Clamping and positioning device for robot welding positioner of large weldment and spring parameter selection method

A robot welding and positioning device technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of labor-consuming, time-consuming, efficiency, unsafe hidden danger, and affecting the quality of construction, positioning and installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

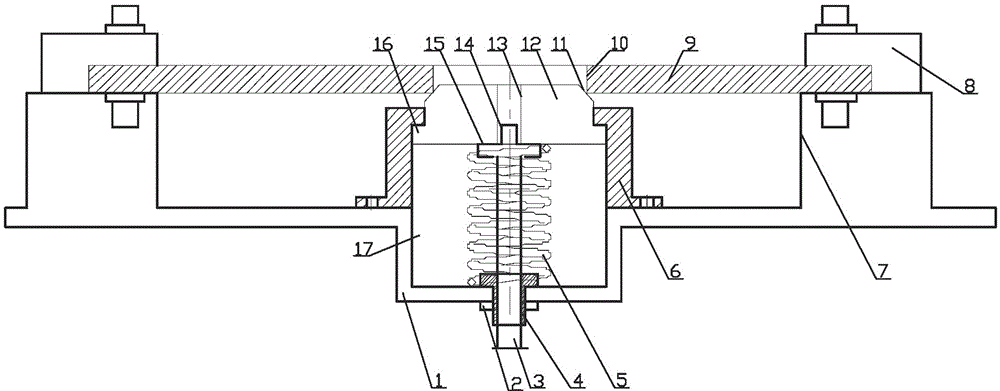

[0064] see figure 1 , a clamping and positioning device for a robot welding positioner for a large-scale weldment, it includes a housing 6, the housing 6 is fixed on the upper surface of the robot welding positioner 1 by bolts and is in contact with the cavity 17 of the positioner Cooperate to form a cylindrical cavity, the central position of the cylindrical cavity is equipped with a locking device 4 through a bolt, the inner of the locking device 4 is set with a clamping screw 3, and the outside of the clamping screw 3 is set with a spring 5; The lower end of the spring 5 is supported and fixed by the upper end surface of the cylindrical cavity, and the upper end is supported and fixed by the collar 15 of the clamping screw 3. The upper end of the collar 15 of the clamping screw 3 cooperates with the lower end surface of the floating cylinder 12, and the floating cylinder 12 is set In the interior of the housing 6 and through the positioning step 16, a positioning hole 13 is...

Embodiment 2

[0111] The following is the data under an actual working condition, and the selection process of the spring parameters through the above parameter selection method is as follows:

[0112] 1) According to the actual working conditions, the load of the floating cylinder 12 can be determined as: 290kg×9.8N / kg=2842N;

[0113] The total load of the workpiece and the floating cylinder 12 is: 2842N+15031kg×9.8N / kg=150127N;

[0114] Further preliminarily determine the minimum working load of spring 5 according to the above-mentioned parameters: P 1=4000N>2842N;

[0115] Maximum working load: P n =6000N<150127N;

[0116] Preliminarily determine the working stroke according to the distance between the housing 6 and the workpiece 9: h=50±1mm;

[0117] Preliminary determination of spring outer diameter according to the diameter of the collar 15: D' 2 ≈200mm;

[0118] The diameter of the spring material used is: d=20mm;

[0119] Spring category: N=103~106 times;

[0120] The end st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com