Molten glass supply device, glass formed product, and method of producing the glass formed product

A technology of molten glass and supply equipment, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems such as the inability to provide countermeasures for furnace heat radiation, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

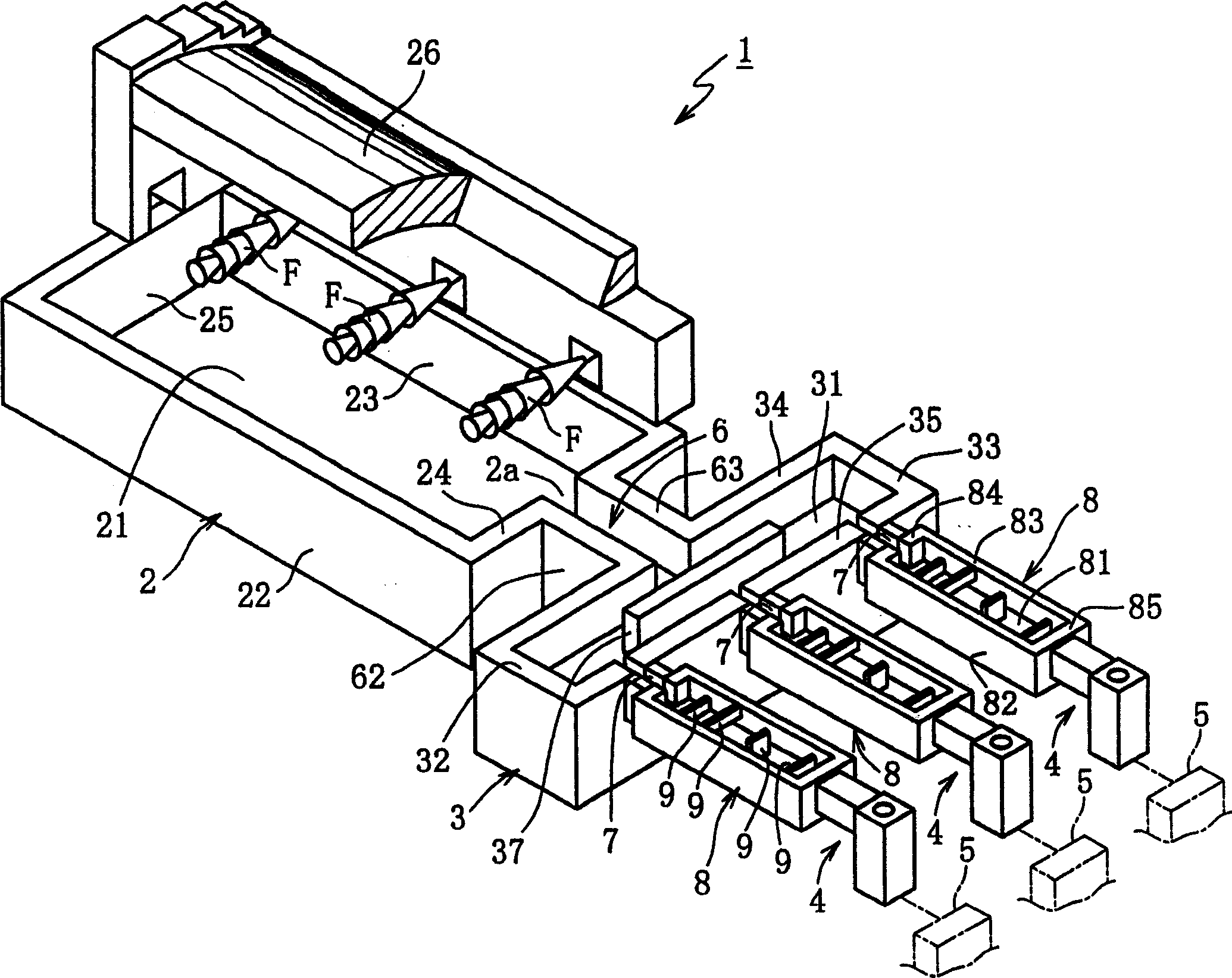

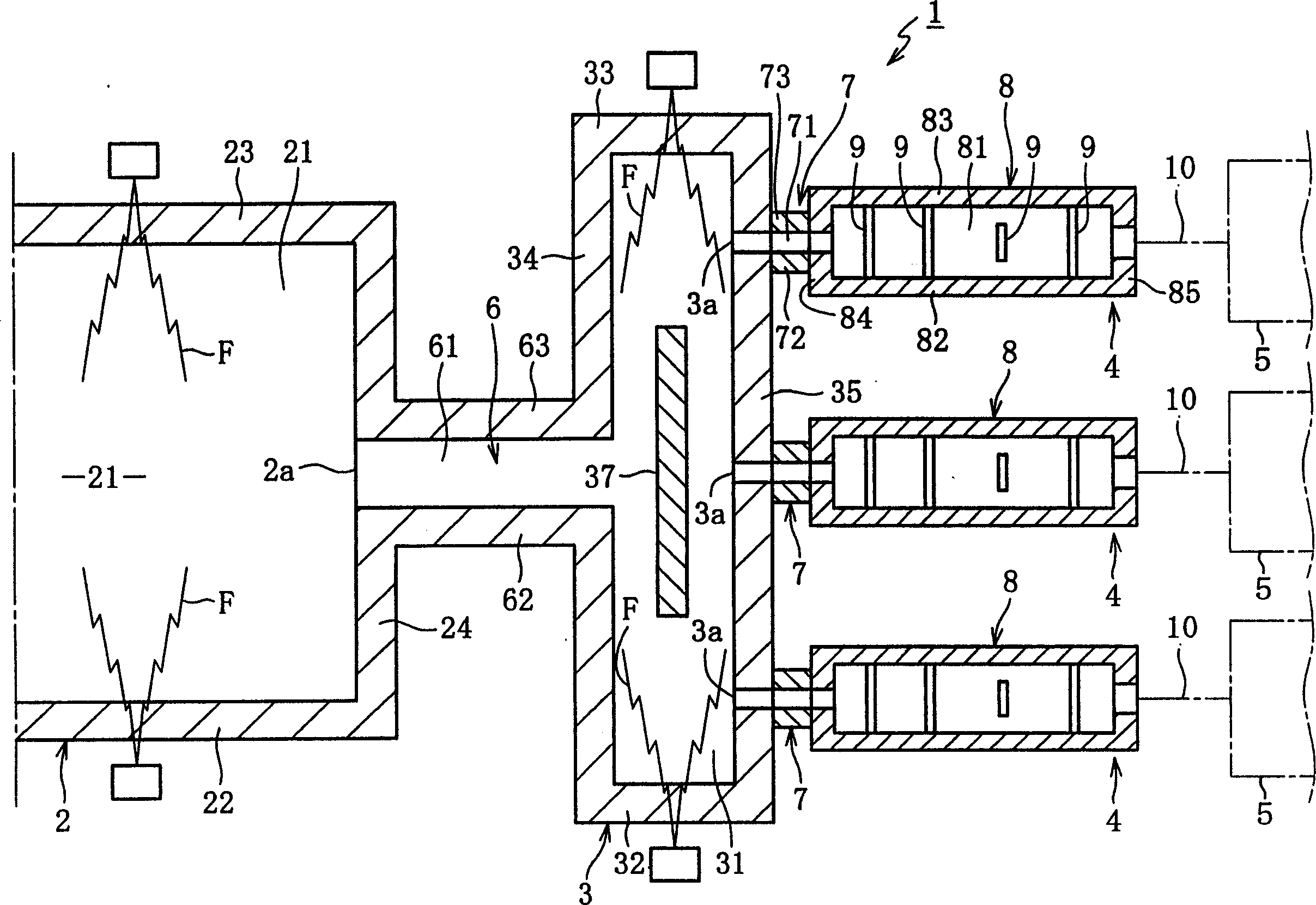

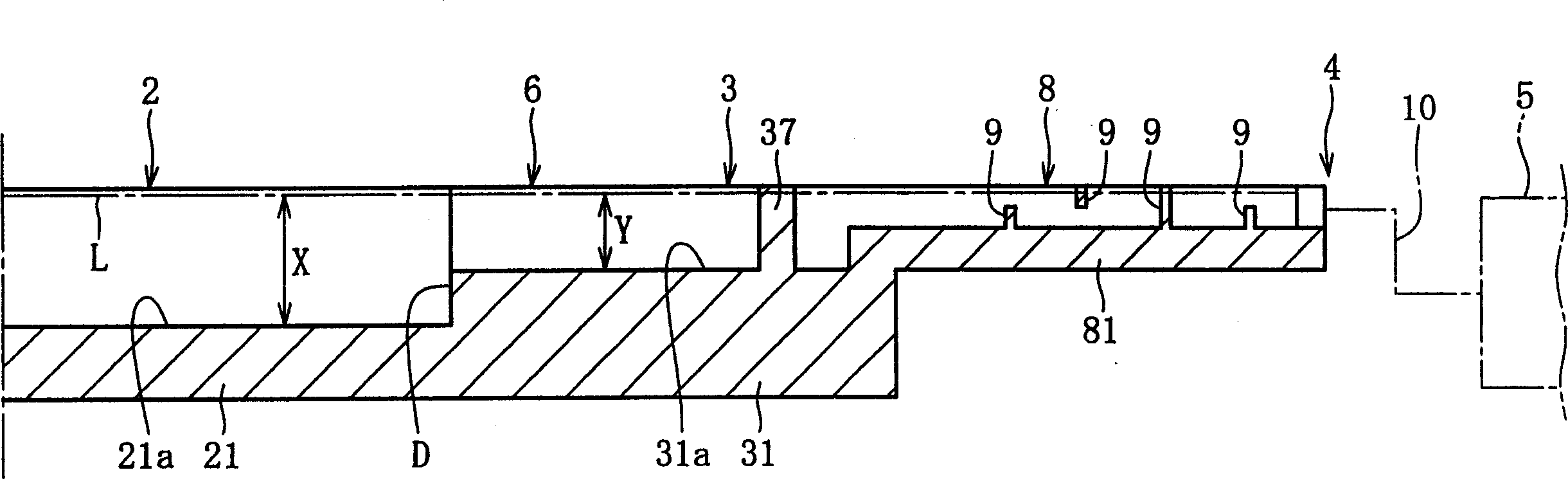

[0097] The following is an embodiment of the present invention, together with corresponding drawings. figure 1 A schematic cross-sectional view showing a partial structure of a molten glass supply device according to an embodiment of the present invention. figure 2 A schematic diagram showing a horizontal sectional plan of a molten glass supply device. image 3 A schematic diagram showing a vertical sectional plan of a molten glass supply device. Please note that in the following description, the direction between the upstream and downstream of the molten glass supply device is defined as the front-to-back direction (back-and-forth direction), and the direction perpendicular to the front-to-back direction is defined as right-to-left Direction (right-to-left direction).

[0098] Such as figure 1 and figure 2 As shown, it depicts a molten glass supply device according to an embodiment of the present invention. The molten glass supply device 1 generally includes a rectan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| high temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com