Remote control grab bucket capable of discharging in stable mode

A kind of grab, stable technology, applied in the direction of load hanging components, fluid pressure actuating devices, servo motor components, etc., can solve the problems of large mechanical damage, potential safety hazards, large vibration, etc., to avoid vibration and smooth unloading , the effect of prolonging the life of the power supply and the working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

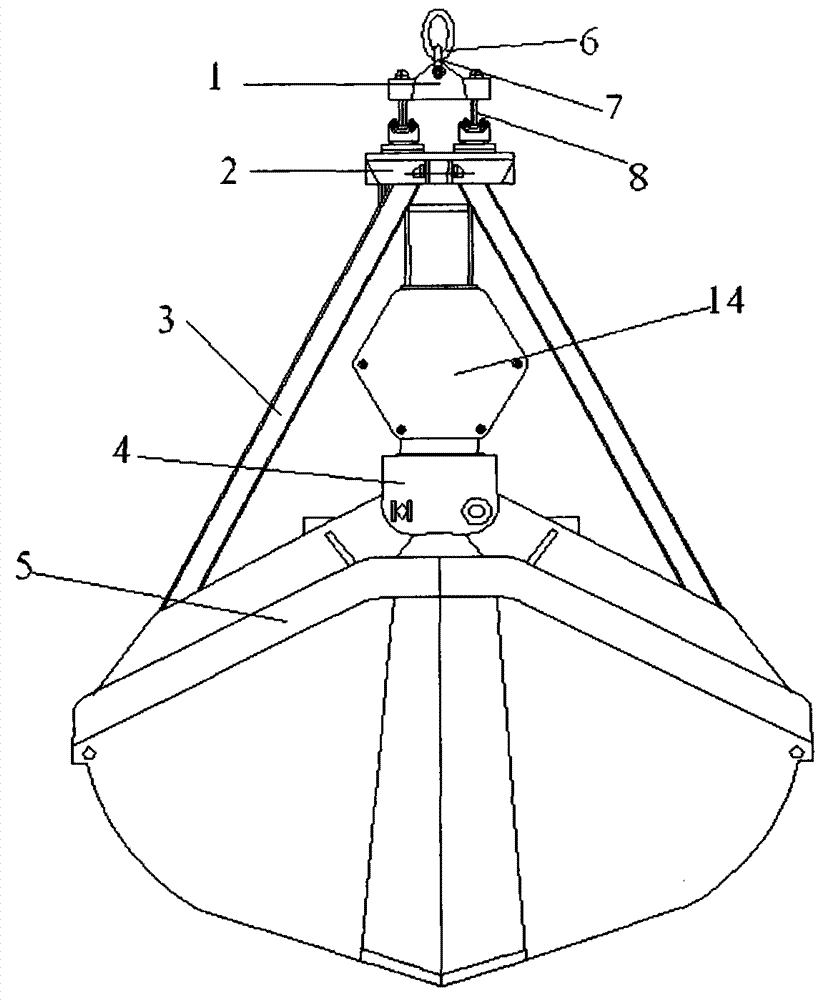

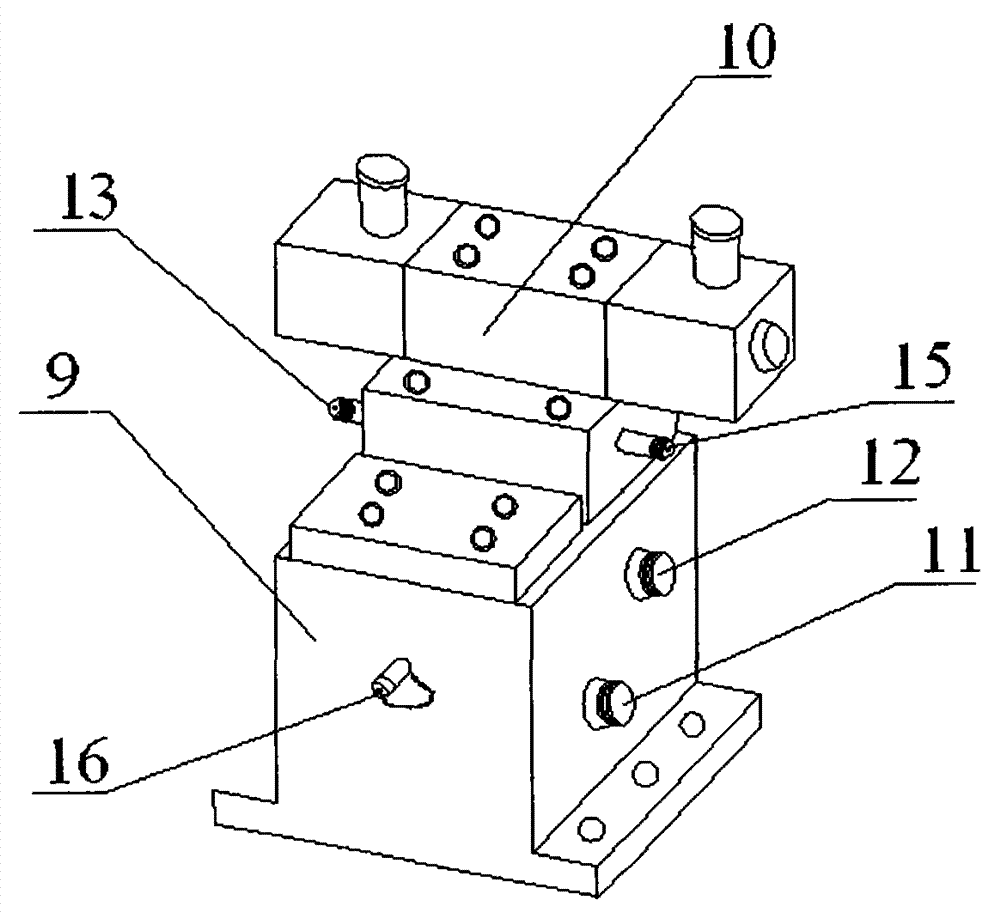

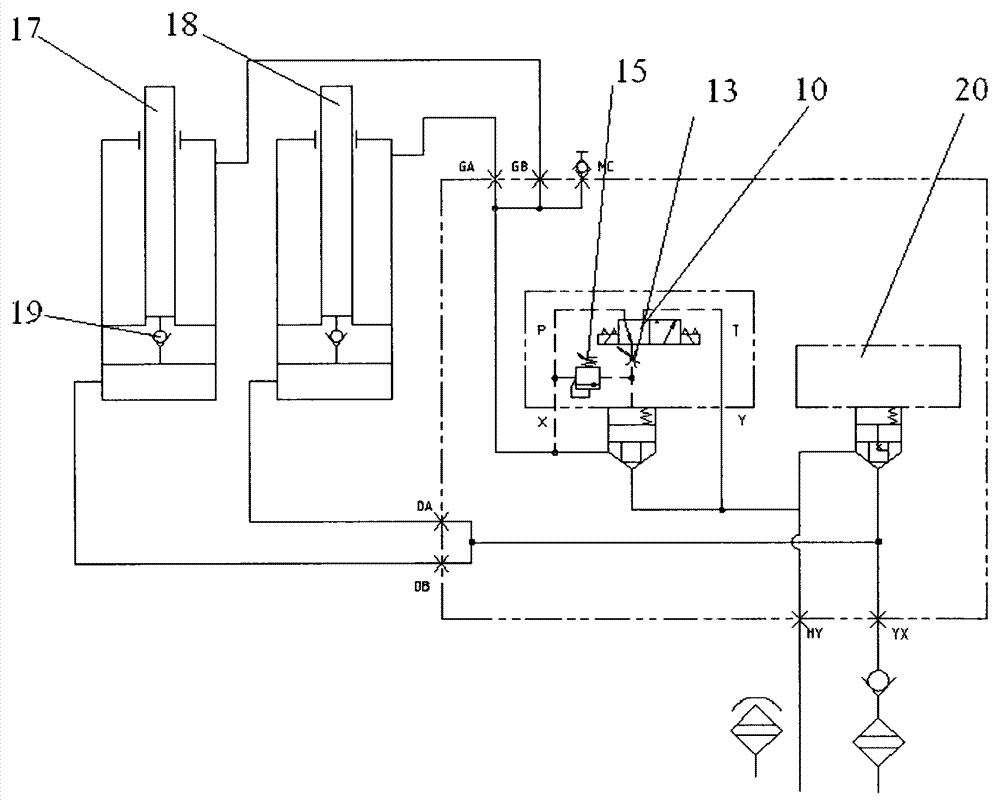

[0020] Such as figure 1 As shown, a schematic diagram of the structure of a remote control grab for stable unloading, the grab includes an upper bolster 2 and a lower bolster 4, the upper bolster 4 is connected with a bucket body 5 and a transmission device, and the lower bolster 4 is provided with a hydraulic pressure circuit, the lower bolster 4 and the bucket body 5 are rotatably connected, the top of the upper bolster 2 is provided with a balance frame 1, and the balance frame 1 is provided with a long ring 6, and the long ring 6 and the balance frame 1 are connected by unloading The buckle 7 is connected, the bucket body 5 is a two-petal type, the upper bolster 2 and the bucket body 5 form a fixed connection through the strut 3, and the lower bolster 4 and the bucket body 5 are movable hinges, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com