Patents

Literature

40results about How to "Reduce frictional heat generation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

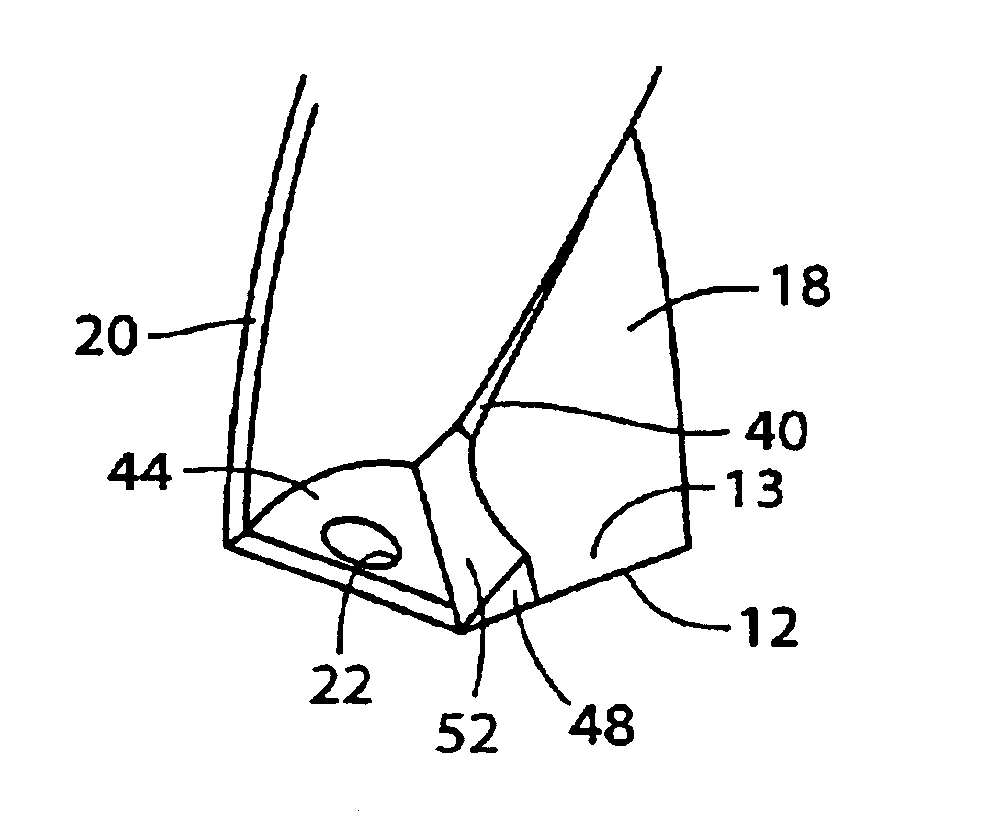

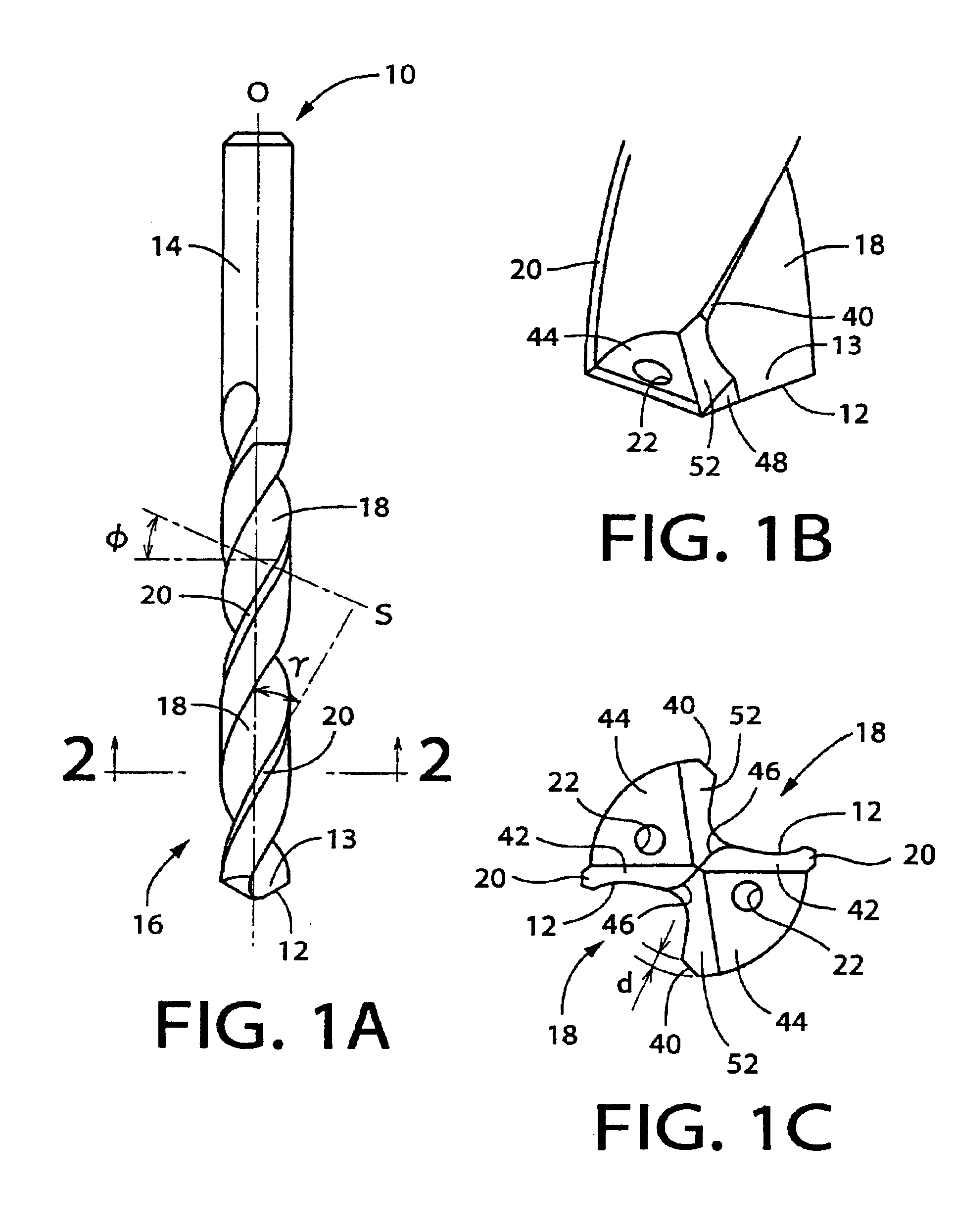

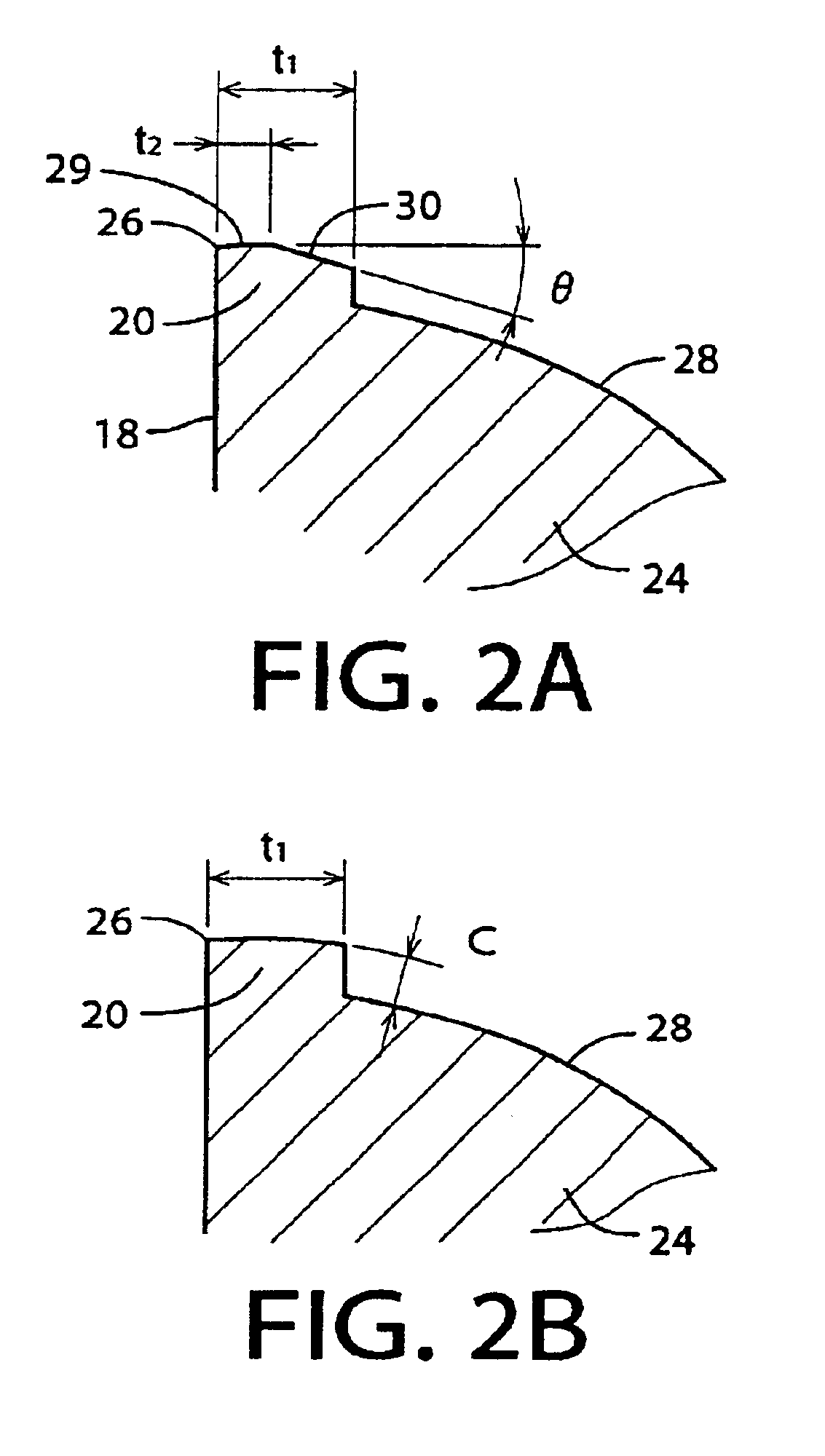

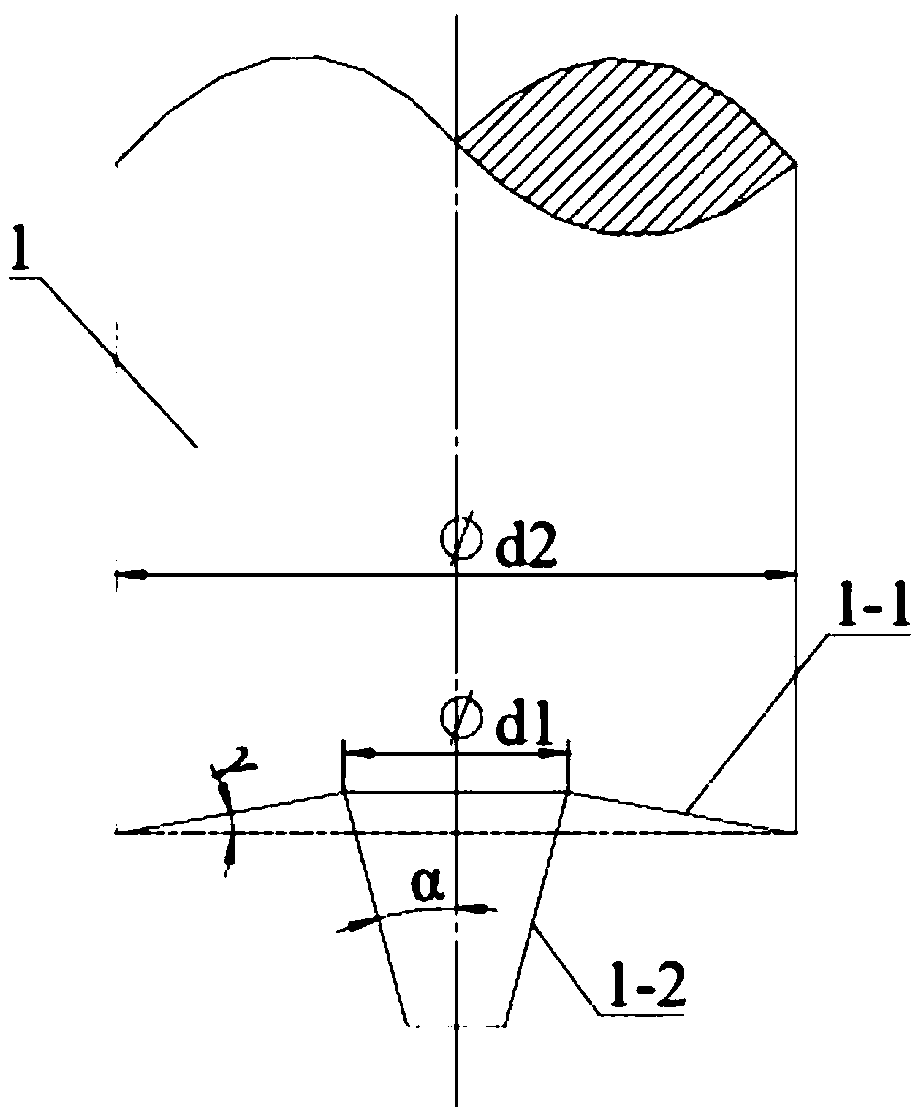

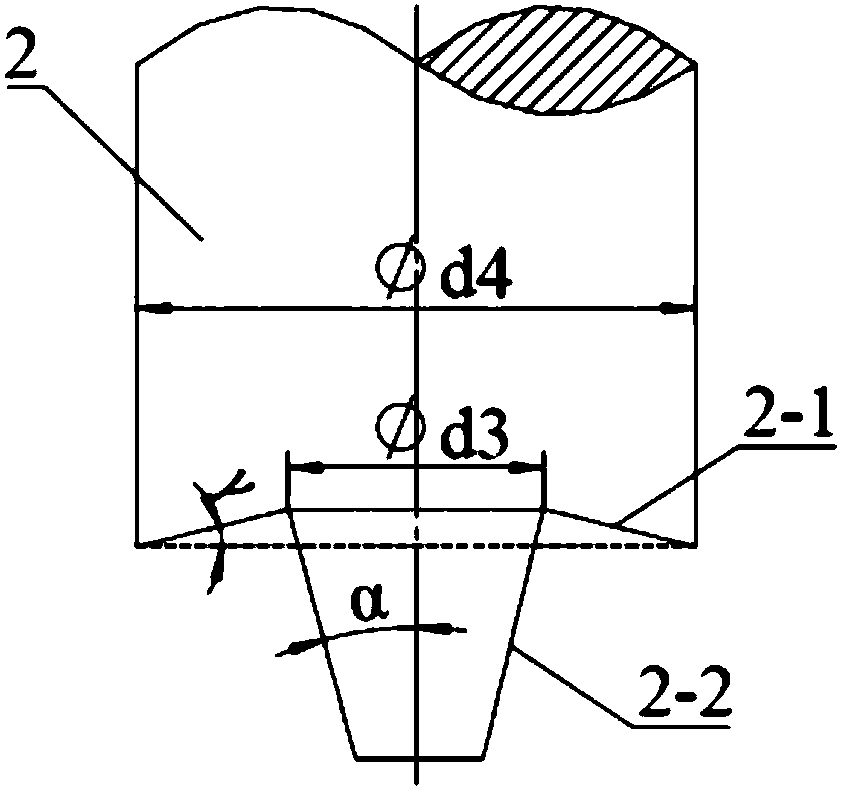

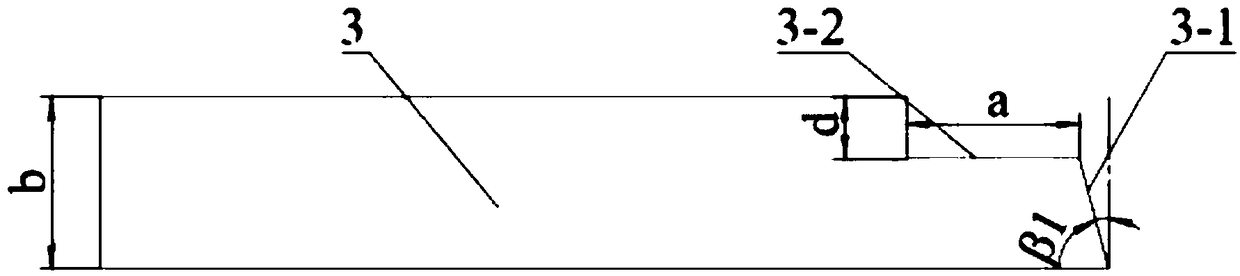

Drill having construction for reducing thrust load in drilling operation, and method of manufacturing the drill

A drill including a shank portion and a cylindrical body portion contiguous to each other. The cylindrical body portion includes (a) primary cutting edges and secondary cutting edges formed in its axially distal end portion such that each of the secondary cutting edges is located on a radially inner side of the corresponding primary cutting edge; (b) primary rake surfaces of the primary cutting edges and secondary rake surfaces of the secondary cutting edges; and (c) inclined surfaces each of which extends from the corresponding secondary rake surface to a periphery of the cylindrical body portion, and is inclined such that an axial distance between each of the inclined surfaces and the shank portion is reduced as viewed in a direction substantially perpendicular to the corresponding secondary cutting edge, from the corresponding secondary rake surface toward the periphery of the cylindrical body portion. Each of the secondary rake surfaces and the corresponding secondary cutting edge are formed together with each other in a web thinning. Each of the secondary rake surfaces and the corresponding inclined surface are connected to each other without a step therebetween.

Owner:OSG

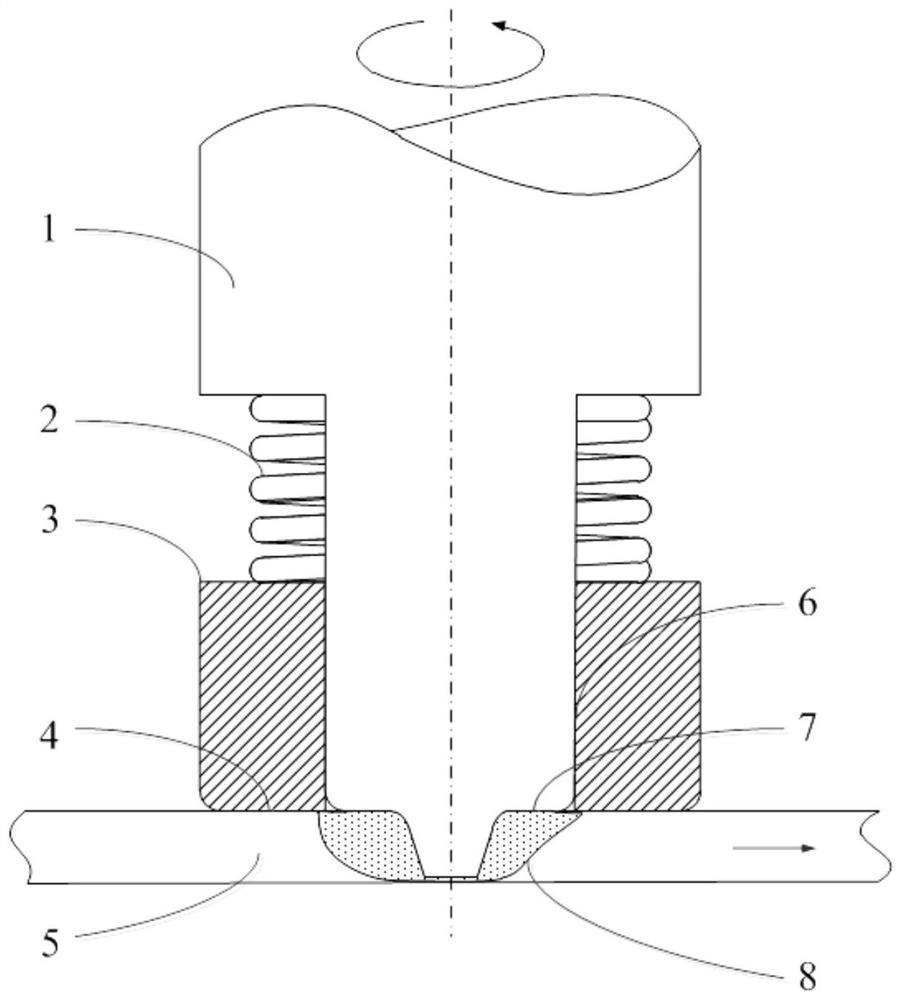

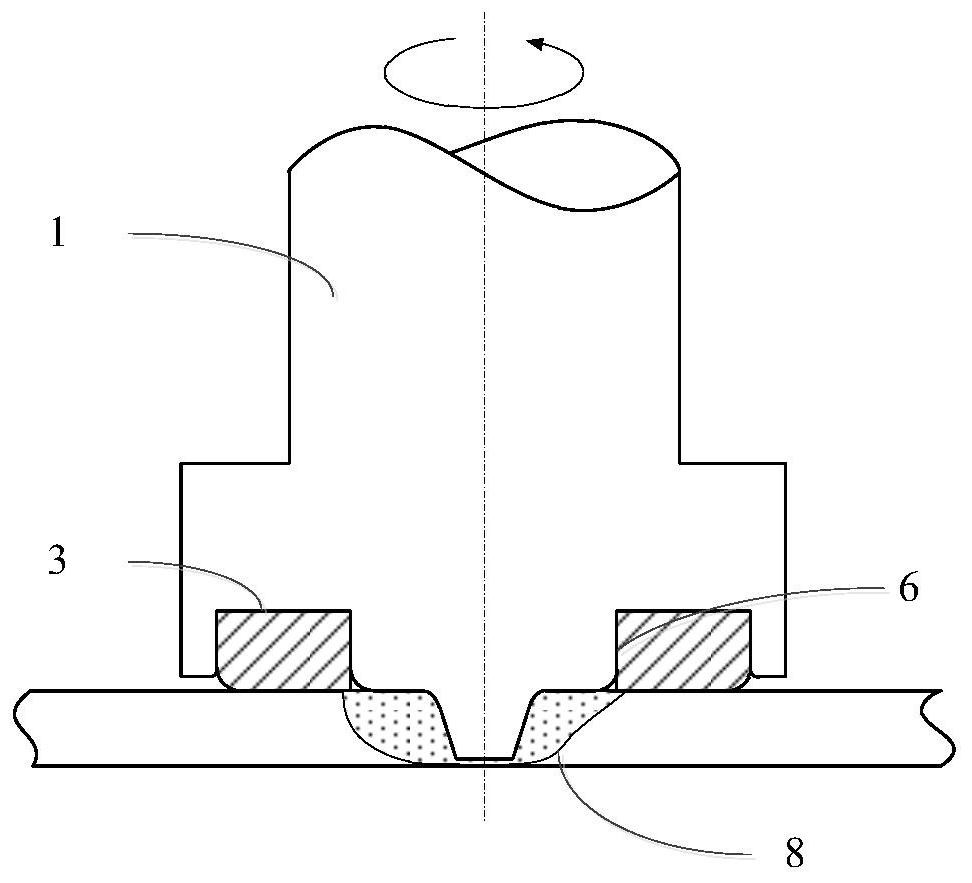

Double-way friction stir welding method for dissimilar material mismatching processing

ActiveCN108127244AReduce contact areaReduce frictional heat generationNon-electric welding apparatusButt jointCopper

The invention discloses a double-way friction stir welding method for dissimilar material mismatching processing. The problems are solved that in the butt joint and friction stir welding process of dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper, the situations easily exist that a stirring head is abraded, formation of welding seams is poor due to a material glued tothe stirring head, and the defects exist in intermetallic compounds in the welding seams and exist in the welding seams. The method comprises the steps that 1, two parent materials to be welded are preprocessed, the thickness of a welding area is subjected to differentiation, and a mismatching connector is formed; 2, firstly, the parent materials to be welded are subjected to ultrasonic cleaning and preprocessing, and then acetone is used for wiping the surfaces of the parent materials; 3, the two parent materials to be welded are clamped and located; 4, the stirring head with a large-sized shaft shoulder is shifted to the sides of the low-melting-point parent materials, a small quantity of high-melting-point parent materials are inserted in the stirring head, and first-time welding is conducted; 5, the stirring head is replaced by a small-sized stirring head, the small-sized stirring head is further shifted to the sides of the low-melting-point parent materials, second-time repair welding is conducted, and accordingly the good-quality connection between dissimilar materials is formed. The double-way friction stir welding method is applied to butt joint and friction stir welding ofthe dissimilar metal such as aluminum / steel, aluminum / copper and magnesium / copper.

Owner:安徽万宇机械设备科技有限公司

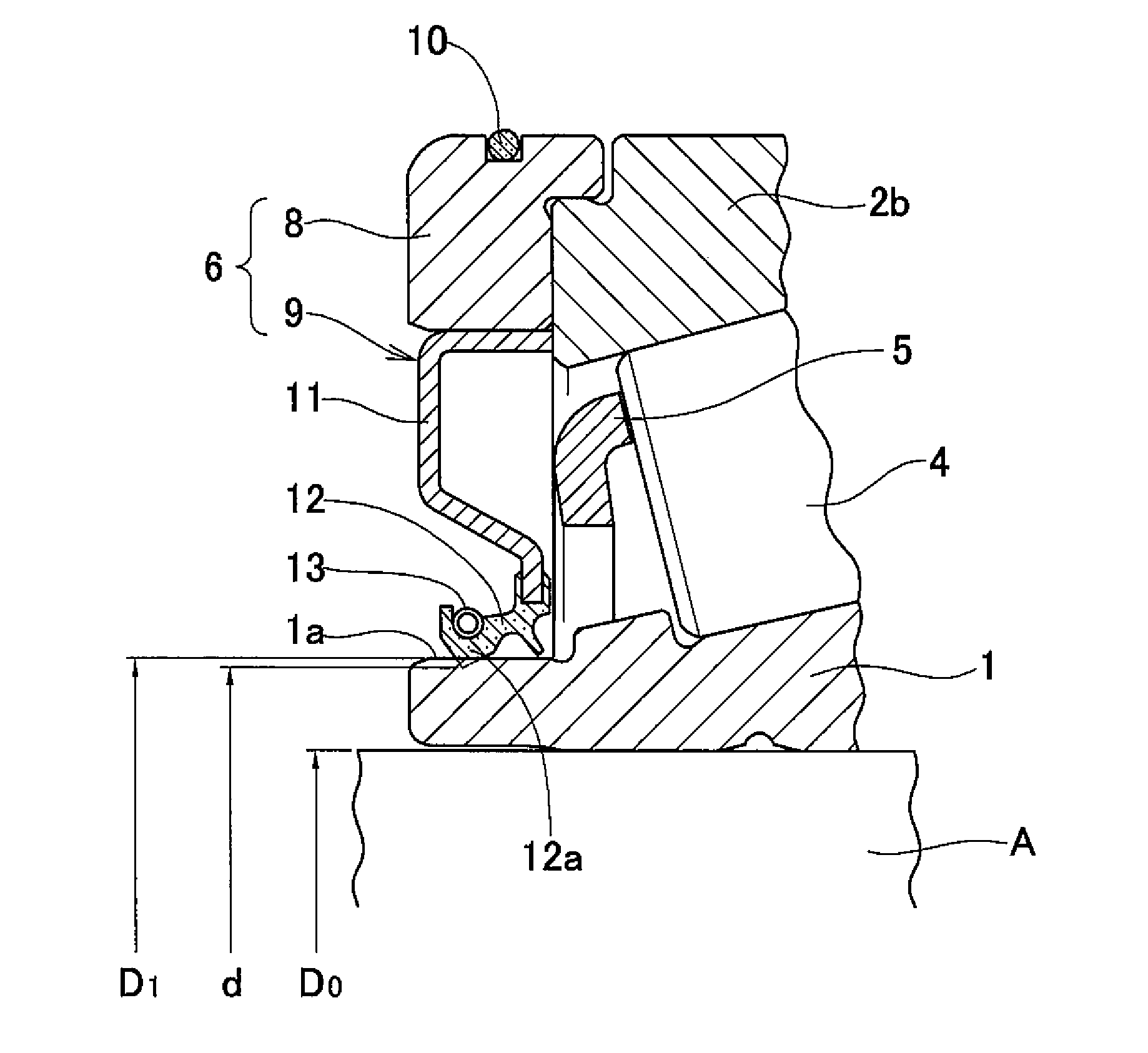

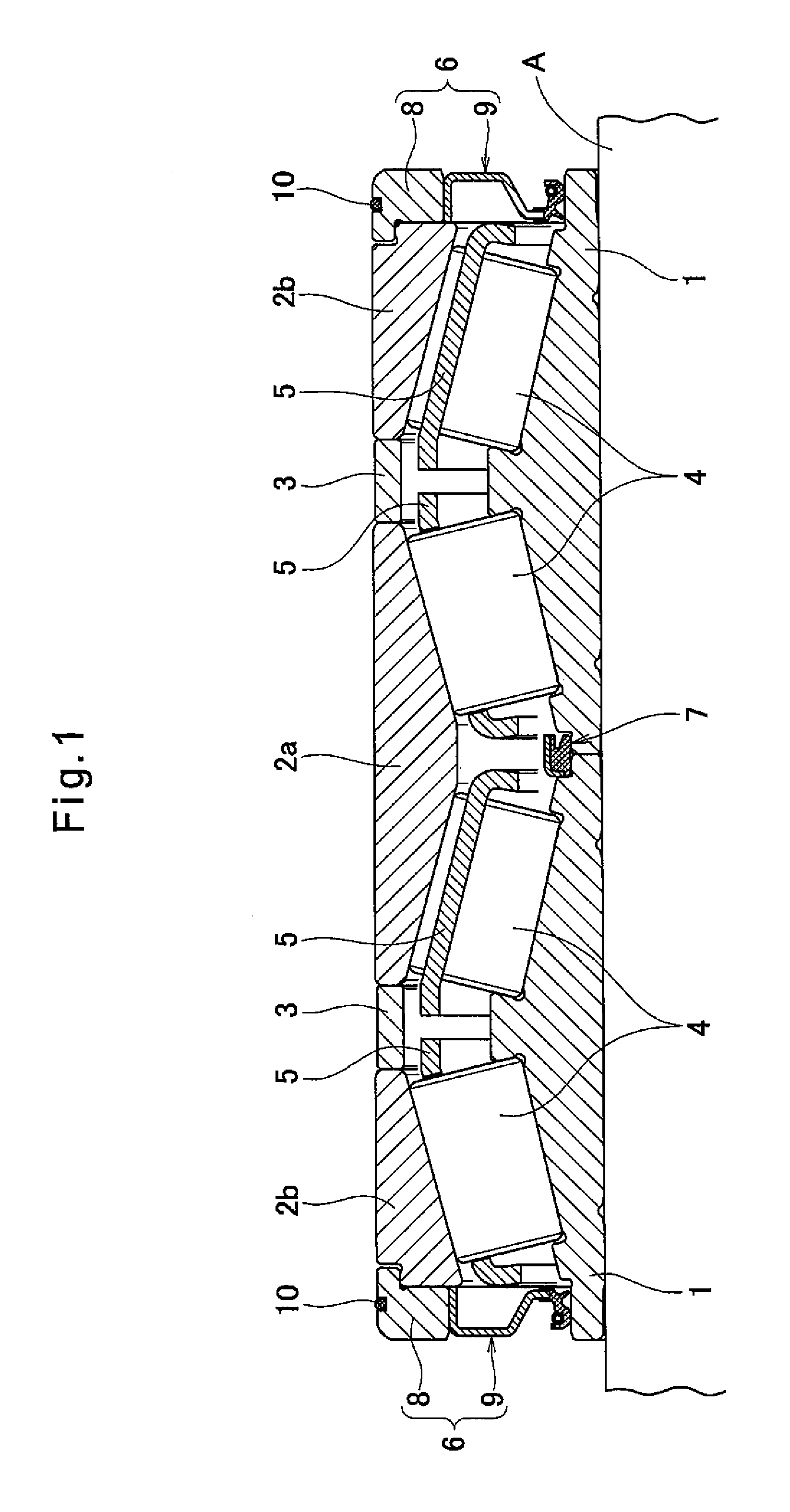

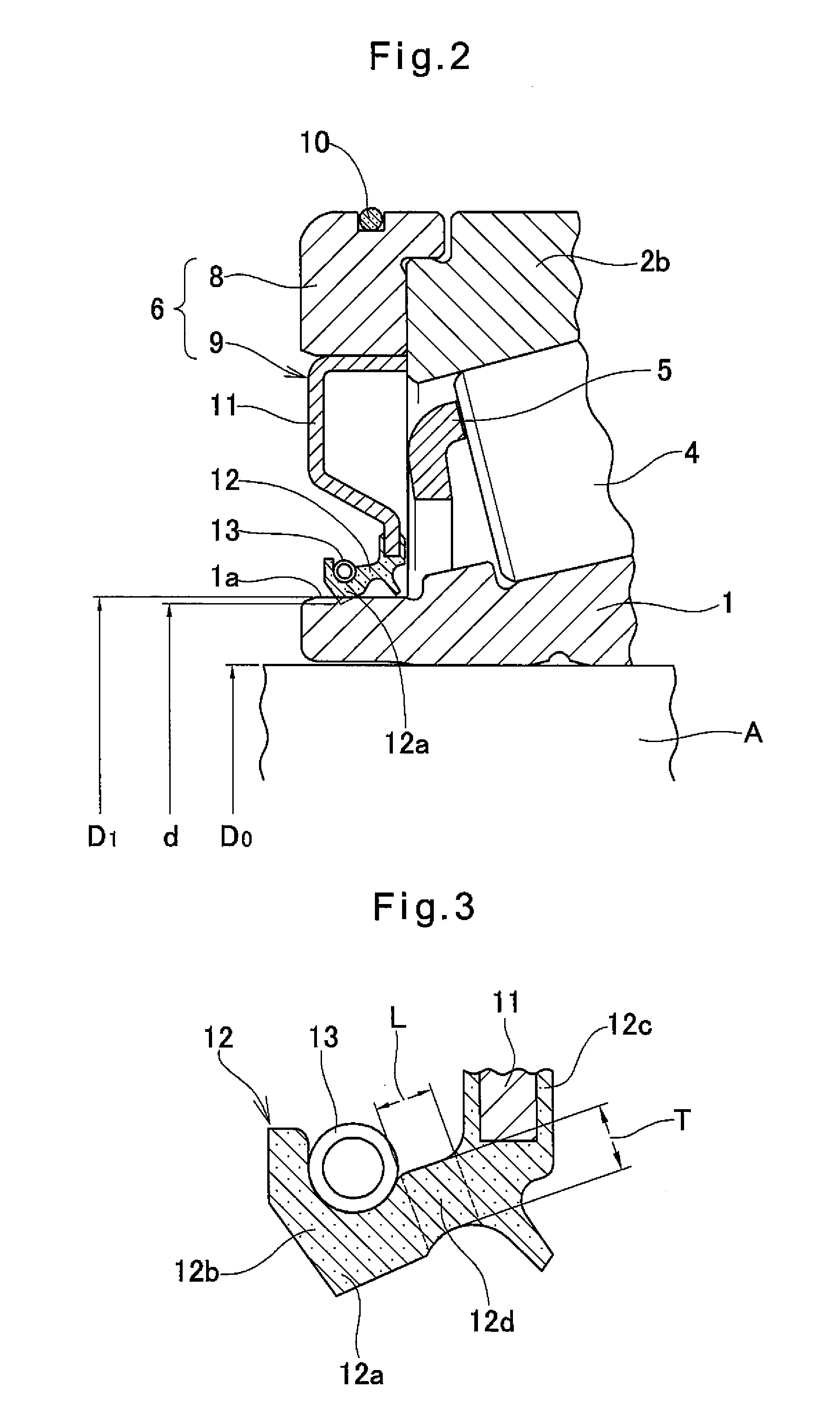

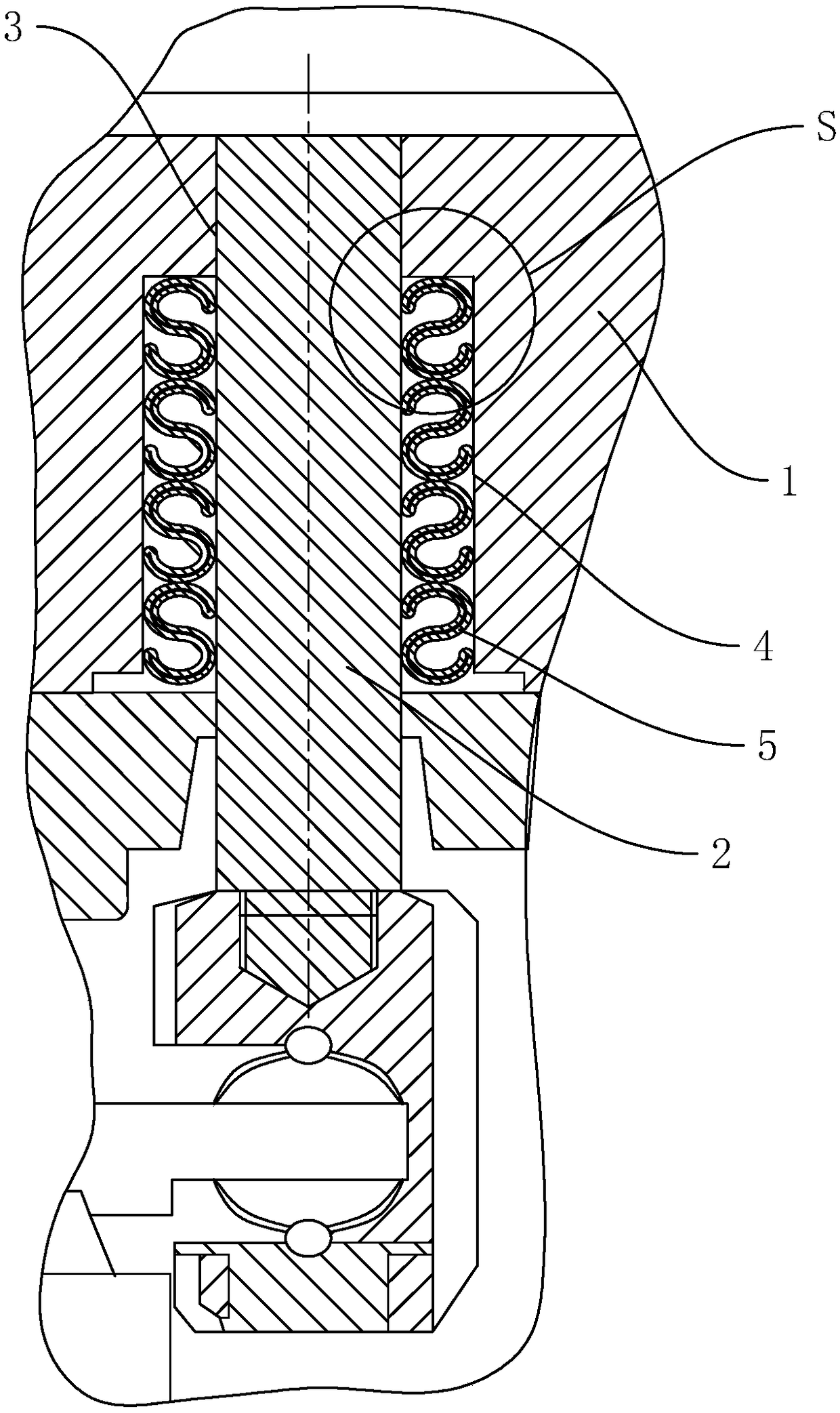

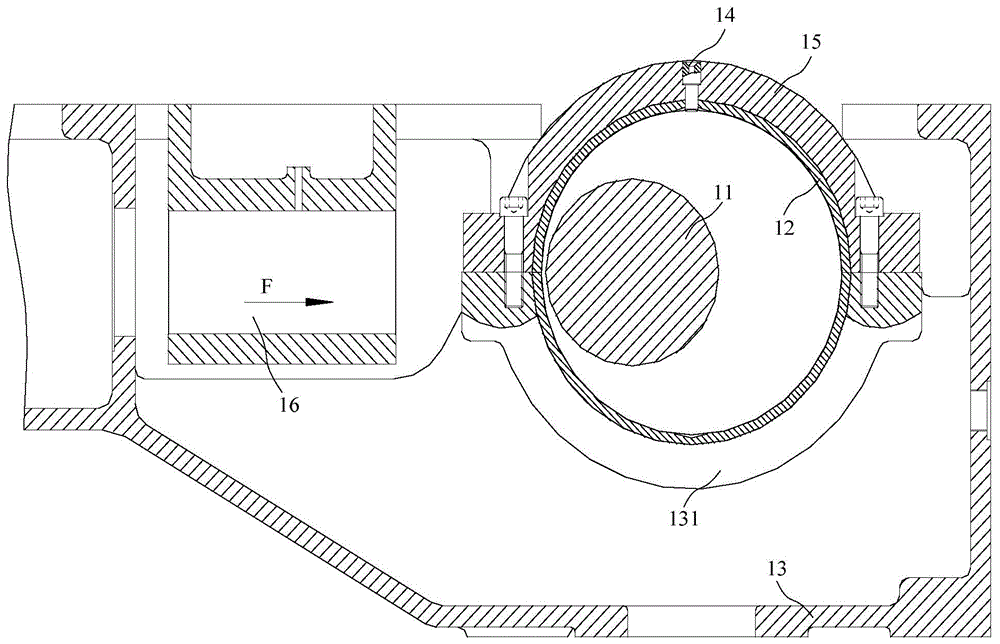

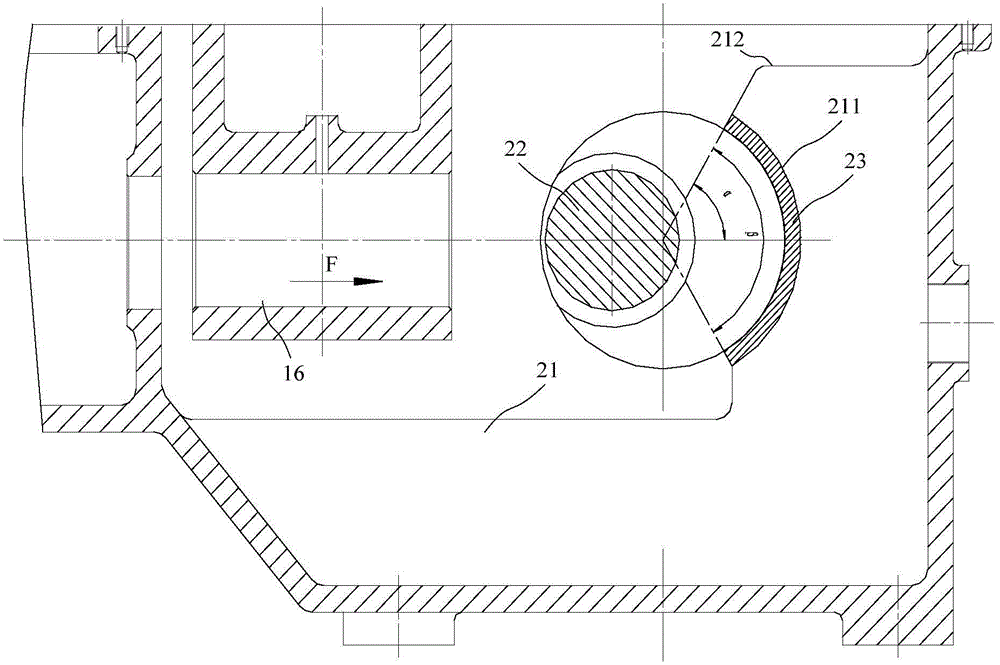

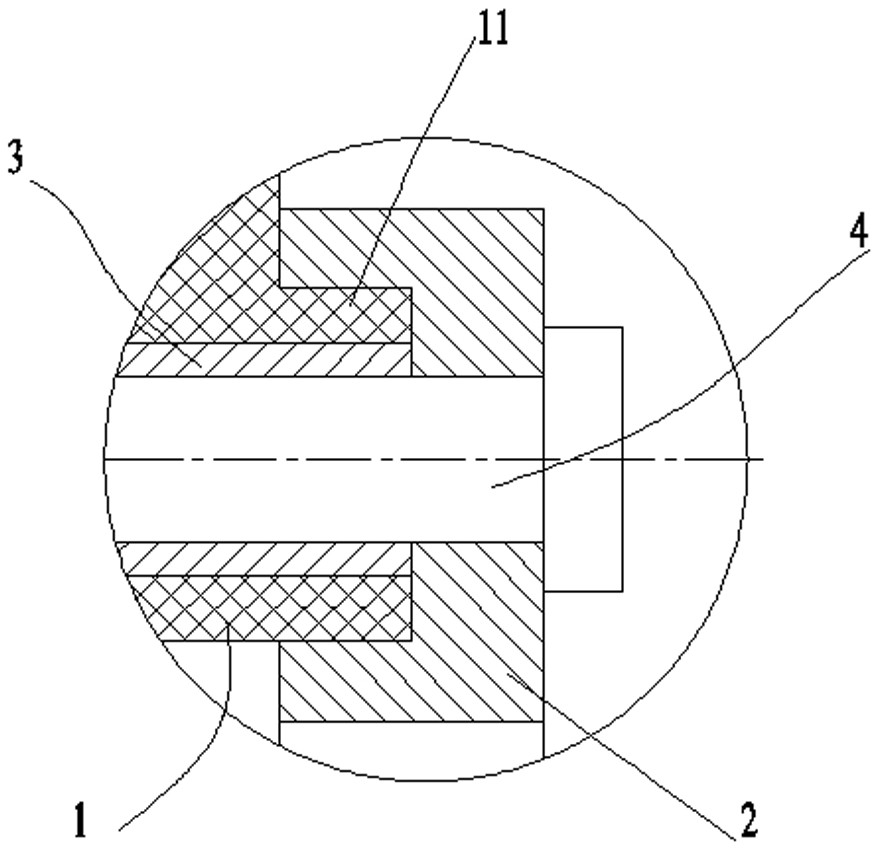

Sealed rolling bearing

InactiveUS20140177991A1Reduce frictional heat generationSufficient pressing forceRolling contact bearingsShaftsInternal pressureRolling-element bearing

In a sealed rolling bearing for use in an environment where a large amount of water is splashed and the internal pressure of the bearing becomes negative, a ratio of the difference between an outer diameter of a seal sliding contact surface of an inner race and an inner diameter of a seal lip of an elastic seal member in its natural state to a diameter of a roll neck portion (shaft) on which the inner race is fitted is in the range of 0.27 to 0.40%. This provides reduced frictional heat generation of the seal lip and adequate pressing force applied to the seal lip, thus securing excellent seal performance without requiring an additional mechanism, such as a vent to a contact seal.

Owner:NTN CORP

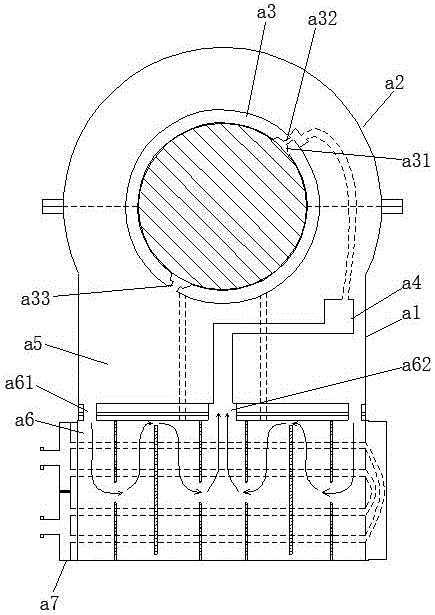

Bearing

PendingCN106678187AAchieve cycleReduce the temperatureHydro energy generationMachines/enginesHigh pressureHigh heat

The invention discloses a bearing. The bearing comprises a bearing pedestal, a bearing cap, a tilting fillet, a supporting bush, a forward thrust pad, a forward thrust disc, a first oil cavity, a second oil cavity, a cooler and an oil-containing cover. The tilting fillet is fixed to the bearing pedestal. The supporting bush is fixed to the inner diameter side of the tilting fillet. The forward thrust pad is fixed to the front side of the tilting fillet. The first oil cavity is a sealing cavity formed by covering the bearing cap and the bearing pedestal. The second oil cavity comprises a hot oil inlet and a cold oil outlet. The second oil cavity communicates with the first oil cavity through the hot oil inlet. The cooler is arranged in the second oil cavity. The oil-containing cover is arranged at the outer diameter side of the forward thrust disc. The oil-containing cover and the forward thrust disc form an oil-containing cavity. An oiling groove is formed in the inner diameter side of the supporting bush. An oil throw-off cavity is formed in the inner diameter side of the forward thrust pad. The oil-containing cavity comprises a high pressure oil outlet and an oil pumping opening. The oil pumping opening communicates with the cold oil outlet of the second oil cavity. The high pressure oil outlet is divided into two oil ducts which communicate with the oiling groove and the oil throw-off cavity correspondingly. The bearing has high heat exchange efficiency, and bearing pad burning can be effectively avoided.

Owner:郭远军

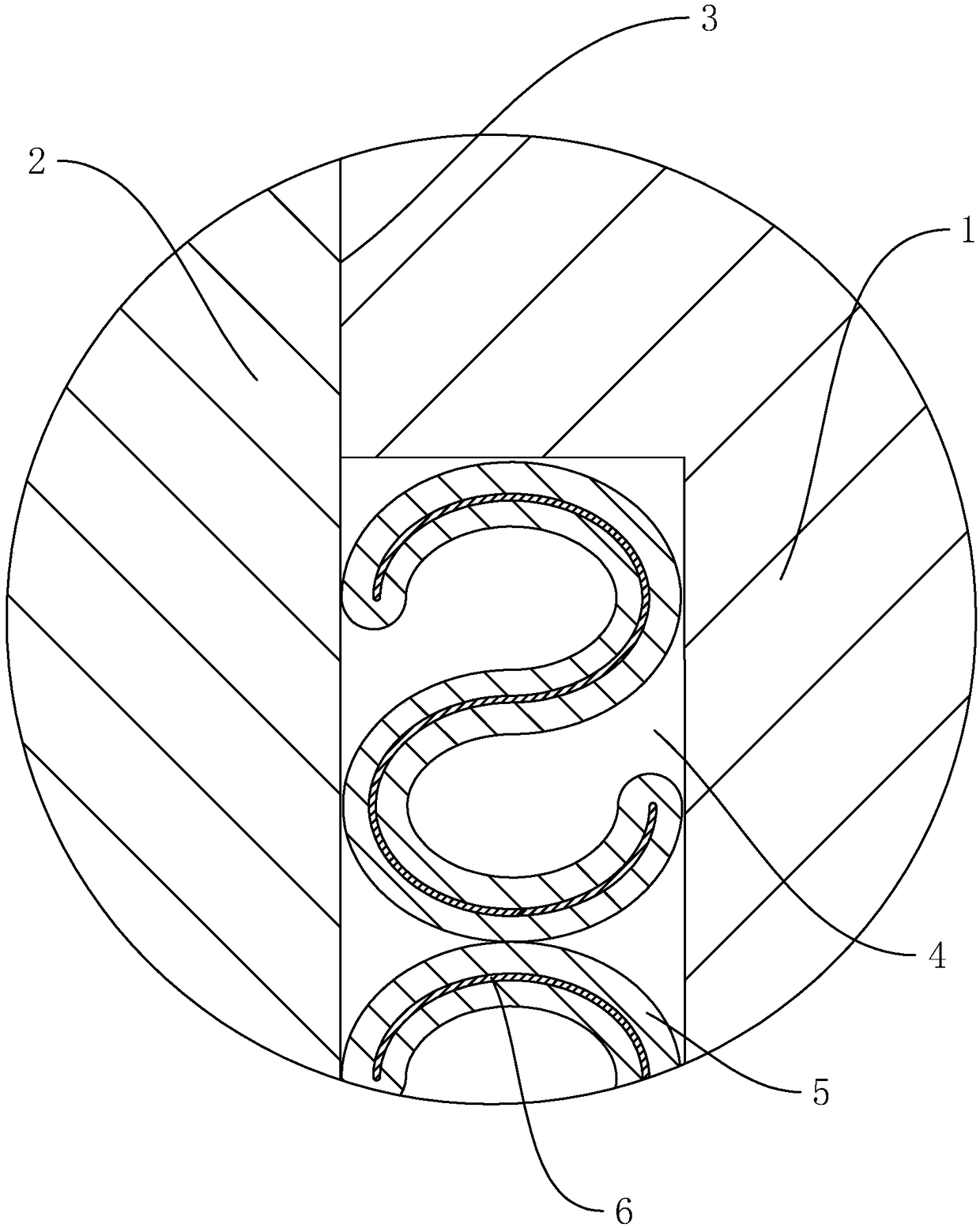

Sealing structure for compressor plunger

PendingCN108644385AGood compensationLarge amount of elastic deformationEngine sealsPositive displacement pump componentsEngineeringMechanical engineering

The invention discloses a sealing structure for a compressor plunger, and aims at improving the sealing performance, and reducing the contact area of a sealing ring and the plunger. The essential of the technical scheme is as follows: the sealing structure for the compressor plunger comprises a cylinder body and a plunger, wherein the cylinder body is provided with a plunger hole allowing the plunger to penetrate; a sealing groove is formed in the sidewall of the plunger hole; the sealing ring is arranged in the sealing groove; the section of the sealing ring is configured to be S-shaped; theinner wall of the sealing ring is bonded onto the sidewall of the plunger; and the outer sidewall of the sealing ring is bonded onto the sidewall of the sealing groove. The sealing structure for the compressor plunger is capable of improving the sealing performance, and reducing the contact area of the sealing ring and the plunger.

Owner:杭州新亚低温科技有限公司

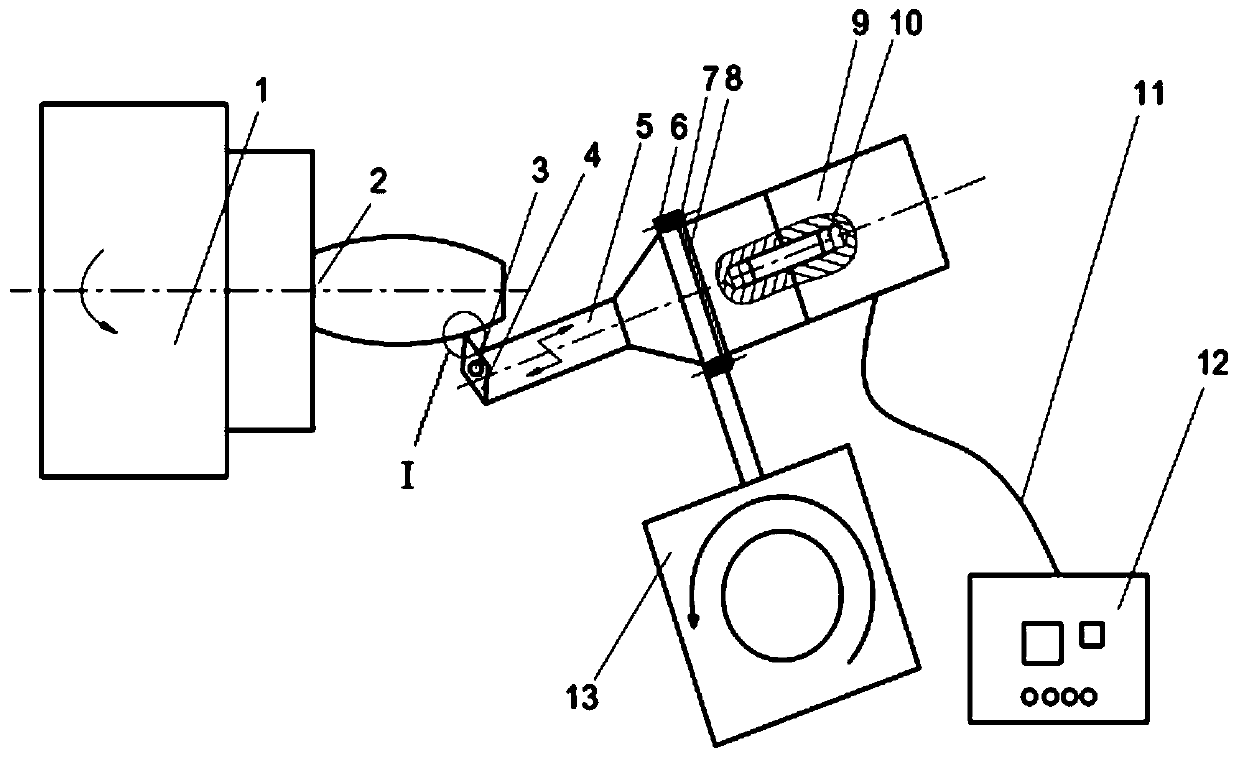

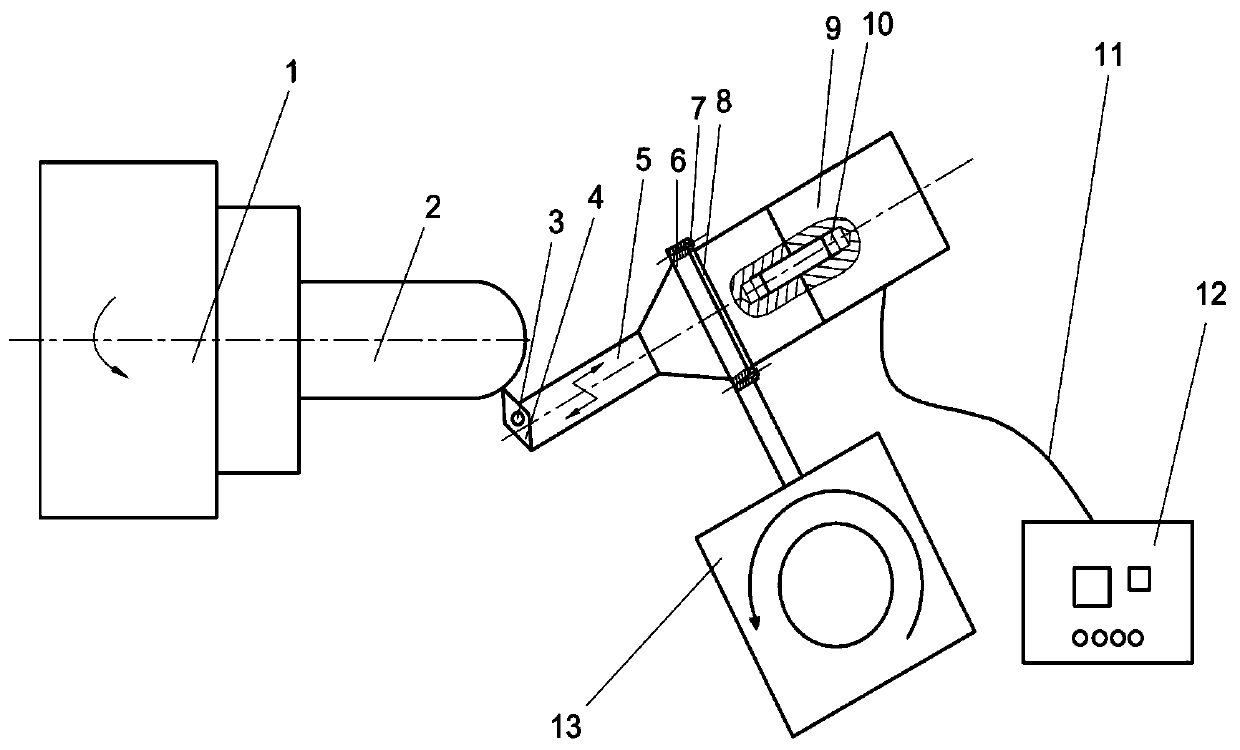

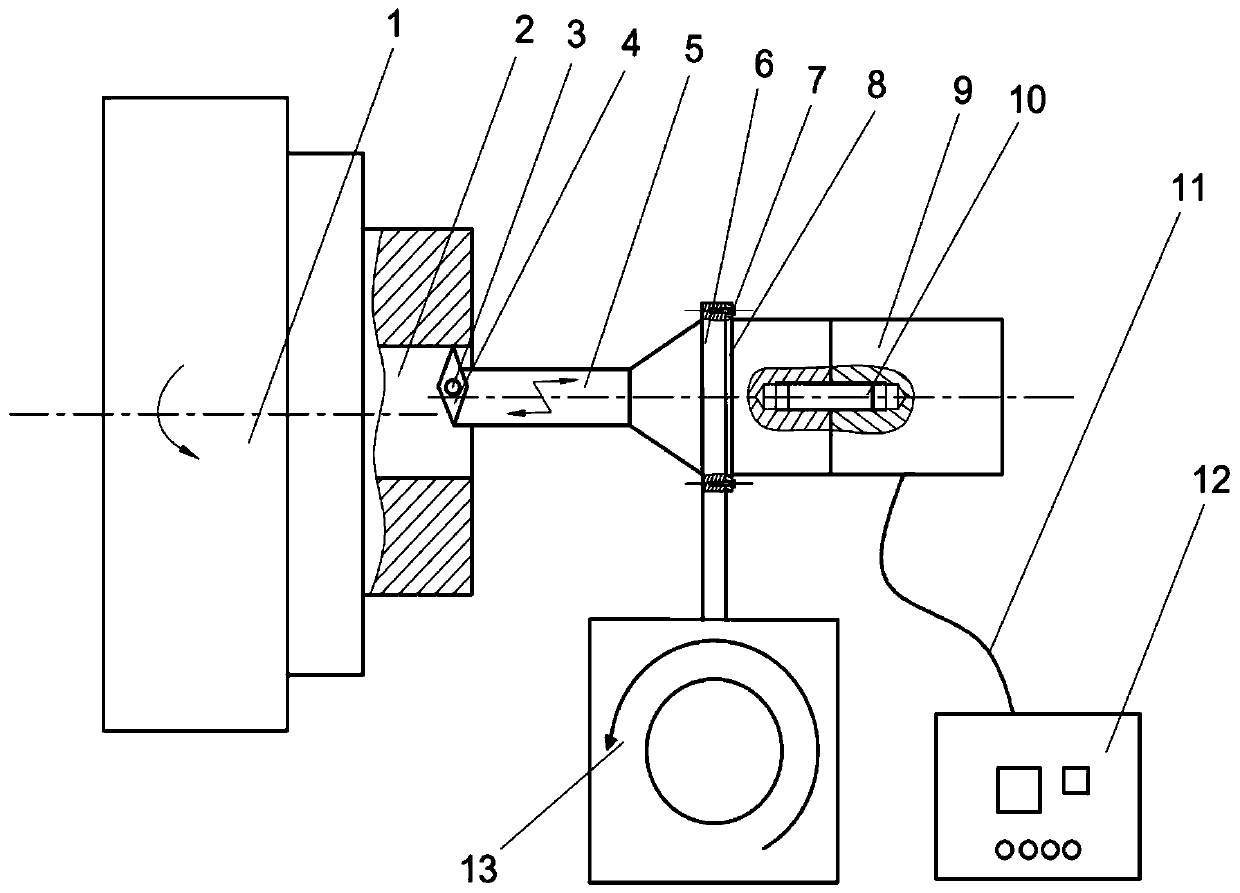

Ultrasonic cutting and polishing machining system

ActiveCN110064764AImprove machined surface qualityReduce the quality of the machined surfaceTurning machinesMetal working apparatusMachined surfaceTransformer

The invention discloses an ultrasonic cutting and polishing machining system. The ultrasonic cutting and polishing machining system comprises an ultrasonic transducer, an amplitude transformer, and awiper blade cutter, wherein the front end of the ultrasonic transducer is tightly and reliably connected with the rear end of the amplitude transformer; the ultrasonic transducer is connected with anultrasonic power supply through a lead; a flange plate is arranged at the vibration displacement node position of the amplitude transformer; the flange plate is connected with a B-axis rotary tool rest through a supporting plate; and the wiper blade cutter is tightly and reliably connected with the front end of the amplitude transformer. According to the ultrasonic cutting and polishing machiningsystem, ultrasonic high-frequency vibration in the feeding direction of the cutter can improve the action length of a wiper blade, reduce the generation of secondary tool marks on the machining surface of the wiper blade, and improve the quality of the machined surface; due to the cleaning effect of the ultrasonic vibration, it is difficult to generate chip accumulation at the wiper edge, and thequality of the machined surface is better guaranteed; the ultrasonic vibration changes the contact state and action mechanism between the cutting edge and the wiper edge and the material to be machined, reduces the cutting force and the cutting temperature, and improves the surface quality after the cutting edge is processed, and thus the quality of the machined surface is further improved due tothe combined action of the polishing edge and the ultrasonic vibration.

Owner:DALIAN JIAOTONG UNIVERSITY

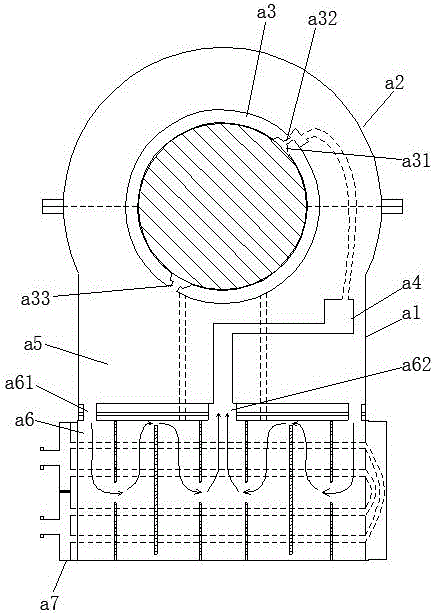

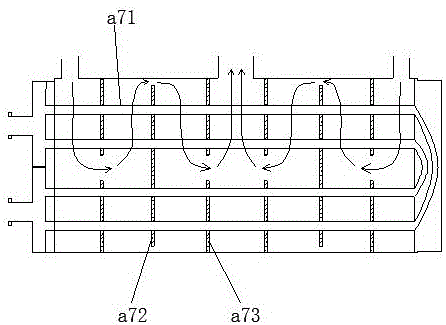

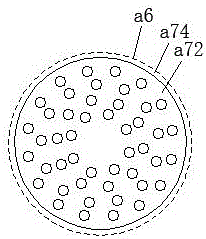

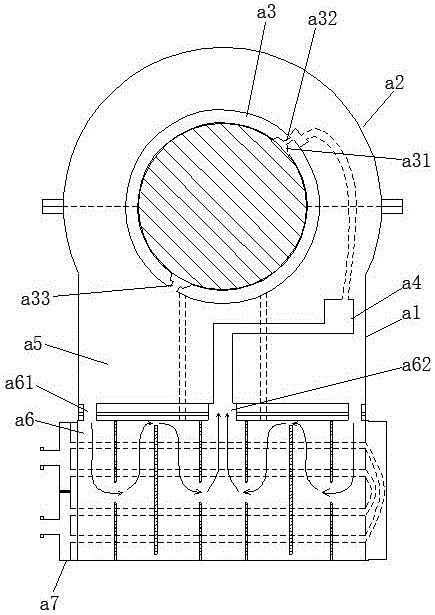

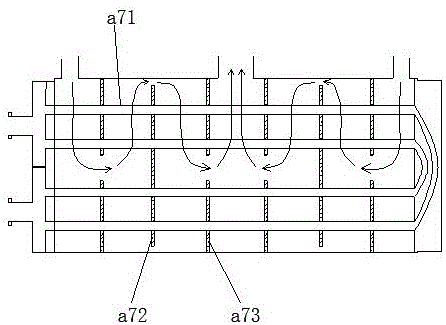

Cooling bearing

The invention discloses a cooling bearing. The cooling bearing comprises a bearing seat, a pad base, a positive thrust plate, a first oil cavity, a second oil cavity, a cooler and an oil driving cover, wherein the pad base is fixed to the bearing seat; a supporting pad is arranged on the inner diameter side of the pad base, and a positive thrust pad is arranged on the front side of the pad base; the second oil cavity communicates with the first oil cavity through a hot oil inlet, and the cooler is installed inside the second oil cavity; the oil driving cover and the positive thrust plate form an oil driving cavity; an oil injecting groove is formed in the inner diameter side of the supporting pad and is of a spiral shape; an oil throwing cavity is formed in the inner diameter side of the positive thrust pad; and the oil driving cavity comprises a high-pressure oil outlet and an oil pumping port, the oil pumping port communicates with the second oil cavity, and the high-pressure oil outlet communicates with the oil injecting groove and the oil throwing cavity. The cooling bearing has high heat exchange efficiency and can effectively prevent a bearing pad from being burnt.

Owner:郭远军

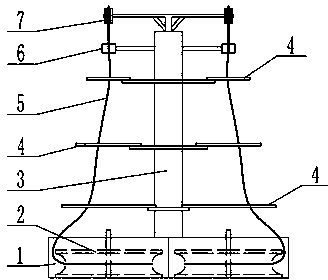

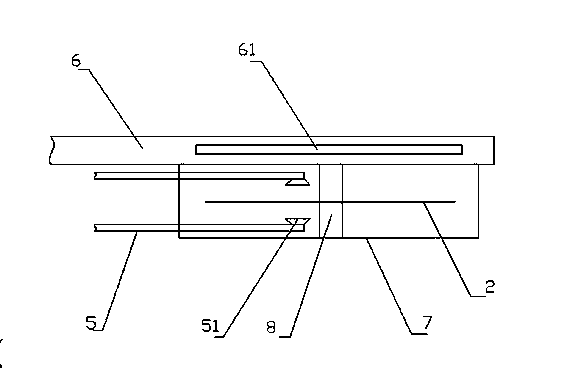

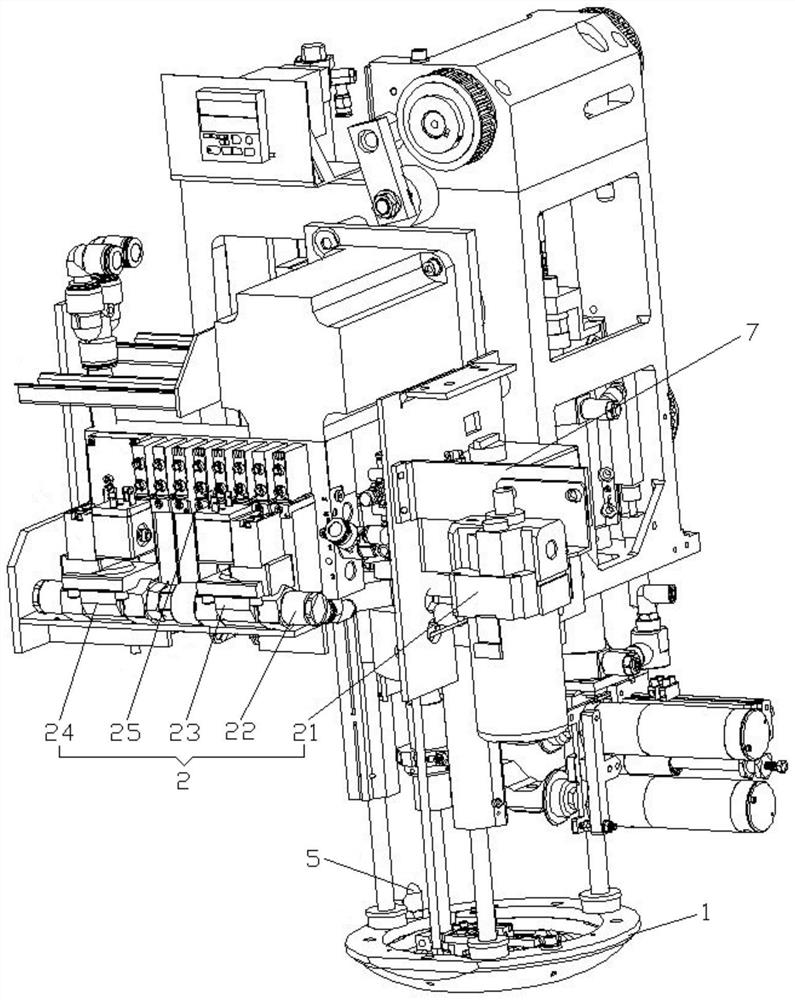

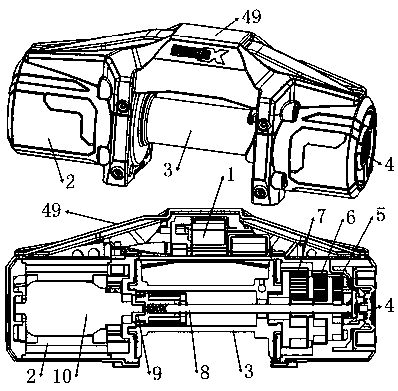

Terminal compression joint device

InactiveCN103872546AReduce use failure rateReduce frictional heat generationLine/current collector detailsFault rateCable harness

A terminal compression joint device is composed of a motor (1), a body (2), an upper mould (3), a pushing device (4), a lower mould (5), a wire winder (6) and a terminal chain (7), and is characterized in that the terminal chain (7) is installed on the wire winder (6) and is pushed to a mould core of the lower mould (5) through a supporting frame (8) and the pushing device (4), the upper mould and the lower mould are combined after a wire harness is placed, and pressing of the wire harness (11), cutting off and feeding are finished. The terminal compression joint device solves the problem that a full-automatic double-station compression joint machine causes winding easily in the process of feeding, effectively lowers the use fault rate of the compression joint machine, adopts a guiding wheel, effectively reduces heat generated by friction in the conveying process of cables, improves the utilization rate of the cables, and lowers production cost for enterprises.

Owner:司马建明

Novel flame-retarding magnesium alloy with high-temperature mechanical property and processing technology thereof

The invention discloses a novel flame-retarding magnesium alloy with high-temperature mechanical property and a processing technology thereof. The alloy is prepared from the following components in percentage by weight: 0.4 to 0.5 percent of Te, 0.6 to 0.8 percent of Li, 1.0 to 1.8 percent of In, 0.3 to 0.5 percent of Os, 1.0 to 1.2 percent of Pd, 0.5 to 0.8 percent of Ag, 2.0 to 3.0 percent of Sc, 10.0 to 12.0 percent of Al and the balance of magnesium. The material provides a flame-retarding scheme for magnesium alloy combustion caused by friction or external fire heating. Predicably, implementation and industrialization of the alloy can greatly push the commercial demand of China in the field of light weight for the novel flame-retarding magnesium alloy.

Owner:GUANGZHOU YUZHI TECH CO LTD

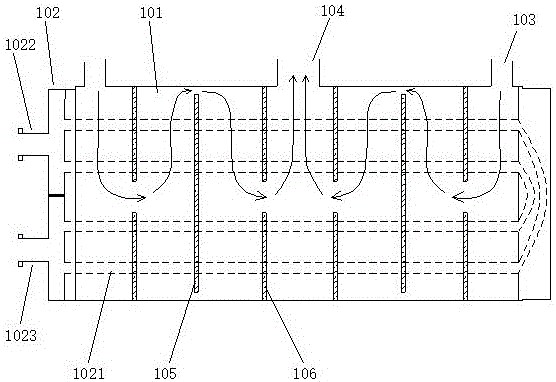

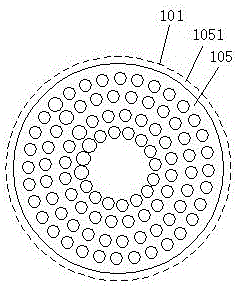

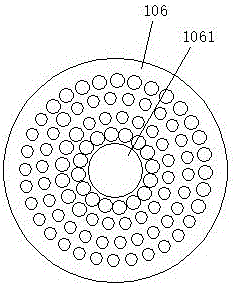

Hydro-generator provided with high-efficient oil-cooling bearings

InactiveCN106763238AAchieve cycleReduce the temperatureHydro energy generationMachines/enginesHigh pressureOil cooling

The invention discloses a hydro-generator provided with high-efficient oil-cooling bearings. The hydro-generator comprises a stator, a rotor, a spindle, a fixed outer housing and the oil-cooling bearings, wherein the rotor is coaxially and fixedly connected with the spindle; the stator is coaxially and fixedly connected with the fixed outer housing; two sides of the fixed outer housing are fixed on two ends of the spindle through the oil-cooling bearings; each oil-cooling bearing comprises a bearing seat, a bush base, a forward pushing force disc, a first oil cavity, a second oil cavity, a cooler and an oil carrying housing; each bush base is fixed on the corresponding bearing seat; a support bush is arranged on the inner diameter side of each bush base; the front side of each bush base is provided with the corresponding forward pushing force bush; each second oil cavity communicates with the corresponding first oil cavity through a hot oil inlet; each cooler is arranged in the corresponding second oil cavity; each oil carrying housing forms an oil carrying cavity with the corresponding forward pushing force disc; an oil injection groove is formed in the inner diameter side of each support bush; the inner diameter side of each forward pushing force bush is provided with an oil shedding cavity; each oil carrying cavity comprises a high-pressure oil outlet and an oil pumping opening; each oil pumping opening communicates with the corresponding second oil cavity; and each high-pressure oil outlet communicates with the corresponding oil injection groove and the corresponding oil shedding cavity. The hydro-generator has high heat exchange efficiency, and bearing bushes can be effectively prevented from being burned.

Owner:郭远军

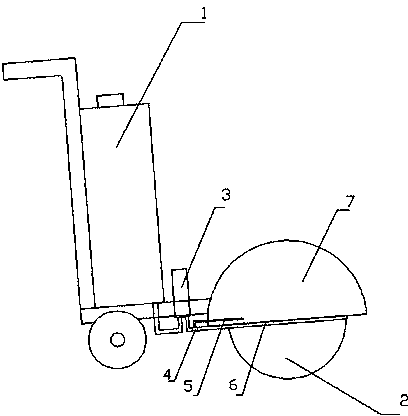

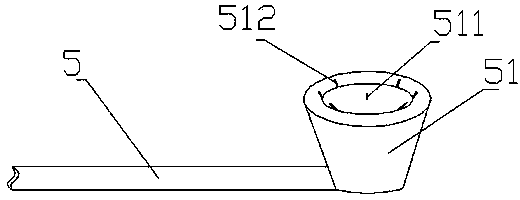

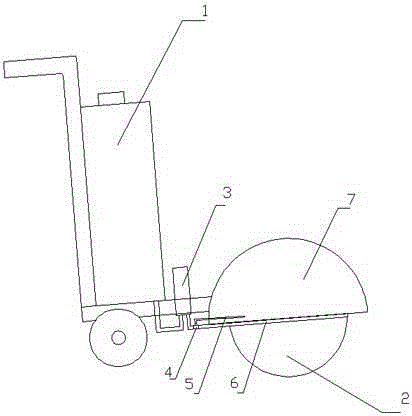

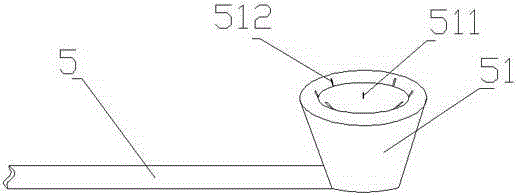

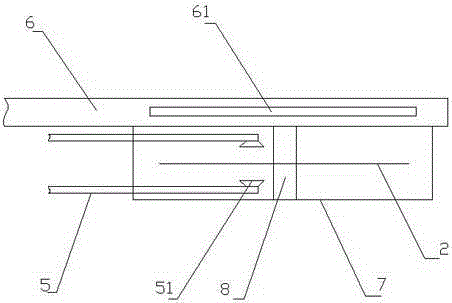

Cooling device of pavement cutting machine

InactiveCN103866679AReduce the temperatureEfficient removalRoads maintainenceFriction reductionWater flow

The invention relates to a cooling device of a pavement cutting machine. The cooling device of the pavement cutting machine comprises a water tank on the cutting machine, a water outlet of the water tank is connected with a water inlet pipe of a booster pump, a water outlet pipe of the booster pump is respectively connected with a water spraying pipe I going into a mask of a cutting disc and a water spraying pipe II at the outer side of the mask by virtue of a three-way pipe, sprayers at the two sides of the cutting disc are respectively arranged on the water spraying pipe I, multiple water spraying holes are formed in each sprayer and comprise center water spraying holes and edge water spraying holes, water flowing out of each center water spraying hole is vertical to the corresponding sprayer, water flowing out of each edge water spraying hole is sprayed out toward the outer side of the corresponding sprayer in an inclined way, one part of water can be sprayed onto a rotating shaft of the cutting machine, and water in the water spraying pipe II is sprayed out in a water curtain shape and acts on a contact part between the cutting disc and a pavement, so that heat produced by friction is reduced. By the cooling device of the pavement cutting machine, the temperature of the cutting disc can be effectively reduced while the rotating shaft of the cutting machine can be cooled, and heat produced by friction between the cutting disc and the pavement can be reduced when the pavement is cut by the cutting disc.

Owner:王威

Homogenizer transmission case structure

InactiveCN104879472ASimplified support designEnough supportGear lubrication/coolingEngineeringBearing surface

The invention relates to a homogenizer transmission case structure comprising a case. An arc bearing surface is arranged in the middle, corresponding to a crankshaft arranged on the case, of the case, and the bearing surface is arranged opposite to the direction that the crankshaft bears piston force. Design of the intermediate support of the crankshaft is simplified, the arc bearing surface is arranged corresponding to the crankshaft and arranged at the position opposite to the direction of the piston force, the crankshaft drives a piston to move, and the crankshaft bears acting force of the piston. The bearing surface is arranged corresponding to the direction of the piston force borne by the crankshaft, enough bearing reaction can be provided for the crankshaft, a half structure is omitted, heat generated by friction in the working process of the intermediate portion, namely a sliding bearing, of the crankshaft is reduced, starting resistance is reduced, convenience is brought to processing, and cost is lowered effectively.

Owner:SHANGHAI SAMRO HOMOGENIZER

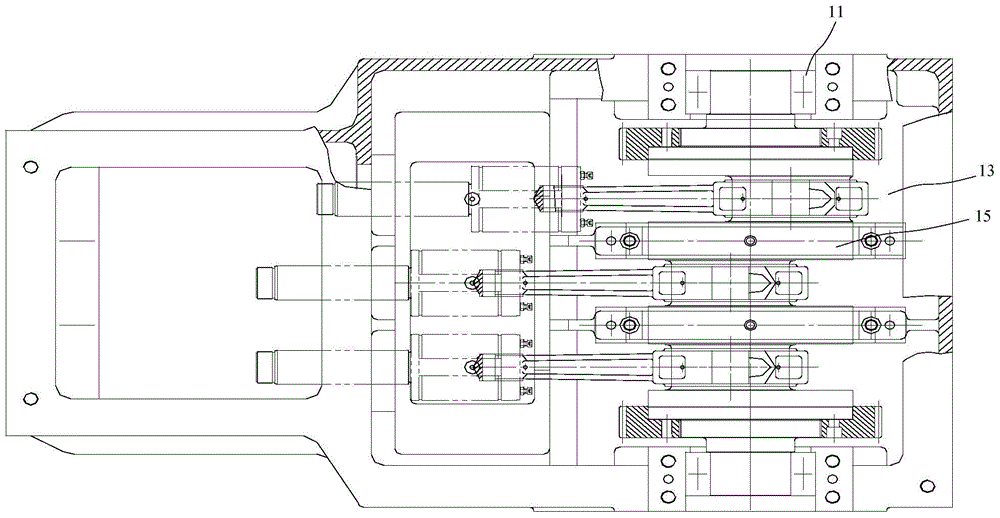

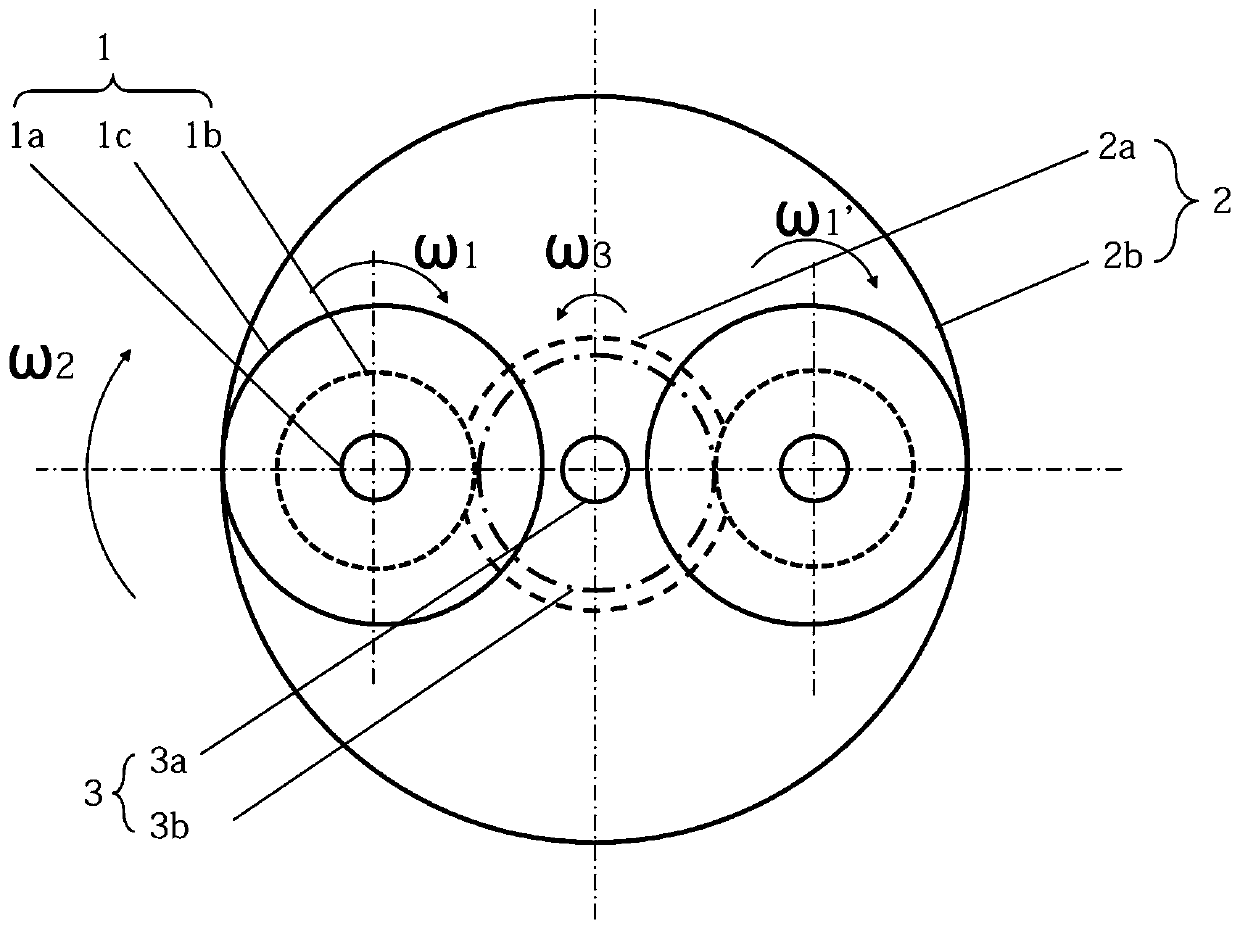

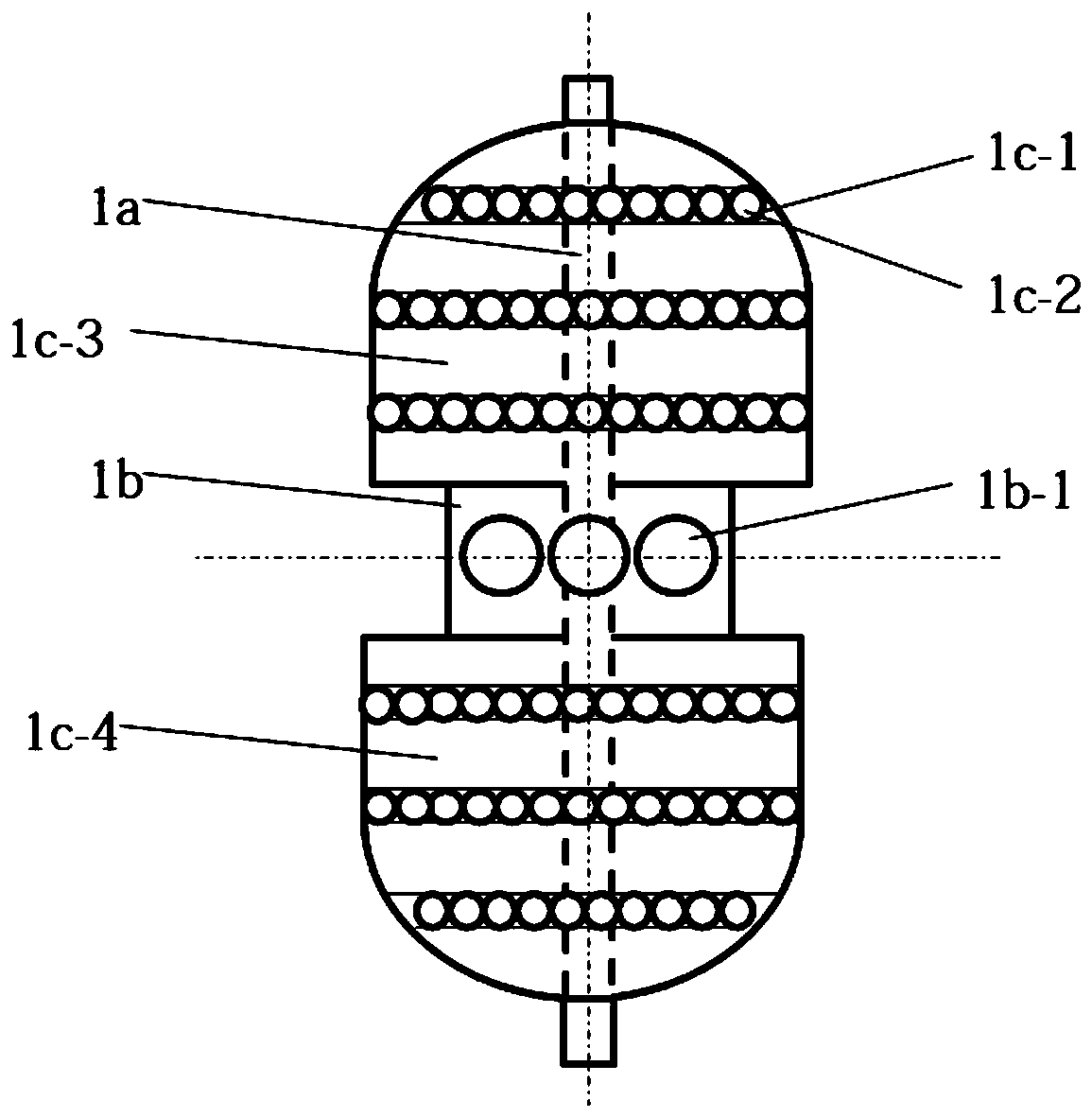

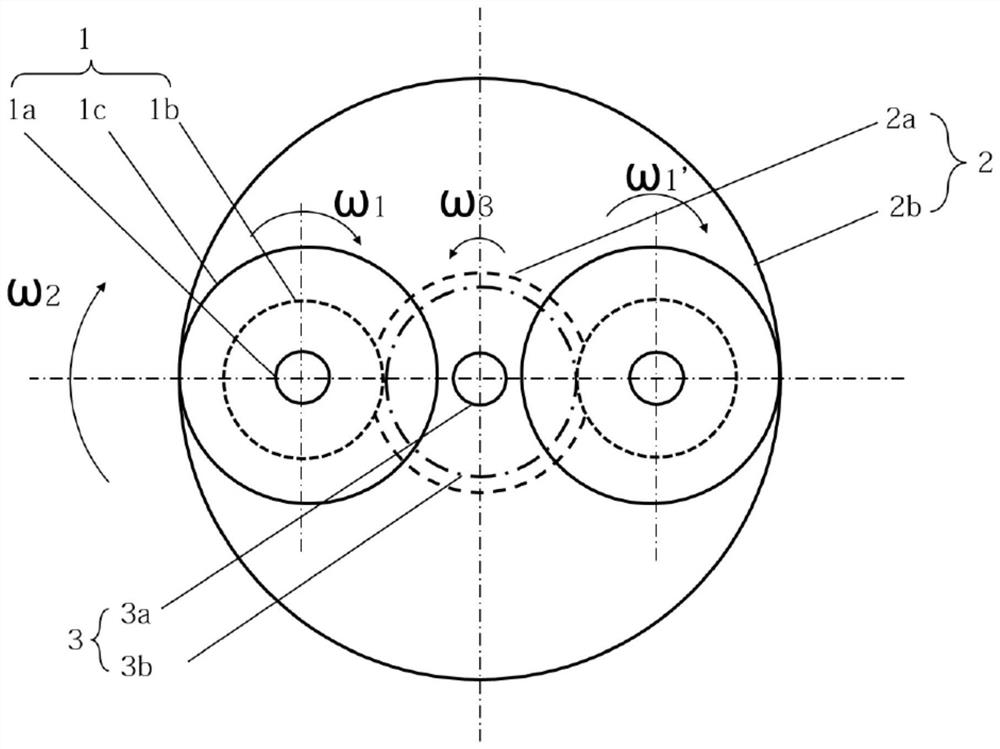

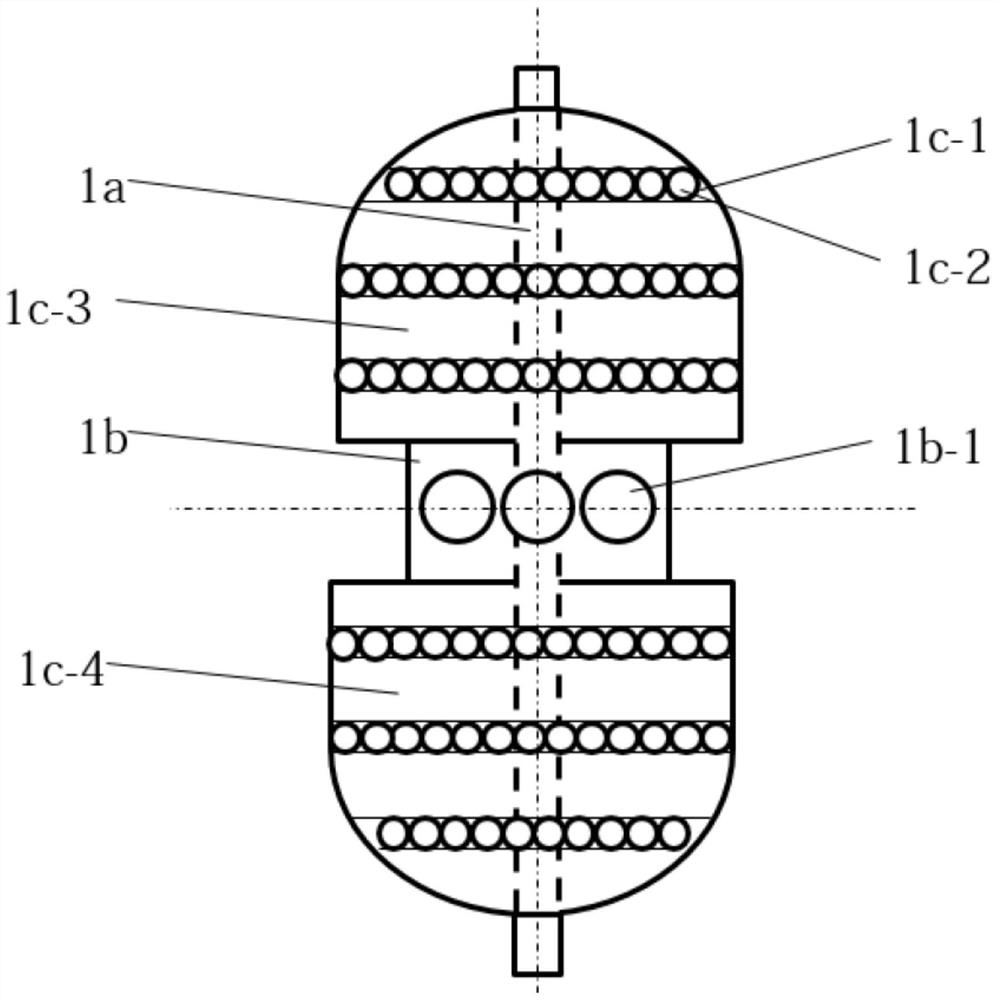

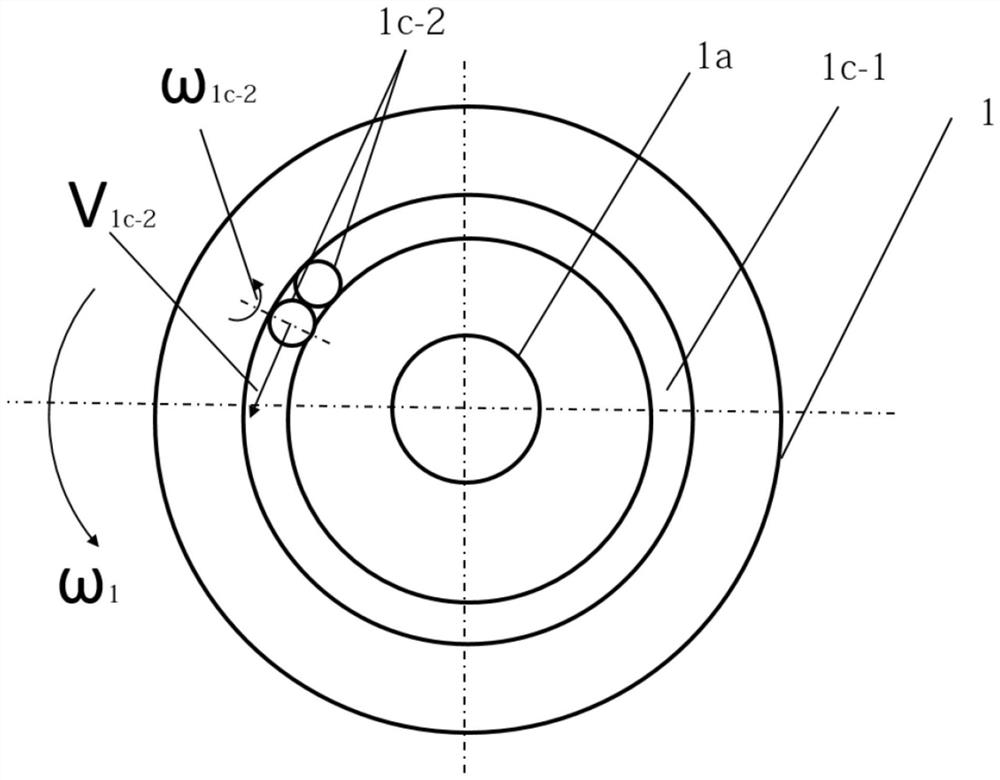

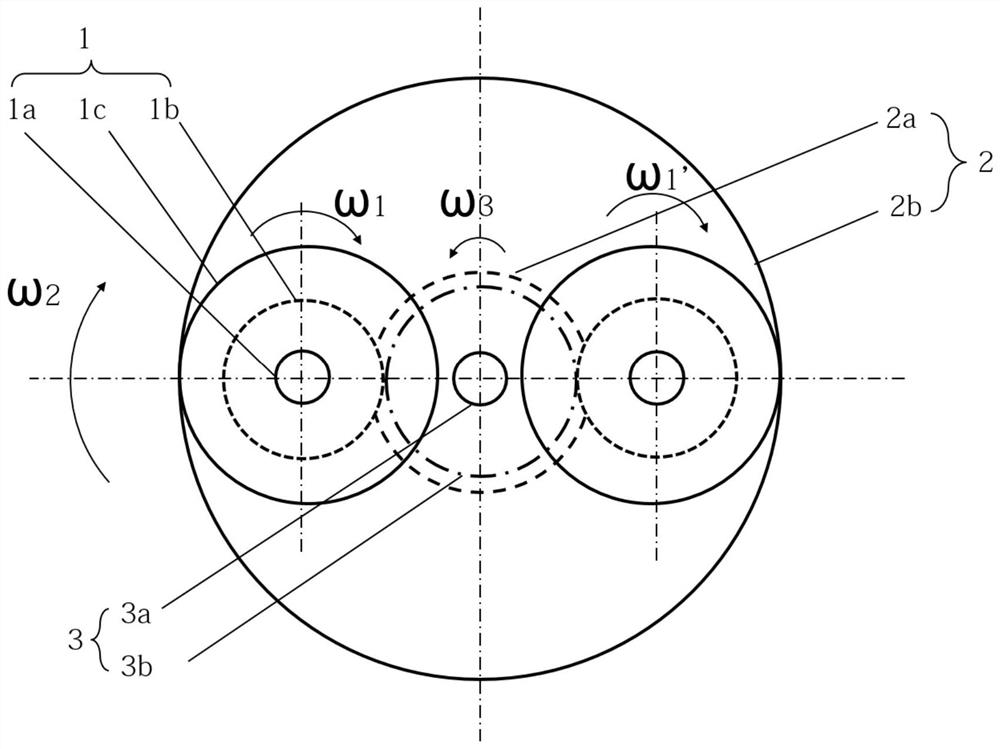

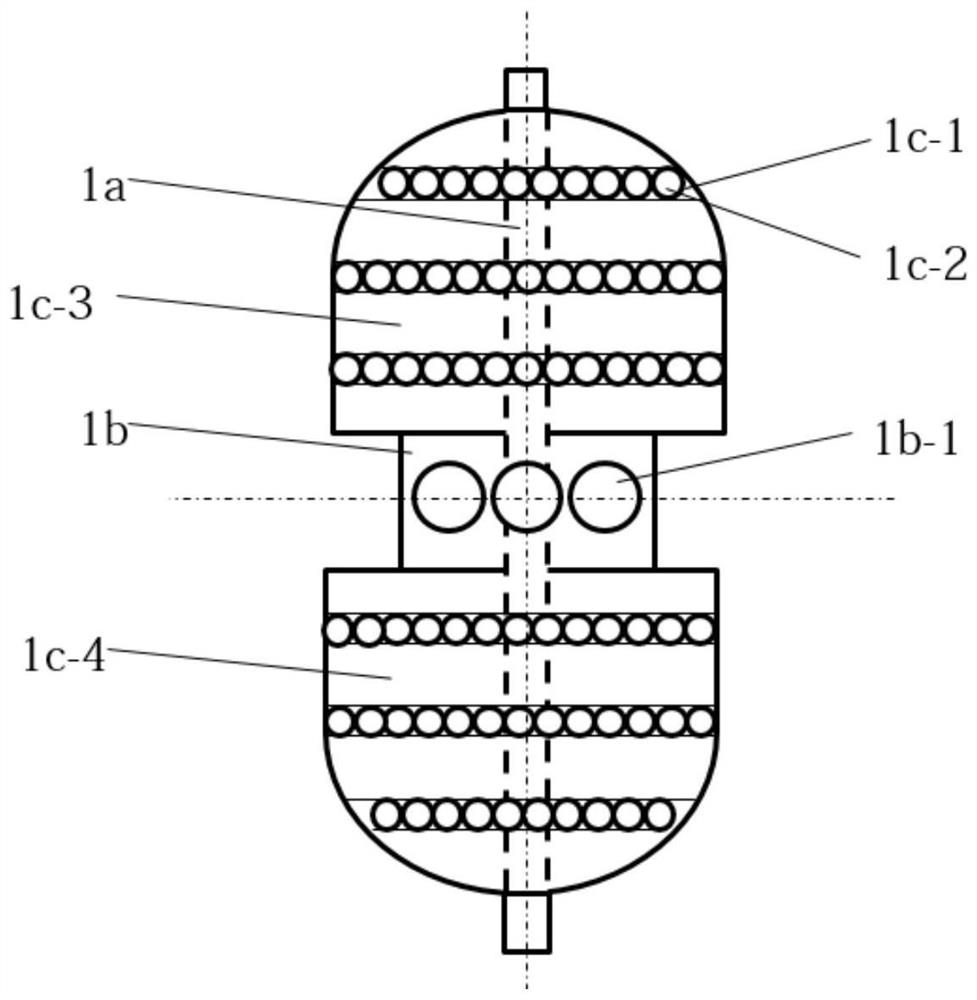

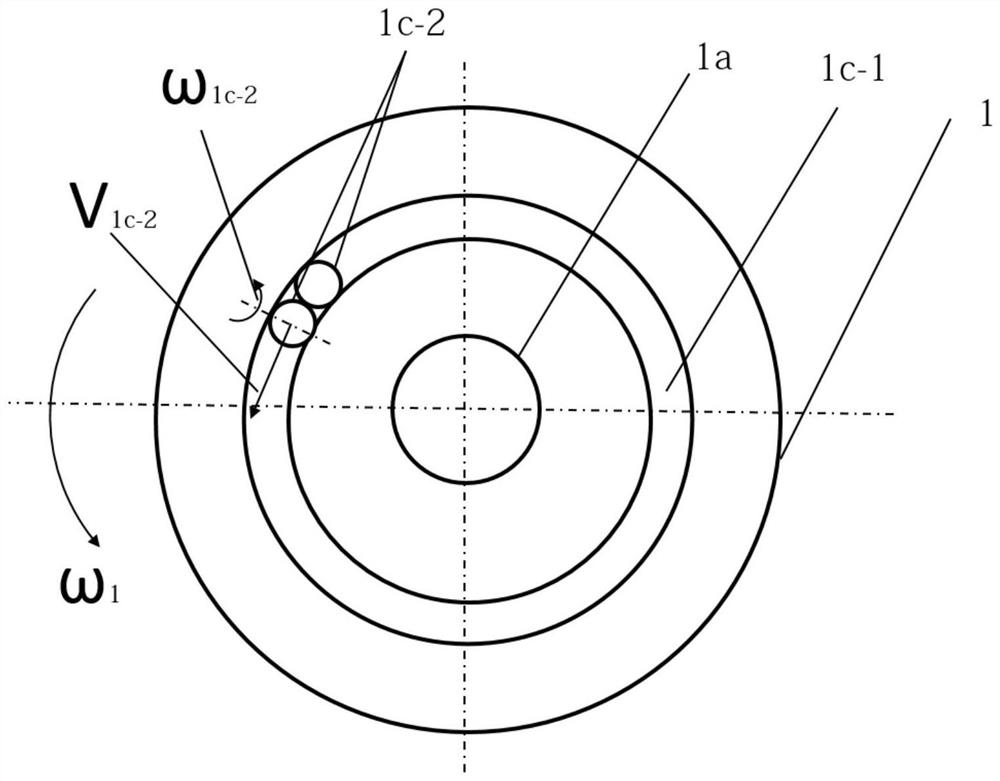

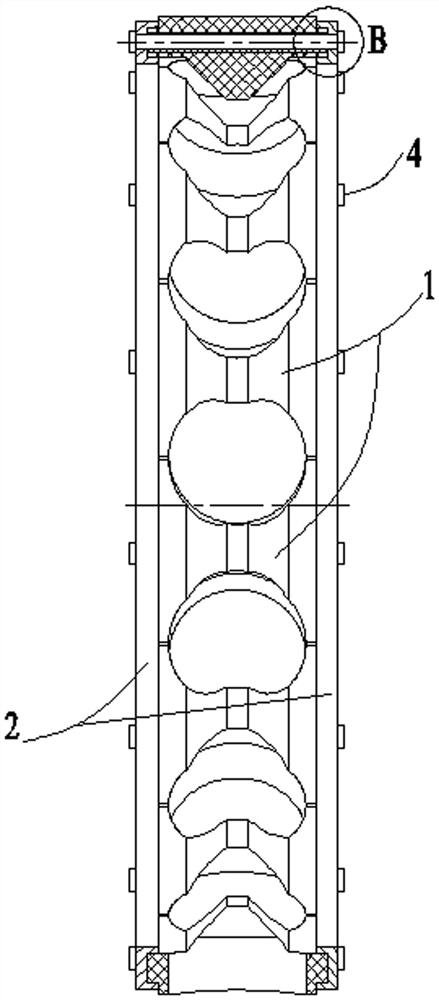

Gyrating device for transmission, transmission device with same and transmission method

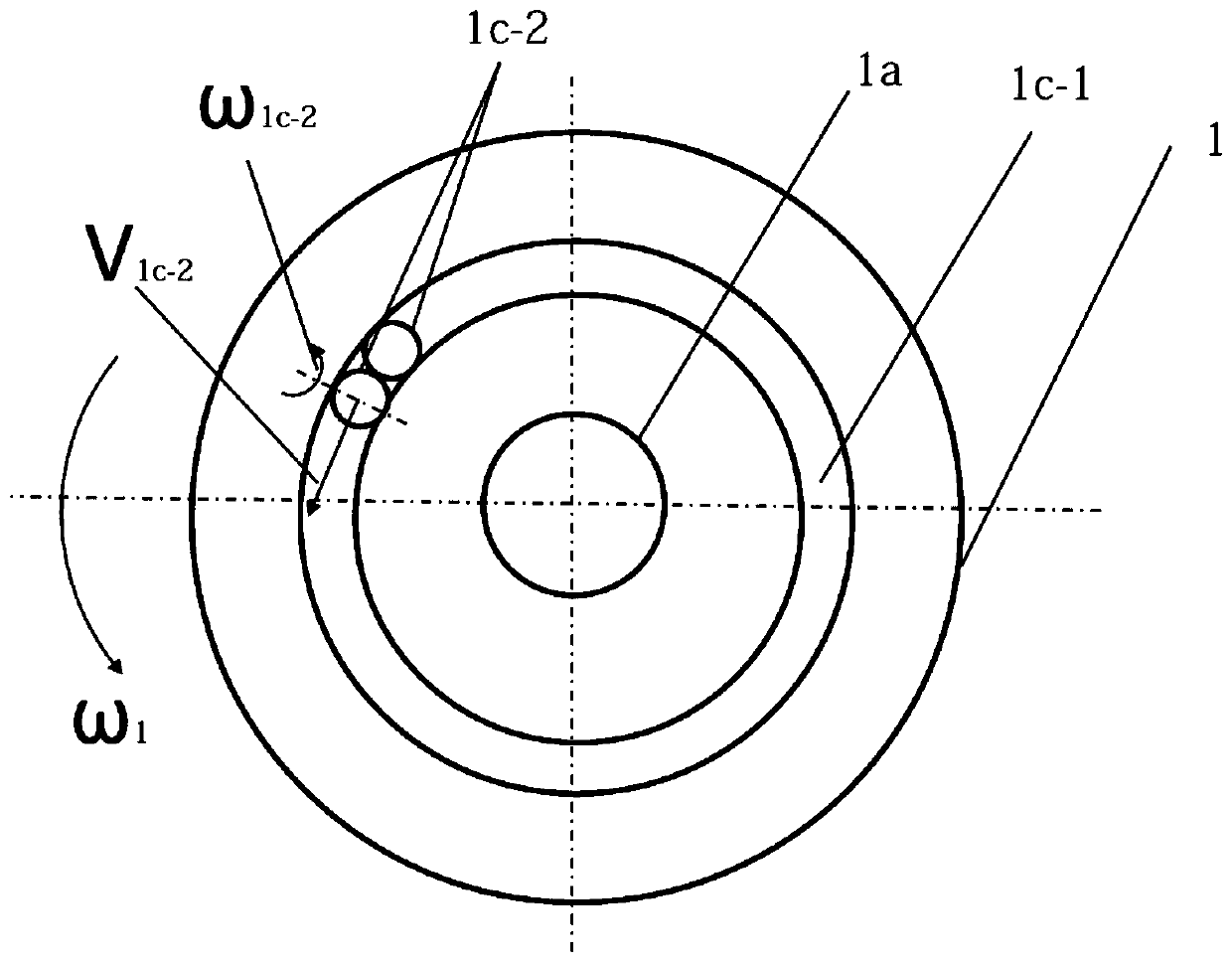

ActiveCN110259900AReduce wearReduce frictional heat generationGear vibration/noise dampingGear lubrication/coolingRolling resistanceEngineering

The invention relates to a gyrating device for transmission, a transmission device with same and a transmission method. The gyrating device comprises a base body, wherein a roller bed in which a plurality of first roller bodies are connected in an end-to-end manner is distributed in the base body; when adjacent two first roller bodies are in local contact, the roller bed is full of the plurality of roller bodies in a manner of being in local contact with the roller bed, so that the base body can be rotated around own axis based on a movable frictional pair which is formed through the first roller bodies and the roller bed in an incomplete pure rolling manner under the condition that at least one of the plurality of first roller bodies are rotated around own axis and move along the roller bed; or at least one of the plurality of first roller bodies can be rotated around own axis based on the rolling frictional pair which is formed by the first roller bodies and the roller bed in an incomplete pour rolling manner and rolls along the roller bed under the condition that the base body is rotated around own axis.

Owner:CHENGDU ZHONGLIANGCHUANGONG TECH CO LTD

Cooling device for road cutting machine

The invention relates to a cooling device of a pavement cutting machine. The cooling device of the pavement cutting machine comprises a water tank on the cutting machine, a water outlet of the water tank is connected with a water inlet pipe of a booster pump, a water outlet pipe of the booster pump is respectively connected with a water spraying pipe I going into a mask of a cutting disc and a water spraying pipe II at the outer side of the mask by virtue of a three-way pipe, sprayers at the two sides of the cutting disc are respectively arranged on the water spraying pipe I, multiple water spraying holes are formed in each sprayer and comprise center water spraying holes and edge water spraying holes, water flowing out of each center water spraying hole is vertical to the corresponding sprayer, water flowing out of each edge water spraying hole is sprayed out toward the outer side of the corresponding sprayer in an inclined way, one part of water can be sprayed onto a rotating shaft of the cutting machine, and water in the water spraying pipe II is sprayed out in a water curtain shape and acts on a contact part between the cutting disc and a pavement, so that heat produced by friction is reduced. By the cooling device of the pavement cutting machine, the temperature of the cutting disc can be effectively reduced while the rotating shaft of the cutting machine can be cooled, and heat produced by friction between the cutting disc and the pavement can be reduced when the pavement is cut by the cutting disc.

Owner:王威

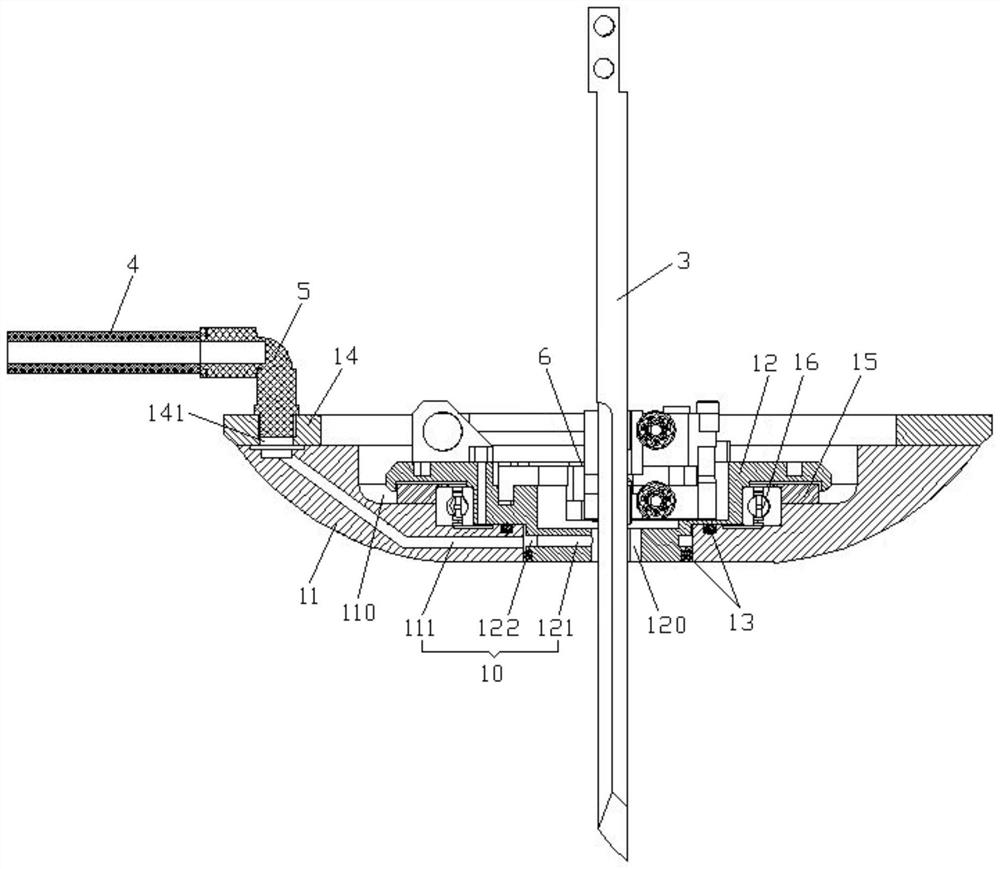

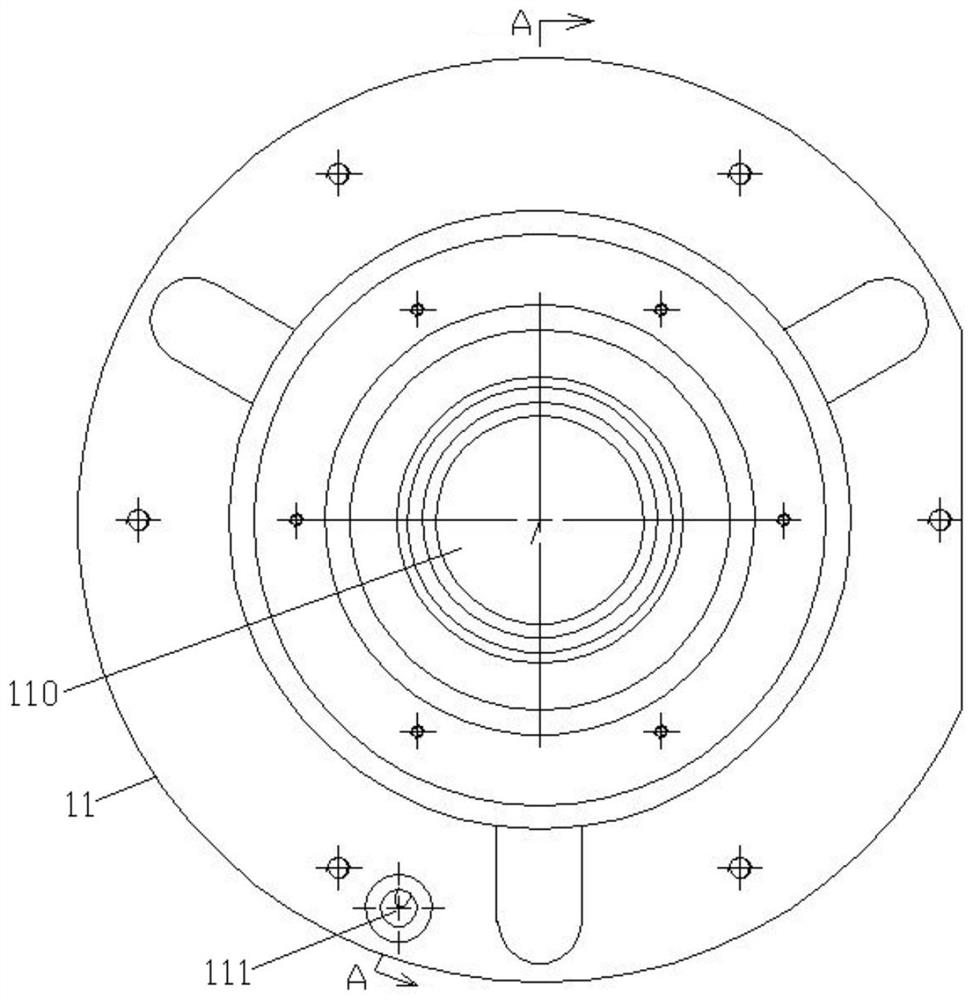

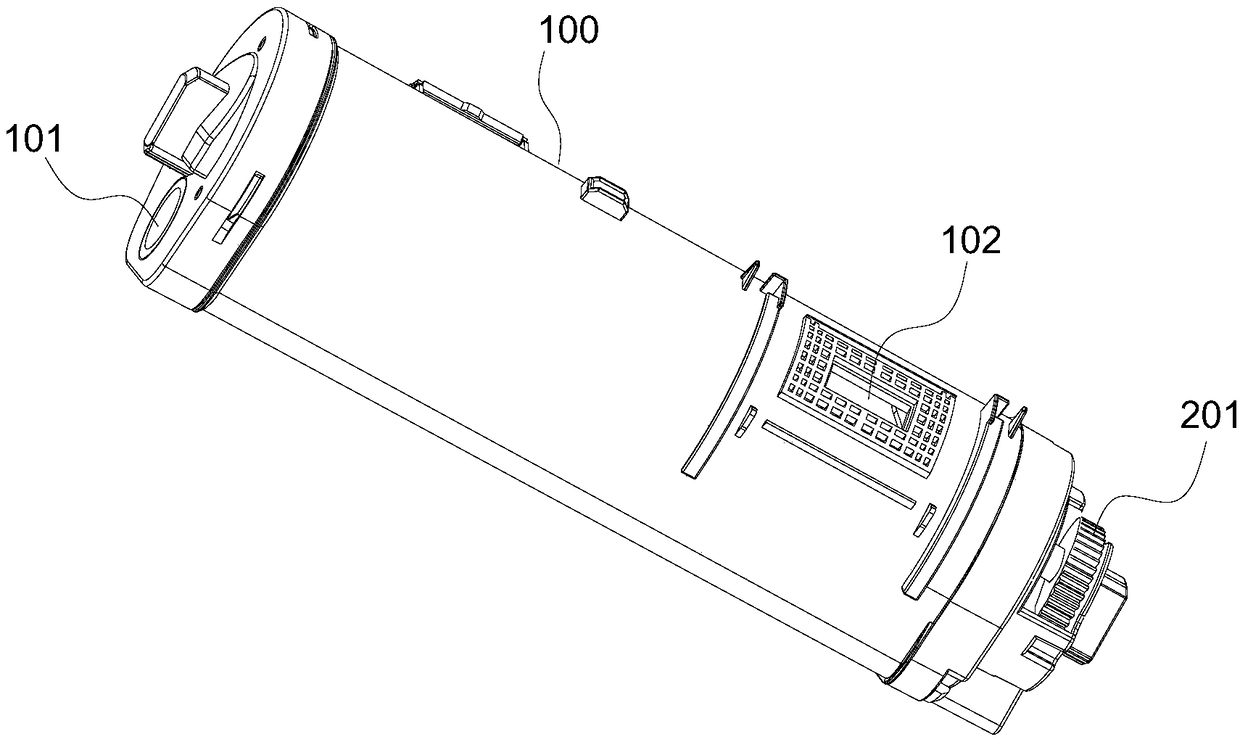

Cutting bed cutter cooling device

PendingCN113547574AReduce frictional heatRelieve adhesionSevering textilesMetal working apparatusEngineeringCooling fluid

The invention relates to the technical field of cutting beds, in particular to a cutting bed cutter cooling device. The device comprises a cutter head assembly used for installing a cutter and a cooling liquid supply assembly used for providing cooling liquid, a cutter edge allowing a cutter to penetrate therethrough and a cooling channel allowing the cooling liquid to pass therethrough are arranged in the cutter head assembly, one end of the cooling channel communicates with the cutter edge, and the other end of the cooling pipe communicates with the cooling liquid supply assembly through a cooling pipe. The cooling liquid provided by the cooling liquid supply assembly can enter the cooling channel in the cutter head assembly through the cooling pipe, reaches the cutter edge through the cooling channel and is sprayed to the cutter, the cutter is cooled, the cooling liquid sprayed to the cutter can also play a role in lubricating the contact between the cutter and fabric, and heat generated by friction between the cutter and the fabric is further reduced. Therefore, through the cooling and lubricating effects of the cooling liquid, the temperature of a heat source and heat generated by the friction can be effectively reduced, and the problem of adhesion of cut pieces after fabric cutting is fundamentally solved on the premise that the cutting efficiency is not affected.

Owner:BULLMER ELECTROMECHANICAL TECH

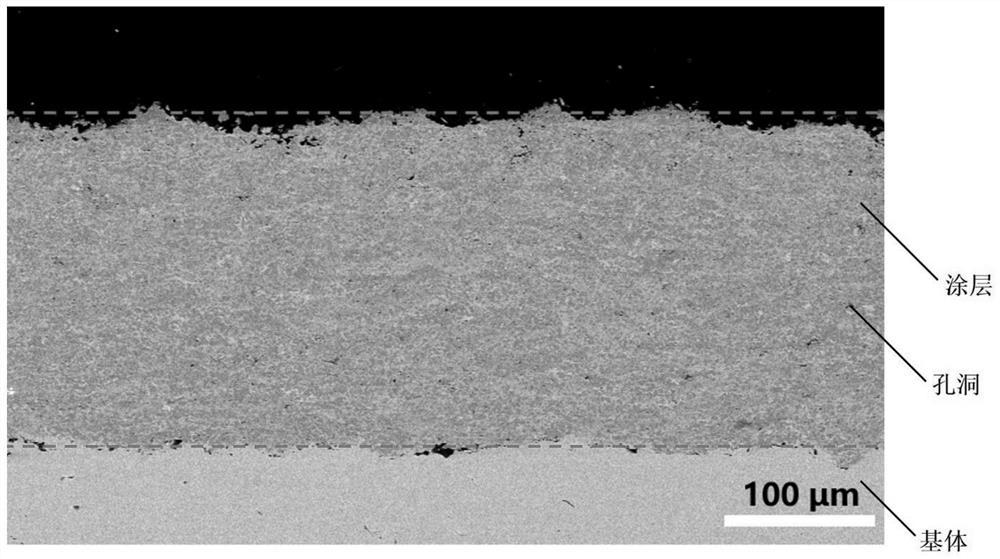

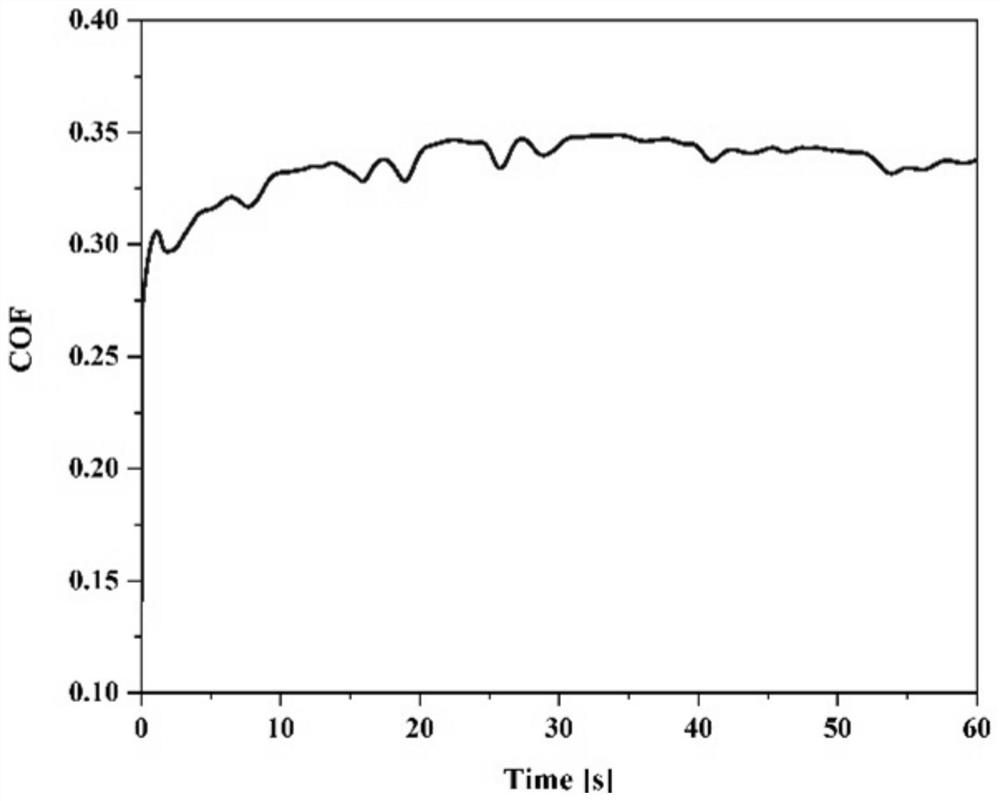

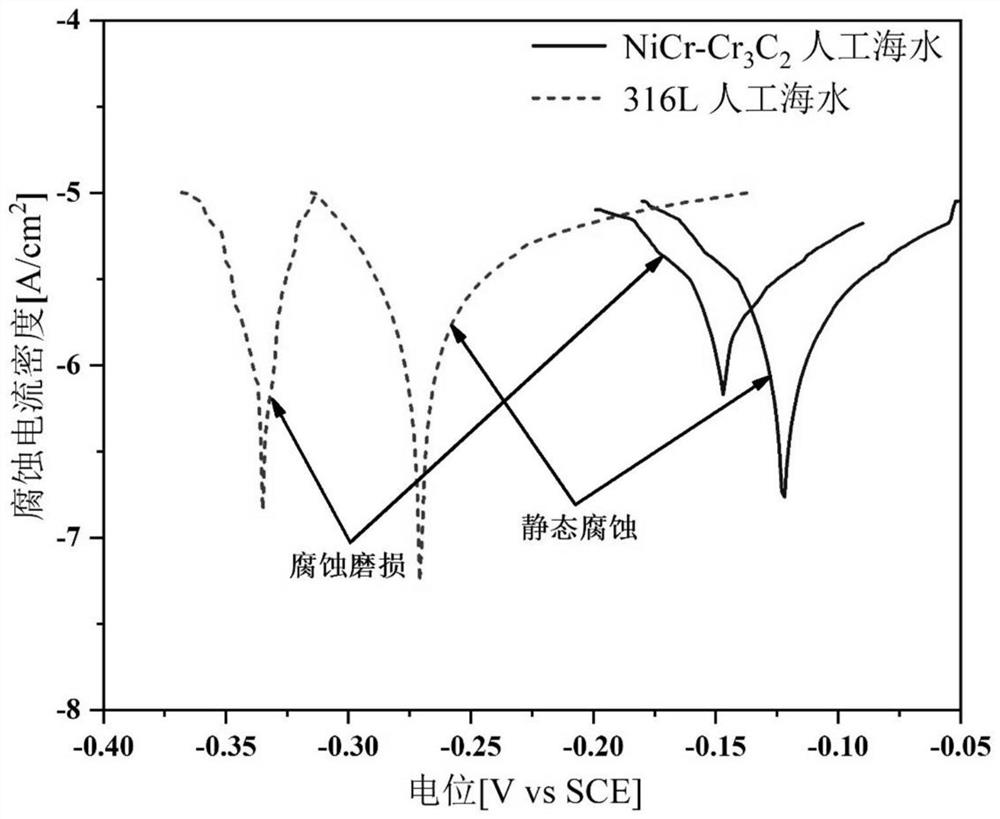

Nickel-chromium/chromium carbide metal ceramic composite coating and preparation method thereof

PendingCN113073283AImprove corrosion resistanceImprove friction resistanceMolten spray coatingChromium carbideAbrasive blasting

The invention provides a nickel-chromium / chromium carbide metal ceramic composite coating and a preparation method thereof. The preparation method comprises the following steps that 1, the surface of a base material is pretreated, and the base material with the flat surface and without oxide skin is obtained; 2, the base material obtained in the step 1 is subjected to sand blasting treatment and then preheated, and the pretreated base material is obtained; and 3, NiCr-Cr3C2 powder is used, the base material obtained in the step 2 is subjected to hypersonic flame spraying, the mass ratio of NiCr to Cr3C2 is 1:3, the spraying distance is 380-400 mm, and the powder feeding rate is 100-120 g / min. The nickel-chromium / chromium carbide metal ceramic composite coating is formed on the base material, and the coating is high in compactness, low in porosity, high in bonding strength and excellent in corrosion and wear resistance.

Owner:SHAANXI UNIV OF SCI & TECH

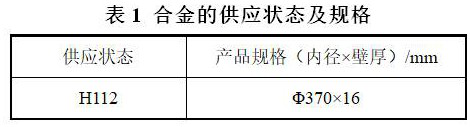

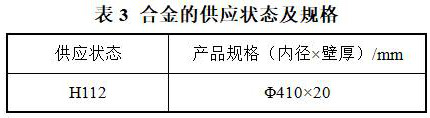

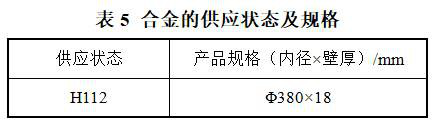

Preparation method of large-diameter 6061 aluminum alloy extruded pipe for hydrogen storage of new energy automobile

The invention discloses a preparation method of a large-diameter 6061 aluminum alloy extruded pipe for a new energy automobile. The preparation method sequentially comprises the working procedures of alloy component optimization, smelting, melt purification, standing, degassing and deslagging, casting, homogenizing annealing, machining and extrusion. The alloy comprises the following elements in percentage by weight: 0.6%-0.70% of Si, 0.15%-0.20% of Fe, 0.28%-0.35% of Cu, 0.15%-0.20% of Mn, 0.85%-1.1% of Mg, 0.18%-0.25% of Zn, 0.14%-0.15% of Ti, 0.1%-0.3% of Cr, 0.05% of Ni and the balance of Al, the ratio of Mg to Si is adjusted to be 1.40%-1.53, and a heat treatment process of a cast ingot is optimized. Meanwhile, in order to ensure that the pipe meets the precision requirement and the surface quality requirement, a tool, a mold and extrusion parameters are designed, the aluminum alloy extruded pipe with good plasticity, toughness and rigidity, uniform component distribution and fine crystal grains is obtained, and therefore the use requirement of a hydrogen storage pipe of a new energy automobile is met.

Owner:西北铝业有限责任公司

Novel flame-retarding magnesium alloy with high heat transfer property and processing technology thereof

The invention discloses a novel flame-retarding magnesium alloy with high heat transfer property and a processing technology thereof. The novel flame-retarding magnesium alloy is prepared from the following components in percentage by weight: 0.2 to 0.4 percent of P, 0.4 to 0.6 percent of Li, 3.0 to 4.2 percent of In, 0.3 to 0.5 percent of Re, 4.0 to 5.0 percent of Co, 0.4 to 0.6 percent of Ta, 1.0 to 2.0 percent of Ge, 6.0 to 8.0 percent of Al and the balance of magnesium. The material provides a flame-retarding scheme for magnesium alloy combustion caused by friction or external fire heating. Predicably, implementation and industrialization of the alloy can greatly push the commercial demand of China in the field of light weight for the novel flame-retarding magnesium alloy.

Owner:GUANGZHOU YUZHI TECH CO LTD

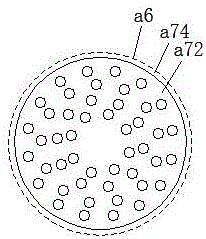

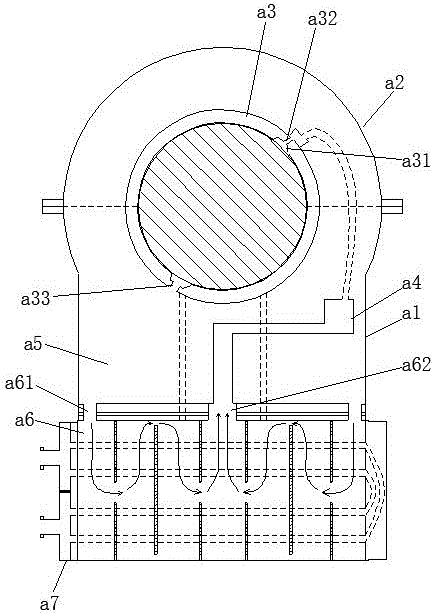

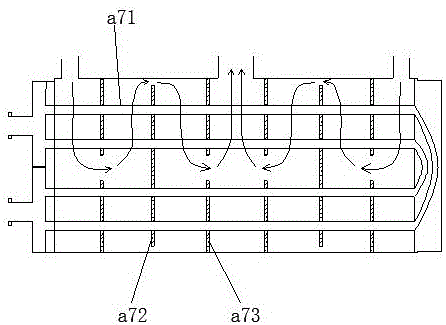

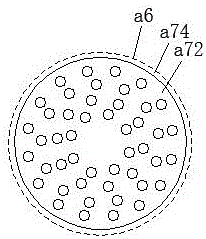

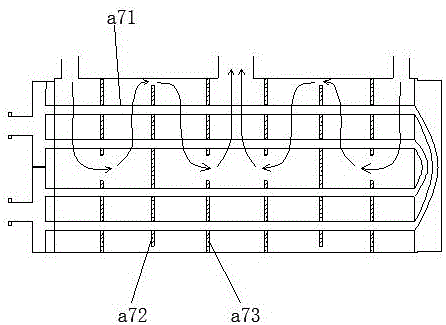

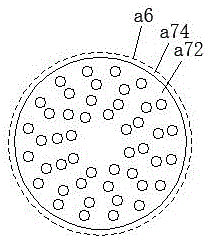

Oil cooling bearing

The invention discloses an oil cooling bearing. A bearing cover is located above a bearing block, a bearing bush is fixed to the bearing block, a cooling oil groove in the axial direction is formed in the inner diameter side of the bearing bush, an oil inlet hole is formed in the middle portion of the cooling oil groove, and the two ends of the cooling oil groove are provided with hot oil discharging ways; a bearing cooling structure comprises a cooling cavity and a cooling body, the cooling body is located in the cooling cavity, the cooling cavity is provided with a hot oil inlet and a cold oil outlet, an oil inlet is communicated with the cold oil outlet of the cooling cavity, and the hot oil discharging ways are communicated with the hot oil inlet of the cooling cavity; and the cooling body comprises a cooling pipe, a bottom hole runner separating plate and a top hole runner separating plate, and the bottom hole runner separating plate and the top hole runner separating plate are distributed in the cooling cavity between the hot oil inlet and the cold oil outlet in a spaced manner. The high heat exchange efficiency is achieved, alarm halting caused by too-high oil temperature can be effectively prevented, and the bush abrasion or burning phenomenon caused by the too-high bearing bush and cooling oil can be effectively avoided.

Owner:郭远军

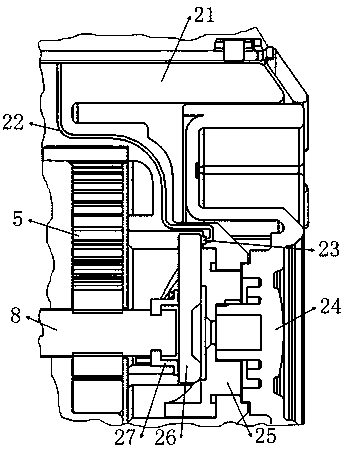

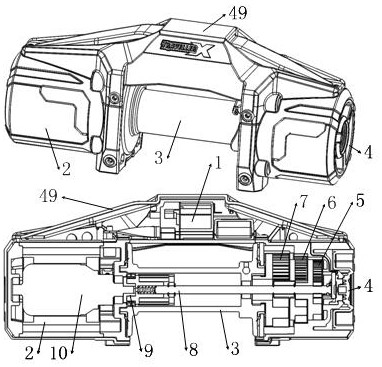

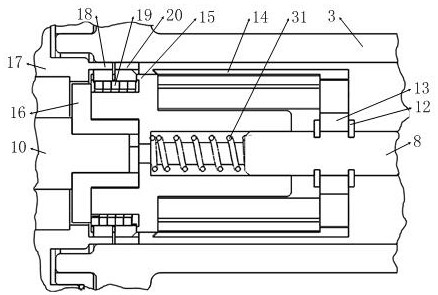

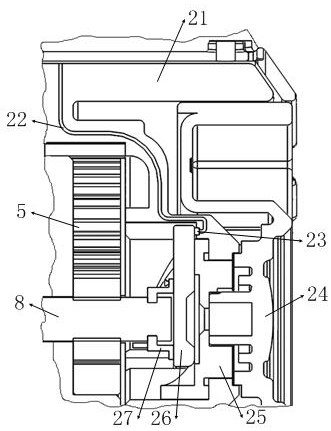

Electric capstan

ActiveCN110745724AImprove the use effectGood braking effectInterengaging clutchesWinding mechanismsPhysicsClutch

The invention belongs to the capstan field, and particularly relates to an electric capstan. The electric capstan comprises an electric control module, a motor module, a roller, a clutch, a first-level speed reduction assembly, a second-level speed reduction assembly, a third-level speed reduction assembly, a transmission shaft and a braking unit. A pressure inductor can recognize whether a third-level sun gear and a second-level planet carrier are completely engaged or not. After the third-level sun gear and the second-level planet carrier are completely engaged, a motor is started so that the capstan can be normally used. A friction block A and a friction block B are designed to conduct friction braking with a friction ring A and a friction ring B, so that braking is established betweenthe transmission shaft and the friction ring at the support position and between the transmission shaft and the friction ring at the roller position, and a better braking effect is achieved. When a coupler A and a coupler B relatively move, a rectangular spring can deform and rub with the friction block A and the friction block B, heat generated due to friction is little, and influences generateddue to rectangular spring failures can be neglected. Accordingly, the service life of the rectangular spring can be prolonged.

Owner:ZHEJIANG RUNVA MECHANICAL & ELECTRICAL

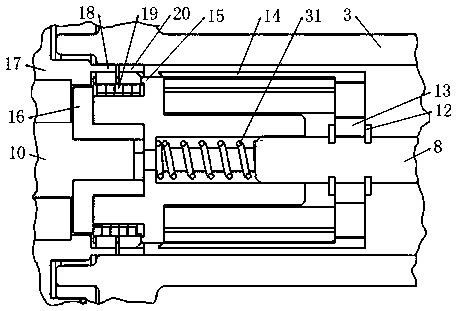

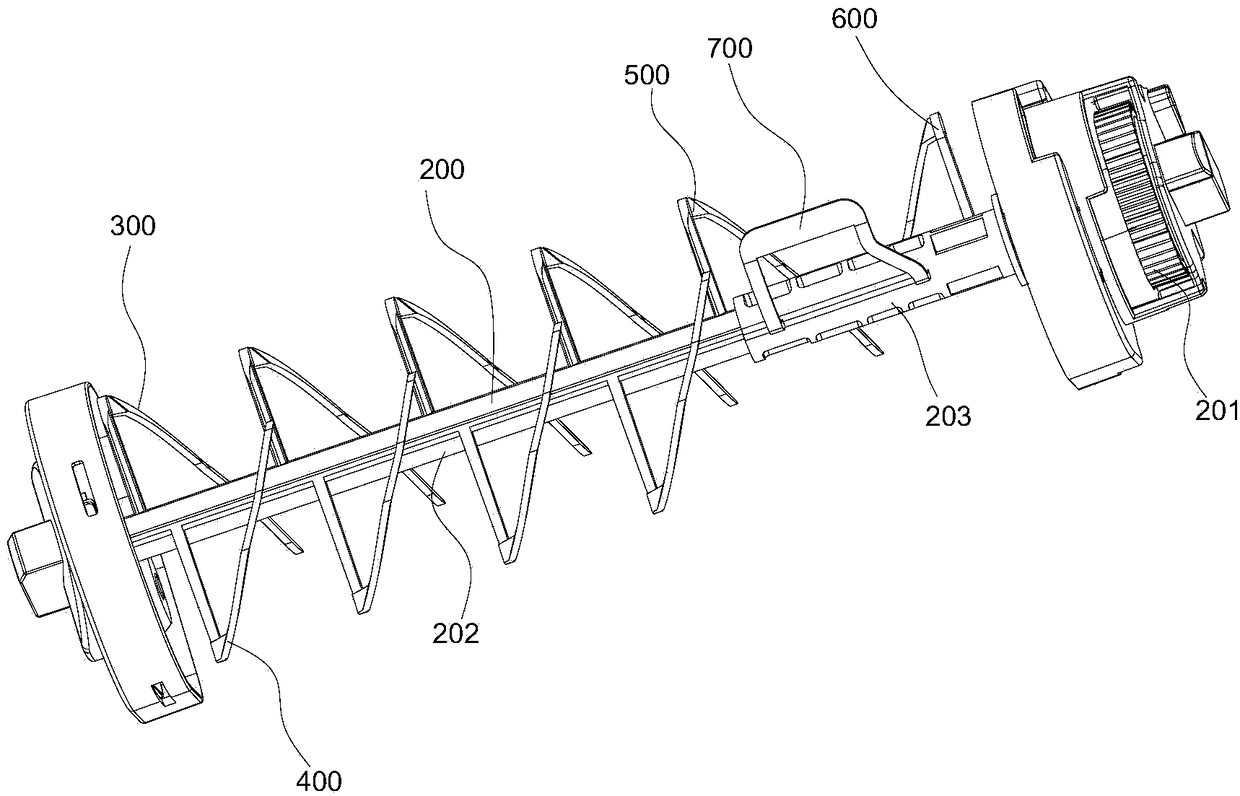

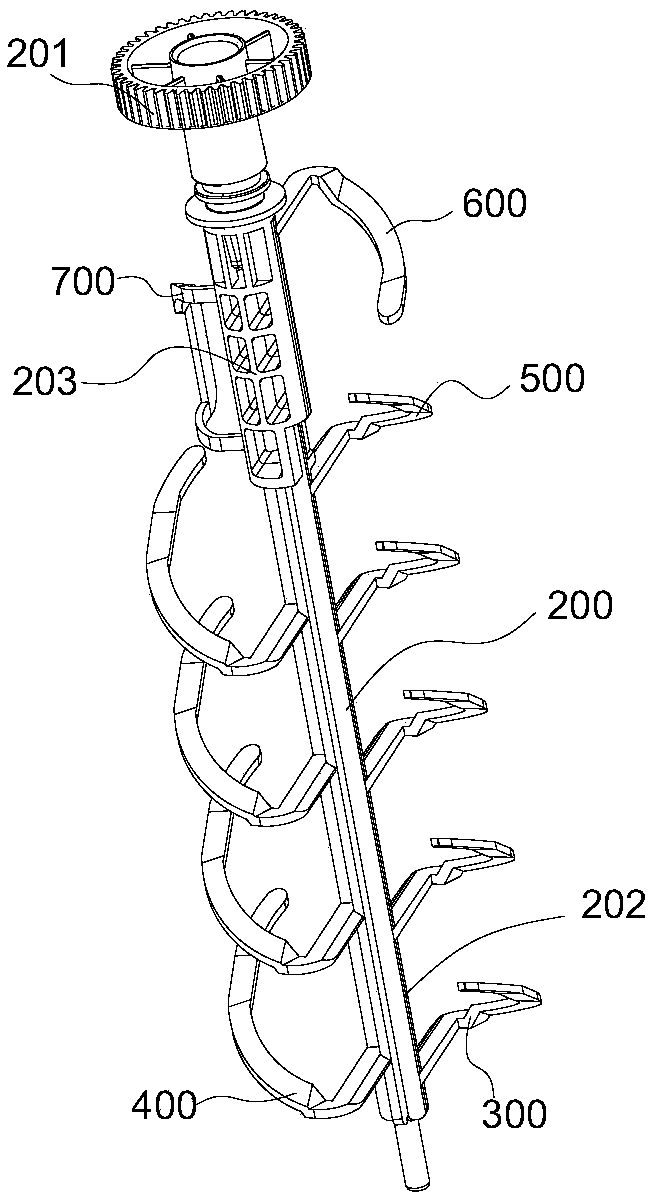

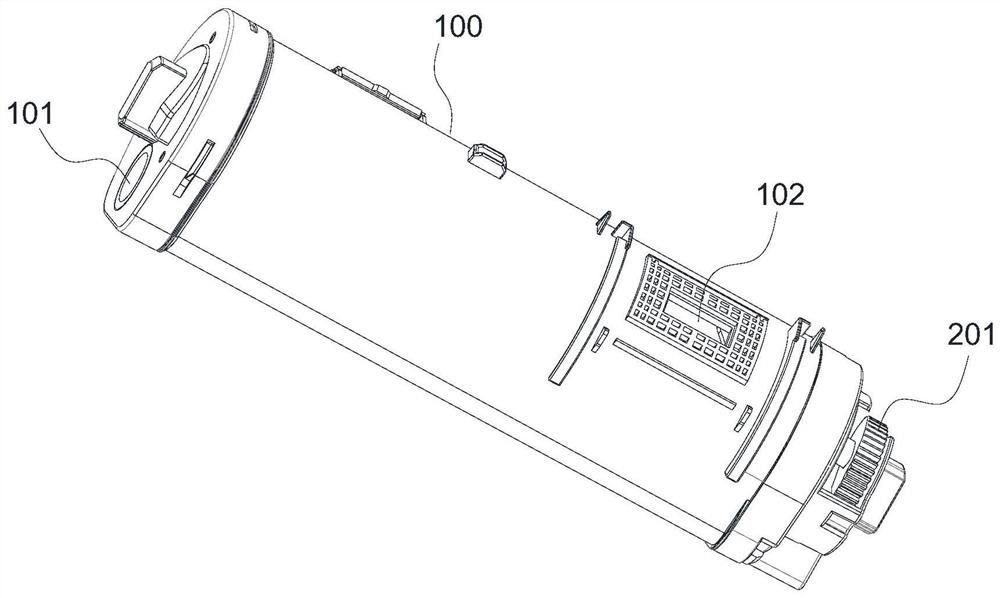

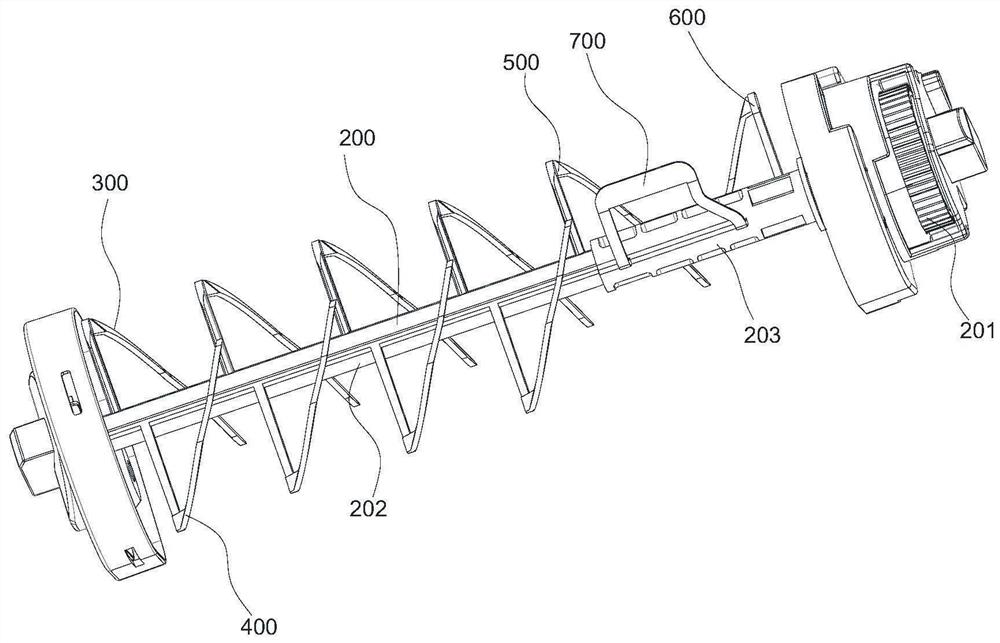

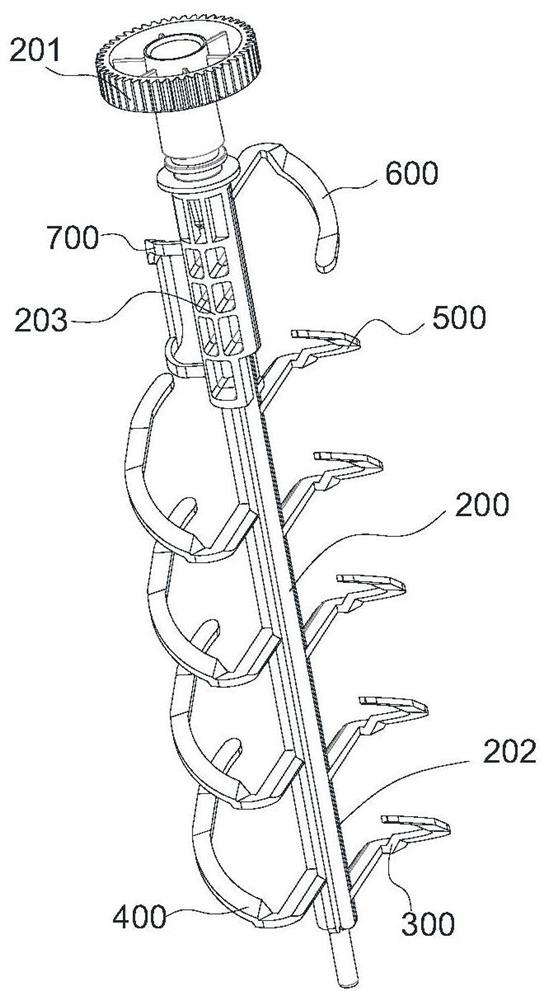

A developer receiving container

ActiveCN109270812AReduce gapImprove transmission uniformityElectrographic process apparatusSpiral bladeEngineering

The invention discloses a developer receiving container, comprising a container body, a rotating shaft located in the container body; The container body is provided with a powder outlet. The rotatingshaft is provided with a powder scraping blade for scraping the toner out of the powder outlet, and a plurality of groups of spiral blade groups arranged at equal intervals along the axial direction of the rotating shaft; Each helical blade group includes a first blade, a second blade, and a second blade on opposite sides of the rotating shaft. The first blade is positioned on a side of the secondblade adjacent to the powder outlet; The first blade and the second blade both comprise straight segments, and the ends of the straight segments are connected with spiral segments. The spiral segmentspirally extends along the circumferential direction of the inner cavity of the container; A spiral segment rotation track of any one of the first blades at least partially overlaps with a straight segment rotation track of an adjacent second blade; The rotational trajectory of the helical section of the second blade is located between the rotational trajectory of the straight section of the second blade and the rotational trajectory of the straight section of the adjacent second blade. The rotational trajectory of the helical section of the second blade is located between the rotational trajectory of the straight section of the second blade and the rotational trajectory of the adjacent straight section of the second blade. Compared with the prior art, the invention has the advantages ofsimple structure, fast and uniform material feeding, and less friction and heat generation.

Owner:JIANGXI KAILIDE TECH CO LTD

Electric winch equipment

ActiveCN112279129AEasy to useImprove braking effectInterengaging clutchesWinding mechanismsElectric machineCoupling

The invention belongs to the field of winches, and particularly relates to electric winch equipment. The electric winch equipment comprises an electric control module, a motor module, a roller, a clutch, a first-stage speed reduction assembly, a second-stage speed reduction assembly, a third-stage speed reduction assembly, a transmission shaft and a brake unit. A pressure sensor can identify whether a third-stage sun gear and a second-stage planet carrier are completely engaged or not; and after the third-stage sun gear is completely engaged with the second-stage planet carrier, a winch can benormally used only when a motor is started. By designing a friction block A and a friction block B to conduct friction braking with a friction ring A and a friction ring B respectively, braking is established between the transmission shaft and the friction ring at the position of a support and between the transmission shaft and the friction ring at the position of the roller, and a better brakingeffect is achieved. When a coupling A and a coupling B generate relative motion, a rectangular spring deforms to generate friction with the friction block A and the friction block B, but the heat generated by the friction is very small, so that the influence on the failure of the rectangular spring can be neglected, and the service life of the rectangular spring can be prolonged.

Owner:ZHEJIANG RUNVA MECHANICAL & ELECTRICAL

Rotary transmission device and method

ActiveCN113090725AReduce wearReduce frictional heat generationGear vibration/noise dampingGear lubrication/coolingEngineeringMechanical engineering

Owner:CHENGDU ZHONGLIANGCHUANGONG TECH CO LTD

developer storage container

ActiveCN109270812BReduce gapImprove transmission uniformityElectrographic process apparatusHelical bladeStructural engineering

The invention discloses a container for developer, which comprises a container body and a rotating shaft located in the container body; the container body is provided with a powder outlet. The rotating shaft is provided with a powder scraping sheet for scraping the carbon powder out of the powder outlet, and multiple sets of helical blade groups arranged at equal intervals along its axial direction; each helical blade group includes first blades located on both sides of the rotating shaft, The second blade; the first blade is located on the side of the second blade close to the powder outlet; the first blade and the second blade both include a straight section, and the end of the straight section is connected with a helical section; the helical section is along the circumferential direction of the inner cavity of the container Helical extension; the rotation track of the helical segment of any one first blade overlaps at least partially the rotation track of the straight segment of the adjacent second blade; Between the straight-line segment rotation tracks of the adjacent second blades. Compared with the prior art, the invention has the advantages of simple structure, fast and uniform material feeding, and less frictional heat generation.

Owner:JIANGXI KAILIDE TECH CO LTD

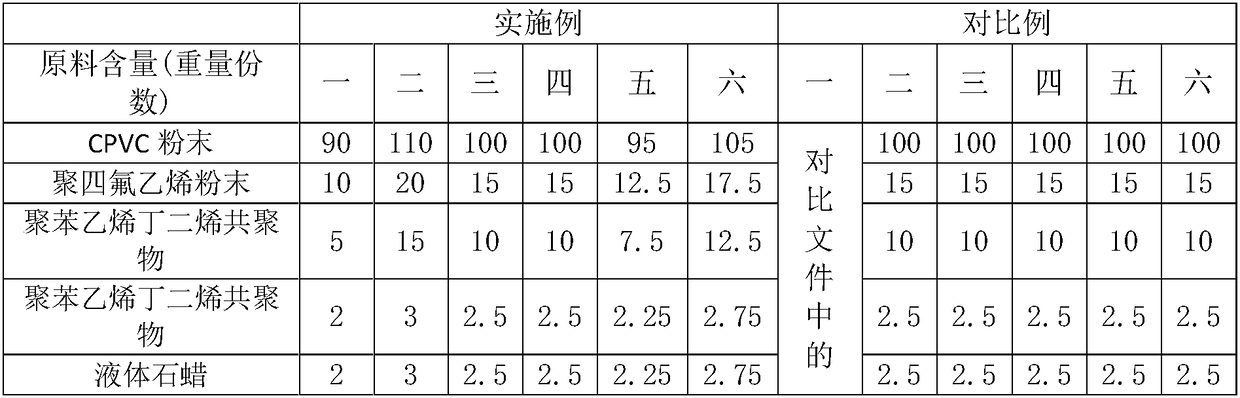

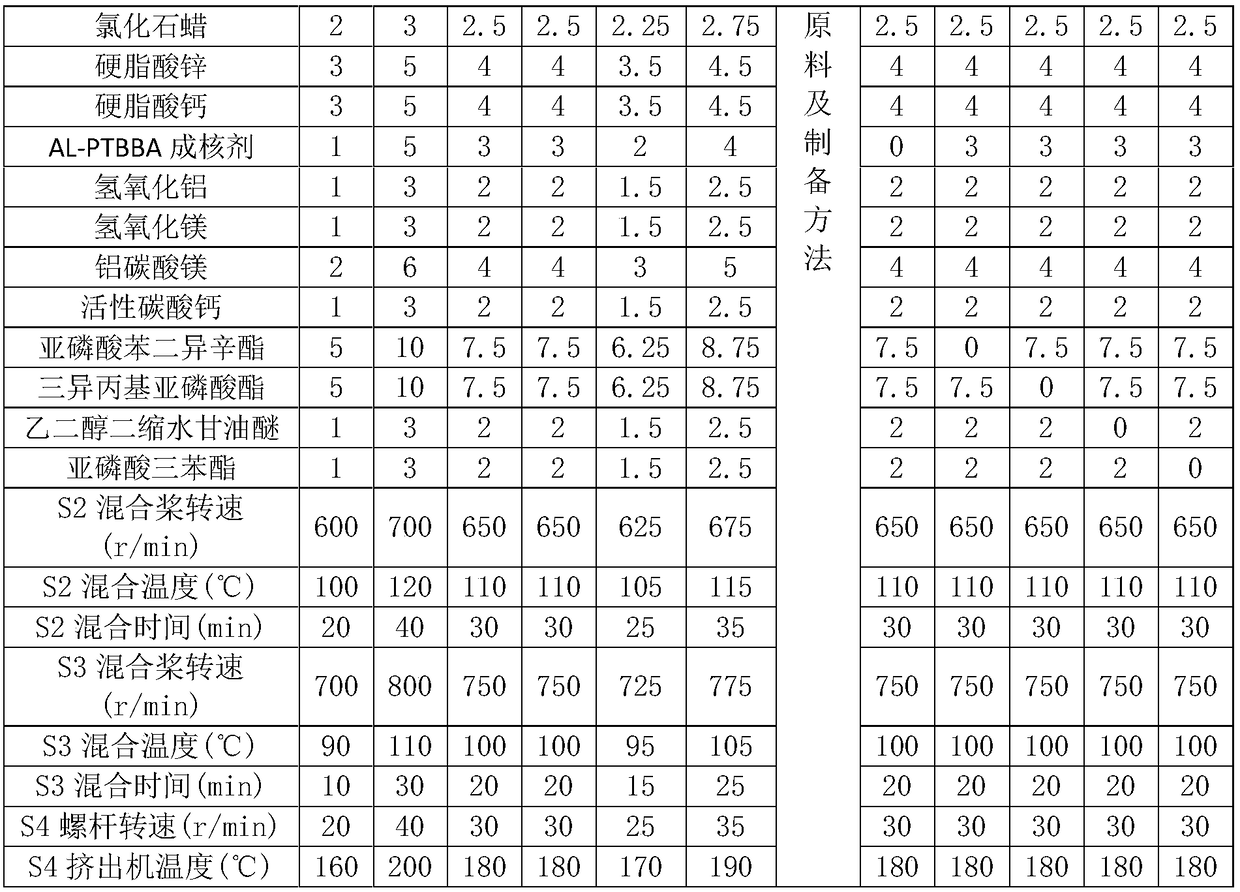

Flame-retardant CPVC tubular product and preparation method thereof

The invention discloses a flame-retardant CPVC tubular product and a preparation method thereof; the flame-retardant CPVC tubular product includes the following components in parts by weight: 90-110 parts of a CPVC powder, 10-20 parts of a polytetrafluoroethylene powder, 5-15 parts of a toughening agent, 6-9 parts of a compound lubricant, 6-10 parts of a stabilizer, 1-5 parts of an AL-PTBBA nucleating agent, 1-3 parts of aluminum hydroxide, 1-3 parts of magnesium hydroxide, 2-6 parts of hydrotalcite, 1-3 parts of active calcium carbonate, 5-10 parts of diisooctyl phenyl phosphite, and 5-10 parts of triisopropyl phosphite. The preparation method of the flame retardant CPVC tubular product includes the steps: S1, weighing the materials; S2, preliminarily mixing to obtain a first mixture; S3,mixing again to obtain a second mixture; and S4, putting the second mixture into a twin-screw extruder, carrying out extrusion molding, and finally obtaining the finished product. The prepared CPVC tubular product has the advantages of slow linear burning rate, excellent flame retardancy and almost no production of burning particles or burning droplets and high tensile strength.

Owner:苏州翠屏塑胶有限公司

Slewing device for transmission, transmission equipment including same and transmission method

ActiveCN110259900BReduce wearReduce frictional heat generationGear vibration/noise dampingGear lubrication/coolingClassical mechanicsControl theory

Owner:CHENGDU ZHONGLIANGCHUANGONG TECH CO LTD

Novel flame-retardant magnesium alloy with high damping performance and processing process of novel flame-retardant magnesium alloy with high damping performance

The invention discloses a novel flame-retardant magnesium alloy with a high damping performance and a processing process of the novel flame-retardant magnesium alloy with the high damping performance.The magnesium alloy comprises, by weight, 0.1-0.2wt% of B, 0.8-1.2wt% of Li, 2.0-2.5wt% of In, 0.4-0.8wt% of Bi, 3.0-4.0wt% of Cu, 0.8-1.2wt% of Hf, 4.0-5.0wt% of Mn, 3.5-3.8wt% of Al and the balancemagnesium. A flame-retardation scheme for magnesium alloy combustion caused by friction or external fire heating is provided. Predictably, implementation and industrialization of the magnesium alloycan greatly promote commercial demands on flame-retardant magnesium alloy in the field of light weight in China.

Owner:GUANGZHOU YUZHI TECH CO LTD

A self-lubricating micro-stir friction welding method with welding friction restraint

ActiveCN110860780BReduce coefficient of frictionAchieving continuous dynamic restraintNon-electric welding apparatusFriction weldingFrictional coefficient

A self-lubricating micro-stir friction welding method with welding friction restraint of the present invention, a low friction coefficient auxiliary shoulder that rotates with the stirring head is added to the outside of the friction stir welding stirring head of the thin-walled member, and the shoulder is adopted with a certain high temperature resistance A self-lubricating material with high capacity, which can partially restrain the material to be welded and roll it after welding, so as to keep the workpiece flat before and after welding. At the same time, the auxiliary shoulder can adjust and control the pressure or displacement of the workpiece. The auxiliary shoulder and the stirring head rotate together, and the welding method with almost no inclination angle can overcome the problem of excessive resistance of the static shoulder. The material has a very small friction coefficient, and its heat production is low, which will not significantly increase the heat input of the welding process, which can ensure the dynamic restraint effect on thin-walled workpieces without affecting the welding process. The invention can effectively solve the problems of difficult assembly, easy deformation and instability, large deformation after welding and the like in the friction stir welding process of thin-walled components.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

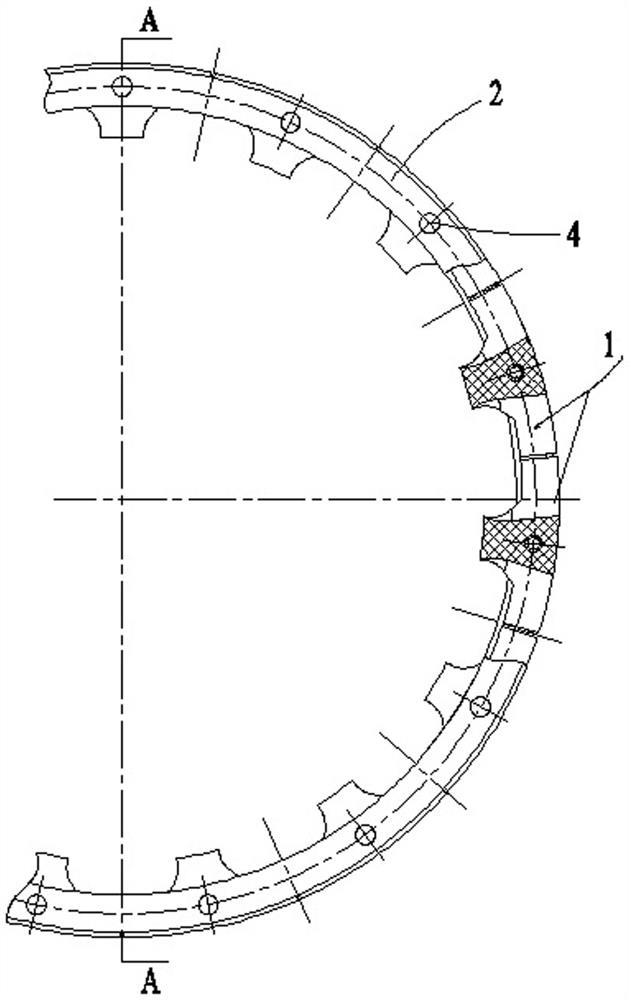

Metal reinforced retainer for main shaft bearing of liquid oxygen pump and preparation process of metal reinforced retainer

PendingCN114576271AReduce frictionReduce frictional heat generationBearing componentsEngineeringSteel ball

The invention relates to a metal reinforced retainer for a liquid oxygen pump main shaft bearing and a preparation process thereof, the retainer comprises a plurality of retainer blocks, a fixing ring and a rivet sleeve, each pocket is composed of two adjacent retainer blocks, two sides of each retainer block are respectively provided with a convex positioning structure, and each convex positioning structure is provided with a convex groove. Limiting grooves matched with the convex positioning structures in shape are evenly formed in the end faces of the fixing rings in the circumferential direction, the fixing rings are arranged on the two sides of the multiple retainer blocks and connected with the convex positioning structures in a matched mode through the limiting grooves in the fixing rings, and the rivet sleeves are installed in rivet holes of the retainer blocks respectively. And a plurality of rivet rods are used for fixing. According to the scheme, the influence of the large linear expansion coefficient of a polytetrafluoroethylene material on the guide gap of the guide flange of the retainer and the gap between the pocket and the steel ball can be avoided, the structural stability, reliability and high-speed performance of the retainer at low temperature are guaranteed, the retainer can be suitable for the low-temperature and high-speed working conditions of the liquid oxygen pump, and meanwhile the weight of the retainer can be reduced as much as possible.

Owner:LUOYANG LYC BEARING

Oil duct balance type bearing

The invention discloses an oil duct balance type bearing. The oil duct balance type bearing comprises a bearing base, a tilting fillet, a positive thrust disc, a first oil cavity, a second oil cavity, a cooler and a cover with oil, wherein the tilting fillet is fixedly arranged on the bearing base; a supporting pad is arranged at the inner radial side of the tilting fillet; a positive thrust pad is arranged at the front side of the tilting fillet; the second oil cavity communicates with the first oil cavity through a hot oil inlet; the cooler is mounted in the second oil cavity; the cover with oil and the positive thrust disc form a cavity with oil; an oil injecting slot is formed in the inner radial side of the supporting pad; an oil throwing cavity is arranged at the inner radial side of the positive thrust pad; the cavity with oil comprises a high-pressure oil outlet and an oil pumping hole; the oil pumping hole communicates with the second oil cavity; the high-pressure oil outlet separately communicates with the oil injecting slot and the oil throwing cavity through a first oil duct and a second oil duct; and a first flow regulating valve and a second flow regulating valve are separately arranged in the first oil duct and the second oil duct. The oil duct balance type bearing has relatively high heat exchange efficiency, and can prevent a bearing bush from being burnt.

Owner:郭远军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com