Mobile delivery wagon

A mobile conveying and movable frame technology, applied in the field of conveying vehicles, can solve the problems of inconvenient unloading, inconvenient unloading, non-adjustable height of the mobile conveying vehicle body, etc., to achieve convenient and stable unloading, and slow down instability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

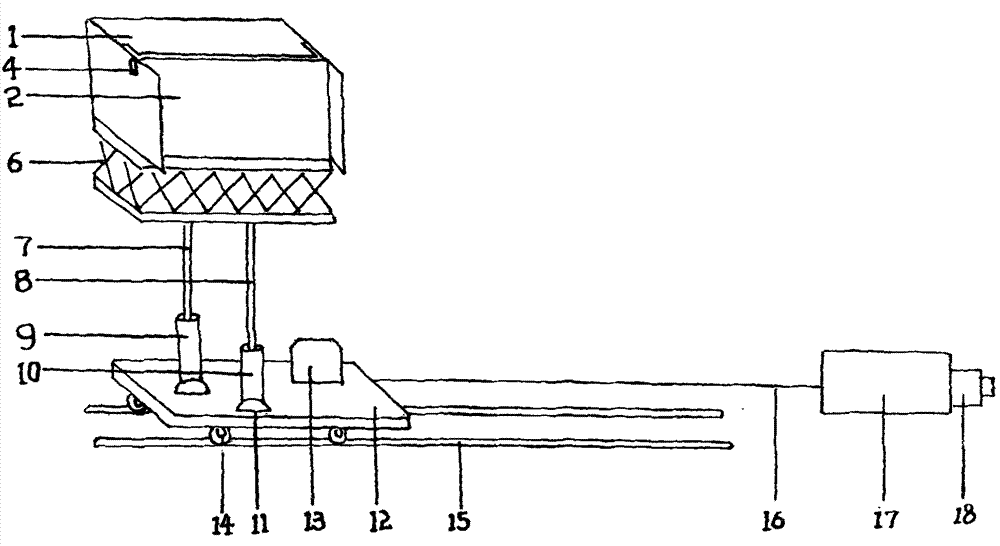

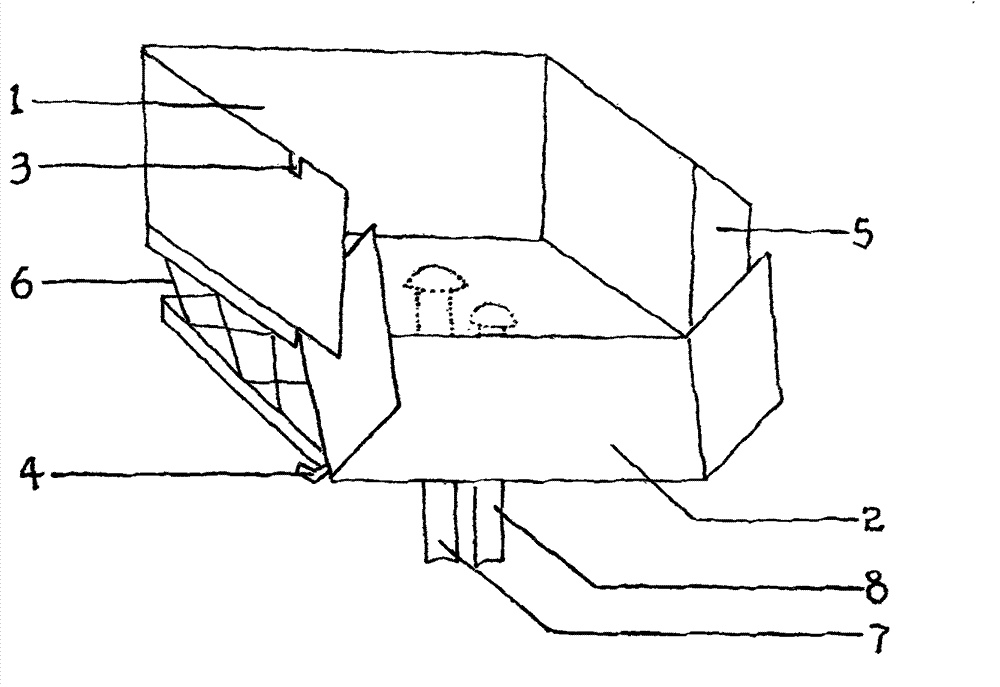

[0008] A mobile transport vehicle, comprising a hopper (1), a movable frame (2), a slot (3), a handle (4), a baffle (5), a spring layer (6), a first piston rod (7), a second Two piston rods (8), the first lifting hydraulic cylinder (9), the second lifting hydraulic cylinder (10), the universal joint seat (11), the base (12), the hydraulic drive device (13), the rollers (14), Track (15), traction rope (16), winch (17), winch driving device (18), movable frame (2) is established on the hopper (1), and described movable frame (2) is the font structure, movable frame (2) A handle (4) is provided on the upper part, a draw-in slot (3) matching the handle (4) is provided on the hopper (1), a spring layer (6) is provided at the lower part of the hopper (1), and a second spring layer (6) is provided at the lower part of the spring layer (6). A piston rod (7), a second piston rod (8), the first piston rod (7) is provided with a first lifting hydraulic cylinder (9), and the second piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com