Double-way friction stir welding method for dissimilar material mismatching processing

A friction stir, dissimilar material technology, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of intermetallic compound welds, stirring head wear, poor weld formation, etc., to achieve simple processing and avoid friction Abrasion, not easy to wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

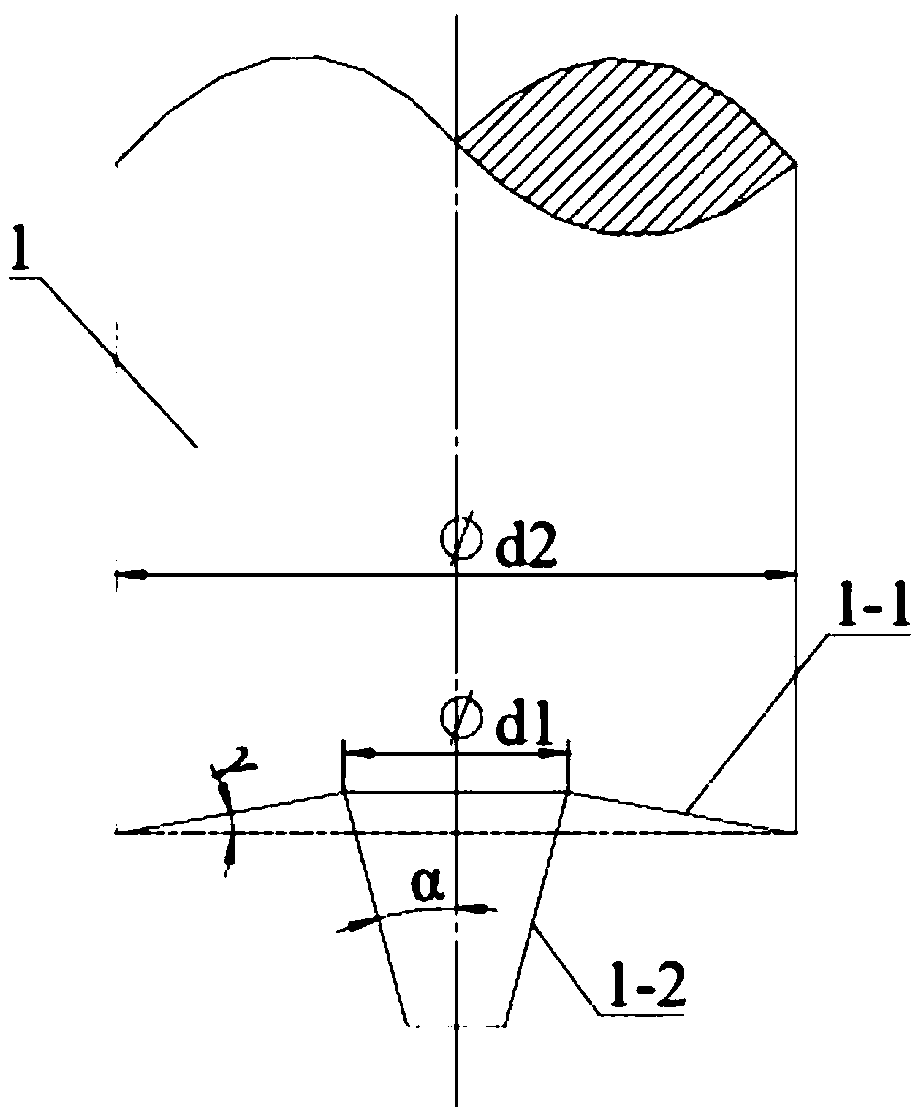

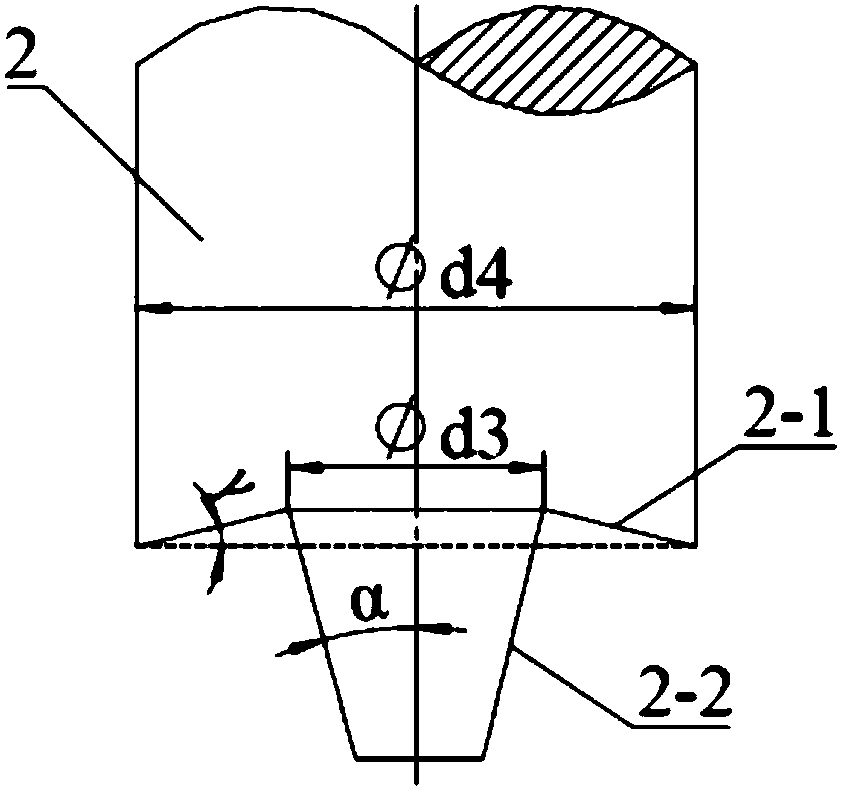

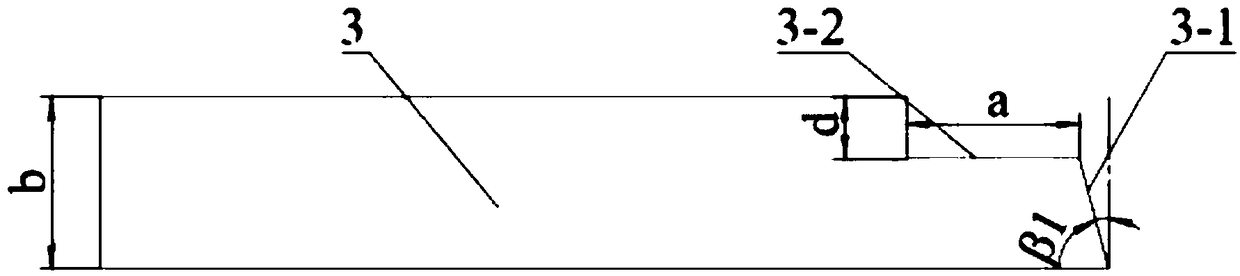

[0023] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this implementation mode, this implementation mode is realized through the following steps:

[0024] Step 1. Pre-processing before welding: before welding, the first base material 3 and the second base material 4 to be welded are processed before welding by mechanical milling, and the upper end face of the first base material 3 close to the butt joint is milled Step 3-2, the depth d of the step 3-2 is 0.3 mm ~ 0.5 mm, the width a of the step 3-2 is 4 mm ~ 14 mm, and the butt surface is processed into a right slope 3 with a right angle β1 with the vertical direction -1, the butt joint surface of the second base material 4 is processed into a left slope 4-1 forming a left angle β2 with the vertical direction;

[0025] Step 2. Cleaning the base material: After milling, first use ultrasonic cleaning to clean the first base material 3 and the second base material 4 to remove milling debris, and then us...

specific Embodiment approach 2

[0030] Specific implementation mode two: combination Figure 3 ~ Figure 6 To describe this embodiment, in this embodiment, in Step 1, the first base material 3 is steel or copper, and the second base material 4 is aluminum alloy or magnesium alloy. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three: combination image 3 and Figure 4 To describe this embodiment, in this embodiment, in Step 1, the original thickness b of the first base material 3 and the second base material 4 is 3 mm to 8 mm. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com