Corrugated paper machine with spiral oblique-tooth-shaped corrugated rollers

A corrugating machine and corrugating roller technology, applied in the direction of mechanical processing/deformation, can solve the problems of easy folding grooves, small thickness of cardboard, exposed flute and washboard, etc., and achieve the effect of convenient thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

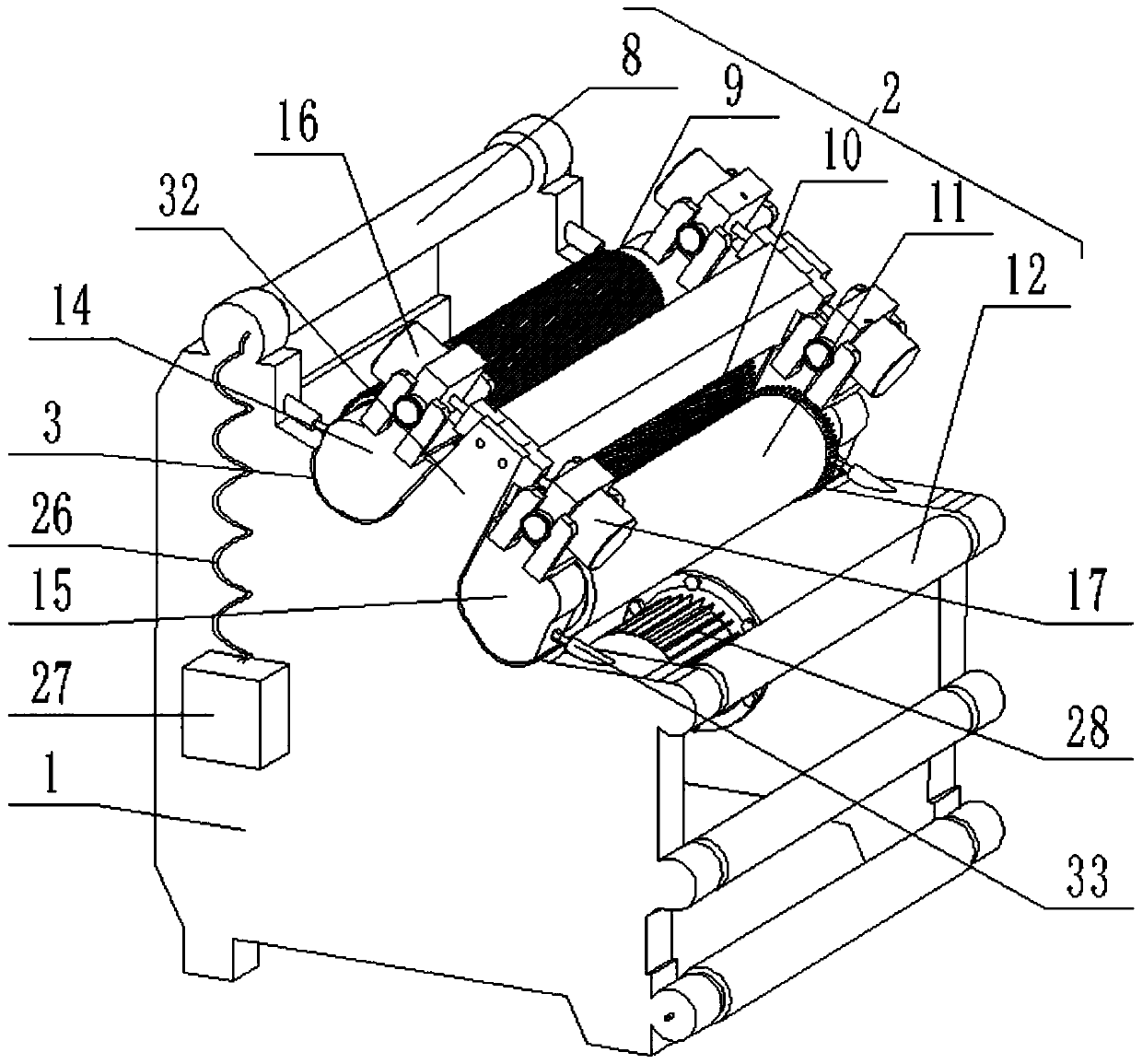

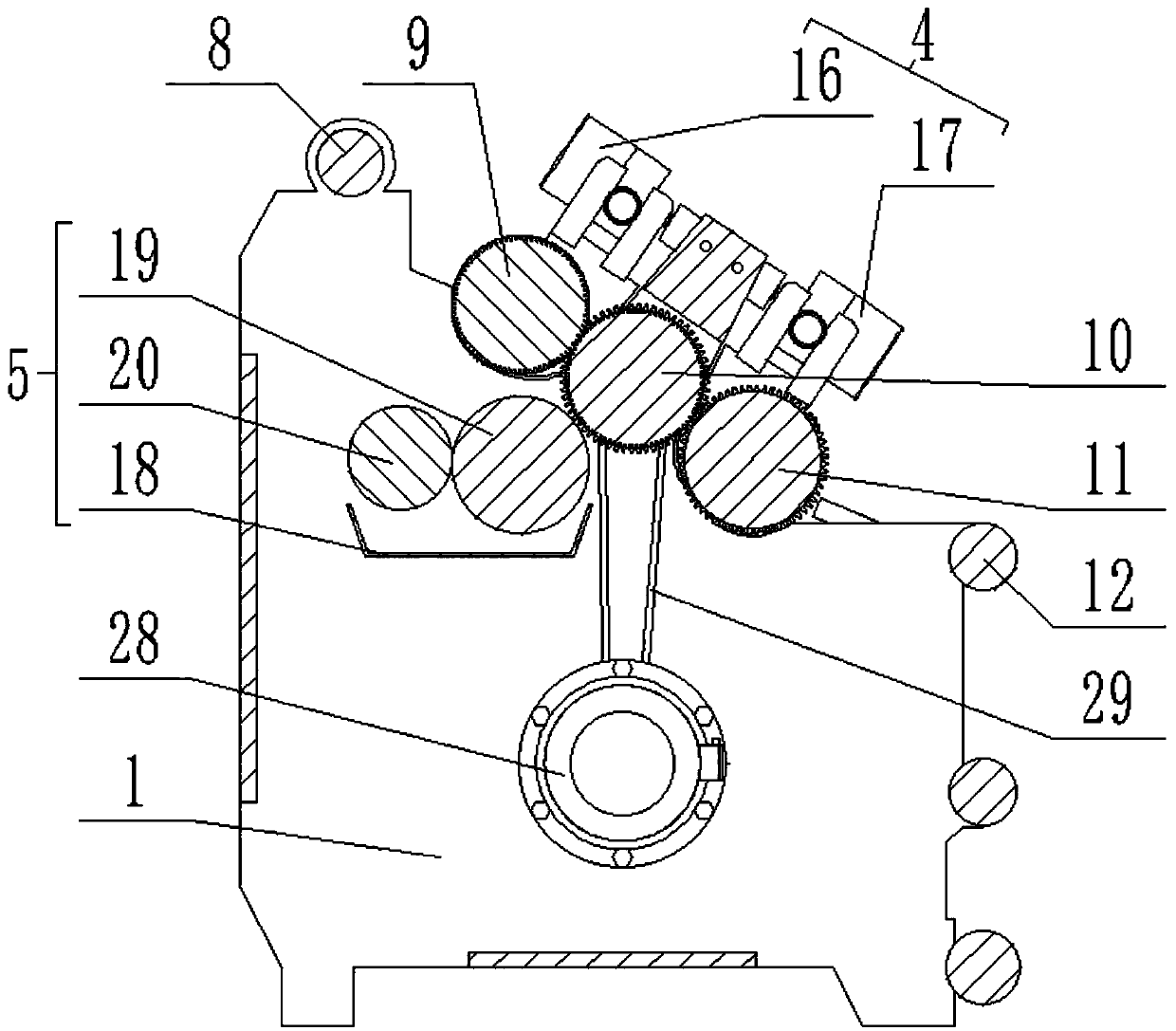

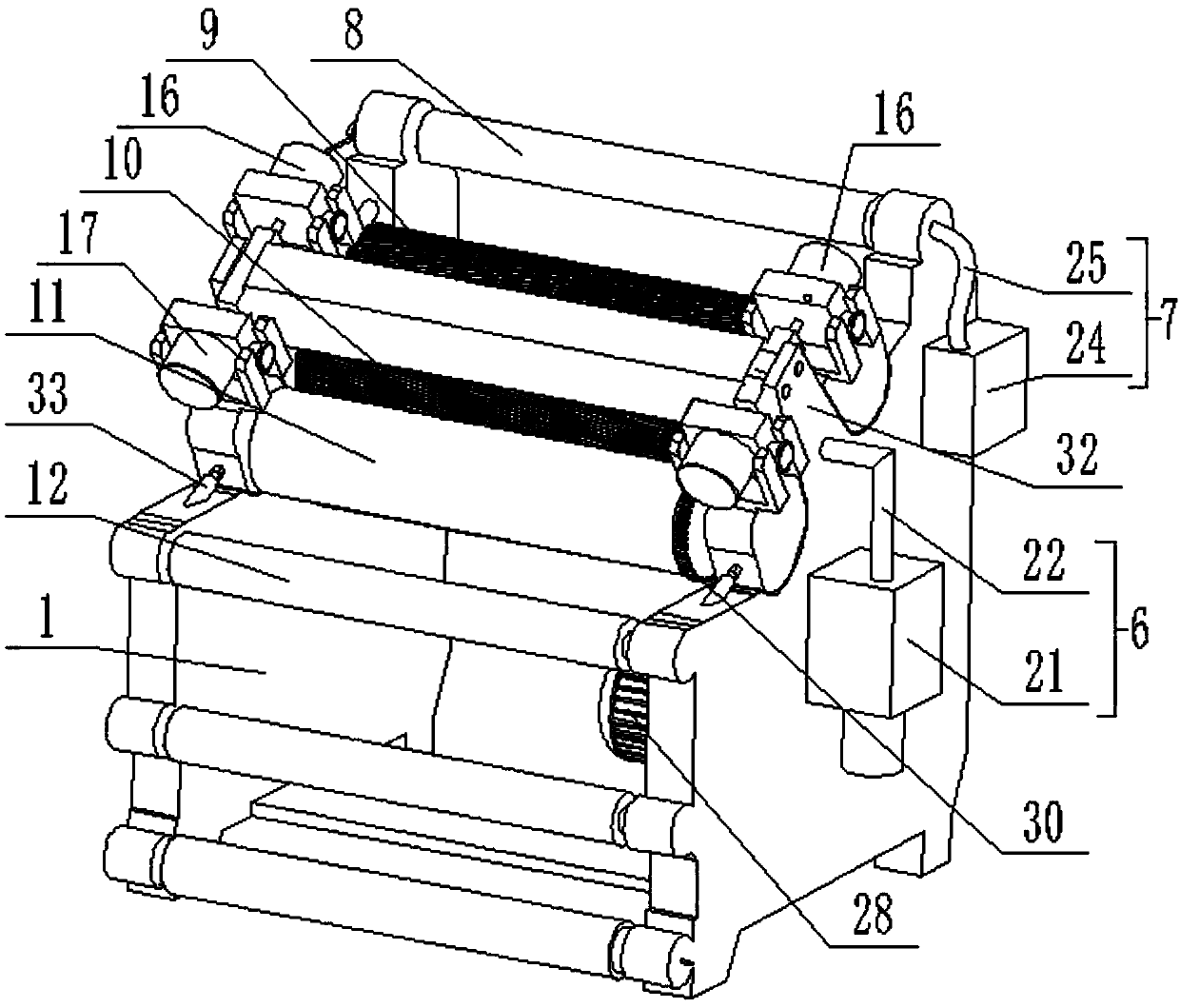

[0027] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-7As shown, a corrugating machine with spiral helical corrugating rollers comprises a frame (1), the inside of the frame (1) is provided with a corrugating roller group (2), and the corrugating roller group (2) is used for To make corrugated paper, the upper side of the frame (1) is provided with adjustment grooves (3) arranged in pairs, and a hydraulic adjustment mechanism (4) is arranged in the adjustment groove (3), and the hydraulic adjustment mechanism (4) is used for Adjust the gap size of each corrugating roller to meet different corrugated paper rolling requirements. The hydraulic adjustment mechanism (4) is arranged on both sides of the corrugating roller group (2), and the hydraulic adjustment mechanism (4) is arranged on the corrugating roller. Both ends are used to adjust the gap through hydraulic cylinders. The frame (1) is provided with a gluing mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com