Patents

Literature

63results about How to "Stable unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

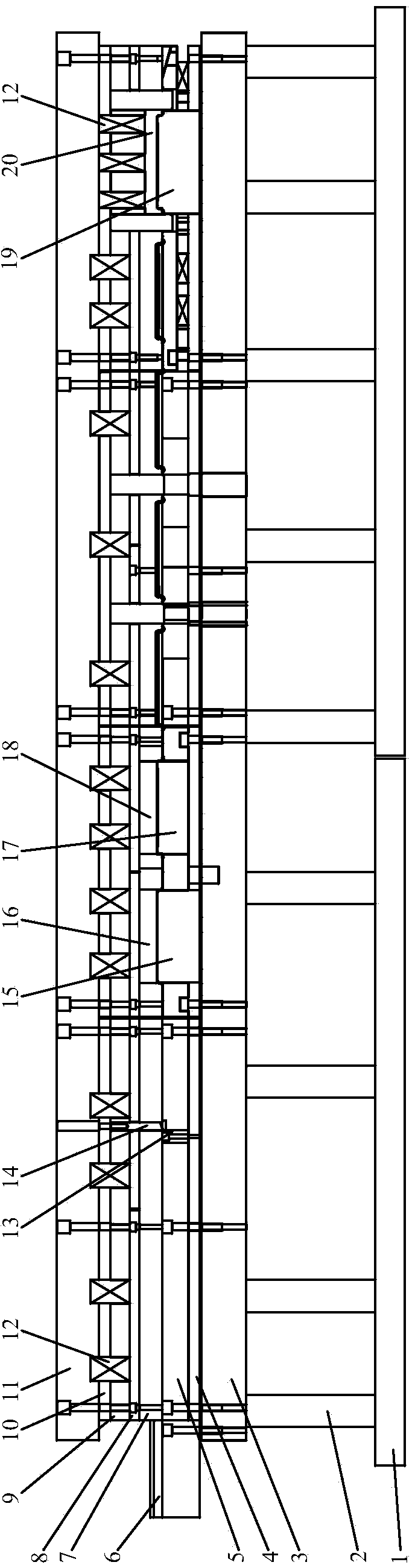

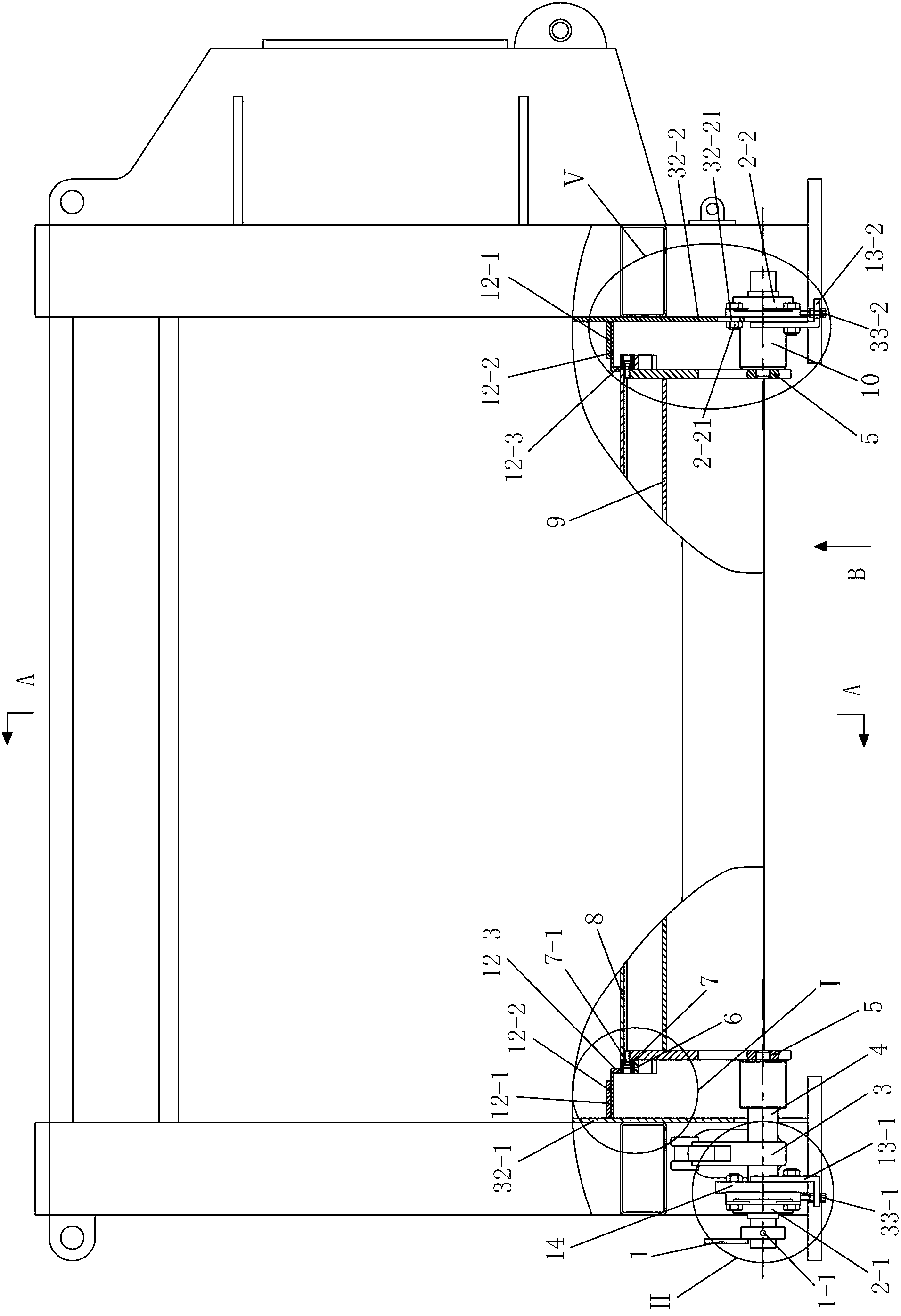

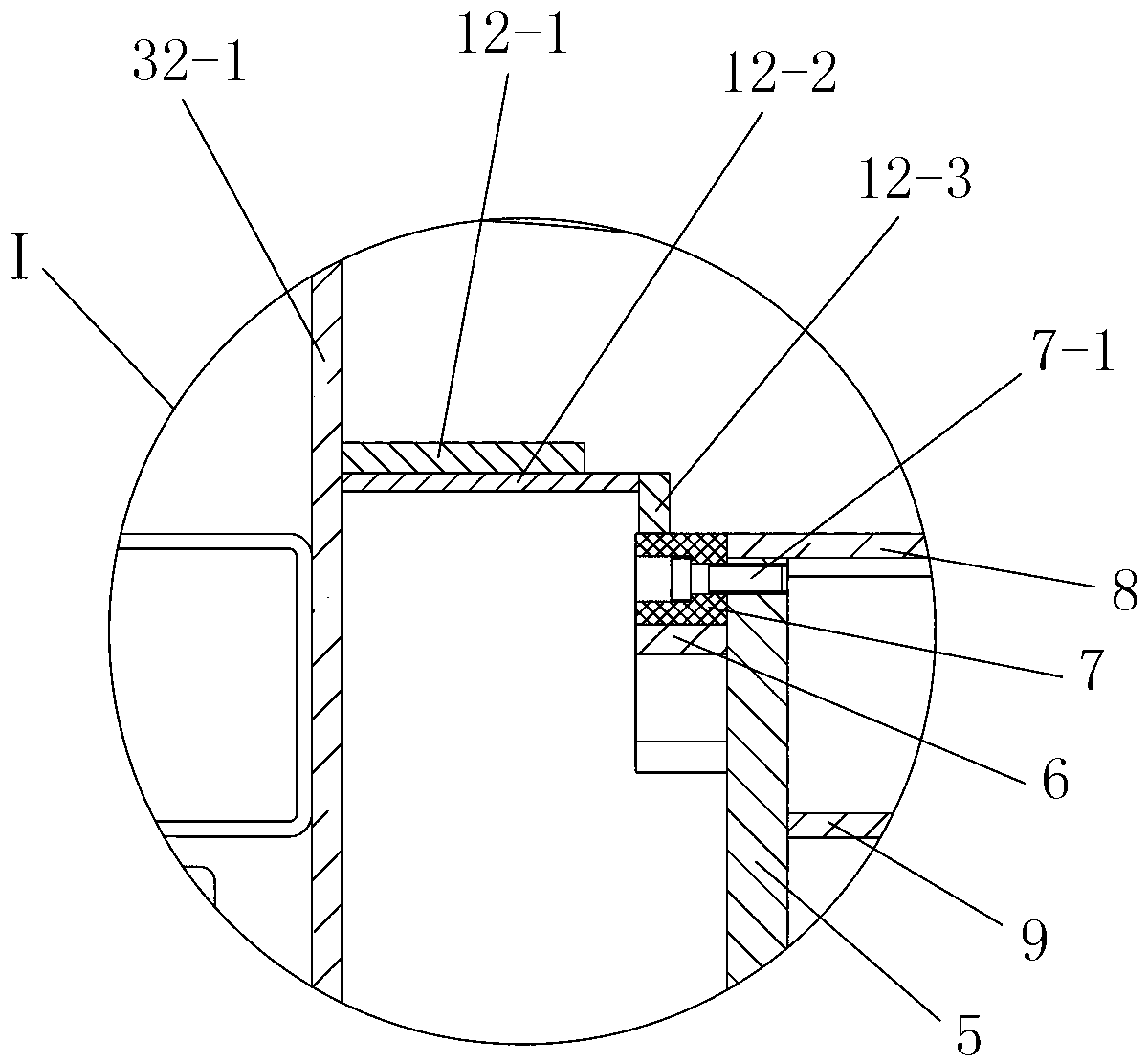

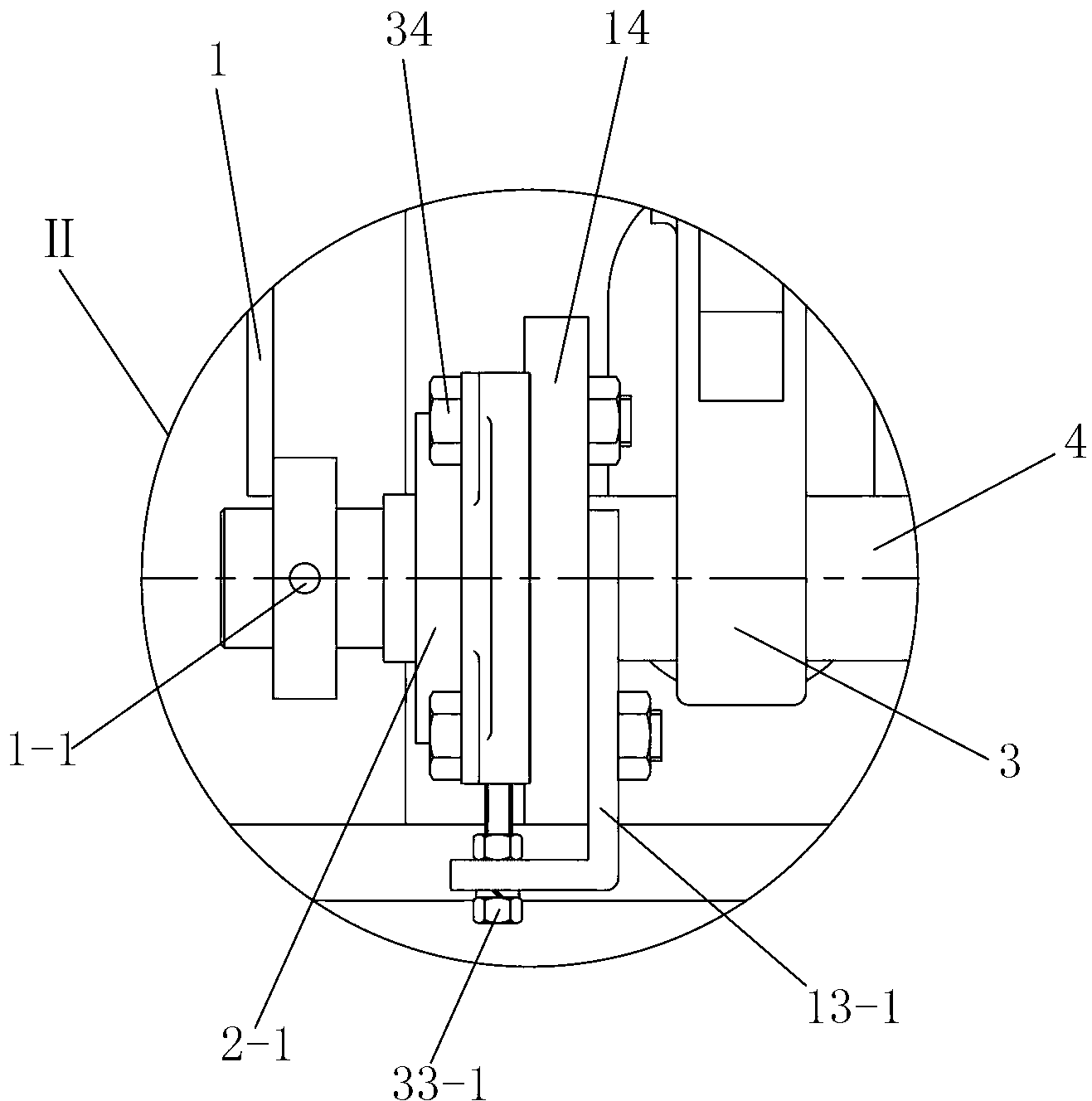

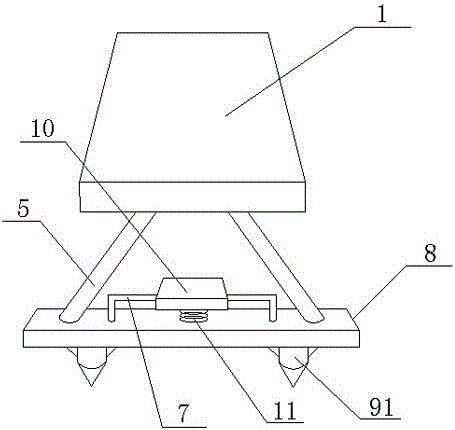

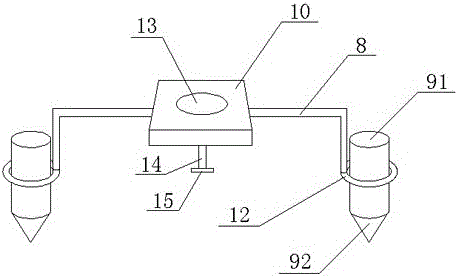

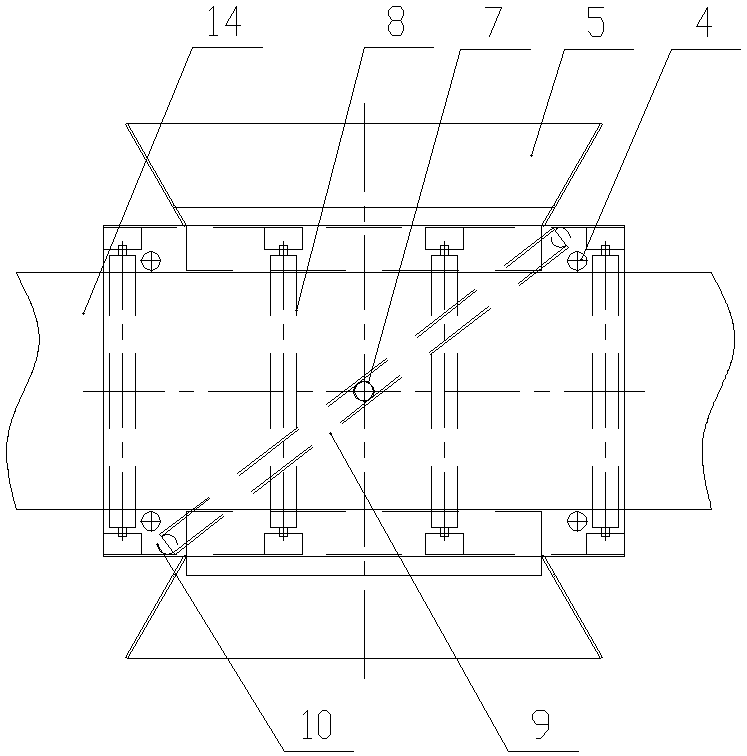

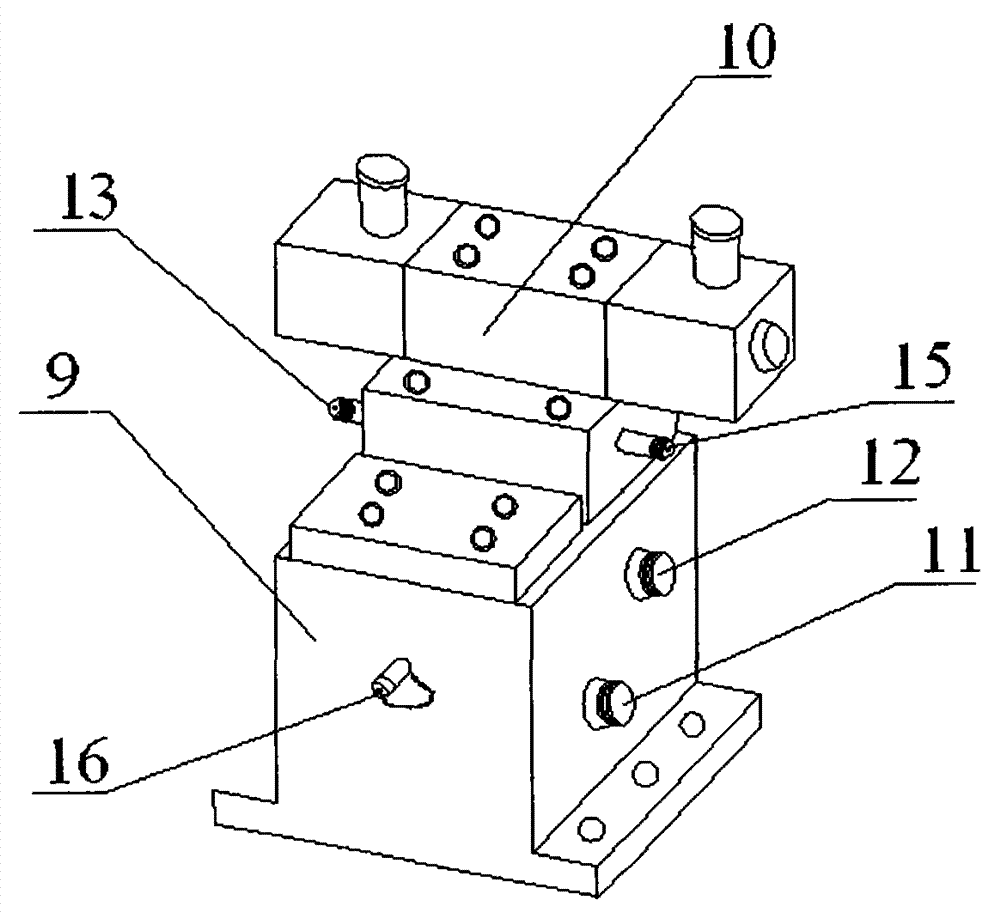

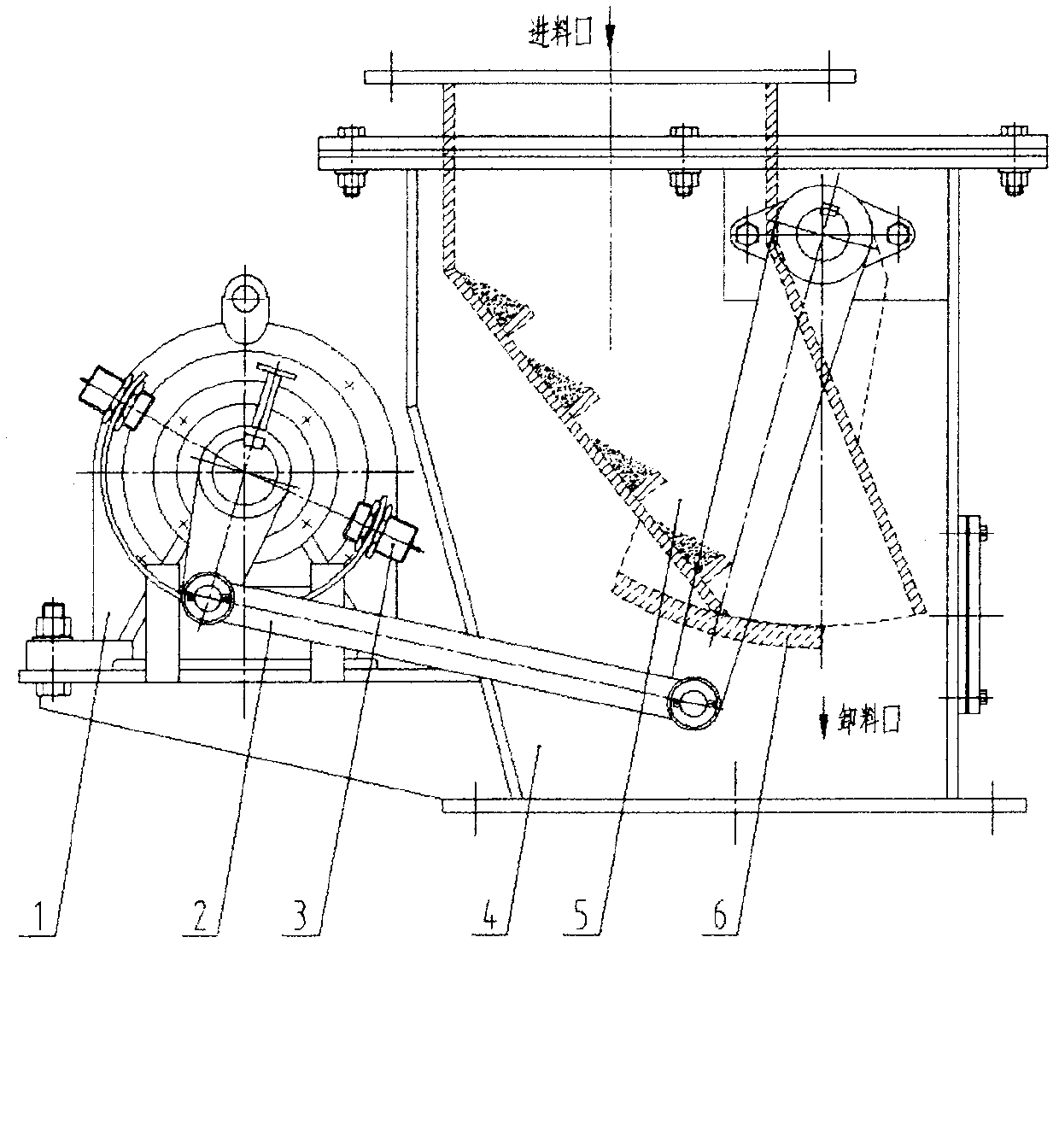

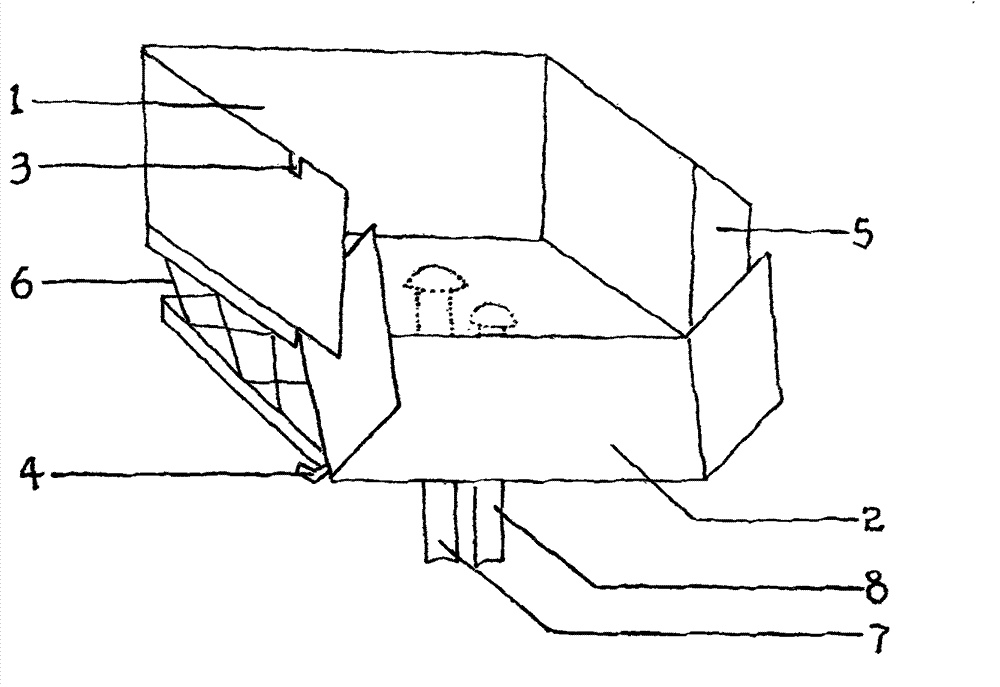

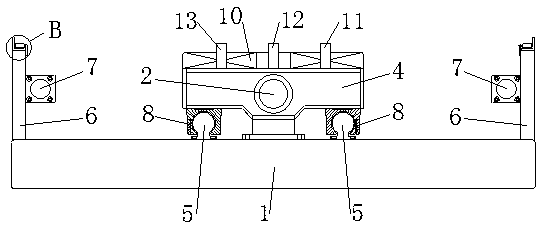

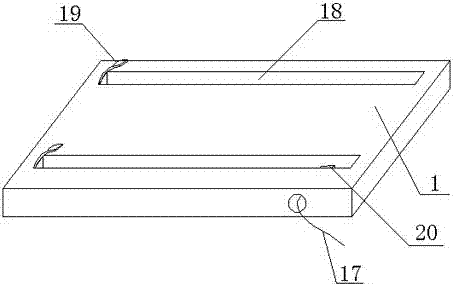

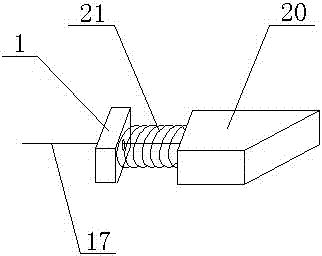

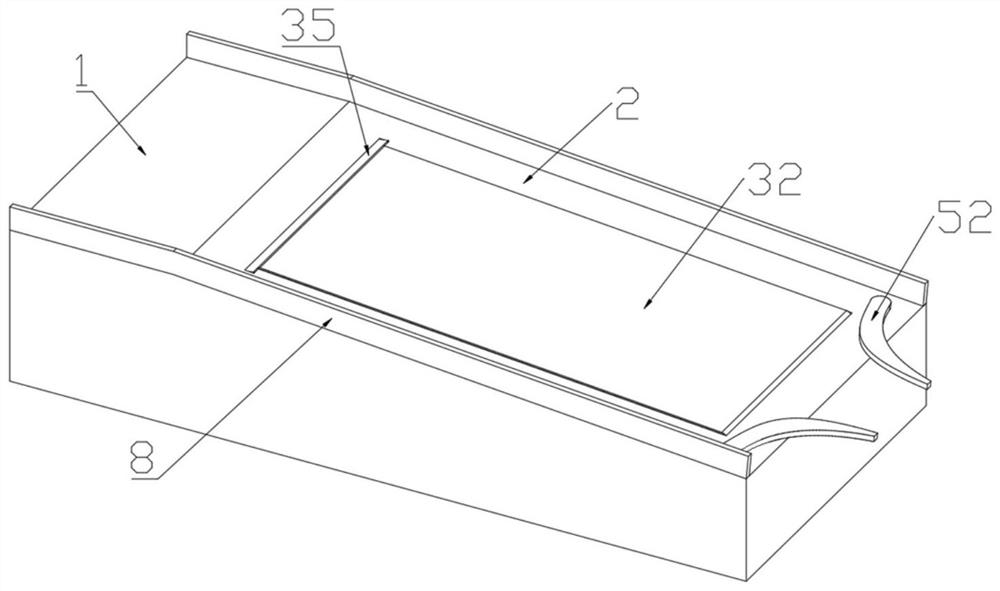

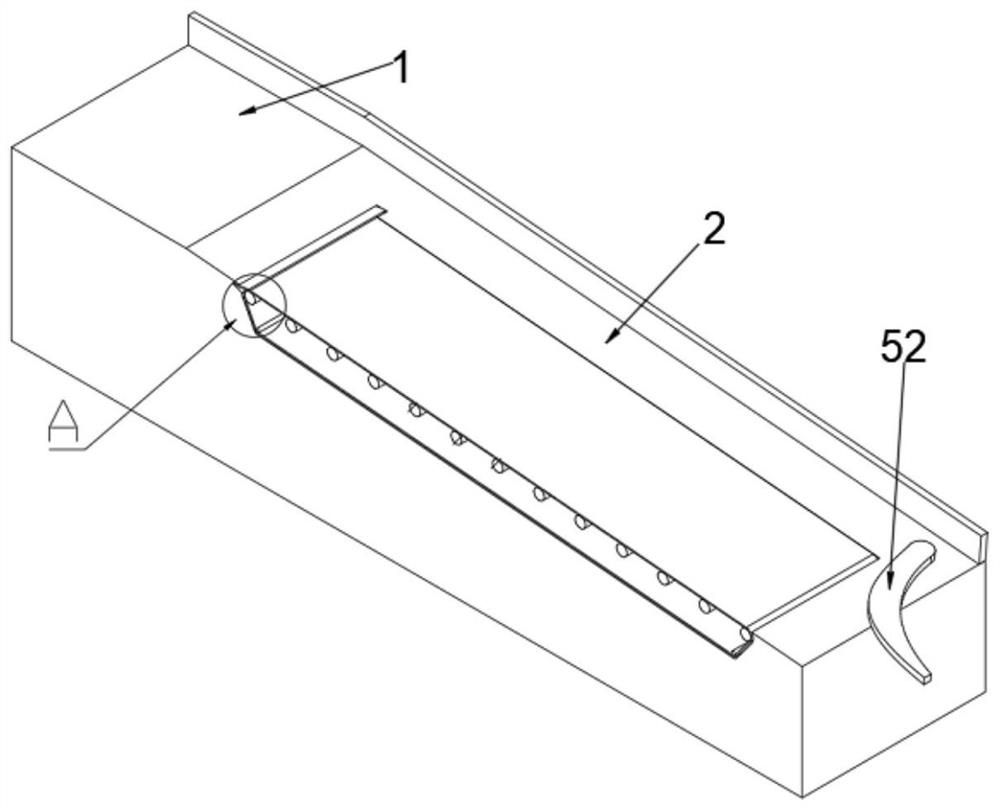

Suspension supporting base multi-station progressive die

ActiveCN103962452ACompact structureHigh guiding precisionShaping toolsPerforating toolsPunchingEngineering

The invention relates to a suspension supporting base multi-station progressive die which comprises an upper die assembly, a lower die assembly, an unloading plate, an unloading plate base plate and a mis-feeding detection device. The upper die assembly is sequentially provided with a corresponding male die in the feeding direction, the lower die assembly is sequentially provided with a female die embedding sleeve matched with the male die of the upper die assembly, corresponding positions on the unloading plate and on the unloading plate base plate are provided with a through hole capable of penetrating through the male die of the upper die assembly, the unloading plate is disposed on the unloading plate base plate, and the unloading plate base plate is arranged on the upper die assembly through an unloading spring. By means of the progressive die, suspension supporting bases are produced in a continuous drawing progressive die mode. The mechanism is compact in structure, high in guide precision, stable in unloading and precise in pitch fixing, and feeding and discharging are convenient to achieve. A quick replacement structure is adopted to a punching male die, and maintenance and replacement time of the die is effectively shortened. After being tried, the mechanism is good in use effect and can meet requirements for high efficiency and high precision of stamping production.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

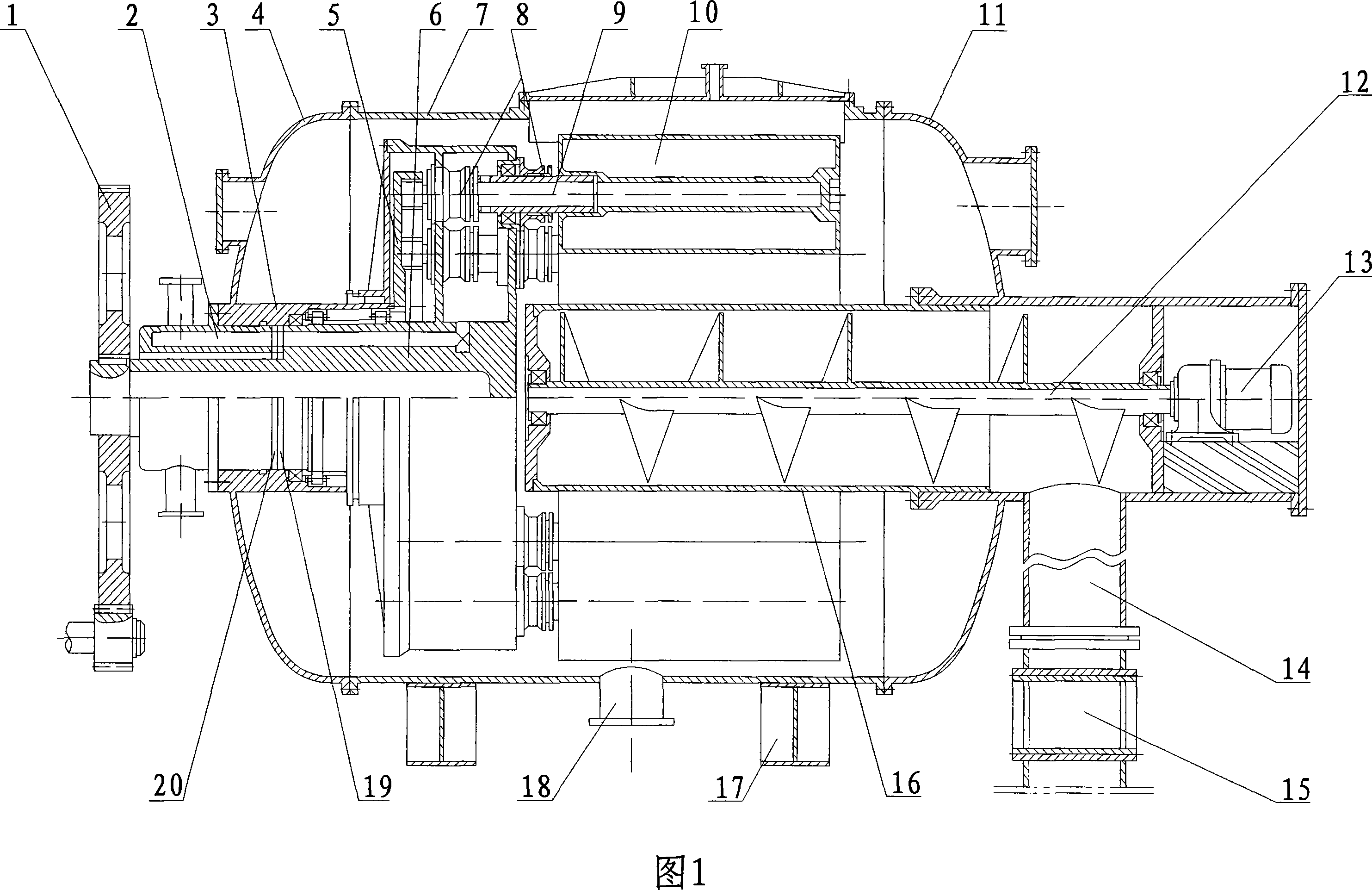

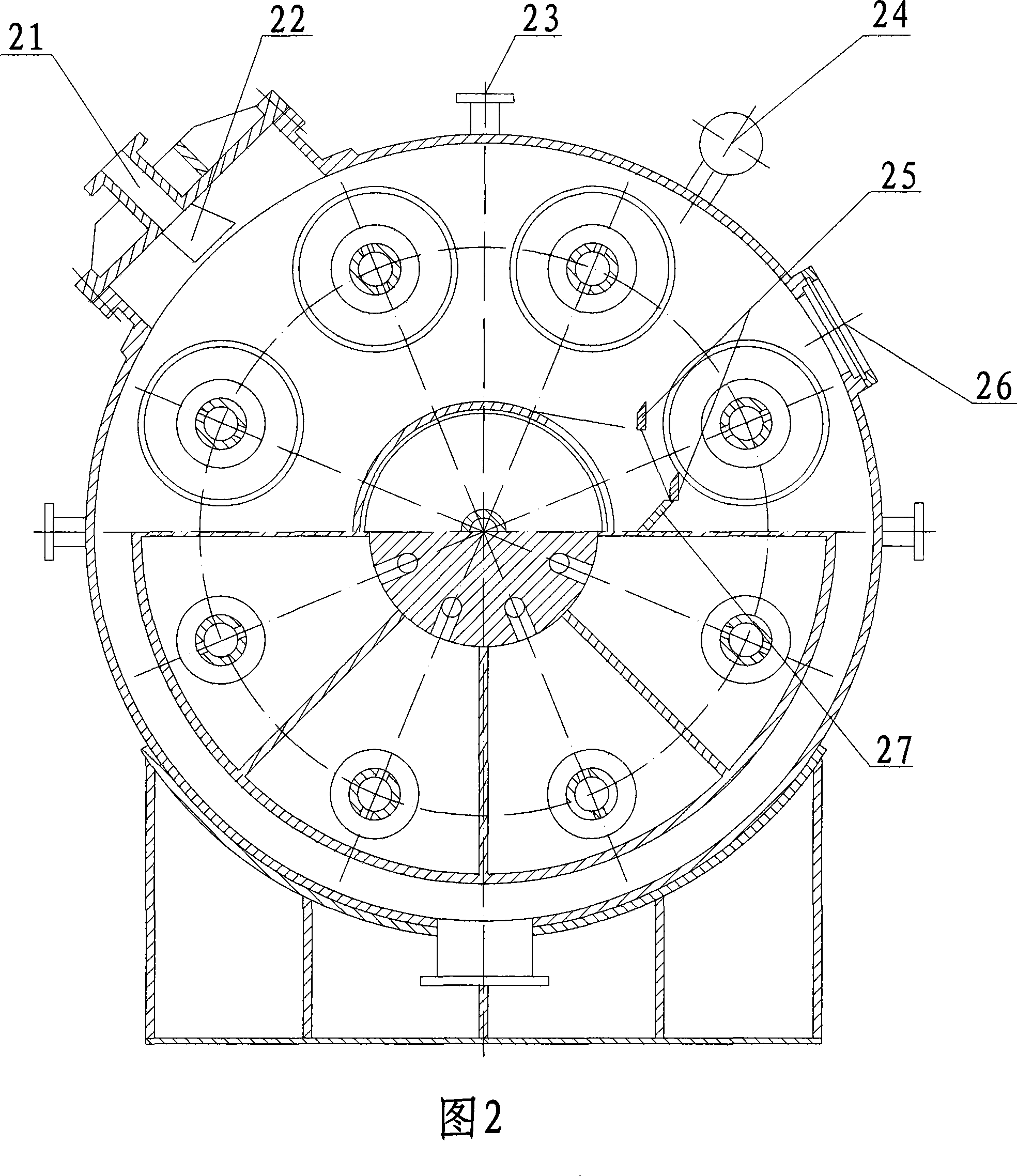

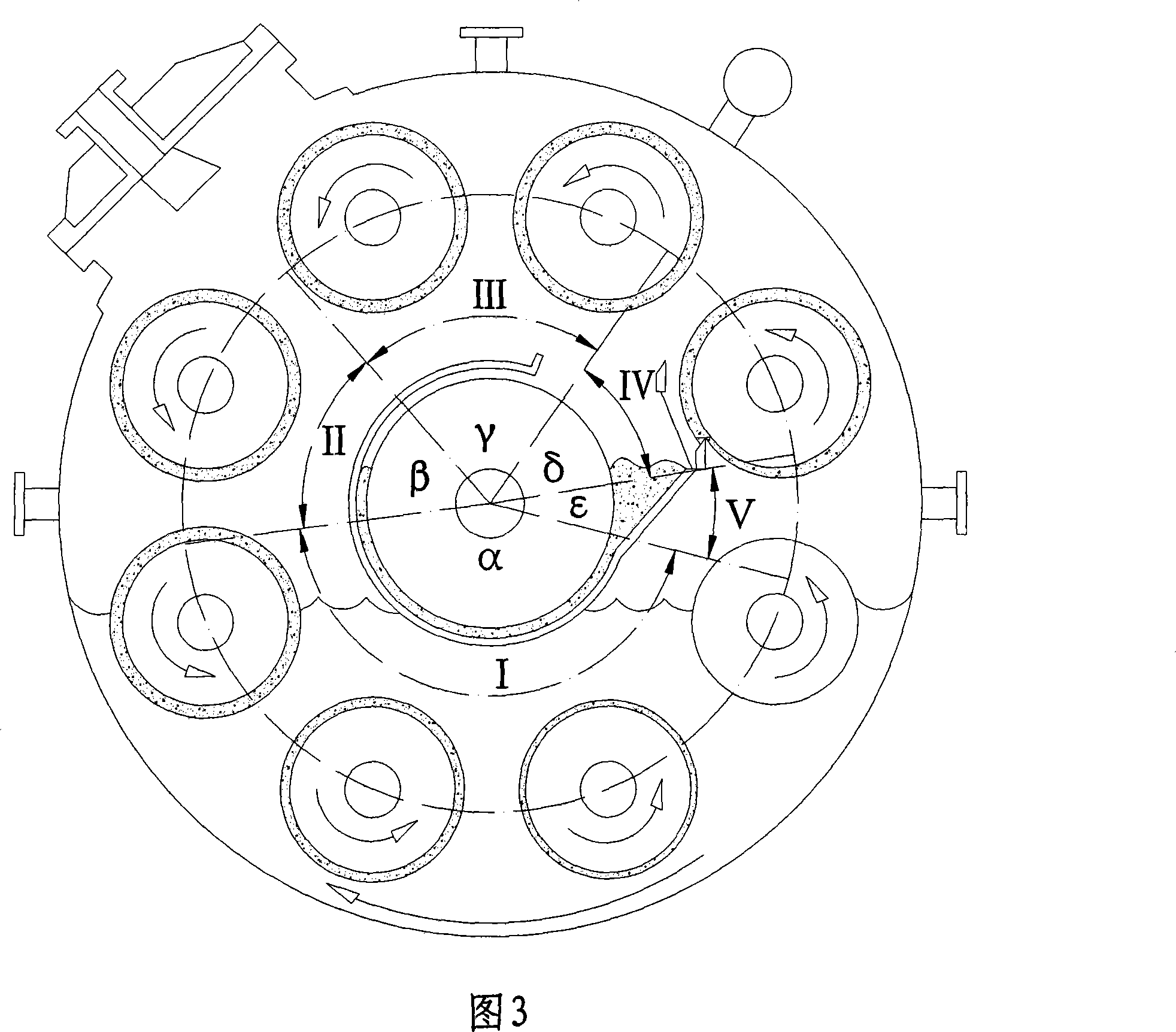

Planet gyration small circular cylinder continuous pressure filtration machine

InactiveCN101234269APrevent precipitationReliable filtration operationMoving filtering element filtersGyrationFilter cake

The invention relates to a continuous pressure filter used for filtering suspension, the main technical characteristics of which is that a plurality of filtering units are arranged in the direction of the inner circumference inside a shell body of the filter; each filtering unit consists of a filter cylinder, a filter axis and an inner channel of a planet carrier communicated with the filter axis. The filter cylinder used as a filter element is fixed and supported on the planet carrier by the filter axis, which executes a planetary motion when working; fluid is collected inside the filter cylinder after going through a filter medium on the filter cylinder, which enters the channel of the planet carrier through a hollow filter axis and is discharged after being switched through a distributing head. The continuous pressure filter of the invention has the main characteristics of high-efficiency filtration dehydration, effectively wash and dry a filter cake, reliable material-discharging way, a blowback regeneration function of the filter medium, and the operating steps are carried out sequentially.

Owner:SICHUAN UNIV

Discharge door device for double-horizontal-shaft concrete mixer

InactiveCN103072208ASolve the sealing problemSolve wear and tearDischarging apparatusEngineeringMechanical engineering

The invention discloses a discharge door device for a double-horizontal-shaft concrete mixer, which comprises a discharge door main body and a drive mechanism, wherein the discharge door main body comprises two sector plates, an arc door plate, a V-shaped plate, a long shaft and a short shaft; the two sector plates are welded at the two ends of the arc door plate respectively; the V-shaped plate is welded with the inner side of the arc door plate; the long shaft and the short shaft are welded on the two sector plates respectively; welding centers are near the opening end of a discharge door; a second mounted bearing is mounted on the short shaft and fixed on a right side wall of a double-horizontal-shaft concrete mixing drum and can move up and down; a first mounted bearing is mounted on the long shaft; a mixing drum side wall ribbed plate is welded on a left side wall of the double-horizontal-shaft concrete mixing drum; a bearing mounting plate is welded on the mixing drum side wall ribbed plate; and the first mounted bearing is fixed on the bearing mounting plate and can move up and down along the bearing mounting plate. The discharge door device is good in sealing effect and high in reliability, and has the effects that the door is looser to open and tighter to close gradually, the wear compensation is facilitated, and the door opening efficiency is high.

Owner:CHANGAN UNIV

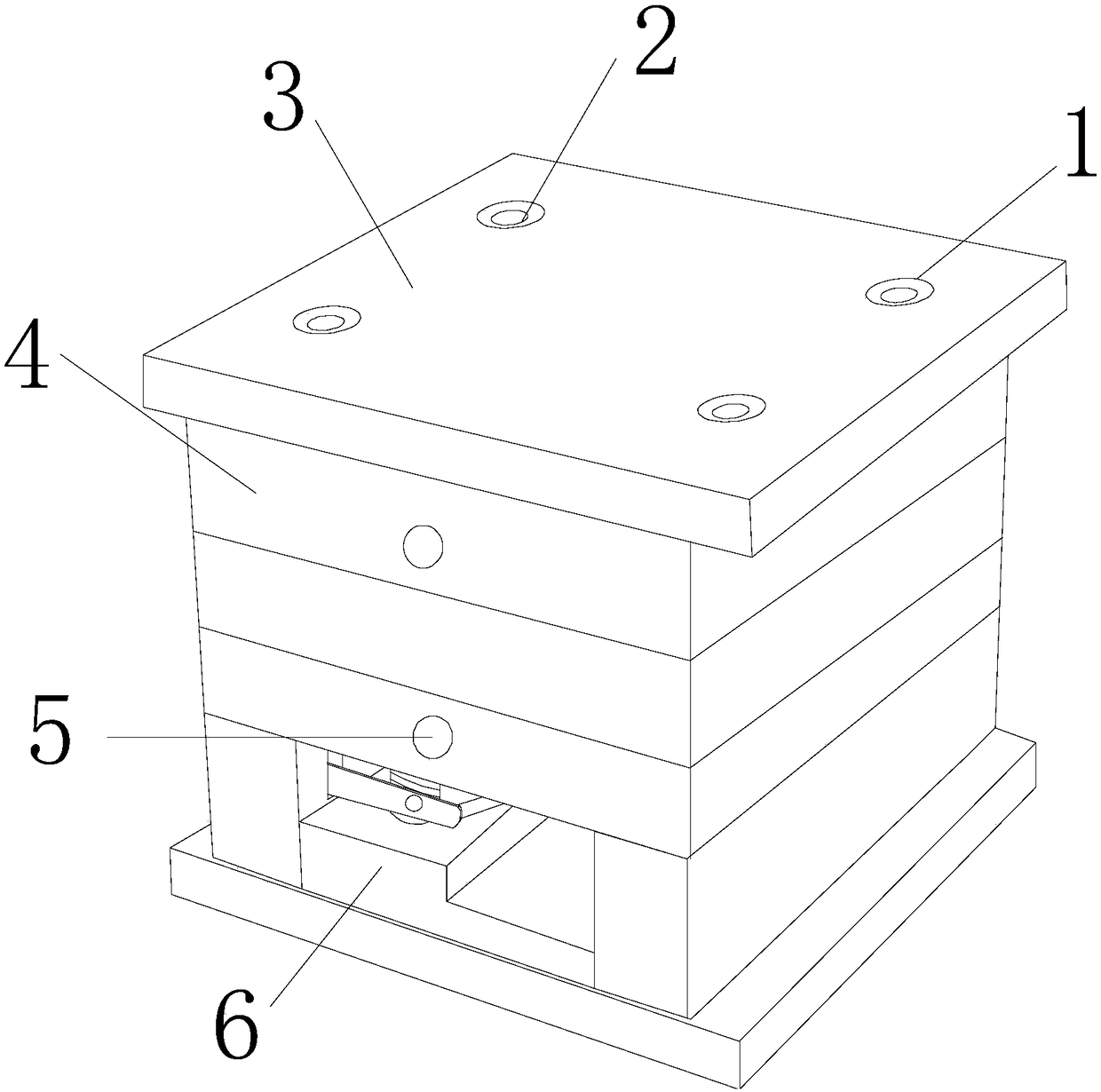

Spring-reset plastic molding mould for pushing and retracting stripping by forced deformation of support group

The invention discloses a spring-reset plastic molding mould for pushing and retracting stripping by forced deformation of a support group. The spring-reset plastic forming mould comprises a guide column hole, a guide column, a fixed die plate, a fixed die holder, a water inlet hole and a molding stripping device, wherein the molding stripping device is positioned on the end face of the lower sideof the fixed die holder and is in fit connection with the fixed die seat. A special-shaped block in the inner part is pushed upwards by a movable column at the lower part, and a regulating bracket onthe upper part moves to deform, so that one side of a pushing column in the inner part is pushed out slightly, the other side of the pushing column is retracted into and matched with the inner part of an unloading bracket, and therefore demoulding gradient is formed. Forced pushing by a rod body is not adopted, so that unloading is more stable, and the safety of finished products is ensured. A permanent magnet repelling a magnetic block is arranged in the inner part of a sliding block and is matched with the magnetic block, and the sliding block is matched with a sliding groove in a sliding mode, so that a block body can move stably along an arc-shaped column, the pushing column rising by forced pushing can be more smooth and stable, and difficult push-out due to aging cannot occur.

Owner:广州市旭匠精密科技有限公司

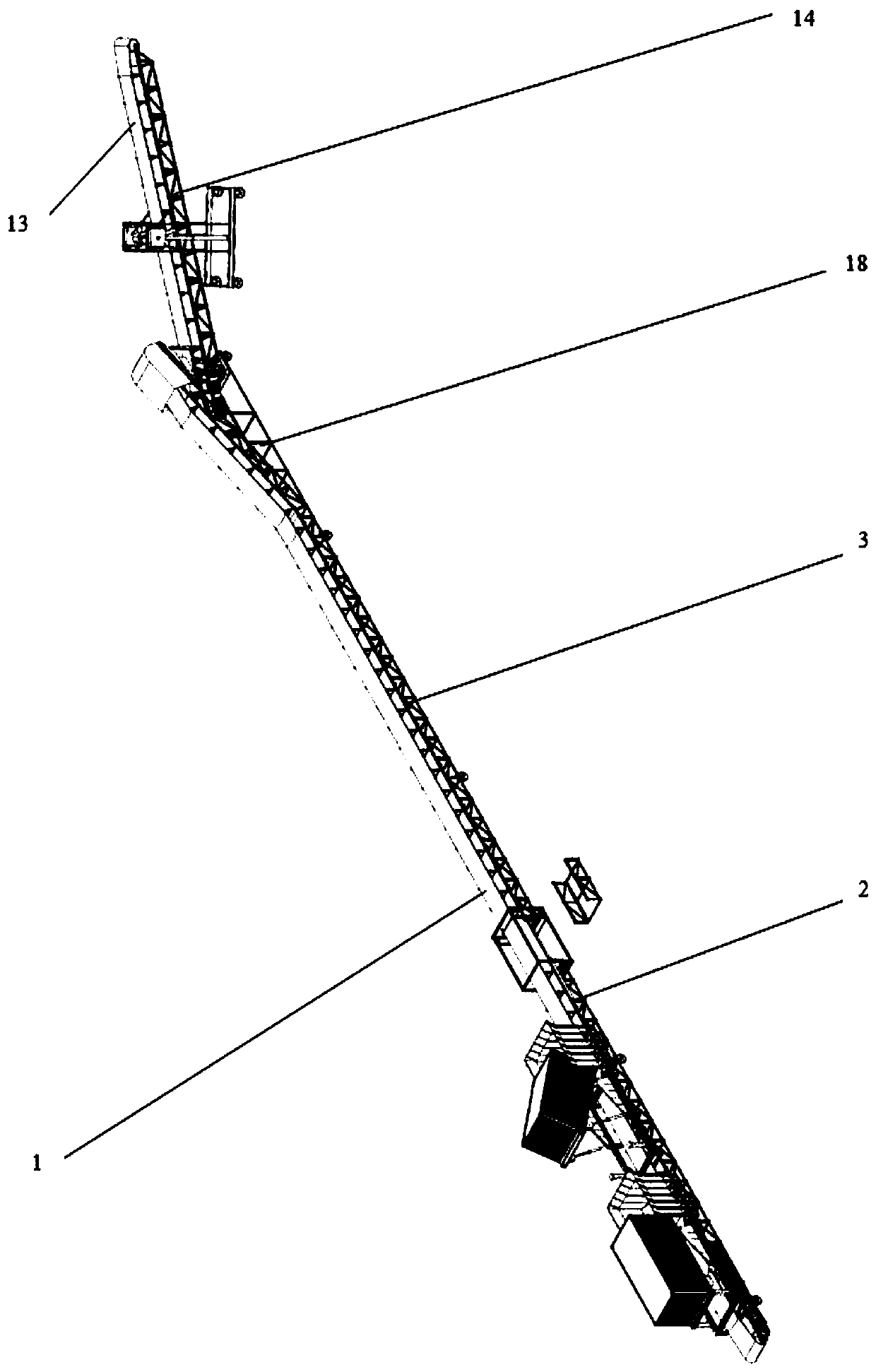

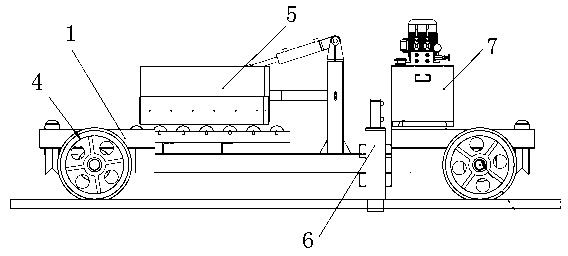

Telescopic integrated system for port coke unloading and stacking

The invention relates to a telescopic integrated system for port coke unloading and stacking, and belongs to the field of mechanical equipment. The system comprises a horizontal belt conveyor, a stacking conveyor and wheels; when the horizontal belt conveyor does not extend, a guide joint is in a non-working state, so the normal work of the integrated system is not affected; when the horizontal belt conveyor needs to extend, a part of the telescopic conveying belt is stored in a first steel frame, and the extension of the conveying belt is achieved through the movement of a rolling shaft; thelength of a telescopic funnel of the telescopic funnel can be changed along with the change of the inclination angle of the stacking conveyor and the increase of the gravity center of the stacking conveyor, and the relative positions of the funnel and a trough are always kept fixed, so coke is prevented from being broken to a certain extent, and materials can accurately and completely flow into ahigh-plate trough of the stacking conveyor. According to the invention, the system is simple in structural design, can reduce the unloading and stacking operation time, has very high flexibility in transition, can decrease the breaking rate of coke in the unloading and stacking process, and greatly increases the utilization rate of a port site.

Owner:江苏环宇起重运输机械有限责任公司 +1

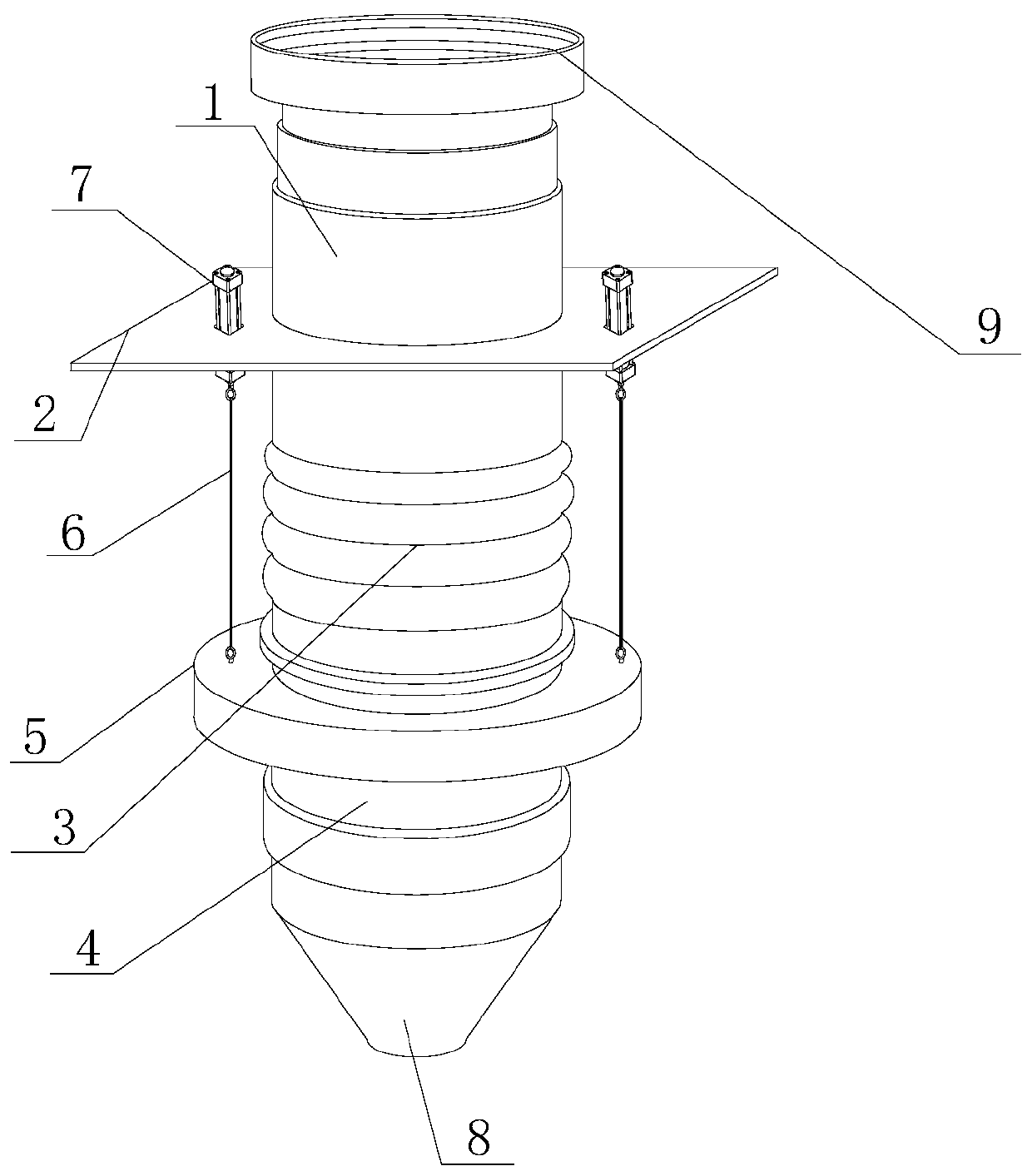

Practical fly ash discharging structure

InactiveCN110406817AInhibit sheddingSolve the problem of reduced efficiency of unloadingLarge containersDischarge efficiencyButt joint

The invention discloses a practical fly ash discharging structure which structurally comprises a discharging pipe, a telescopic pipe, a buffer guide structure and a stable connecting piece. Accordingto the practical fly ash discharging structure, a buffer guide structure is arranged at the lower end of the discharging pipe, a discharging hopper is in butt joint with an external ash receiving mechanism, fly ash enters an ash storage bin from the discharging hopper, then a guide plate compresses a compression spring on a connecting plate, vibration generated during discharging is absorbed, an auxiliary damping function is achieved, a fixing rod and a nut are unscrewed, so that a first rotating frame rotates with a second rotating frame through a rotating shaft, the discharging hopper is separated from the discharging pipe, therefore discharging is more stable, the discharging efficiency is improved, and the detachable connection function is realized. A stable connecting piece is arranged at the upper end of the discharging pipe, and a reinforcing pipe, a connecting pipe, a connecting sleeve, an upper spiral pipe and a lower spiral pipe are connected with the discharging pipe, so that the discharging pipe is prevented from falling off from an ash outlet of the ash bin.

Owner:XINZHONGTIAN ENVIRONMENTAL PROTECTION

Novel arc valve

InactiveCN102052471AControl switch angleReduce power consumptionSlide valveEngineeringMechanical engineering

The invention discloses a novel arc valve, which is a key component in a clinker cooler of production equipment in the cement industry. The main structure of the arc valve comprises a planetary cycloidal speed reducing motor, a crankshaft connecting rod transmission mechanism, a sensor, a travel switch, a shell, an inner cylinder and a valve plate.

Owner:马世中

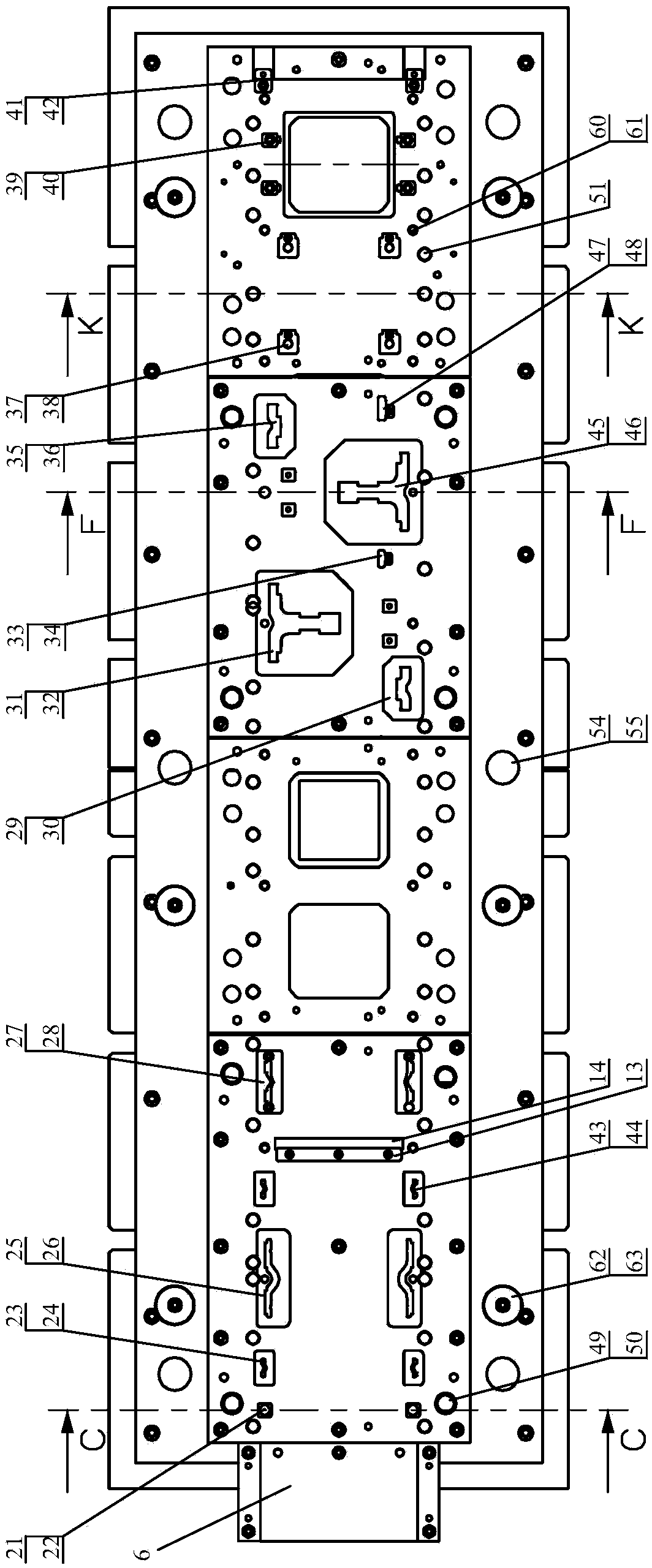

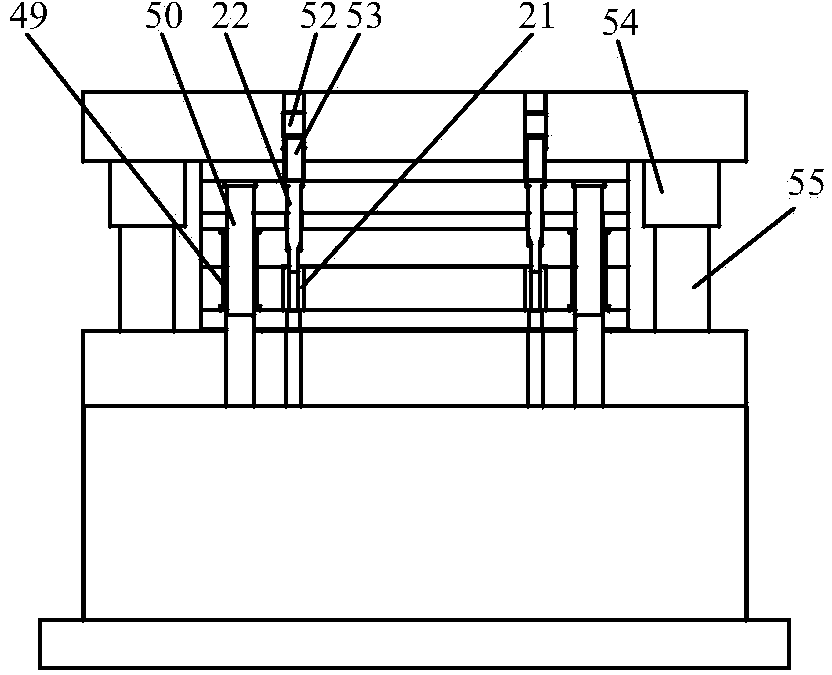

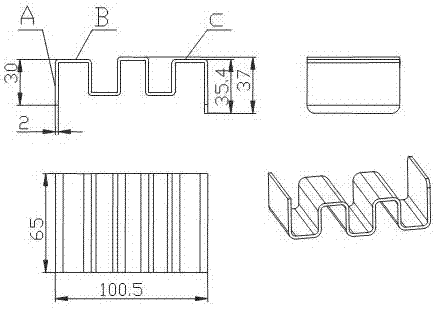

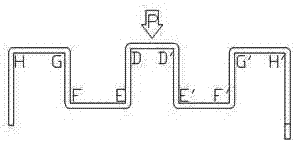

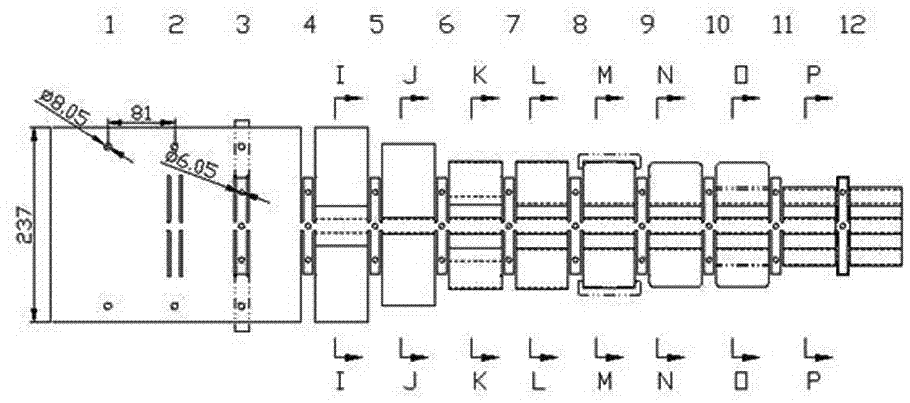

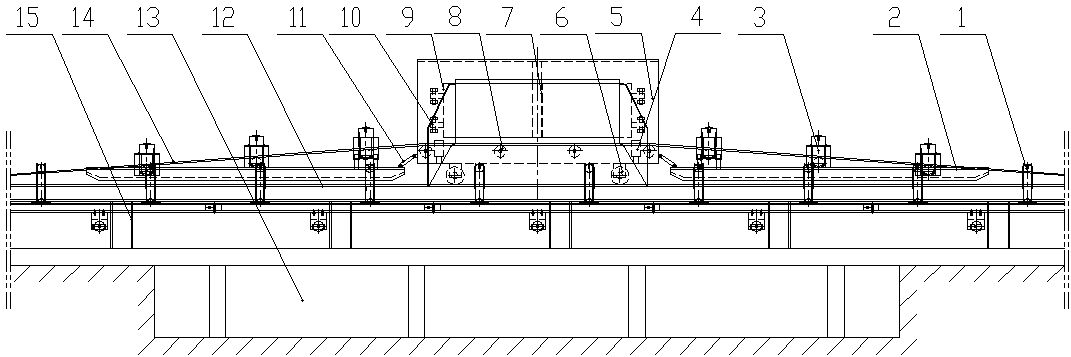

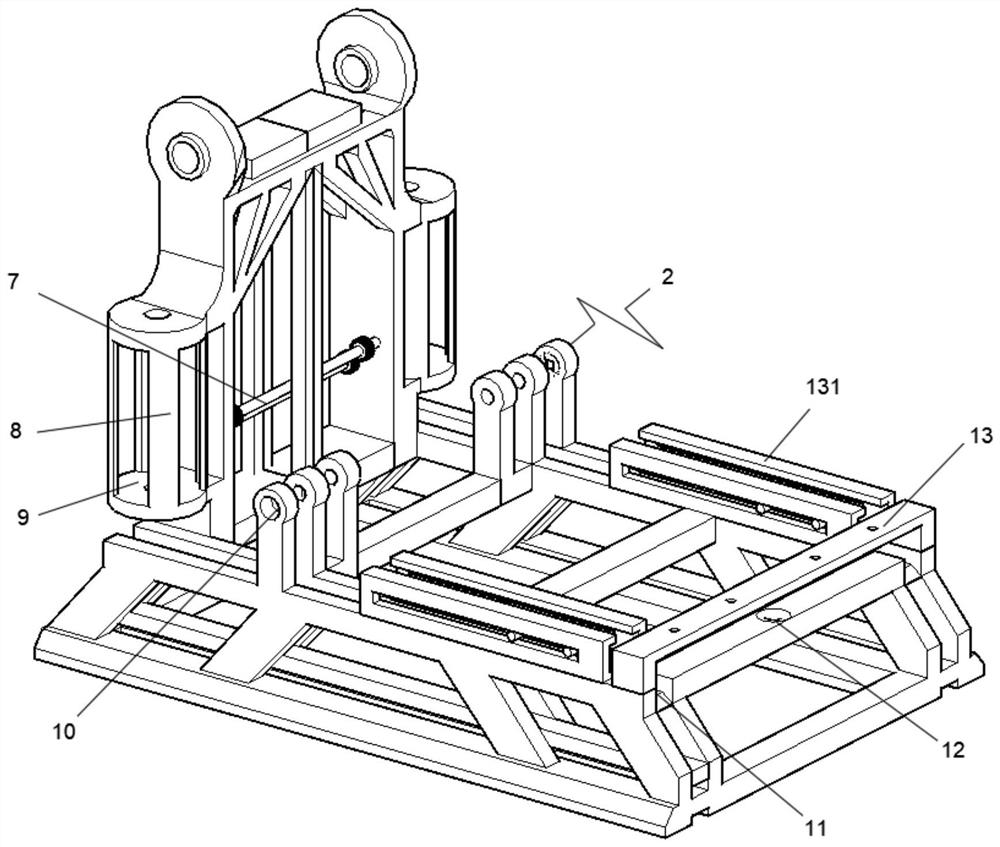

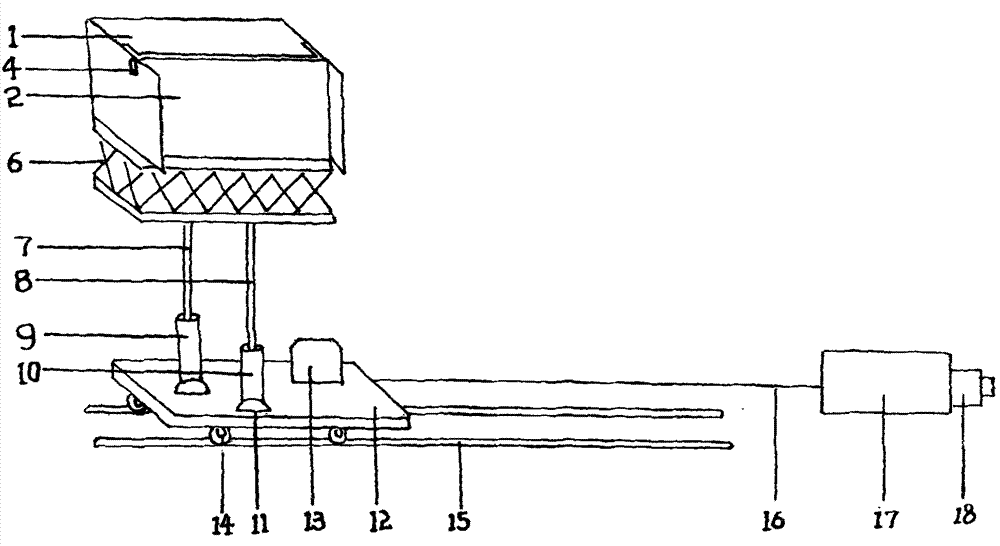

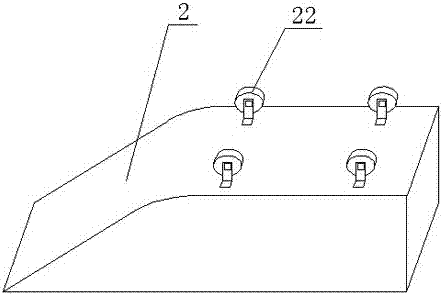

Connecting strengthening plate multi-station progressive die

InactiveCN106862388ARealize continuous automatic stampingGuaranteed StrengthShaping toolsPerforating toolsPunchingFolded form

The invention discloses a connecting strengthening plate multi-station progressive die. The connecting strengthening plate multi-station progressive die comprises a jigger pin assembly I, a jigger pin assembly II, an equal-height sleeve assembly, an ejector block, an upper spring, a spring fixing base, a jacking block assembly, a lower die base, a retainer plate, a punching male die, a lower spring, an elastic lifting pin assembly, a pilot pin, a male die fixing plate, a stripper plate and a sliding guide column assembly. The invention meanwhile discloses a connecting strengthening plate machining technology. The technology comprises 12 work steps including the first step of auxiliary hole punching, the second step of long hole punching, the third step of trimming, the fourth step of upward edge folding and pre-bending by 45 degrees, the fifth step of downward edge folding, the sixth step of downward edge folding and pre-bending by 45 degrees, the seventh step of upward edge folding, the eighth step of end cutting, the ninth step of no operation, the tenth step of downward edge folding, the eleventh step of no operation and the twelfth step of cutting out. According to the connecting strengthening plate multi-station progressive die, die positioning, floating jacking, unloading and discharging are good, the manufacturability is good, and the requirement for high-speed and precision production can be met; and the production efficiency is improved, the production cost is reduced, the product precision requirement is guaranteed, and benefits are obvious by the adoption of the progressive die form for multi-time edge folding formed components.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

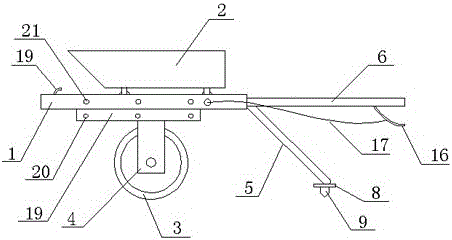

Hand-push type delivery device applied to construction sites

ActiveCN105882697AAchieve fixationConsistent insertion depthSupporting partsHand carts with one axisTerrainBuilding construction

Owner:CHINA MCC5 GROUP CORP

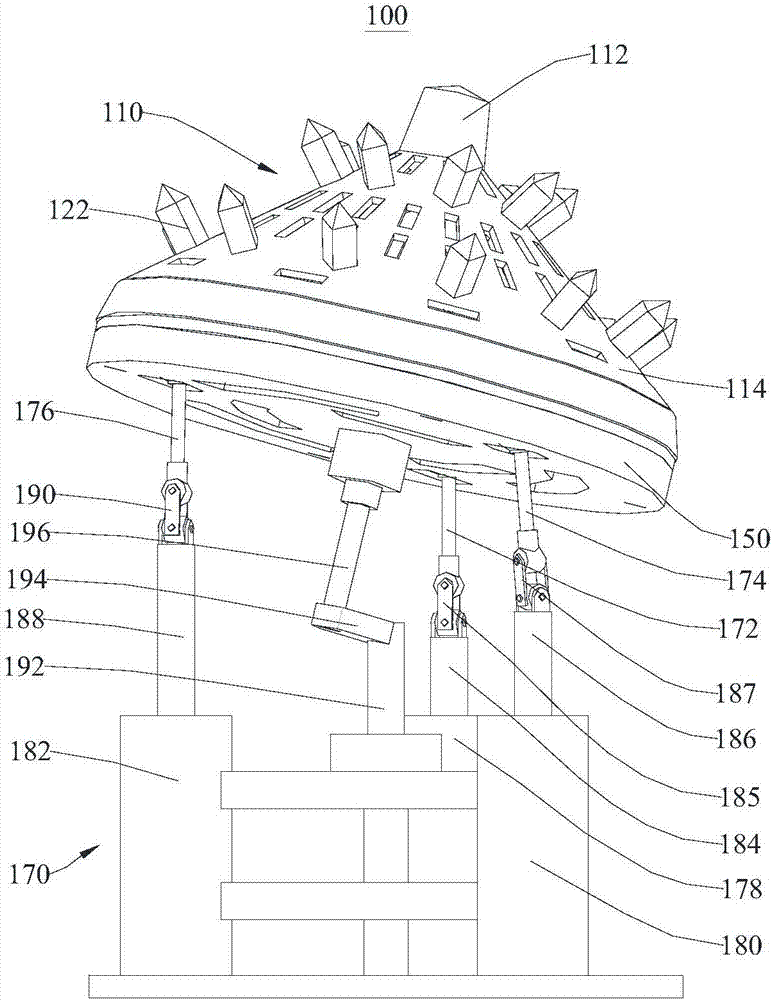

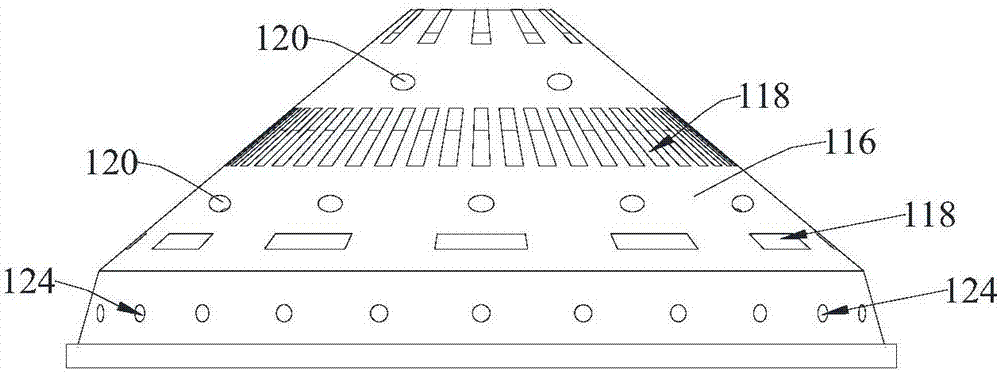

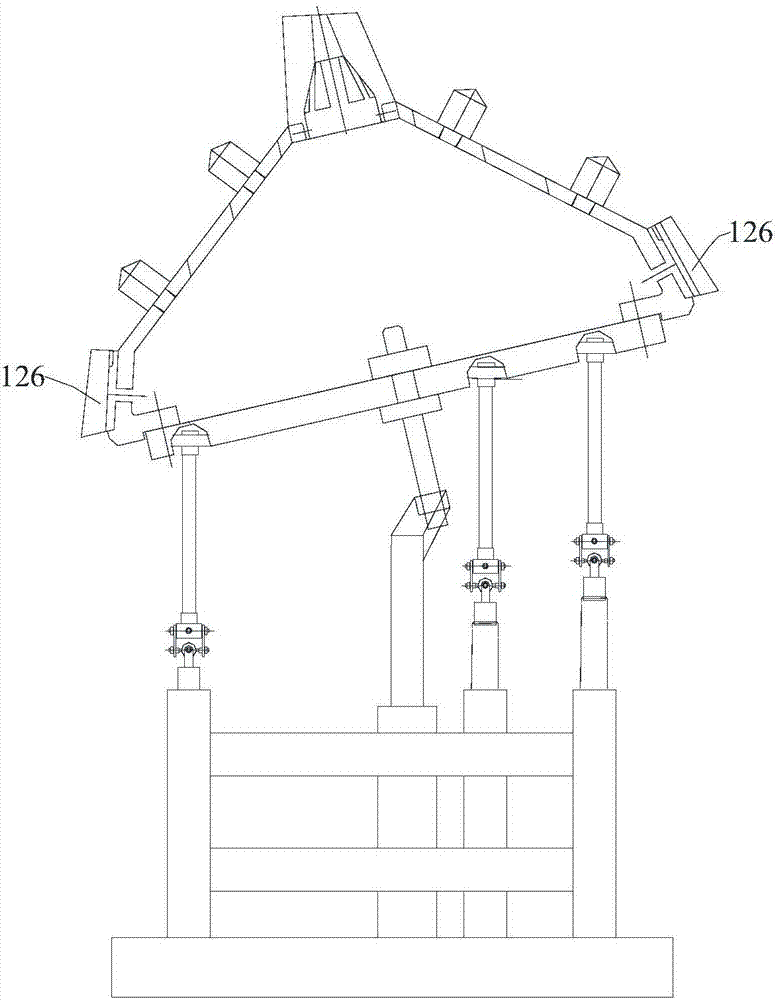

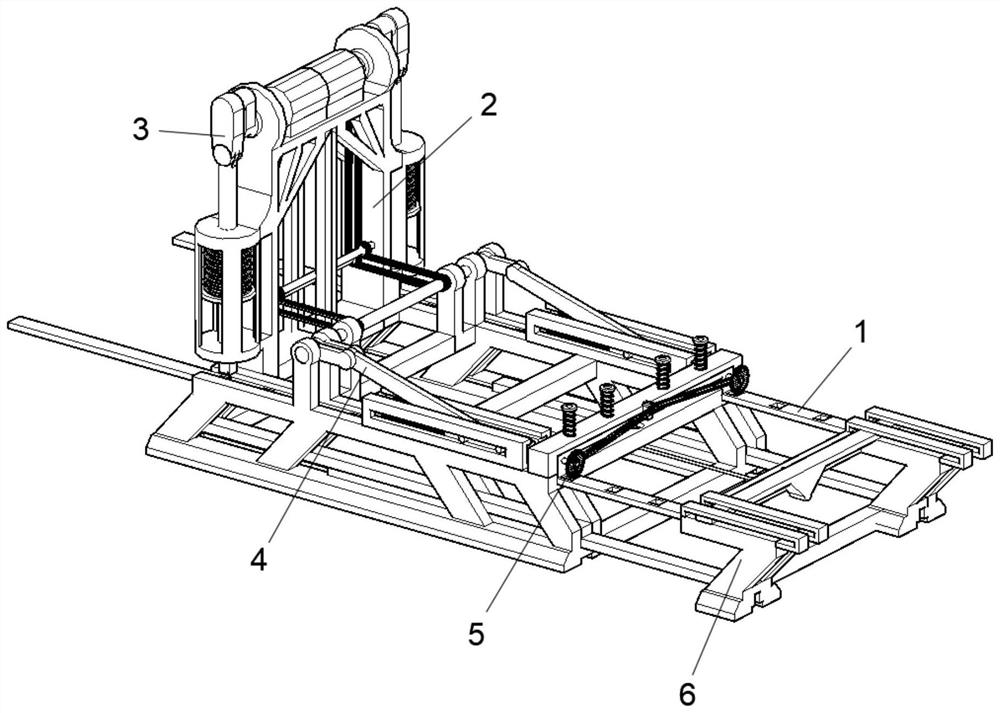

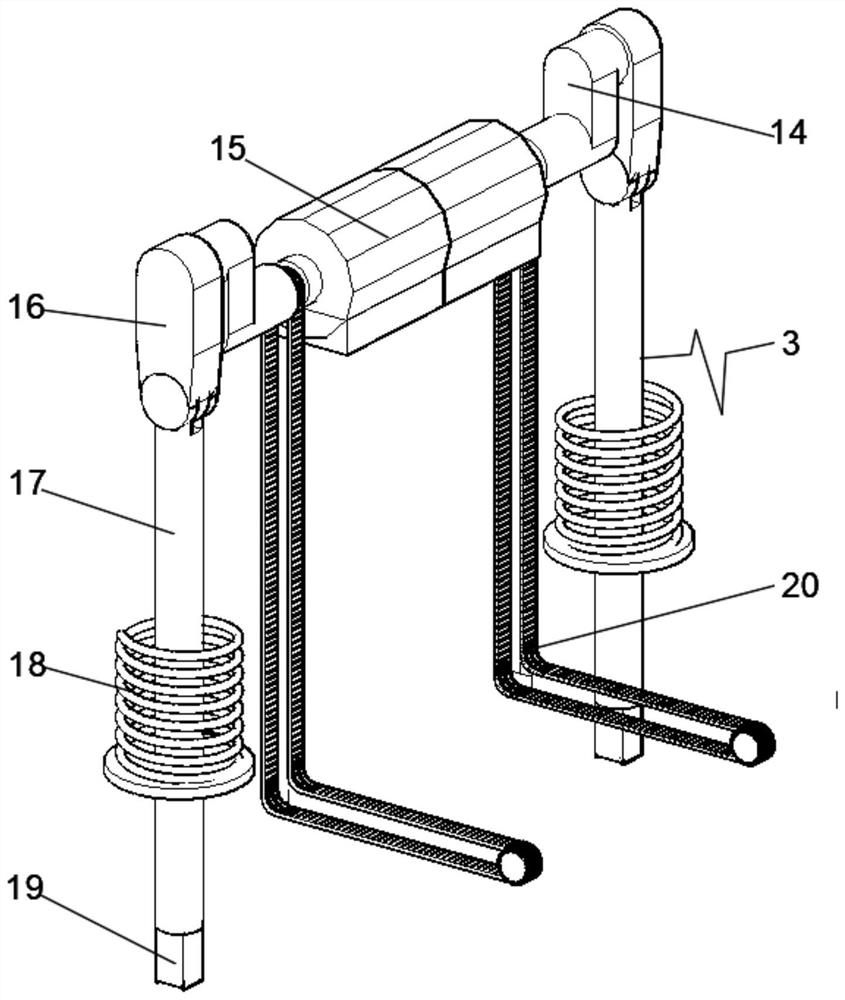

Unloading device, incinerator and sludge treatment method

ActiveCN107504498AImprove load-bearing stabilityImprove incineration efficiencyIncinerator apparatusSludgeEngineering

The invention provides an unloading device, an incinerator and a sludge treatment method and relates to the technical field of environment protection. The unloading device comprises a supporting assembly and a supporting plate, which are connected with each other. The supporting assembly comprises a first supporting rod and a second supporting rod. The first supporting rod and the second supporting rod are in rotary connection with the supporting plate. The first supporting rod can be retracted in the length direction of the first supporting rod so that the supporting plate can rotate in the vertical direction. The second supporting rod can be retracted in the length direction of the second supporting rod so that the supporting plate can rotate in the vertical direction. A first through hole is formed in the supporting plate. The two supporting rods are used for commonly supporting the supporting plate so that the bearing stability of the unloading device is improved. The two supporting rods are in retractable matching, so that the supporting plate can rotate in the vertical direction to form jolted swinging; and meanwhile, materials on the supporting plate are turned and loosened by utilizing the swinging, so that the materials are in sufficient contact with the air and the incineration efficiency of the materials is improved. The invention further provides the incinerator and the sludge treatment method.

Owner:YANCHENG HAIDENENG WATER TREATMENT ENVIRONMENTAL ENG

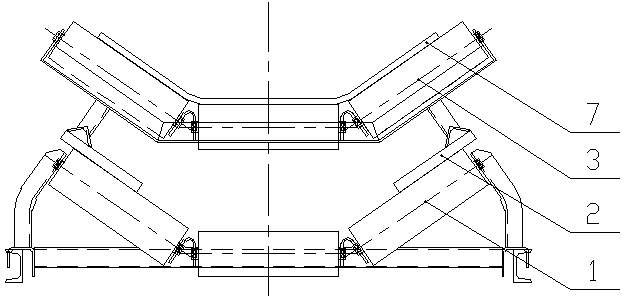

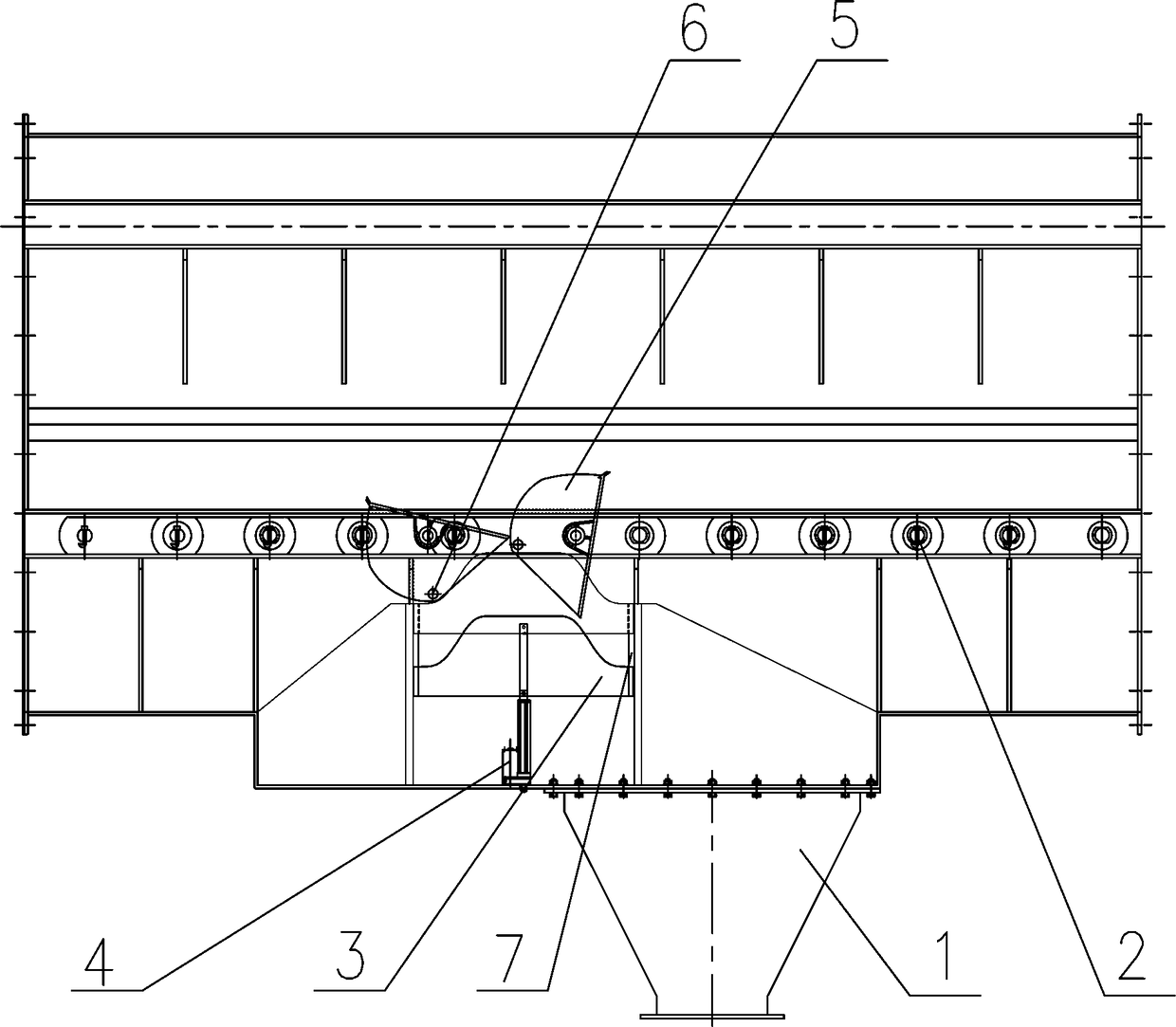

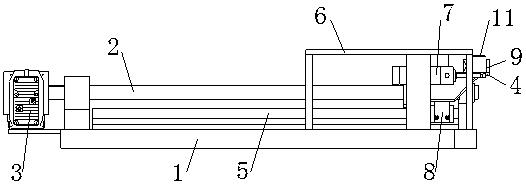

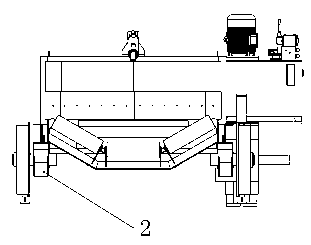

Sliding boot type moving discharging device for belt conveyor

ActiveCN107934485AGuaranteed to be straightReduce wearConveyor partsControl engineeringControl theory

The invention provides a sliding boot type moving discharging device for a belt conveyor. The device comprises a movable discharging hopper and sliding boot devices, the sliding boot devices are arranged on the two sides of the movable discharging hopper, each sliding boot device comprises a sliding boot plate and a sliding boot carrier roller set, the movable discharging hopper is connected withthe sliding boot plates, the sliding boot plates are matched with the groove-shaped carrier roller sets, the groove-shaped carrier roller sets are arranged on a frame body, and the sliding boot carrier roller sets are arranged on the sliding boot plates. The device has the beneficial effects that reciprocated moving can be achieved, multi-point or any-point discharging is achieved, the structure is simple, flexibility is high, arrangement is convenient, equipment investment cost can be effectively saved, the two ends of the movable discharging hopper are hinged, the device can adapt to belt conveyor angle changes, and discharging stability is ensured.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

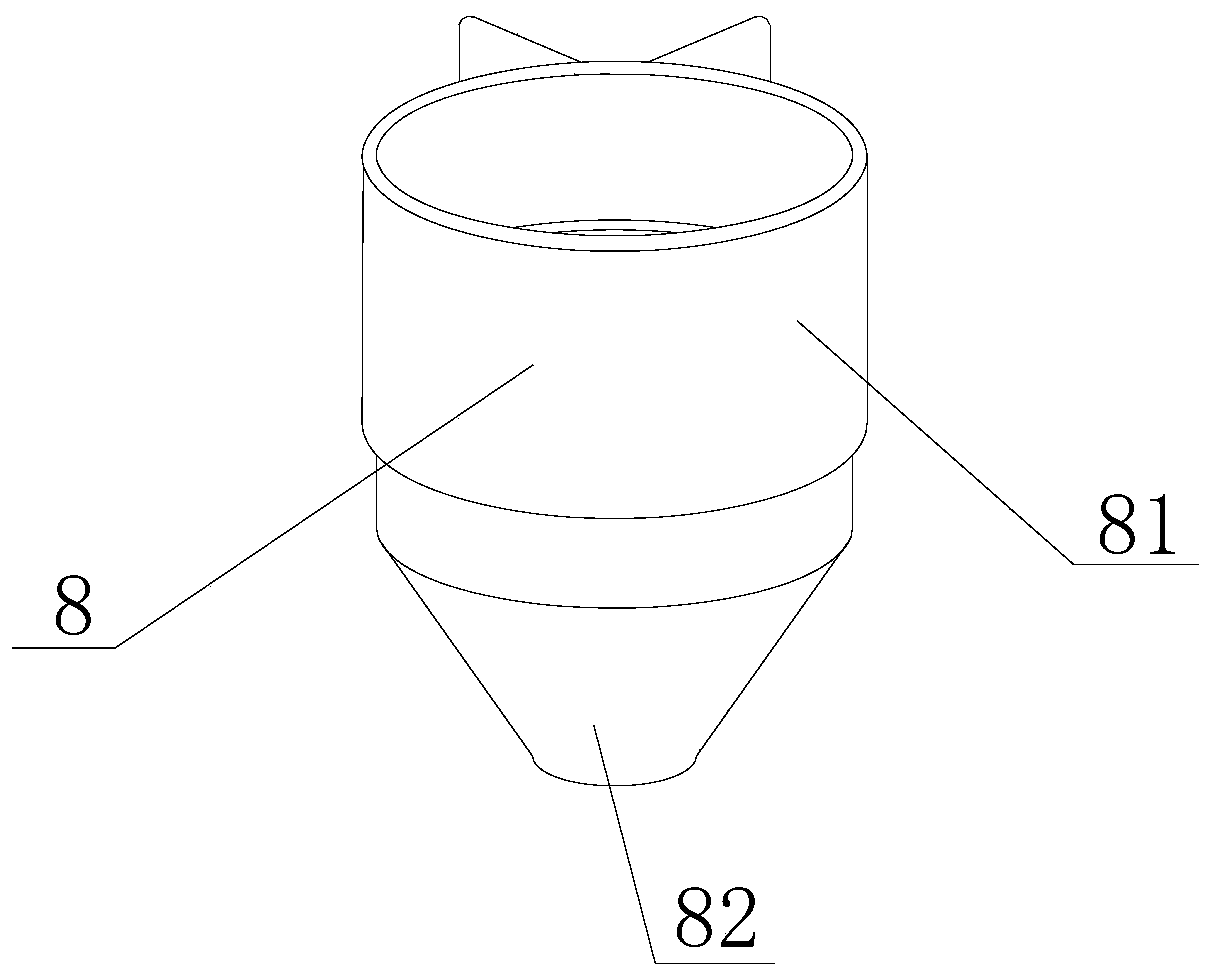

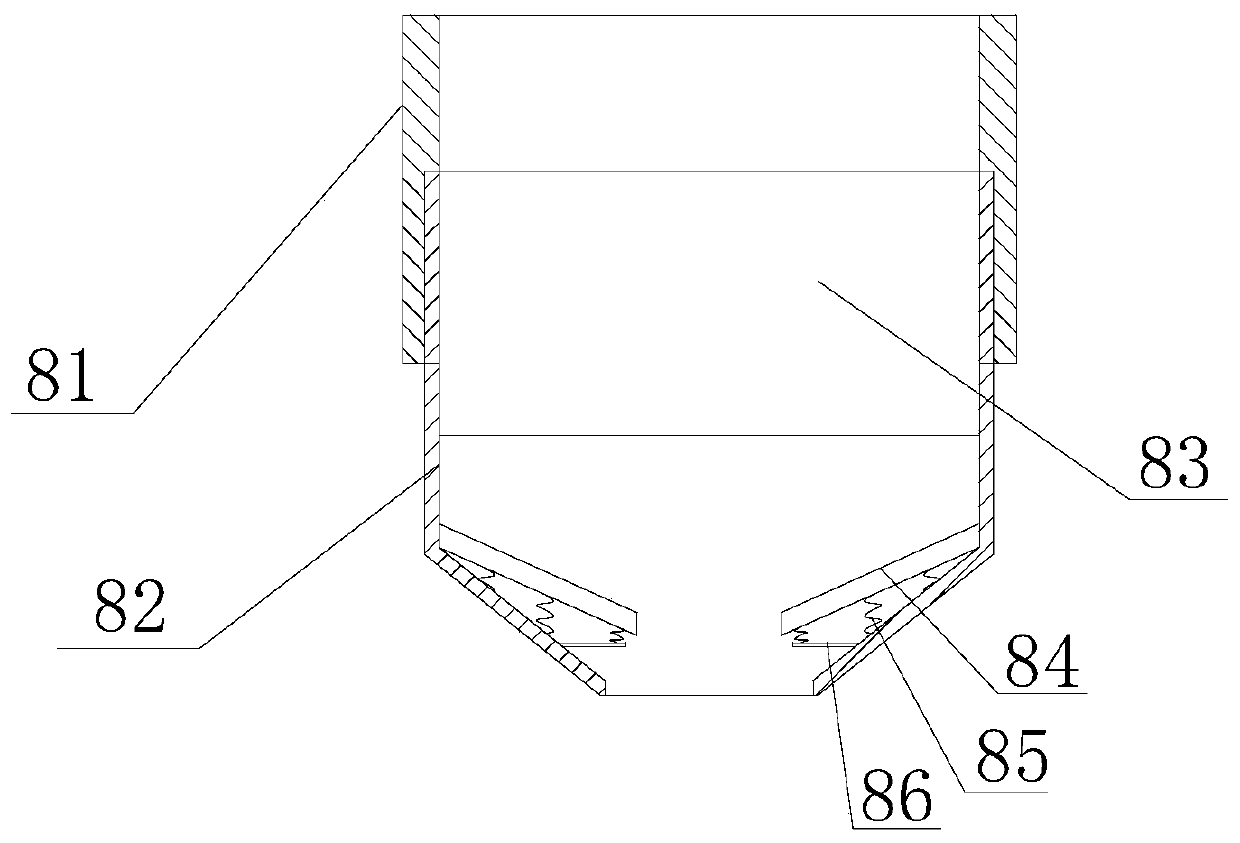

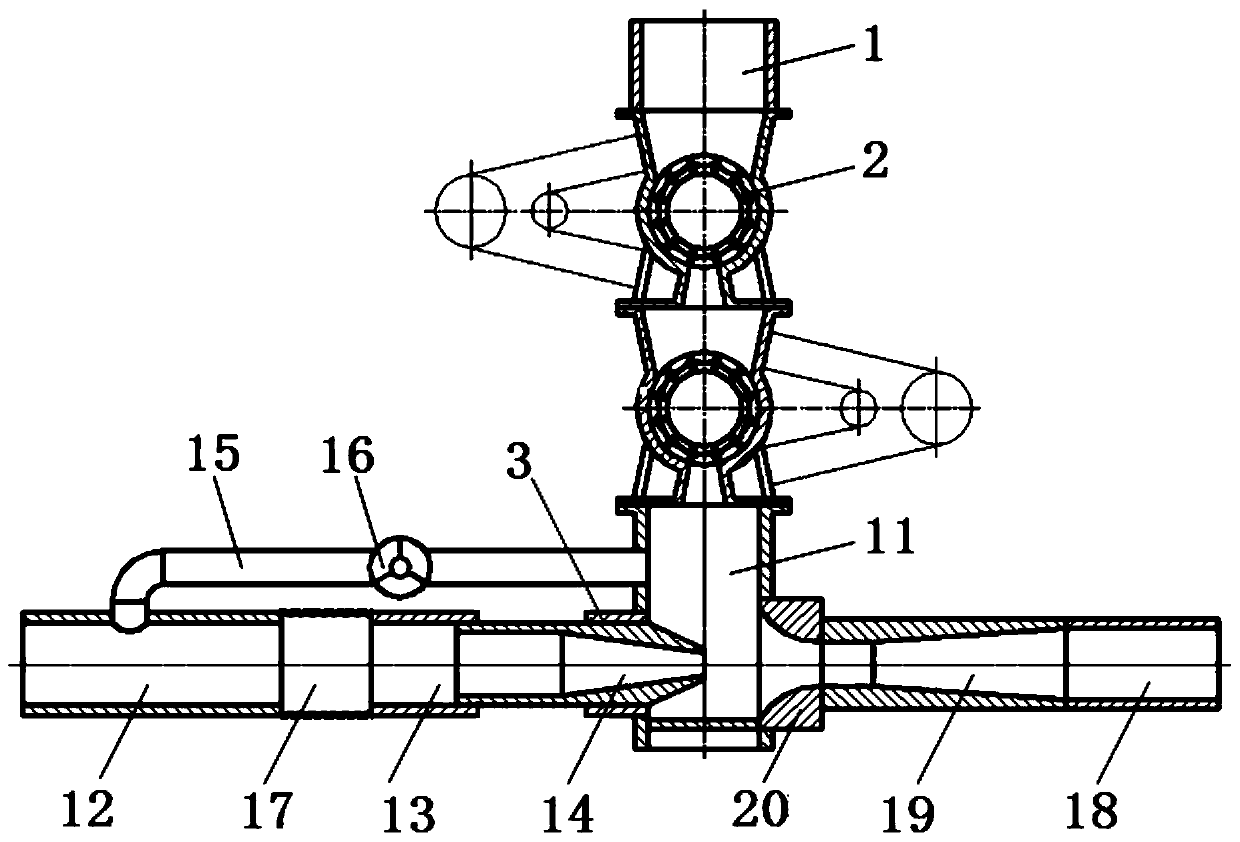

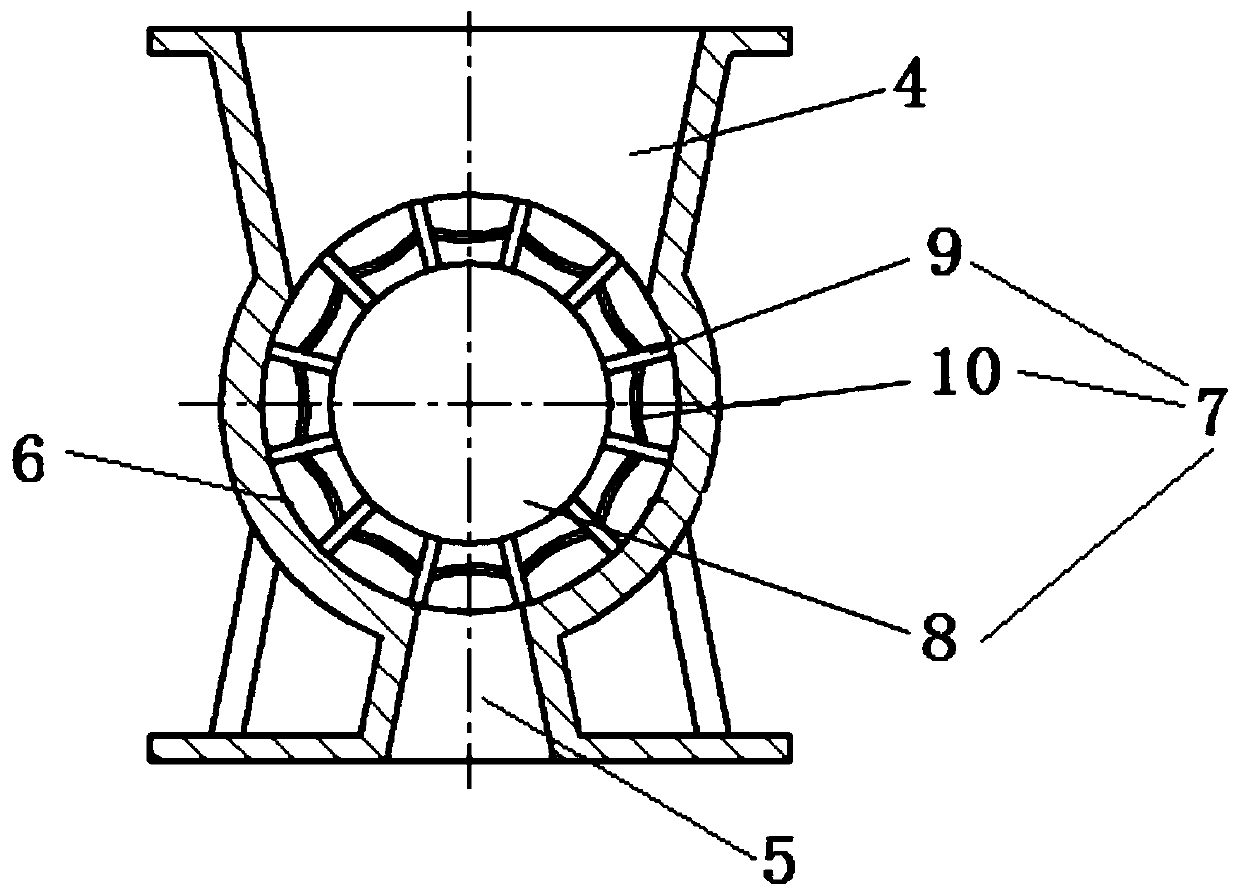

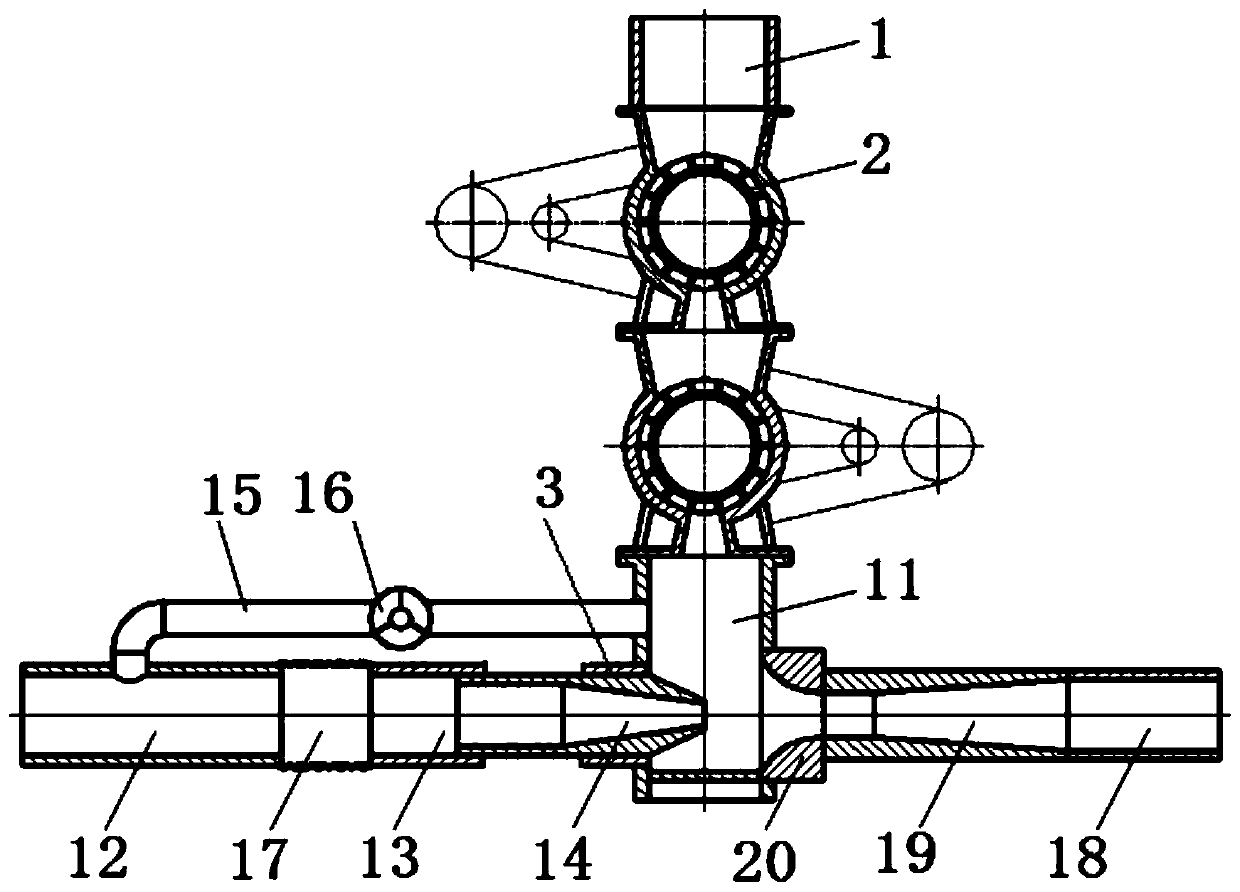

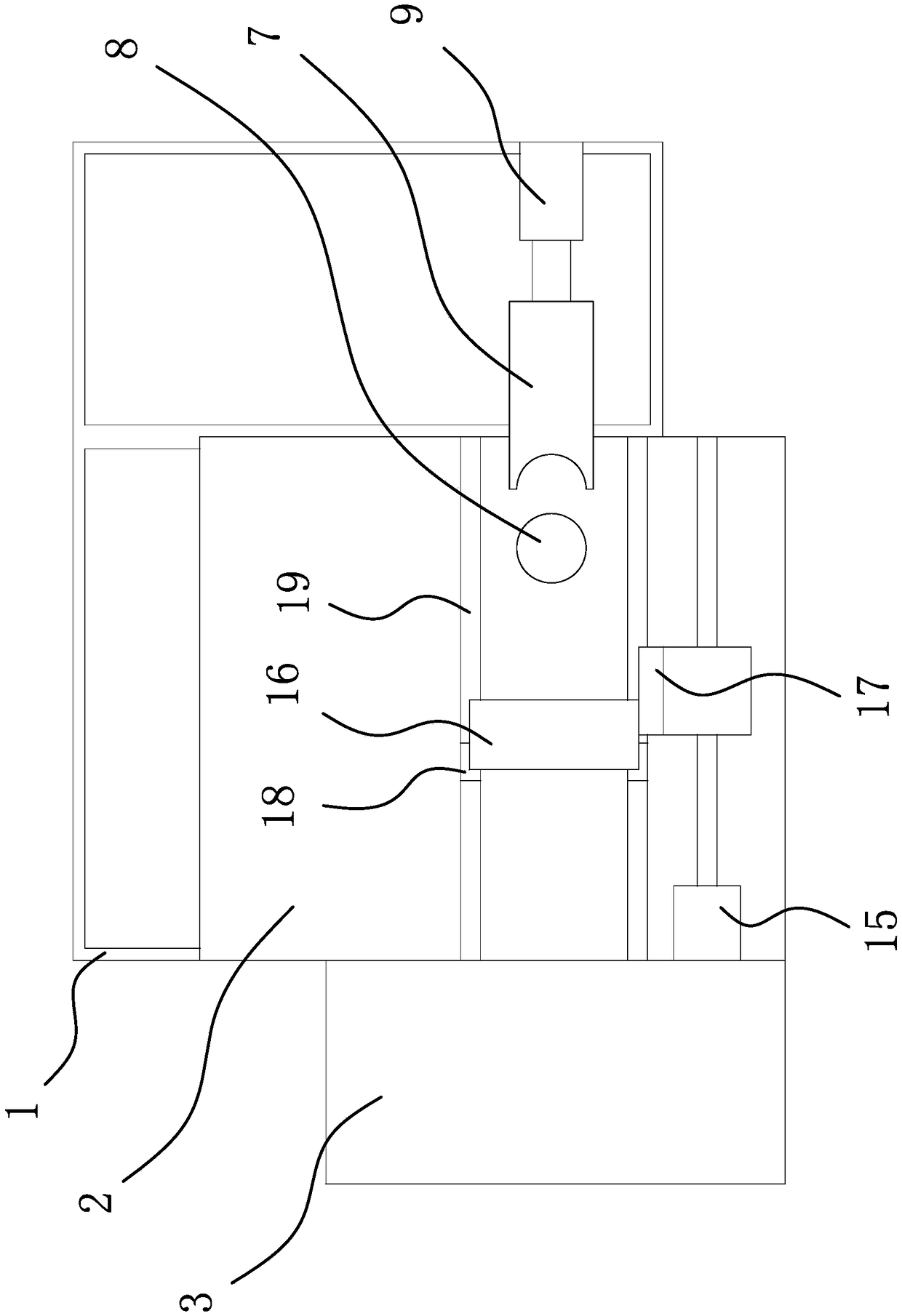

A Feeder Coupled with Double Discharge Valve and Venturi Tube

The invention relates to a feeder with coupled double discharging valves and Venturi tubes. The feeder comprises a mixing room with an open top and a sealed bottom, two discharging valves stacked up and down are mounted on the top of the mixing room, upper and lower ends of the discharging valves are both provided with openings, wherein the upper opening end is a charging port in the shape of an inverted circular truncated cone, the lower opening end is a discharging port in the shape of a circular truncated cone, a rotary chamber is arranged between the charging port and the discharging port, an impeller is rotatably arranged in the rotary chamber, the impeller comprises a horizontally arranged discharging shaft rotatably connected to the rotary chamber, blades circumferentially and uniformly arranged on the discharging shaft, and bottom plates arranged between every two adjacent blades, a material cavity for filling materials is formed between each bottom plate and the corresponding two adjacent blades, the material cavities filled with materials are sealed with the side walls of the rotary chamber, the first Venturi tube and the second Venturi tube are tightly connected on the side wall of the mixing room, and the axes of the first Venturi tube and the second Venturi tube are collinear.

Owner:CHINA COAL RES INST CCRI ENERGY SAVING TECH CO LTD +1

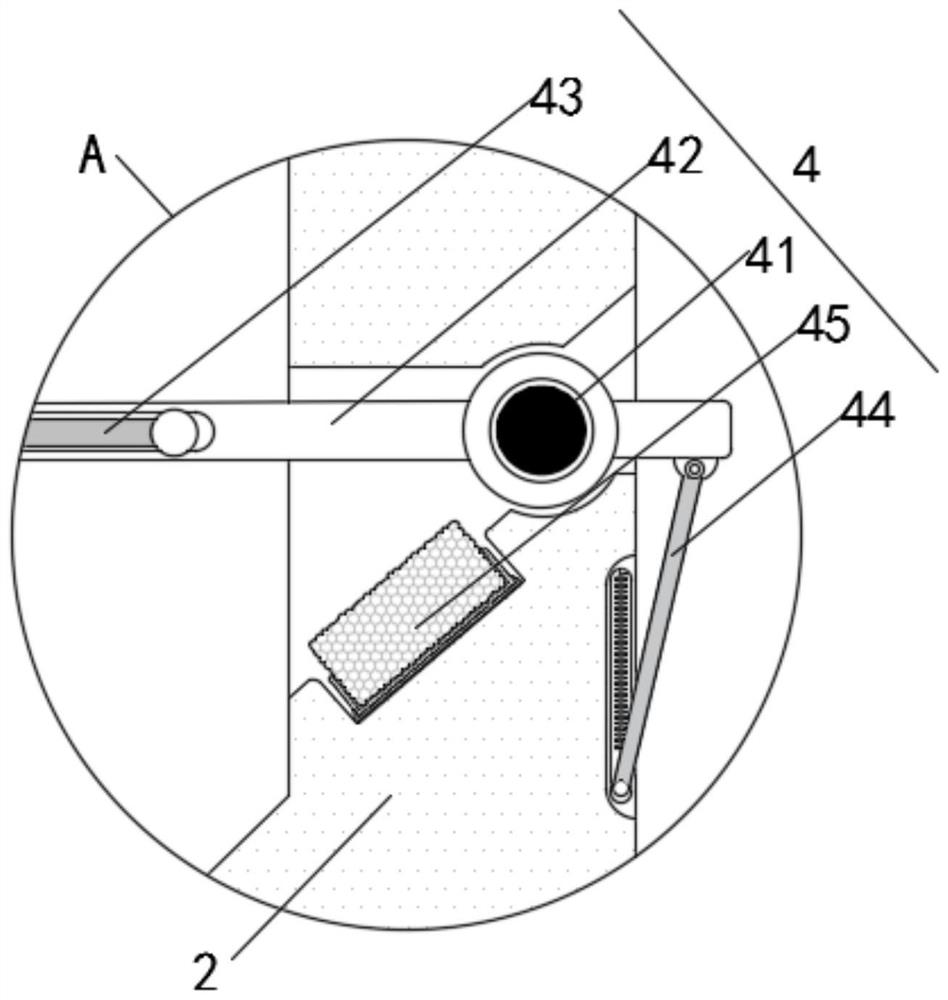

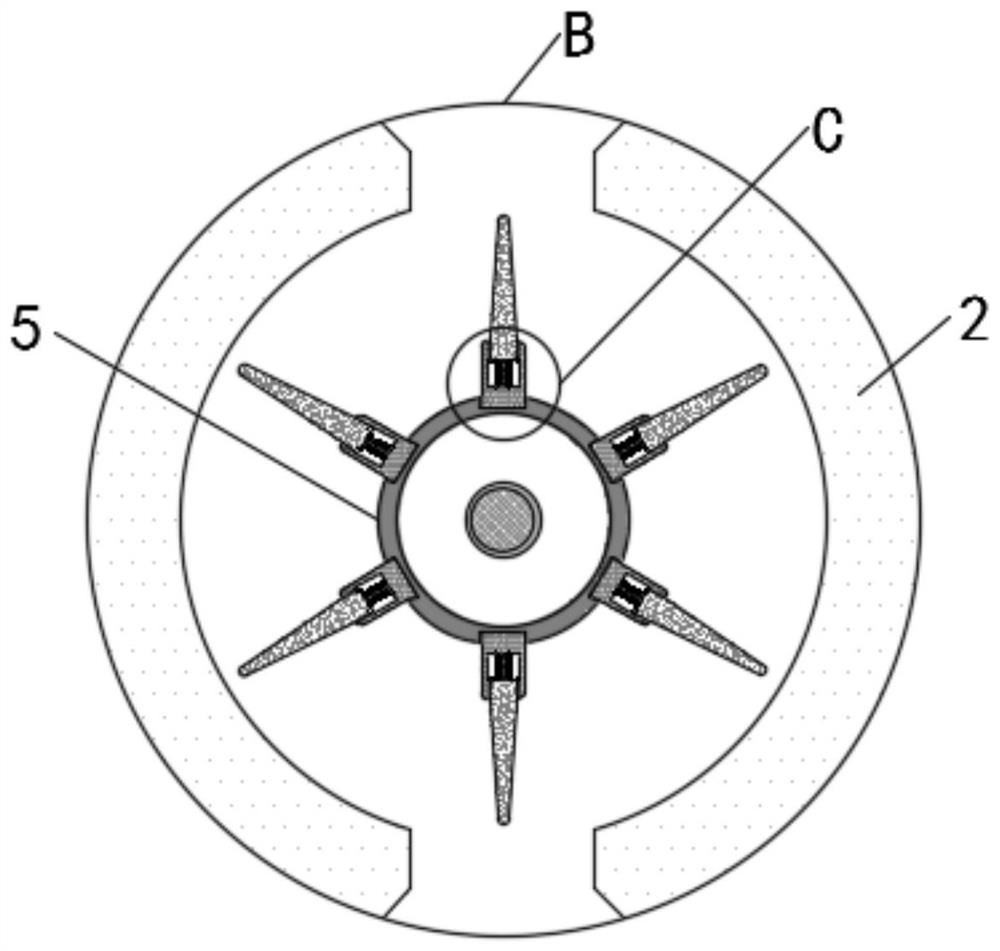

Ring unloading mechanism in sealing ring feeding device

The invention provides a ring unloading mechanism in a sealing ring feeding device, and belongs to the technical field of luggage accessory assembly. According to the ring unloading mechanism in the sealing ring feeding device, a feeding device comprises a supporting frame, one end of the supporting frame is provided with a material taking table, and the other end of the supporting frame is provided with a workbench the device, the ring unloading mechanism in the sealing ring feeding device is characterized by comprising a material carrying column, the material carrying column is cylindrical,a round groove is formed in the lower end of the material carrying column, a round table is fixed at the bottom of the round groove, the wide face of the round table is fixedly connected with the bottom of the round groove, and the narrow face of the round table faces downwards, gaps for clamping the sealing ring are formed between the conical surface of the round table and the side wall of the round groove, a plurality of discharging holes communicated with the gaps are vertically formed in the material carrying column, the discharging holes are formed in the discharging holes, discharging pieces are arranged in the discharging holes, and a telescopic structure capable of driving the discharging pieces to perform telescopic movement is arranged between the material taking table and the upper end of the material carrying column. The ring unloading mechanism has the advantages that the sealing ring can be rapidly and accurately detached.

Owner:浙江御匠箱包股份有限公司

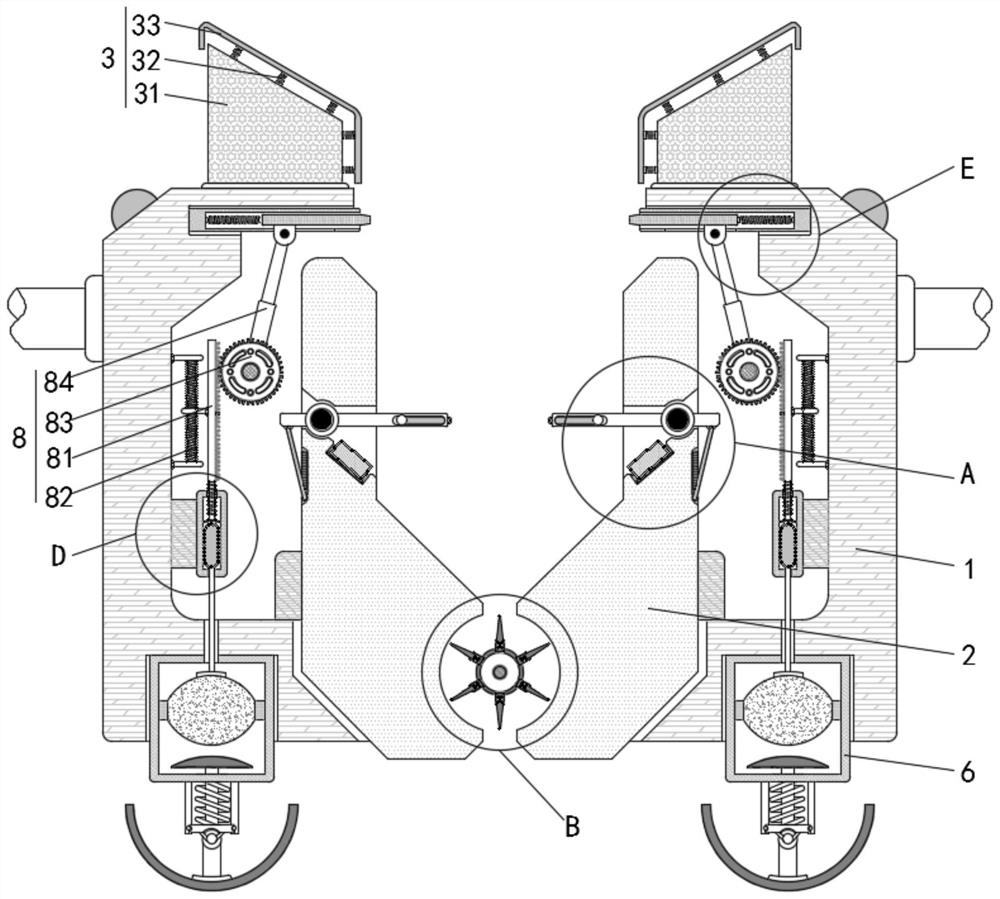

Equipment for filling according to depth of collapse pit of decommissioned uranium mine

PendingCN113187541AAvoid OverloadingReduce labor intensityMaterial fill-upVibration suppression adjustmentsMining engineeringGear wheel

The invention provides equipment for filling according to the depth of a collapse pit of a decommissioned uranium mine. The equipment comprises a main body; a fixed part is fixedly mounted in the main body; a limiting push assembly is fixedly mounted on the lower side of the main body; air bag linkage assemblies are fixedly mounted on the left and right sides of the inner wall of the main body; the upper side of each air bag linkage assembly is connected with a gear linkage assembly; the upper end of each gear linkage assembly is movably connected with a material limiting assembly; and each material limiting assembly comprises a mounting block. According to the equipment for filling according to the depth of the collapse pit of the decommissioned uranium mine, along with continuous adding and filling of fillers, when the collapse pit of the decommissioned uranium mine is gradually filled with the fillers, the upper ends of movable push rods are used for driving material limiting baffles to move relatively, and the material limiting baffles are prompted to be in a mutual closed state, so that the equipment achieves the purpose of automatic closing when the collapse pit of the uranium mine is filled up; and the equipment does not need the assistance of manual supervision, so that the labor intensity of workers is reduced, and the practicability of the equipment is further improved.

Owner:江西核工业建设有限公司

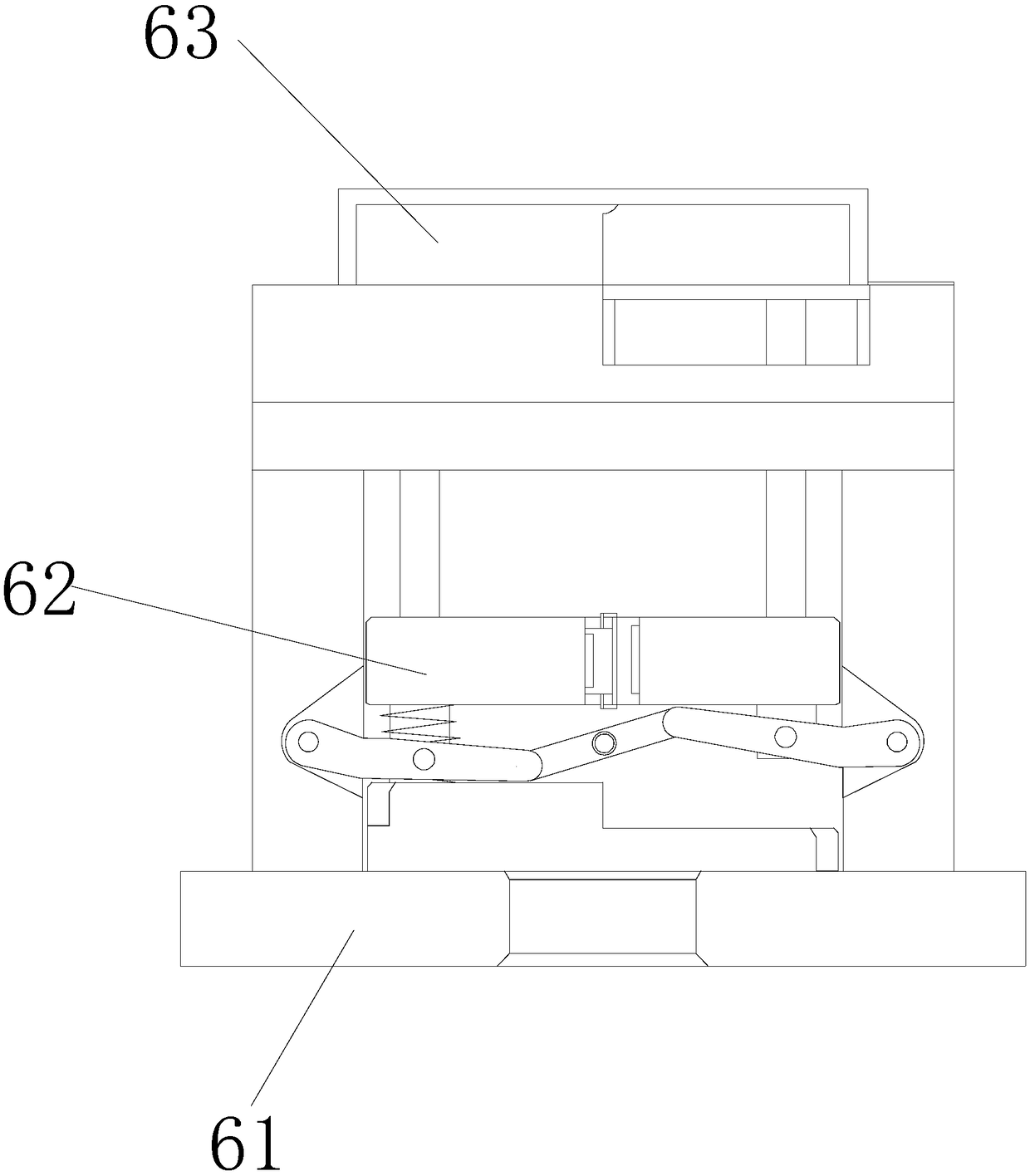

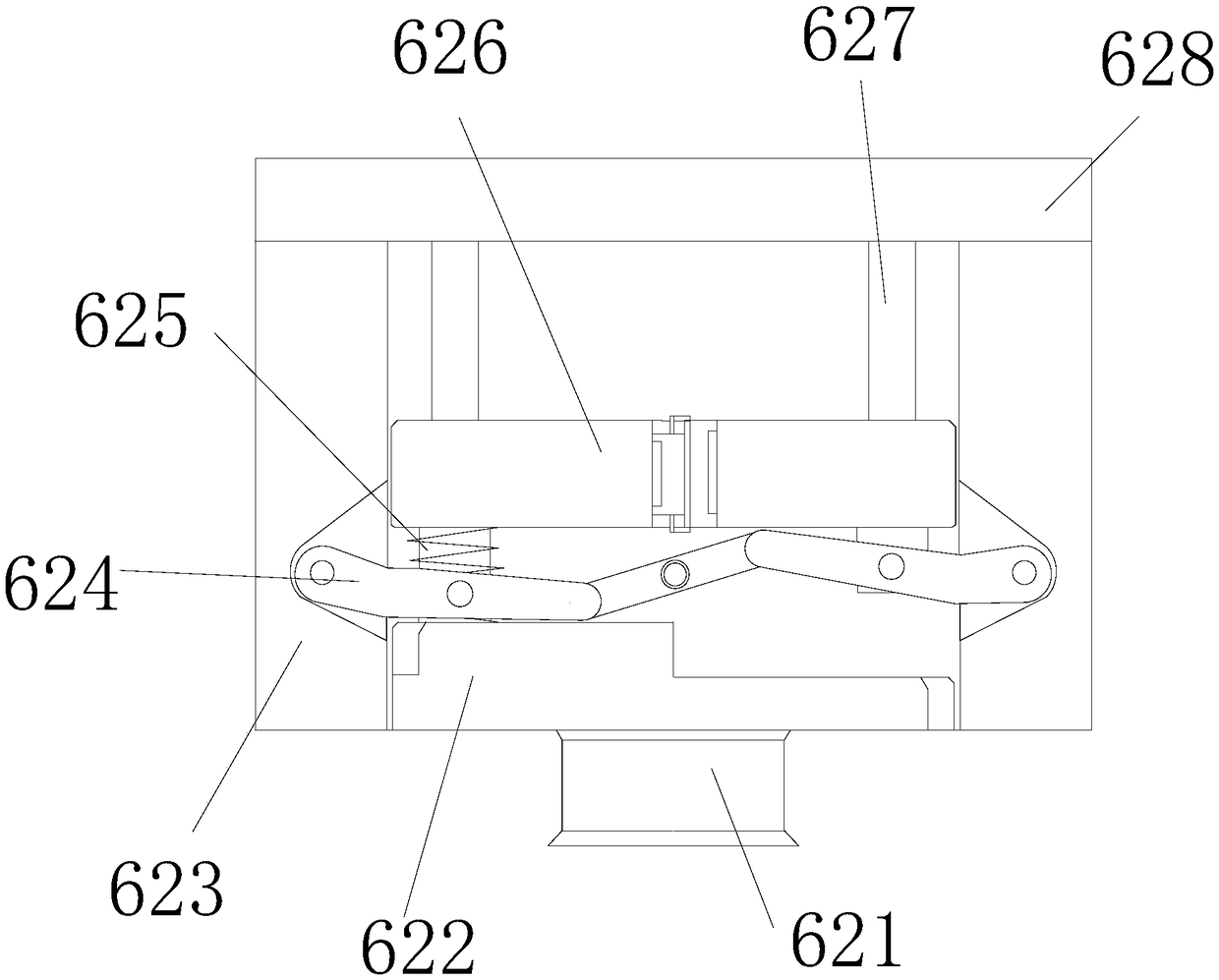

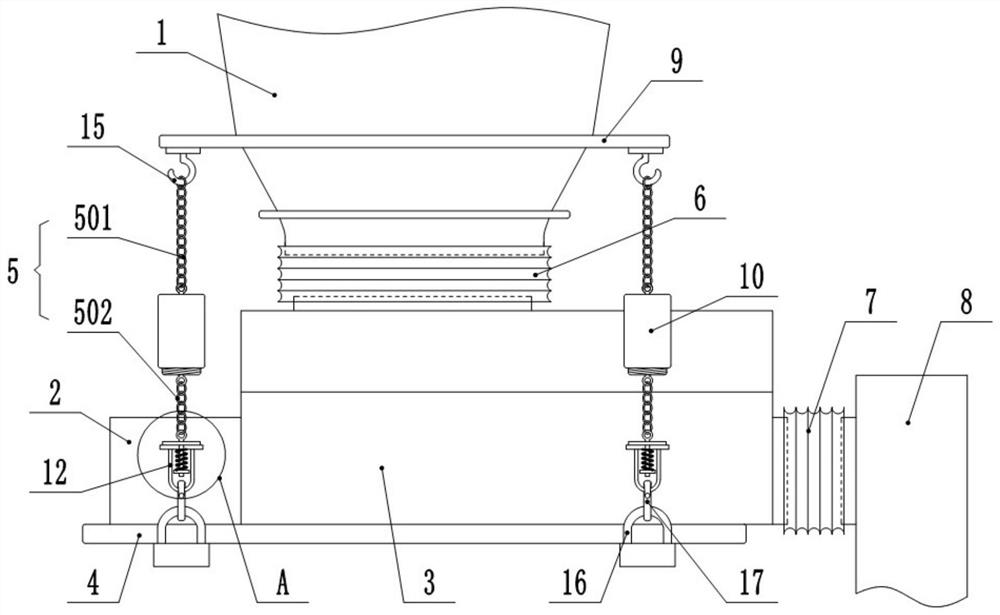

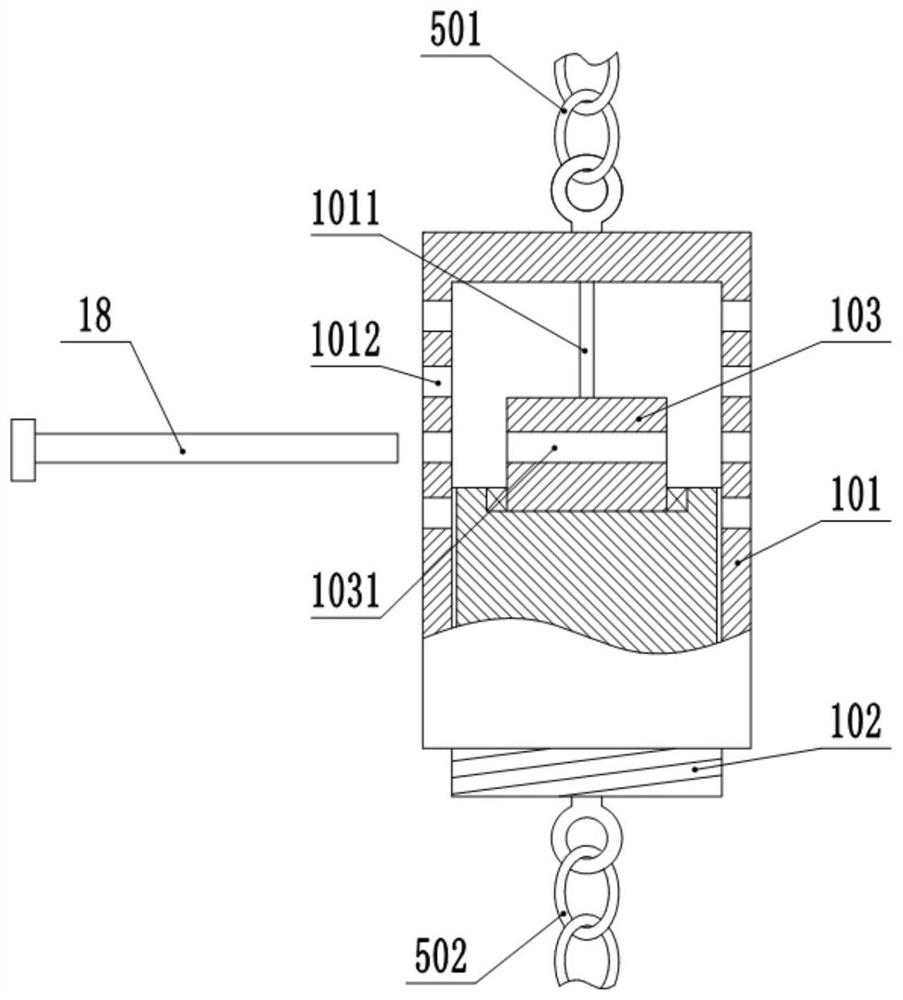

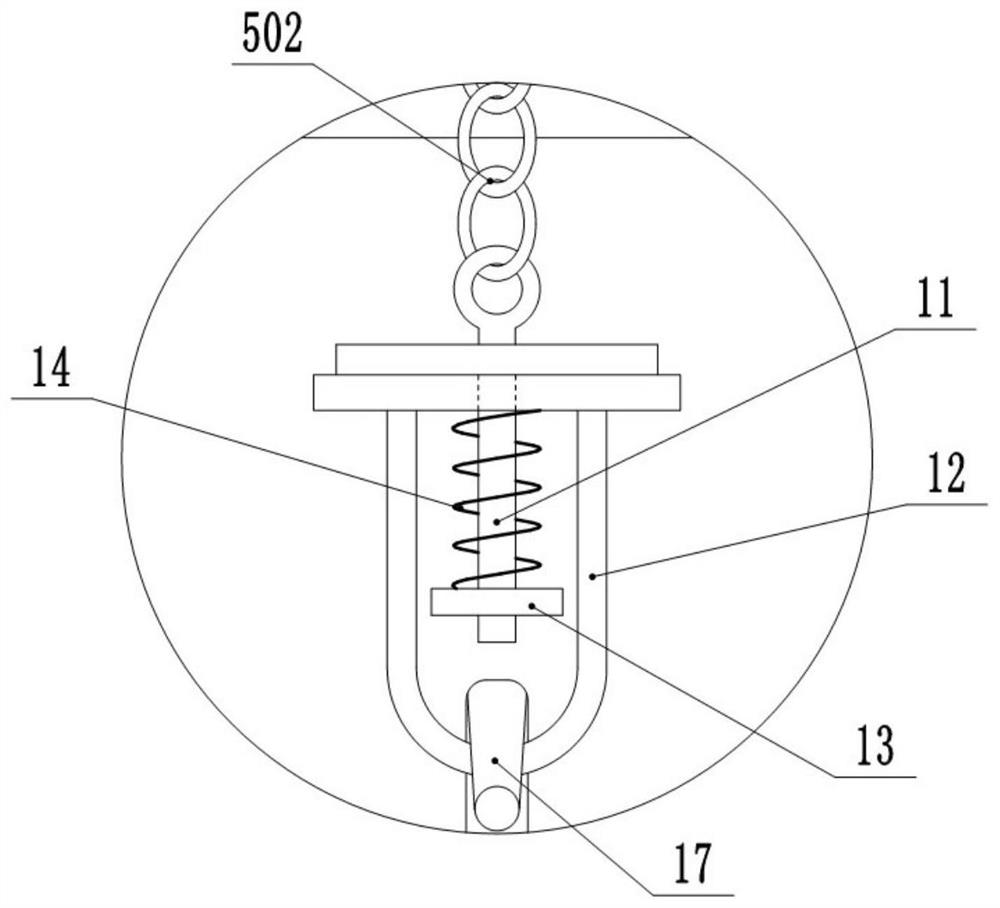

Anti-blocking raw material unloading system

ActiveCN112429417AAvoid cloggingGuaranteed not to leakBio-packagingLarge containersElectric machineryChain link

The invention relates to the field of material conveying, and discloses an anti-blocking raw material unloading system. The anti-blocking raw material unloading system comprises an anti-blocking mechanism mounted below a material tank in a suspended manner, wherein the anti-blocking mechanism comprises a vibration motor, a horizontal box, a mounting frame and a plurality of cable chains; the vibration motor is used for driving the horizontal box to vibrate; the horizontal box is provided with a feeding port and a discharging port; the feeding port communicates with a discharging port of the material tank through a soft connecting pipe I; a mounting plate is arranged at the bottom of the material tank and connected with the mounting frame through the cable chains; each cable chain is provided with an adjusting assembly used for adjusting the length of the cable chain; each adjusting assembly comprises an adjusting barrel and an adjusting threaded rod in threaded connection into the adjusting barrel; and each cable chain comprises an upper-section chain connected with the corresponding adjusting barrel and a lower-section chain connected with the corresponding adjusting threaded rod.According to the anti-blocking raw material unloading system, raw materials are vibrated through the vibration motor, the discharging port of the material tank is prevented from being blocked, and stable unloading is achieved. In addition, the inclination angle of the horizontal box can be changed through the adjusting assemblies, and therefore the unloading speed is changed.

Owner:CHONGQING YUHU GLASS

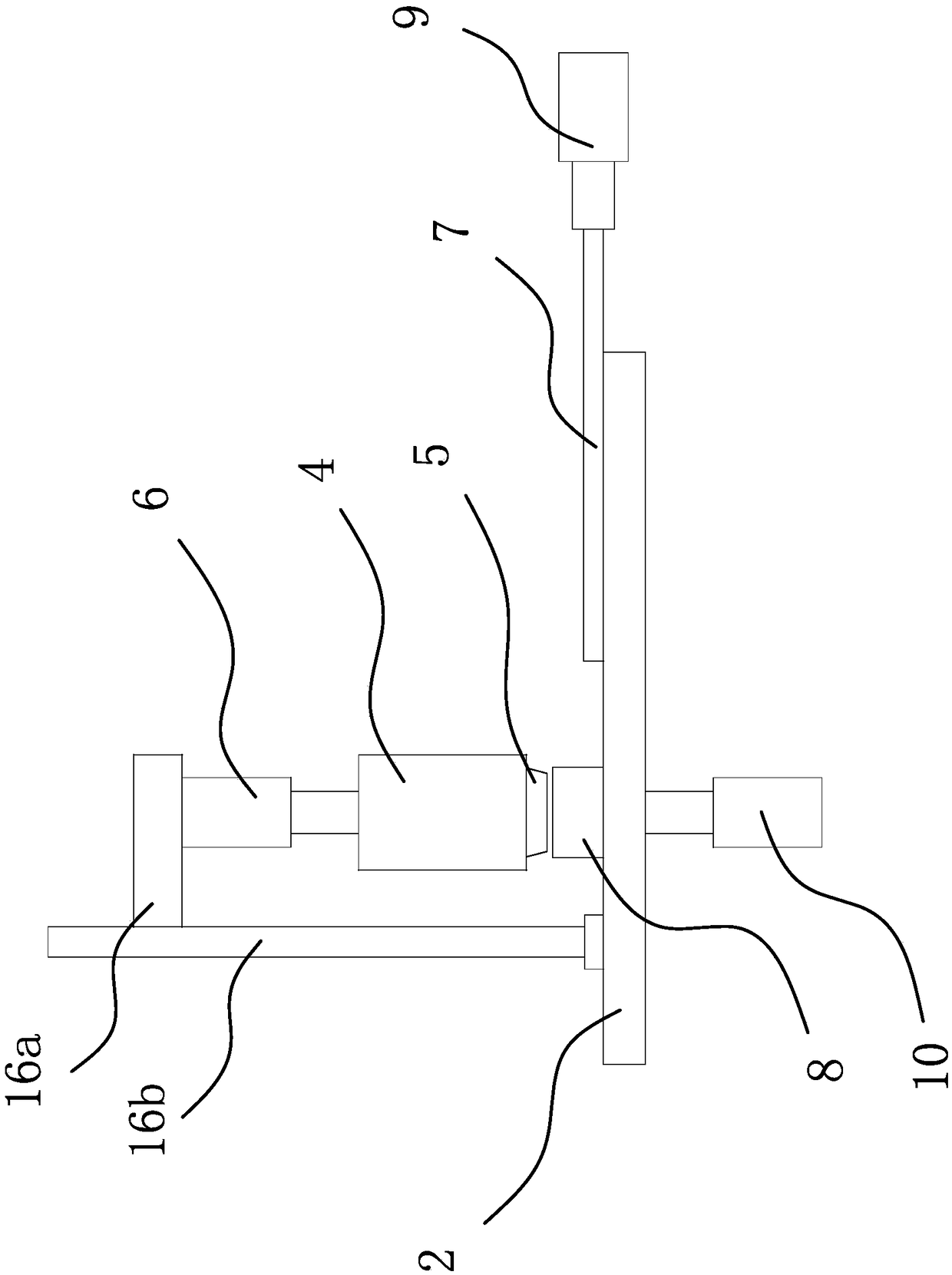

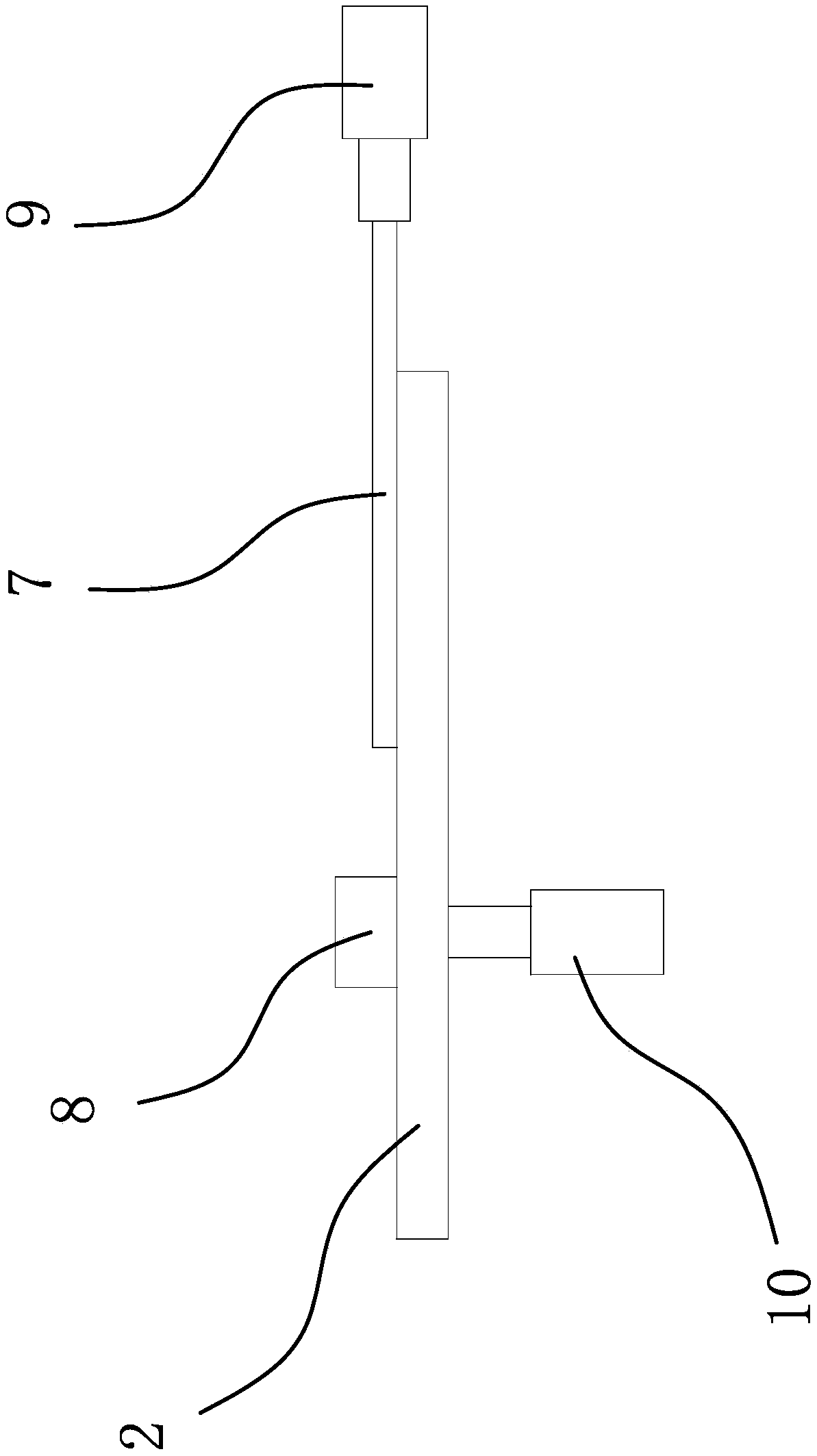

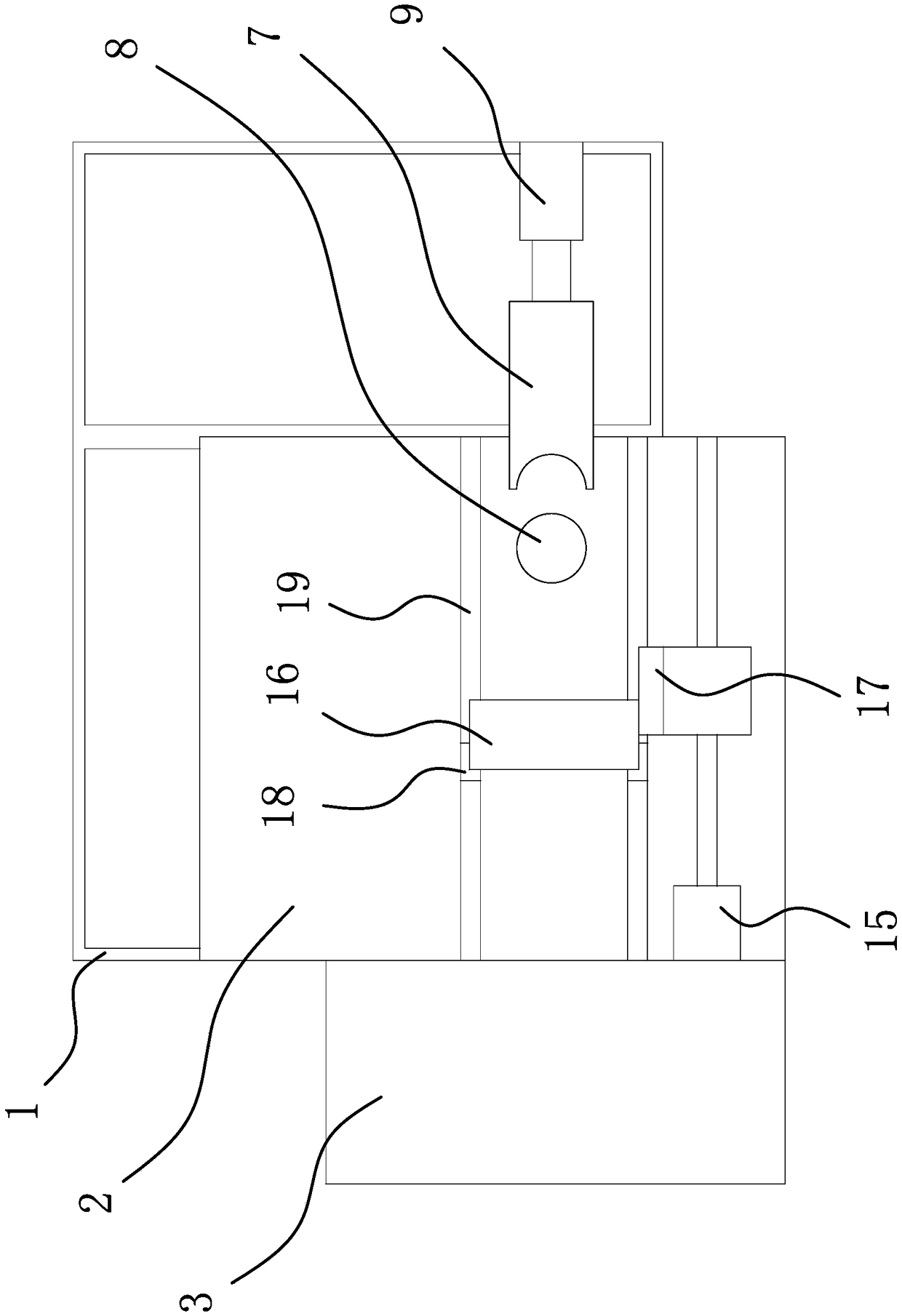

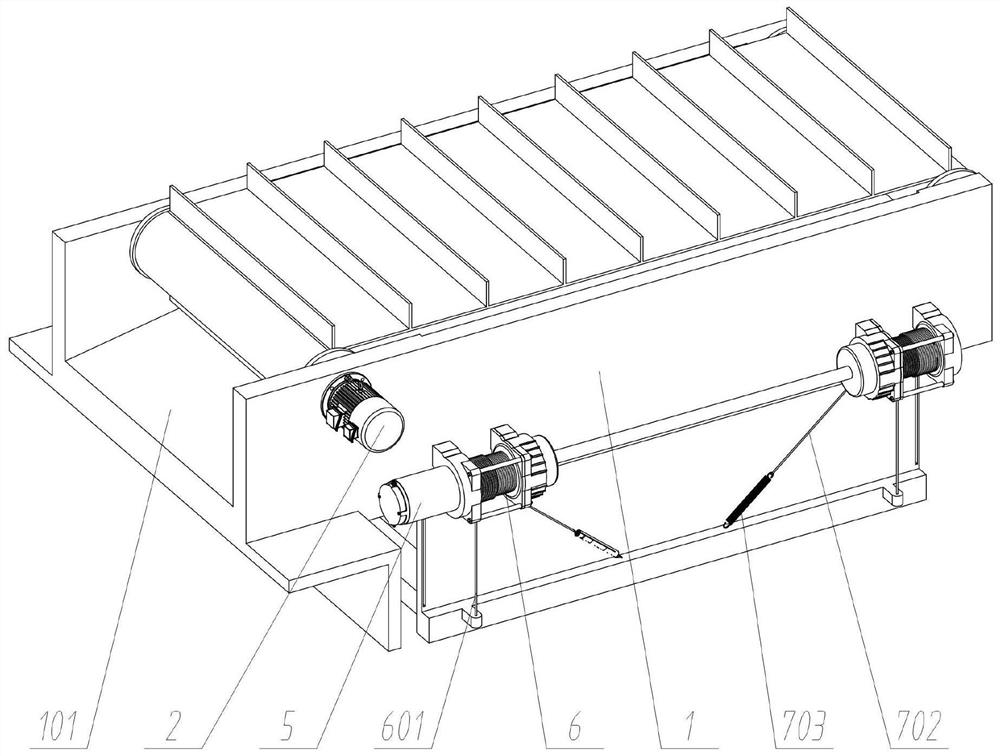

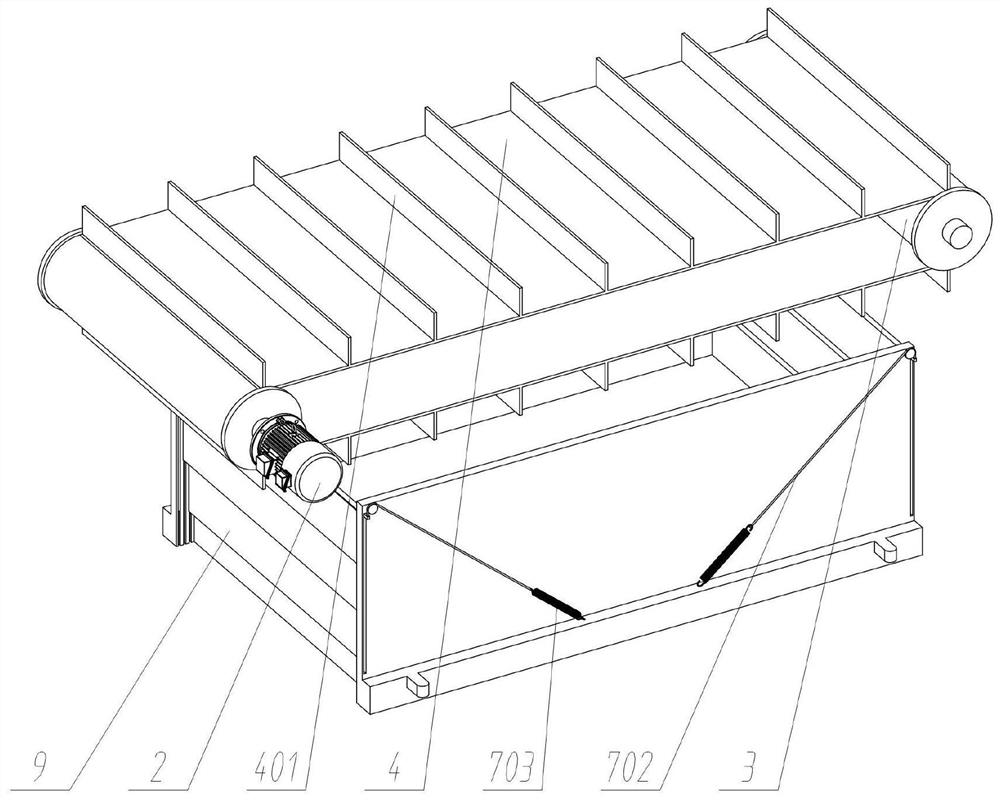

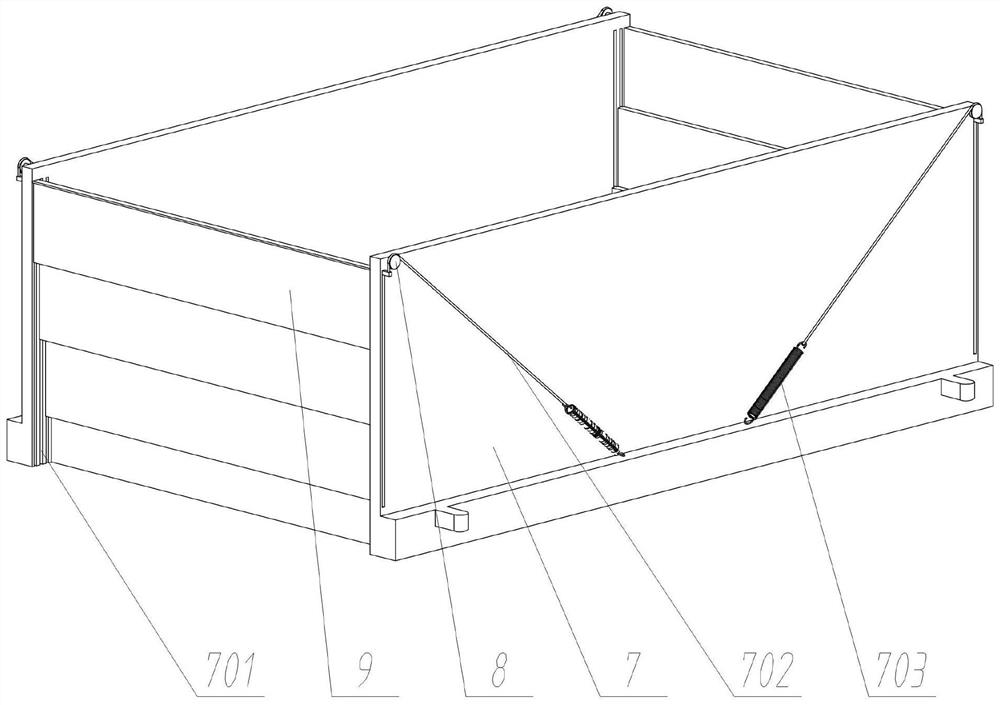

Automatic steel bar unloading mechanism

PendingCN113247526AStable unloadingSafe and reliable noiseConveyor partsRoller-waysRebarManufacturing engineering

The invention belongs to the technical field of steel bar unloading, and discloses an automatic steel bar unloading mechanism which comprises an unloading support; a transverse conveying device which is mounted on the unloading support and is used for conveying steel bars; an aligning and supporting device which is located on the unloading support and used for aligning, positioning and supporting the steel bars conveyed by the transverse conveying device; and a longitudinal unloading device which is arranged on the unloading support and is used for unloading the steel bars supported by the aligning and supporting device. According to the automatic steel bar unloading mechanism, the steel bars are conveyed to the aligning and supporting device through the transverse conveying device and are aligned through the aligning and supporting device, then the steel bars are sheared by a matched shearing mechanism, the aligned steel bars are supported through the aligning and supporting device after shearing is finished, and then the steel bars are unloaded to the outside of the unloading support through the longitudinal unloading device and conveyed to a receiving bin or other equipment. The automatic steel bar unloading mechanism can achieve smooth unloading of the steel bars, and is safe, reliable and low in generated noise.

Owner:TJK MACHINERY TIANJIN

Equal-distance machining and synchronous conveying and cutting integrated device for strip-shaped plates

InactiveCN114102143AAct as a limiting supportPlay a buffer roleOther manufacturing equipments/toolsMetal working apparatusPunchingStructural engineering

The invention discloses a strip-shaped plate equidistant machining and synchronous conveying and cutting integrated device which comprises a strip-shaped plate, a machining bed, a machining device, a conveying device, a cutting device and a guiding device, the machining device is fixedly installed on the upper surface of the edge of one end of the machining bed, and the conveying device is rotatably installed on the edge of the center of the top of one end of the machining bed; the cutting device is slidably mounted on the edge of the top of one end of the machining bed, the guiding device is slidably mounted on one end face of the machining bed, and the strip-shaped plates are symmetrically slidably inserted into the edges of the two sides of the end face of the machining bed. The strip-shaped plates are conveyed through the conveying device, it can be guaranteed that the machining bed conducts cooperative punching on the strip-shaped plates, it can be guaranteed that the cutting device conducts equidistant cutting on the strip-shaped plates, continuous machining on the strip-shaped plates is facilitated, and automatic discharging can be achieved.

Owner:王德龙

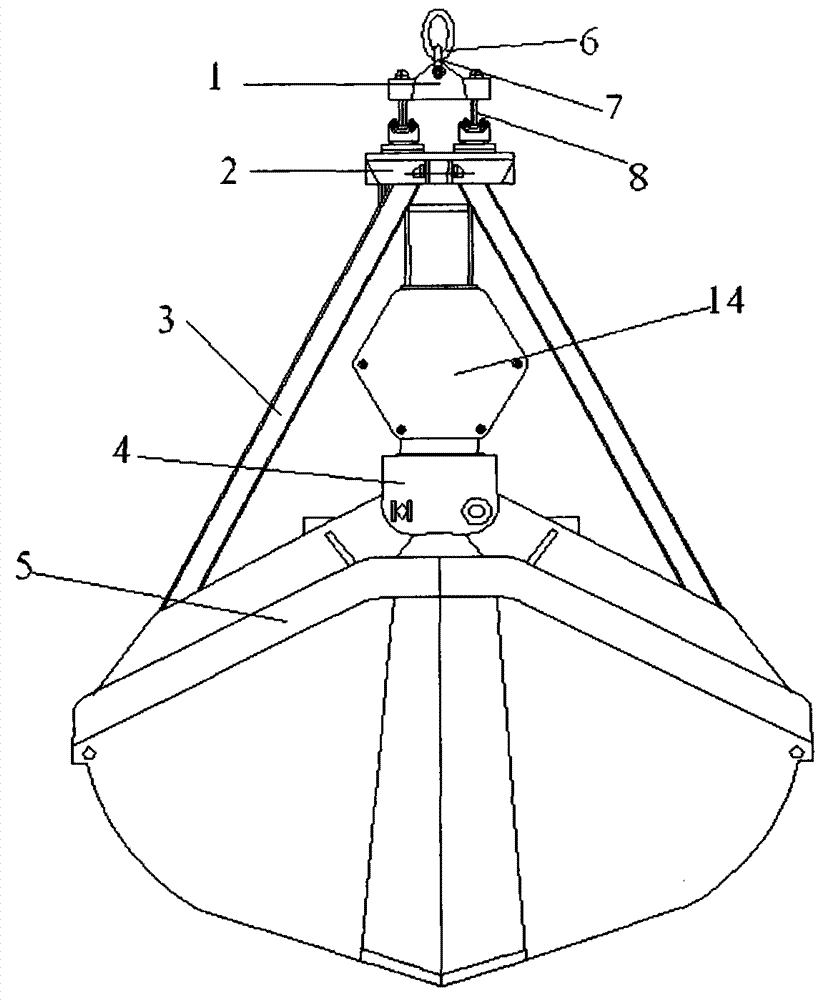

Remote control grab bucket capable of discharging in stable mode

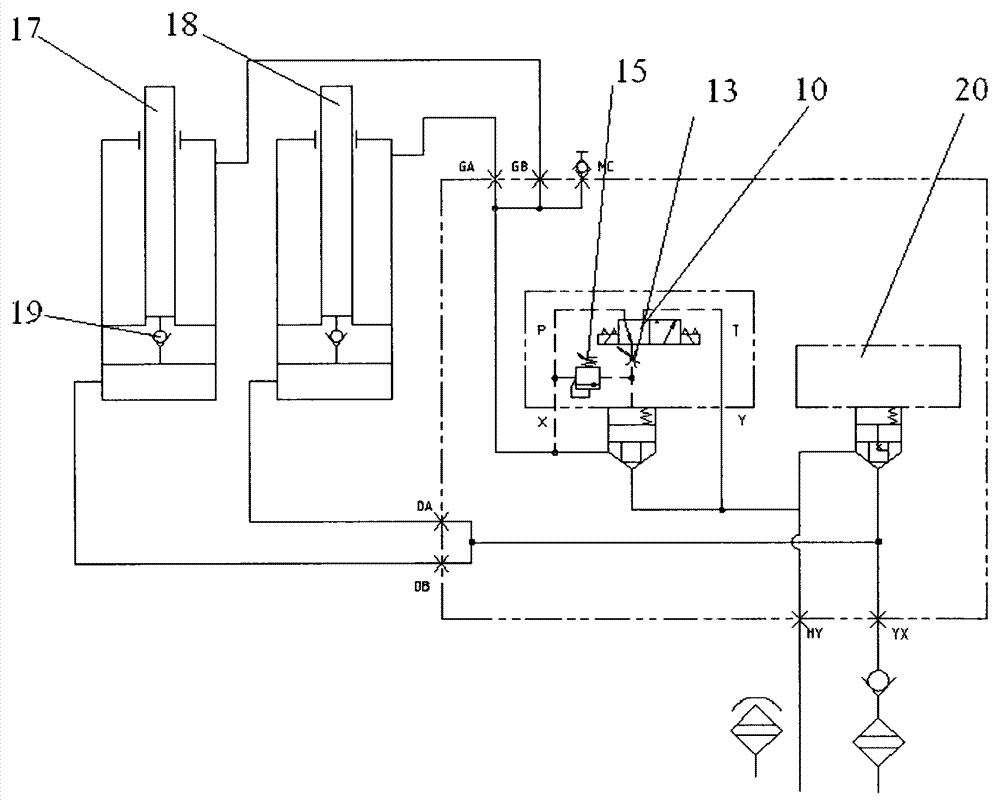

InactiveCN104291214AAvoid vibrationExtend life timeServomotor componentsLoad-engaging elementsSolenoid valveRemote control

The invention discloses a remote control grab bucket capable of discharging in a stable mode, the grab bucket comprises an upper bearer and a lower bearer, the upper bearer is connected to a bucket body and a transmission apparatus, a hydraulic system is arranged at the lower bearer, the lower bearer and the bucket body enable rotatable connection, the bucket body completes opening and closing under cooperation of the transmission apparatus and the hydraulic system, the hydraulic system comprises a housing and a solenoid valve reversing valve fixed at top of the housing, an oil inlet interface of the hydraulic system and an oil outlet interface of the hydraulic system are arranged at bottom of two sides of the housing, a buffer speed regulating valve is arranged at upper part of the left side, a buffer pressure-regulating valve is arranged at upper part of the right side, a safety valve is arranged at front part, and an oil return tube is arranged in the the grab bucket. According to the invention, based on the conventional hydraulic system, the buffer speed regulating valve and the buffer pressure-regulating valve are added, large pressure is removed, then a main valve is opened, great shock generated through instant release by a high-pressure oil-way is prevented, so that stable discharging can be realized.

Owner:上海港怡动力系统有限公司

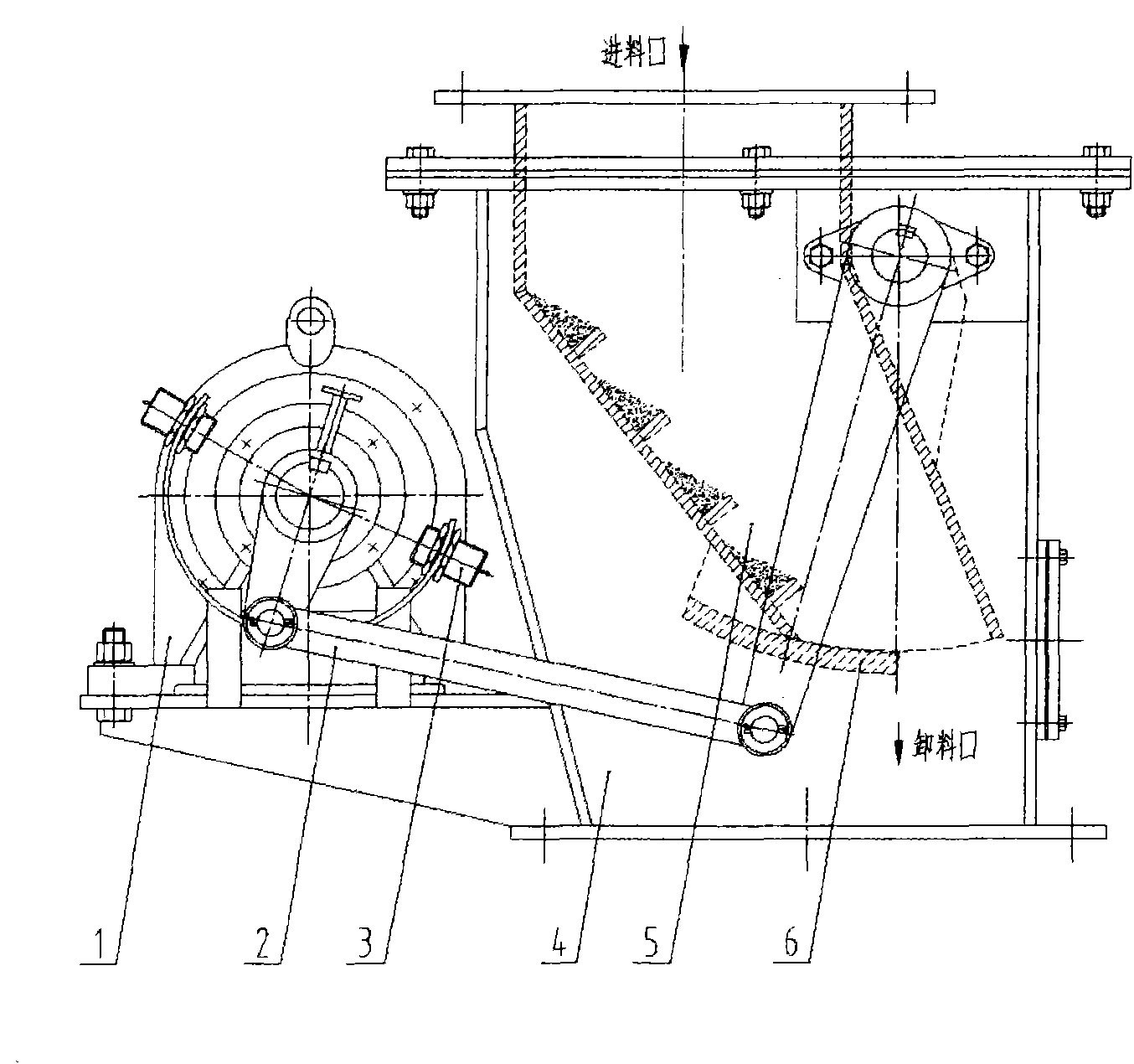

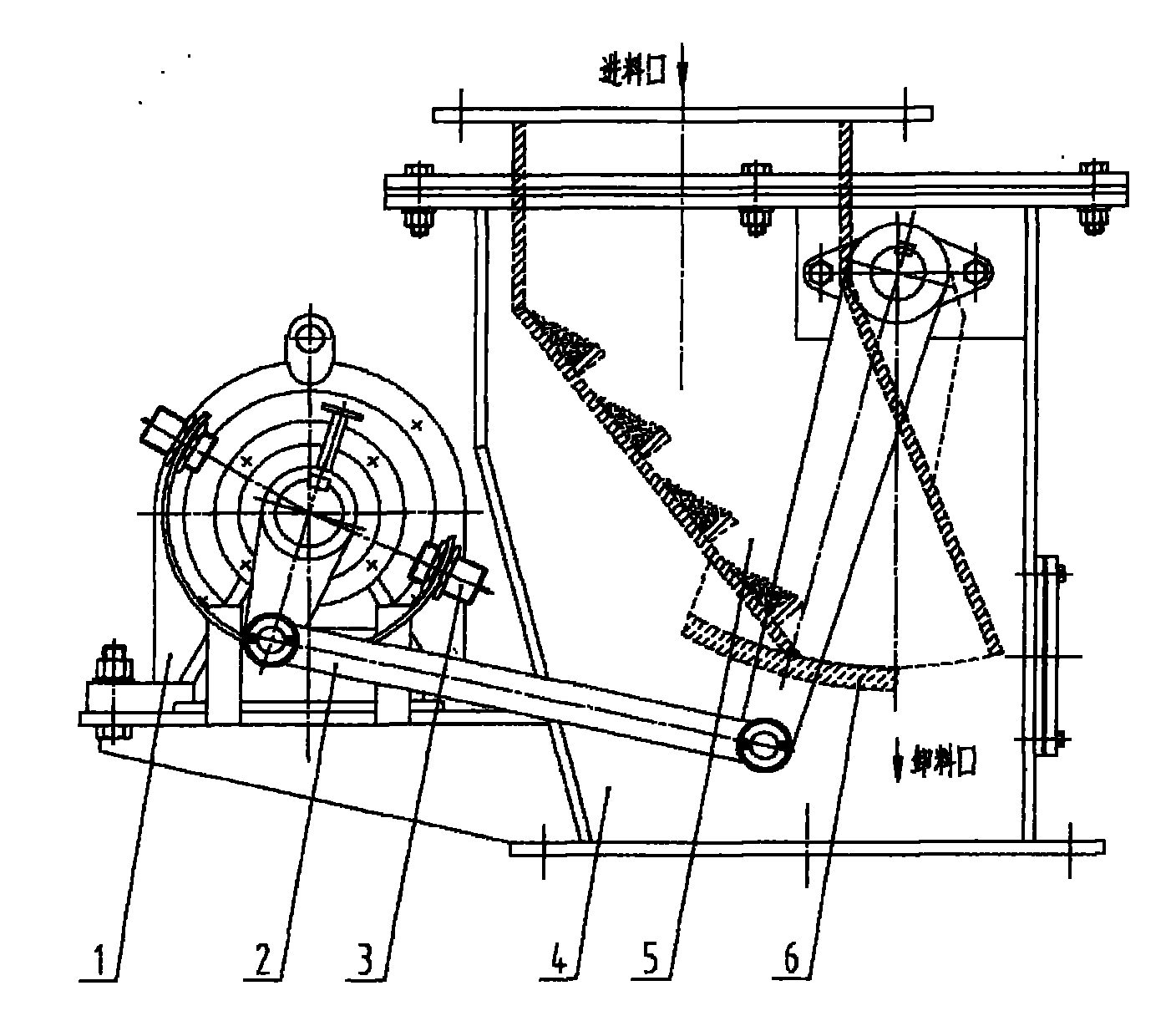

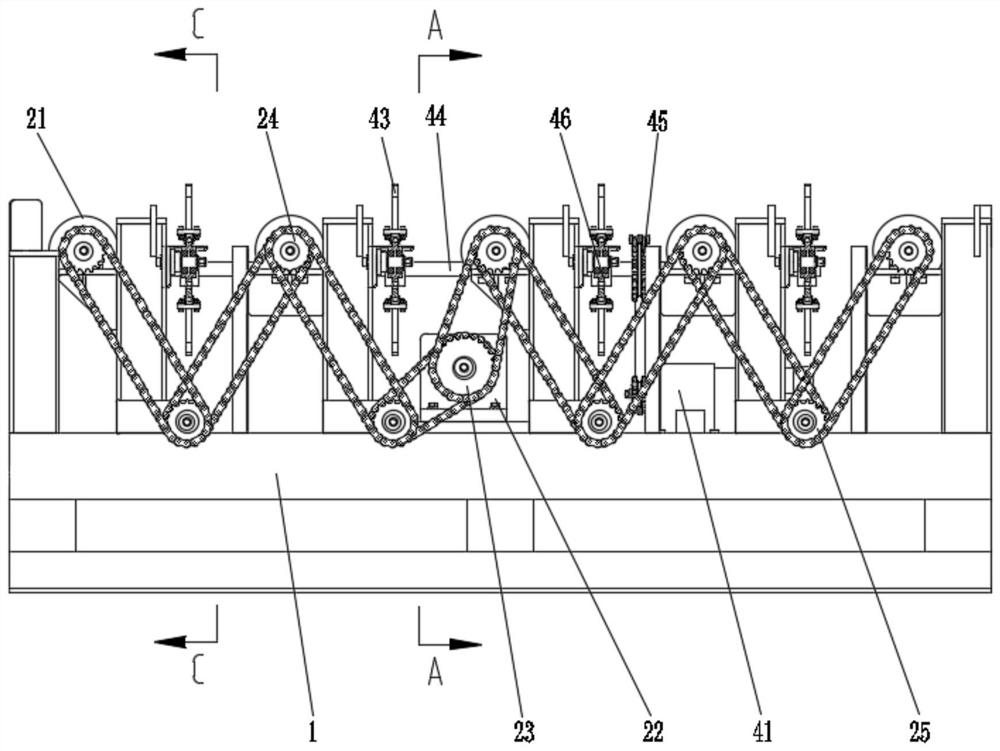

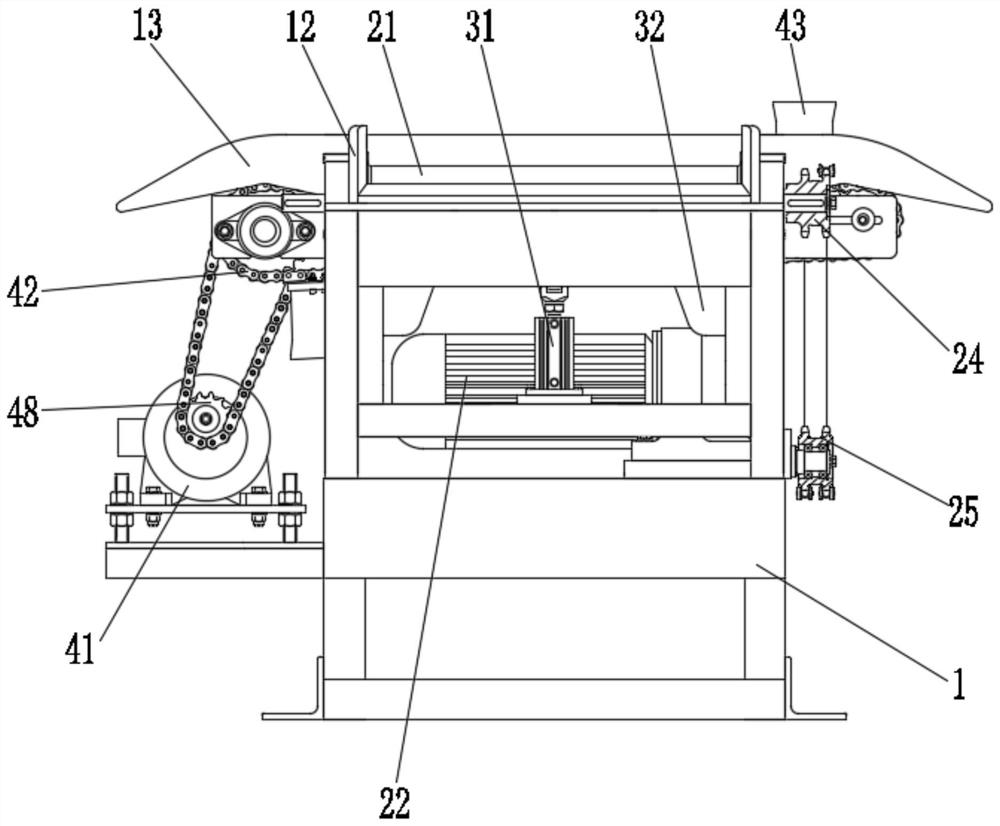

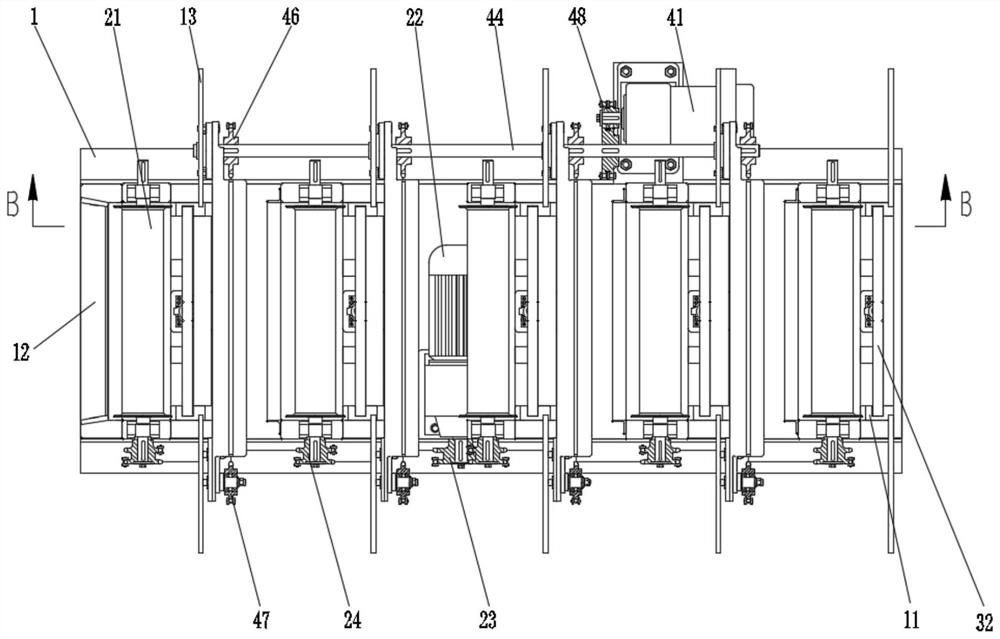

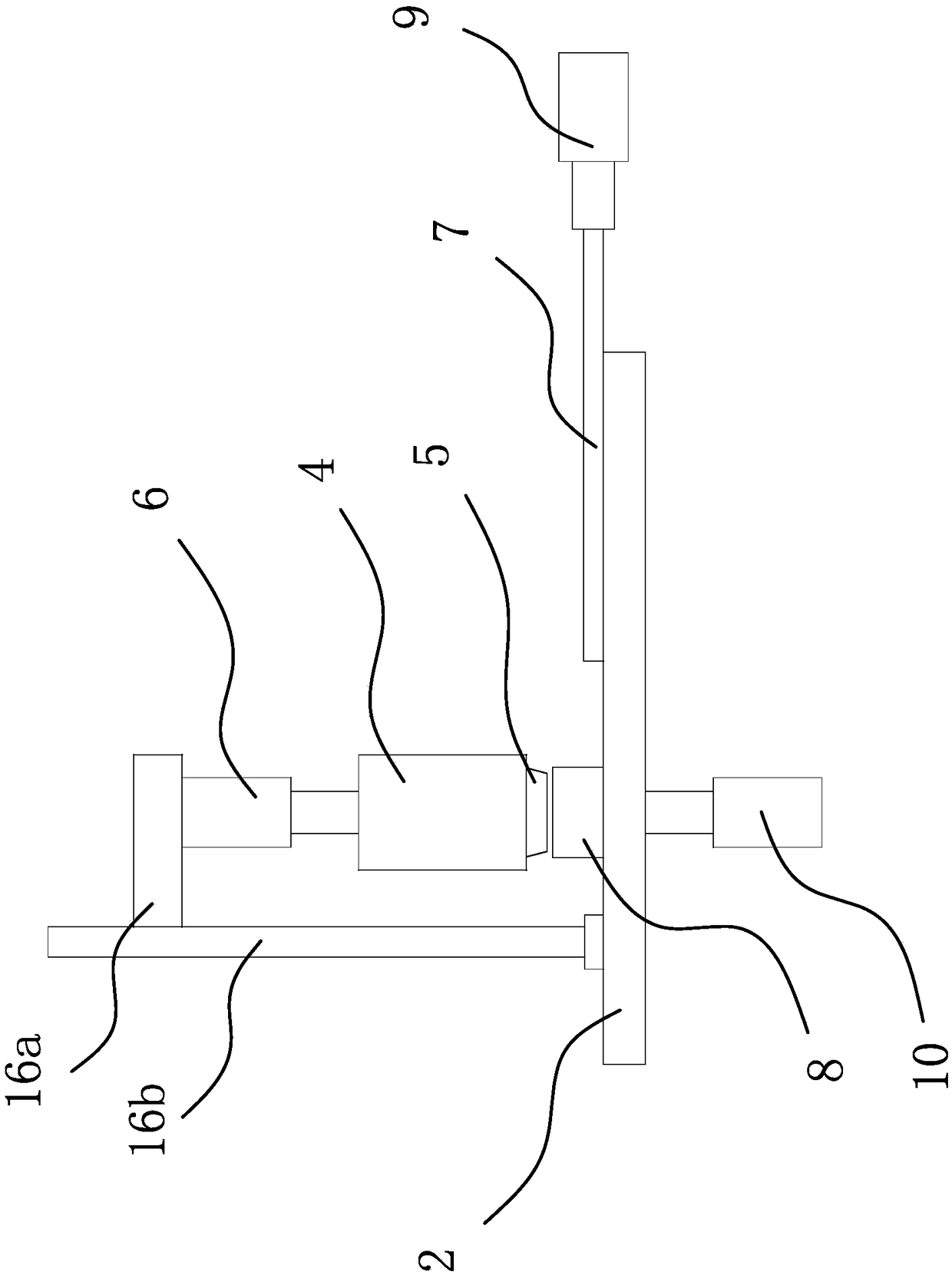

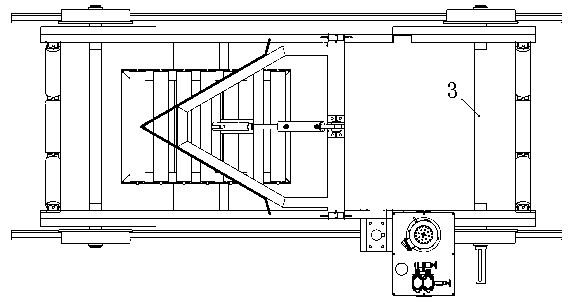

Automatic turnover mechanism for unloading of Z-shaped chain bucket elevator

InactiveCN109081083AStable unloadingMeet the requirements of multi-point unloadingConveyor partsEngineeringBucket elevator

The invention relates to an automatic turnover mechanism for unloading of a Z-shaped chain bucket elevator. The automatic turnover mechanism for unloading of the Z-shaped chain bucket elevator comprises an unloading port arranged at any position of the elevator, wherein a flange curve push plate is arranged above the unloading port and under a traction chain, and can slide up and down through a push rod; and the flange curve surface of the flange curve push plate dynamically contacts or separates from a protruding rod on a turnover hopper during the lifting process so as to drive the hopper inthe operating state to turn over for unloading or reset. According to the automatic turnover mechanism for unloading of the Z-shaped chain bucket elevator provided by the invention, the lifting flange curve push plate is arranged on the unloading port and is matched with the protruding rod on the turnover hopper, so that multipoint unloading of the Z-shaped chain bucket elevator is realized.

Owner:HUBEI YIDU YIYUN ELECTROMECHANICAL ENG CO LTD

Feeding device of sealing ring in luggage accessory

The invention provides a feeding device of a sealing ring in a luggage accessory, and belongs to the technical field of assembly of luggage accessories. The feeding device of the sealing ring in the luggage accessory is characterized in that the sealing ring is O-shaped and is made of a rubber material, the feeding device is characterized in that the feeding device comprises a supporting frame, amaterial taking table is arranged at one end of the supporting frame, and the other end of the supporting frame is provided with a workbench, a gantry bracket and a screw rod motor are arranged on thematerial taking table in a sliding mode, and a ball is arranged on a screw rod of the screw rod motor; a connecting base is arranged on the outer sleeve of the ball, the connecting base is fixedly connected to the gantry bracket, a material carrying column is arranged right below the gantry bracket, a round groove is formed in the lower end of the material carrying column, and a round table is fixed at the bottom of the round groove; and a plurality of discharge holes are vertically formed in the material carrying column, and discharge sheets are arranged in the discharge holes correspondingly, and a conveying and positioning structure capable of conveying the sealing ring to a designated station is further arranged on the material taking table. The feeding device of the sealing ring in the luggage accessory has the advantages of being capable of picking, transporting and dismounting the sealing ring.

Owner:浙江御匠箱包股份有限公司

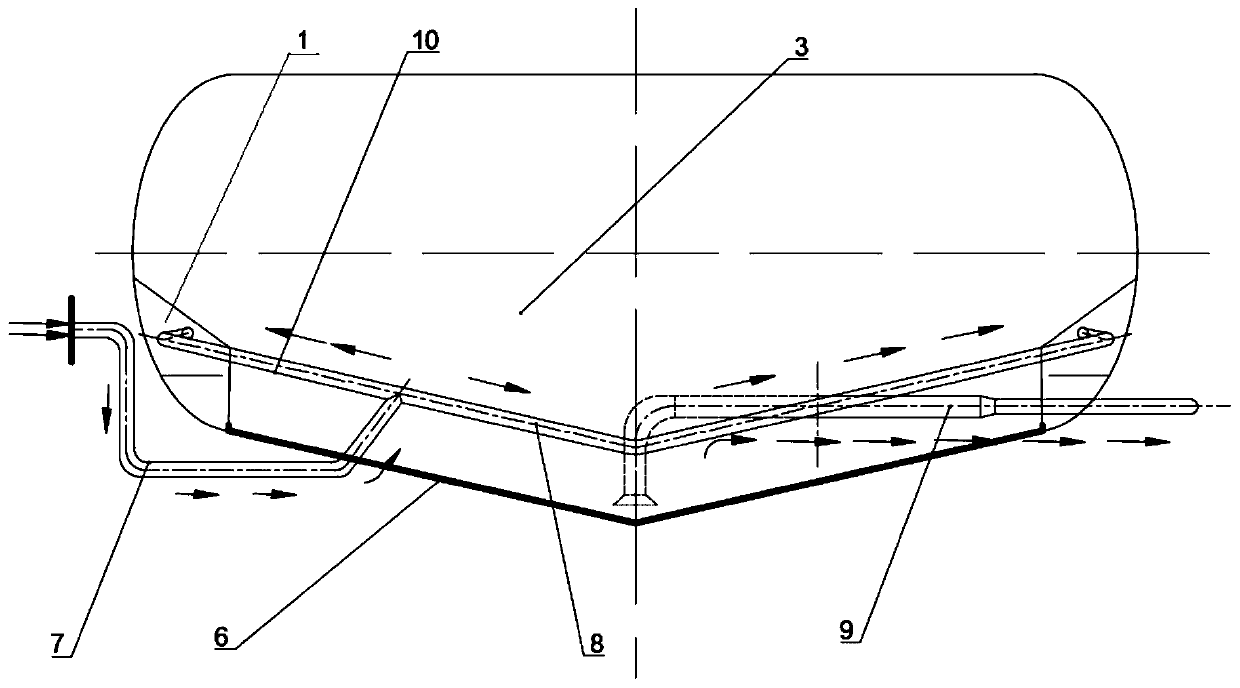

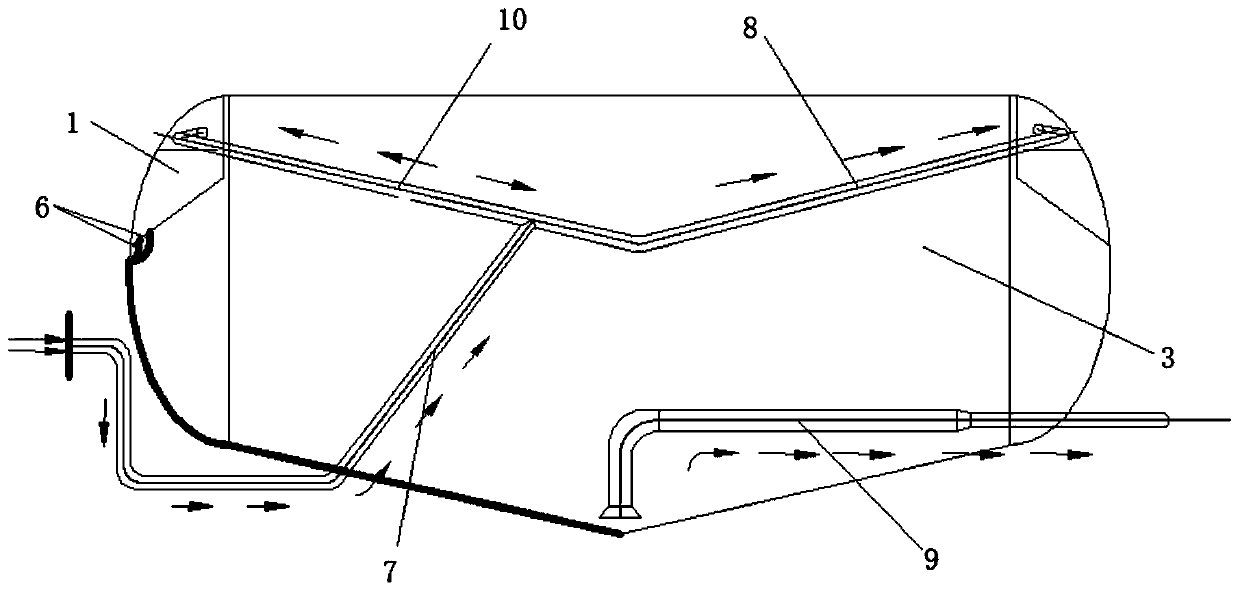

Improved air chamber and powder tank truck using the same

ActiveCN111483387ASpread evenlyFlow fastTank vehiclesItem transportation vehiclesThermodynamicsTank truck

The invention discloses an improved air chamber and a powder tank truck using the same. A gas inlet for introducing gas is formed in the air chamber; a gas outlet for discharging gas is also formed inthe air chamber. The air chamber is characterized in that a flow limiting plate is arranged in the air chamber, the air chamber is divided into an air inlet cavity with an air inlet and an air outletcavity with an air outlet by the flow limiting plate, and a gap for allowing an airflow to pass through and rectifying and accelerating the airflow exists on the flow limiting plate and / or between the flow limiting plate and the wall of the air chamber. The air chamber of the powder tank truck is moved upwards, and the ventilation proportion of the cloth bag is changed; an intelligent ash discharging system is additionally arranged, and the ash accumulation problem of three large ash accumulation prone parts of a traditional powder tank truck is solved.

Owner:HEFEI UNIV OF TECH

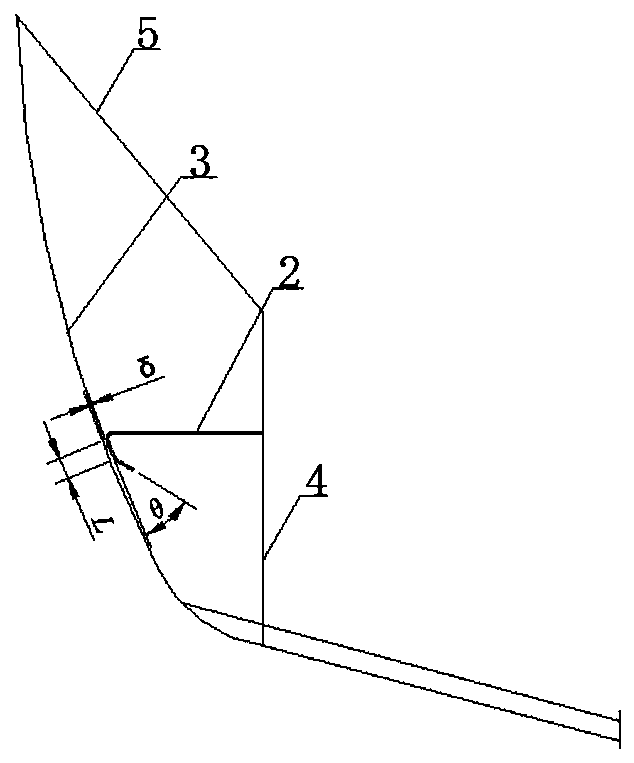

Novel arc-shaped valve

InactiveCN102927344AControl switch angleReduce power consumptionOperating means/releasing devices for valvesSlide valveTransducerEngineering

The invention relates to a key part of a grog cooling machine in production equipment of the cement industry. The primary structure of a novel arc-shaped valve comprises a planet cycloid deceleration motor, a slot-and-crank drive mechanism, a transducer as well as a travel switch, a shell, an inner barrel and a valve plate.

Owner:高勐

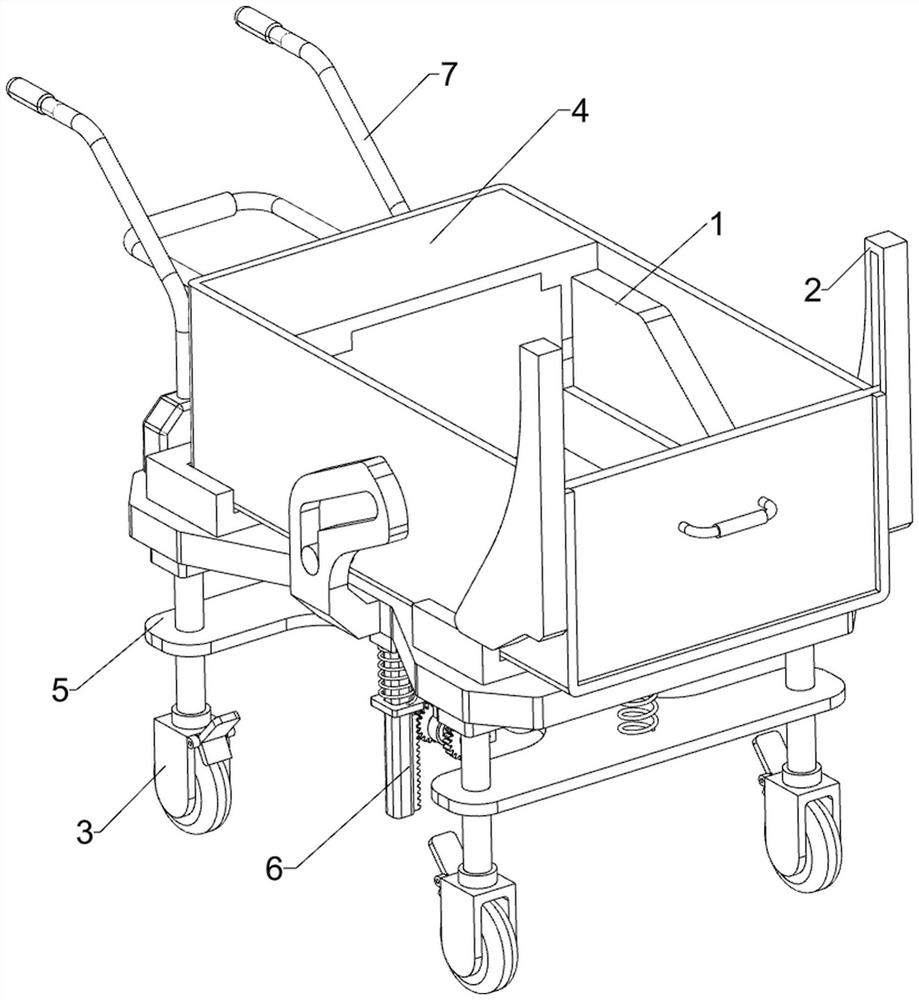

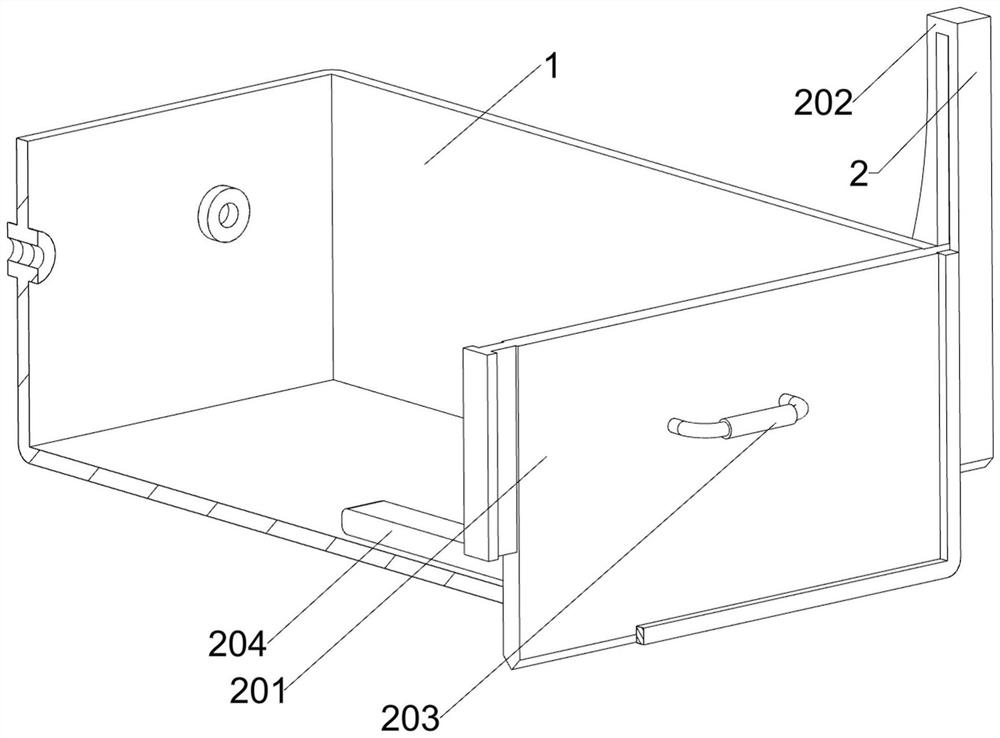

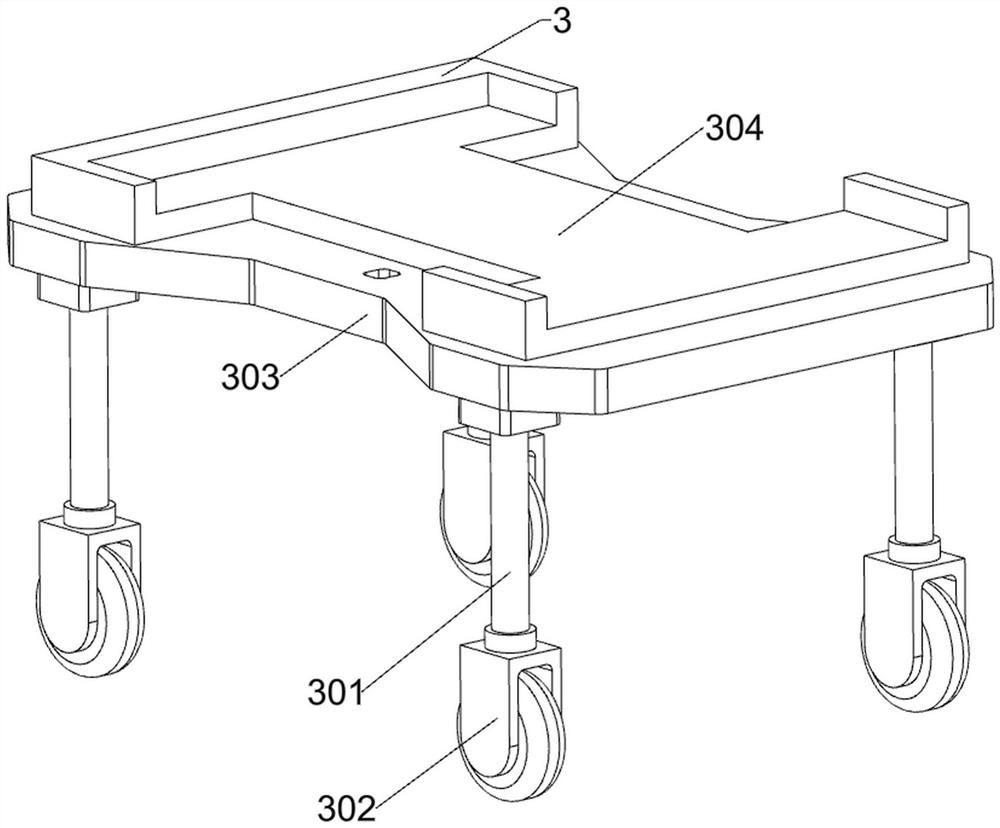

Rice conveying device convenient facilitating unloading

InactiveCN112829816AEasy to operateStable unloadingHand carts with multiple axesHand cart accessoriesAgricultural engineeringSlide plate

The invention relates to a transportation device, in particular to a rice conveying device facilitating unloading. According to the technical purpose, the rice conveying device facilitating unloading is convenient to unload, easy to operate and capable of freely moving. According to the technical scheme, the rice conveying device convenient to unload comprises a supporting assembly; a charging box which is placed at the top of the supporting assembly; and a baffle assembly which is arranged on one side of the charging box. The device has the beneficial effects that under the action of a baffle assembly, people place a charging box at the top of a second supporting frame, then place rice in the charging box, people move a first handle upwards, the first handle can drive a first sliding plate and a first contact rod to move upwards along the track of a first guide rail, then people slightly turn over the charging box, so that the rice is discharged; and due to the effect of the universal wheels, the rice is convenient to transport.

Owner:JIANGXI DONGJIAN AGRI DEV CO LTD

Mobile delivery wagon

InactiveCN103481897AHeight adjustableReduce instabilityTipping wagonsChinese charactersHydraulic ram

The invention discloses a mobile delivery wagon. The mobile delivery wagon comprises a hopper, a movable frame, a clamping groove, a handle, a baffle, a spring layer, a first piston rod, a second piston rod, a first lifting hydraulic ram, a second lifting hydraulic ram, universal connecting bases, a base, a hydraulic drive device, idler wheels, tracks, a hauling cable, a winch and a winch driving device. The movable frame is arranged on the hopper, wherein the movable frame is shaped like a Chinese character 'er', the handle is arranged on the movable frame, the clamping groove is formed in the hopper, the spring layer is arranged below the hopper, the first piston rod and the second piston rod are arranged below the spring layer, the first lifting hydraulic ram is arranged below the first piston rod, the second lifting hydraulic ram is arranged below the second piston rod, the universal connecting bases are arranged below the lifting hydraulic rams respectively, the universal connecting bases and the hydraulic drive device are arranged on the base, the idler wheels are arranged below the base, the tracks are arranged below the idler wheels, and the base is connected with the winch through the hauling cable. According to the mobile delivery wagon, the height of the hopper can be adjusted, and the spring layer can mitigate the situation that the hopper is unstable at the time of discharging.

Owner:SHANYIN XUANANG BUILDING MATERIAL

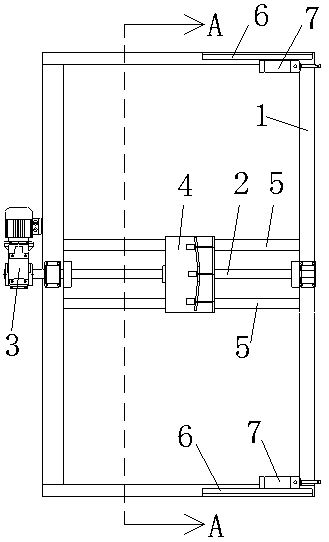

Solid-state fermentation discharging device

PendingCN110964632AIncrease productivityStable unloadingBioreactor/fermenter combinationsBiological substance pretreatmentsElectric machineryDrive motor

The invention discloses a solid-state fermentation discharging device. The device comprises a rack, a screw rod, a driving motor, a push-pull block, a guide rail, auxiliary frames, a sliding block, apull plate, a push plate and guide supporting seats, wherein the number of the auxiliary frames is two; the two auxiliary frames are arranged on the front side edge and the rear side edge of the rackrespectively; the screw rod is transversely arranged in the middle of the rack; the left end of the screw rod is connected with a power output end of the driving motor; the guide rail is transverselyarranged on the rack; the push-pull block is in threaded connection with the screw rod; the sliding block is arranged on the lower portion of the push-pull block; the guide rail is sleeved with the sliding block in a sliding mode; and the guide supporting bases are arranged at the top ends of the two auxiliary frames respectively. The solid-state fermentation discharging device is very suitable for a tank-type solid-state fermentation process, can be matched with a fermentation tank to realize mechanical and efficient discharging operation, and is time-saving and labor-saving, stable in discharging and high in production efficiency when being used for discharging the fermentation tank.

Owner:WUHAN GUIYAN MACHINERY MFG CO LTD

Mobile dumping dolly

The invention discloses a mobile dumping dolly which comprises a big frame, a bearing pedestal, an axletree, wheels, a plowshare assembly, a rear axes brake mechanism and a hydraulic power station, wherein the bearing pedestal is in bolted connection with the big frame, the axletree is mounted in the bearing pedestal, the wheels are connected to the shaft through keys, and the plowshare assembly, the rear axes brake mechanism and the hydraulic power station are welded on the big frame. According to the dolly provided by the invention, effective dumping can be realized under various severe environments, especially the arrangement of the rear axes brake mechanism better solves the problem that the dolly move back and forth as the braking friction of the dolly is insufficient, so as to enable the dumping to be more stable and the efficiency to be improved greatly.

Owner:JIANGSU XINLIAN HYDRAULIC MECHANICAL & ELECTRICALCO

A hand-push conveying device applied to a construction site

ActiveCN105882697BAchieve fixationConsistent insertion depthSupporting partsHand carts with one axisTerrainEngineering

Owner:CHINA MCC5 GROUP CORP

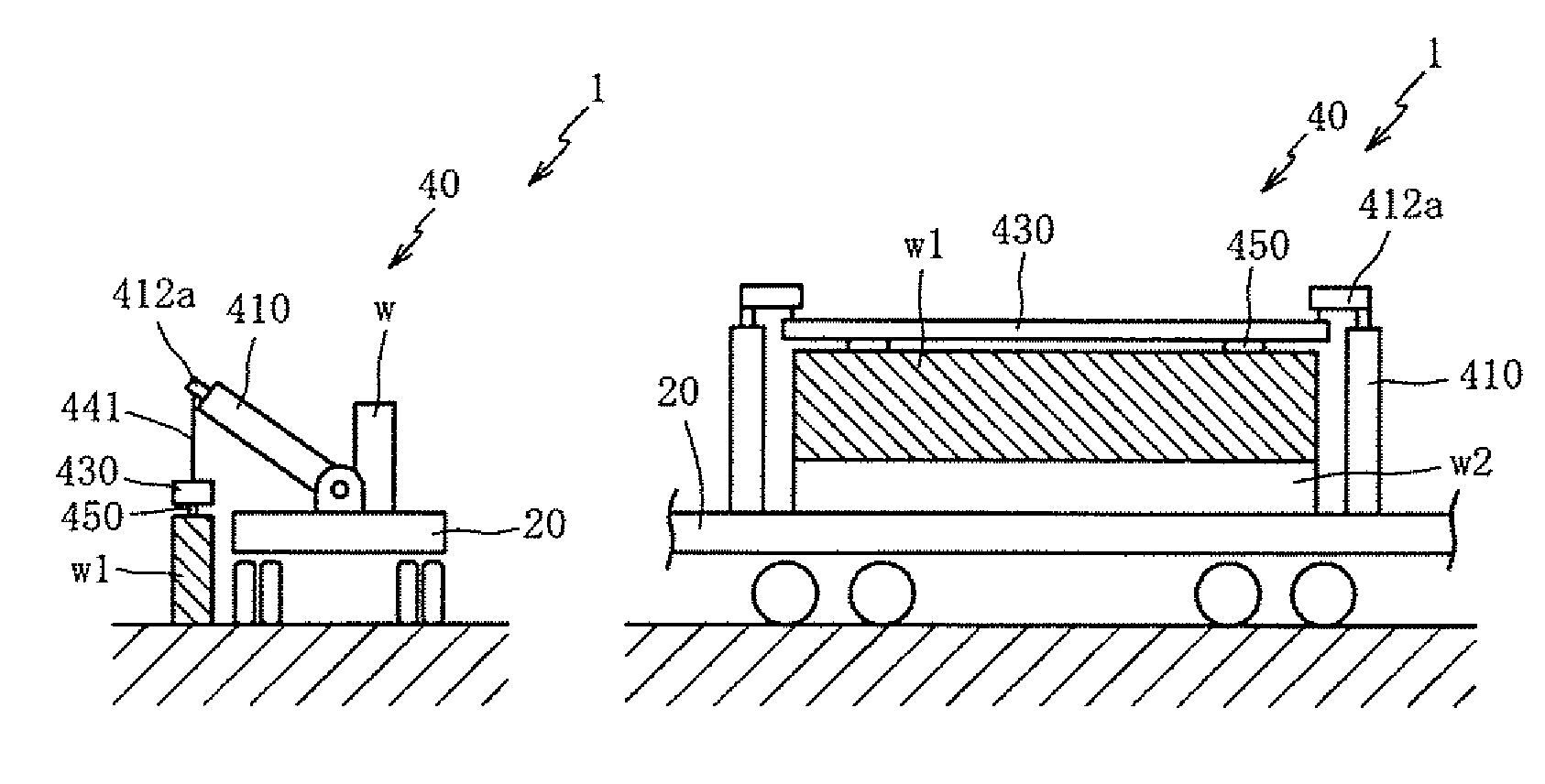

Vehicle

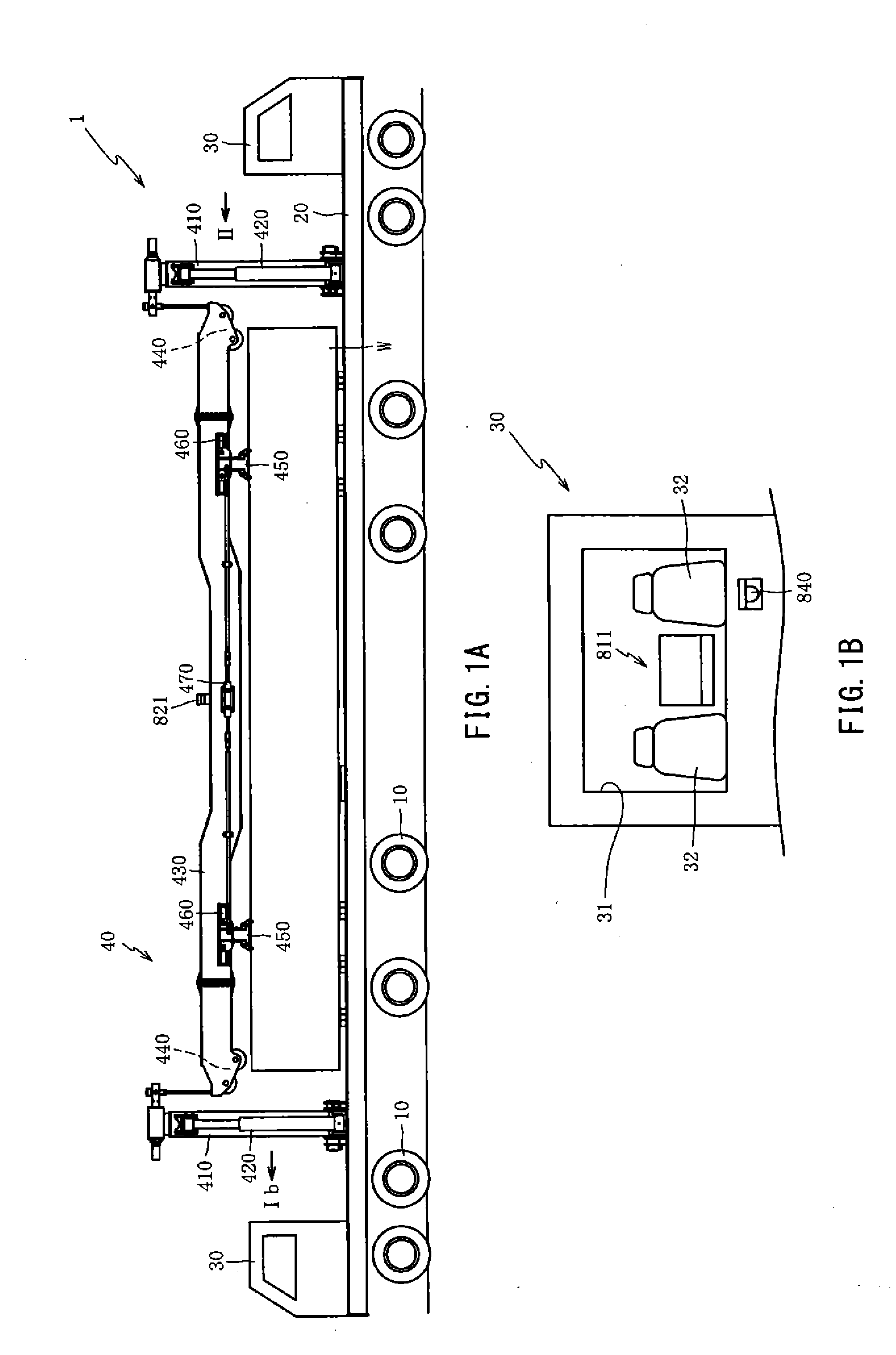

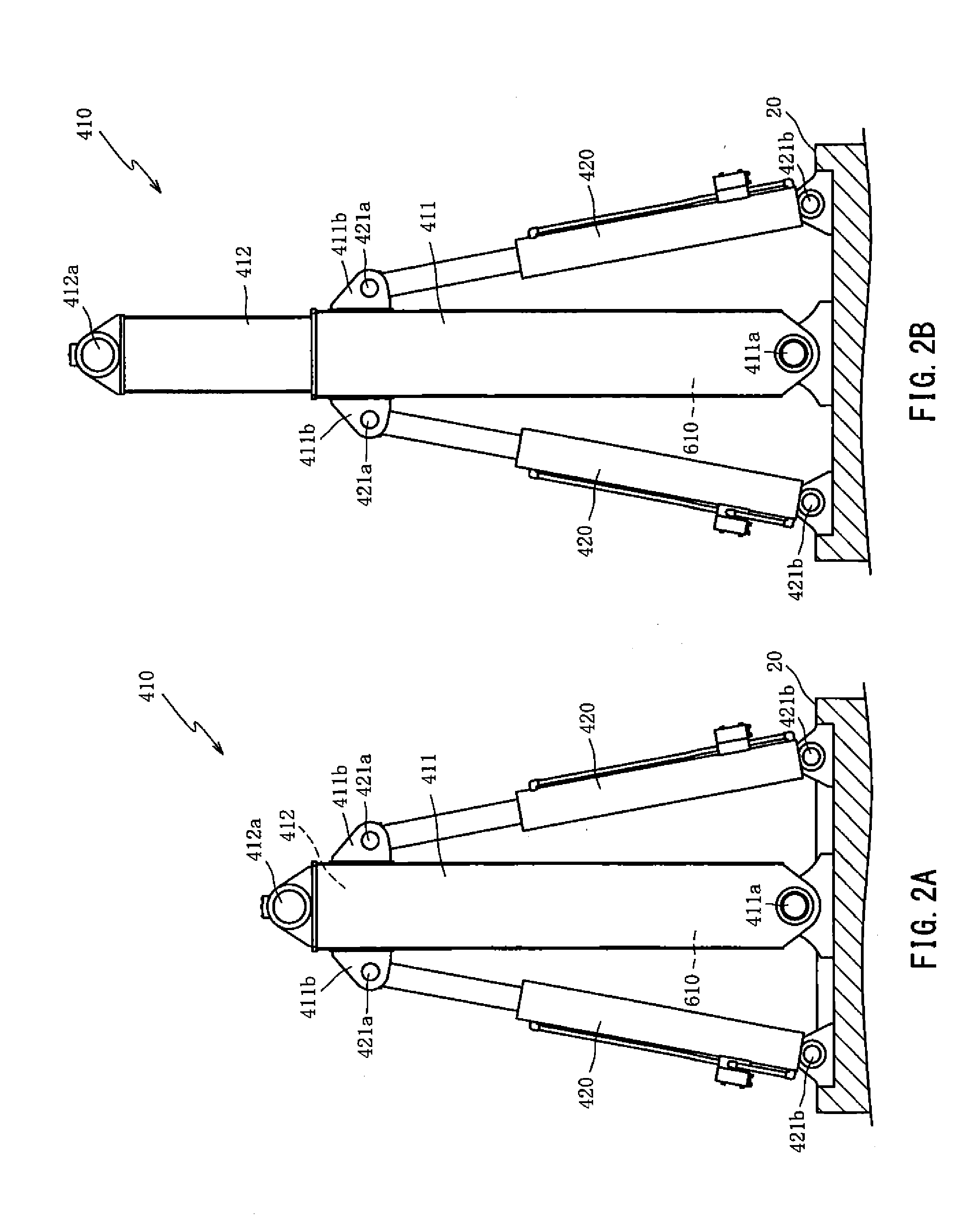

InactiveUS20130034417A1Stable unloadingLower overall heightVehicles with cranesRefuse receptaclesHeavy loadWorking space

There is provided a vehicle which can stably load or unload a long heavy load and lower a height of a working space necessary for loading or unloading the weight body. The loading / unloading apparatus suspends and maintains a load in a working beam installed between a pair of booms and rotates the pair of booms toward the left or right direction of a vehicle body, such that the load is unloaded from the vehicle body in a construction field or loaded from the construction field onto the vehicle body. Thus, the height of the working space necessary when the load is loaded or unloaded can be reduced as compared with a crane structure for loading and unloading the load by the fluctuation of a boom.

Owner:CENTRAL JAPAN RAILWAY COMPANY +1

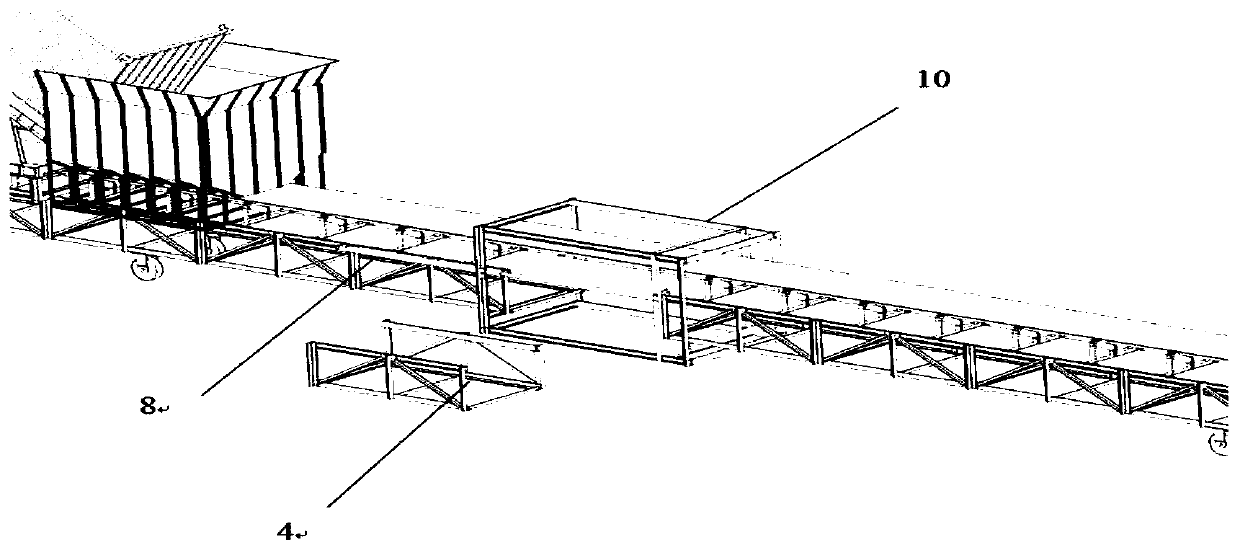

Discharging device applied to mechanical carrying engineering

ActiveCN114394412AEasy to unloadEasy to put inConveyorsConveyor partsConstruction engineeringStructural engineering

The invention relates to the technical field of mechanical carrying engineering, and discloses a discharging device applied to mechanical carrying engineering, which comprises a horizontally arranged first bracket, a second bracket which is connected with the first bracket and is obliquely arranged, and a transmission component which is arranged on the second bracket and is used for discharging containers, the conveying device comprises a first support, a second support and a conveying component, baffles are arranged on the two sides of the top end of the first support and the two sides of the top end of the second support correspondingly, the conveying component comprises multiple supporting shafts arranged on the second support and a conveying belt arranged on the supporting shafts, and by arranging the first support, the second support and the conveying component, containers can be conveniently placed and conveyed to the conveying device; by means of the container unloading device, unloading of containers can be facilitated, the situation that the falling speed of the containers is too high can be avoided, the containers can be protected, and the problems that an existing container is not prone to being placed on a conveying belt in the carrying process, unloading of the containers is not convenient enough, the falling speed of the containers is increased when the containers leave the conveying belt, and the containers are prone to being damaged are solved.

Owner:CHONGQING UNIV

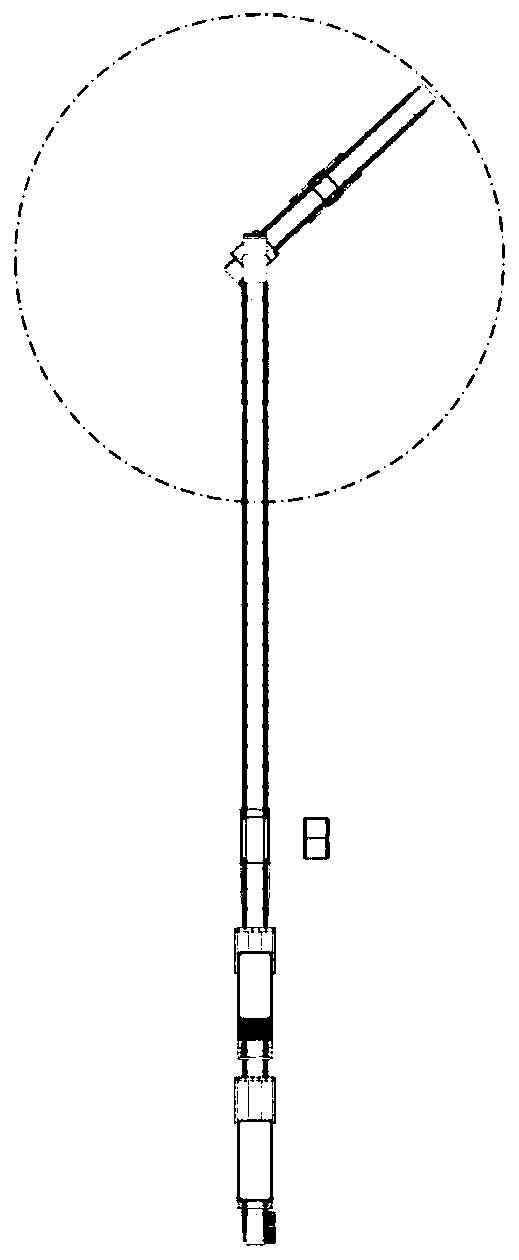

Extension type construction feeding device for building construction

InactiveCN112942830AReduce labor intensityStable unloadingConveyorsBuilding material handlingArchitectural engineeringWinch

The invention discloses an extension type construction feeding device for building construction, and relates to the technical field of building construction. The problems that when an existing construction feeding device is used, a worker needs to carry out materials in a bearing part, operation is troublesome, the labor amount of the worker is large, the discharging speed is high, the amount can only be fixed every time during discharging, and discharging cannot be flexible according to the requirement are solved. The automatic discharging device comprises a mounting seat, a group of discharging driving pieces are fixedly connected to the front end surface of the mounting seat; a group of discharging driven roller shafts are rotationally connected with the right side of the top of the mounting seat; and a group of lifting winches are fixedly connected to the left side and the right side of the front end surface and the rear end of the mounting seat. According to the extension type construction feeding device for building construction, materials are lifted, meanwhile, the materials can be automatically discharged in the lifting process, manual unloading is not needed, the labor intensity of workers is reduced, discharging is more stable, the discharging speed is high, the discharging amount and the discharging speed can be controlled according to needs, and using is more convenient and flexible.

Owner:纪蕾

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com