Suspension supporting base multi-station progressive die

A technology of multi-station progressive dies and support seats, applied in the direction of perforating tools, forming tools, stripping devices, etc., can solve the problems of shape and size errors of unfolded materials, inability to guarantee the quality of parts, and unfavorable mass production, etc. Longer service life, reasonable layout design, shortened maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

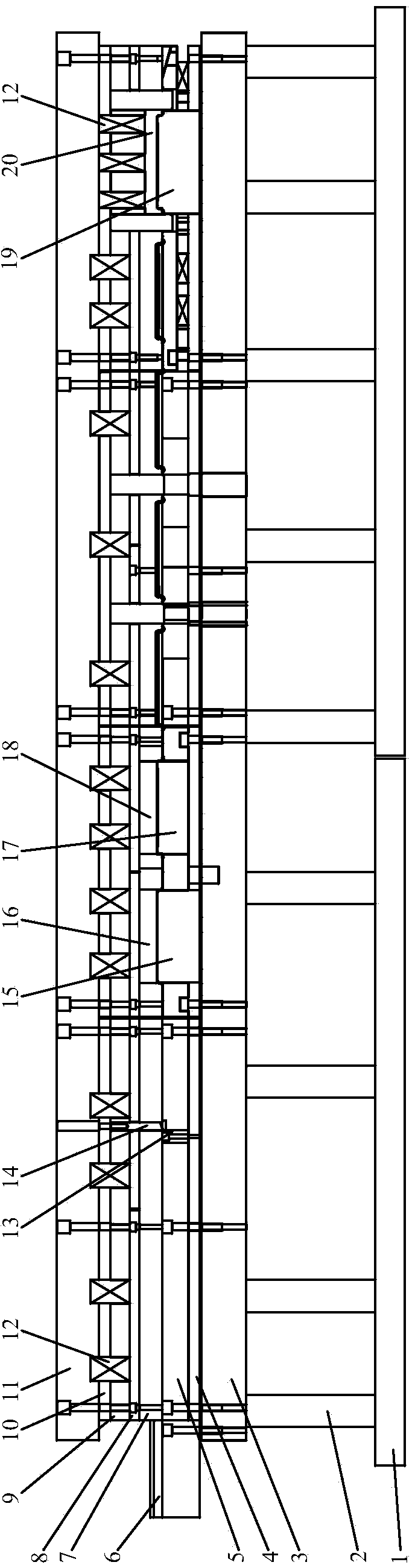

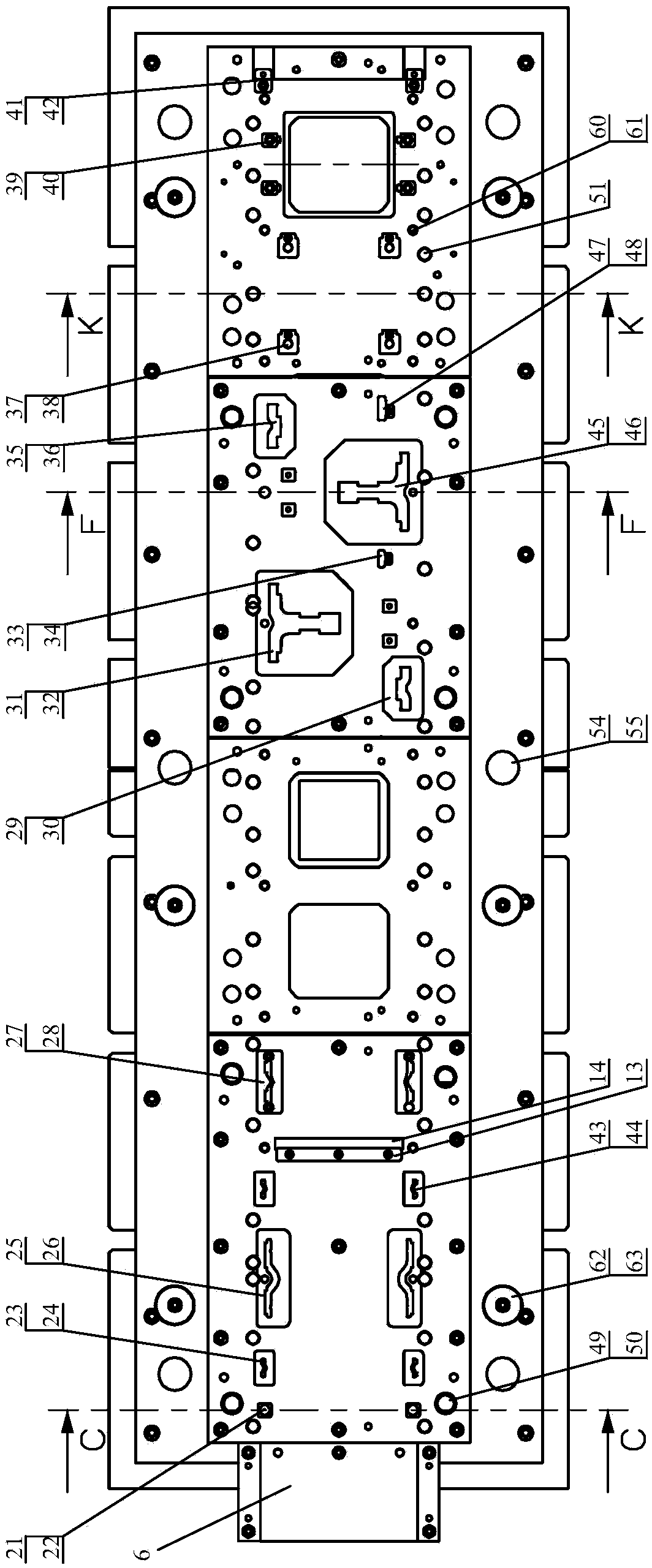

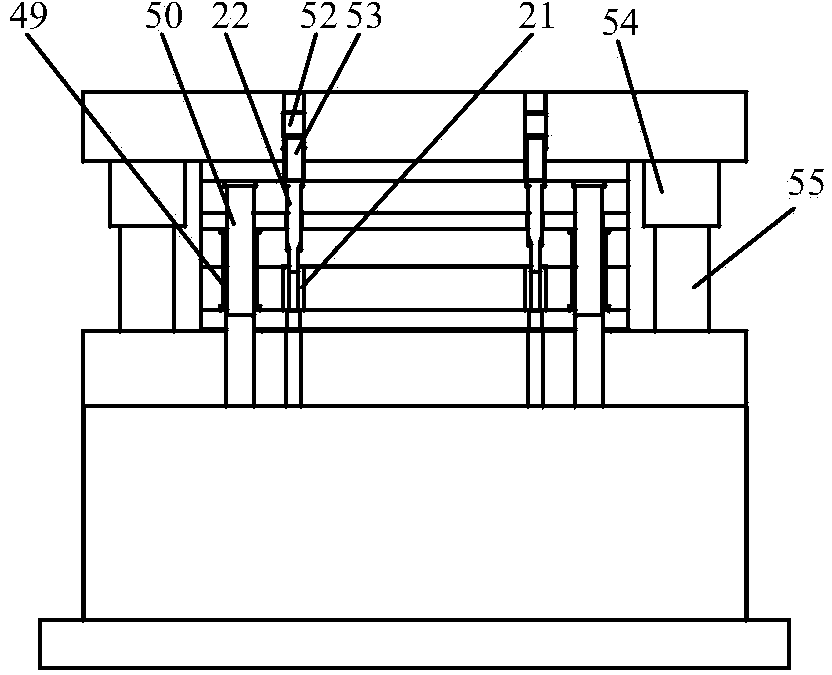

[0050] Embodiment 1: A multi-station progressive die for a suspension support seat, including an upper die assembly, a lower die assembly, a stripping plate, a stripping plate backing plate, and a misfeed detection device,

[0051] The upper die assembly includes an upper die base 11, an upper backing plate 10 installed on the upper die base and a punch fixing plate 9 connected to the upper backing plate, and the punch fixing plate 9 is arranged along the feeding direction. There are 2 punching guide positive pin hole punches 22, 2 punching right side V-shaped notch punches 24, 2 transverse large V-shaped partial punching profile punches 26, 2 left side V-shaped notch punches 44, 1 Punch 14 for punching the process gap between adjacent stations, 2 Punches 28 for lateral small V-shaped local punching and cutting the shape, 1 Punch 16 for box-shaped small step drawing, 1 box-shaped small step for embossing and shaping Punch 18, 1 transverse lower part shape punching punch 30, 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com