Precise ingredient activation feeder

An activated feeder, accurate technology, applied in the direction of conveyors, conveyor objects, loading/unloading, etc., can solve the problems of small conveying volume range, inability to adjust the total amount of belt materials, and high requirements on the properties of upper materials, so as to ensure stability output effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

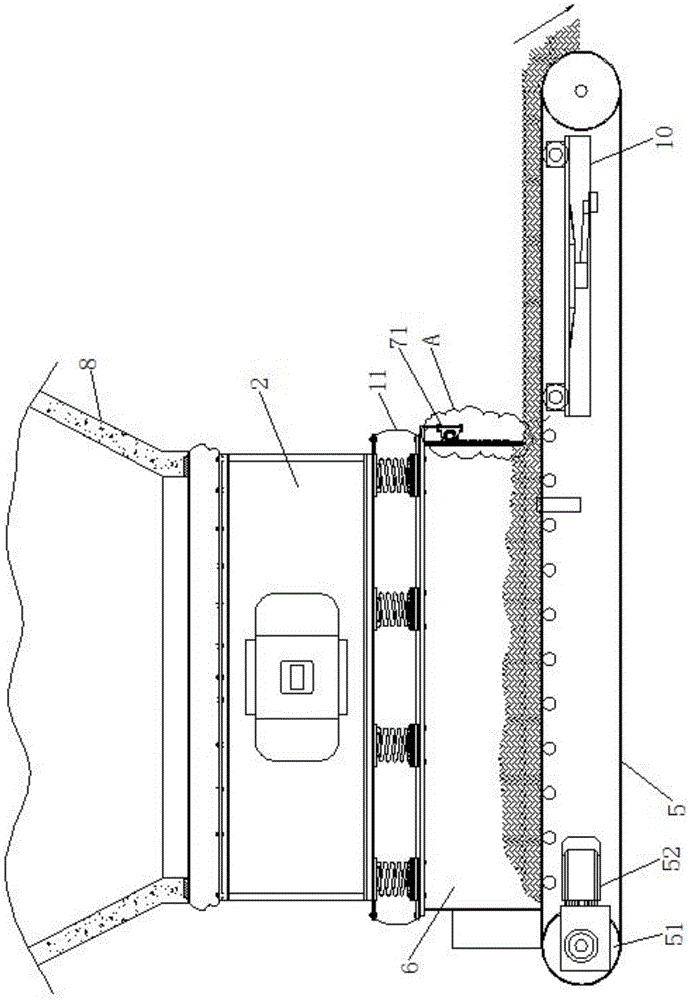

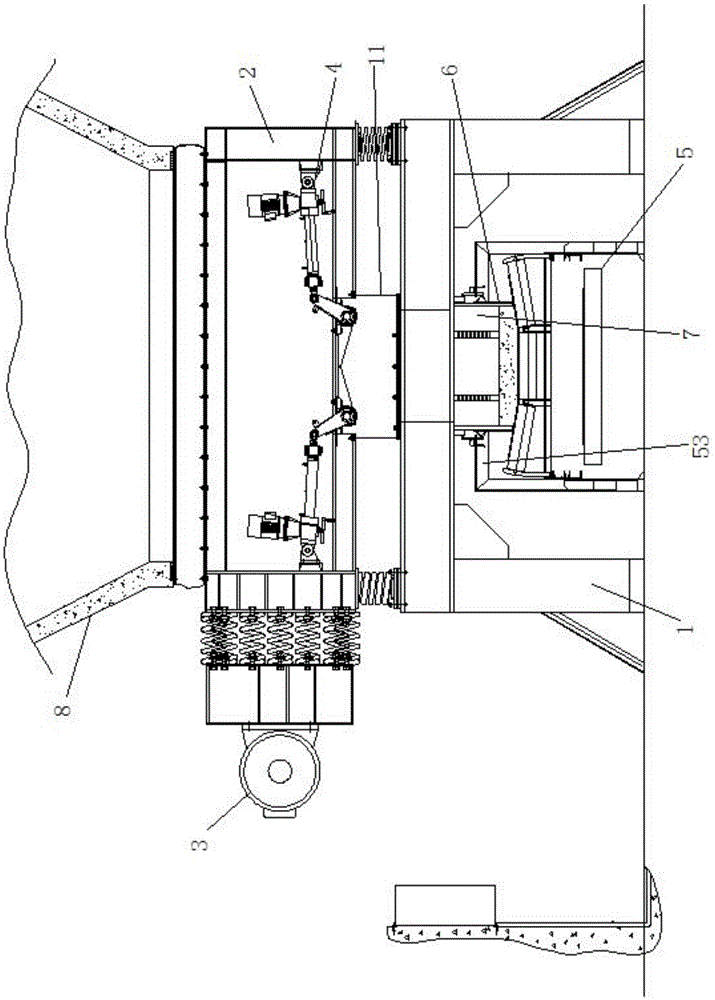

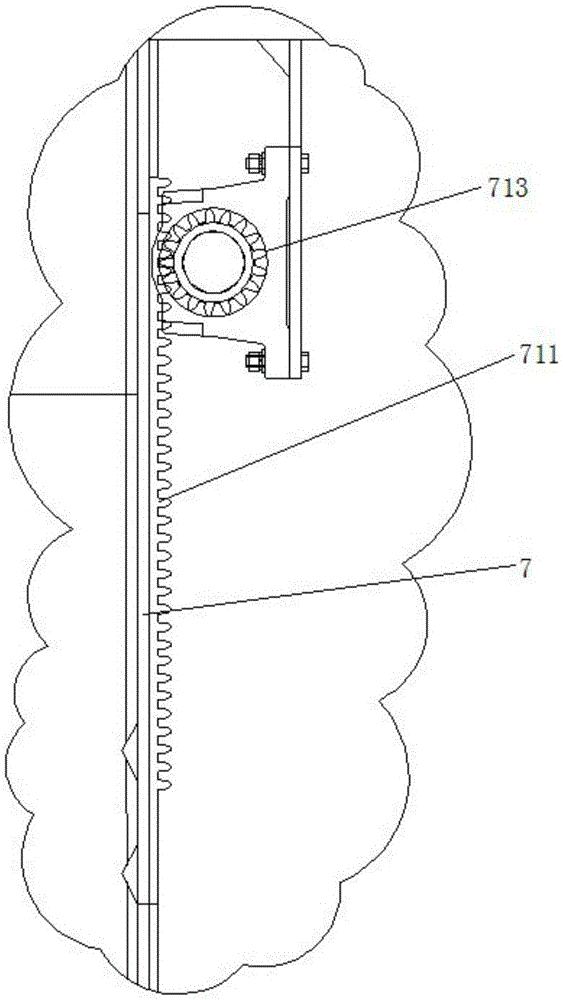

[0041] Example: such as Figures 1 to 3As shown, the precise batching activation feeder of this embodiment includes a frame 1, a feeding vibration bin 2, a vibrating motor 3 and a conveyor belt mechanism 5, and also includes a buffer bin 6 and a flashboard 7, and the feeding vibration bin 2. The bottom is installed on the top table of the frame 1 through an elastic connector. The vibration end of the vibration motor 3 is connected to the side of the feeding excitation chamber 2 through an elastic connector. There is a feeding port at the bottom, which is connected to the inside of the feeding and vibrating bin 2, and a feeding channel that runs through it up and down is provided on the table of the frame 1, and the feeding channel is located directly below the feeding port, so The conveyor belt mechanism 5 is horizontally arranged below the feeding channel, and the belt of the conveyor belt mechanism 5 is located directly below the feeding channel. Outside the discharge port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com