Unloading device, incinerator and sludge treatment method

A technology of unloading device and incinerator, which is applied in the direction of combustion method, incinerator, combustion type, etc., and can solve the problems of insufficient sludge combustion and low efficiency of incinerator treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

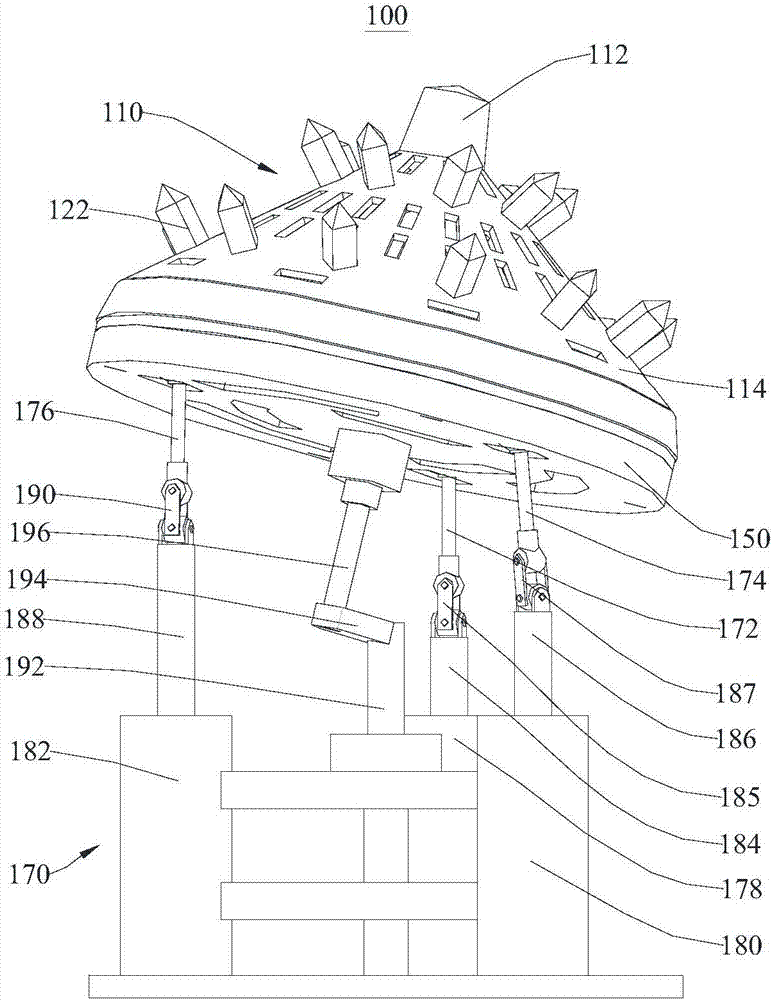

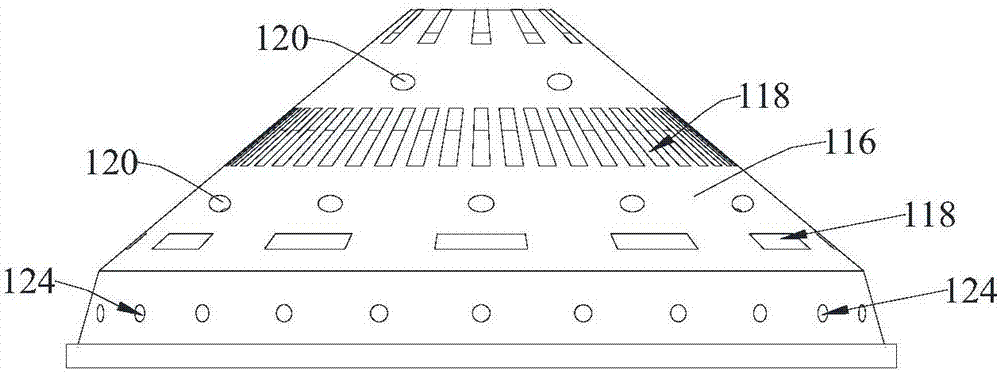

[0038] Please refer to figure 1 , figure 1Shown is a schematic structural view of the unloading device 100 . This embodiment provides a discharge device 100, which is mainly used for incinerating sludge with a sludge incinerator, and supporting and discharging the sludge.

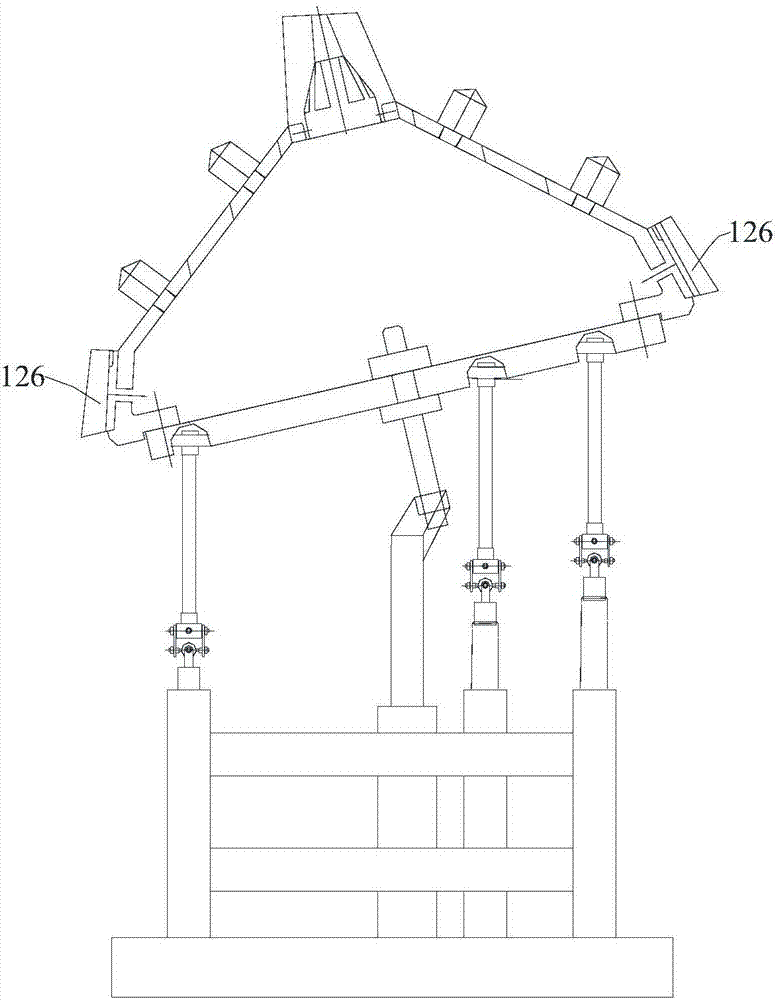

[0039] In this embodiment, the unloading device 100 includes a unloading tower 110 , a support plate 150 and a support assembly 170 connected in sequence. The support assembly 170 provides support for the unloading tower 110 and the support plate 150, so that the unloading tower 110 can provide stable support for the materials in the combustion process (mainly referring to sludge in this embodiment), and can also discharge the burned materials. Perform stable discharge. The support assembly 170 can also swing the unloading tower 110 through the support plate 150, so as to tumbling and loosen the burning materials, so that the materials can be burned more fully, and the combustion treatment efficiency of ...

Embodiment 2

[0055] Please refer to Figure 5 , Figure 5 Shown is a schematic structural view of the incinerator 300 . This embodiment provides an incinerator 300 , including a furnace body 310 and a discharge device 100 , and the discharge device 100 is located at the bottom of the furnace body 310 . The inner furnace wall of the furnace body 310 is provided with a second jaw plate 312 , and the second jaw plate 312 is spaced apart from the first jaw plate 126 . When the unloading tower 110 is in a bumpy state, the slag after the incineration of the material (mainly referring to sludge in this embodiment) passes through the gap between the first jaw plate 126 and the second jaw plate 312 and the unloading tower 110 itself has opening for unloading. Both the first jaw plate 126 and the second jaw plate 312 are made of wear-resistant materials, and the surfaces of the two jaw plates are concave-convex. During mutual movement, the slag can be crushed to make the discharge even.

[0056]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com