Gas-liquid distributor for fluidized bed reactor

A technology of ebullating bed reactors and gas-liquid distributors, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as check ball disturbance, large distribution plate openings, wear, etc., to prevent backflow and strengthen Effect of Gas-Liquid Feed Mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

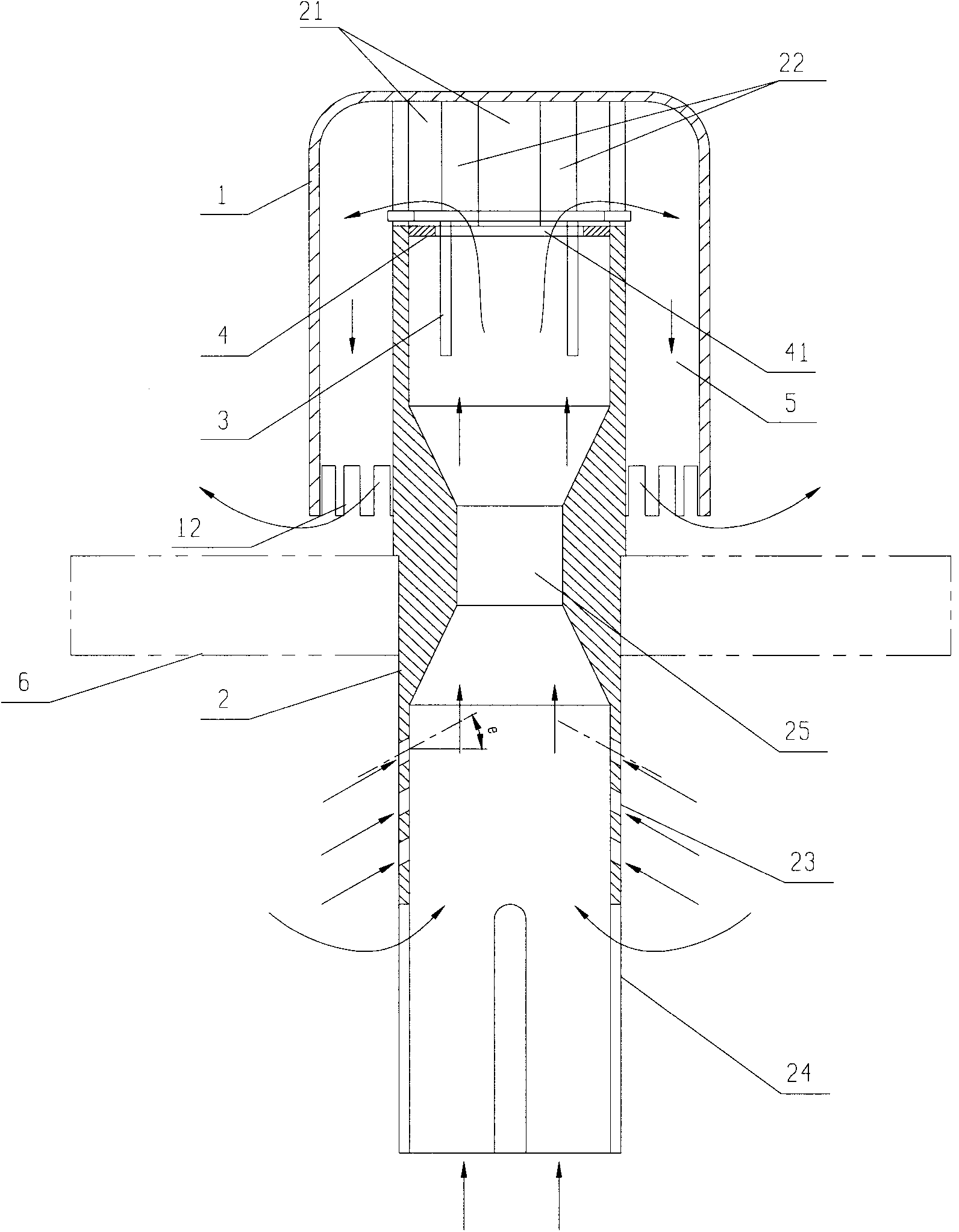

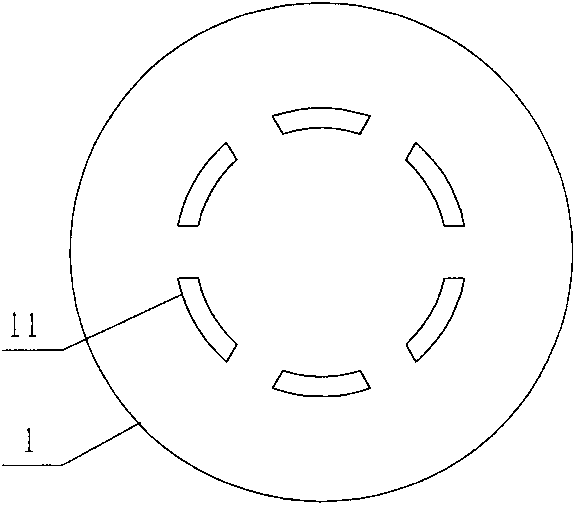

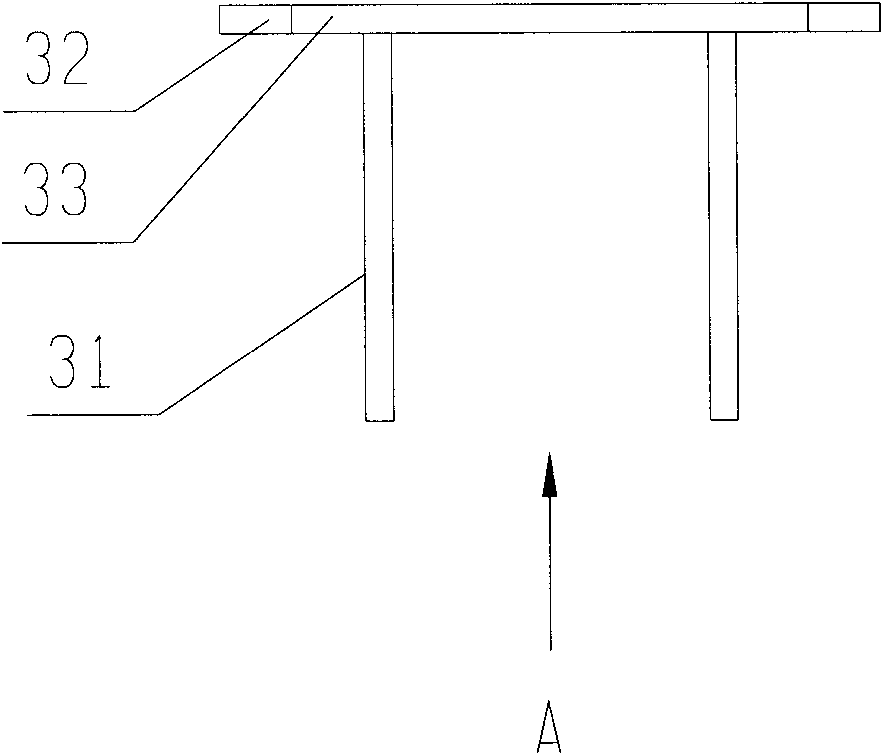

[0022] Such as figure 1 As shown, the gas-liquid distributor for ebullated bed reactor provided by the present invention is mainly made up of center tube 2, bubble cap 1, float valve 3 and valve seat 4; Bubble cap 1 bottom (being the blind end of bubble cap) is Circular plane, the connection between the bottom of the bubble cap and the tube wall is a round transition, the tube wall at the open end of the bubble cap 1 is provided with a slit 12 that runs through the end along the axial direction of the bubble cap 1, and the bubble cap 1 is covered by the central tube 2 At the end of the upper section, an annular channel 5 is formed between the inner wall of the bubble cap 1 and the outer wall of the central tube 2, and the bottom of the bubble cap 1 has a bubble cap hole 11 (such as figure 2 shown); the central pipe 2 passes through the installation hole on the distri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com