Combined vehicle weighing module and split vehicle weighing system

A vehicle weighing and weighing module technology, which is applied in the direction of weighing indicating device, detailed information of weighing equipment, weighing, etc., can solve the problem of affecting the accuracy of sensor measurement data, large weight unbalanced weighing loss, and unbalanced pressure of the weighbridge. Balance and other issues, to achieve the effect of intelligent management, saving occupied area, and enhancing load-bearing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

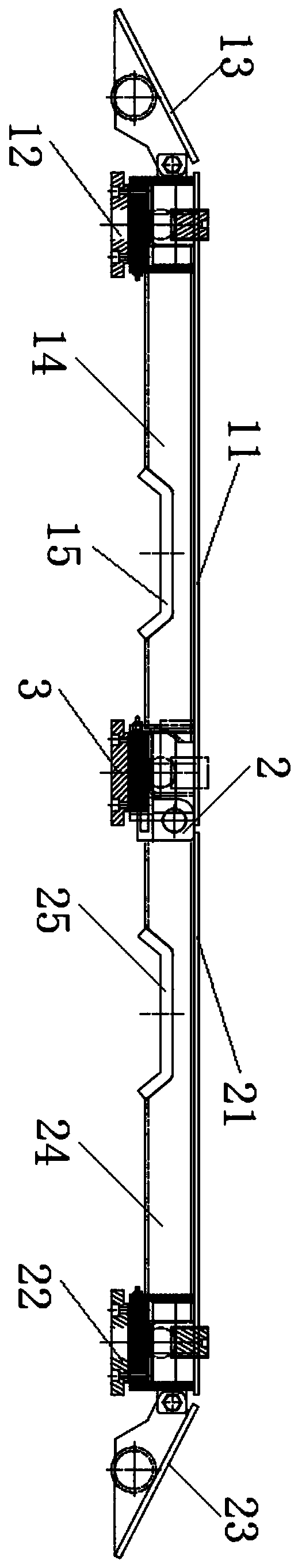

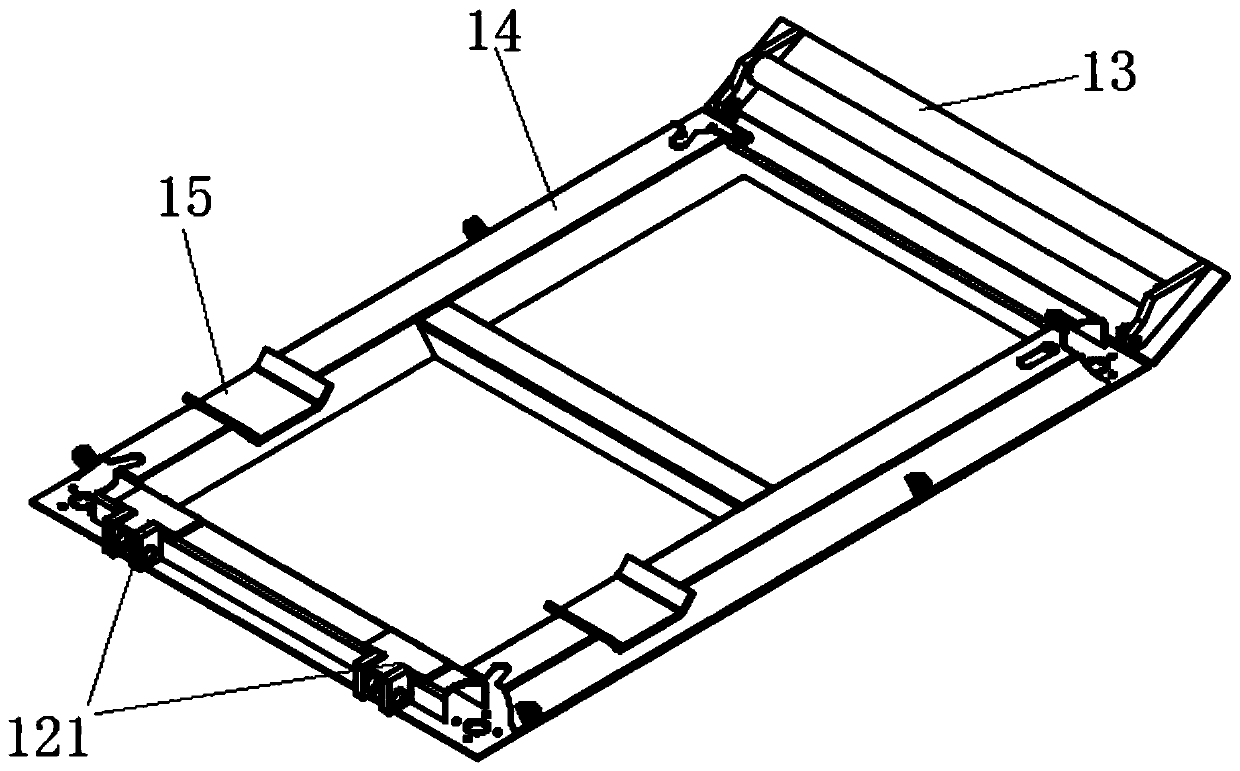

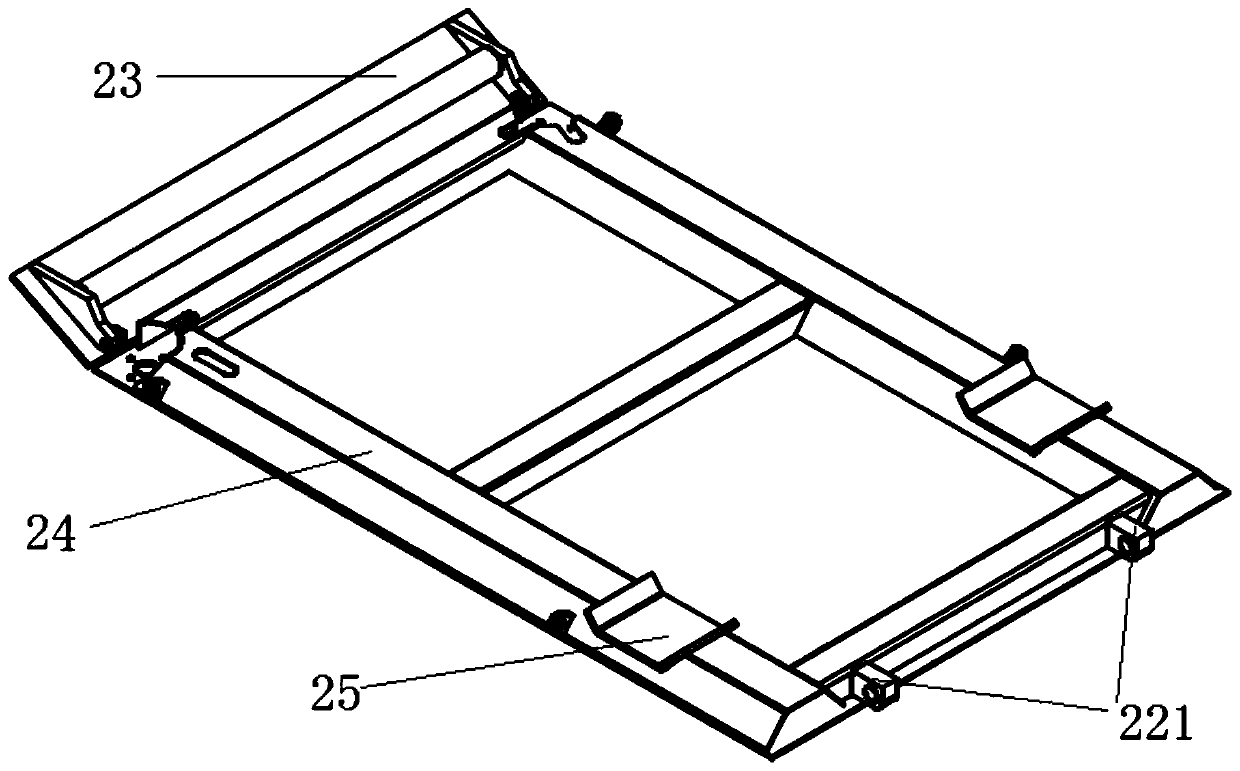

[0026] The combined vehicle weighing module of the present invention is composed of at least two load-bearing panels, and the weighing data of the whole vehicle can be obtained after measuring the local load value of the vehicle. Compared with the traditional large scale, the present invention can be flexible according to actual use requirements Assembled, compared with the traditional weighbridge, it is more flexible to use, and has lower requirements on the ground conditions of the weighing site. It does not need to deal with the ground when using it. The small load-bearing panel does not need to occupy a large area of the site, and it is easy to move. It is convenient to load, unload and transport through the connection of the hinge structure, which can greatly reduce the occupied area of the product storage site; correspondingly, the split vehicle weighing system of the present invention can select different combinations of load-bearing panels according to the weighing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com