Automatic turnover mechanism for unloading of Z-shaped chain bucket elevator

An automatic turning and hoisting technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of large space occupation, complex layout, high operating cost, etc., and achieve the effect of stable unloading, smooth reset action and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

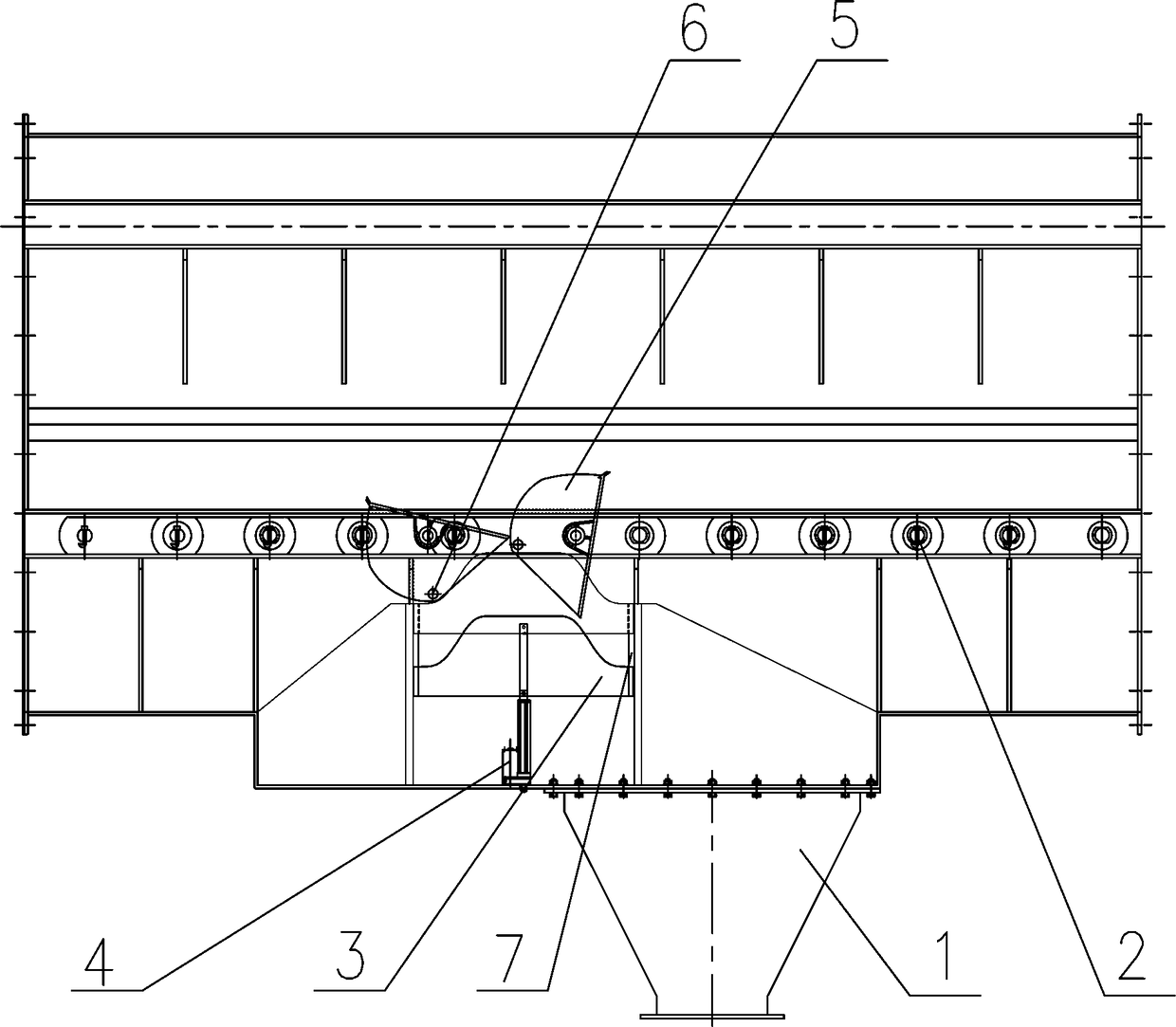

[0018] Such as figure 1 As shown, a Z-type chain bucket elevator unloading automatic turning mechanism includes a discharge port 1 arranged at any position of the elevator, and a guide chute 7 is assembled on the middle shell close to the top of the discharge port 1, and the traction Chain 2 below. A flange curve push plate 3 is slidingly provided in the guide chute 7, and the flange curve push plate 3 is pushed to slide up and down by the push rod 4, and the upper limit position is limited by a limit device. The speed and stroke of the flange curve push plate are controlled by the controller. During the rising process of the flange curve push plate, the flange curve push plate 3 is in dynamic contact with the protruding rod 6 on the hopper 5, driving the running hopper 5 to turn over and unload. The edge curve push plate 3 is dynamically disengaged from the protruding rod 6 of the hopper, and the hopper 5 rotates along the hinge point at its upper end to realize automatic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com