Double-pendulum three-dimensional laser cutting machine

A three-dimensional laser and cutting machine technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem of unsatisfactory focusing effect of laser cutting machine, and achieve the effect of convenient focusing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

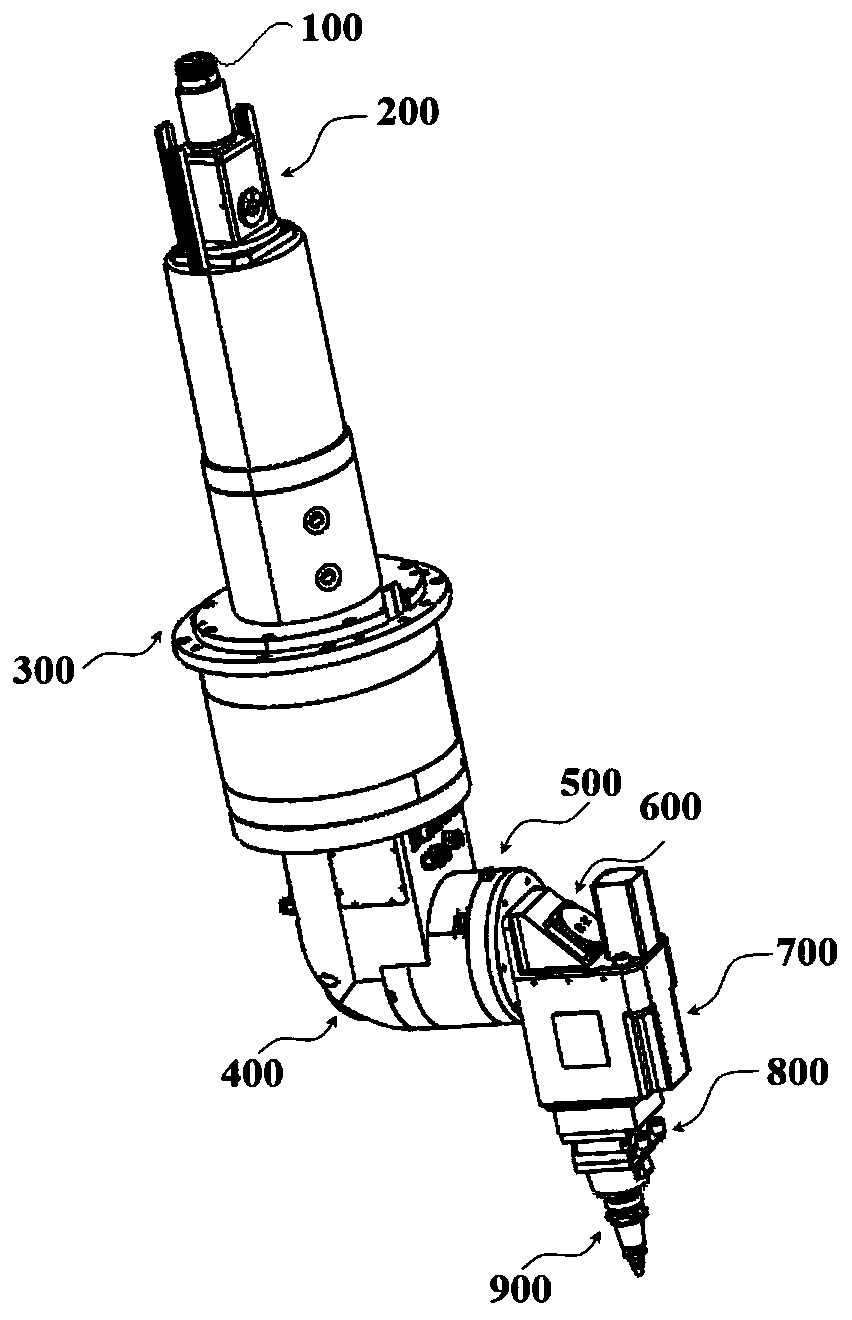

[0051] combine figure 1 , a double pendulum three-dimensional laser cutting machine in this embodiment includes a focus adjustment mechanism 200, a first reflection mechanism 400, a second reflection mechanism 600 and a cutting head 900, wherein the first reflection mechanism 400 is arranged at the center of the focus adjustment mechanism 200 Below, the laser beam transmitted in the focusing mechanism 200 is reflected, passed through the swing mechanism 500, and then directed to the second reflection mechanism 600, and then reflected by the second reflection mechanism 600 to the cutting head 900, and then emitted by the cutting head 900 to process the workpiece to be processed. laser cutting. During the whole laser cutting process, such as figure 1 As shown, when processing parts in different positions, the parts below the focusing mechanism 200 can rotate axially, and the swing mechanism 500 between the first reflecting mechanism 400 and the second reflecting mechanism 600 c...

Embodiment 2

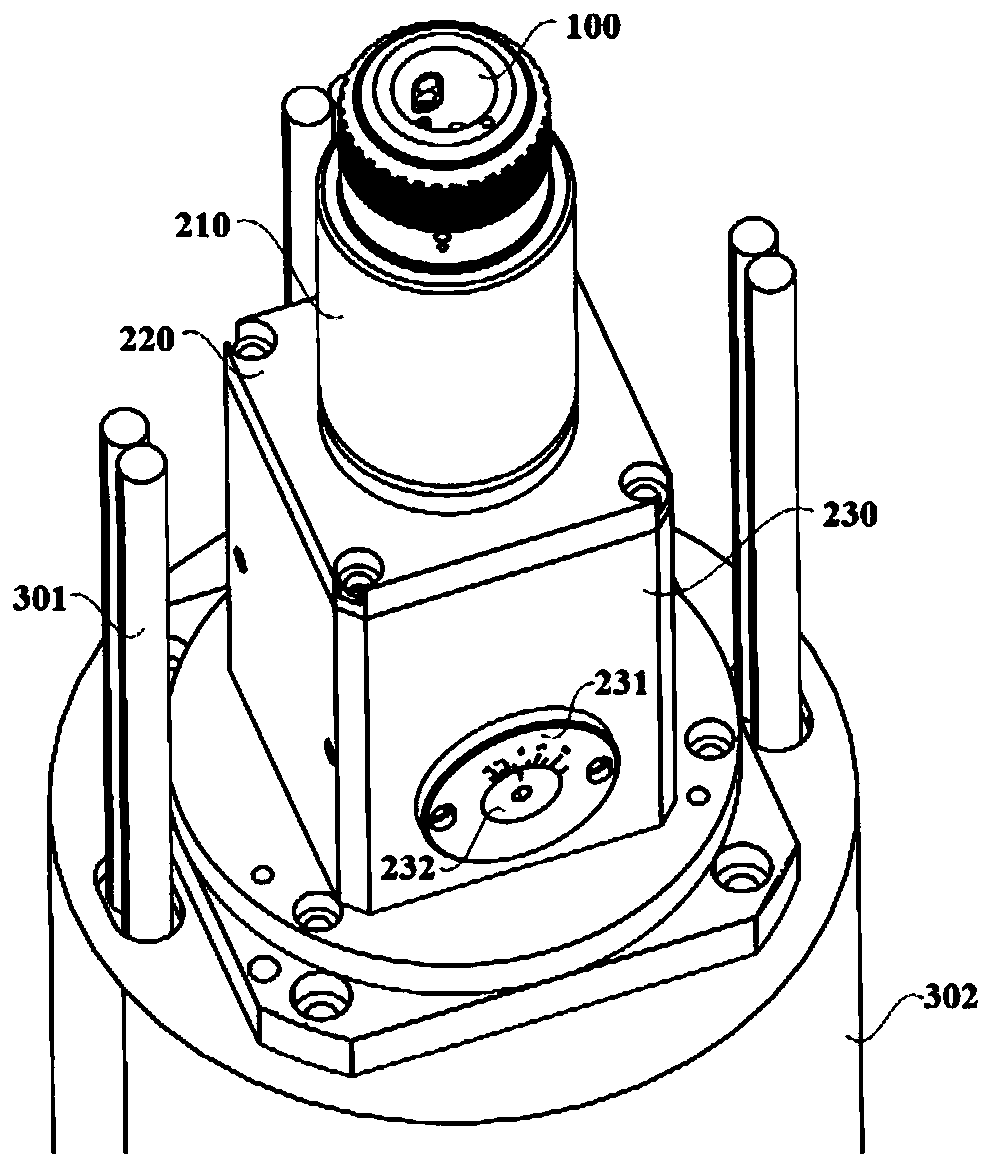

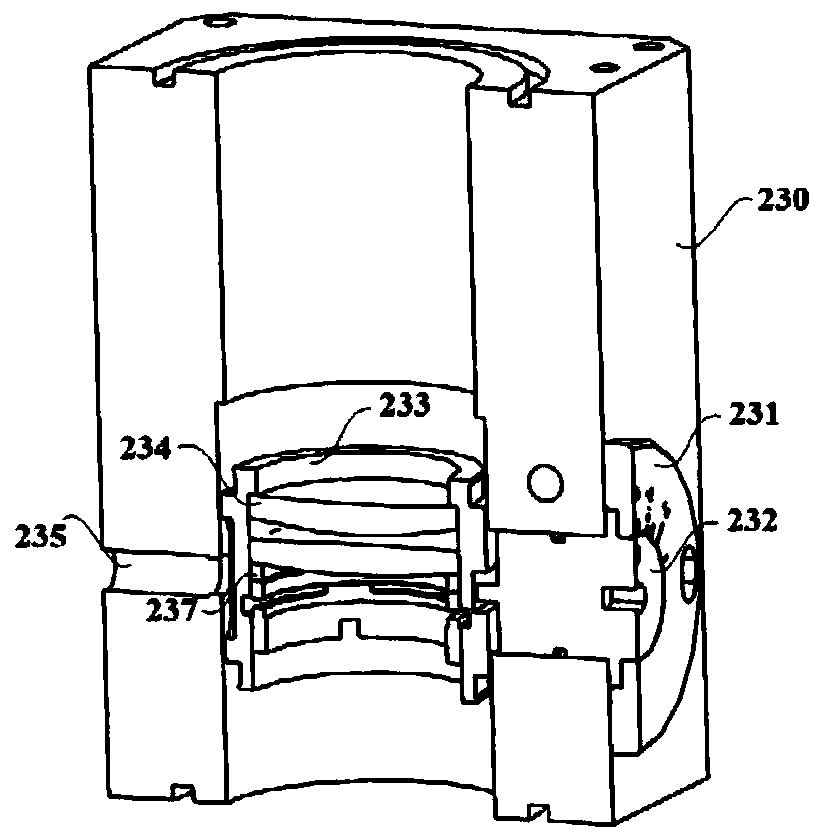

[0055] A kind of double-pendulum three-dimensional laser cutting machine of this embodiment is basically the same as Embodiment 1, and its difference is: combined figure 2 , image 3 and Figure 4 , the focusing mechanism in this embodiment includes a focusing lens barrel 230, a collimating lens holder 233 and a first composite lens 234, wherein a fixing seat 220 is fixedly installed above the focusing lens barrel 230, and a mirror is arranged on the fixing seat 220. Barrel 210, lens barrel 210 is connected with focusing lens barrel 230, and focusing lens barrel 230 is connected with lens barrel 2 240 at the bottom of focusing mechanism 200, which is convenient for laser beam to pass through; 233, the collimating lens mount 233 is set in the cavity of the focusing lens barrel 230, such as image 3 As shown, in order to facilitate the adjustment of the focus position, a hole is opened on the focusing lens barrel 230 in this embodiment, and the adjusting dial 232 is inserted ...

Embodiment 3

[0058] A kind of double-pendulum three-dimensional laser cutting machine of this embodiment is basically the same as Embodiment 2, and its difference is: in this embodiment, in order to further ensure that the focus position of the laser beam will not changes happened. Such as image 3 and Figure 4 As shown, in this embodiment, a guide groove 236 is provided on the outer wall of the collimating lens base 233 along its height direction, and a fixing hole 235 is provided on the focusing lens barrel 230. When the adjusting dial 232 is rotated, the laser beam After the focus is adjusted, the fixing piece is inserted into the fixing hole 235 and connected with the guide groove 236 . On the one hand, the fixing member in this embodiment can fix the collimating lens base 233 in the inner cavity of the focusing lens barrel 230 to prevent it from moving, that is, when the focusing mechanism 200 rotates, the focusing mechanism is stably fixed on the focusing lens barrel 230 inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com