Nickel-chromium/chromium carbide metal ceramic composite coating and preparation method thereof

A metal-ceramic composite, chromium carbide technology, applied in metal material coating process, coating, melt spraying and other directions, can solve problems such as wear and material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

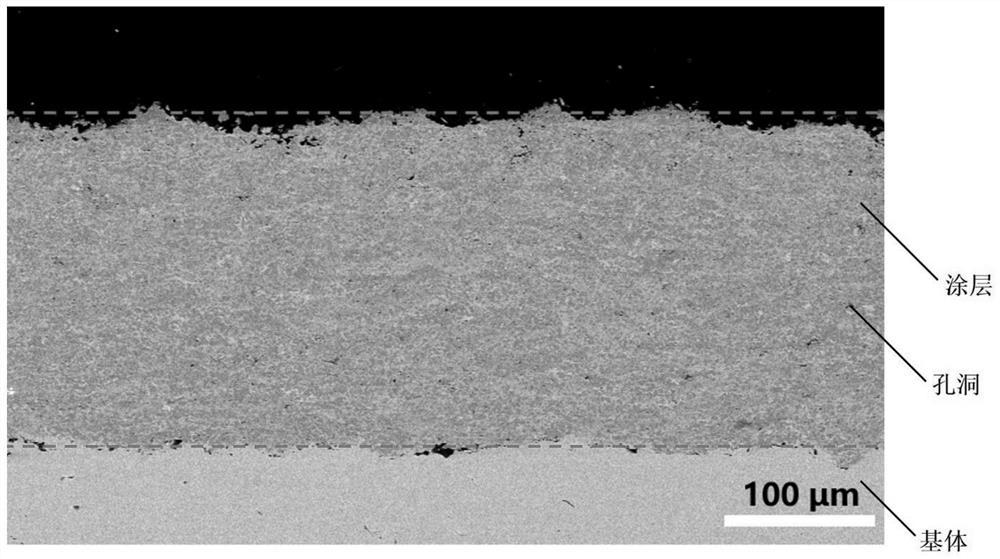

[0030] A method for preparing a low-porosity, corrosion-resistant and wear-resistant nickel-chromium / chromium carbide cermet composite coating of the present invention comprises the following steps:

[0031] 1) Substrate surface pretreatment

[0032] First, use a grinding and polishing machine to polish the base material, generally 316L, to remove the surface oxide skin while ensuring the surface flatness of the base material;

[0033] Then use alcohol for ultrasonic cleaning to remove surface oil;

[0034] Finally, use 60-mesh white corundum for sandblasting. The sandblasting pressure is 0.6-0.65Mpa. After sandblasting, the surface is uniform, and the surface roughness is greater than 5 μm and less than 10 μm. After sandblasting, use compressed air to blow off the residual sand on the surface of the base material;

[0035] 2) dry powder

[0036] The prepared NiCr-Cr 3 C 2 Put the powder into a glass petri dish and spread the powder; will contain NiCr-Cr 3 C 2 Put the pe...

Embodiment 1

[0043] The preparation method of the low-porosity, corrosion-resistant and wear-resistant nickel-chromium / chromium carbide cermet composite coating comprises the following steps:

[0044] 1) Substrate surface pretreatment

[0045] First, the base material 316L was polished with a polishing machine to remove the surface oxide skin while ensuring the surface smoothness of the base material; then, ultrasonic cleaning was performed with alcohol to remove surface oil; finally, 60-mesh white corundum was used for sandblasting, and the sandblasting pressure was 0.6Mpa, the surface is uniform after sandblasting, and the surface roughness is 8μm. After sandblasting, use compressed air to blow off the residual sand particles on the surface of the base material;

[0046] 2) dry powder

[0047] The prepared NiCr-Cr 3 C 2Put the powder into a glass Petri dish, spread the powder flat, put it into a drying oven, set the drying temperature of the oven to 110°C for 4 hours, and remove exces...

Embodiment 2

[0054] The preparation method of the low-porosity, corrosion-resistant and wear-resistant nickel-chromium / chromium carbide cermet composite coating comprises the following steps:

[0055] 1) Substrate surface pretreatment

[0056] First, the base material 316L was polished with a polishing machine to remove the surface oxide skin while ensuring the surface smoothness of the base material; then, ultrasonic cleaning was performed with alcohol to remove surface oil; finally, 60-mesh white corundum was used for sandblasting, and the sandblasting pressure was 0.6Mpa, the surface is uniform after sandblasting, and the surface roughness is 8μm. After sandblasting, use compressed air to blow off the residual sand particles on the surface of the base material;

[0057] 2) dry powder

[0058] The prepared NiCr-Cr 3 C 2 Put the powder into a glass petri dish, spread the powder flat, put it into a drying oven, set the drying temperature of the oven to 100°C for 4 hours, and remove exce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Micro vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com