Connecting strengthening plate multi-station progressive die

A multi-station, reinforced plate technology, applied in the field of mold manufacturing, can solve problems such as difficulty in meeting mass production, low production efficiency, and poor positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

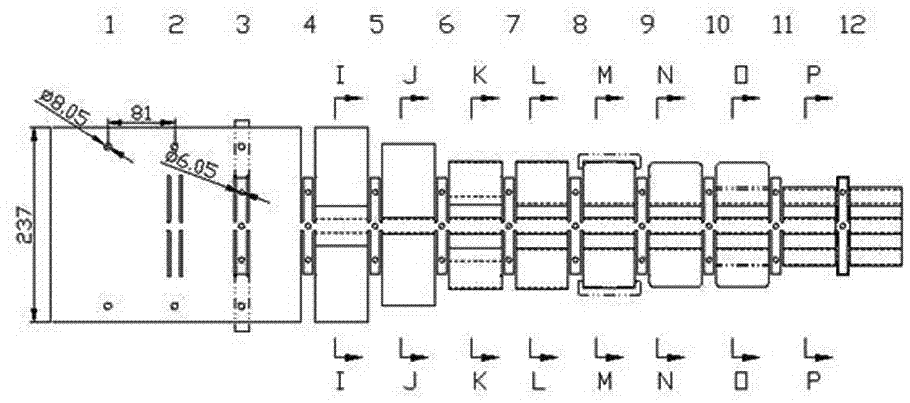

[0085] First analyze the stamping process of the parts, formulate the process plan, design the layout diagram, and then carry out the mold design and manufacture. Stamping process formulation is the basis of mold design.

[0086] 1. Stamping process

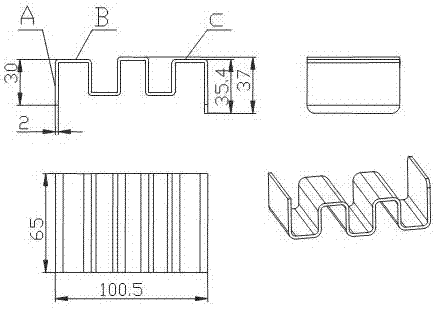

[0087] The material of the connecting reinforcement plate parts is cold-rolled plate DC01 t2.0 mm, including multiple folds, and the inner bending radius is 1 mm. Its processing adopts progressive die production method.

[0088] (1) Stamping process analysis

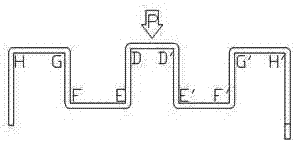

[0089] Progressive dies generally include multiple forming and blanking processes, and this part is determined to be blanked first and then folded. The hemming step affects the product quality, and the degree of deformation of each step should not be too large. The part is folded several times, which is conducive to the adjustment and maintenance of the mold. This part has many vertical folds. In order to avoid the stretching of the material in the deformation zone of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com