Anti-slip system realized by using anti-slip machine in ocean engineering

A marine engineering and anti-slip technology, which is applied to ship parts, ships, transportation and packaging, etc., can solve the problems of quality and safety accidents, out-of-synchronization of gas welding and cutting, uneven sliding force, etc., and achieve safe and reliable anti-slip force, structure Reasonable and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

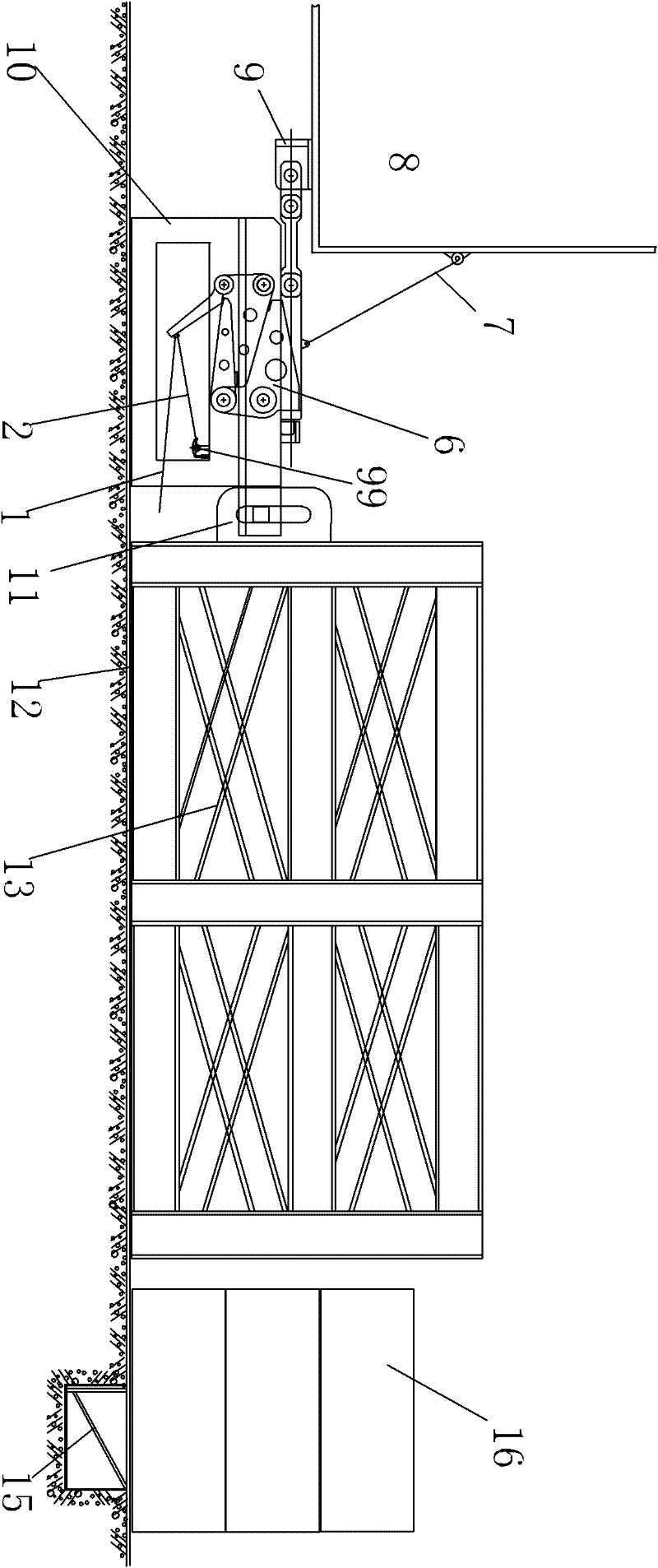

[0017] like figure 1 As shown, the eye plate 9 is set on the edge of the ship and the offshore engineering platform 8, and the anti-slip mechanism is connected through the eye plate 9. The rear end of the anti-slip mechanism is provided with a hanging plate, and the anti-slip mechanism is connected to the ballast basket 13 through the hooking of the hanging plate and the eye plate 11 of the ballast basket. Load-bearing objects are arranged in the ballast basket 13 . In addition, both the anti-slip mechanism and the ballast basket 13 are placed on the steel plate 12 laid on the ground. The rear end lower surface of the steel plate 12 is provided with a ground anchor or baffle plate 15 buried in the ground. At the ground anchor or baffle plate 15, load-bearing objects 16 are also arranged on the top of the steel plate 12.

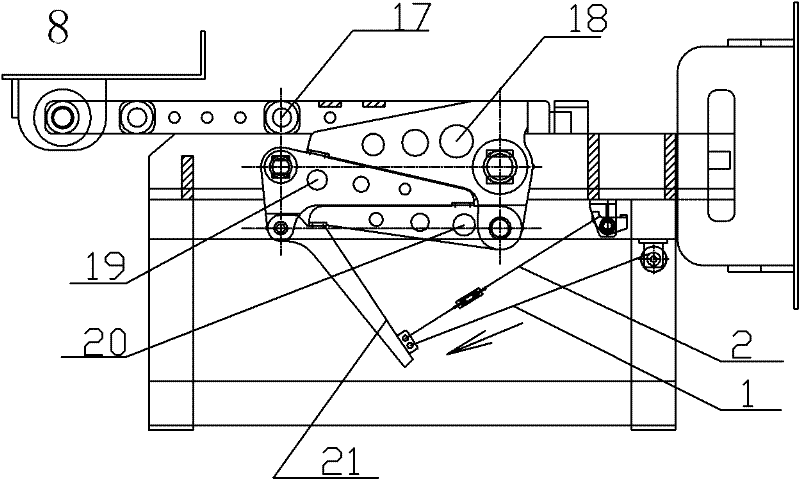

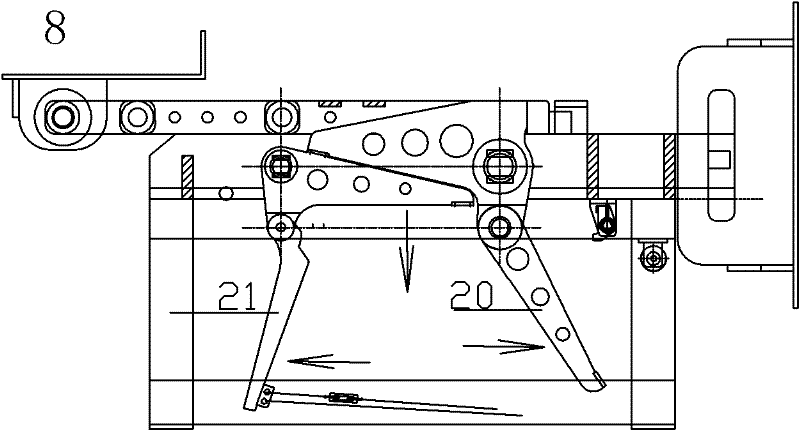

[0018] Among them, the anti-skid machine is composed of five parts, which are active decoupling, anti-skid frame, ballast loading device, hydraulic contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com