Spheroidizing annealing furnace

A spheroidizing annealing furnace and annealing furnace technology, applied in the field of heat treatment, can solve problems such as high cost, increase workpiece production cost, uneven heating of tools, etc., and achieve the effects of reducing contact area, facilitating heating wires, and increasing heat radiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

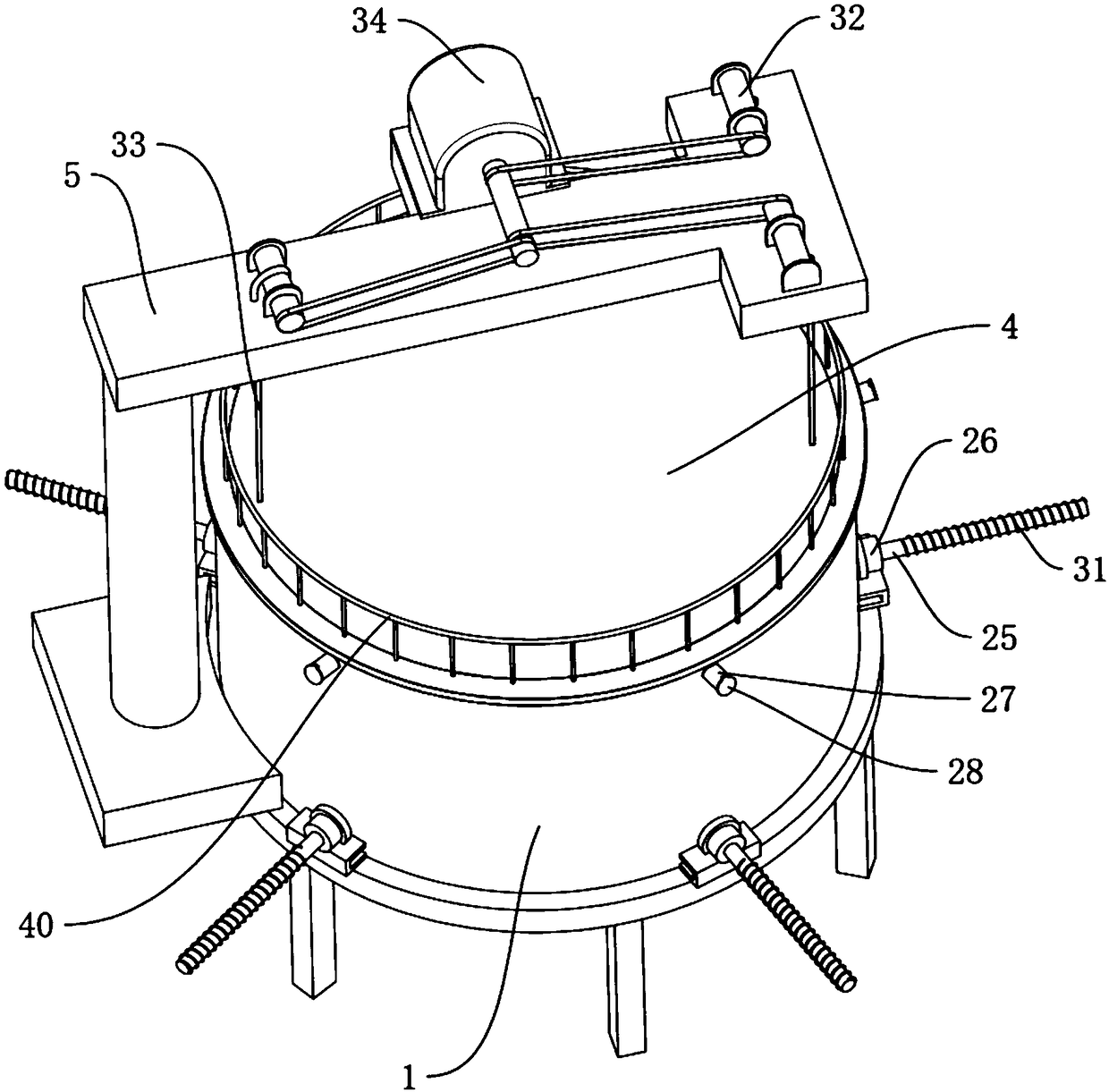

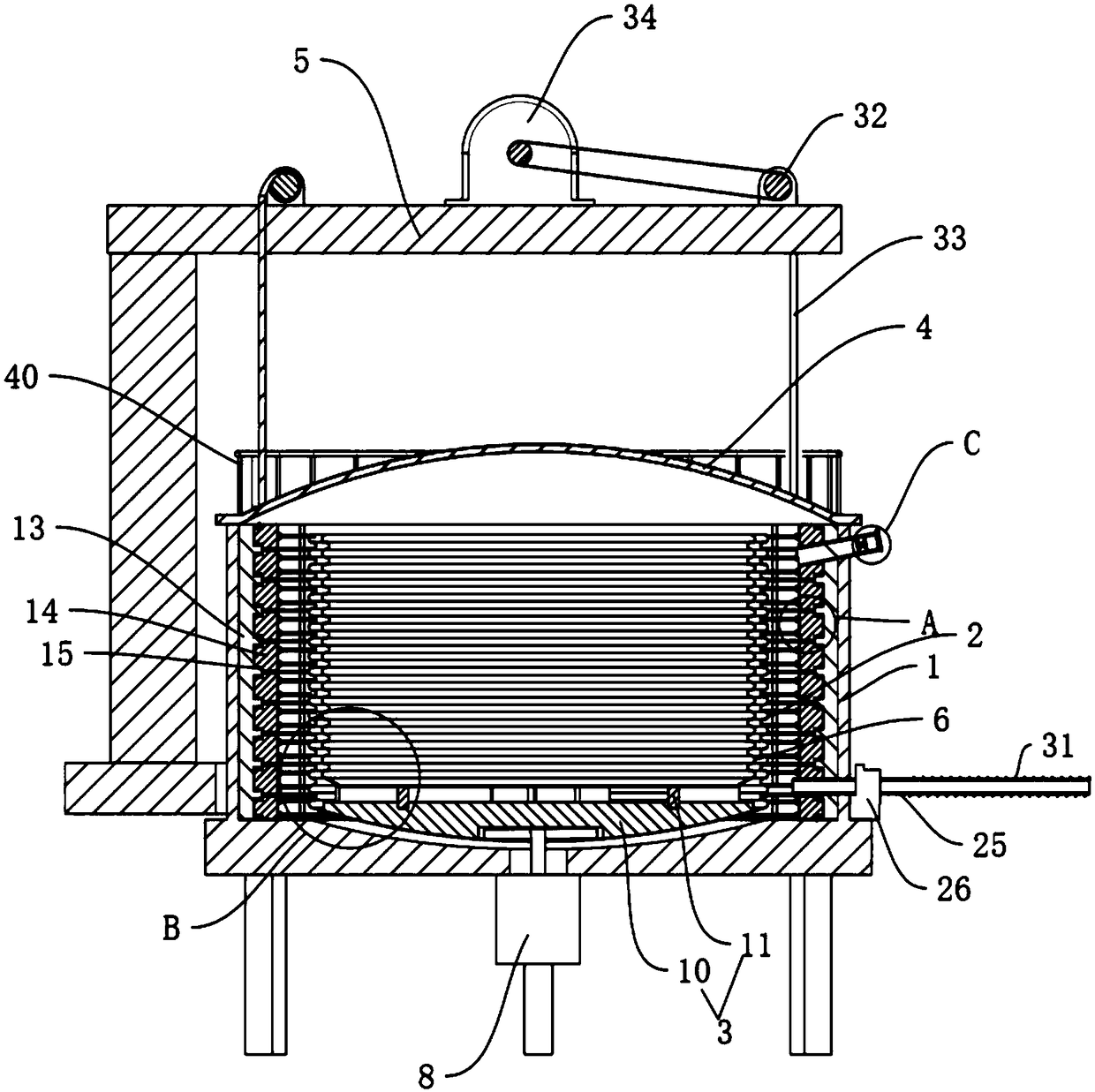

[0034] Embodiment one: if Figure 1 to Figure 7 As shown, a kind of spheroidizing annealing furnace proposed by the present invention includes an annealing furnace main body 1, an inner barrel 2, a loading platform 3, a furnace cover 4 and a cantilever 5, and a convection system is arranged in the annealing furnace main body 1 for controlling the annealing furnace The thermal insulation system for the main body 1 and the heating system for heating the material in the inner barrel 2.

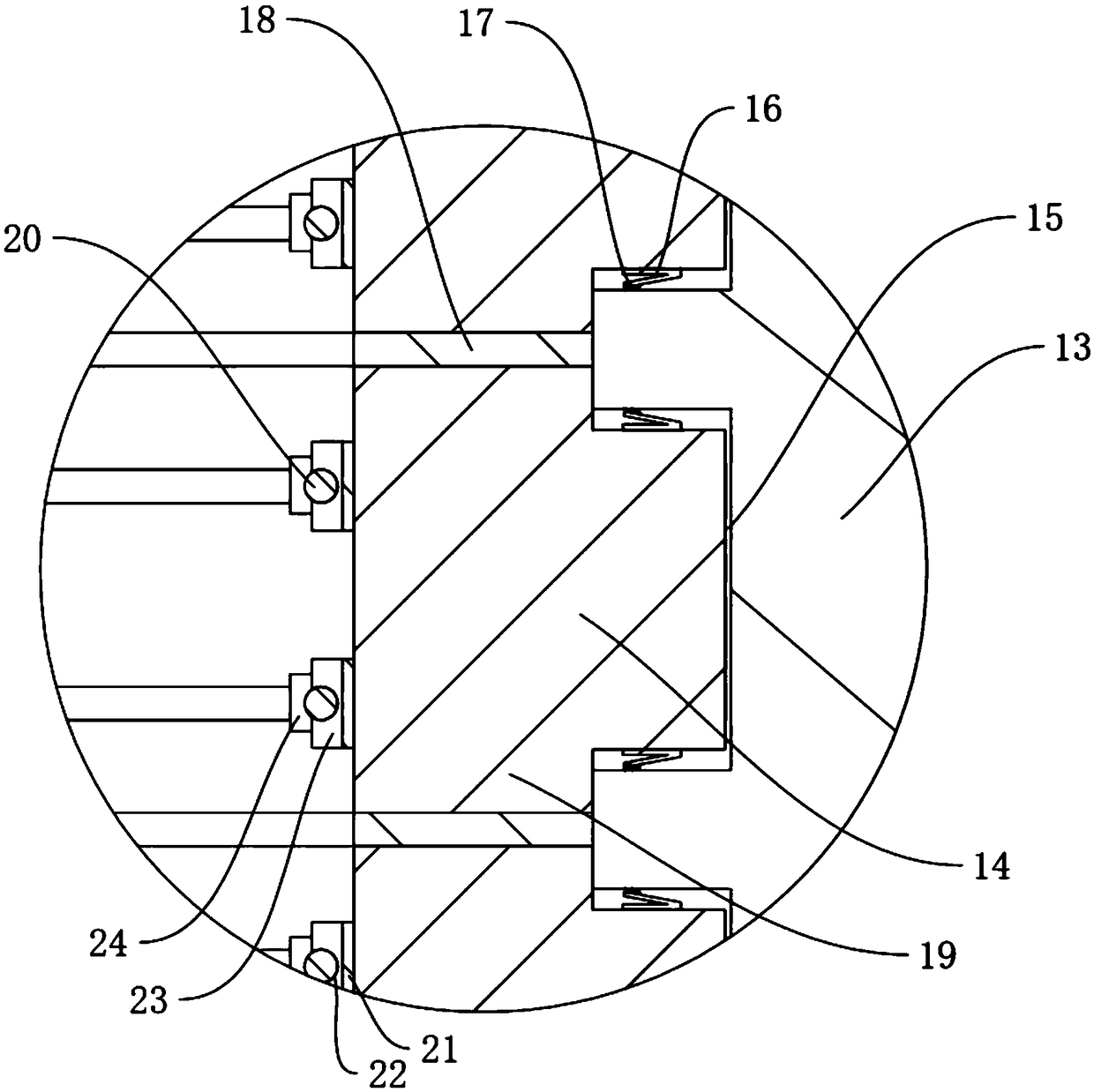

[0035] The convection system includes a convection barrel 6 installed in the inner cavity of the inner barrel 2. The bottom surface of the convection barrel 6 is open. The hot air in 6 flows into the gap 7 between the convection barrel 6 and the inner barrel 2. The side walls of the convection barrel 6 and the inner barrel 2 are corrugated. The convection fan 8. In this way, the hot air in the convection barrel 6 is driven to flow downward by the convection fan 8, and the hot air at the bottom ...

Embodiment 2

[0052] Embodiment 2 is different from Embodiment 1 in that: as Figure 8 and Figure 9 As shown, an anti-sway device is provided between the cantilever 5 and the furnace cover 4. The anti-sway device includes a first sleeve 35 sleeved on the corresponding chain 33 and fixed to the lower end surface of the cantilever 5, sleeved on the corresponding chain 33 and fixedly connected. The second bushing 36 on the upper end surface of the furnace cover 4, the third bushing 37 is pierced between the first bushing 35 and the second bushing 36, the third bushing 37 is sleeved on the corresponding chain 33, and the third bushing The upper and lower ends of the tube 37 are respectively passed through the first sleeve 35 and the second sleeve 36, and there is a gap between the first sleeve 35 and the third sleeve 37 to prevent the third sleeve 37 and the first sleeve 35 from Separate anti-breakout components. In this way, the first casing 35 , the second casing 36 and the third casing 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com