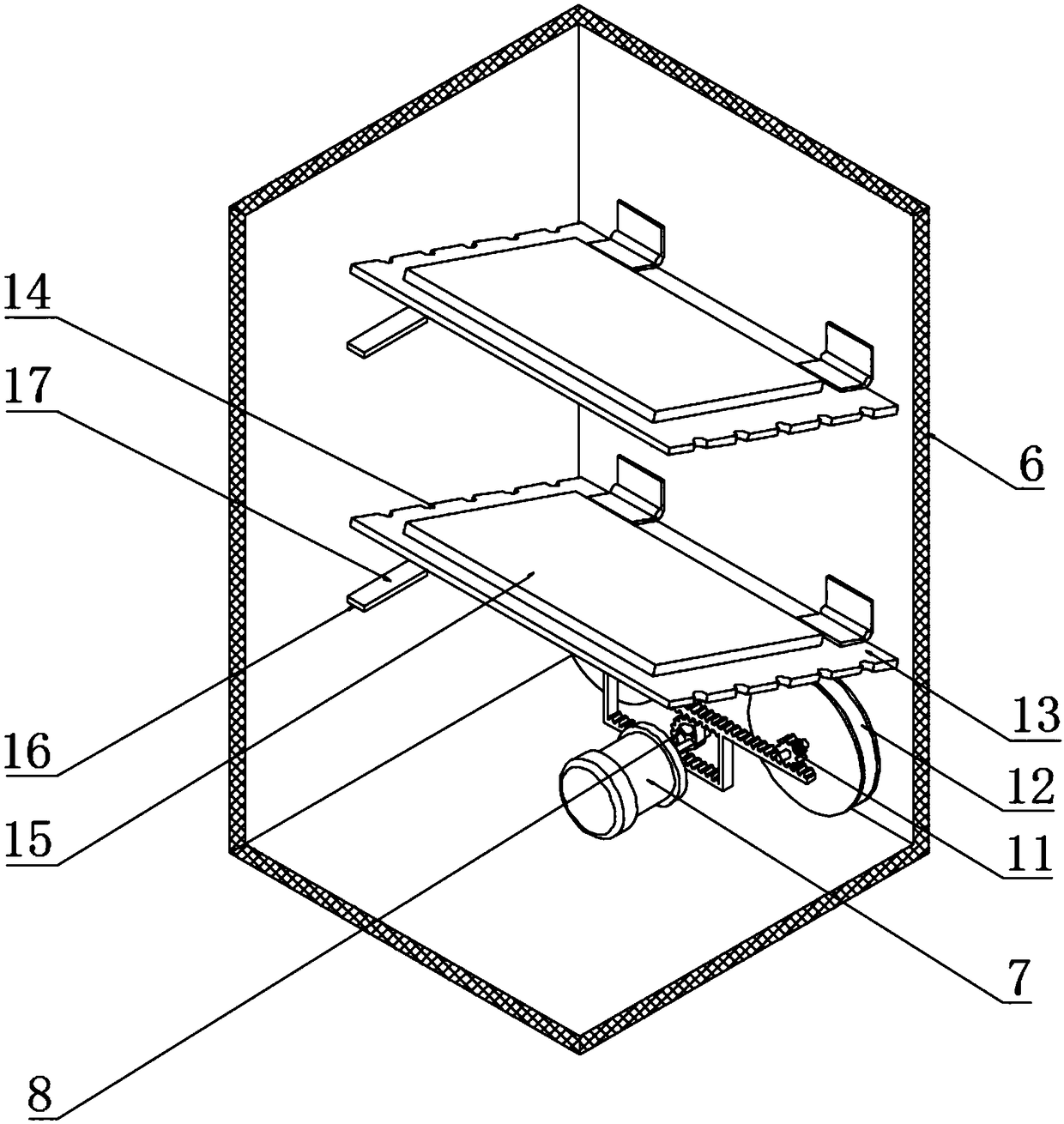

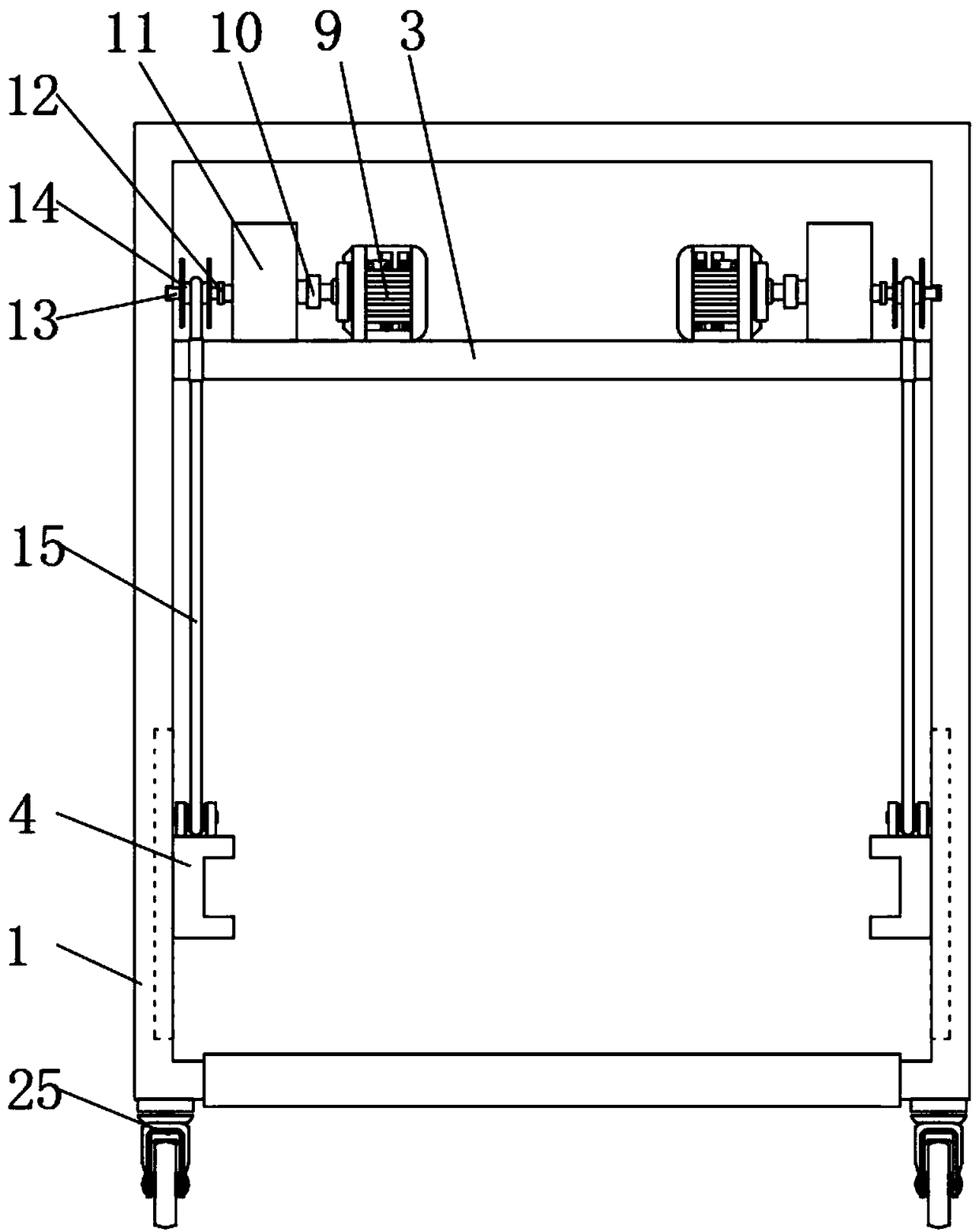

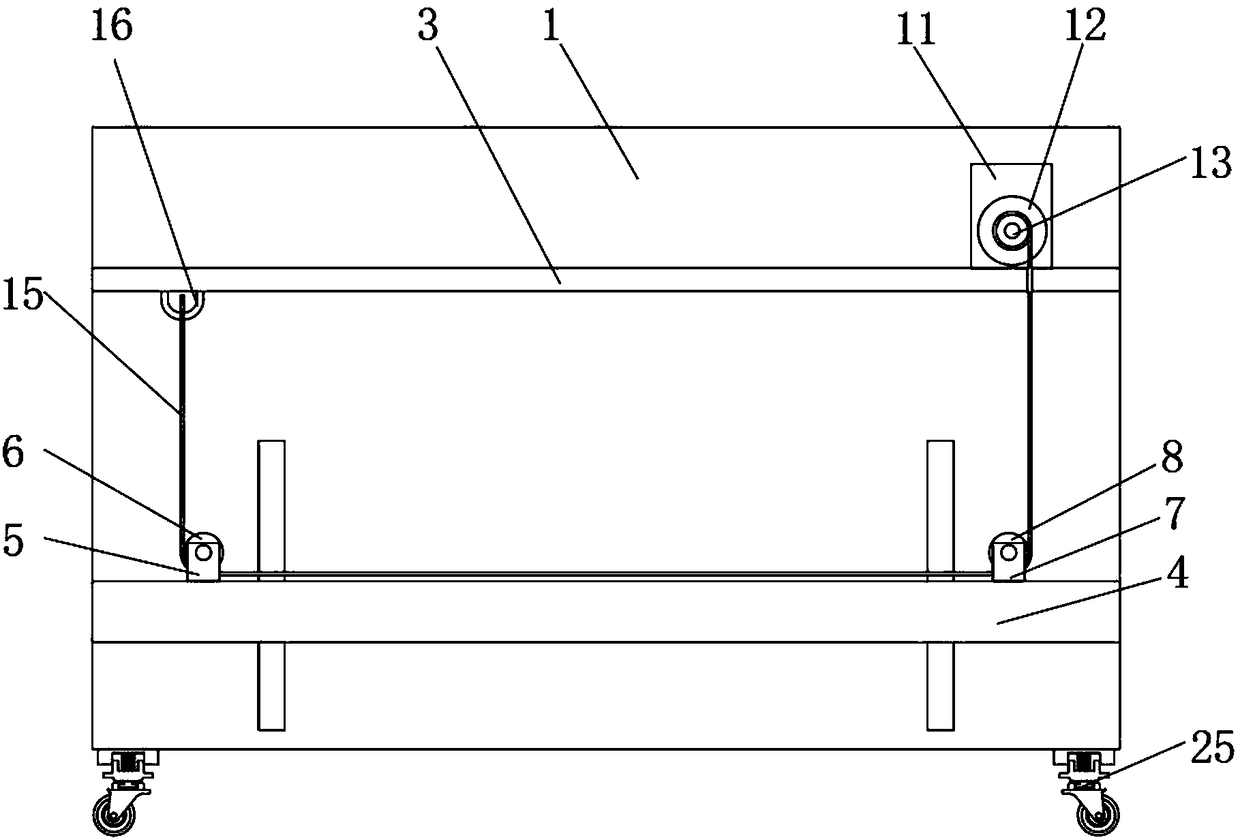

Portable space transporting device

ActiveCN108263995AGuaranteed to move up and downRealize immediate loadingNon-rotating vibration suppressionCastorsReduction driveEngineering

The invention discloses a portable space transporting device. The portable space transporting device comprises a box body and a bearing plate, wherein a partition plate is fixedly connected between the two opposite sides of the inner wall of the box body, the two sides of the inner wall of the box body are in sliding connection with sliding blocks, the top of the partition plate is fixedly connected with a motor, the output shaft end of the motor is fixedly connected with a rotating shaft through a speed reducer, the surface of the rotating shaft is fixedly connected with a steel cable througha reel, the top of the bearing plate is fixedly connected with an object carrying box through a damping device, one side of the bearing plate is fixedly connected with a rotating block, the center ofthe rotating block is in rotating connection with a rotating rod, one end of the rotating rod is in rotating connection with a pull rod, the end, far from the rotating rod, of the pull rod is in rotating connection with a clamping device, the end, far from the pull rod, of the rotating rod is fixedly connected with a pedal, and the two sides of the bottom of the bearing plate are fixedly connected with fixed legs. The invention relates to the technical field of space transportation. The portable space transporting device solves the problem that taking and putting are difficult due to small space and at the same time saves loading and unloading time.

Owner:盐城新汇村镇建设发展有限公司

Metal plating part surface continuous cleaning process and control system

The invention provides a metal plating part surface continuous cleaning process which includes the steps: rust removal; washing; oil removal; washing. The invention further provides a metal plating part surface continuous cleaning control system which comprises a data input module, an instruction output module and a PLC (programmable logic controller). The data input module comprises an approach switch, a liquid level sensor, a temperature sensor and an emergency switch, and the instruction output module comprises a first motor, an electric heater, a second motor and a draught fan. According to the metal plating part surface continuous cleaning process and the metal plating part surface continuous cleaning control system, the qualification rate of an electroplated metal plating part can be increased and reaches 99%, water is saved, the water consumption of the process for cleaning metal plating parts is about half of that of a conventional method, and resources are saved.

Owner:KAIFENG UNIV

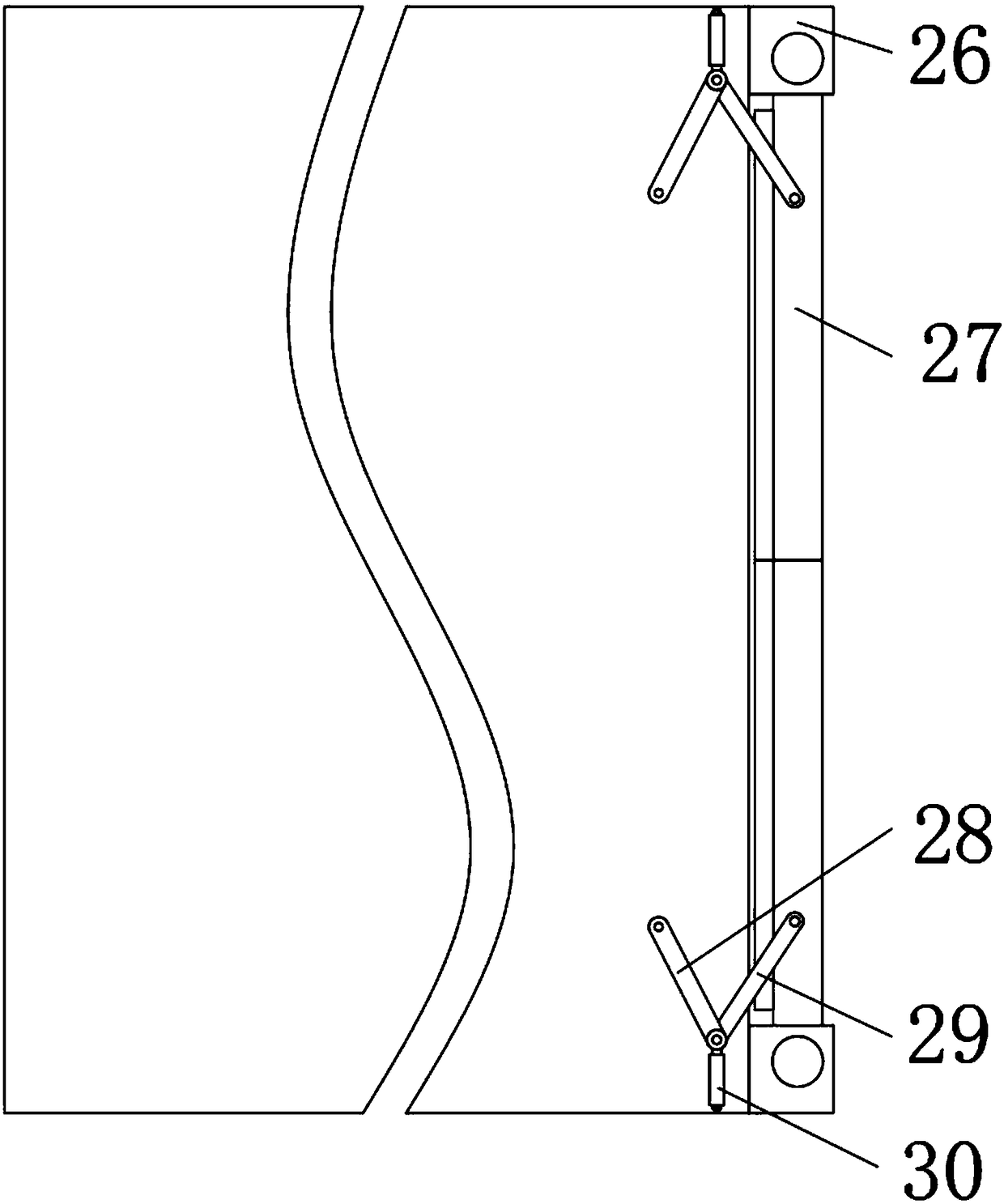

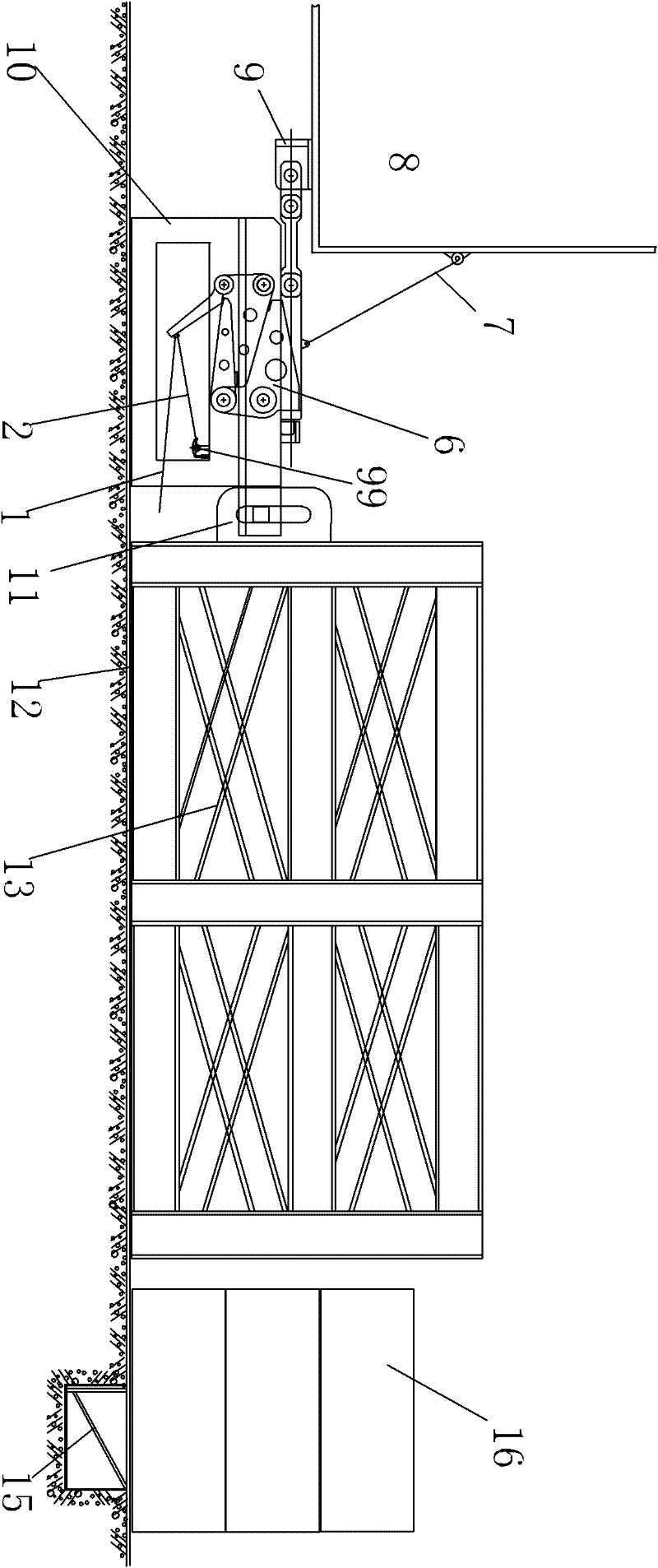

Anti-slip system realized by using anti-slip machine in ocean engineering

ActiveCN102476698AReasonable structureGuaranteed to move up and downVessel partsMarine engineeringEngineering

The invention discloses an anti-slip system realized by using an anti-slip machine in ocean engineering. The edge of a ship or ocean engineering platform is provided with an eye bracket (9); a loose connecting rod (17) in an anti-slip mechanism is hung through the eye bracket; the back end of the anti-slip mechanism is provided with a hanging plate for hanging a ballast basket eye bracket (11) on a ballast basket (13); a load bearing object is arranged in the ballast basket; the anti-slip mechanism comprises first to fourth connecting rods of which the end parts are hinged on the anti-slip frame (10); and the first connecting rod (18) is hooked in a groove hole at the back end of the loose connecting rod, and is separated from the loose connecting rod through rotation around a hinged end under the action of gravity. In the invention, four-connecting-rod anti-slip is adopted for an anti-slip device, so that tensile force of 300 tons in maximum can be born, an anti-slip function can be controlled at any time as required, and launching of a ship or platform can be controlled effectively; and the anti-slip system has the advantages of safety, reliability, simple structure, light weight, convenience for operating and reasonable design.

Owner:大连船舶重工集团海洋工程有限公司

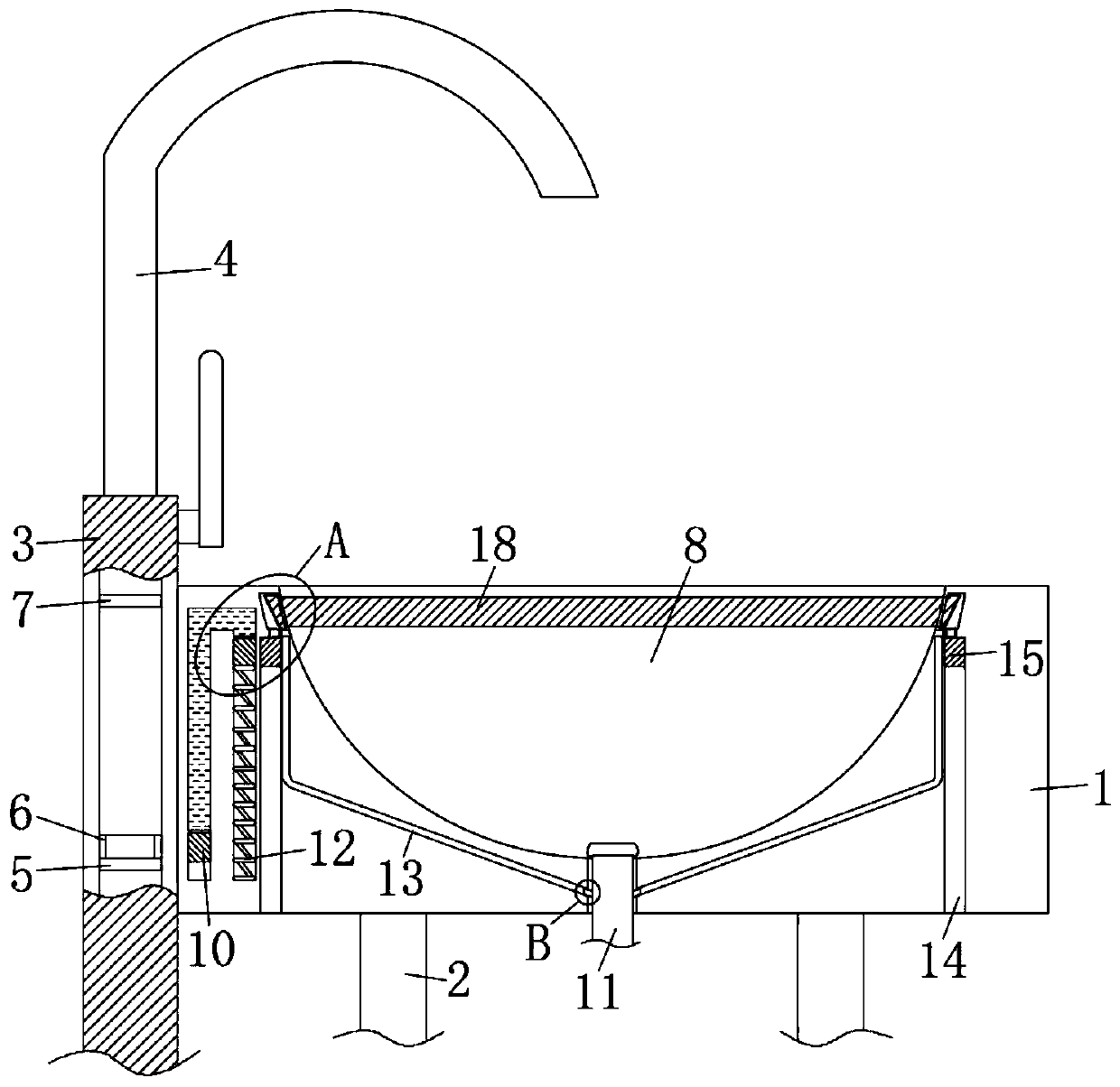

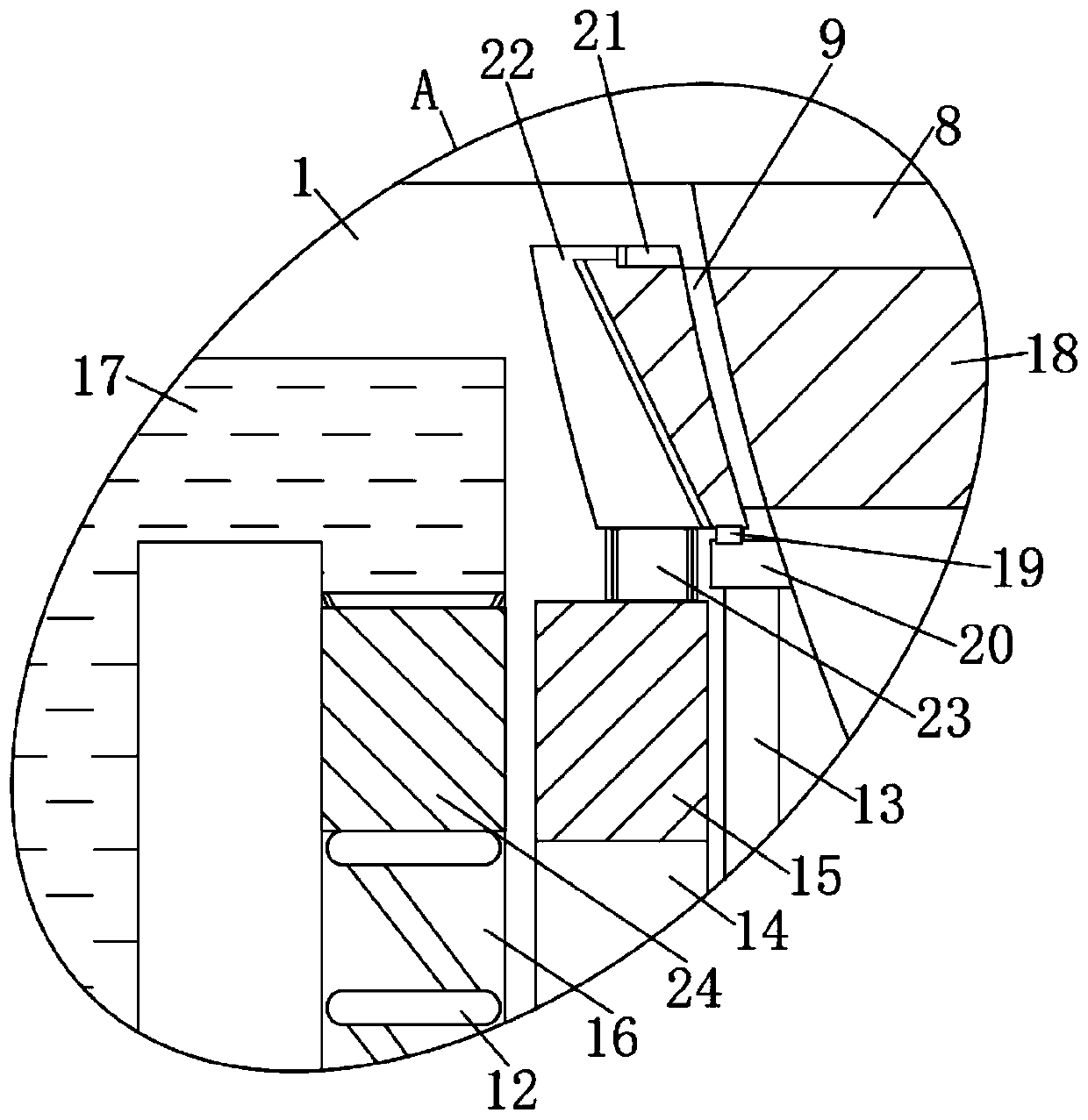

Anti-sputtering wash device

PendingCN110144998AGuaranteed to move up and downRealize pumping workDomestic plumbingSputteringWaste management

The invention discloses an anti-sputtering wash device. The device comprises a wash table and a wash tank arranged on the upper portion of the wash table. A plurality of supporting rods are arranged at the bottom of the wash table. A water pipe is mounted on the side wall of the wash table. A faucet is mounted at a water outlet of the water pipe. A first limit bar and a second limit bar are arranged on the inner side of the water pipe from bottom to top in sequence. An annular magnetic patch is arranged between the first limit bar and the second limit bar. A U-shaped cavity is formed in the wash table. A first magnetic sliding plug and a second magnetic sliding plug are arranged inside the U-shaped cavity. Hydraulic oil is arranged between the first magnetic sliding plug and the second magnetic sliding plug. A plurality of springs are connected between the bottom of the second magnetic sliding plug and the inner bottom of the U-shaped cavity. The anti-sputtering wash device is reasonable in structural design, sputtering water drops can be prevented from influencing the wash table and clothes of a user during water receiving work, and accordingly, normal wash work of the user is guaranteed.

Owner:厦门曦哲贸易有限公司

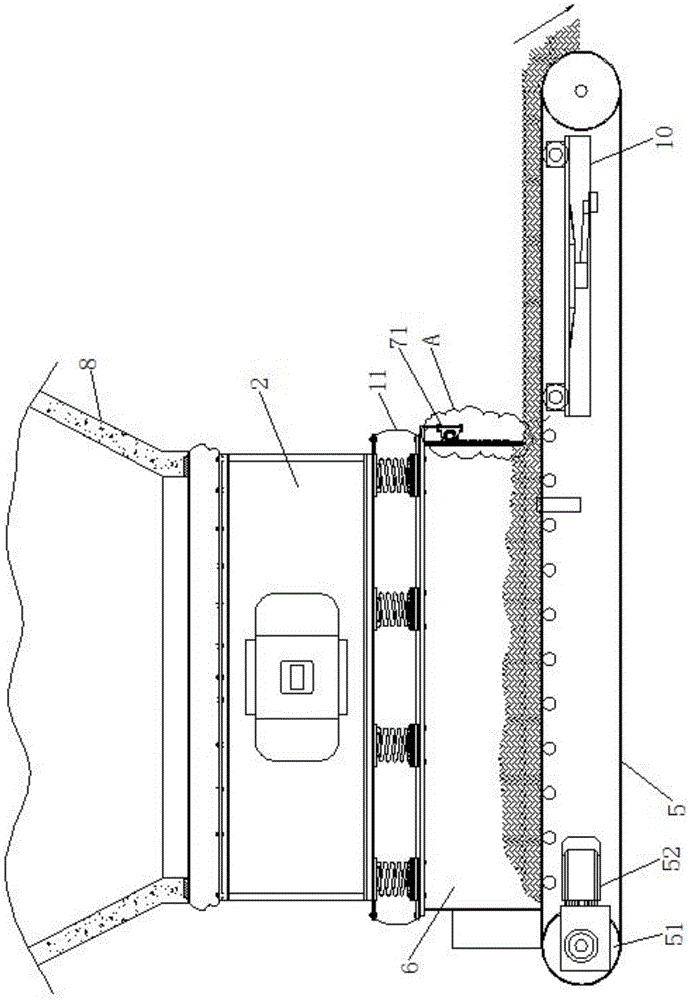

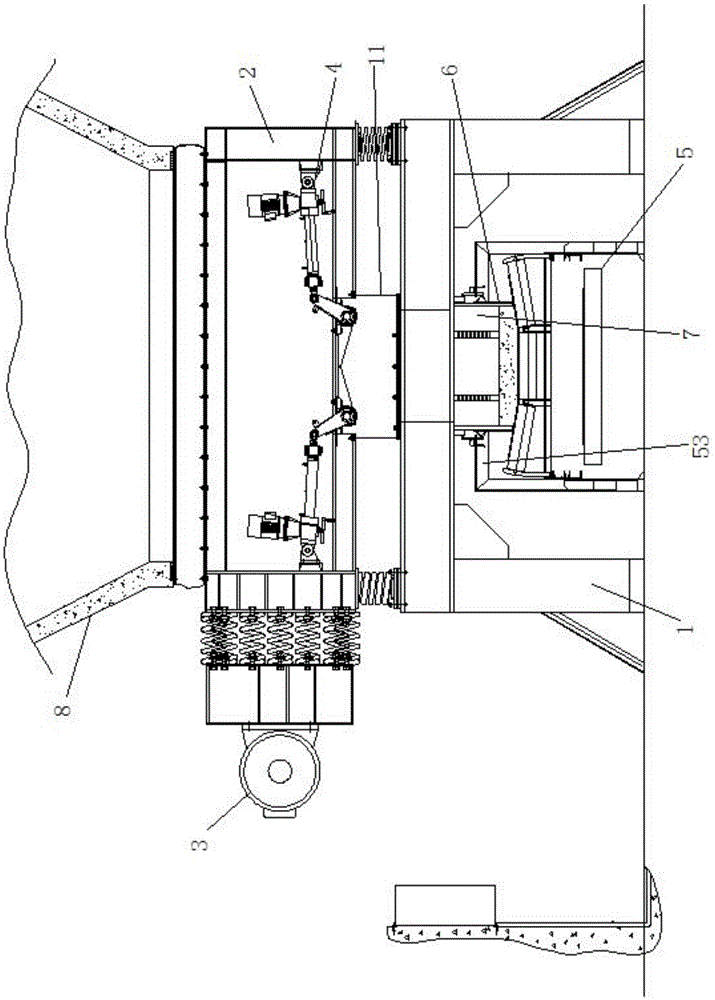

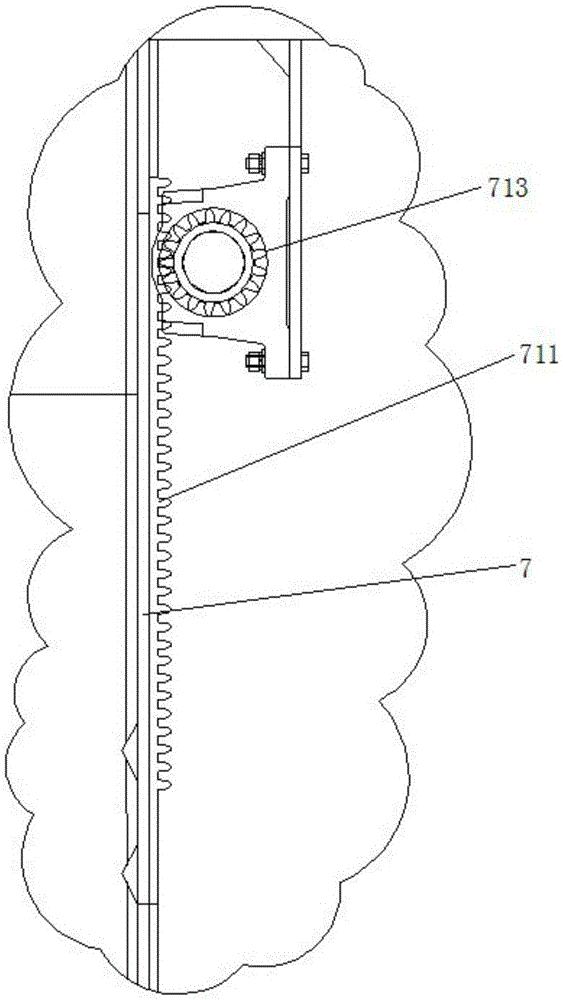

Integrated attached lifting scaffold

InactiveCN109184170APrevent slippingGuaranteed to move up and downBuilding support scaffoldsElectric machineryArchitectural engineering

The invention provides an integrated attached lifting scaffold, which comprises a base, a battery and a building. The top of the base is welded with a fifth fixing block. The top of the fifth fixing block is fixed with a battery and a motor through bolts. The output end of the motor is connected with a second rotating disk through a key. A third sleeve is welded at the central shaft of one side ofthe second rotating disk, and one end of the third sleeve is provided with a through hole. The inner wall of the through hole is carved with thread, the third sleeve is connected with a first screw through thread, one end of the first screw is welded with a second fixing plate, one side of the second fixing plate is welded with a second sliding plate, two edges of the top of the base are welded with a protective net and a first fixing plate, and one side of the first fixing plate is welded with a pedal. Generally, through multiple safeguards, the scaffold can be prevented from falling down, the life safety of an operator on the scaffold can be ensured, and the potential safety hazards are reduced.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

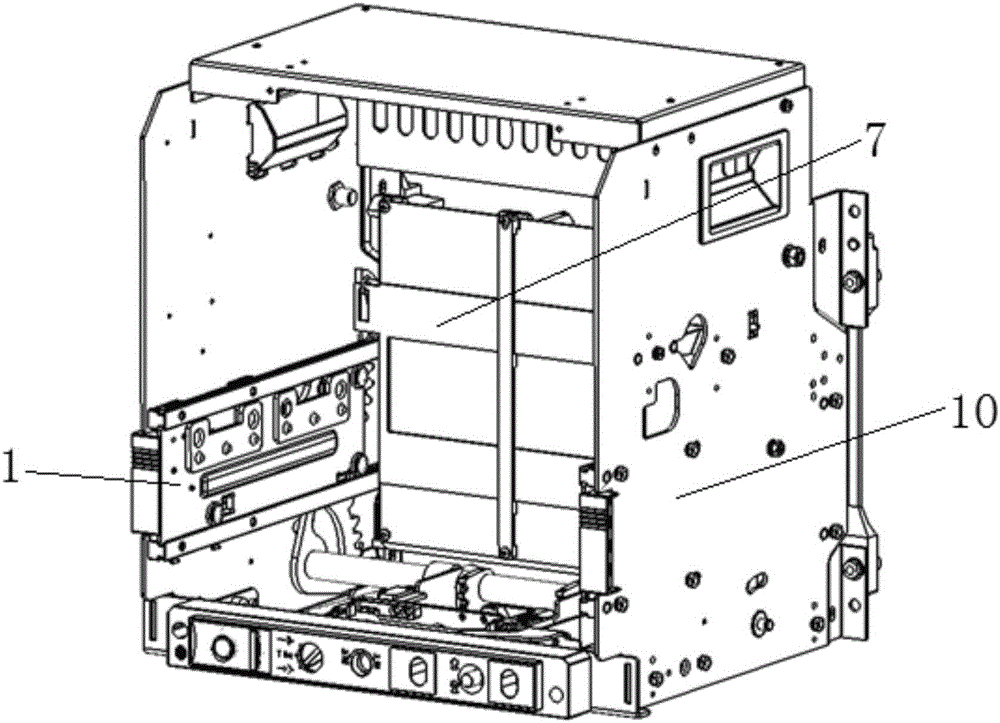

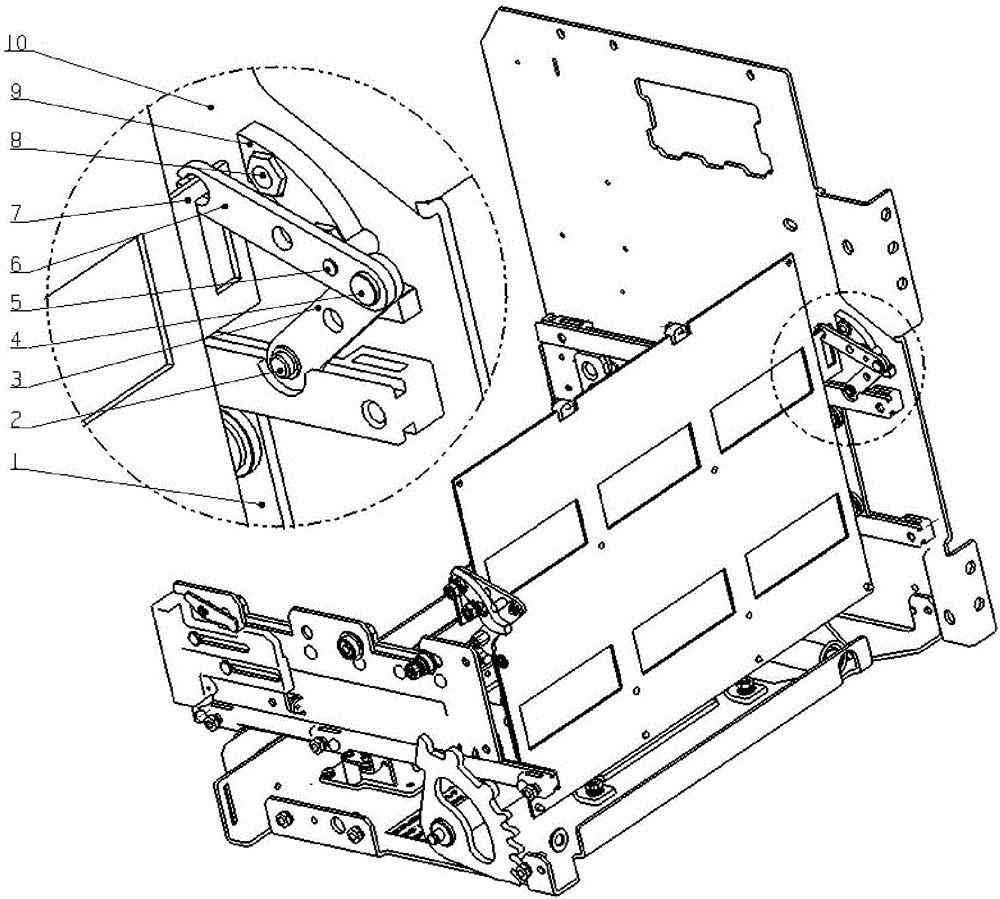

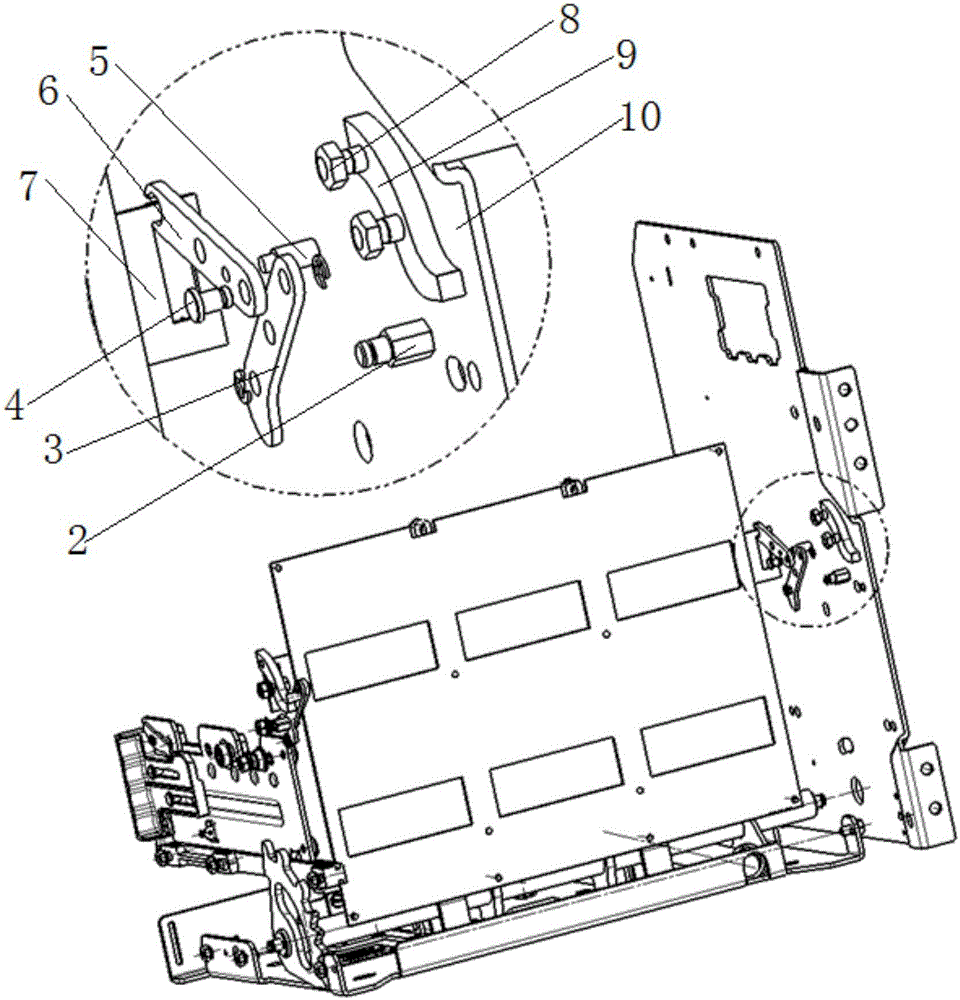

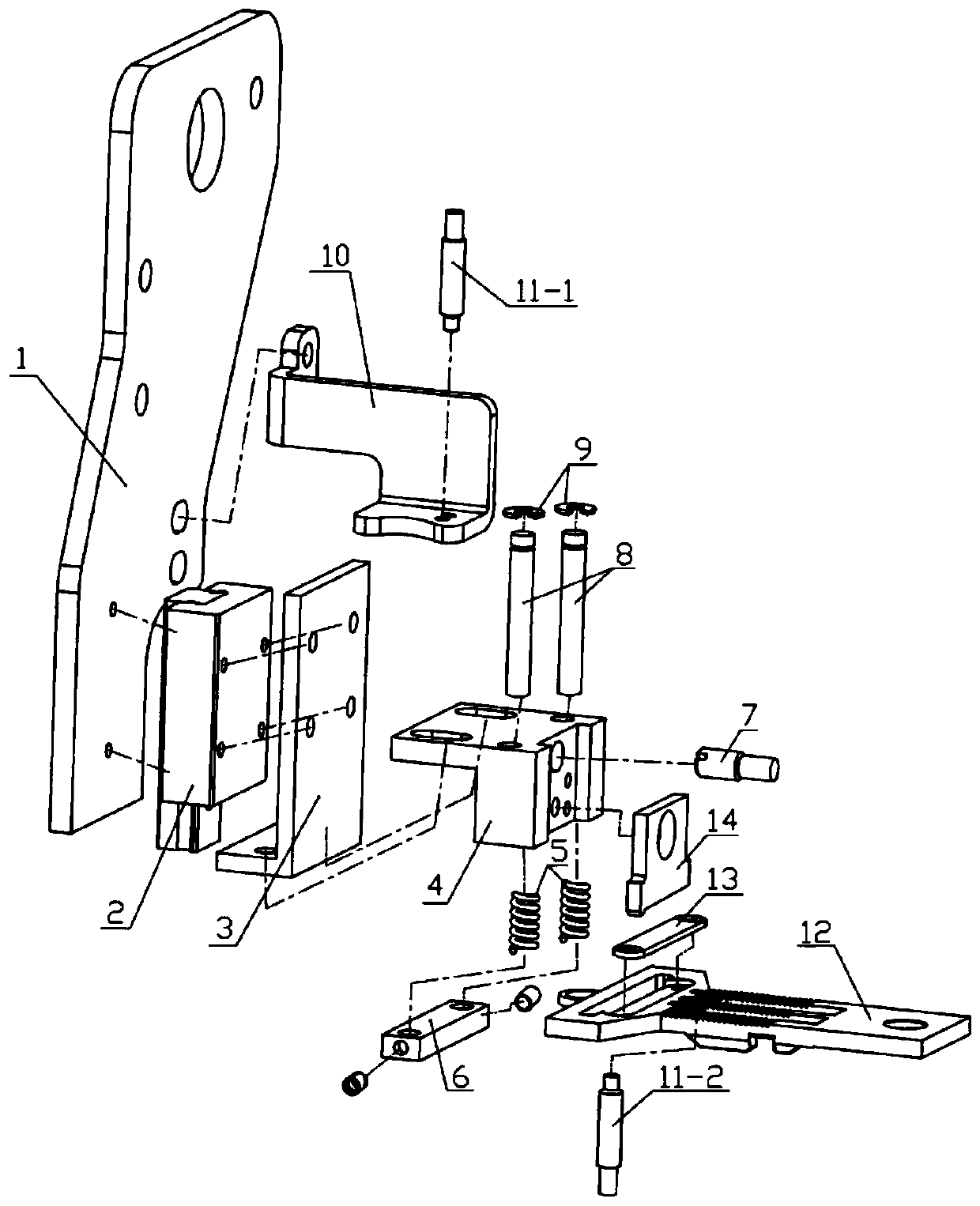

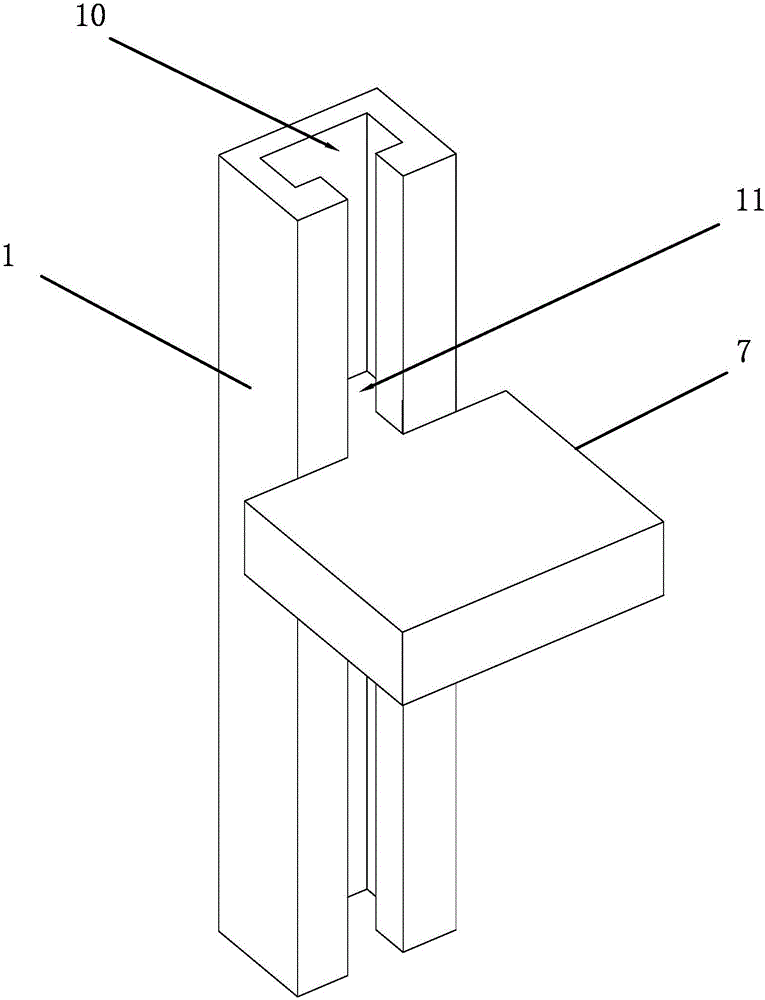

Movement mechanism of separation plate in drawer seat of drawer type circuit breaker

ActiveCN106786092ALimit motion angleGuaranteed to move up and downSwitchgear with withdrawable carriageCircuit breakerEngineering

The invention relates to a movement mechanism of a separation plate in a drawer seat of a drawer type circuit breaker. The mechanism comprises an upper connecting rod, a lower connecting rod, a sliding shaft, a guide rail and a movement side plate, wherein the lower connecting rod is rotatably connected with a side plate of the drawer seat; the upper end of the upper connecting rod is connected with the separation plate and the lower end of the upper connecting rod is hinged to the lower connecting rod; the sliding shaft is arranged on the upper connecting rod and the guide rail is arranged on the side plate of the drawer seat; the guide rail is used as a movement limiting rail of the sliding shaft, so that when the upper connecting rod moves, the vertex at the upper end of the upper connecting rod moves up and down; the movement side plate is parallel to the side plate of the drawer seat; in a horizontal sliding process of the movement side plate, the lower connecting rod is pushed to rotate, so that the upper connecting rod is driven to move; the movement of the upper connecting rod drives the separation plate to move up and down. Compared with the prior art, the upper connecting rod and the lower connecting rod are hinged, a clamping condition does not occur and the stability is high; compared with other mechanisms, door opening movement is more rapid. The movement angle of the connecting rods is limited by the shapes of the connecting rods, so that the mechanism does not pass through a dead point, and the reliability performance of movement is ensured.

Owner:SHANGHAI RENMIN ELECTRICAL APP WORKS

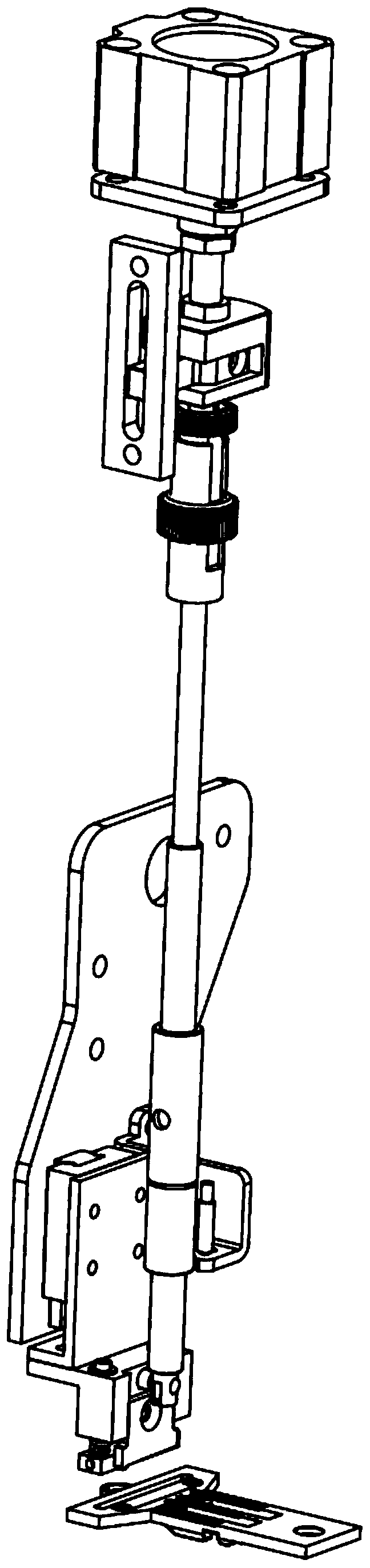

Rear belt cutting device of double-needle lockstitch sewing machine

PendingCN110735249AMesh arbitrary adjustmentGuaranteed to move up and downSewing-machine casingsWorkpiece carriersSewing machineScrew thread

The invention relates to a rear belt cutting device of a double-needle lockstitch sewing machine. In an operation process, a moving cutter is controlled by an air cylinder to move up and down along aguide rail, so as to mesh with a fixed cutter on a needle plate to cut belts. The technical scheme includes that a slider component and a detector support are arranged in parallel on the lower portionof one side face of a rail mounting plate, a first photoelectric detection head is arranged on an inner connecting lug of the detector support, and a slider cover plate is fixedly arranged on the right side face of the slider component; the moving cutter is vertically arranged in a slot on the right side face of a moving cutter holder, a threaded shaft is penetratingly arranged on a recessed surface of the slot, and a slotted hole is formed in the lateral side of the moving cutter holder; two stepped through holes are formed at the joint of two sides of the moving cutter holder; a pair of press plate shafts of an 'E'-shaped snap spring are clamped into an upper ring groove, and pass through the stepped through holes to be fixedly connected with a press plate below the longitudinal side ofthe moving cutter holder; springs sleeve the press plate shafts, and are arranged in large holes on the lower portions of the stepped through holes; the fixed cutter is arranged on the needle plate,and a second photoelectric detection head is arranged on the lower portion of the fixed cutter.

Owner:XIAN TYPICAL IND

Automatic cloth coiling device of rapier loom

The invention provides an automatic cloth coiling device of a rapier loom and belongs to the technical field of fabric equipment. The automatic cloth coiling device comprises a rack, a first rotating shaft and a second rotating shaft, the first rotating shaft is rotatably connected to the rack through a bearing, a licker-in roller is fixed on the first rotating shaft, the rack is in sliding connection with a mounting seat, the second rotating shaft is rotatably connected on the mounting seat through the bearing, a cloth roller is fixed on the second rotating shaft, the mounting seat comprises a support frame and a connecting plate, an opening is formed in the support frame, the bearing is mounted in the opening, the connecting plate is located at the lower end of the support frame, a weighing sensor is arranged in the connecting plate, an air cylinder is arranged at the bottom of the rack, the end of a piston rod of the air cylinder is connected to the lower end of the connecting plate, a sliding chute is further vertically formed in the rack, a slidably embedded portion matched with the sliding chute is arranged in one side of the connecting plate, and a driving structure driving the first and second rotating shafts to rotate synchronously is further arranged on the rack. The automatic cloth coiling device is high in adjusting performance, wide in application and consistent in specification of each roll of cloth.

Owner:HAINING SURTEX TEXTILE

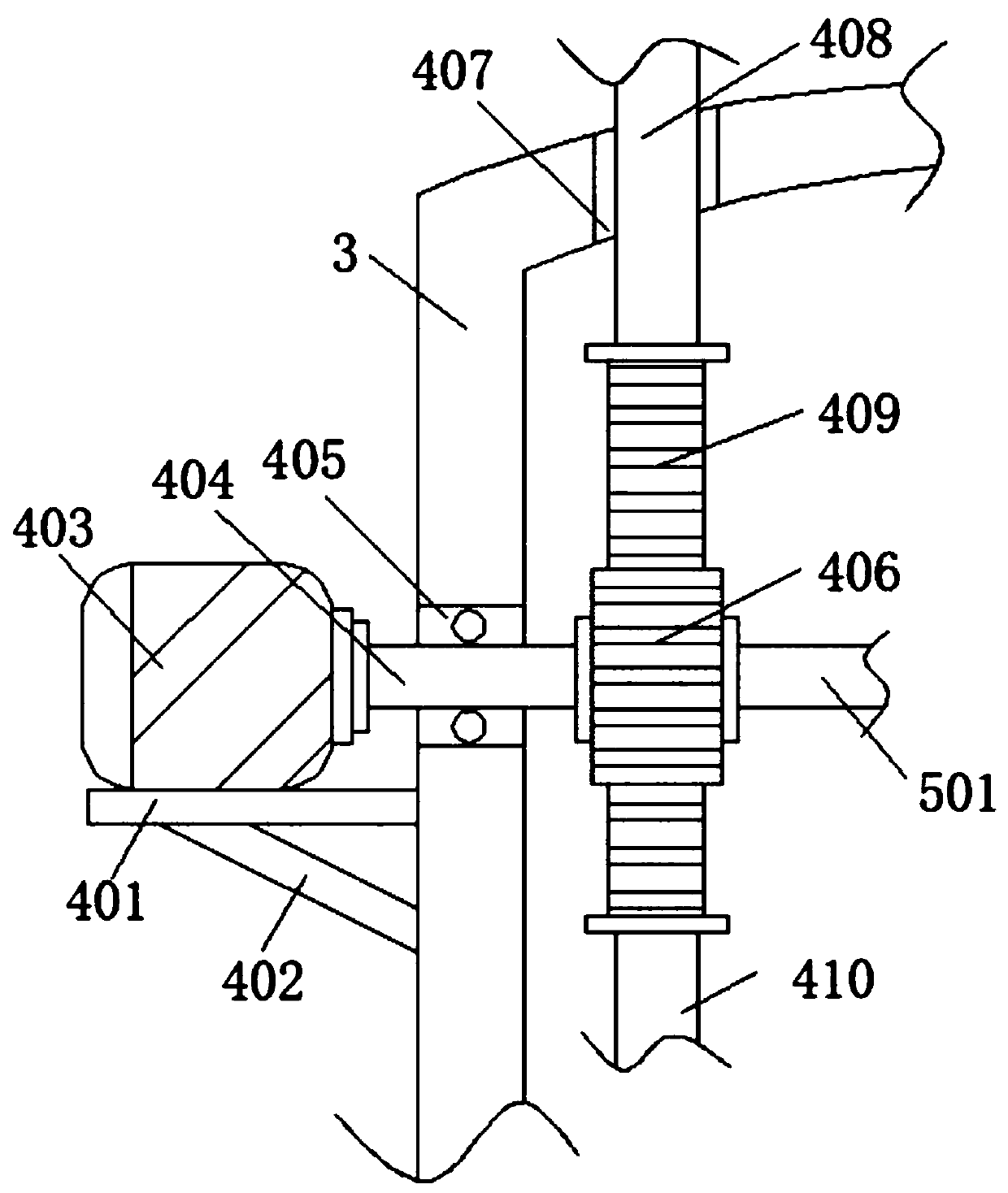

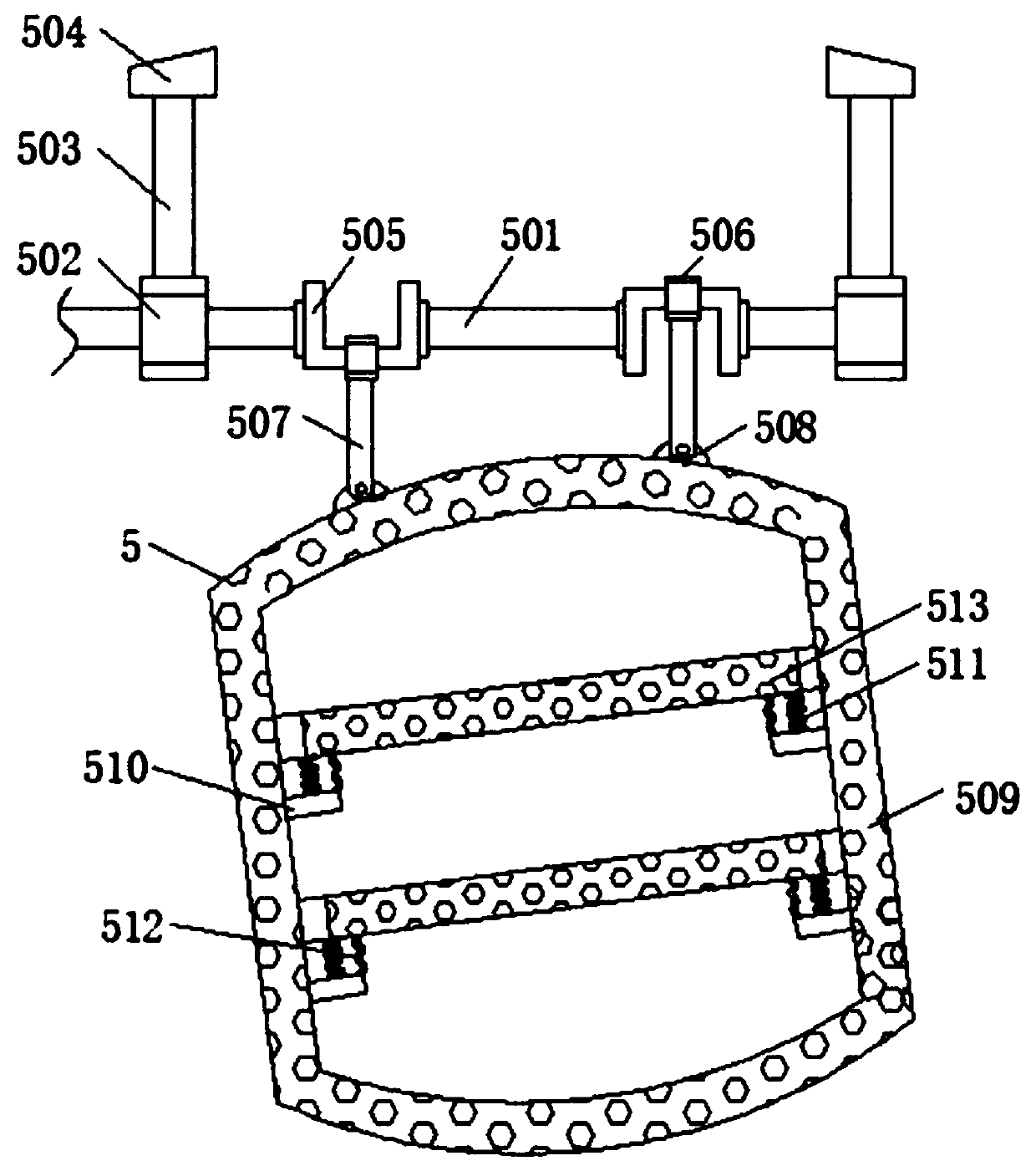

Spheroidizing annealing furnace

InactiveCN109468440AEasy accessAvoid flow backFurnace typesHeat treatment furnacesThermal insulationMetallurgy

The invention discloses a spheroidizing annealing furnace, and the technical scheme is that the furnace a furnace body, an inner barrel, a loading platform, a furnace cover and a cantilever. The furnace body is provided with a convection system, a heat preservation system and a heating system. The convection system comprises a convection fan arranged at the bottom of the furnace body and a convection barrel arranged in the inner cavity of the inner barrel. The heat preservation system comprises a plurality of heat preservation cotton blocks arranged on the inner wall of the furnace body, a mounting frame fixed on the inner wall of the furnace body and used for mounting a plurality of heat preservation cotton blocks, and a connecting assembly arranged between the heat preservation cotton blocks and the mounting frame to keep the heat preservation cotton blocks fixed on the mounting frame. The invention can effectively improve the hot air convection efficiency in the inner barrel, and ensure that the materials can be uniformly heated, and at the same time, through a plurality of independent thermal insulation cotton blocks, one of the thermal insulation cotton blocks can be replacedindependently, thereby reducing the maintenance cost.

Owner:嘉善奥力科机械制造有限公司

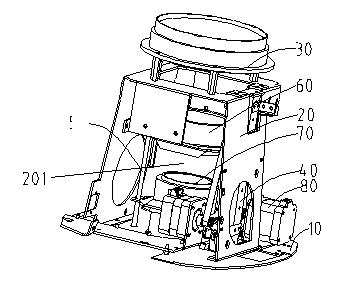

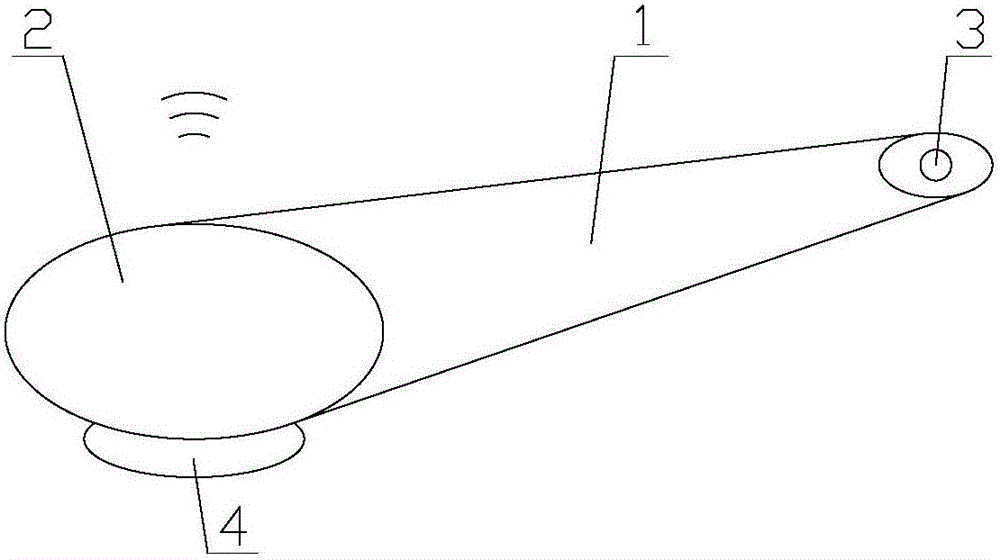

Novel massage device with remote control function

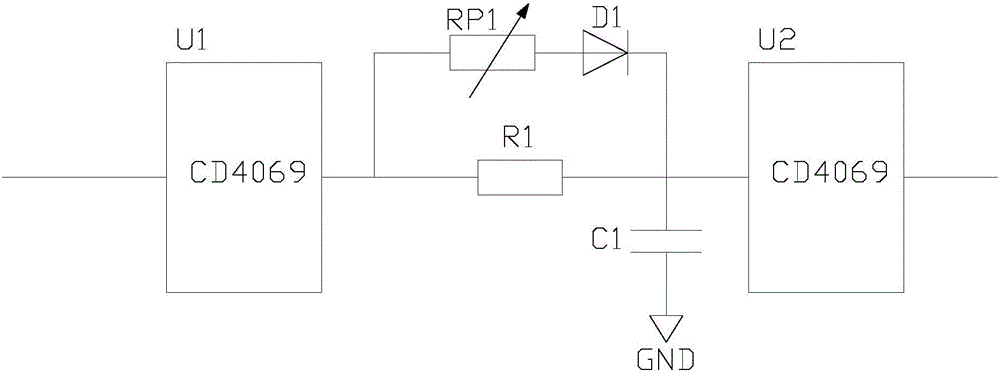

ActiveCN105853185AGuaranteed to move up and downGuaranteed distanceVibration massageElectrical resistance and conductanceRemote control

The invention relates to a novel massage device with a remote control function. The novel massage device comprises a handheld bar, a power button and a central control box, wherein a massage mechanism is arranged under the central control box. According to the novel massage device with the remote control function, remote control over the device by a user is realized through a wireless communication module, and the intelligence of the device is improved accordingly; three rotating wheels are controlled by rotating motors to rotate, and the beating function is realized; meanwhile, rotation of a screw is controlled by a driving turbine, up and down movement of transmission bars is guaranteed through transmission, the pushing distance of the rotating wheels to a beating board is realized, and accordingly, the beating strength is adjusted, and the production cost is greatly reduced; moreover, by setting the ratio of resistance value of a resistor to that of an adjustable resistor in a speed adjusting circuit, adjustment to the pulse width is realized, so that while adjustment to the rotating speed of the rotating motors is realized, the peripheral circuit structure of the circuit is decreased, and the production cost is further lowered.

Owner:长沙福诺鑫电子商务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com