Metal reinforced retainer for main shaft bearing of liquid oxygen pump and preparation process of metal reinforced retainer

A spindle bearing, metal reinforcement technology, applied in the direction of shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems affecting the stable rotation and high-speed rotation ability of the cage, unfavorable heat dissipation and high-speed performance, and the reduction of the gap between the pocket hole and the steel ball. Small and other problems, achieve good high-speed performance, high dimensional stability, and avoid the effect of guiding gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

The detailed structure of this embodiment is described below in conjunction with the accompanying drawings:

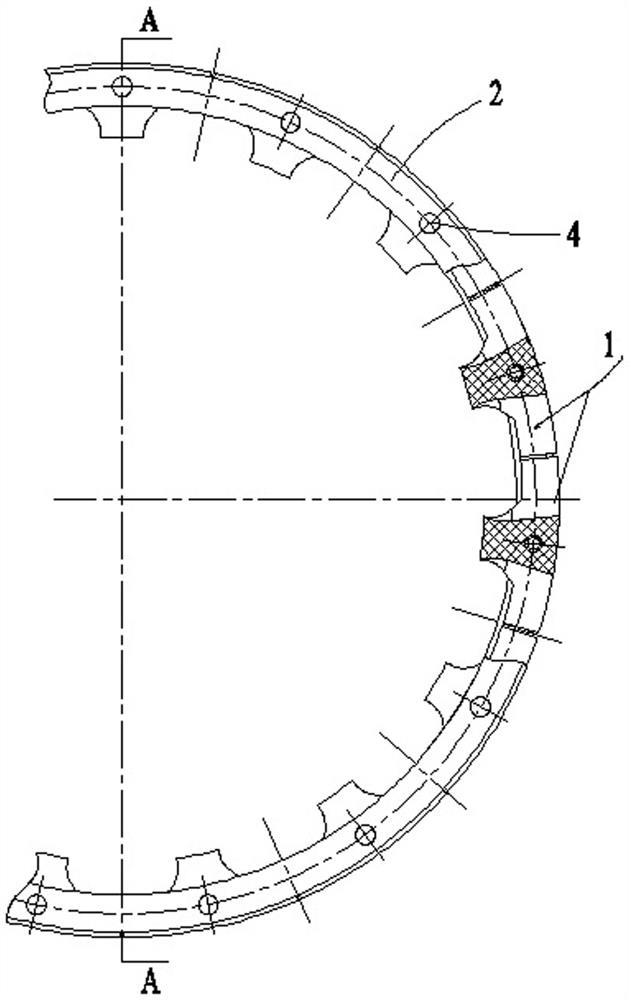

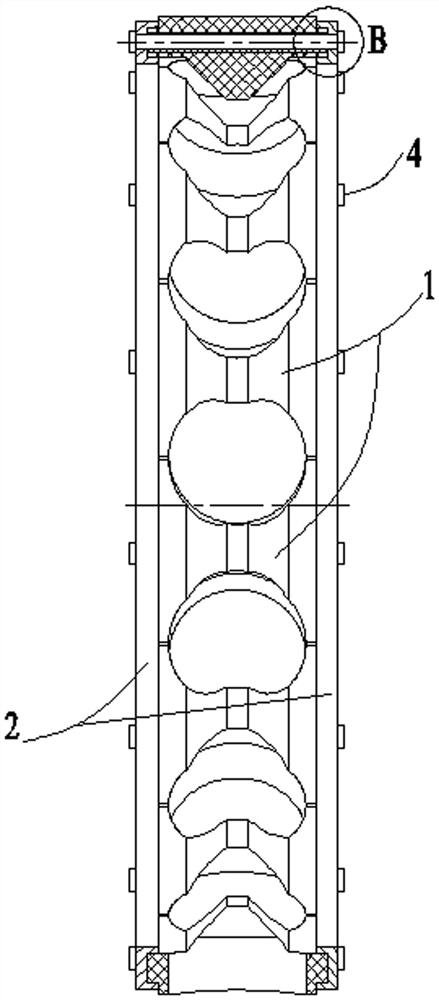

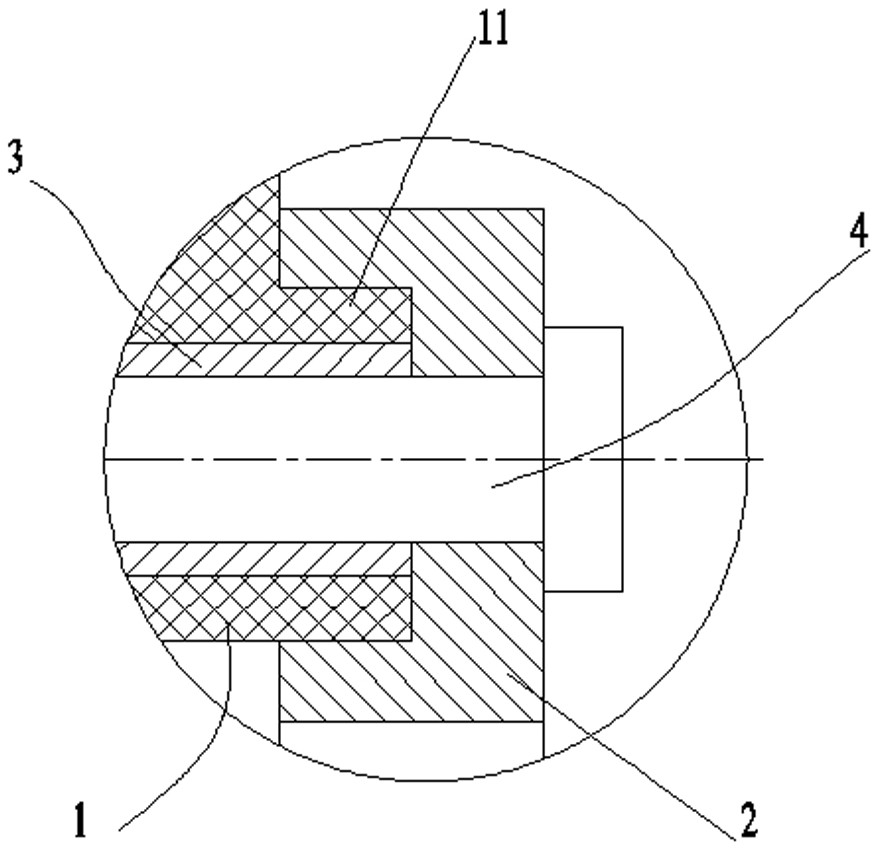

As shown in the figure, a metal reinforced cage for the main shaft bearing of a liquid oxygen pump is mainly composed of a number of cage blocks 1 made of PTFE material, a fixing ring 2 and a plurality of rivet sleeves 3 and rivets The rod 4 is composed of a plurality of cage blocks 1 made of polytetrafluoroethylene as a whole to form a ring-shaped cage body, and two fixing rings 2 are provided, which are respectively in the form of a ring structure and are fixed on the cage block 1. On the end faces on both sides of the annular cage body, the fixing ring can be made of metal material, each pocket is composed of two adjacent cage blocks 1, and the two sides of each cage block 1 are respectively provided with convex positioning structures 11. The end face of the fixing ring 2 is evenly provided with a limiting groove whose shape matches the convex positioning structure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com