Telescopic integrated system for port coke unloading and stacking

An integrated system and coke technology, applied in the direction of loading/unloading, conveyor, transportation and packaging, etc., can solve the problems of large area of stacking, long time required for stacking and serious accumulation of goods, etc., to achieve The effect of reducing cost input, convenient transition, and preventing spilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Enumerate the specific example of implementing the content of the above invention. If there are drawings, describe in detail in conjunction with the drawings. The description of the examples shall include: specific implementation schemes, constitutions, material selections, components, functions and other necessary technical materials and the effects of the examples, and multiple examples may be listed if necessary.

[0045] Below in conjunction with embodiment, the specific implementation manner of the patent of the present invention is further described.

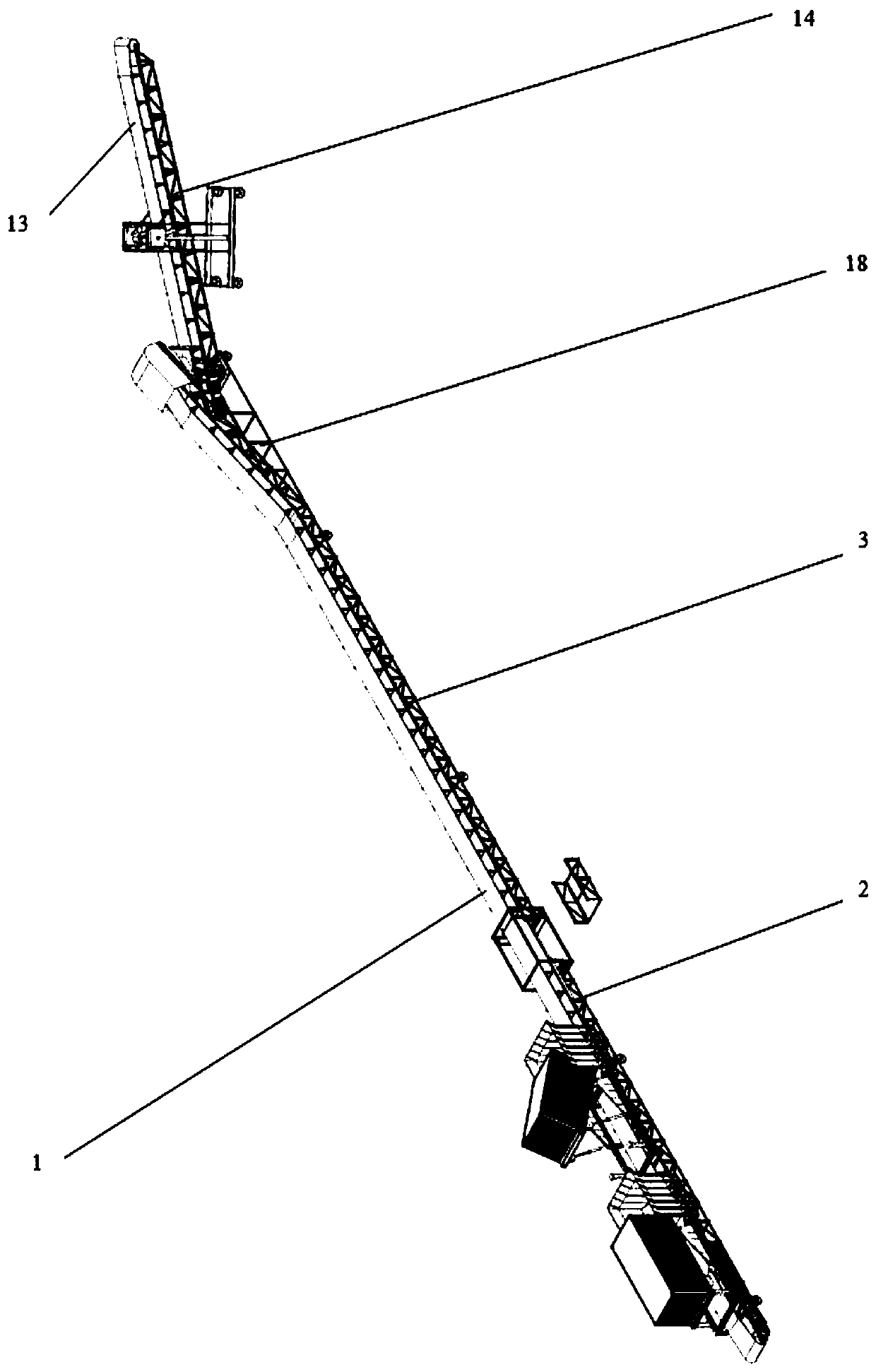

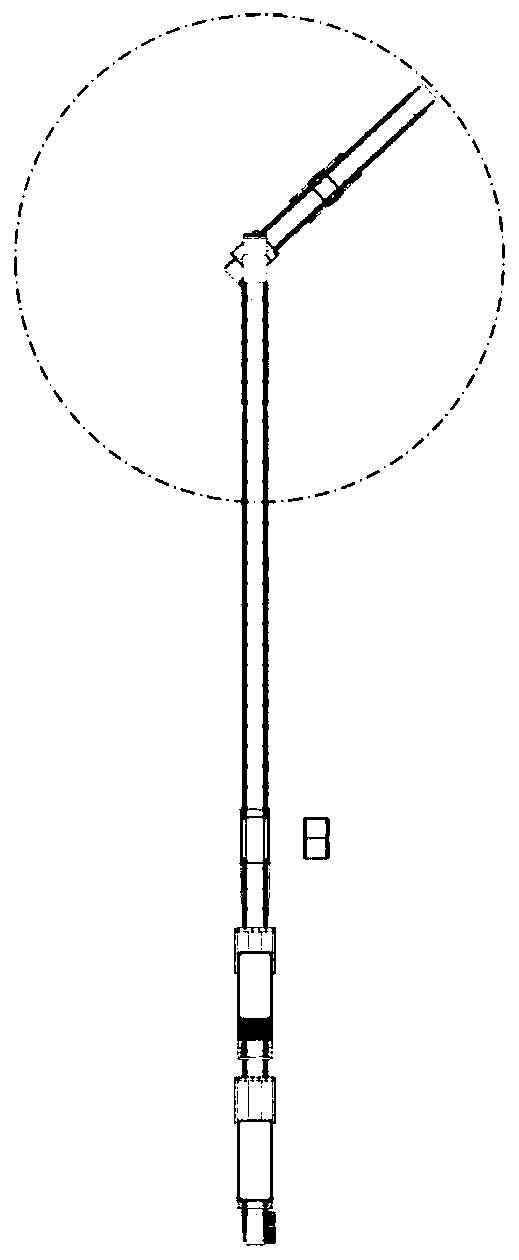

[0046] A scalable integrated system for port coke unloading and stockpiling, such as figure 1 , 2 shown;

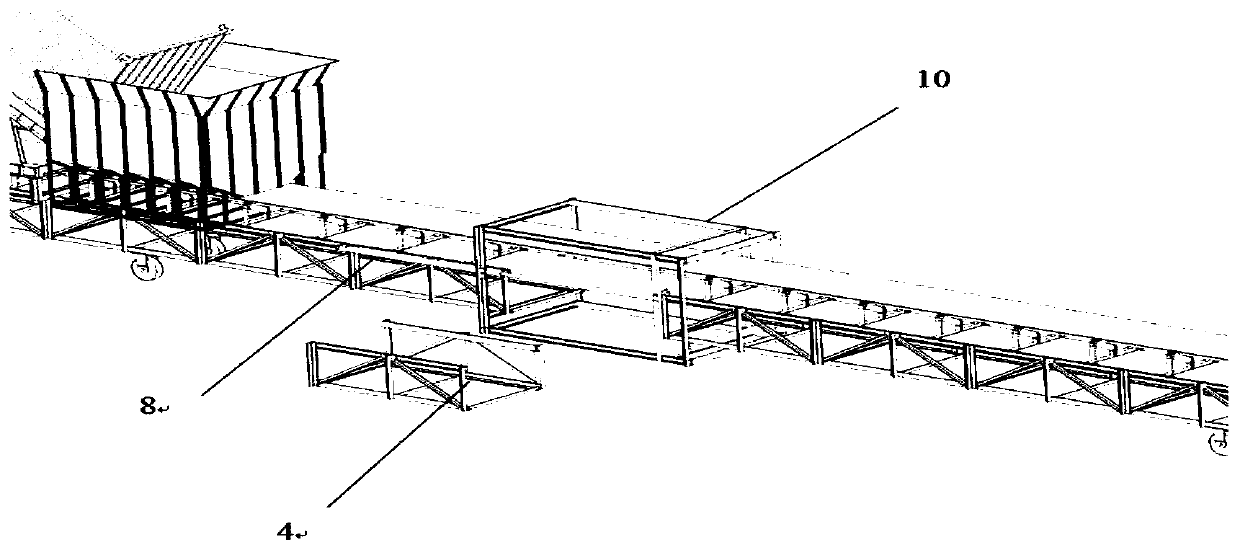

[0047] The horizontal belt conveyor includes: a horizontal section and an ascending section; the horizontal section includes: a retractable conveyor belt 1, a first steel frame 2, a second steel frame 3, a standard section 4, a first hydraulic cylinder 5, and a container bracket 6. High plate trough 7, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com