A Feeder Coupled with Double Discharge Valve and Venturi Tube

A technology of Venturi tube and discharge valve, which is used in conveying bulk materials, transportation and packaging, conveyors, etc., can solve the problems of unstable material supply, blockage of Venturi structure, large fluctuation of material supply, etc., so as to facilitate material output. , The effect of small discharge impact and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

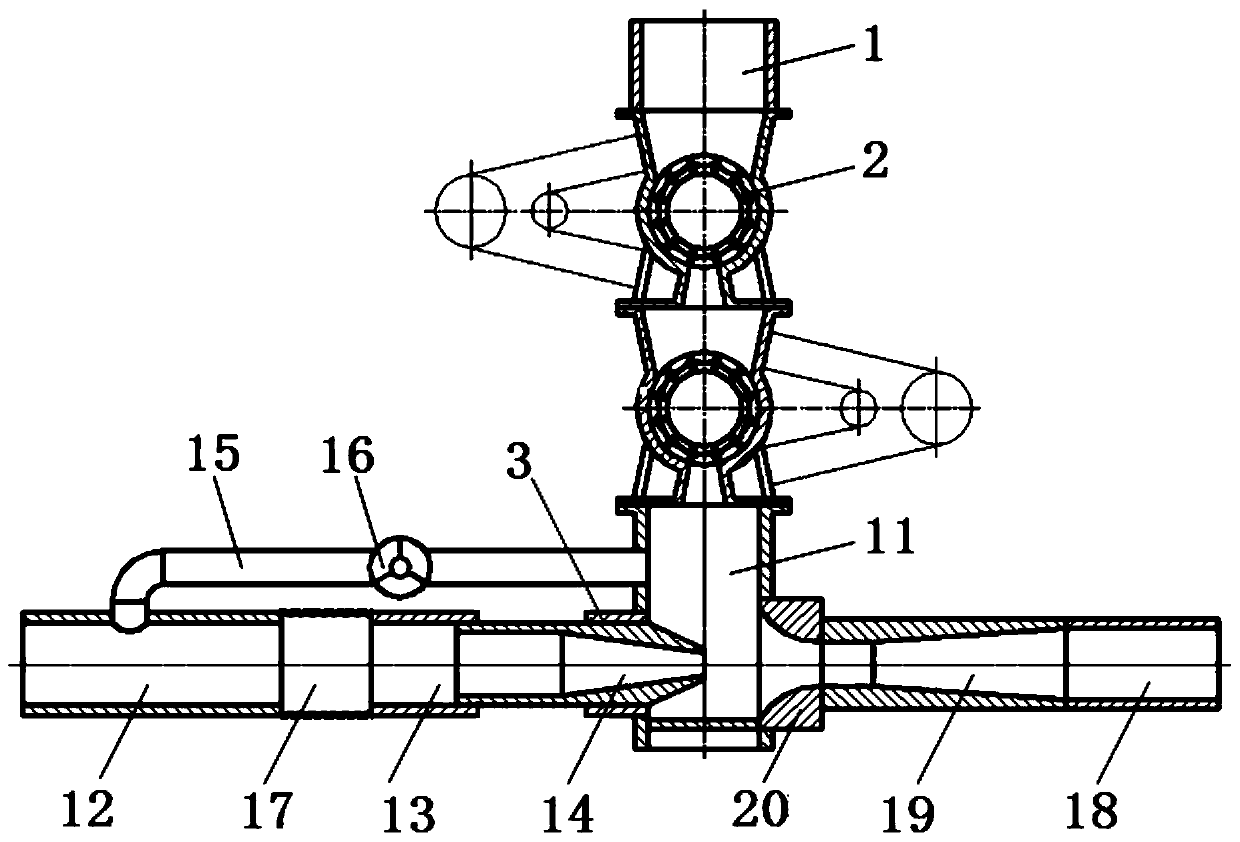

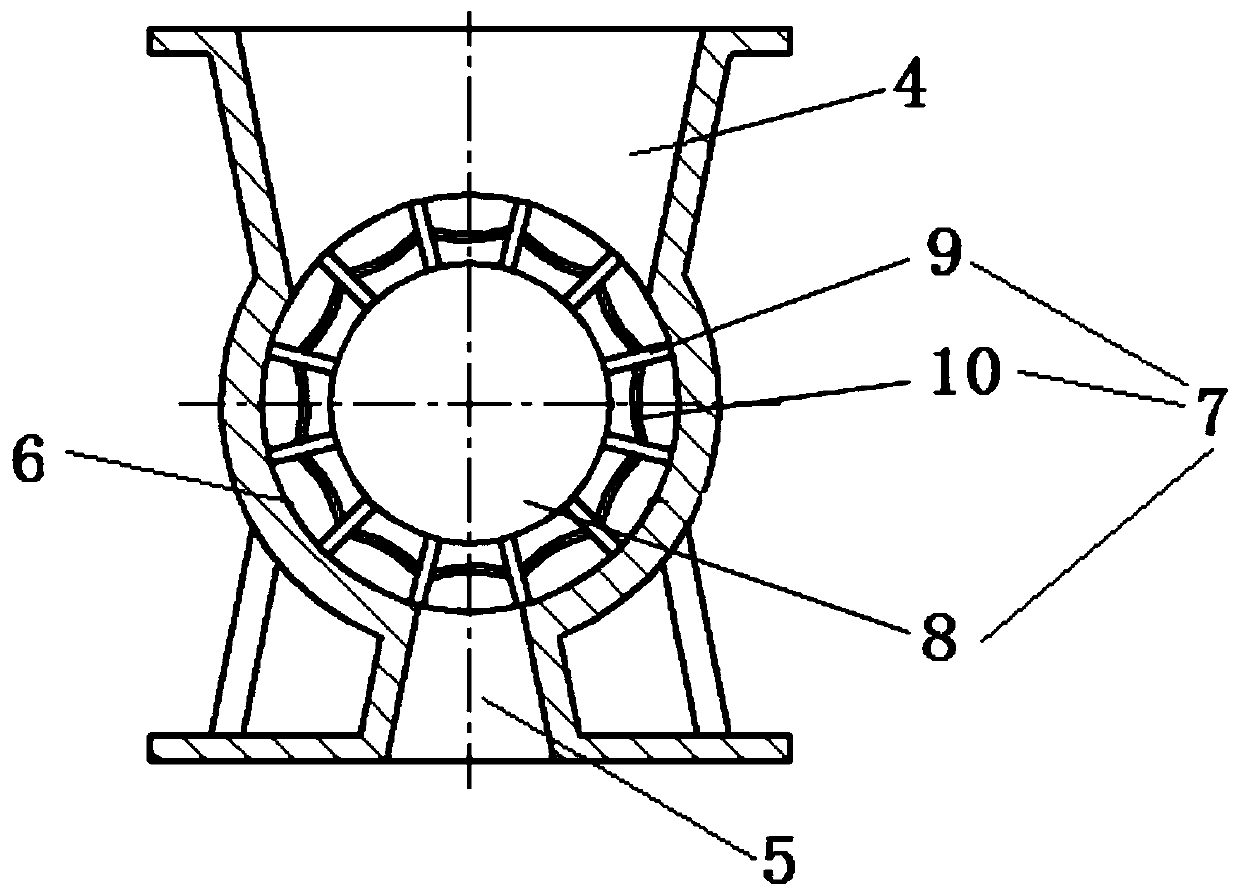

[0032] Such as figure 1 , figure 2As shown, the inner diameter of the rotating chamber 6 is 200mm, and there are 12 blades 9 evenly arranged in the circumferential direction on the discharge shaft 8, and the positions of the 12 base plates 10 on the impeller 7 are the same, so that the volumes of the 12 material cavities are the same, The sum of the volumes of the 12 chambers is 2.7L. The lower end of the material inlet 4 in the discharge valve 2 corresponds to 4 to 5 material cavities on the impeller 7, and the upper end of the material outlet 5 corresponds to 1 to 2 material cavities. The solid material enters the material chamber of the upper discharge valve 2 through the upper discharge pipe 1. When the speed of the discharge shaft 8 of the upper discharge valve 2 is 25r / min, since there are 12 material cavities in one circle of the impeller 7 , the discharge valve 2 at the upper end has 5 material cavities per second to participate in the discharge, and the material is...

Embodiment 2

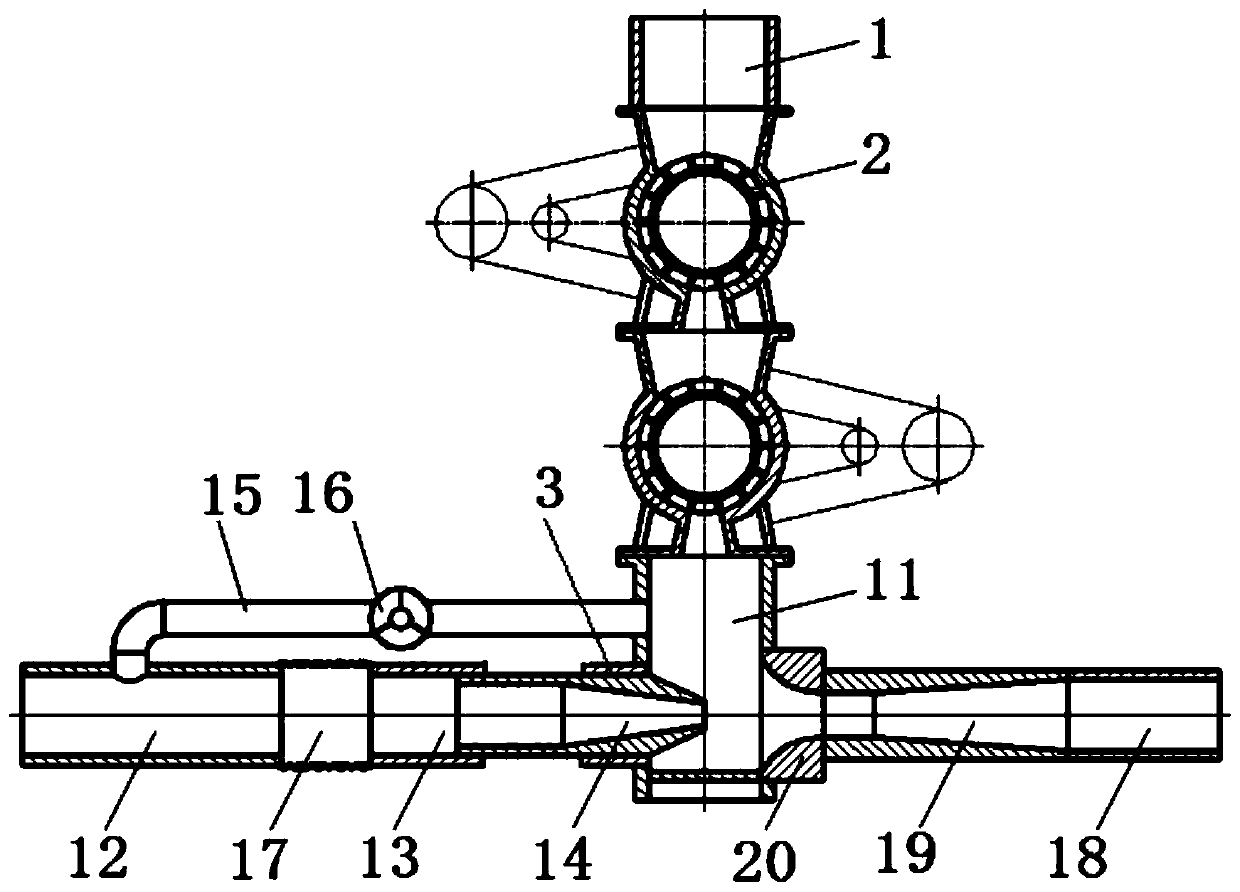

[0034] Such as image 3 , Figure 4 As shown, the inner diameter of the rotating chamber 6 is 250mm, and there are 14 blades 9 evenly arranged in the circumferential direction on the discharge shaft 8, and the positions of the 14 base plates 10 on the impeller 7 are the same, so that the volumes of the 14 material cavities are the same, The sum of the volumes of the 14 chambers is 5.7L. The lower end of the feed port 4 in the discharge valve 2 corresponds to 3 to 4 material cavities on the impeller 7, and the upper end of the discharge port 5 corresponds to 1 to 2 material cavities. The solid material enters the material chamber of the upper discharge valve 2 through the upper discharge pipe 1. When the speed of the discharge shaft 8 of the upper discharge valve 2 is 25r / min, since there are 14 material cavities in one circle of the impeller 7 , the discharge valve 2 at the upper end has about 5.8 material cavities per second to participate in the discharge, and the material...

Embodiment 3

[0036] Such as Figure 5 , Figure 6 As shown, the inner diameter of the rotating chamber 6 is 300mm, and there are 16 blades 9 evenly arranged in the circumferential direction on the discharge shaft 8, and the positions of the 16 base plates 10 on the impeller 7 are the same, so that the volumes of the 16 material cavities are the same, The sum of the volumes of the 16 chambers is 8.8L. The lower end of the feed port 4 in the discharge valve 2 corresponds to 3 to 4 material cavities on the impeller 7, and the upper end of the discharge port 5 corresponds to 1 to 2 material cavities. The solid material enters the material chamber of the upper discharge valve 2 through the upper discharge pipe 1. When the speed of the discharge shaft 8 of the upper discharge valve 2 is 25r / min, since there are 16 material cavities in one circle of the impeller 7 , the discharge valve 2 at the upper end has about 6.7 material cavities per second to participate in the discharge, and the materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com