Garment processing fabric cutting device

A fabric and cutting technology, which is applied in the field of garment processing, can solve the problems of fabric damage, fabric prone to wrinkles, and affecting the quality of fabric cutting, so as to prevent wrinkles and improve the cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

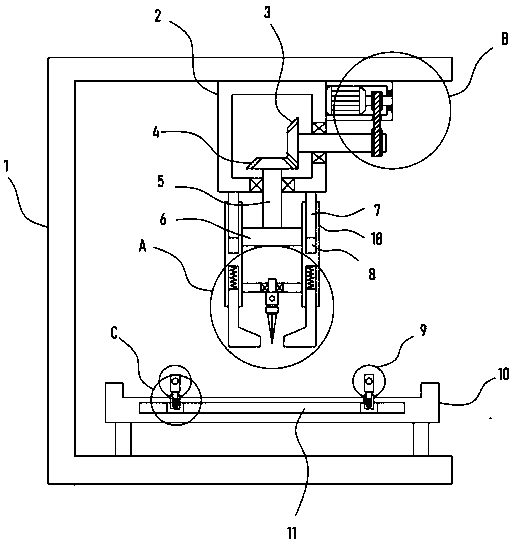

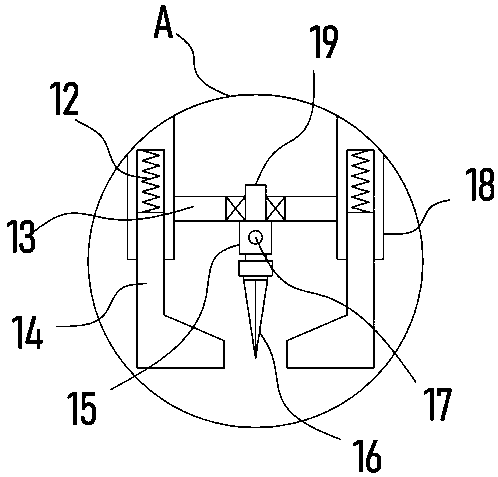

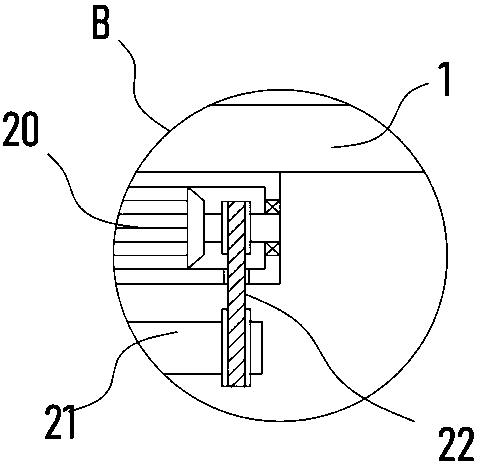

[0024] see Figure 1-6 , a cloth cutting device for garment processing, comprising a support frame 1, a support table 10 for placing cloth is fixed on the support frame 1, a cutter 16 for cutting cloth is provided above the support table 10, and the support frame 1 A gear box 2 is fixed on the top, and the driven shaft 5 is driven and connected to the gear box 2 through a driving mechanism. The inner threaded block 18 is arranged under the gear box 2, and the inner threaded block 18 is connected with an internal thread and fixed on the bottom of the driven shaft 5. The external thread column 6 of the internal thread cover block 18 is horizontally fixed with a horizontal plate 13, the cutter 16 is fixedly installed on the bottom of the horizontal plate 13 through a steering mechanism, and two The pressing block 14 is arranged symmetrically with respect to the cutting knife 16 , and the limiting spring 12 is fixedly connected between the pressing block 14 and the inner thread sl...

Embodiment 2

[0031] In order to facilitate the adjustment of the cloth cutting angle, on the basis of Embodiment 1, in addition, the steering mechanism includes a sleeve 15 fixed on the bottom of the horizontal plate 13, and the sleeve 15 is movably provided with a steering wheel pivotally connected with the horizontal plate 13. The shaft 19 and the cutter 16 are fixed on the lower end of the steering shaft 19 , and the side wall of the casing 15 is threadedly connected with a locking screw 17 abutting against the steering shaft 19 .

[0032] Through the above settings, when it is necessary to adjust the cutting angle, the steering shaft 19 can be turned, and the steering shaft 19 rotates relative to the sleeve 15. At this time, the cutter 16 is deflected at a certain angle, and then the locking screw 17 is turned to the side of the steering shaft 19. Screw in until the locking screw 17 is tight against the steering shaft 19 to realize the fixing of the steering shaft 19 and the sleeve pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com