Plate-and-frame filter press convenient for discharging

A technology of plate and frame filter press and unloading plate, which is applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., and can solve problems such as unloading of easily damaged receiving equipment, reduction of unloading efficiency, and transfer of filter cakes. , to achieve a good cushioning effect, reduce the impact force, and improve the efficiency of collecting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

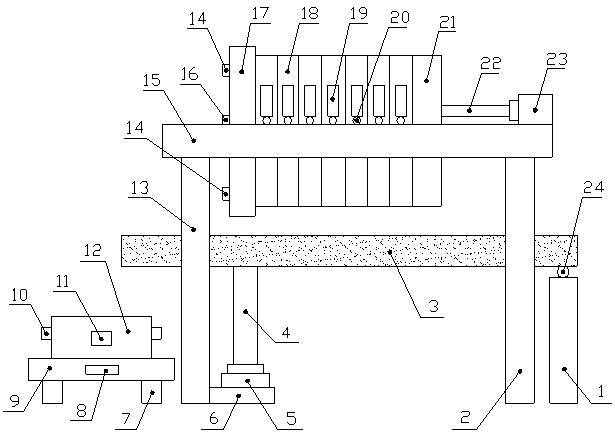

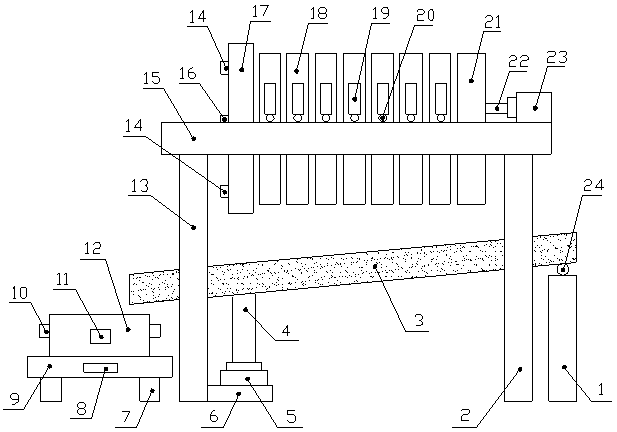

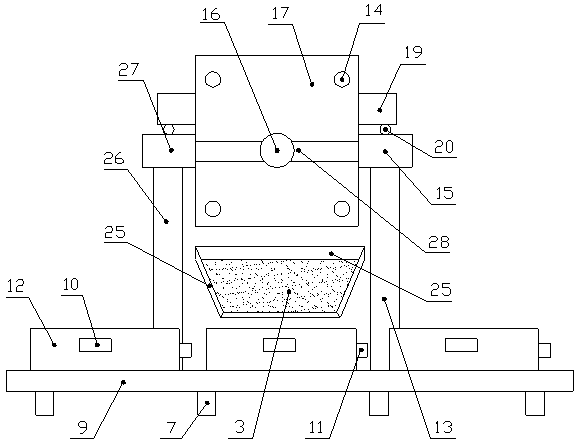

[0020] Such as Figure 1-4 As shown, a plate and frame filter press that is convenient for unloading includes a support beam A15 and a support beam B27, and the left side of the lower end of the support beam A15 and the support beam B27 is fixedly installed with a left leg A13 and a left support beam respectively. Leg B26, the right side of the lower end of the support beam A13 and the support beam B26 is fixedly installed with the right leg 2, and the connecting rod 28 and the thrust plate 17 are fixedly connected between the support beam A13 and the support beam B26, The upper ends of the support beam A15 and the support beam B27 are slidably connected with a filter plate 18, and the filter plate 18 is located on the right side of the thrust plate 17, and the upper parts of the front and rear ends of the filter plate 18 are fixedly connected with a connecting plate 19 , the lower end of the connecting plate 18 is equipped with a traveling wheel 20, the traveling wheel 20 is ...

Embodiment 2

[0023] Such as Figure 1-4As shown, a plate and frame filter press that is convenient for unloading includes a support beam A15 and a support beam B27, and the left side of the lower end of the support beam A15 and the support beam B27 is fixedly installed with a left leg A13 and a left support beam respectively. Leg B26, the right side of the lower end of the support beam A13 and the support beam B26 is fixedly installed with the right leg 2, and the connecting rod 28 and the thrust plate 17 are fixedly connected between the support beam A13 and the support beam B26, The upper ends of the support beam A15 and the support beam B27 are slidably connected with a filter plate 18, and the filter plate 18 is located on the right side of the thrust plate 17, and the upper parts of the front and rear ends of the filter plate 18 are fixedly connected with a connecting plate 19 , the lower end of the connecting plate 18 is equipped with a traveling wheel 20, the traveling wheel 20 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com