Discharge door device for double-horizontal-shaft concrete mixer

A technology of concrete mixer and discharge door, which is applied in the direction of the discharge device, etc., can solve the problems of good door closing, high door opening efficiency, and poor sealing, so as to achieve a stable unloading process, reduce maintenance costs, and good sealing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

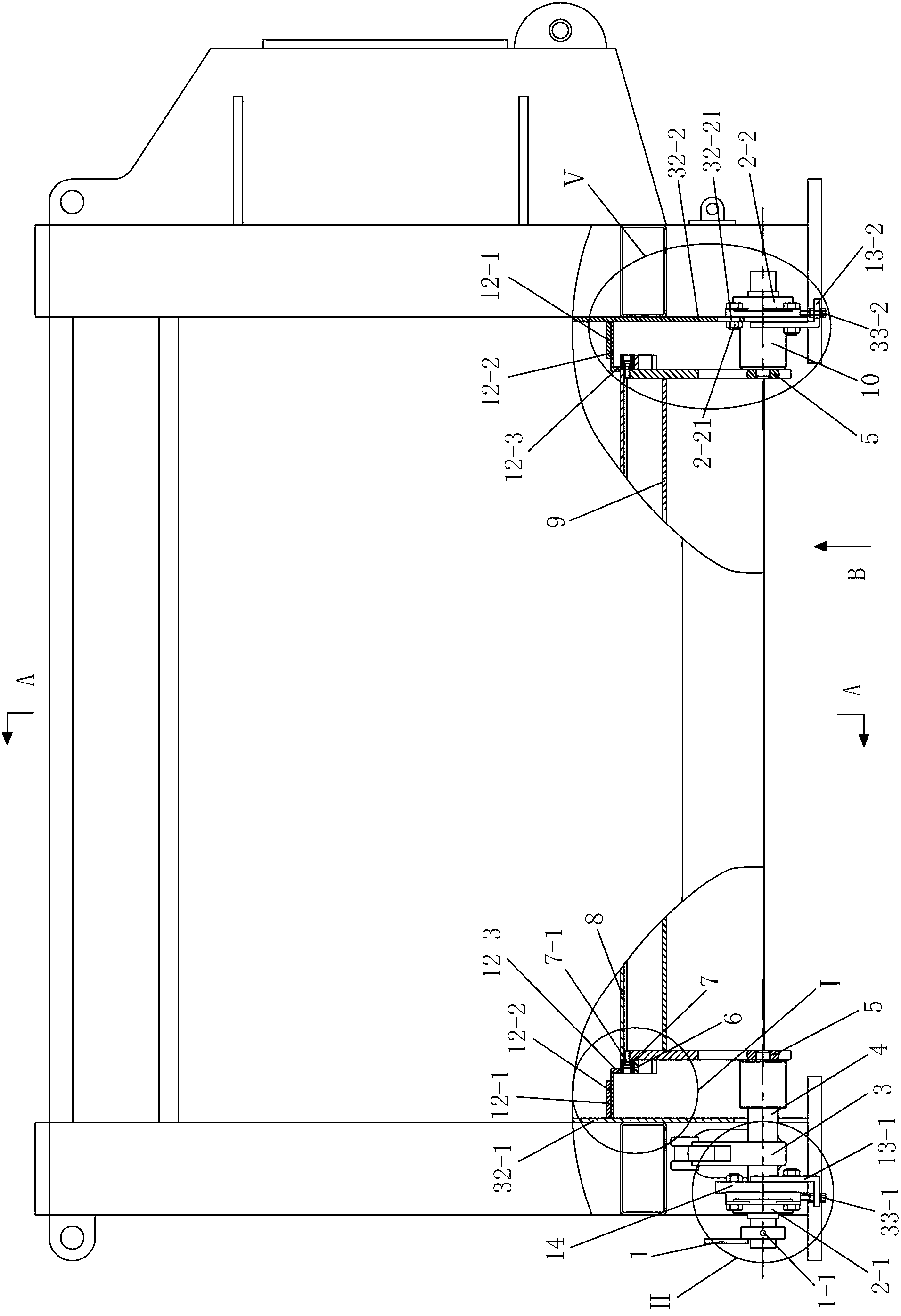

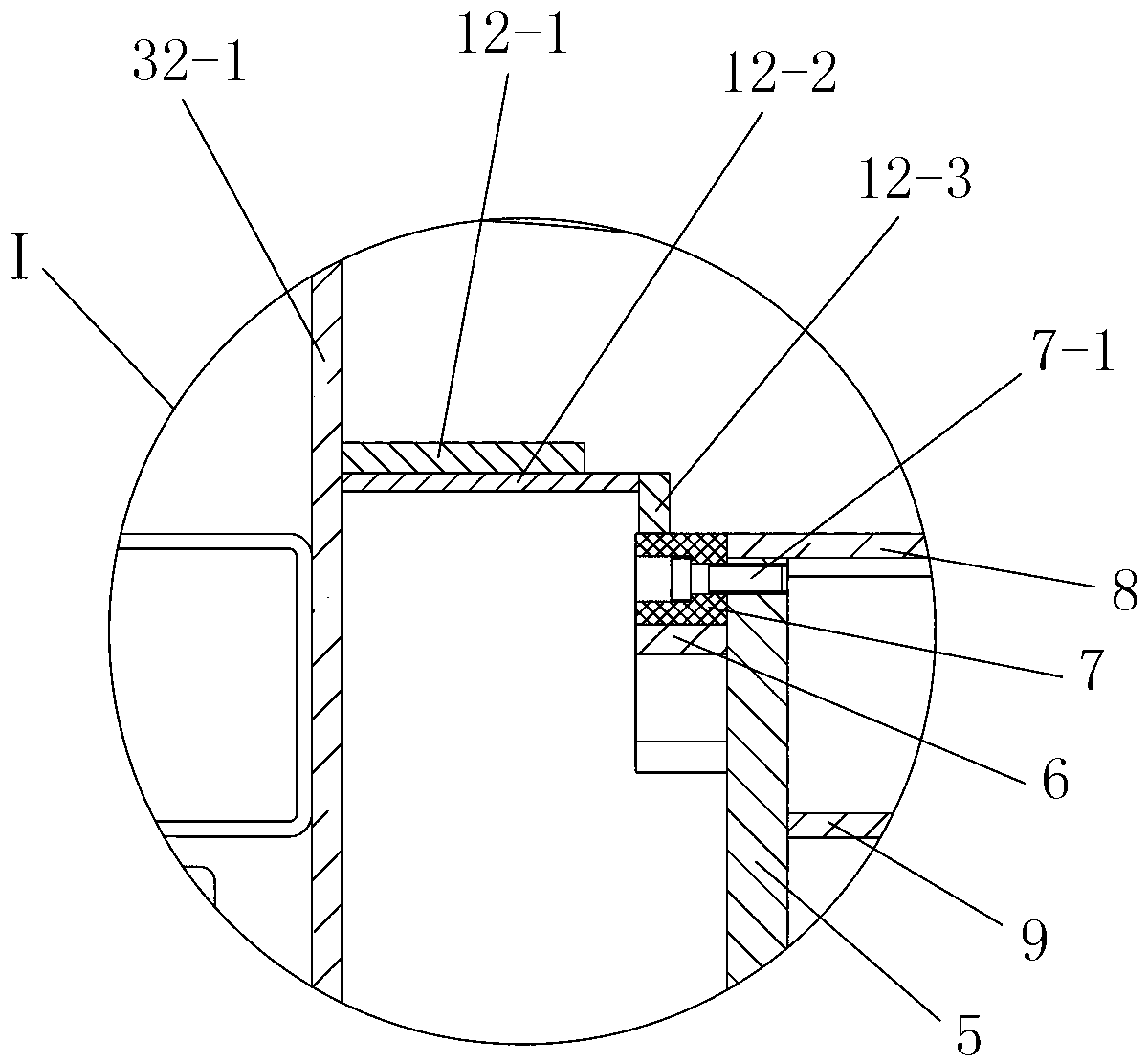

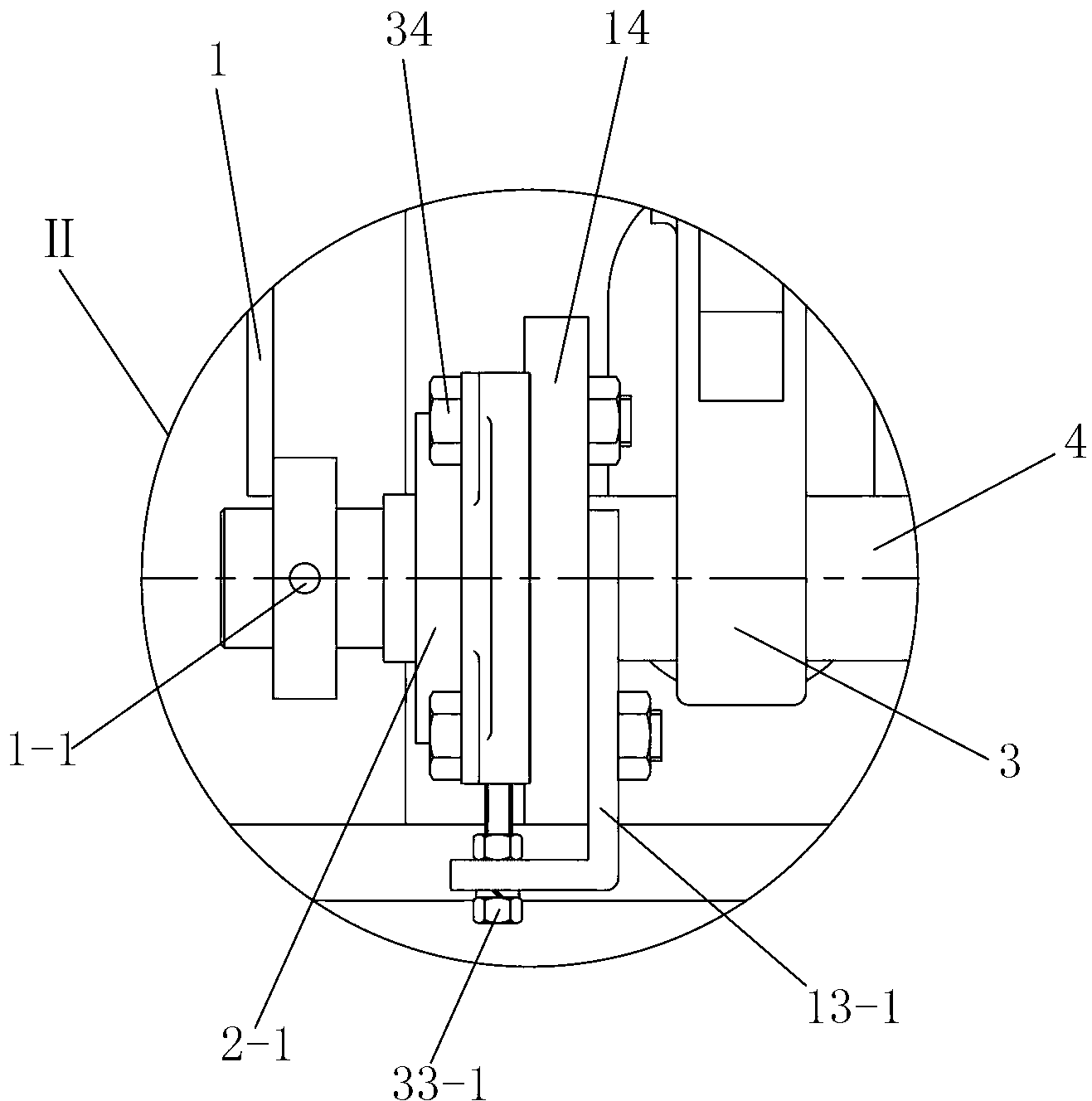

[0047] Such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 10 and Figure 11 As shown, the present invention includes a discharge door main body and a drive mechanism for driving the rotation of the discharge door main body. The discharge door main body includes a fan-shaped plate 5, an arc-shaped door plate 8, a V-shaped plate 9, a long axis 4 and The short axis 10, the number of the fan-shaped plates 5 is two, and the two fan-shaped plates 5 are respectively welded on the inner sides of the two ends of the arc-shaped door panels 8, and the end faces of the fan-shaped panels 5 and the arc-shaped door panels 8 are located at the same plane, the V-shaped plate 9 is located between the two fan-shaped plates 5 and its upper end is welded to the inner side of the arc-shaped door panel 8, the major axis 4 and the short axis 10 are respectively welded on the two fan-shaped plates 5 and the welding centers are all biased The opening end of the discharge door (because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com