Patents

Literature

37results about How to "Solve the problem of easy winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Household garbage crushing sorting system

ActiveCN104874582AThere will be no stuckStuck situation solvedSolid waste disposalGrain treatmentsSocial benefitsLitter

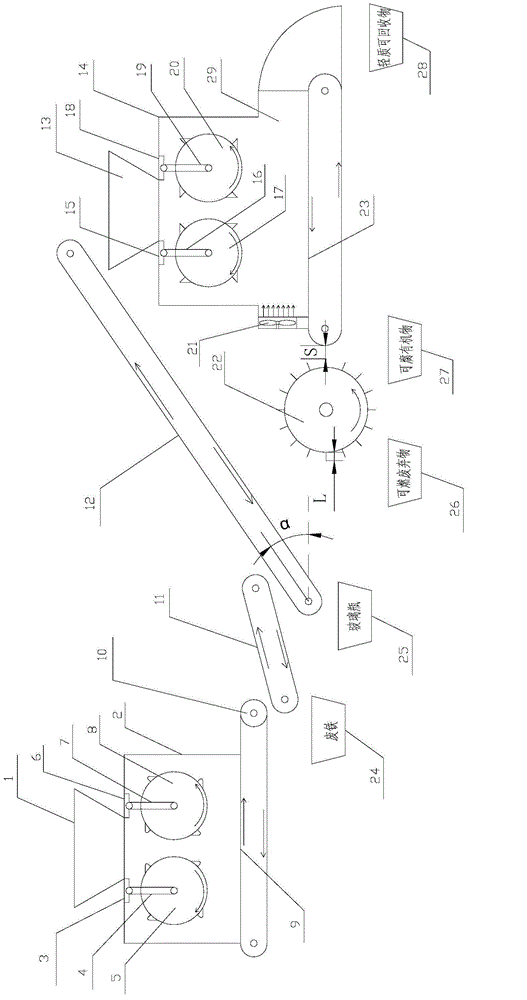

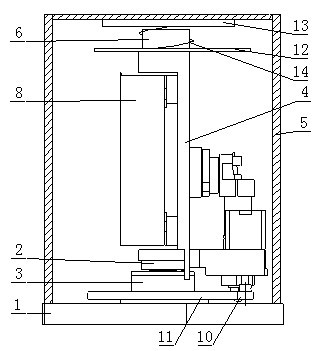

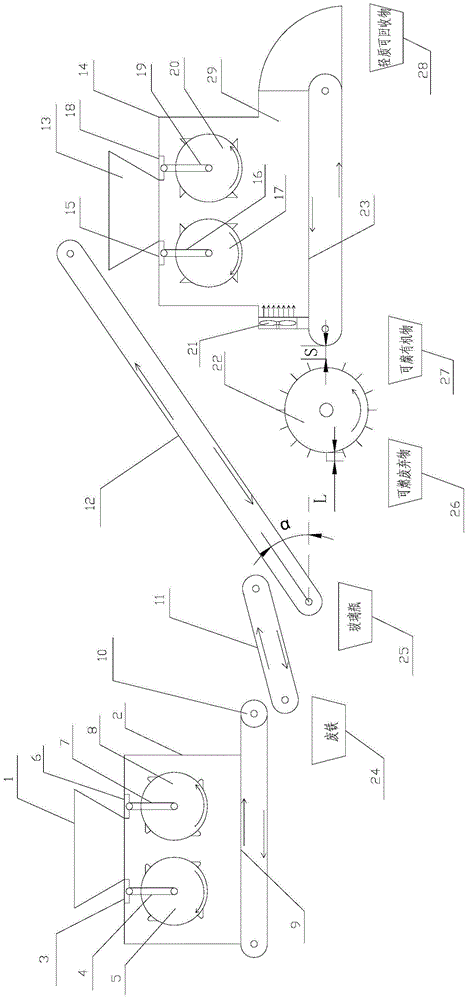

The invention discloses a household garbage crushing sorting system. The sorting system consists of a quantitative feeding device, a magnetic separation device, a gravity gradient sorting device, a pendulum type crushing device, an air separation device, a needle selection device and a material conveying device. The sorting system is compact in structure, can achieve continuous production, is high in production efficiency, simple to operate, safe and reliable, and can divide urban household garbage into decayable organic matter, combustible wastes, metal, glass and light recoverable matter, so that the urban household garbage can be sufficiently utilized as a resource, and the sorting system has very high environmental benefit and social benefit simultaneously.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

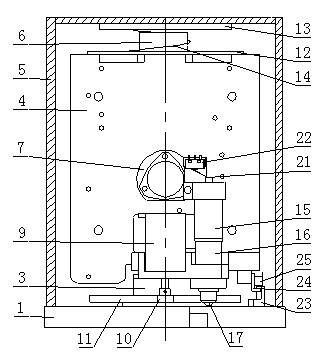

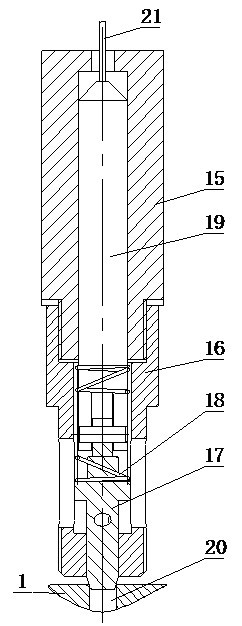

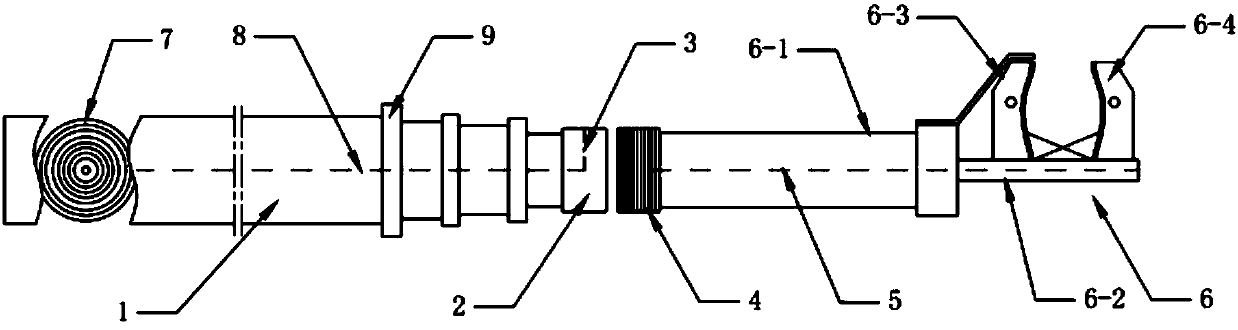

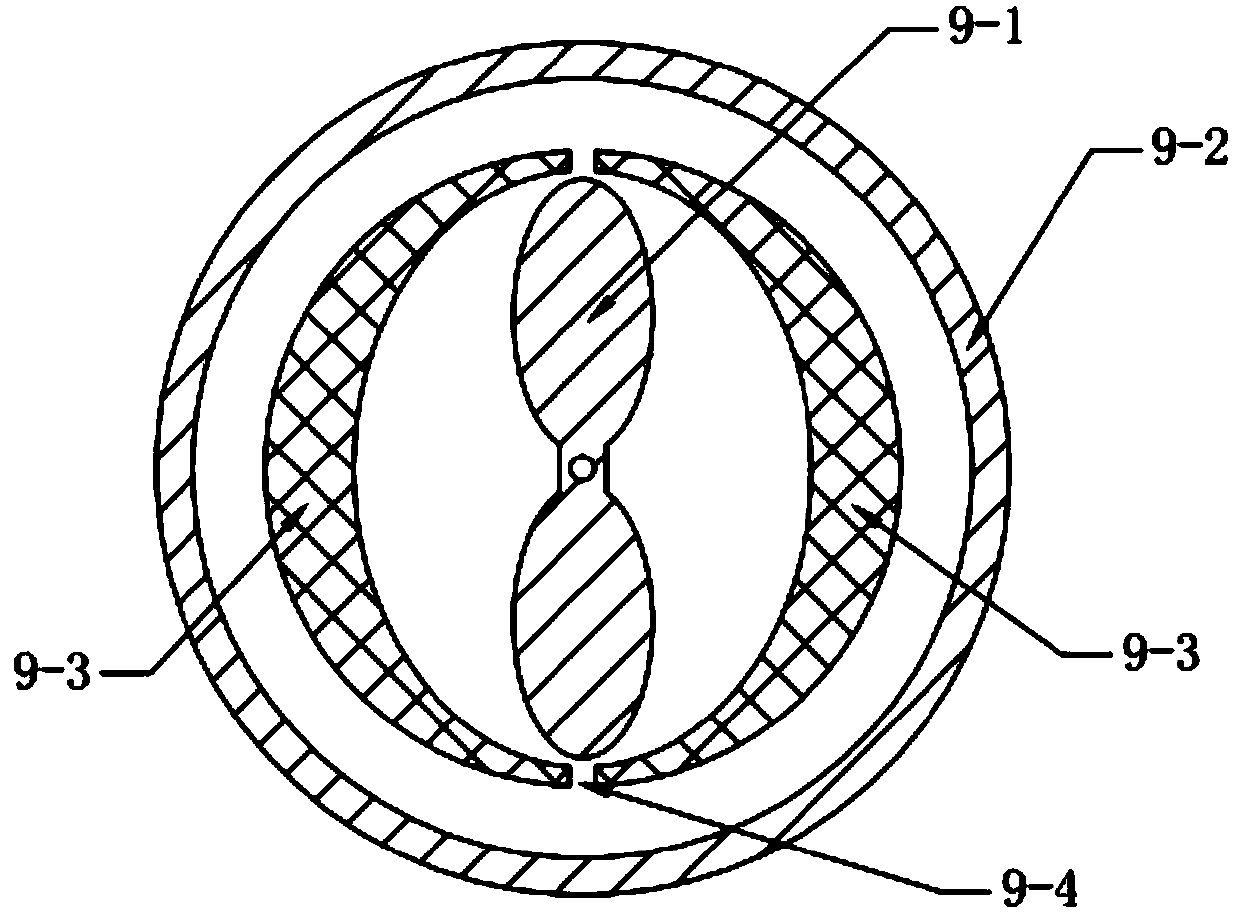

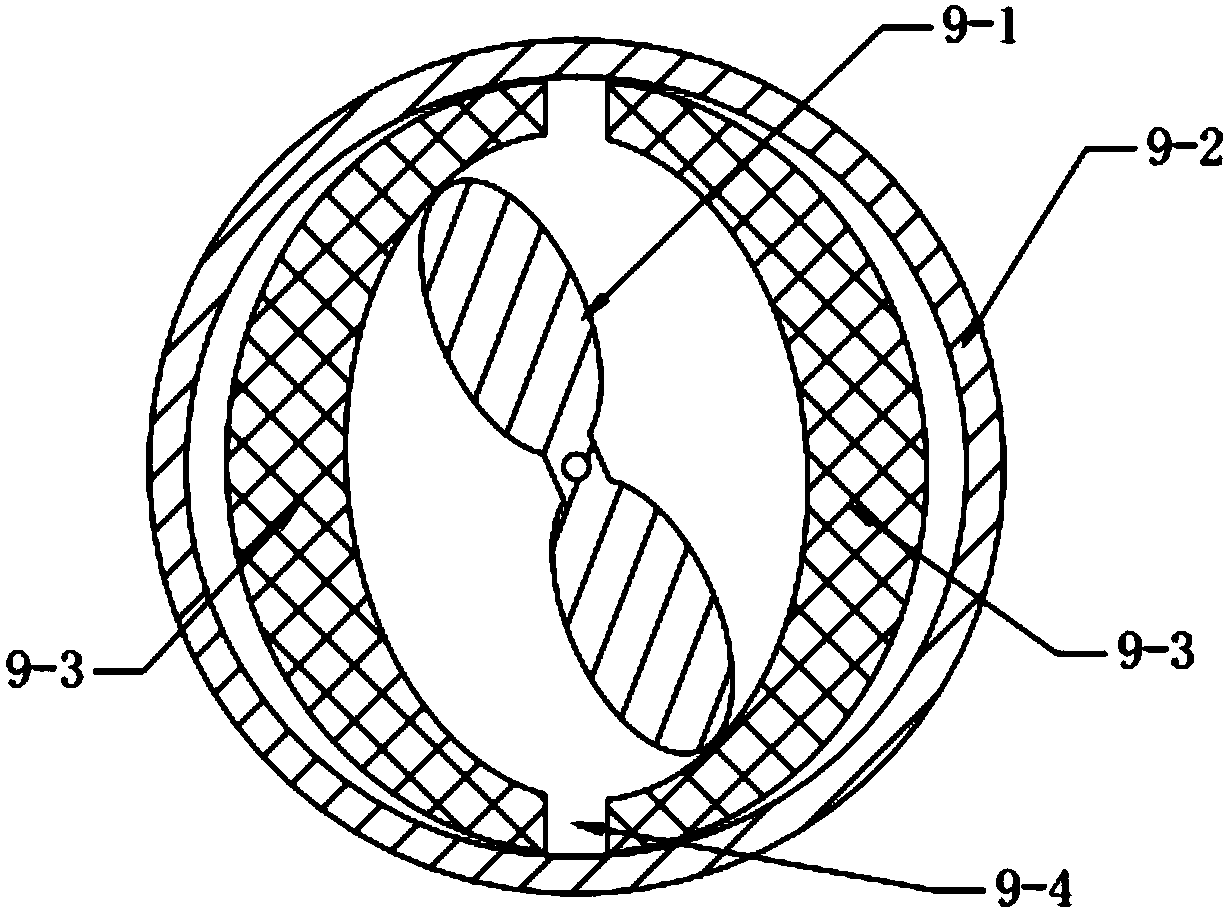

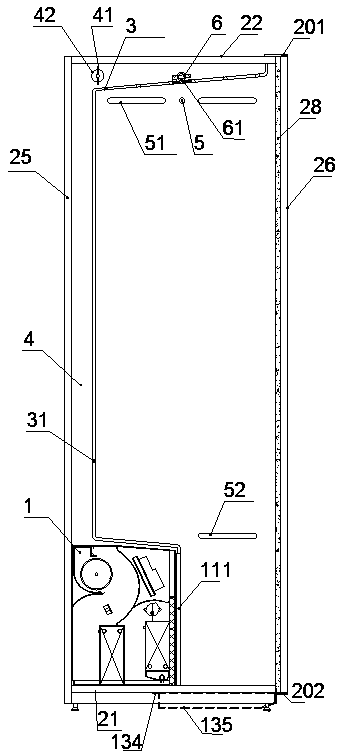

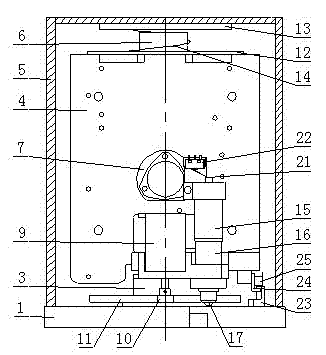

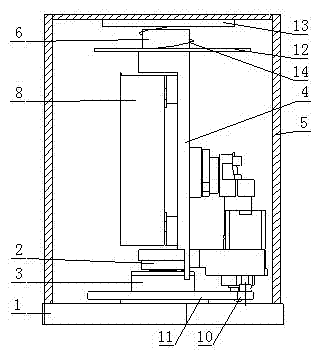

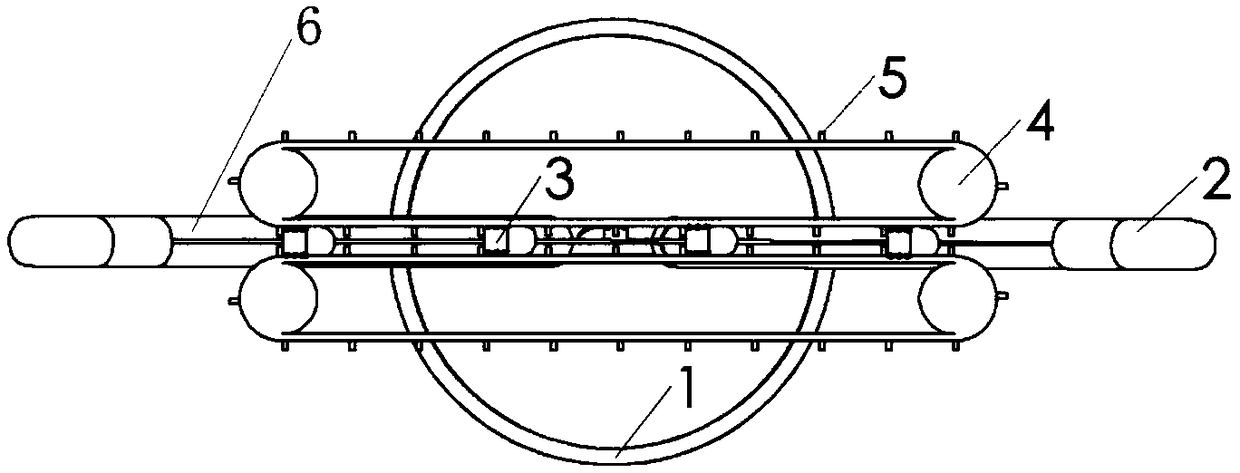

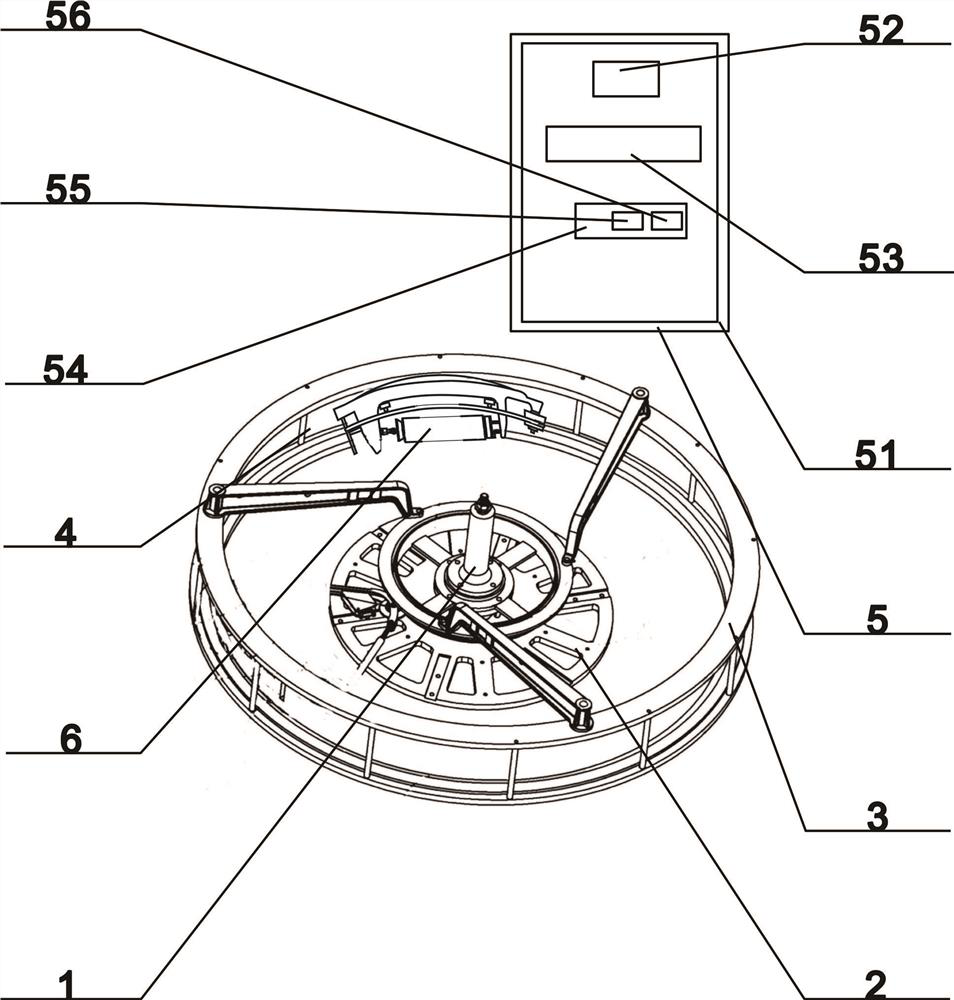

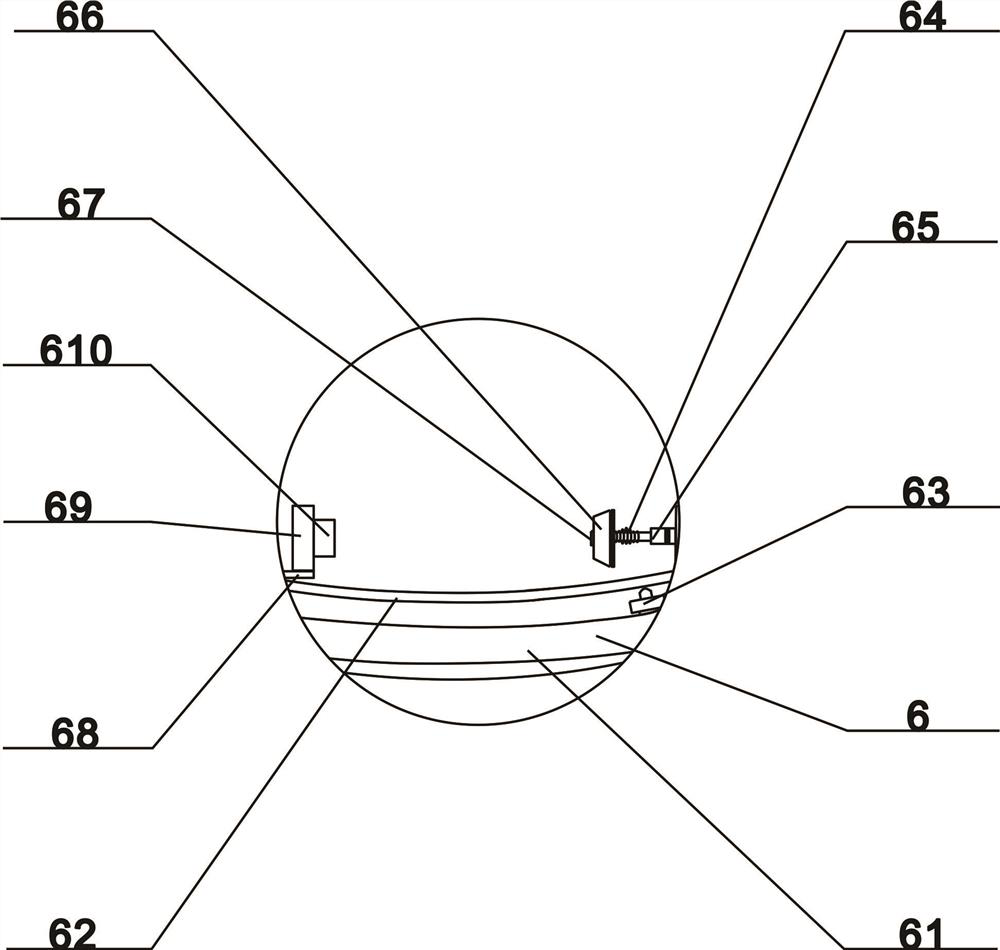

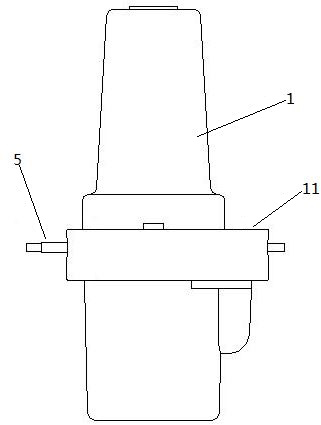

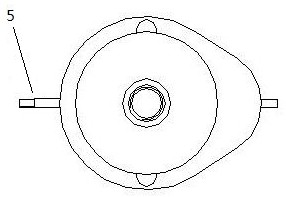

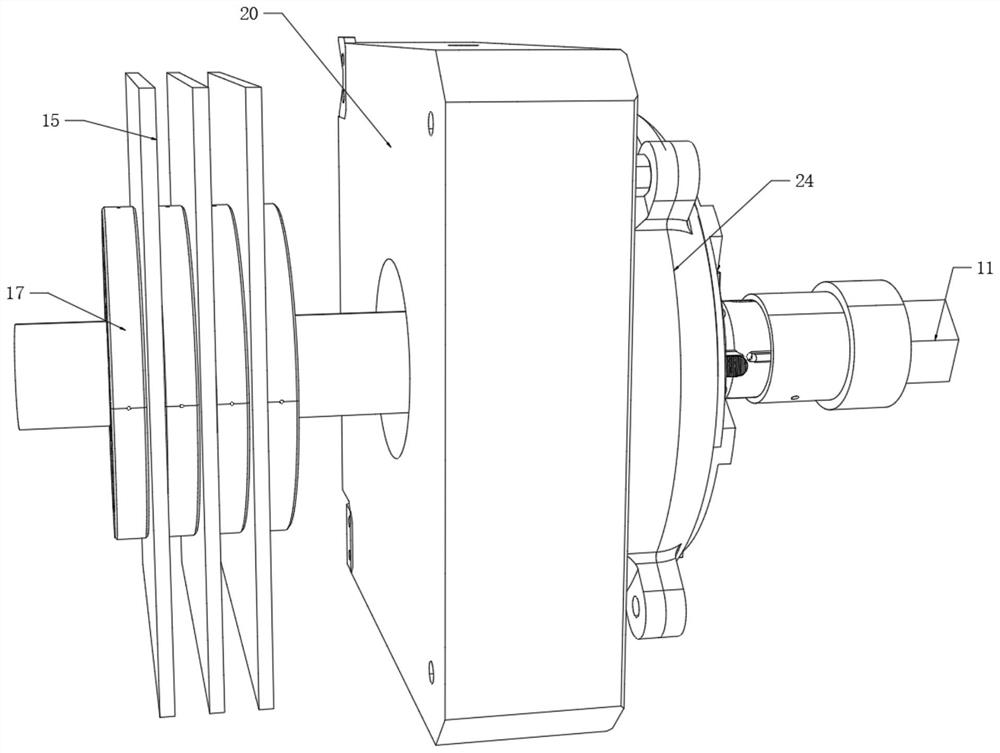

Portable fibre optic gyroscope north seeker

ActiveCN102012228AReduce volumeHigh precisionNavigation by speed/acceleration measurementsSagnac effect gyrometersFibre optic gyroscopeEngineering

The invention discloses a portable fibre optic gyroscope (FOG) north seeker, comprising a circular installing plate and a rotating shaft vertically arranged on the circular installing plate, wherein one end of the rotating shaft is connected with the circular installing plate by a bearing in a rotatable manner; a support is fixedly arranged on the rotating shaft; a shell containing the support is fixedly arranged on the circular installing plate; the support is provided with a detecting system, a rotating system and a positioning system; and the detecting system comprises a horizontal accelerometer, a vertical accelerometer and an FOG. The north seeker has the advantages of reliable measurement, small size, convenient carrying, low cost and the like.

Owner:CHONGQING AEROSPACE NEW CENTURY SATELLITE APPL TECH

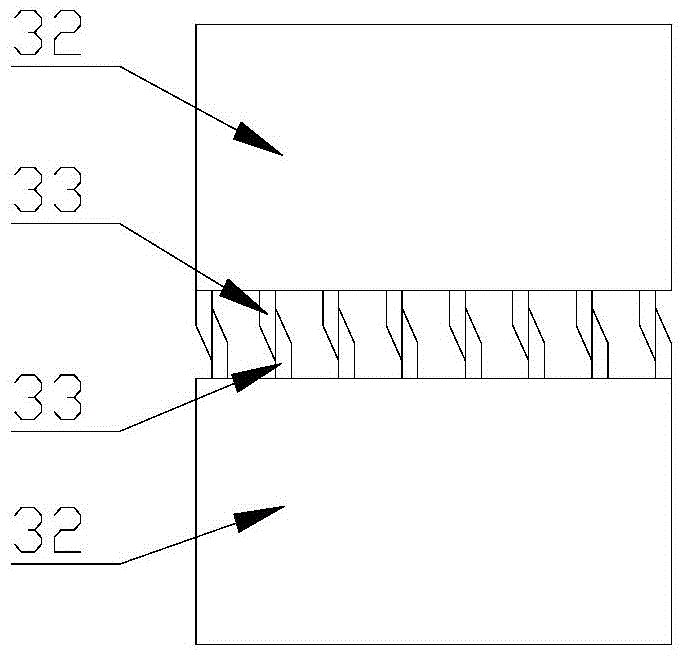

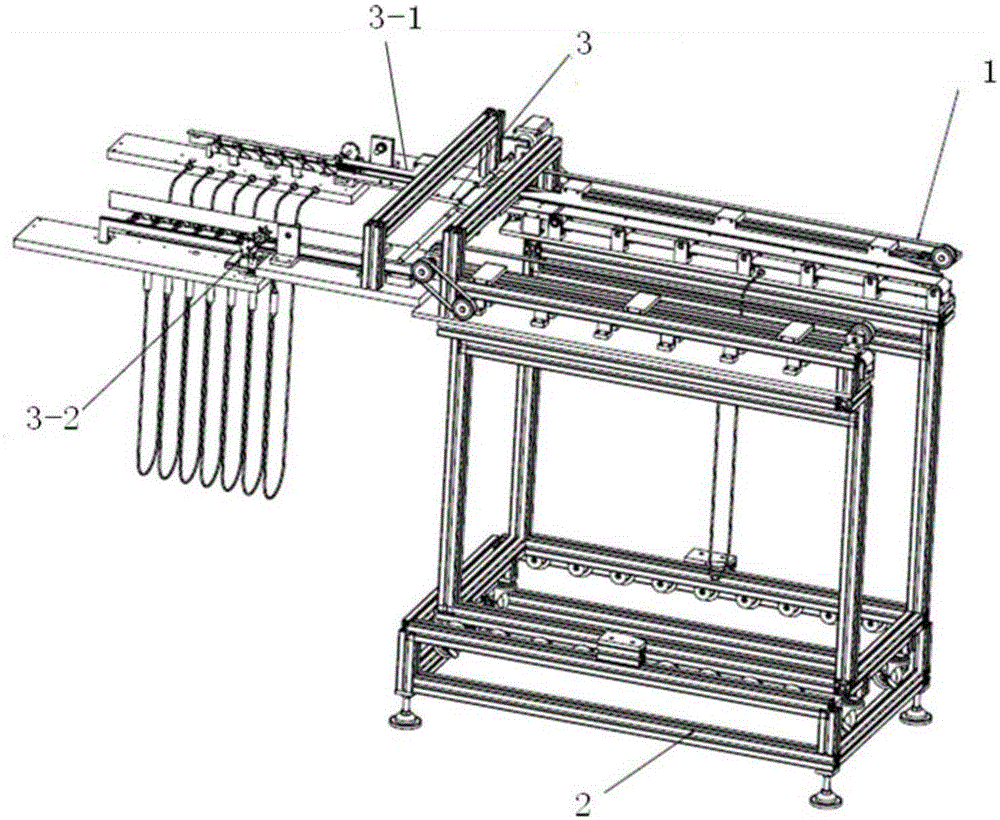

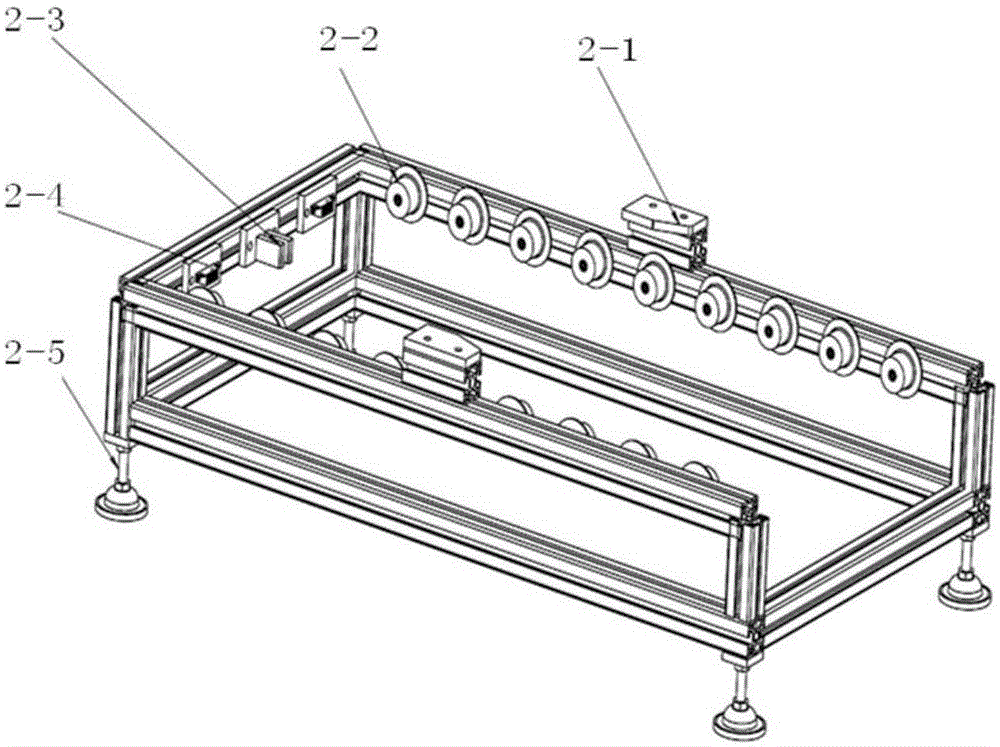

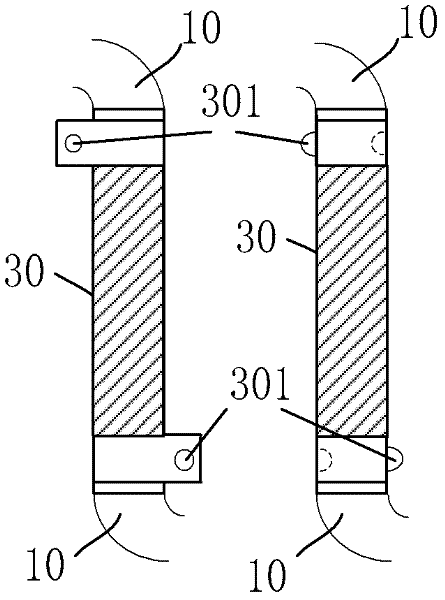

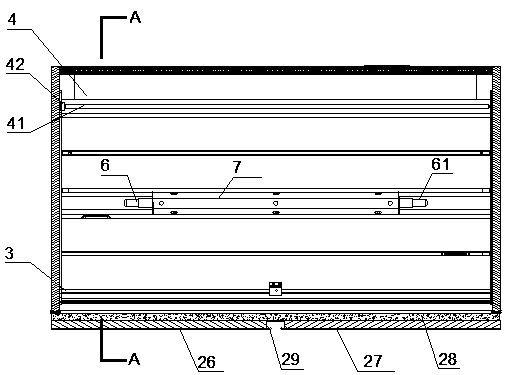

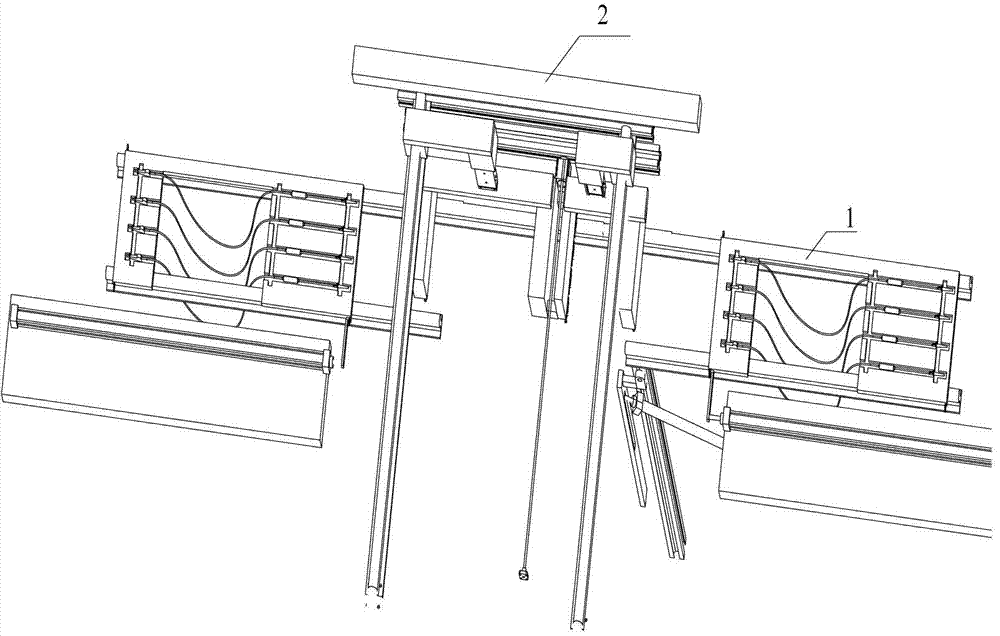

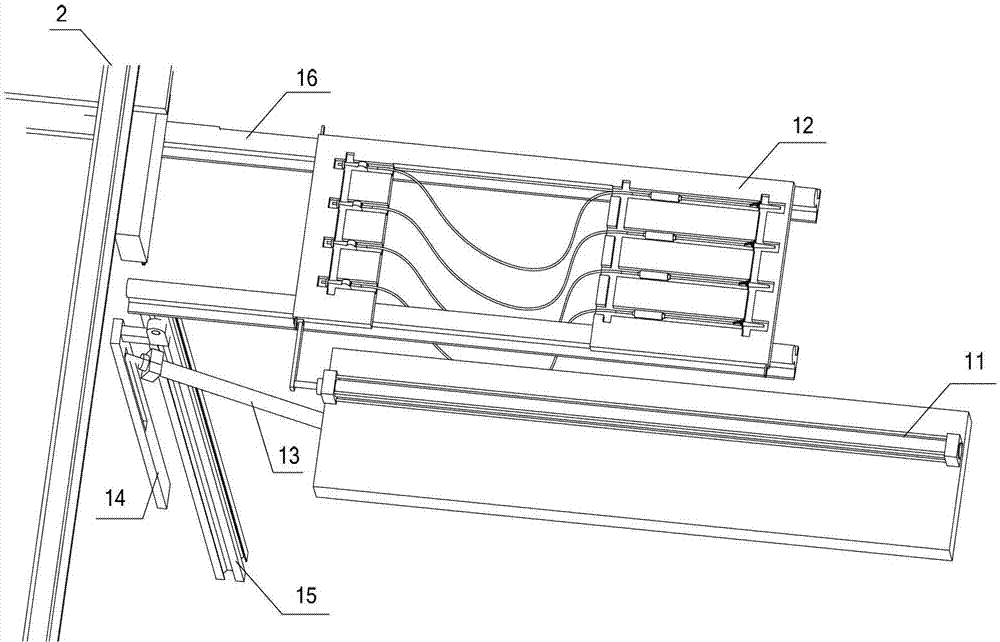

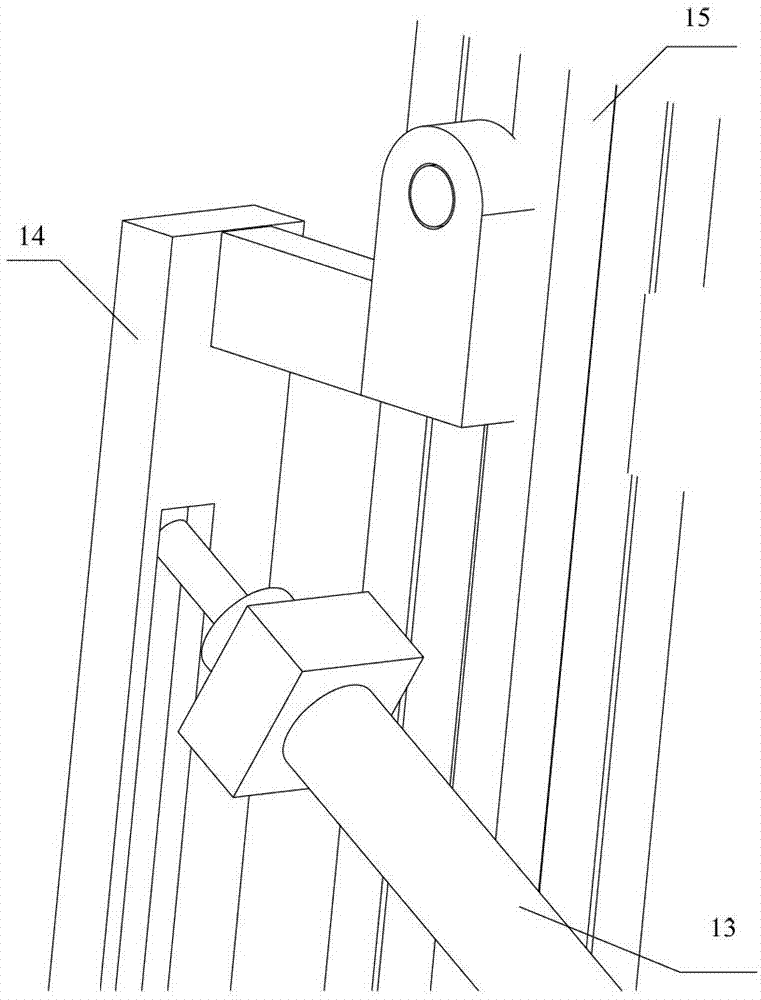

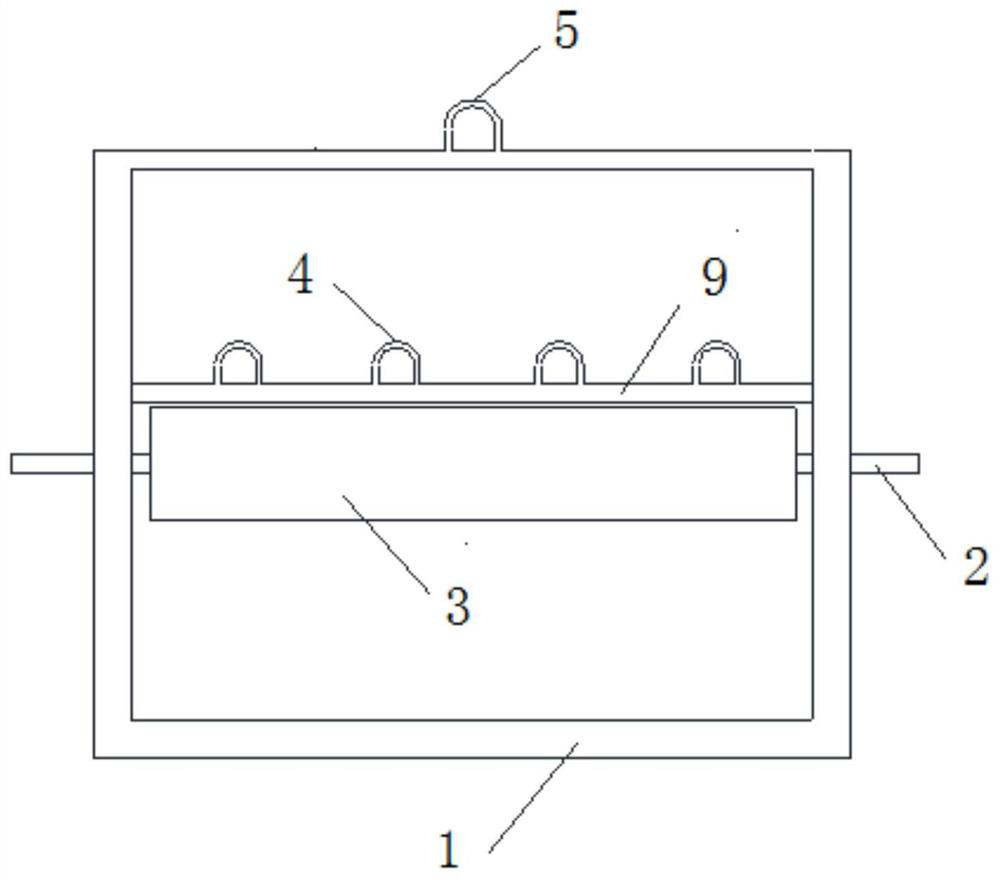

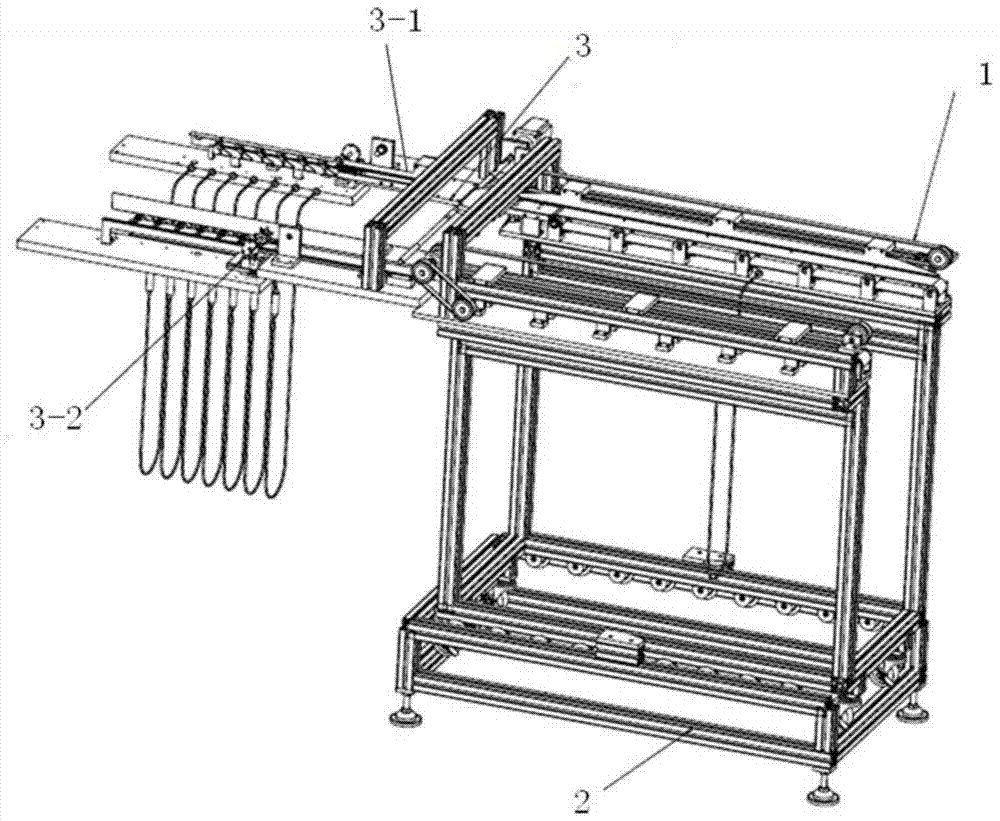

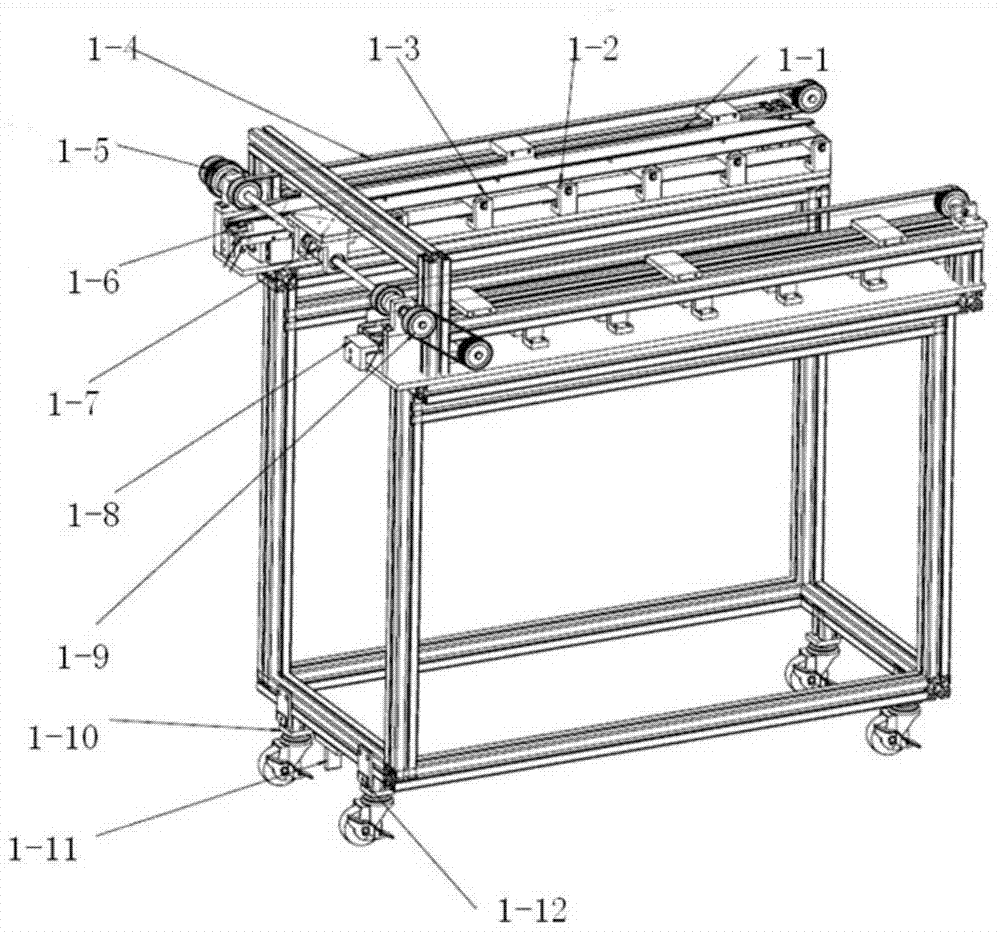

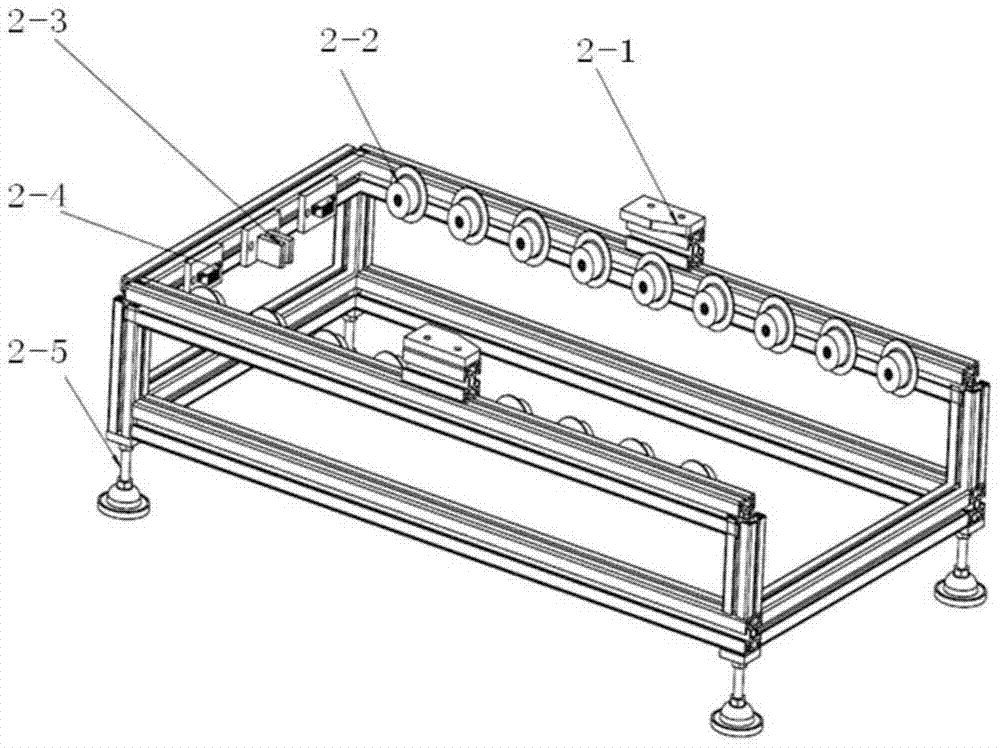

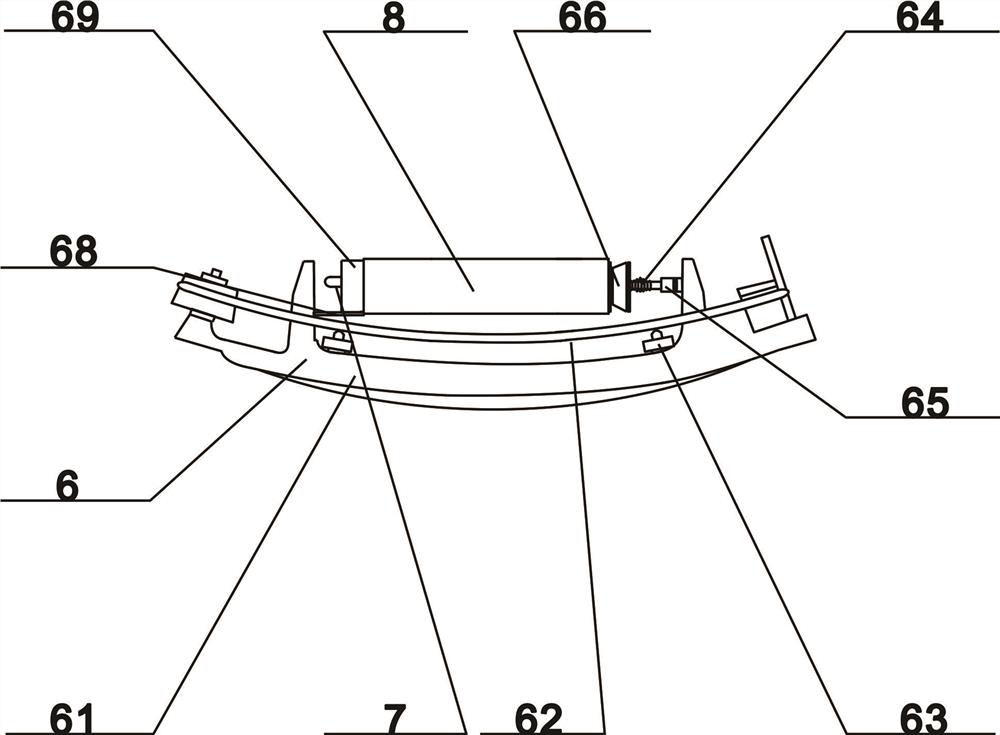

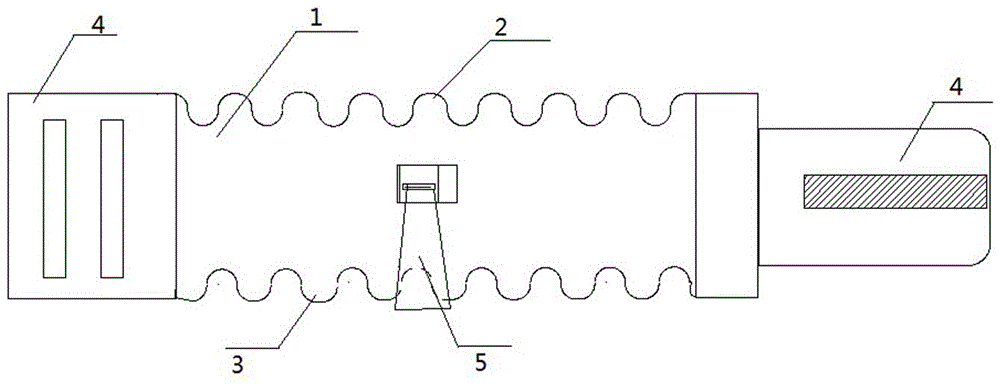

Infusion pipe conveying mechanism

ActiveCN105109945ASolve the problem of easy windingEasy to operateSupporting framesMechanical conveyorsButt jointEngineering

The invention discloses an infusion tube conveying mechanism. The infusion tube conveying mechanism comprises a loading mechanism and a storage mechanism in butt joint with the loading mechanism, the loading mechanism is used for feeding and conveying infusion tubes, and the storage mechanism is used for separating the infusion tubes conveyed from the loading mechanism to enable the infusion tubes to be arranged at preset intervals. The infusion tube conveying mechanism further comprises a loading mechanism limiting device which is arranged at the bottom of the loading mechanism and used for supporting the loading mechanism. According to the infusion tube conveying mechanism, separating operation and the like are carried out on the automatically-conveyed infusion tubes through a separating mechanism, and the problem that the tubes are likely to be wound is solved, so that subsequent packaging operation is more convenient. The butt joint mode of the ingeniously-designed separating mechanism and a loading trolley is adopted, so that the conveying process of the infusion tubes is smoother. The arrangement mode of a limiting mechanism is adopted in the design of the loading trolley, so that friction of trundles is avoided, and the service life of the loading mechanism is prolonged.

Owner:HUAZHONG UNIV OF SCI & TECH

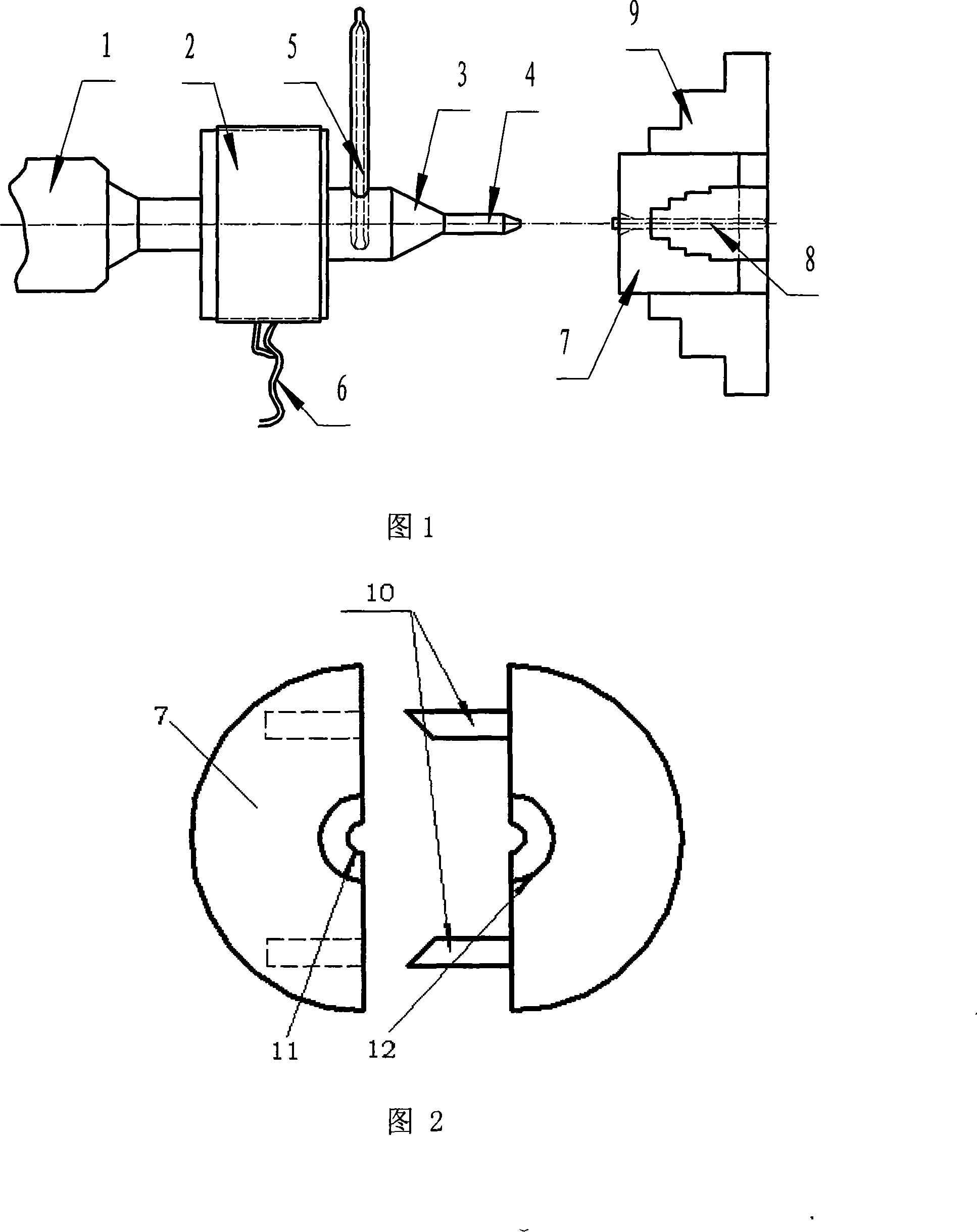

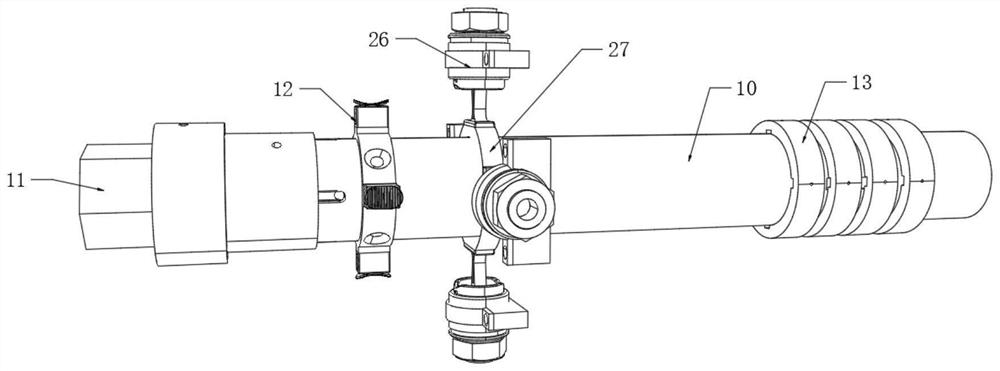

Producing method forming and model hot enlarge fluorine plastic tube

The invention relates to a preparation method and a molding mold of thermal flared end fluoroplastic pipe, which is that a flared end fluoroplastic pip is clamped in a mounting hole of a flared end cavity die with a trumpet flared end and rotates with a chuck of a lathe spindle; a male die expander with a heater and temperature control device is used for heating the head the flared end to flaring temperature and the head the flared end is fed through a lathe tail spindle to ensure that the fluoroplastic pipe is intenerated in rotating and tightly joined and matched with trumpet flared end of the flared end cavity die and cooled to form mold. The heater is fixedly connected on a the male die expander and electrically connected with the temperature control device controlled the temperature of the flared end; the flared end cavity die clamped in a rotator comprises two symmetrical clutch semicylinders is positioned on the same central line with the flared end head of flared end cavity die. The utility model takes advantage of the cold flow property of fluoroplastic to solve the defects that stress centralizes and leaves at the flared end, material is easily decomposed and the flared end is easily cracked. The invention ensures that the wall thickness of expanded trumpet flared end is more uniform and the surface of the flared end is smoother and avoids the occurrences of crinkle, forting and rippling.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

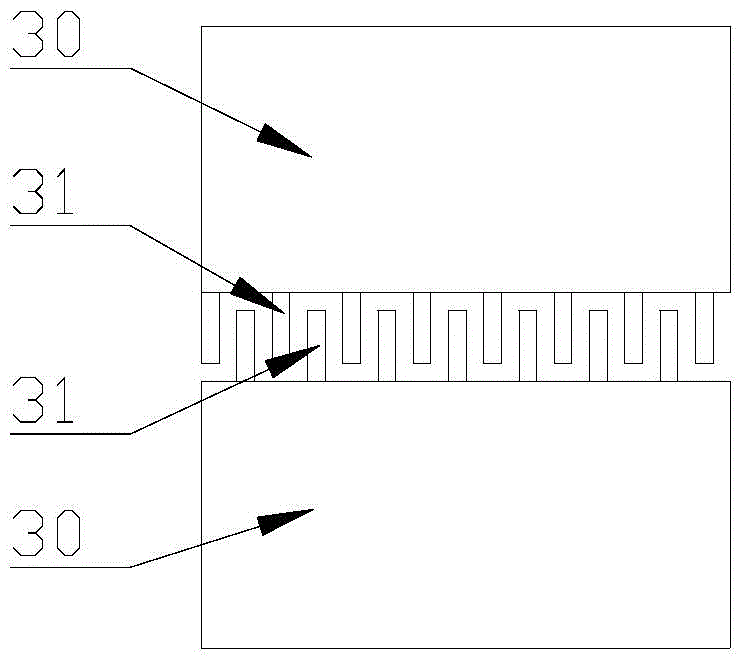

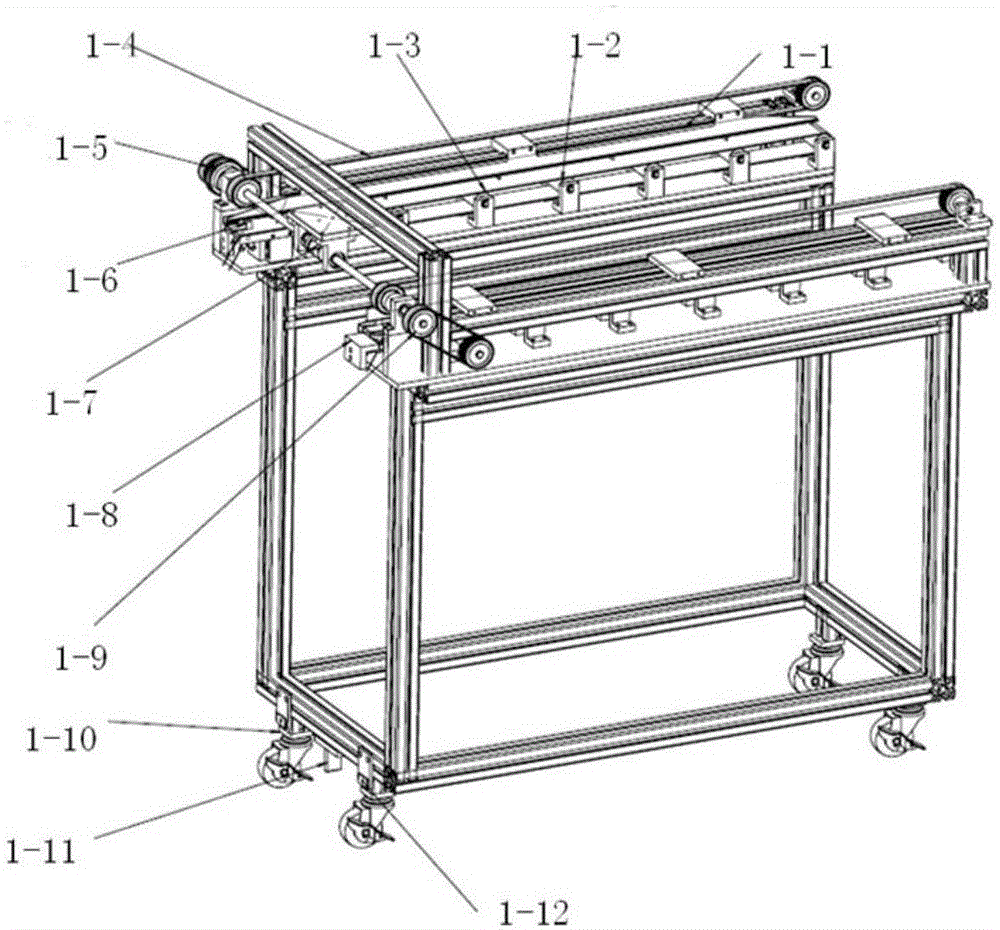

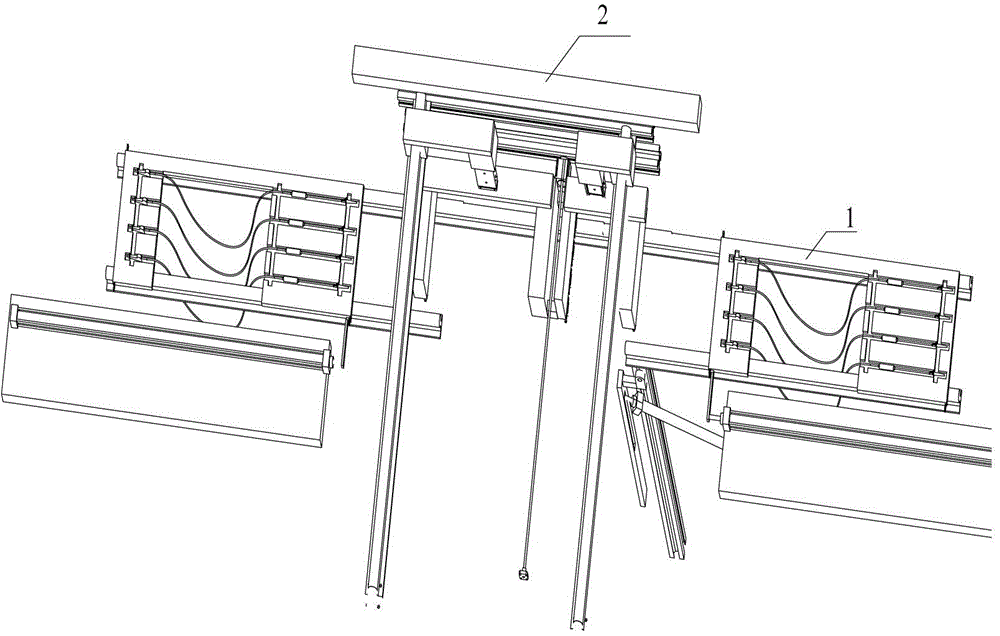

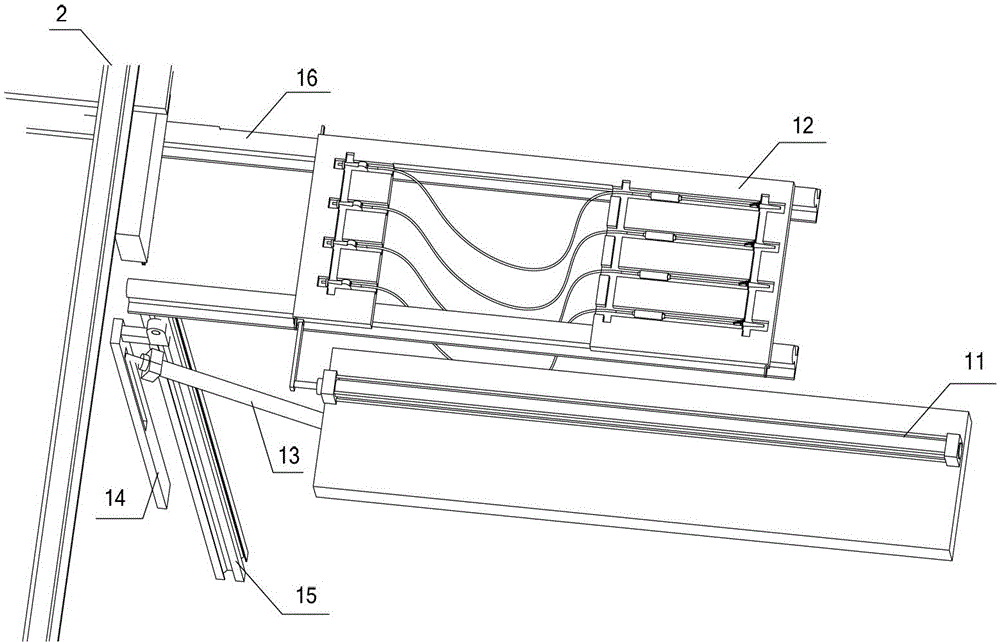

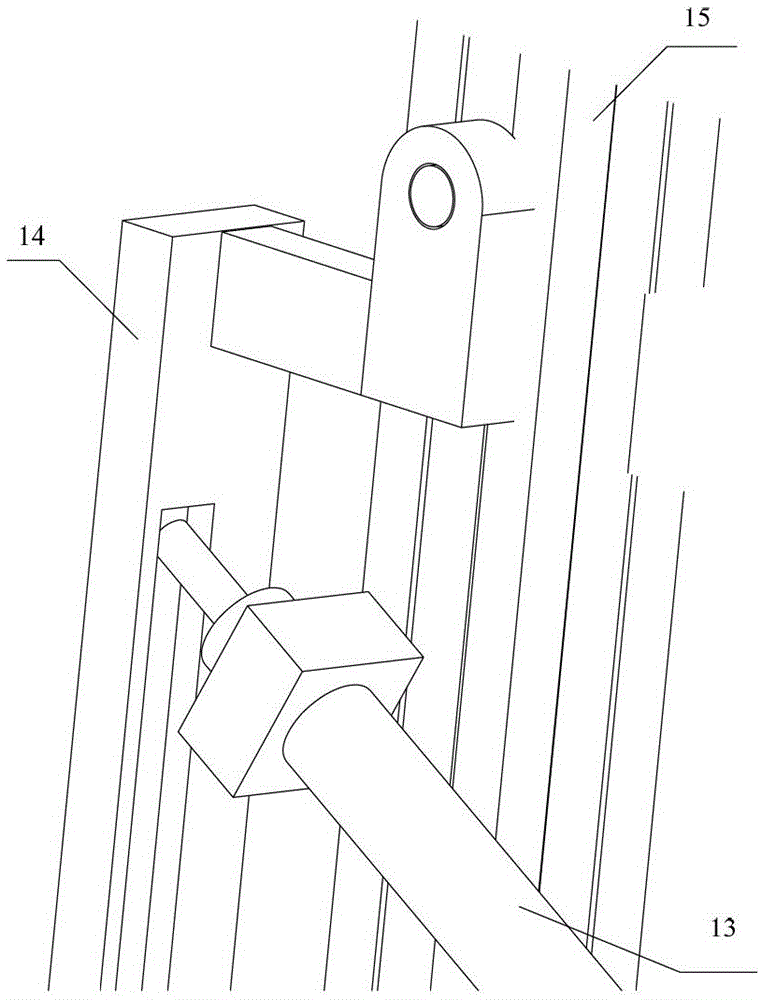

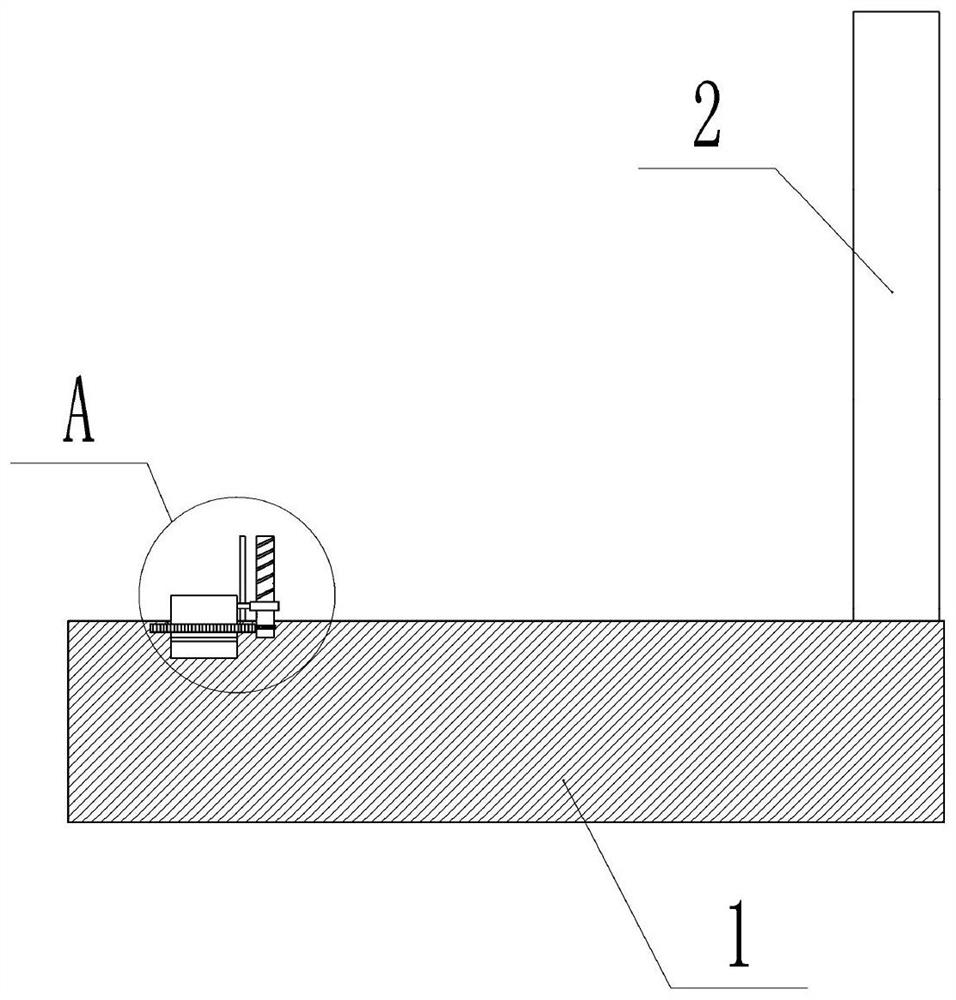

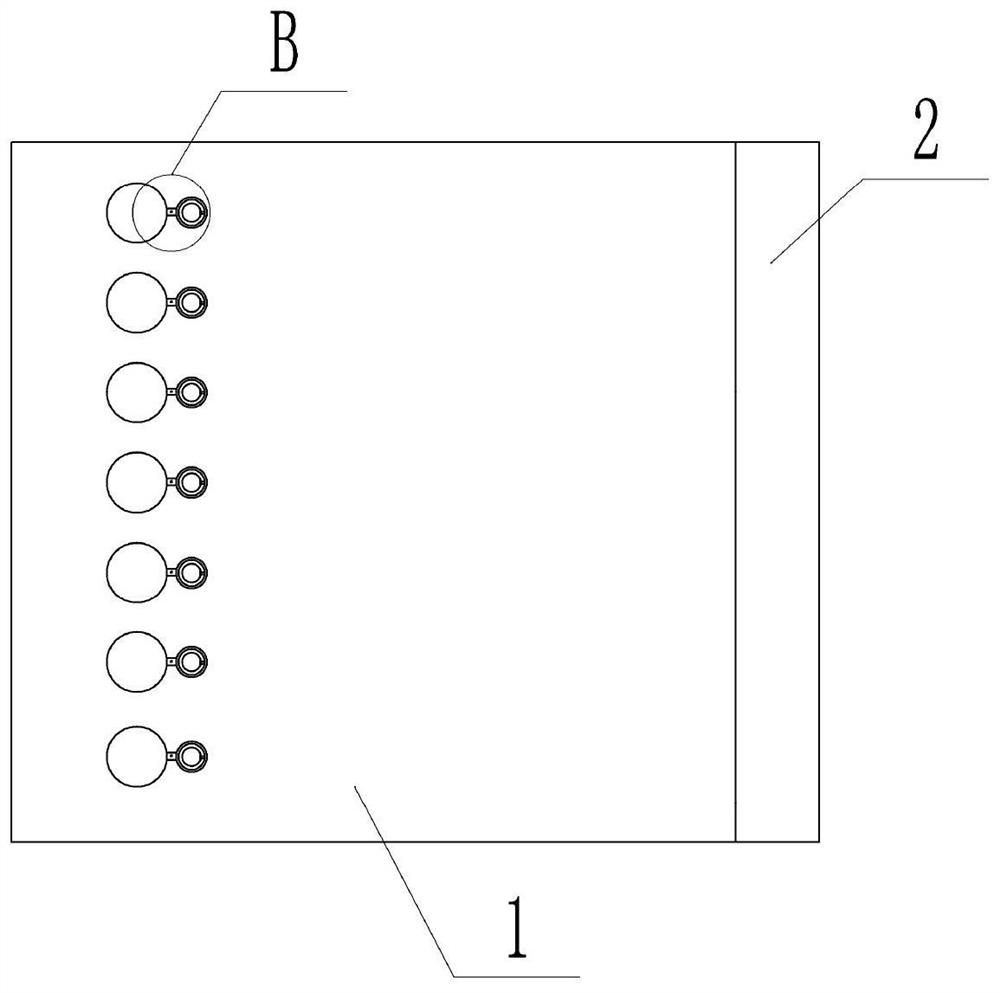

Feeding mechanism of infusion tubes

ActiveCN103057946ASolve the problem of easy windingIncrease work intensityConveyor partsProduction lineEngineering

The invention discloses a feeding mechanism of infusion tubes. The feeding mechanism is arranged on an assembling production line of the infusion tubes and used for achieving automatic feeding of raw material tube bodies of the infusion tubes and comprises a feeding assembly and a conveying assembly, wherein the feeding assembly is used for loading the tube bodies of the infusion tubes, and the conveying assembly is used for grabbing the tube bodies of the infusion tubes on the feeding assembly and conveying the tube bodies of the infusion tubes onto the station of the next procedure. The feeding assembly comprises a movable feeding frame, and a plurality of troughs used for containing the tube bodies of the infusion tubes are arranged on the feeding frame. The conveying assembly comprises a movable support, a plurality of gas claws are arranged at the lower end of the support and used for grabbing the tube bodies of the infusion tubes on the movable feeding frame. The movable support drives the gas claws grabbing the tube bodies of the infusion tubes to move to convey the tube bodies of the infusion tubes to the station of the next procedure, and automatic feeding is achieved. The feeding mechanism solves the problem of easiness in winding of pipes through the movable feeding frame, and accordingly is convenient to operate; improves feeding efficiency due to the fact that two-side alternating feeding is adopted; and avoids various problems caused by manual operation due to the fact that automation devices are adopted for both the feeding assembly and the conveying assembly.

Owner:HUAZHONG UNIV OF SCI & TECH

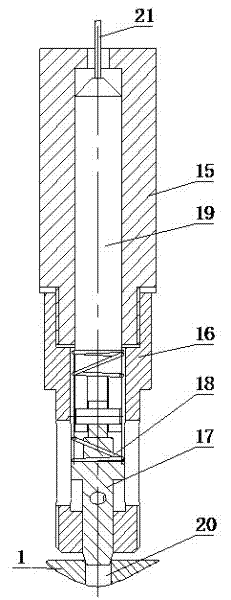

Transformer test bar

ActiveCN107561477ASolve the problem of easy windingSolve problems such as inconvenient organizationElectrical measurement instrument detailsElectrical testingElectrical conductorTransformer

The invention provides a transformer test bar and belongs to the field of transformer test tools. The transformer test bar comprises a telescopic operation rod, a cable clamp used for tightly clampingto-be-tested equipment and located at the top of the operation rod and an automatic take-up and payoff device located at the bottom of the operation rod, a lead is wound on the automatic take-up andpayoff device, and one end of the lead is connected with a conductor pull wire arranged in the cable clamp. By the arrangement, working at heights can be avoided, a tester can complete wire dissembling and assembling work through operation on the ground, convenience in use is achieved, working efficiency is improved, and the transformer test bar is safer.

Owner:STATE GRID CORP OF CHINA +2

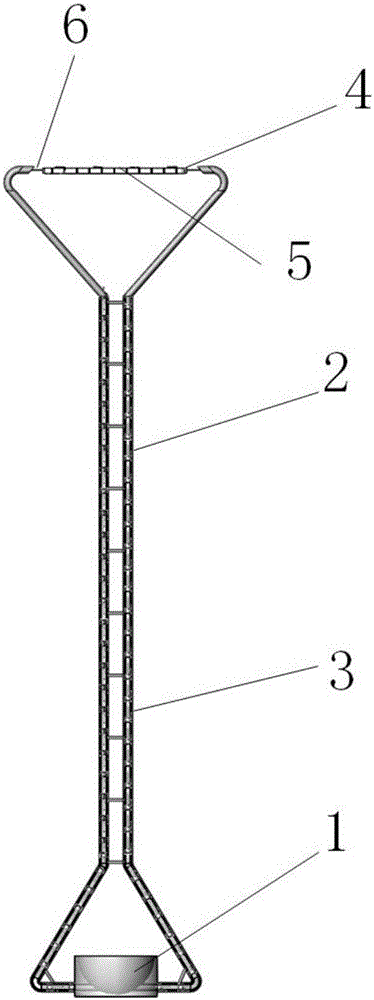

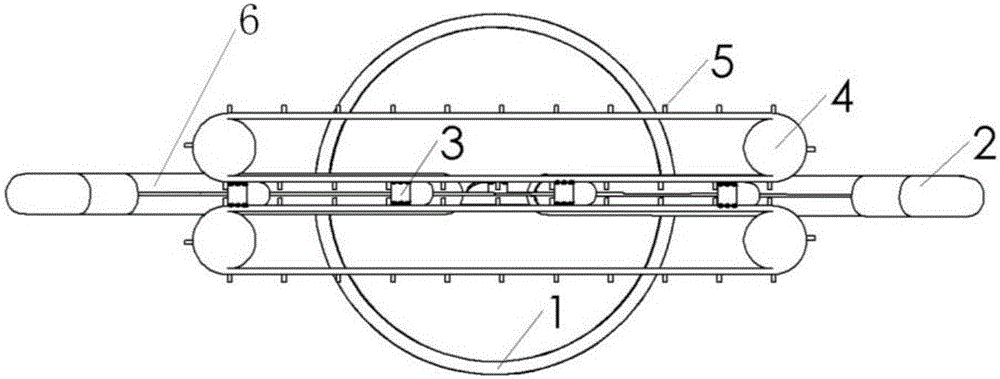

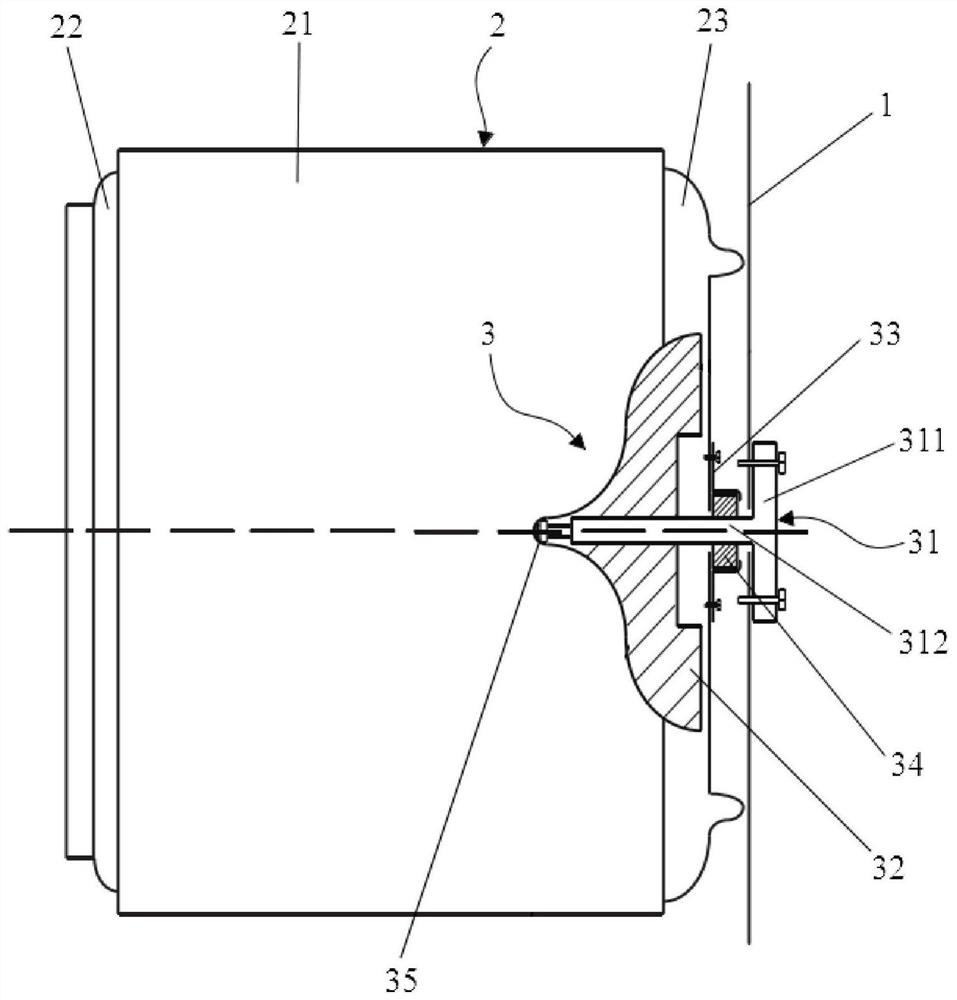

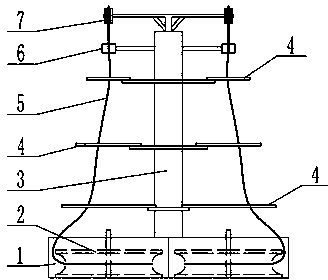

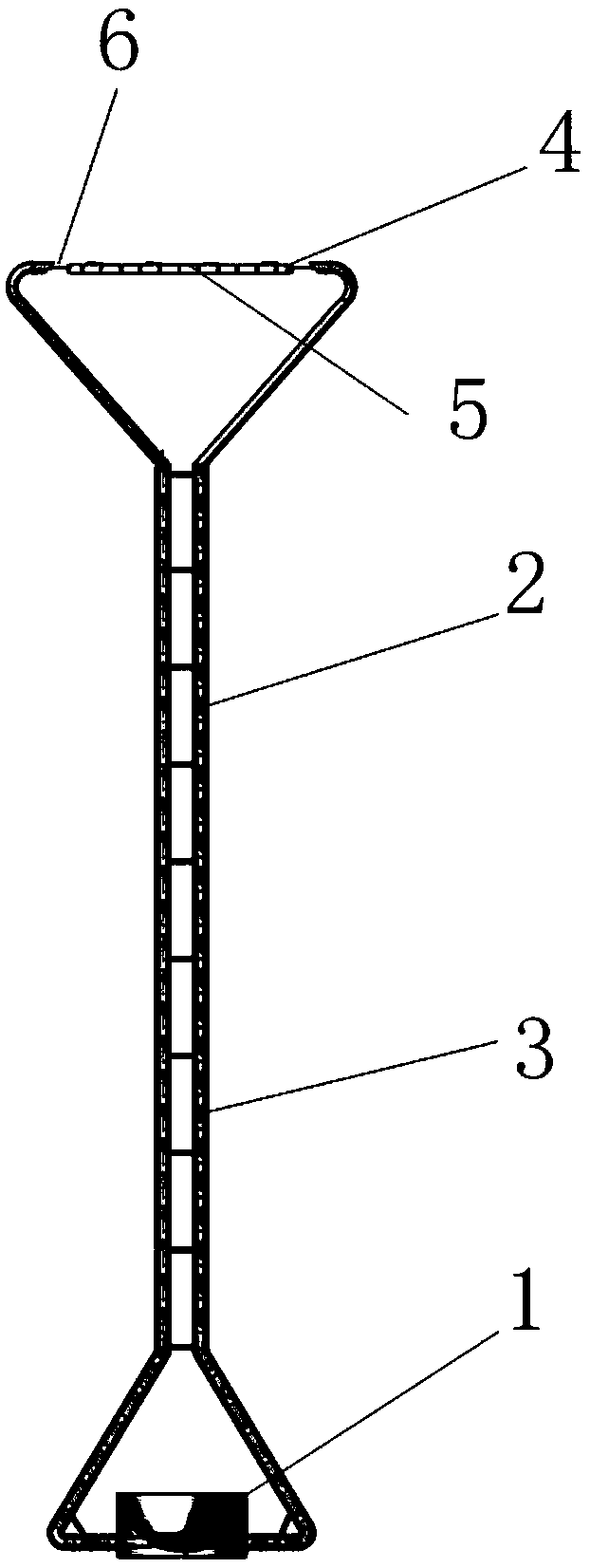

Mechanical mineral lifting device

ActiveCN105645037ASolve the problem of easy windingImprove efficiencyConveyorsMineral miningElectric machineHigh probability

The invention discloses a mechanical mineral lifting device. The mechanical mineral lifting device comprises a crawler type power device, a support frame (2), n collecting barrels (3), a cable (6) and a relay bin (1), wherein the crawler type power device comprises two symmetric crawlers arranged on two sides of the cable (6) and the collecting barrels (3), two motors (4) are arranged in each crawler, the support frame (2) adopts an overall support structure, the cable (6) is a center cable connecting the collecting barrels (3), the relay bin (1) is a relay opening container placed under the water surface, the crawler type power device transfers power to the collecting barrels (3) through the crawlers to drive to collecting barrels (3) to move, movement of one collecting barrel (3) is transferred to the following collecting barrels (3) under the action of the cable (6), the following collecting barrels (3) are driven to move, and when passing by the relay bin (1), the bottommost collecting barrel (3) collects substances in the relay bin (1). By means of the mechanical mineral lifting device, the problem of high probability of winding of the cable in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

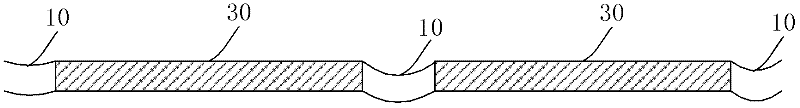

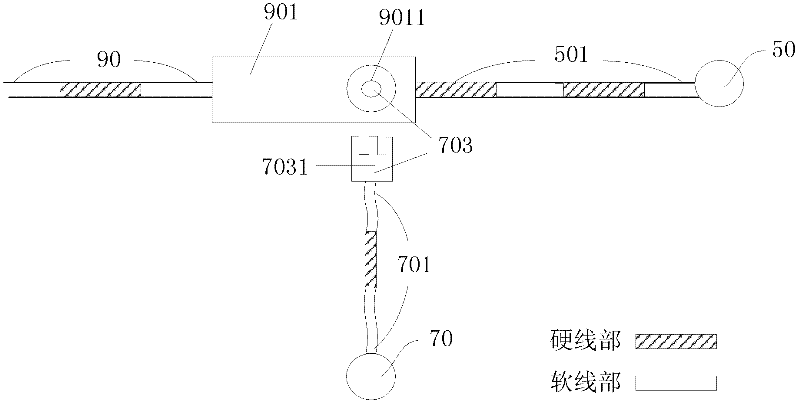

Earphone and processing method thereof

InactiveCN102547510ASolve the problem of easy windingSolve problems such as not easy to separateMicrophonesLoudspeakersEngineering

The invention provides an earphone and a processing method thereof, wherein the earphone comprises an earphone line. The earphone line comprises flexible line portions and hard line portions, and the flexible line portions and the hard line portions are arranged at intervals. By means of the technical means, the problems that the earphone line is easy to wind, not prone to separate and the like in the related technology are solved, the effect of avoiding the earphone line from being wound and not easy to separate is further achieved effectively, and user experience is improved.

Owner:ZTE CORP

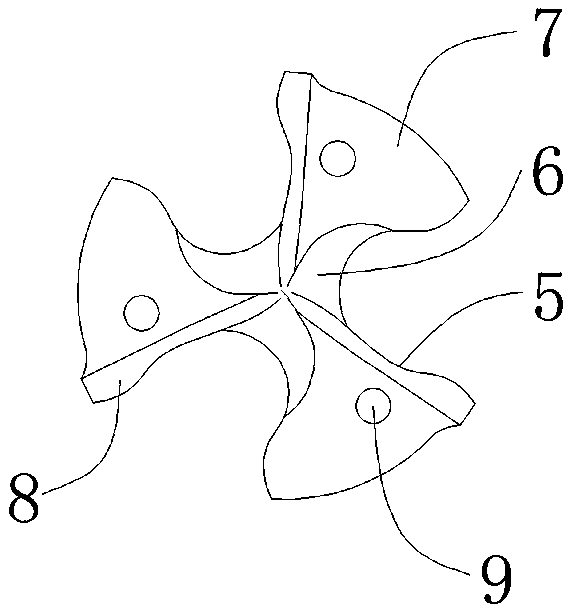

Clothes dryer

PendingCN113308862AAvoid entanglementDry evenlyTextiles and paperLaundry driersHeavy loadHome appliance

The invention relates to the technical field of household appliances, and discloses a clothes dryer. The clothes dryer comprises a rear plate and a drum, wherein a stirring wheel mechanism is arranged at the bottom of the drum, and the stirring wheel mechanism comprises a stirring wheel and is fixedly connected with the rear plate or connected with a rotary driving part, so that the drum can rotate relative to the stirring wheel. The stirring wheel mechanism is arranged at the bottom of the drum, when the drum runs, the stirring wheel mechanism can keep a relative movement state with the drum and clothes in the drum, the effects of scattering the clothes and preventing winding are achieved, and it is guaranteed that the clothes dryer dries the clothes more evenly and is higher in efficiency. Moreover, the stirring wheel mechanism is arranged at the bottom of the drum, so that a small and heavy load can be ensured to effectively avoid the bottom of the drum and smoothly slide to the opening of the drum, and the humidity judgment accuracy of software is improved.

Owner:QINGDAO HAIER DRUM WASHING MACHINE +1

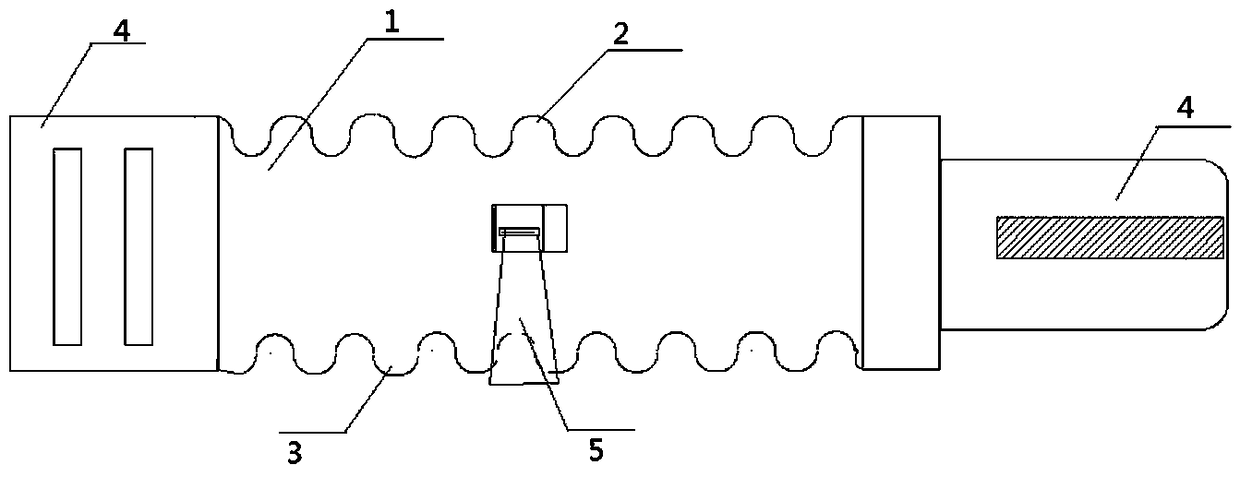

Terminal compression joint device

InactiveCN103872546AReduce use failure rateReduce frictional heat generationLine/current collector detailsFault rateCable harness

A terminal compression joint device is composed of a motor (1), a body (2), an upper mould (3), a pushing device (4), a lower mould (5), a wire winder (6) and a terminal chain (7), and is characterized in that the terminal chain (7) is installed on the wire winder (6) and is pushed to a mould core of the lower mould (5) through a supporting frame (8) and the pushing device (4), the upper mould and the lower mould are combined after a wire harness is placed, and pressing of the wire harness (11), cutting off and feeding are finished. The terminal compression joint device solves the problem that a full-automatic double-station compression joint machine causes winding easily in the process of feeding, effectively lowers the use fault rate of the compression joint machine, adopts a guiding wheel, effectively reduces heat generated by friction in the conveying process of cables, improves the utilization rate of the cables, and lowers production cost for enterprises.

Owner:司马建明

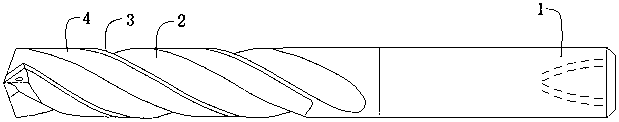

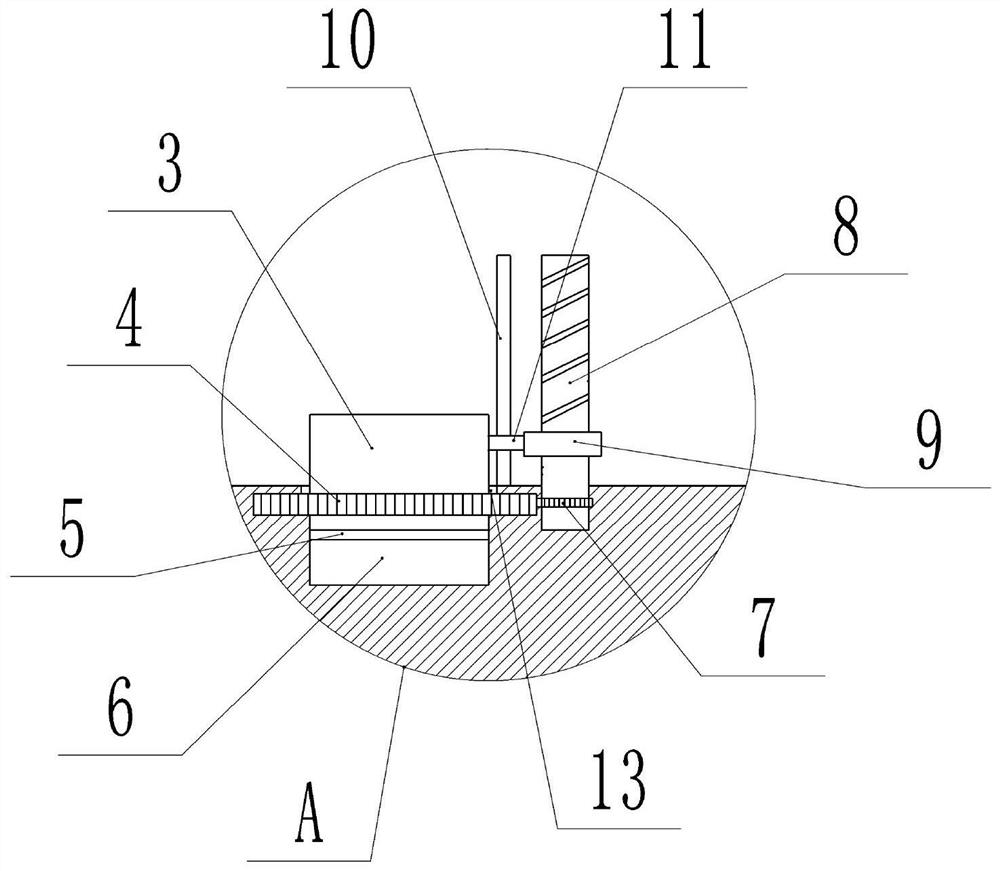

Drill bit with automatic chip removal function

InactiveCN111347087AReduce low dragIncreased ability for stable chip breakingTransportation and packagingTwist drillsDrill bitStructural engineering

The invention relates to the technical field of alloy drill bits, in particular to a drill bit with an automatic chip removal function. The drill bit comprises a shank part, a cutter bar, main cuttingedges and a cooling hole. The shank part and the cutter bar are integrally formed, the cutter bar is provided with an edge ditch, an edge belt and an edge back, the edge belt is arranged between theedge ditch and the edge back, a rear cutter face and a front cutter face are arranged at the tip end, far away from the shank part, of the cutter bar, a cooling hole is formed in the rear cutter face,the cutting edge of the front cutter face is a main cutting edge, and the tip end is further provided with a transverse edge. By means of the designed edge type and the wide chip containing groove, namely the wide edge ditch capable of smoothly discharging chip, the low resistance of an edge drill is reduced, and the ability of stable chip breaking is improved; due to the cutting segmentation property and the shape stability system of the designed drill bit, the problem that chips are likely to wind is solved, the drill bit can adapt to a wide range of machining materials, and stable and high-efficiency machining is realized; and due to the three main cutting edges which are innovatively designed, the balance and stability of the tool in machining are improved.

Owner:吉林省恒丰数控工具有限公司

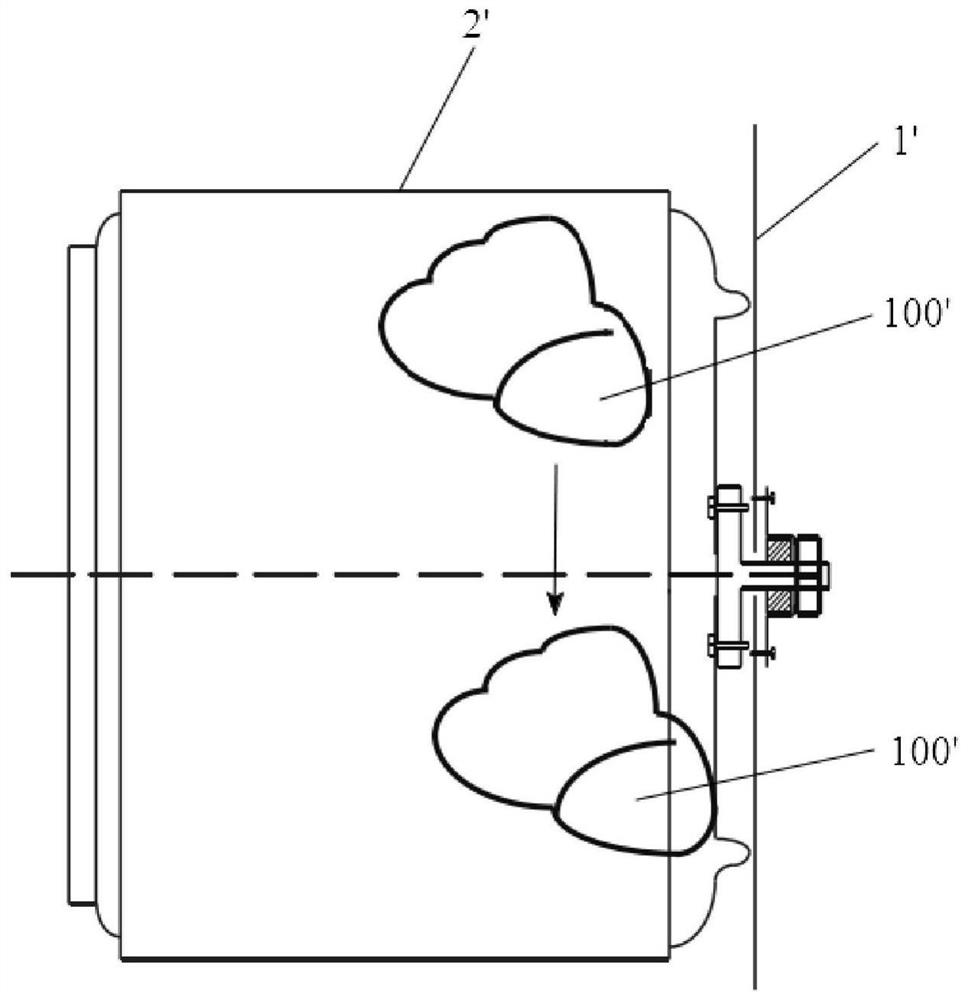

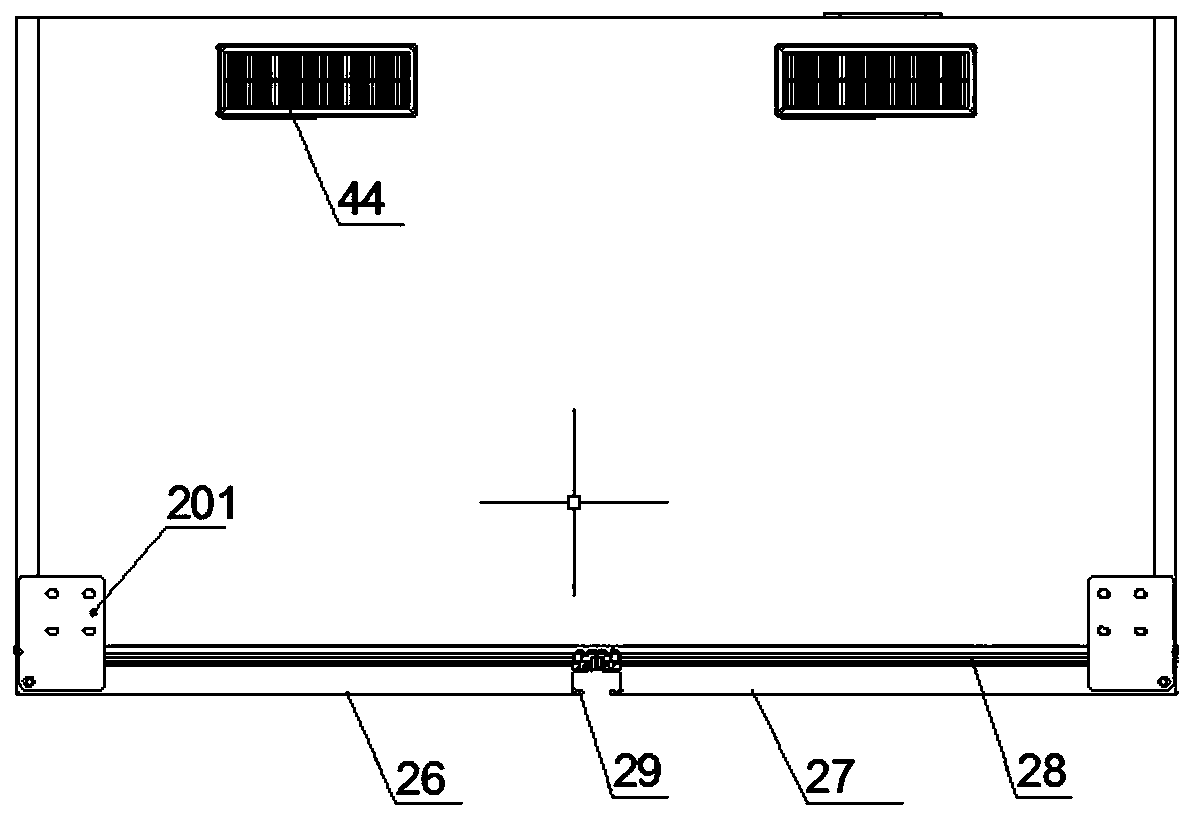

Multifunctional cabinet type heat pump clothes dryer

PendingCN111041797ASolve the problem of easy windingWinding will notDispersed particle separationLavatory sanitoryThermodynamicsEngineering

The invention discloses a multifunctional cabinet type heat pump clothes dryer. The multifunctional cabinet type heat pump clothes dryer comprises a cabinet body and a dehumidification main machine arranged in the cabinet body, wherein a combined air duct is arranged in the cabinet body through a partition plate; an air supply outlet is further formed in the top of the cabinet body; an air outletof the dehumidification main machine and the air supply outlet in the top of the cabinet body communicate with the combined air duct respectively; and a clothes airing rod is arranged below the air supply outlet. The multifunctional cabinet type heat pump clothes dryer can effectively solve a series of problems that an existing clothes dryer is limited in clothes drying capacity, clothes are proneto being wound, different types of clothes cannot be dried synchronously, clothes which are not resistant to abrasion cannot be dried, clothes which are not resistant to high temperature cannot be dried, and electric heating clothes drying energy consumption is too large.

Owner:成都佳阳智能家居有限公司

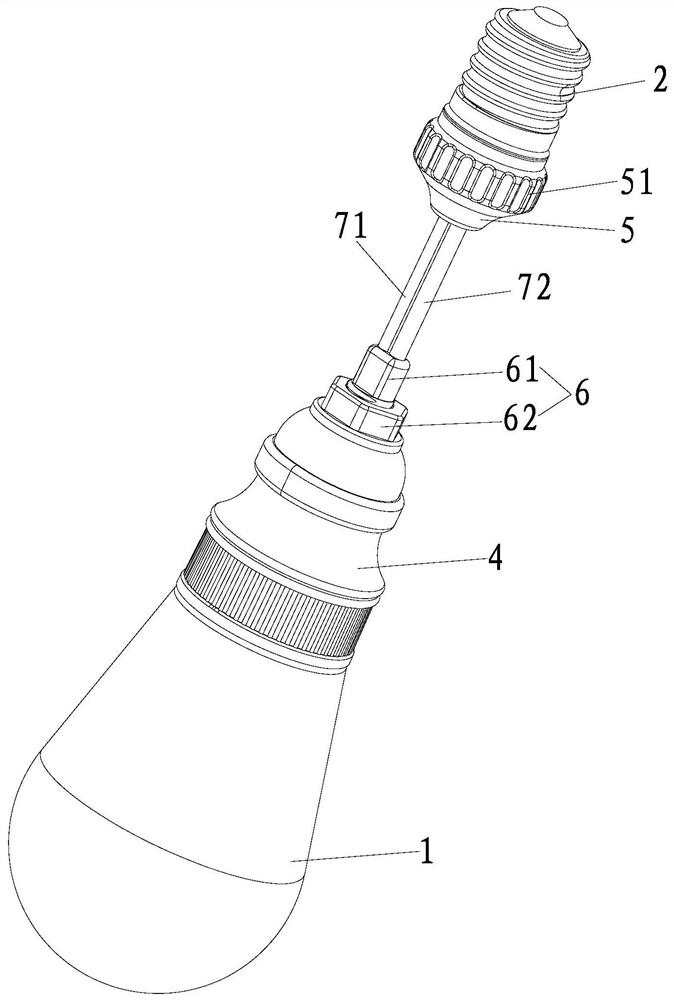

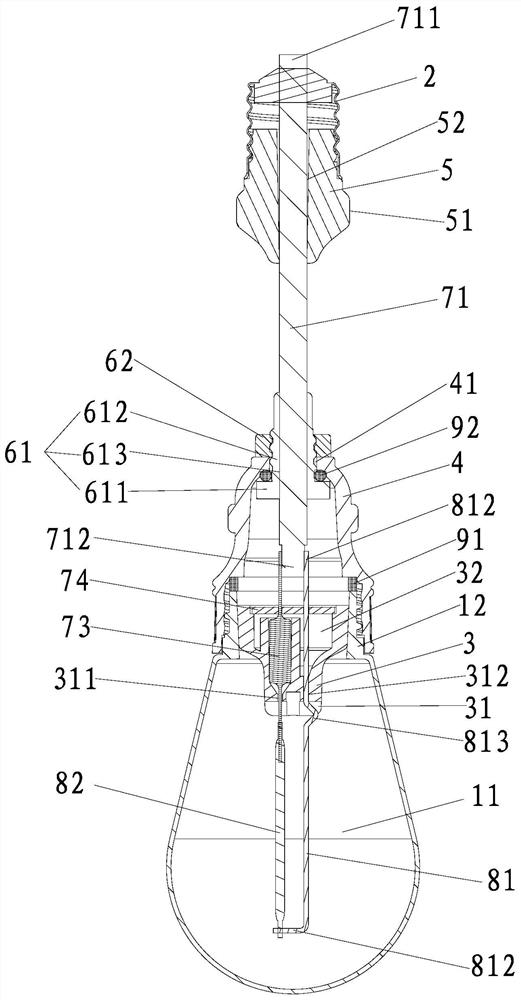

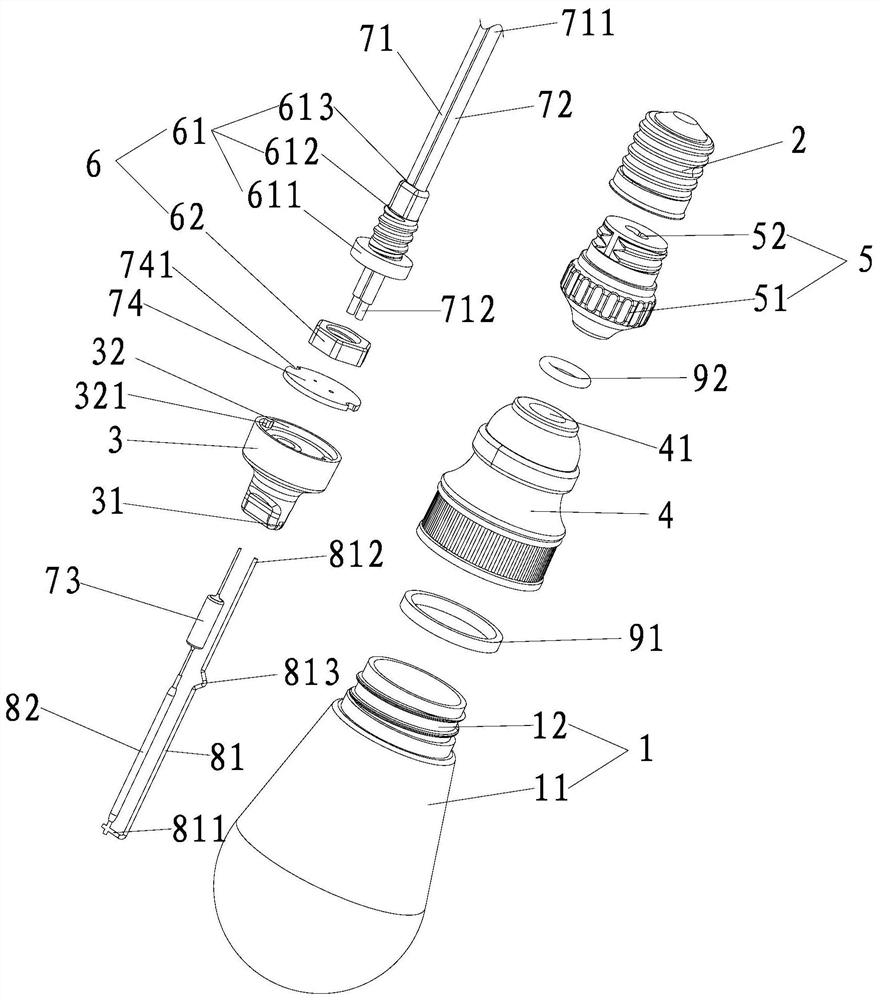

Decorative bulb and decorative lamp string

PendingCN113483280AEasy to storeLow costElectric circuit arrangementsLight effect designsEngineeringLight source

The invention discloses a decorative bulb and a decorative lampstring . The decorative bulb comprises a lampshade, a lamp holder, a light source device, a power source device, a lampshade base and a lamp holder base, a mounting part is inserted into the lampshade base, the lamp holder base is inserted into the lamp holder, the power source device comprises a wire, and the lampshade base and the lamp holder base are each provided with a through hole allowing a wire to penetrate through; and the decorative lamp string comprises a main cable, a plurality of bulb holders and a plurality of decorative bulbs, and the decorative bulbs and the bulb holders are arranged in a one-to-one correspondence mode. According to the decorative bulb, a traditional auxiliary cable is replaced with the wire, when the lamp string is stored, the situation that the auxiliary cable and the main cable are knotted cannot be caused, the wire is arranged on the decorative bulb, the lamp string is easier to store, and meanwhile when the main cable is produced, the cost is lower, and the process is simpler; and the decorative lamp string is lower in production cost, long in service life and attractive and elegant in appearance, and meanwhile, the lamp string provided with the decorative bulbs is suitable for more occasions and is more interesting.

Owner:JINJIANG WONDERFUL PHOTOVOLTAIC LIGHTING

Portable fibre optic gyroscope north seeker

ActiveCN102012228BReduce volumeHigh precisionNavigation by speed/acceleration measurementsSagnac effect gyrometersAccelerometerEngineering

The invention discloses a portable fibre optic gyroscope (FOG) north seeker, comprising a circular installing plate and a rotating shaft vertically arranged on the circular installing plate, wherein one end of the rotating shaft is connected with the circular installing plate by a bearing in a rotatable manner; a support is fixedly arranged on the rotating shaft; a shell containing the support isfixedly arranged on the circular installing plate; the support is provided with a detecting system, a rotating system and a positioning system; and the detecting system comprises a horizontal accelerometer, a vertical accelerometer and an FOG. The north seeker has the advantages of reliable measurement, small size, convenient carrying, low cost and the like.

Owner:CHONGQING AEROSPACE NEW CENTURY SATELLITE APPL TECH

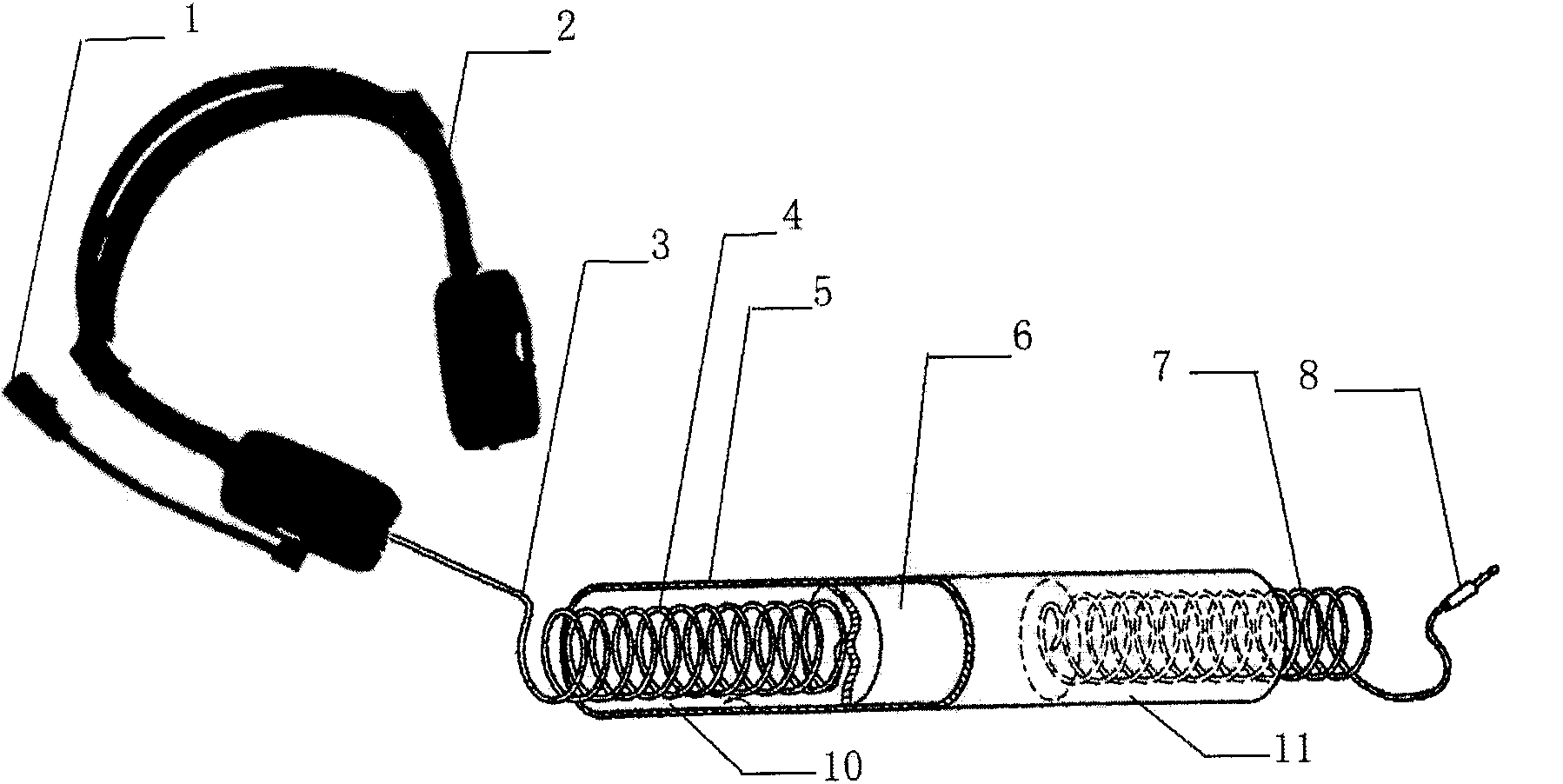

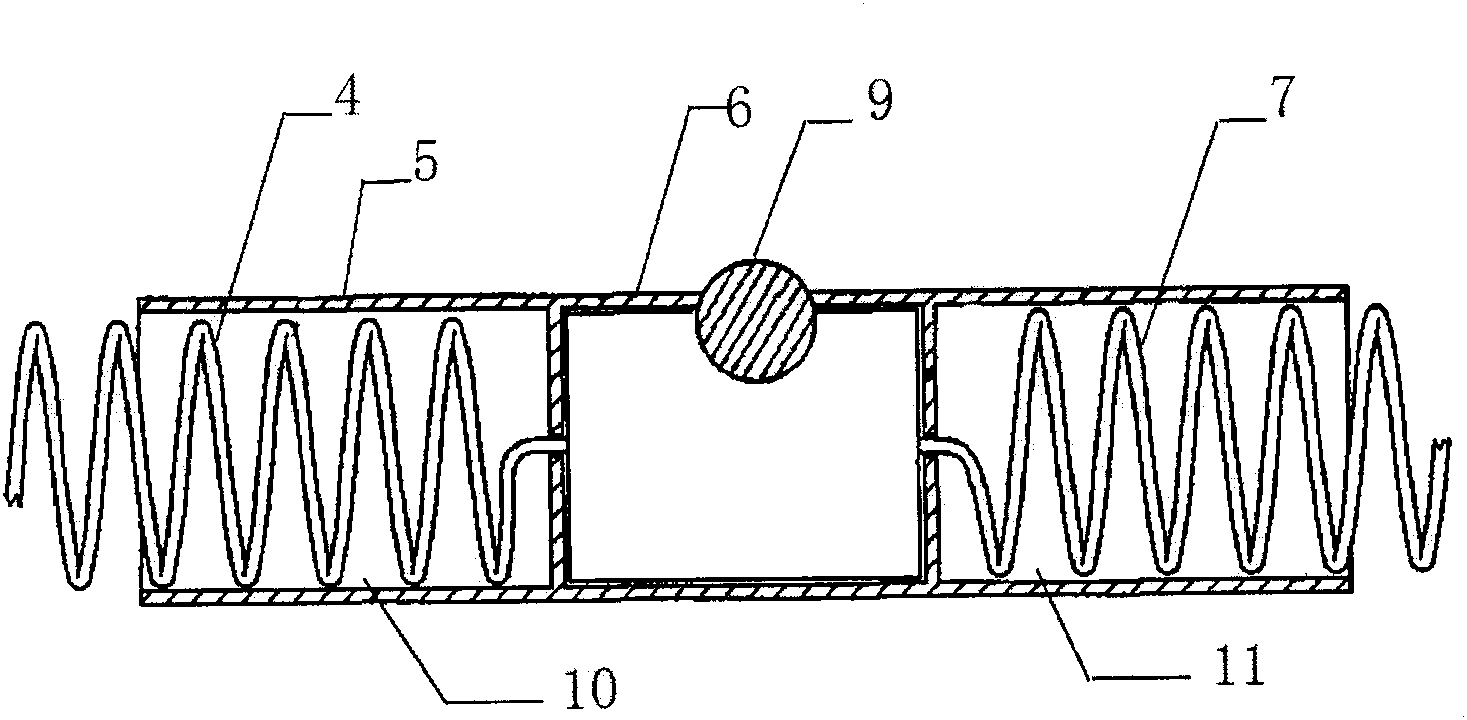

Novel headset wire

InactiveCN103313163AEasy to carry and useImprove protectionEarpiece/earphone attachmentsEngineeringElectrical and Electronics engineering

The invention discloses a novel extensible headset wire. An extension principle of a spring-shaped extensible lead is utilized for changing a common straight wire to the spring-shaped extensible lead on the premise of unaffecting functions of the headset wire, and a length-changeable function of the headset wire is realized; meanwhile, by the aid of elasticity of a spring-shaped extensible lead material, spiral threads are arranged on the inner walls inside a lead outlet cavity and a lead inlet cavity, so that the lead can be fixed after the threads are pressed in. By the design, the headset wire is convenient to use and carry, wire winding is prevented, the problem that the headset wire is easy to wind when a headset is used is solved, and protection to the headset wire is enhanced.

Owner:赵剑毅

Feeding mechanism of infusion tubes

ActiveCN103057946BSolve the problem of easy windingIncrease work intensityConveyor partsProduction lineEngineering

The invention discloses a feeding mechanism of infusion tubes. The feeding mechanism is arranged on an assembling production line of the infusion tubes and used for achieving automatic feeding of raw material tube bodies of the infusion tubes and comprises a feeding assembly and a conveying assembly, wherein the feeding assembly is used for loading the tube bodies of the infusion tubes, and the conveying assembly is used for grabbing the tube bodies of the infusion tubes on the feeding assembly and conveying the tube bodies of the infusion tubes onto the station of the next procedure. The feeding assembly comprises a movable feeding frame, and a plurality of troughs used for containing the tube bodies of the infusion tubes are arranged on the feeding frame. The conveying assembly comprises a movable support, a plurality of gas claws are arranged at the lower end of the support and used for grabbing the tube bodies of the infusion tubes on the movable feeding frame. The movable support drives the gas claws grabbing the tube bodies of the infusion tubes to move to convey the tube bodies of the infusion tubes to the station of the next procedure, and automatic feeding is achieved. The feeding mechanism solves the problem of easiness in winding of pipes through the movable feeding frame, and accordingly is convenient to operate; improves feeding efficiency due to the fact that two-side alternating feeding is adopted; and avoids various problems caused by manual operation due to the fact that automation devices are adopted for both the feeding assembly and the conveying assembly.

Owner:HUAZHONG UNIV OF SCI & TECH

Electrocardio monitoring device

PendingCN112244854ASolve complexitySolve the problem of easy windingSensorsTelemetric patient monitoringEngineeringBiomedical engineering

The invention relates to the field of medical instruments, in particular to an electrocardio monitoring device. The electrocardio monitoring device comprises a display instrument, an electrode slice,a wireless signal transmitting box and a wireless signal receiving box, wherein the wireless signal receiving box is located on the display instrument, the wireless signal receiving box is electrically connected with the display instrument, and the electrode slice is located at the bottom of the wireless signal transmitting box; and the electrode slice is electrically connected with the wireless signal transmitting box, and the wireless signal transmitting box is connected with the wireless signal receiving box through wireless signals. According to the scheme, no lead wire is needed to transmit signals, so that the technical problem that a plurality of lead wires are intertwined is solved.

Owner:THE FIRST AFFILIATED HOSPITAL OF ARMY MEDICAL UNIV

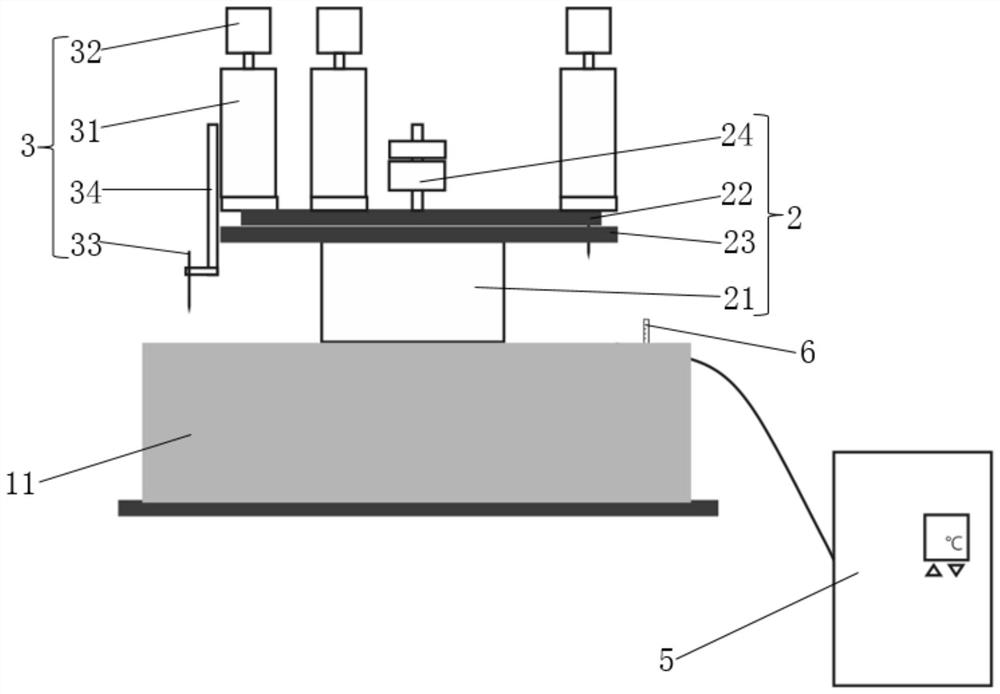

Multifunctional continuous online gas preparation and introduction device

ActiveCN111948277AShorten the timeSave human effortSamples introduction/extractionPreparing sample for investigationWater storageElectric machine

The invention provides a multifunctional continuous online gas preparation and introduction device which comprises a sample table unit, a rotating unit and a plurality of sample introduction units; the sample table unit comprises a sample disc, a water storage ring and a sample disc cover, a plurality of blind holes are formed in the upper part of the sample disc, the water storage ring is locatedin the sample disc, and the sample disc cover sleeves the outer side of the sample disc; the rotating unit is located above the sample disc and comprises an electric rotating table and an annular guide rail, the electric rotating table is fixed to the middle of the sample disc, the annular guide rail is installed above the electric rotating table, and at least one sliding block is arranged on theannular guide rail; each sample injection unit comprises a screw rod sliding table, a driving motor and a needle head, the screw rod sliding table is installed on the sliding block, the driving motoris connected with the guide rail sliding block, and the needle head is fixed to the outer side of the guide rail sliding block through a needle head clamping groove. The device has the beneficial effects that gas preparation and introduction are carried out in a rotating mode, multiple pretreatment operations can be carried out on multiple sample bottles at the same time, and thedevice is particularly suitable for experimental analysis needing a complex pretreatment sample injection mode.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A domestic waste crushing and sorting system

ActiveCN104874582BThere will be no stuckStuck situation solvedSolid waste disposalGrain treatmentsSocial benefitsPendulum

Disclosed is a domestic waste crushing and sorting system. The system comprises a quantitative feeding device, a magnetic separation device (10), a gravity gradient sorting device (12), a pendulum-type crushing device, a wind separation device (29) and a needle separation device (22) and a material conveying device. The system has a compact structure, is easy to operate, is safe and reliable, and can sort urban domestic wastes into corrodible organic substances, combustible wastes, metals, glasses and light recyclable substances, thereby not only making full use of the urban domestic wastes but also having high environmental benefits and social benefits.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

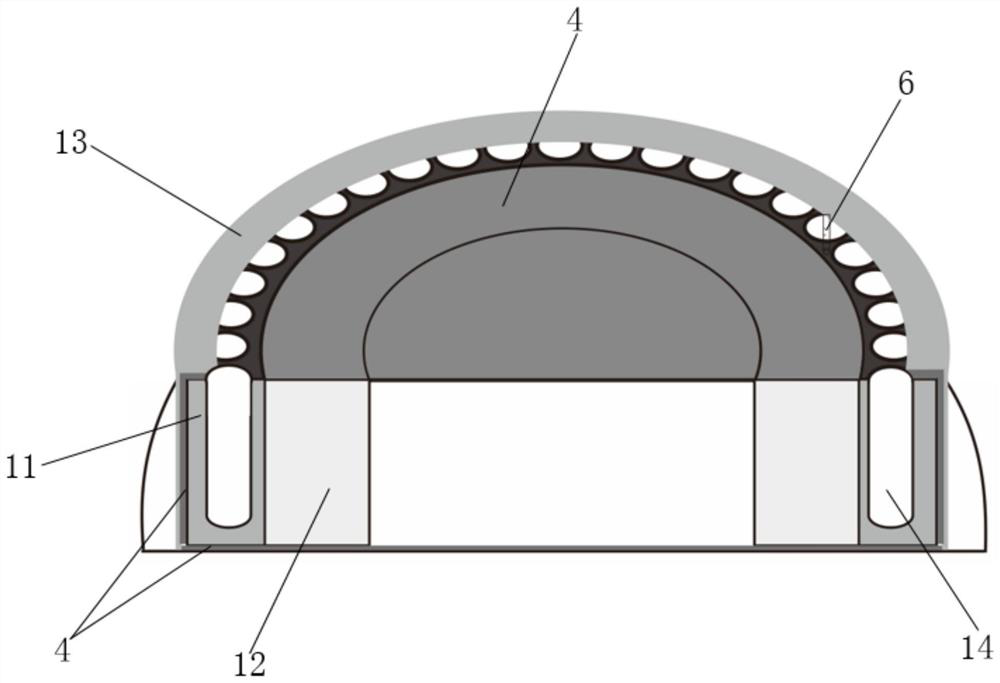

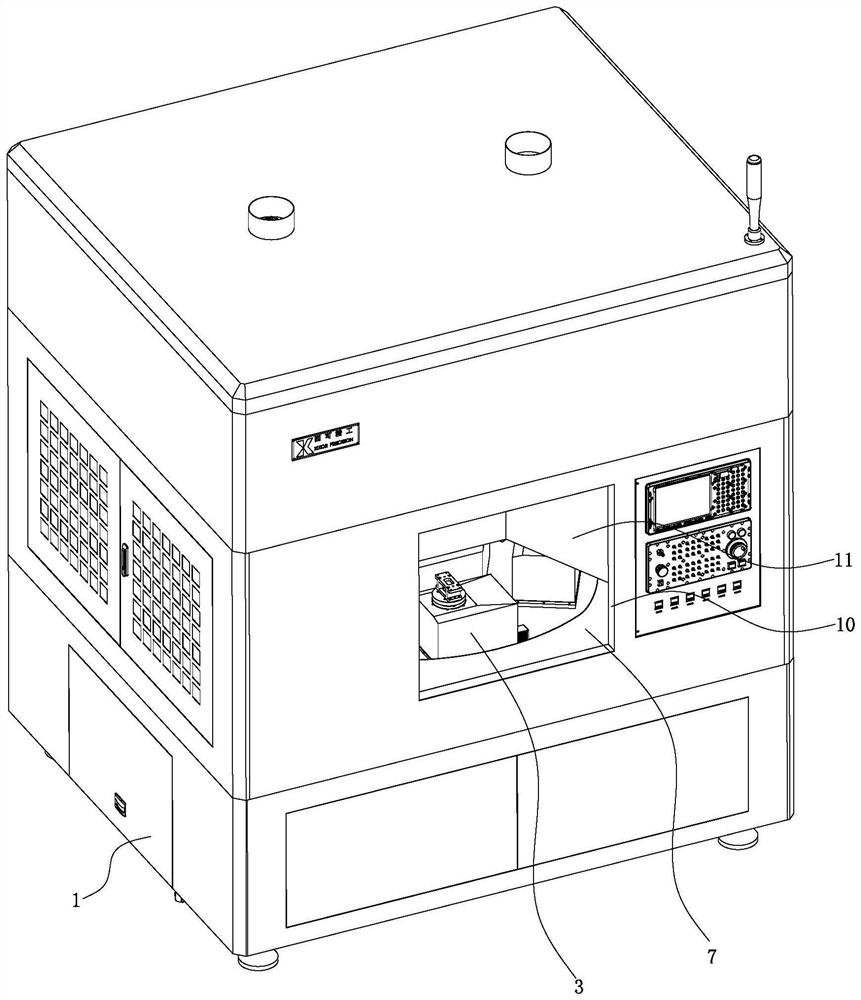

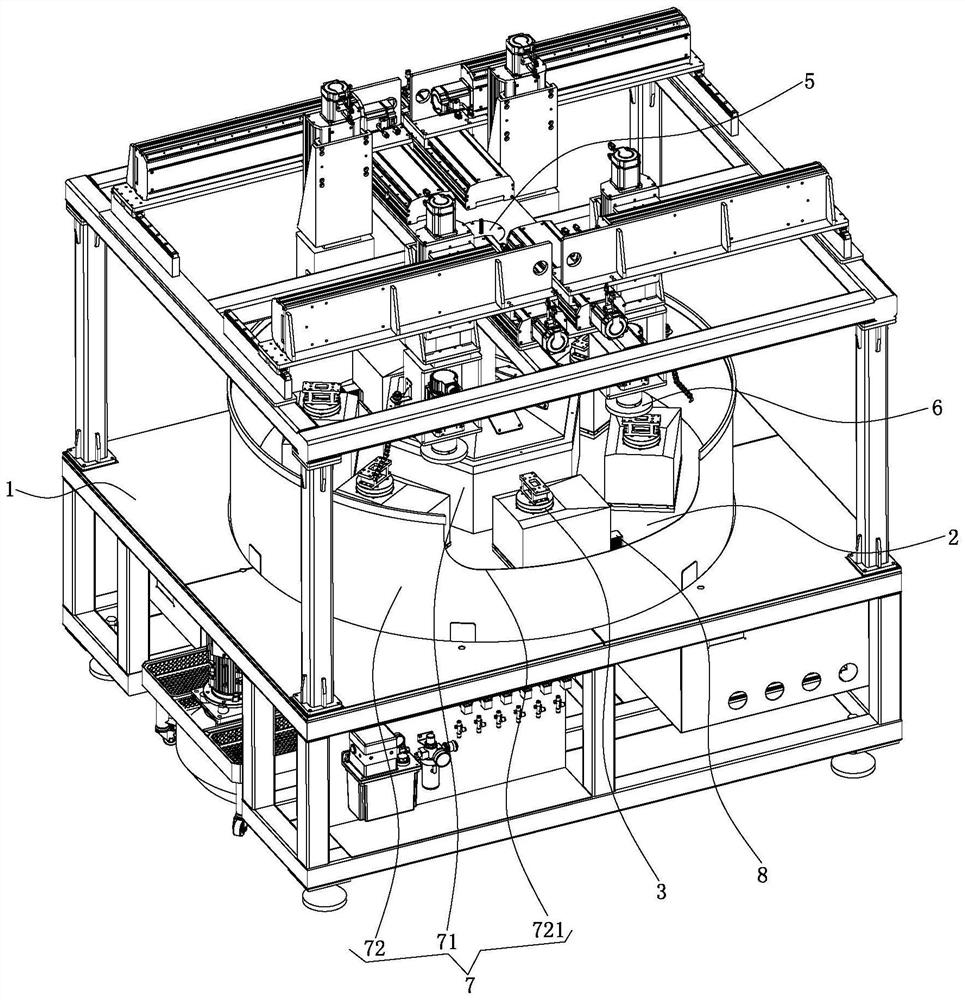

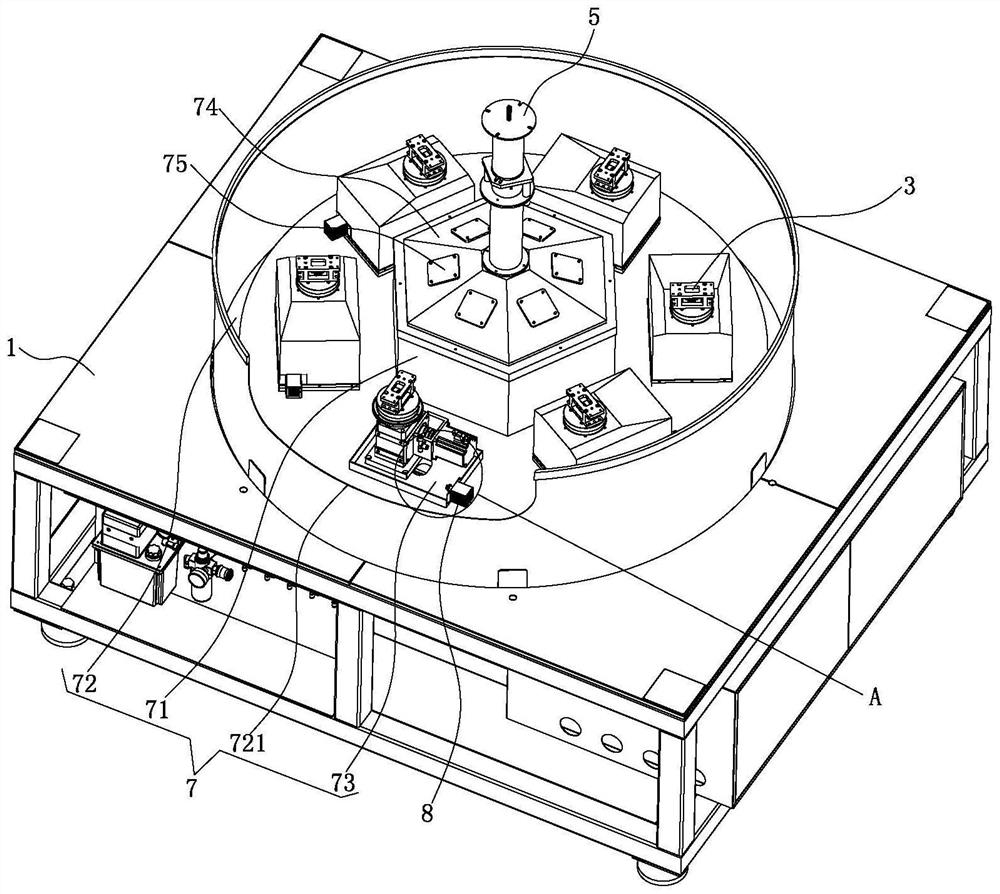

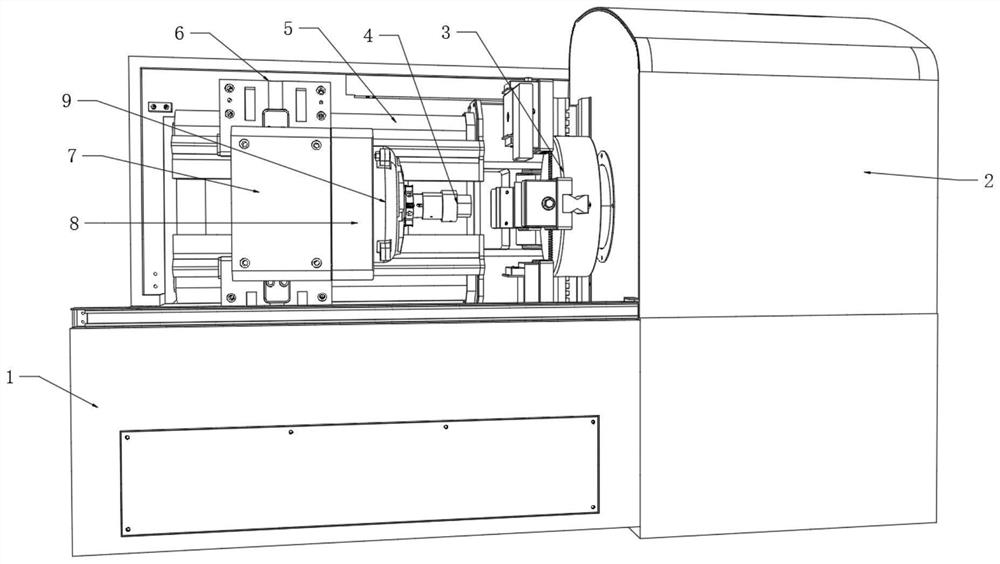

Full-automatic intelligent polishing machine

PendingCN114851062AReduce mistakesImprove machining accuracyGrinding carriagesPolishing machinesProcessing accuracyPolishing

The invention discloses a full-automatic intelligent polishing machine. The rotating transposition mechanism is arranged in the middle of the rack and used for switching stations, and the bearing positioning devices are installed on the rotating transposition mechanism in a circumferential mode and used for fixing workpieces. The gas distribution module and the power distribution module are arranged in the middle of the rotary transposition mechanism; and the polishing manipulators are arranged at the upper end of the rack and used for machining workpieces on the bearing and positioning device. The multiple bearing and positioning devices are evenly arranged on the rotary transposition mechanism in the circumferential direction, the multiple polishing manipulators used for machining the workpieces are arranged above the rotary transposition mechanism, the rotary transposition mechanism drives the bearing and positioning devices to be switched between the polishing manipulators, and machining of the workpieces in different procedures is completed through the different polishing manipulators; and the workpiece or the polishing disc does not need to be disassembled and assembled repeatedly, so that errors caused by clamping are reduced, and the machining precision is improved.

Owner:深圳西可精工科技有限公司

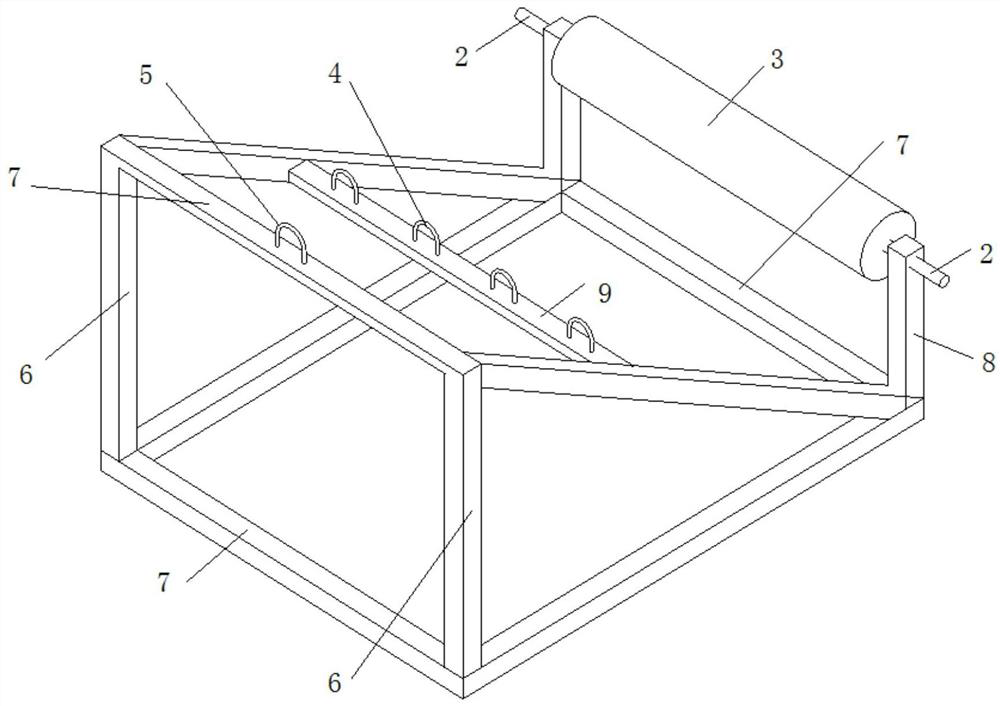

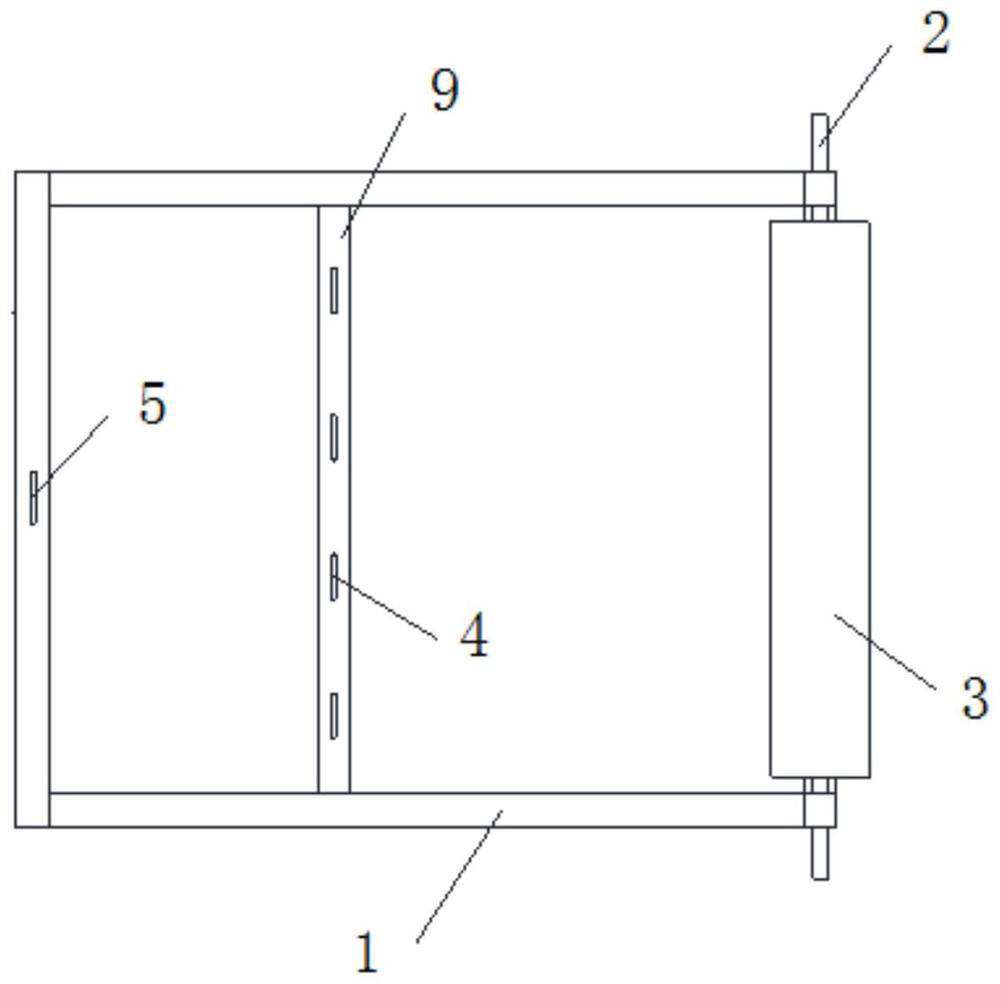

Device for doubling on construction site and using method thereof

PendingCN114030941ASolve the problem of easy windingSolve efficiency problemsFilament handlingApparatus for laying cablesEngineeringIndustrial engineering

The invention relates to a device for doubling on a construction site and a using method thereof. The device comprises a chassis support and a movable roller. The upper end of the chassis support is obliquely arranged downwards from left to right. A doubling guide hole is formed in the left side of the upper end of the chassis support, and a plurality of branching guide holes are formed in the middle of the upper end of the chassis support side by side. The movable roller is installed on the right side of the upper end of the chassis support. According to the invention, the problems of easy winding and low working efficiency in the doubling process of electric wires in a construction site are solved, the construction difficulty is reduced, the labor is reduced, the working efficiency and quality are improved, and the use effect is remarkable.

Owner:SHANGHAI SENXIN CONSTR ENG

An infusion tube transmission mechanism

ActiveCN105109945BSolve the problem of easy windingEasy to operateSupporting framesMechanical conveyorsTube SpacerButt joint

Owner:HUAZHONG UNIV OF SCI & TECH

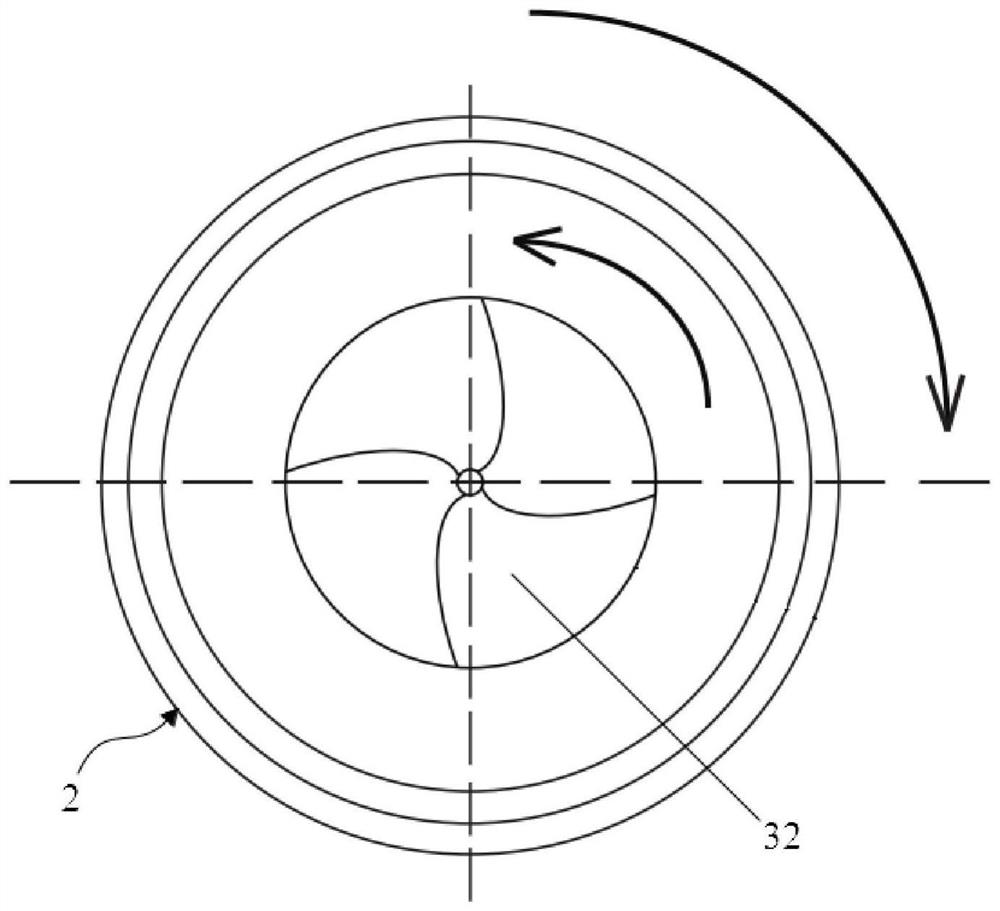

A mechanical mining device

ActiveCN105645037BSolve the problem of easy windingImprove efficiencyConveyorsMineral miningHigh probabilityEngineering

The invention discloses a mechanical mineral lifting device. The mechanical mineral lifting device comprises a crawler type power device, a support frame (2), n collecting barrels (3), a cable (6) and a relay bin (1), wherein the crawler type power device comprises two symmetric crawlers arranged on two sides of the cable (6) and the collecting barrels (3), two motors (4) are arranged in each crawler, the support frame (2) adopts an overall support structure, the cable (6) is a center cable connecting the collecting barrels (3), the relay bin (1) is a relay opening container placed under the water surface, the crawler type power device transfers power to the collecting barrels (3) through the crawlers to drive to collecting barrels (3) to move, movement of one collecting barrel (3) is transferred to the following collecting barrels (3) under the action of the cable (6), the following collecting barrels (3) are driven to move, and when passing by the relay bin (1), the bottommost collecting barrel (3) collects substances in the relay bin (1). By means of the mechanical mineral lifting device, the problem of high probability of winding of the cable in the prior art can be solved.

Owner:SHANGHAI JIAO TONG UNIV

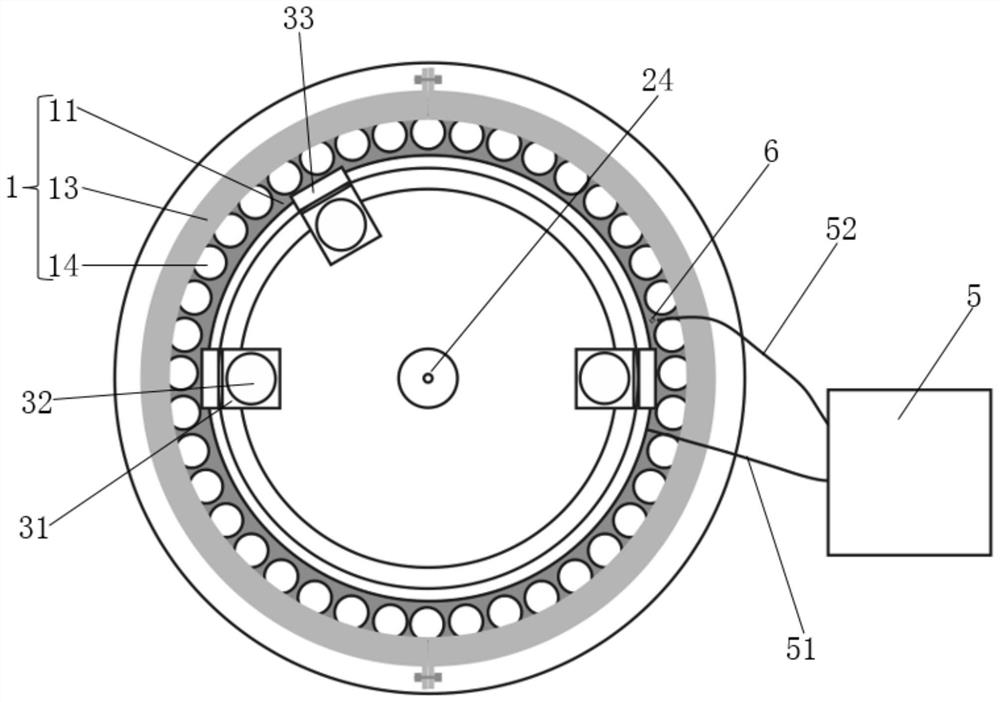

Wireless induction shuttle for circular weaving machine

PendingCN113322566AImprove accuracyTroubleshoot abnormal downtimeCircular loomsYarnTextile technology

The invention belongs to the technical field of spinning of polypropylene yarns, and discloses a wireless induction shuttle for a circular weaving machine. An interactive operation cabinet is fixedly arranged on one side of a rack of the circular weaving machine; shuttles are fixedly arranged on the inner side of a track; the shuttles are uniformly arranged around the track at equal intervals in the circumferential direction; Bluetooth transceivers B are fixedly arranged on the shuttles and used for detecting the rotating speeds of yarn bobbins on the shuttles in real time and transmitting rotating speed signals of the yarn bobbins; the yarn bobbins are fixedly installed in the middles of the upper portions of the shuttles; and the yarn bobbins are hollow. According to the invention, the manufacturing cost of the shuttle and the power consumption in the operation process are reduced, the maintenance cost of the shuttle is reduced, the problem of abnormal shutdown of the circular weaving machine due to the complicated structure of the shuttle is solved, the operation efficiency of the circular weaving machine is improved, and the problem that a connecting wire is easy to wind is thoroughly solved.

Owner:洛阳市大资塑业有限公司

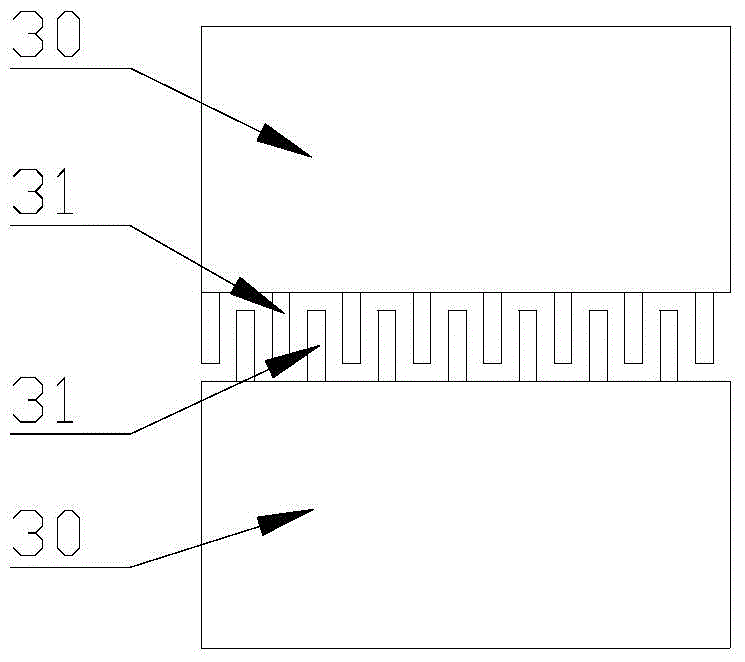

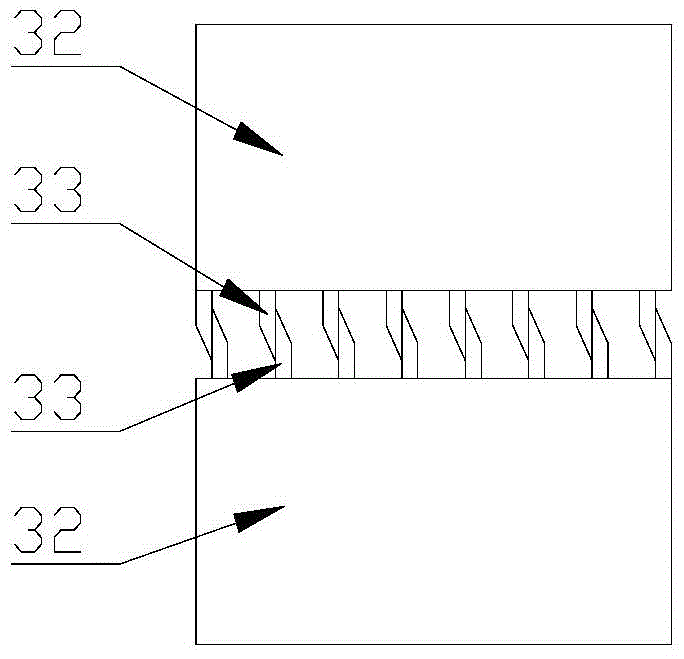

An anti-tangle winder for heat dissipation of electric wires and its processing technology

The invention discloses an anti-twining wire winder for wire heat dissipation. The anti-twining wire winder comprises a wire winder body, wherein first teeth and second teeth are arranged on the upper side and the lower side of the wire winder body respectively, and lock catch devices are arranged at two ends of the wire winder body. According to the anti-twining wire winder for wire heat dissipation, the first teeth and the second teeth are arranged on the upper side and the lower side of the wire winder body respectively, so that a wire can be uniformly wound in grooves of the teeth and prevented from being twined together, and the wire can be well stored and arranged; and meanwhile, the problem of a circuit fault due to high temperature caused by wire twining is also well solved, so that an extremely good protection effect on the wire itself and the whole circuit is achieved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

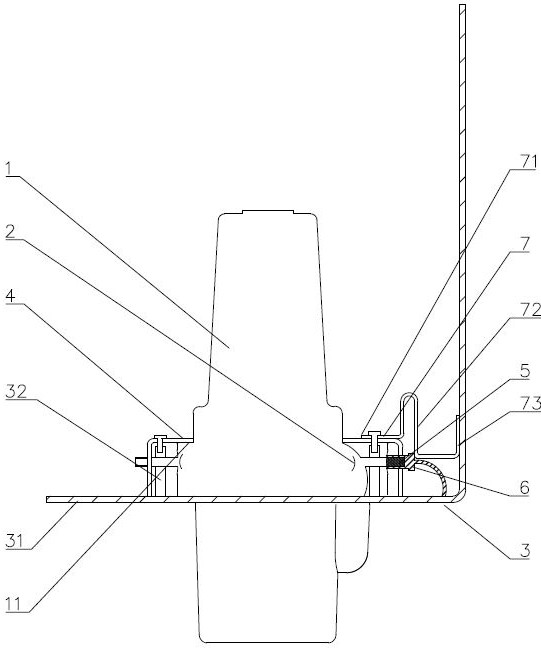

Live indicator lead structure for closed switchgear

ActiveCN110854686BSolve the problem of easy windingEasy to fixBus-bar/wiring layoutsSupervisory desks/panelsEngineeringStructural engineering

The invention relates to a live indicator lead wire structure of a closed switchgear. The live indicator lead structure of closed switchgear includes: gas box, insulating bushing and indicator lead terminal, the insulating bushing is fixed on the gas box wall of the gas box; the insulating bushing includes the bushing body, and the bushing body is equipped with In the induction ring, an outlet terminal is provided on the outer peripheral surface of the bushing main body, and the outlet terminal is conductively connected with the induction ring. The indicator lead terminal is connected with a live indicator lead for connecting to the outlet terminal; a lead terminal crimping piece is fixed on the gas box, and the lead terminal crimping piece is pressed on the indicator lead terminal to make the indicator lead terminal Keep connected to the outgoing terminal. The lead terminal crimping piece is used to press on the indicator lead terminal, which can not only keep the indicator lead terminal and the outlet terminal in a connected state, but also solve the problem that the wire of the charged indicator is easy to be entangled.

Owner:XUJI GRP +3

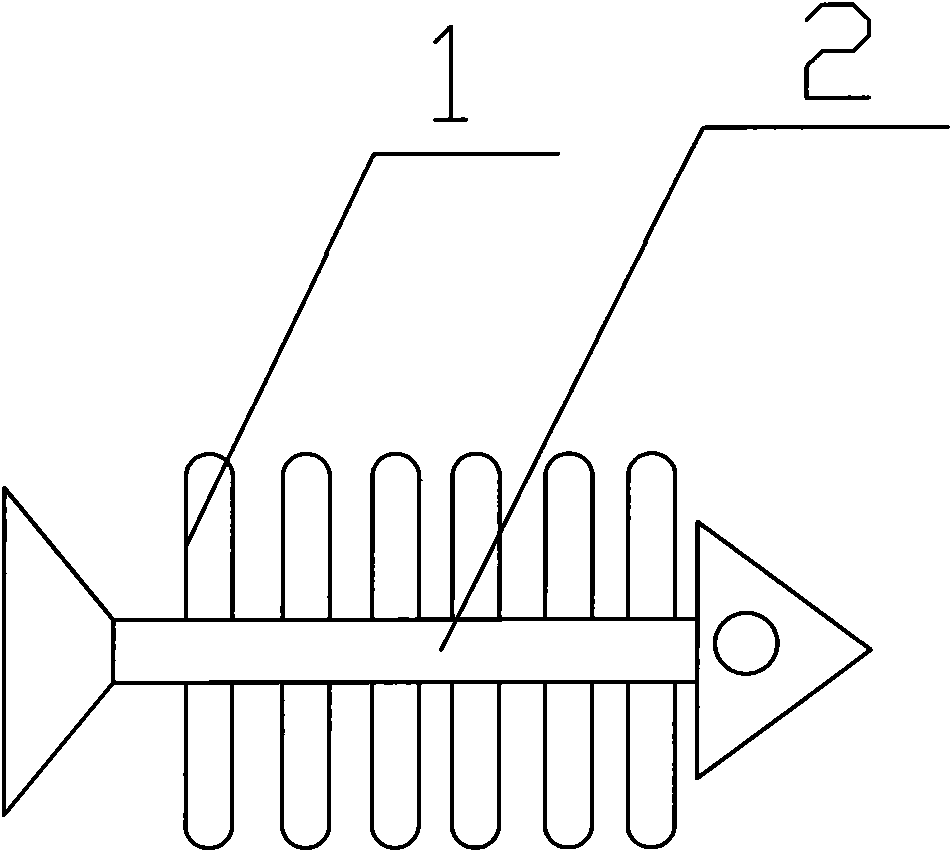

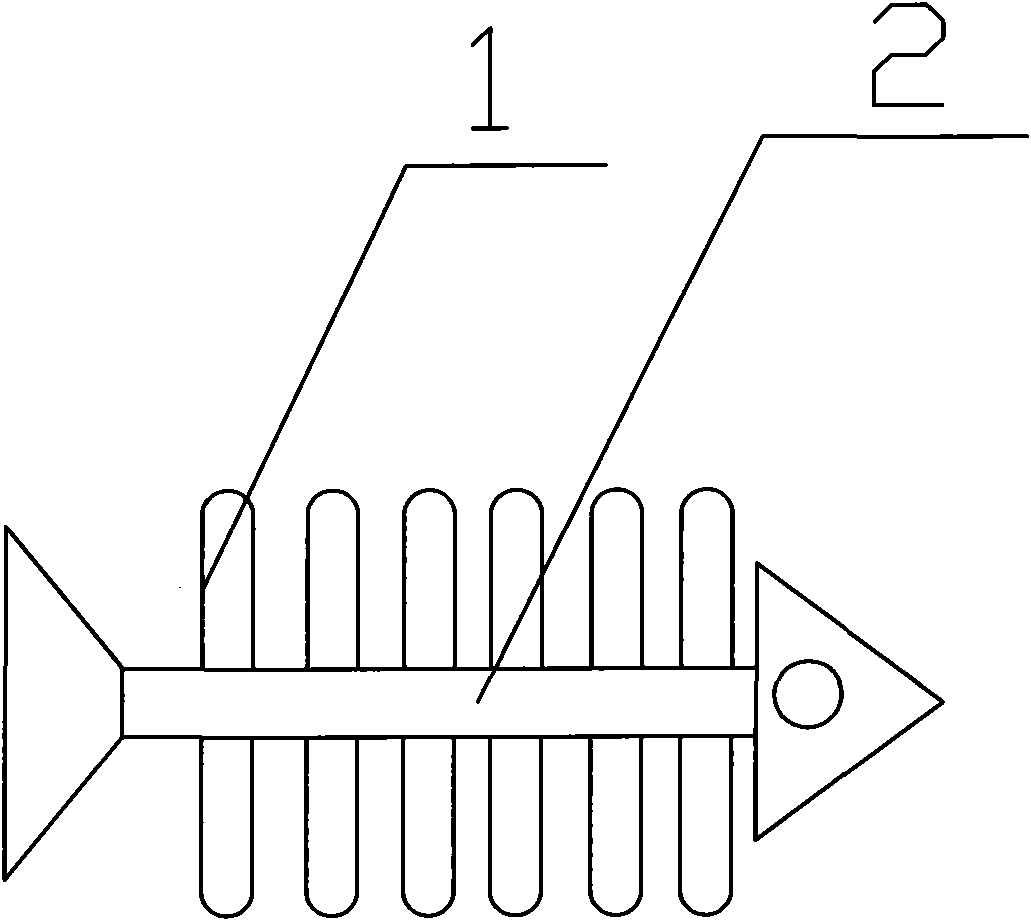

Cord storage device

The invention discloses a storage appliance and particularly discloses a cord storage device. The cord storage device comprises a main post and is characterized in that both sides of the main post are provided with ribs. The cord storage device has the advantages that the problem that a cord is easy to twine when being stored is solved; the structure is simple; the appearance of the cord storage device can be made into various shapes, such as a fishbone shape, a centipede shape and the like according to personal preference; and the appearance is attractive.

Owner:杜志柏

Horizontal battery measuring equipment

InactiveCN112904214ASolve the problem of easy windingReduce vibration energyElectrical testingElectrical batteryControl theory

A horizontal battery measuring device disclosed by the present invention comprises a working platform, a first driving module and clamps, the first driving module is installed above the working platform, the four clamps are symmetrically installed at one end of the first driving module along the center, the clamps and the working platform are installed in a matched mode, a rotating mechanism is arranged on the right sides of the clamps, a second driving module is installed above the working platform, a moving table is installed on the surface of the second driving module, a current detection mechanism is installed on the upper surface of the moving table, and an inertia force removal balance mechanism is installed on the surface of the current detection mechanism.Through the current detection mechanism, the problem that during the rotation process, when the battery is discharged, a measuring lead is easy to wind is solved; and through the inertia force removing balancing mechanism, the rotating inertia force is balanced, the vibration energy and the vibration amplitude are reduced, vibration is reduced through vibration buffering of the damper on the rotating shaft and absorption of the vibration energy, and the practicability is high.

Owner:CHANGSHA NINGHU MACHINERY CO LTD

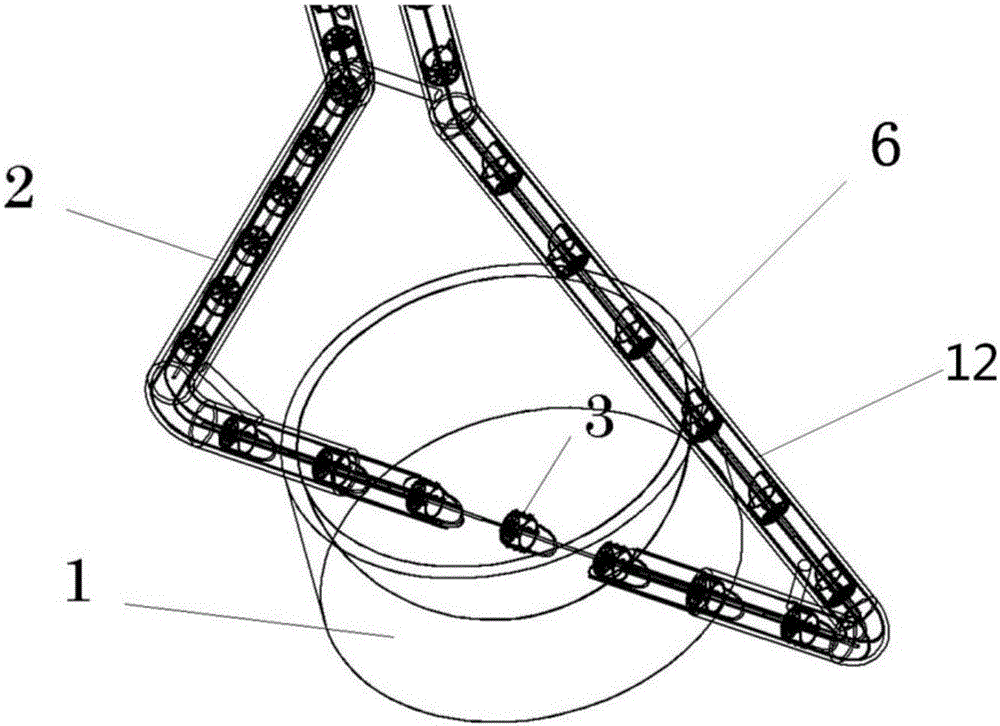

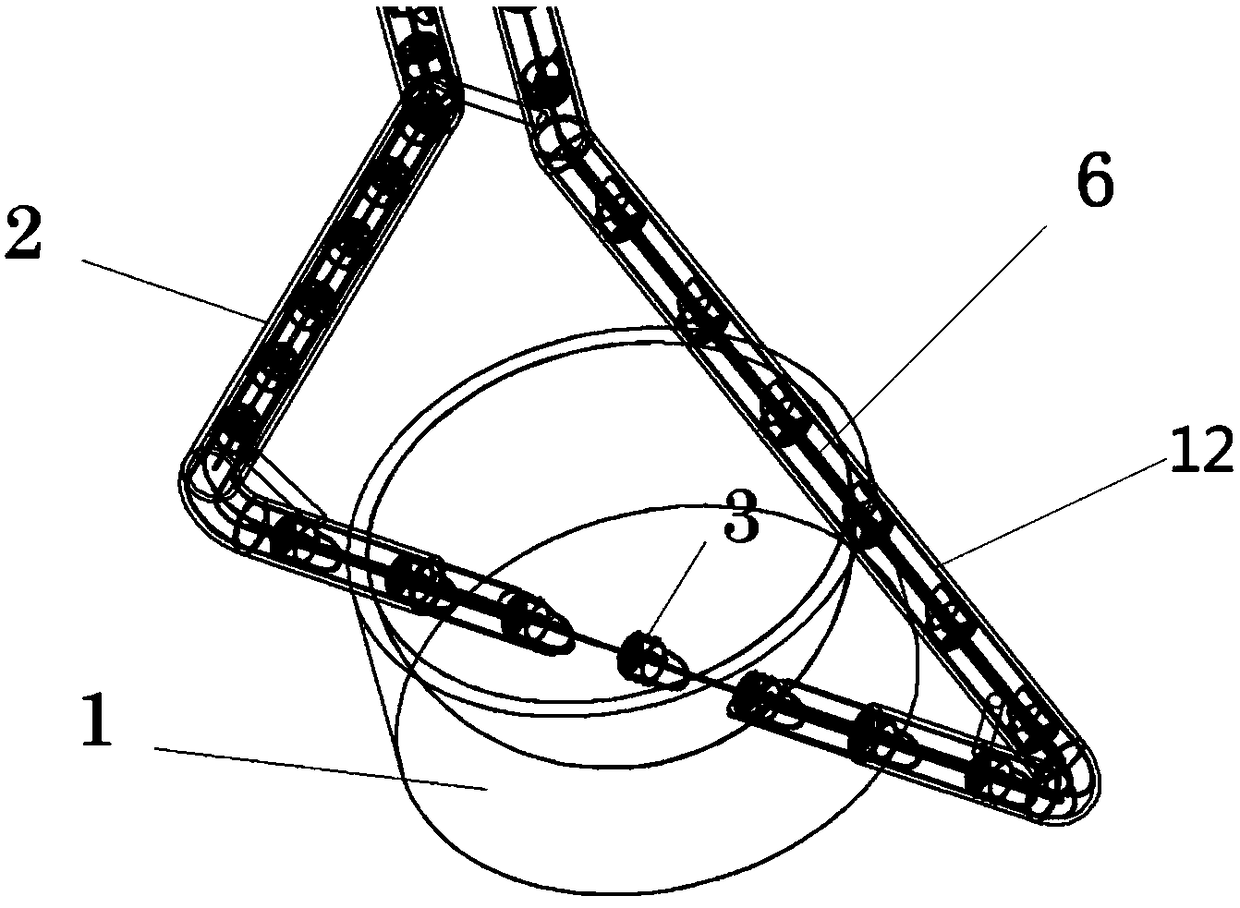

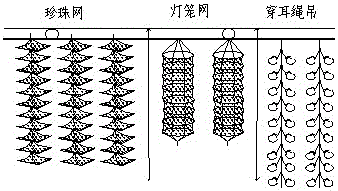

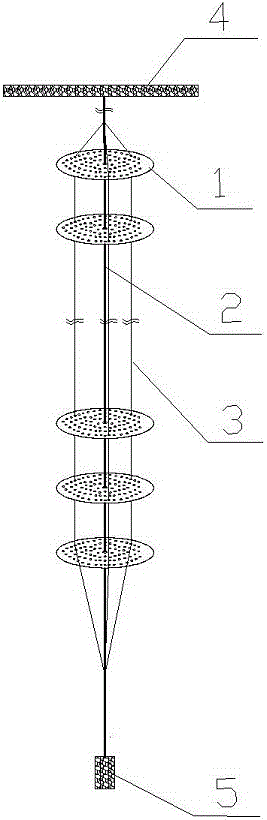

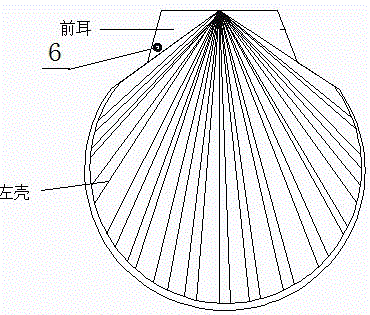

Ear-puncturing and hanging cultivation device for patinopecten yessoensis and hanging cultivation method

InactiveCN106212347AGuaranteed water filtration performanceSolve the problem of easy windingClimate change adaptationPisciculture and aquariaEngineeringPatinopecten yessoensis

The invention discloses an ear-puncturing and hanging cultivation device for patinopecten yessoensis and a hanging cultivation method. The device comprises multiple mutual parallel culture hanging plates, a vertical lifting rope penetrating the center of plates, the lifting rope penetrating the center of plates penetrates the centers of the culture hanging plates and enables the culture hanging plates to isometrically fix on the lifting rope penetrating the center of plates; plate edges of adjacent culture hanging plates are connected through plate edge lifting ropes, and each culture hanging plate is enabled to be vertical to the lifting rope penetrating the center of plates; the plate edges of the culture hanging plates at the head end and the tail end are fixedly connected with the lifting rope penetrating the center of plates through plate edge lifting ropes; the upper end of the lifting rope penetrating the center of plates is fixed on a floating raft, and the lower end of lifting rope penetrating the center of plates is provided with a sinker. The device disclosed by the invention adopts the culture hanging plates to ensure the drainability of the device. According to the hanging cultivation method, the patinopecten yessoensis is isometrically hung on the culture hanging plates in each layer of the device, then is put in the raft area for cultivation, and the problem of easy twining when ear-puncturing and rope hanging is solved, according to the device disclosed by the invention, due to the fact that netting is not needed for wrapping, the problem that fluid mud and other marine organisms are easily adhered during culturing in a lantern net is solved, and a good growth condition is provided for culturing the patinopecten yessoensis.

Owner:DALIAN OCEAN UNIV

Anti-twining wire winder for wire heat dissipation and machining process thereof

The invention discloses an anti-twining wire winder for wire heat dissipation. The anti-twining wire winder comprises a wire winder body, wherein first teeth and second teeth are arranged on the upper side and the lower side of the wire winder body respectively, and lock catch devices are arranged at two ends of the wire winder body. According to the anti-twining wire winder for wire heat dissipation, the first teeth and the second teeth are arranged on the upper side and the lower side of the wire winder body respectively, so that a wire can be uniformly wound in grooves of the teeth and prevented from being twined together, and the wire can be well stored and arranged; and meanwhile, the problem of a circuit fault due to high temperature caused by wire twining is also well solved, so that an extremely good protection effect on the wire itself and the whole circuit is achieved.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com