Alignment film pre-solidifying device

A pre-curing, oriented film technology, applied in lighting and heating equipment, drying solid materials, heating to dry solid materials, etc., can solve the problems affecting the quality of the oriented film, poor display quality, display highlights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

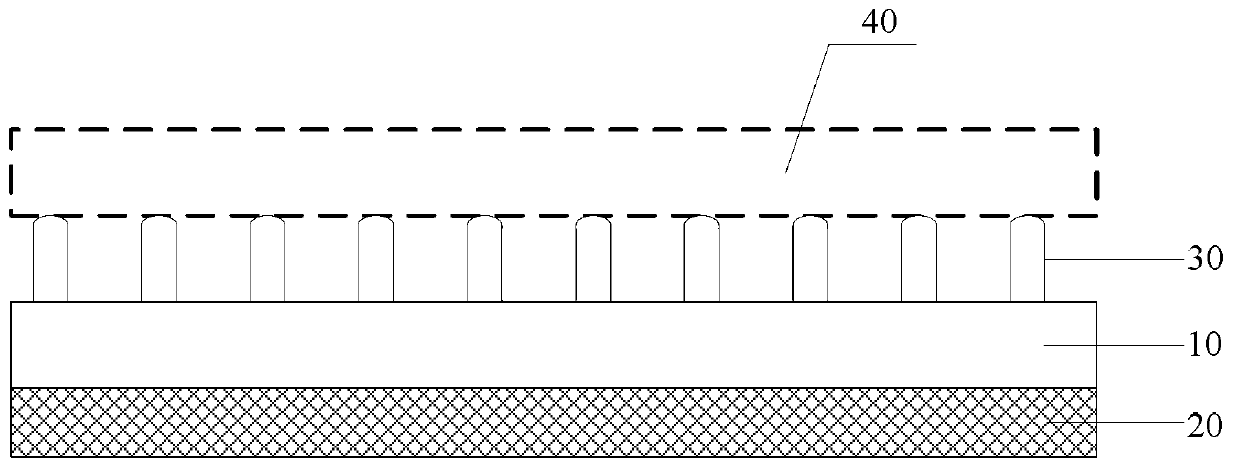

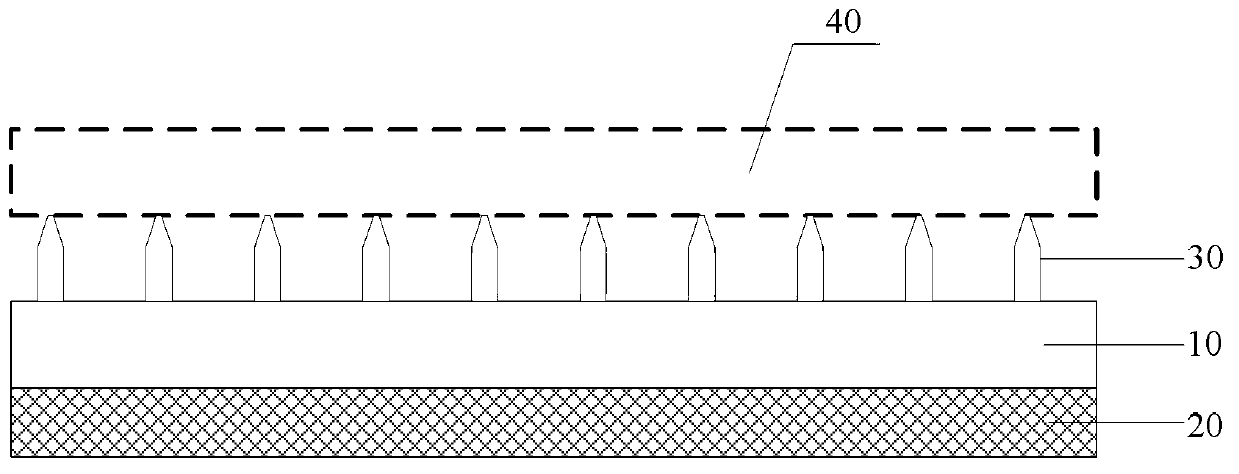

[0039] Embodiment 1, the embodiment of the present invention provides an alignment film pre-curing equipment, such as figure 2 As shown, it includes a workbench 10, a heating plate 20 arranged under the workbench, and a plurality of support pins 30, the plurality of support pins are used to support the substrate 40, and the plurality of support pins 30 are arranged on the between the substrate 40 and the workbench 10 .

[0040] Wherein, the diameter of the tip of each of the plurality of support pins 30 is 0.5 mm, and each of the support pins 30 is made of PEEK or PI.

[0041]In this way, on the one hand, since PEEK or PI have the characteristics of high temperature resistance and low thermal conductivity, when each support pin 30 is made of PEEK or PI, the heat transferred to the corresponding place on the surface of the substrate 40 through the support pin 30 can be reduced. , on the other hand, since the diameter of the top of each support pin is only 0.5 mm, that is, the...

Embodiment 2

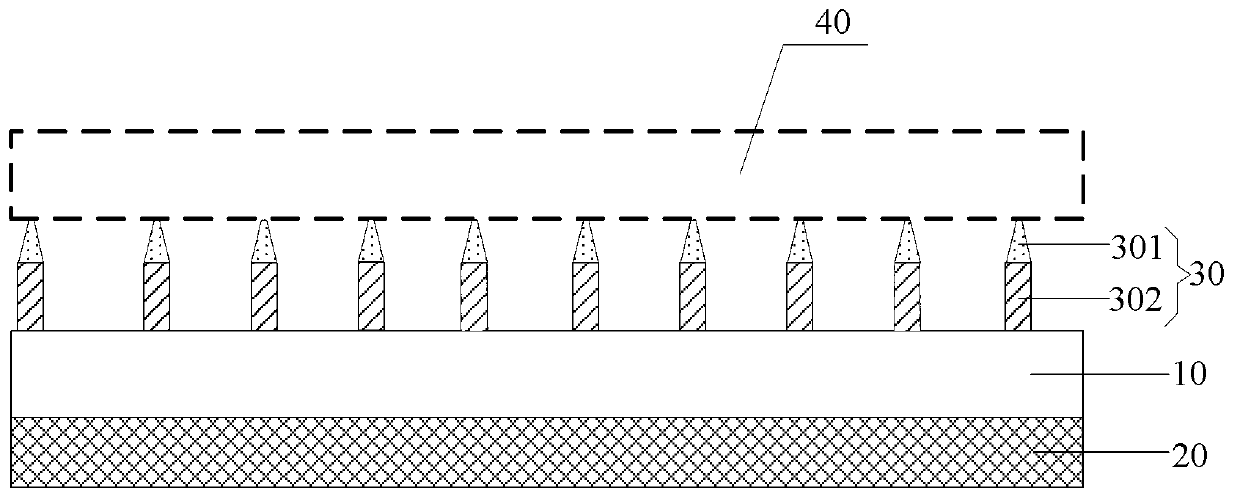

[0050] Embodiment 2, the embodiment of the present invention provides an alignment film pre-curing equipment, such as image 3 As shown, the pre-curing equipment includes a workbench 10, a heating plate 20 arranged below the workbench, and a plurality of support pins 30, the plurality of support pins are used to support the substrate 40, and the plurality of support pins 30 is disposed between the substrate 40 and the workbench 10 . Each support needle 30 includes a support needle 301 and a support column 302 , the support column 302 is located below the support needle 301 and is used to support the support needle 301 .

[0051] Wherein, the supporting needle 301 is conical, and the diameter of its tip is 0.5 mm; the supporting column 302 is cylindrical. The support needle 301 is made of PEEK or PI; the support column 302 is made of stainless steel SUS.

[0052] Like this, on the one hand, because PEEK or PI has the characteristics of high temperature resistance and low ther...

Embodiment 3

[0062] Embodiment three, such as Figure 6 As shown, the embodiment of the present invention provides an alignment film pre-curing equipment, the pre-curing equipment includes: a workbench 10, a heating plate 20 arranged under the workbench, and a plurality of support pins 30, the plurality of The support pins are used to support the substrate 40, and the plurality of support pins 30 are arranged between the substrate 40 and the workbench 10 and pass through the workbench 10 and the heating plate 20; further comprising: fixing the A fixing device 50 for supporting the needle, a lifting device 60 for driving the fixing device up and down, and an exhaust device 70 arranged around the working table 10 .

[0063] Wherein, each support needle 30 includes a support needle 301 and a support column 302 , the support column 302 is located below the support needle 301 and is used to support the support needle 301 . The fixing device 50 is located below the heating plate 20 and does not...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| High temperature resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com