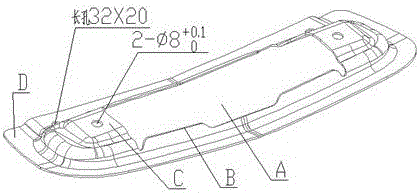

Multi-station progressive die for trunk tail gate reinforcing plate and processing technology

A reinforced plate, multi-station technology, applied in the field of stamping processing, can solve the problems of deep drawing, trimming and punching, flanging, punching, general operation performance, low production efficiency, etc., to ensure product accuracy requirements, manufacturing Good manufacturability and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

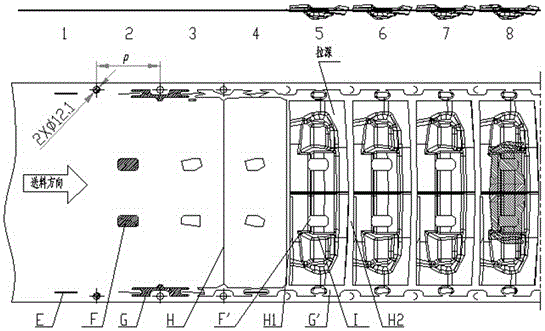

[0038] 1. The basic technical scheme of applying for a patent:

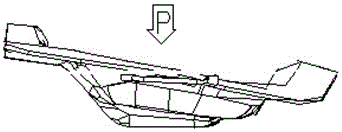

[0039] Progressive die is an advanced and efficient stamping die in cold stamping dies. Stamping parts with complex shapes that require multiple processes such as punching and bending can be punched on a pair of progressive dies. Progressive die is a mold structure that realizes automatic production and ensures stable processing quality. The reinforcement plate of the trunk and tailgate adopts the progressive die production method.

[0040] The structure of the progressive die is more complicated than that of the general stamping die, and the manufacturing difficulty and precision requirements are high. In the design of progressive die, the stamping process of the part should be considered first, and the layout drawing should be designed, then the mold structure should be designed, and finally the single-piece manufacturing, assembly and debugging should be carried out.

[0041] 1. Stamping process

[0042] (1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com