Hydro-generator provided with high-efficient oil-cooling bearings

A hydroelectric generator and oil cooling technology, applied in hydroelectric power generation, bearing components, shafts and bearings, etc., can solve problems such as high-temperature burning and scraping of tiles, time-consuming and labor-intensive processes, deformation of supporting tiles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

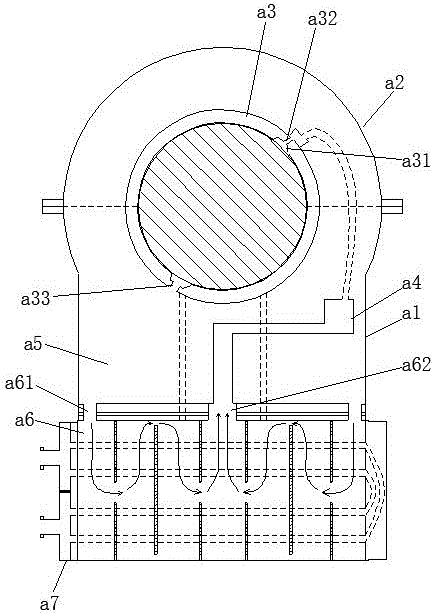

[0119] A hydroelectric generator with high-efficiency oil-cooled bearings, such as Figure 5 As shown, it includes a stator 101, a rotor 102, a main shaft 103, a fixed outer cover 104 and an oil-cooled bearing. The rotor 102 is coaxial with the main shaft 103, and the rotor 102 is fixed on the outer wall of the main shaft 103. The radially outer layer of the rotor 102 is the stator 101 , the stator 101 is coaxial with the fixed outer cover 104, the stator 101 is fixed on the inner wall of the fixed outer cover 104, the two sides of the fixed outer cover 104 are respectively the first cover opening 105 and the second cover opening 106, the first cover opening 105 and the second cover opening 106 Oil-cooled bearings are respectively installed on the two cover ports 106, and both ends of the main shaft 103 are installed in the oil-cooled bearings;

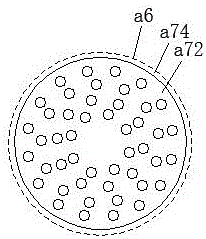

[0120] The oil-cooled bearings, such as Figure 6 and Figure 7 As shown, it includes bearing seat 1, bearing cover 2, shoe seat 3...

Embodiment 2

[0133] The difference from Embodiment 1 is that: Figure 19 As shown, the inner surface of the support shoe 41 includes at least two oil injection grooves 411 , and the oil injection grooves 411 are spirally distributed on the inner surface of the support shoe 41 . With the conventional oil tank structure, the oil film fracture is prone to occur in the area far away from the oil tank. The sliding friction of the oil film fracture zone produces large heat, the heat conduction speed is slow, and it is easy to cause the burning of the pads; this method can effectively prevent the fracture of the oil film between the bearing pad and the shaft body.

[0134] Using the implementation of the above example, it is used to test the support shoe 41 and the oil temperature of the bearing. After three hours of operation, the temperature of the support shoe 41 tends to be stable within 44.5°C, and the oil temperature tends to be stable at about 35°C.

Embodiment 3

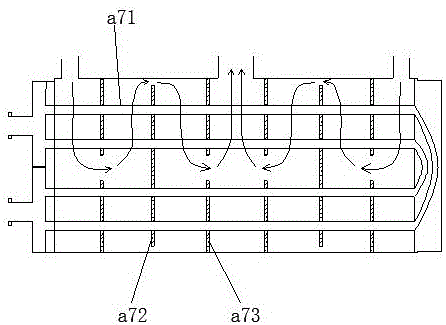

[0136] The difference from Embodiment 1 is that: Figure 20 As shown, the oil discharge groove 412 includes a first oil discharge groove 412a and a second oil discharge groove 412b, the first oil discharge groove 412a and the second oil discharge groove 412b are respectively located at the two ends of the oil injection groove 411, and the first oil discharge groove 412a is connected to the oil injection groove 412b. The distance between the oil grooves 411 is 30mm, the distance between the second oil discharge groove 412b and the oil injection groove 411 is 30mm, and the first oil discharge groove 412a is provided with an oil discharge hole 414, and the first oil discharge groove 412a passes through the oil discharge hole 414 and The first oil chamber 6 communicates, and the second oil discharge groove 412 b is a semi-open groove, directly communicating with the first oil chamber 6 .

[0137] Using the implementation of the above example, it is used to test the support shoe 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com