Flame-retardant CPVC tubular product and preparation method thereof

A CPVC pipe and powder technology, which is applied in the field of flame-retardant CPVC pipe and its preparation, can solve the problems that the flame-retardant performance of the pipe has not been actually improved, the compatibility is not high, and the pipe leaks, etc., so as to reduce the probability of thermal decomposition , reduce the probability of ignition, improve the effect of thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

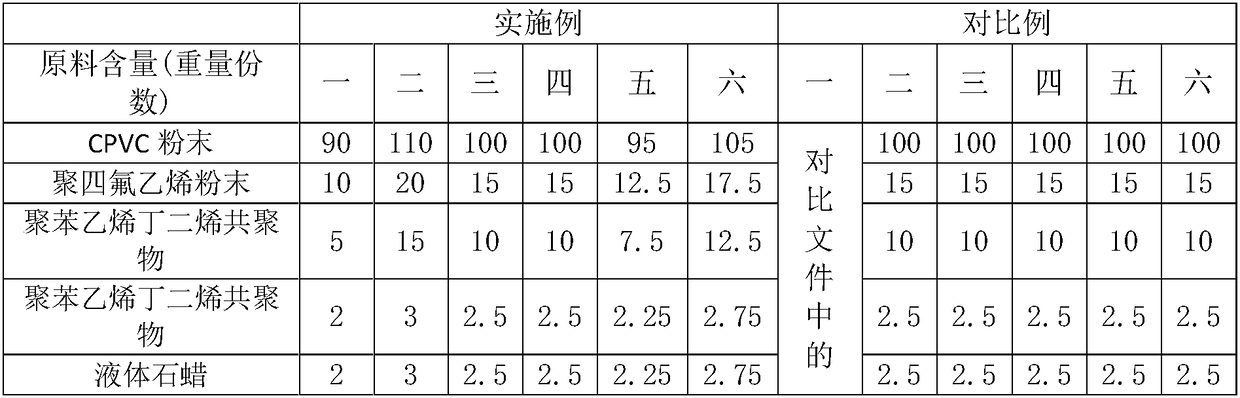

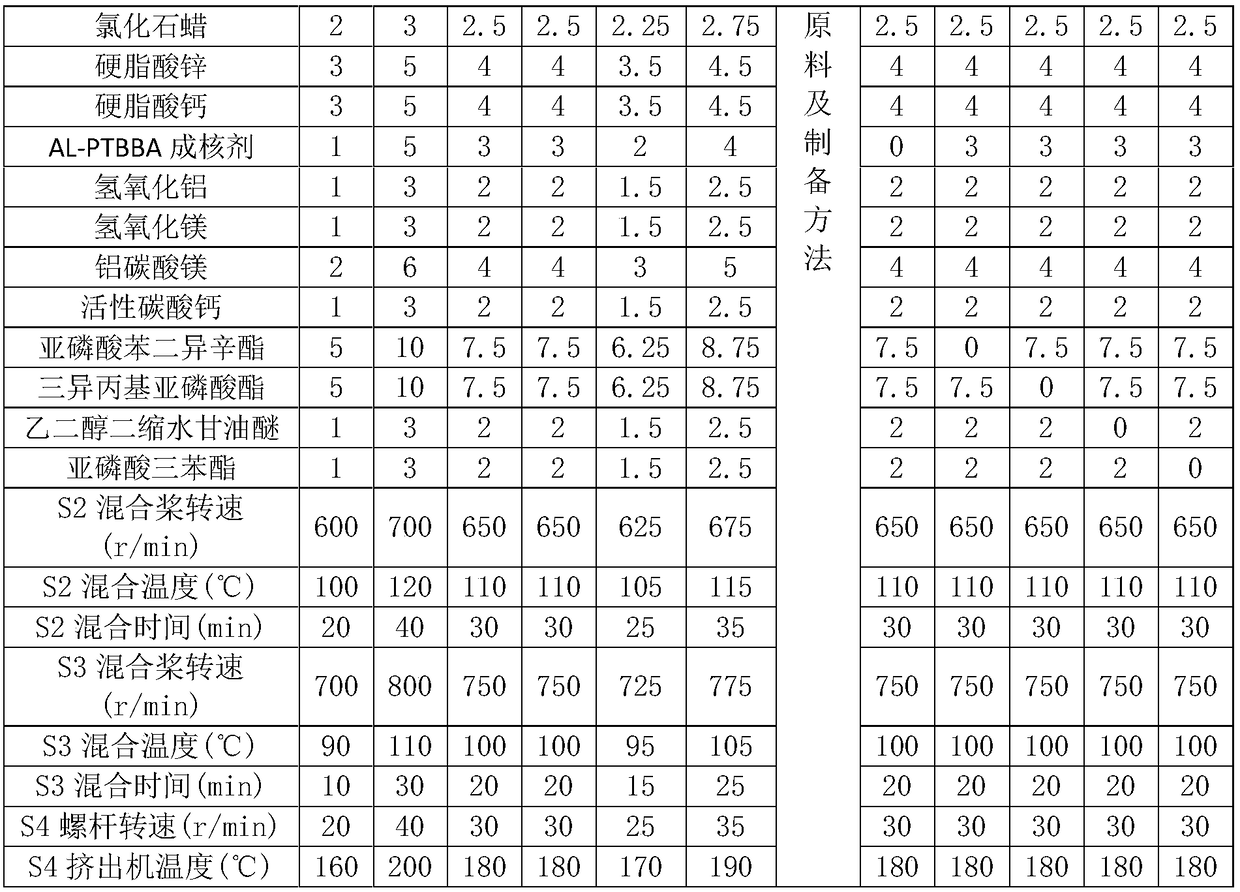

Embodiment 1

[0051] A flame-retardant CPVC pipe, which comprises the following components in parts by weight: 90 parts of CPVC powder, 10 parts of polytetrafluoroethylene powder, 5 parts of polystyrene butadiene copolymer, 2 parts of low-density polyethylene, 2 parts of liquid paraffin, 2 parts of chlorinated paraffin, 3 parts of zinc stearate, 3 parts of calcium stearate, 1 part of AL-PTBBA nucleating agent, 1 part of aluminum hydroxide, 1 part of magnesium hydroxide, 2 parts of aluminum magnesium carbonate 1 part, 1 part of activated calcium carbonate, 5 parts of phenylene diisooctyl phosphite, 5 parts of triisopropyl phosphite, 1 part of ethylene glycol diglycidyl ether, and 1 part of triphenyl phosphite.

[0052] A preparation method of flame-retardant CPVC pipe, which comprises steps:

[0053] S1. Take by weight 90 parts of CPVC powder, 10 parts of polytetrafluoroethylene powder, 5 parts of polystyrene butadiene copolymer, 2 parts of low density polyethylene, 2 parts of liquid paraffi...

Embodiment 2

[0058] A flame-retardant CPVC pipe, which comprises the following components in parts by weight: 110 parts of CPVC powder, 20 parts of polytetrafluoroethylene powder, 15 parts of polystyrene butadiene copolymer, 3 parts of low-density polyethylene, 3 parts of liquid paraffin, 3 parts of chlorinated paraffin, 5 parts of zinc stearate, 5 parts of calcium stearate, 5 parts of AL-PTBBA nucleating agent, 3 parts of aluminum hydroxide, 3 parts of magnesium hydroxide, 6 parts of aluminum magnesium carbonate 3 parts, 3 parts of activated calcium carbonate, 10 parts of phenylene diisooctyl phosphite, 10 parts of triisopropyl phosphite, 3 parts of ethylene glycol diglycidyl ether, 3 parts of triphenyl phosphite.

[0059] A preparation method of flame-retardant CPVC pipe, which comprises steps:

[0060] S1. Take by weight 110 parts of CPVC powder, 20 parts of polytetrafluoroethylene powder, 15 parts of polystyrene butadiene copolymer, 3 parts of low density polyethylene, 3 parts of liqui...

Embodiment 3

[0065] A flame-retardant CPVC pipe, which comprises the following components in parts by weight: 100 parts of CPVC powder, 15 parts of polytetrafluoroethylene powder, 10 parts of polystyrene butadiene copolymer, 2.5 parts of low-density polyethylene, 2.5 parts of liquid paraffin, 2.5 parts of chlorinated paraffin, 4 parts of zinc stearate, 4 parts of calcium stearate, 3 parts of AL-PTBBA nucleating agent, 2 parts of aluminum hydroxide, 2 parts of magnesium hydroxide, 4 parts of aluminum magnesium carbonate 2 parts, 2 parts of activated calcium carbonate, 7.5 parts of phenylene diisooctyl phosphite, 7.5 parts of triisopropyl phosphite, 2 parts of ethylene glycol diglycidyl ether, and 2 parts of triphenyl phosphite.

[0066] A preparation method of flame-retardant CPVC pipe, which comprises steps:

[0067]S1. Take by weight 100 parts of CPVC powder, 15 parts of polytetrafluoroethylene powder, 10 parts of polystyrene butadiene copolymer, 2.5 parts of low density polyethylene, 2.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com