Patents

Literature

81results about How to "Good for high speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Noise adding signal synchronization clock extraction device based on FPGA (field programmable gate array)

InactiveCN102611447AImprove noise immunityGood for high speedPulse automatic controlFinite impulse responseLow-pass filter

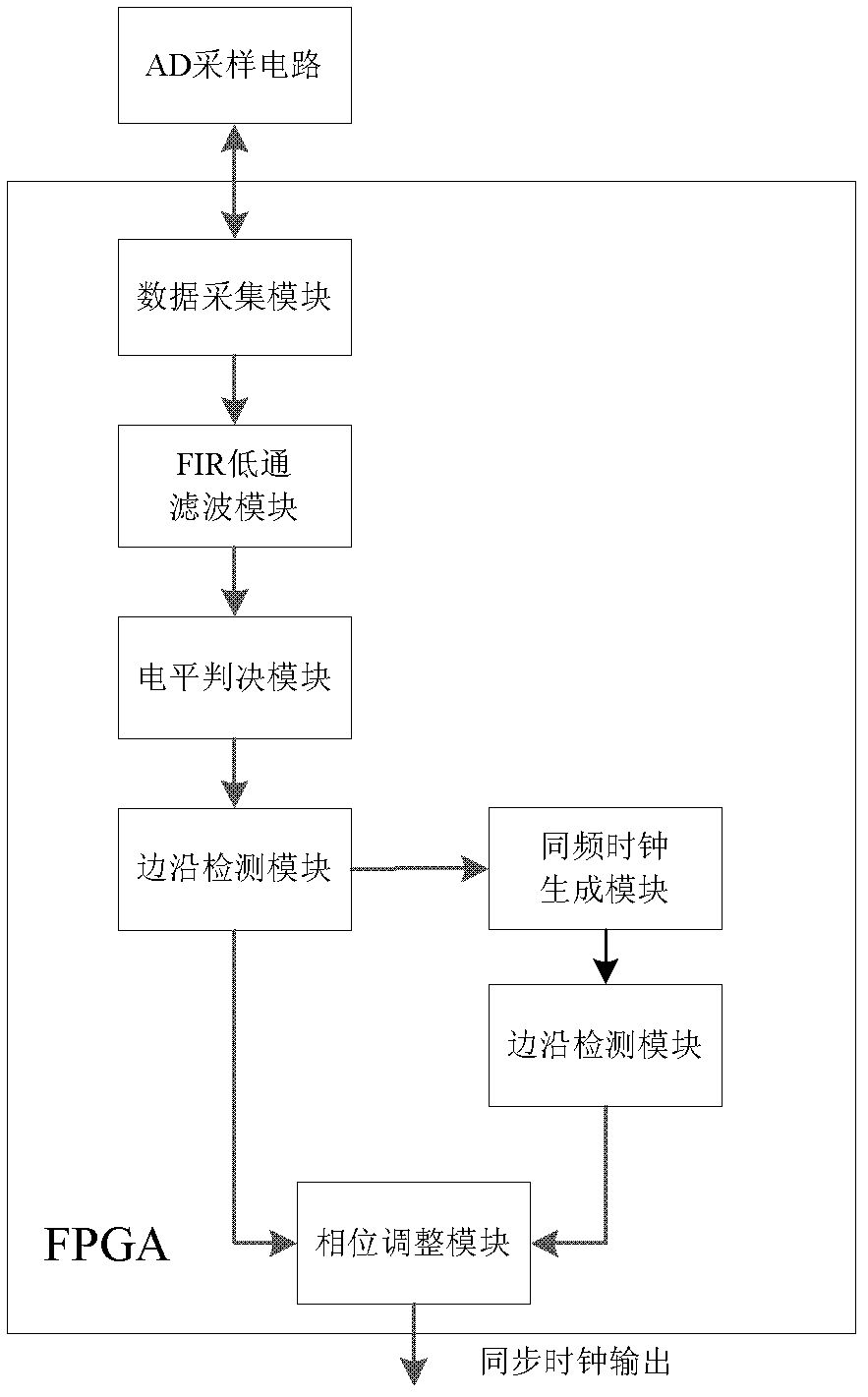

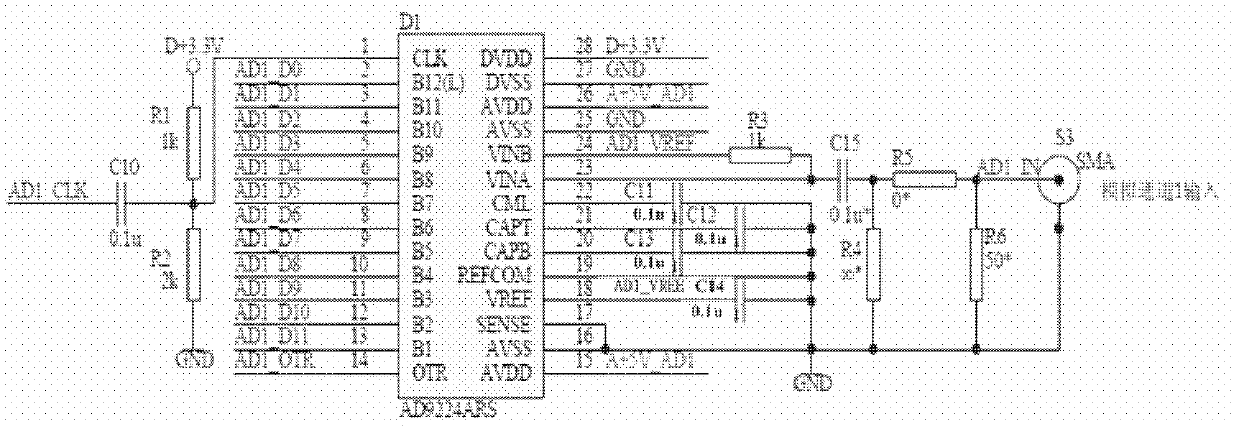

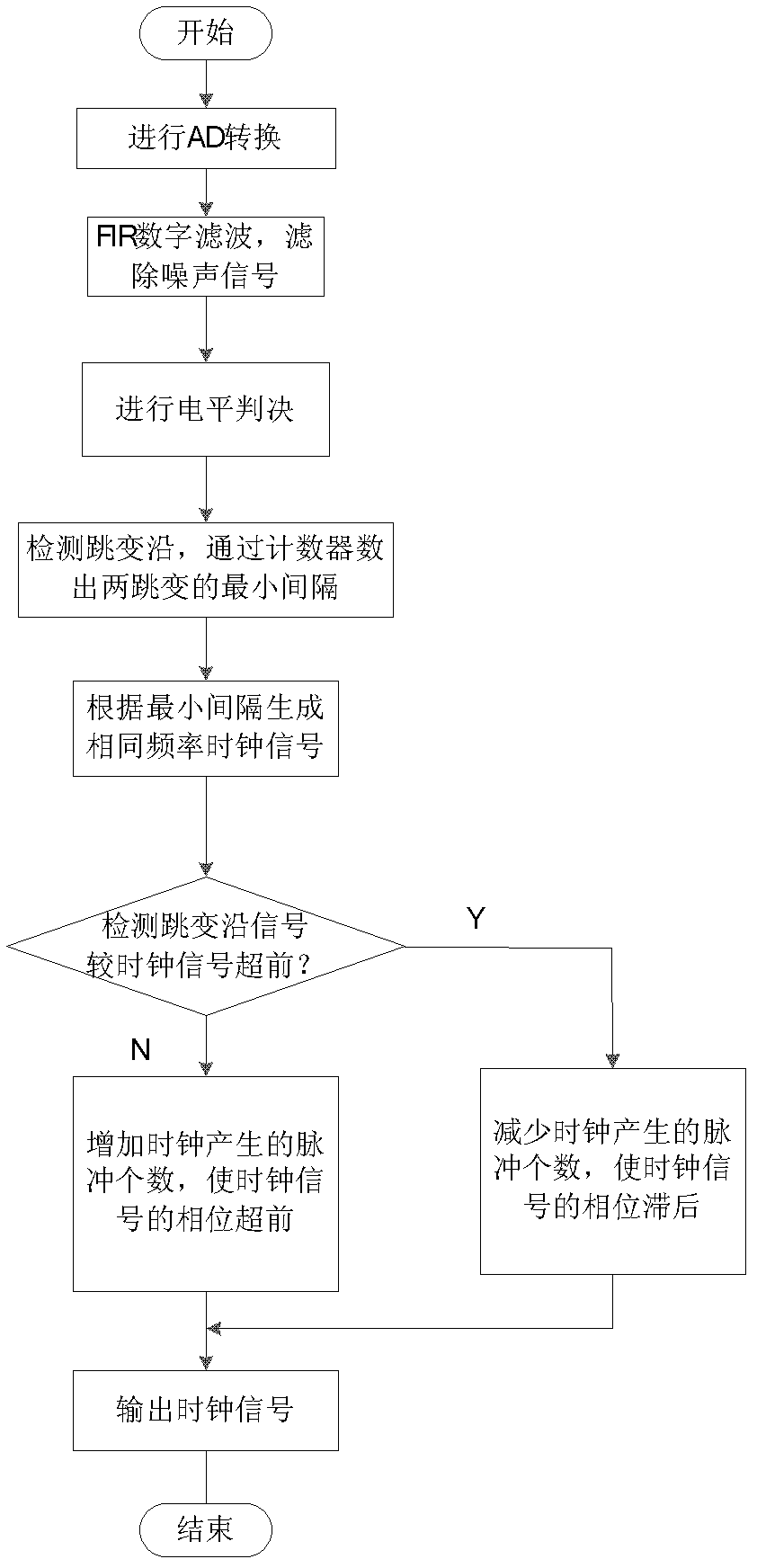

The invention discloses a noise adding signal synchronization clock extraction device based on an FPGA (field programmable gate array), belonging to the field of communication control. The noise adding signal synchronization clock extraction device comprises an AD (analog-digital) sampling circuit, a data acquisition module, an FIR (finite impulse response) low-pass filter module, a level judgment module, an edge detection module, a common-frequency clock generation module and a phase adjusting module, wherein the data acquisition module, the FIR (finite impulse response) low-pass filter module, the level judgment module, the edge detection module, the common-frequency clock generation module and the phase adjusting module are realized in the FPGA. According to the noise adding signal synchronization clock extraction device based on the FPGA, both data acquisition and data processing are realized by hardware, and the advantage of hardware acceleration is brought into full play; and on an FPGA platform, a verilog language is used for programming, a system is modularized, a 150-order FIR low-pass filter is designed, the rising and falling edges of a filtered signal are detected, a cycle of a synchronized signal is obtained, then the synchronized signal is extracted by a synchronizing phase, and the advantages of good noise resistance, high speed and high precision of the system are achieved.

Owner:NORTHEASTERN UNIV

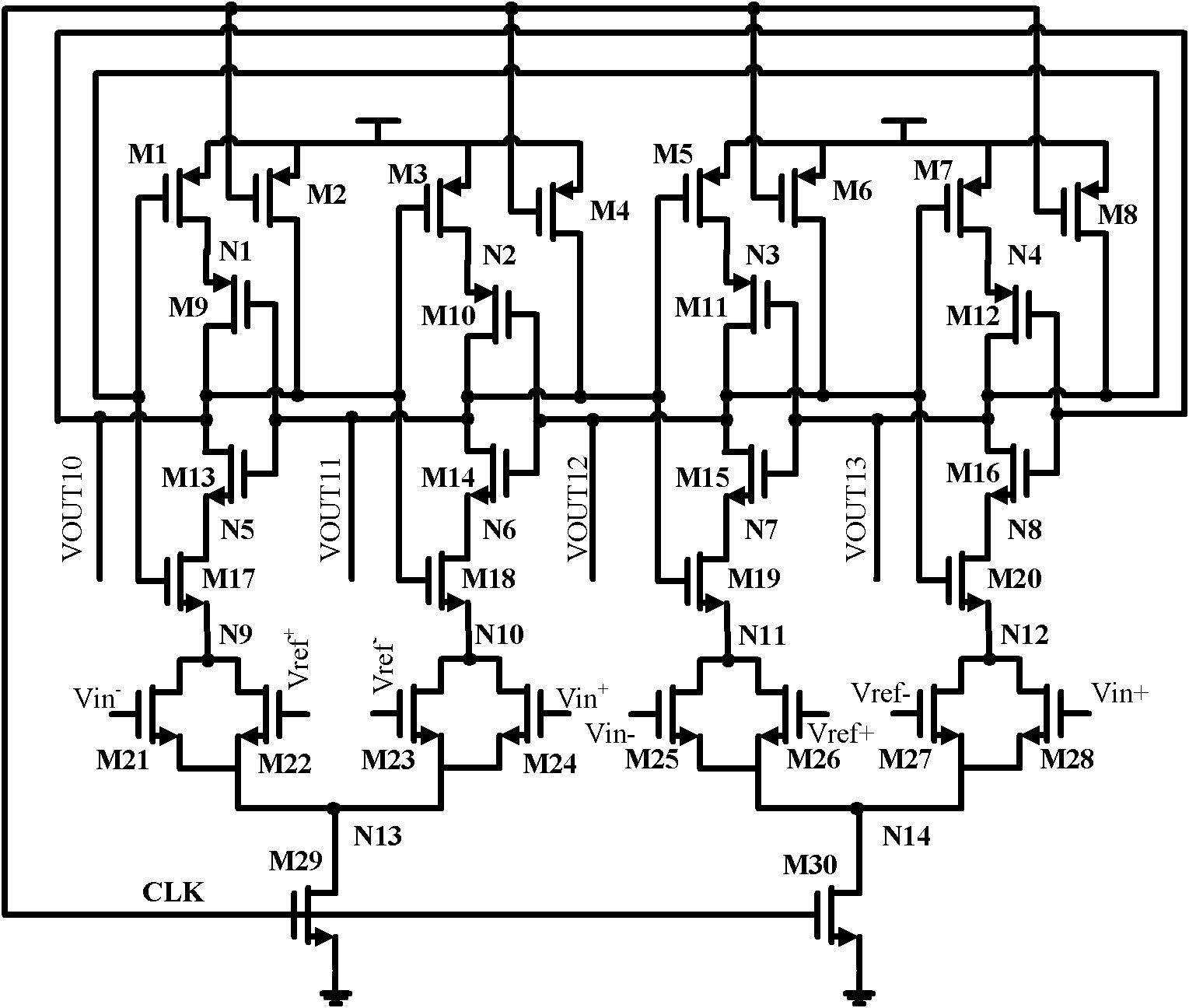

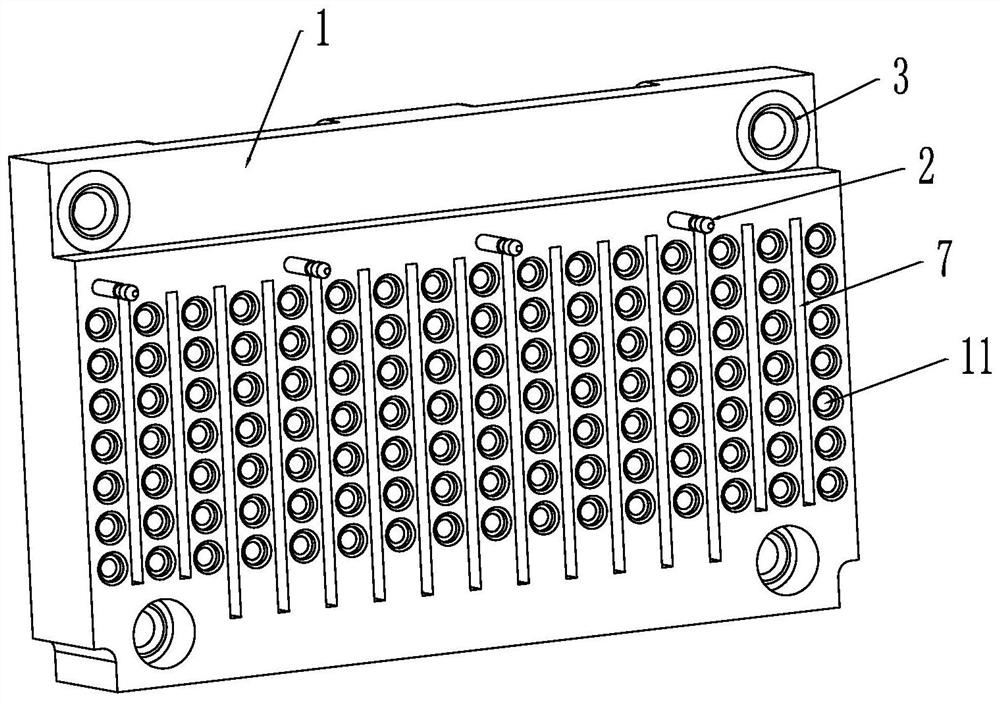

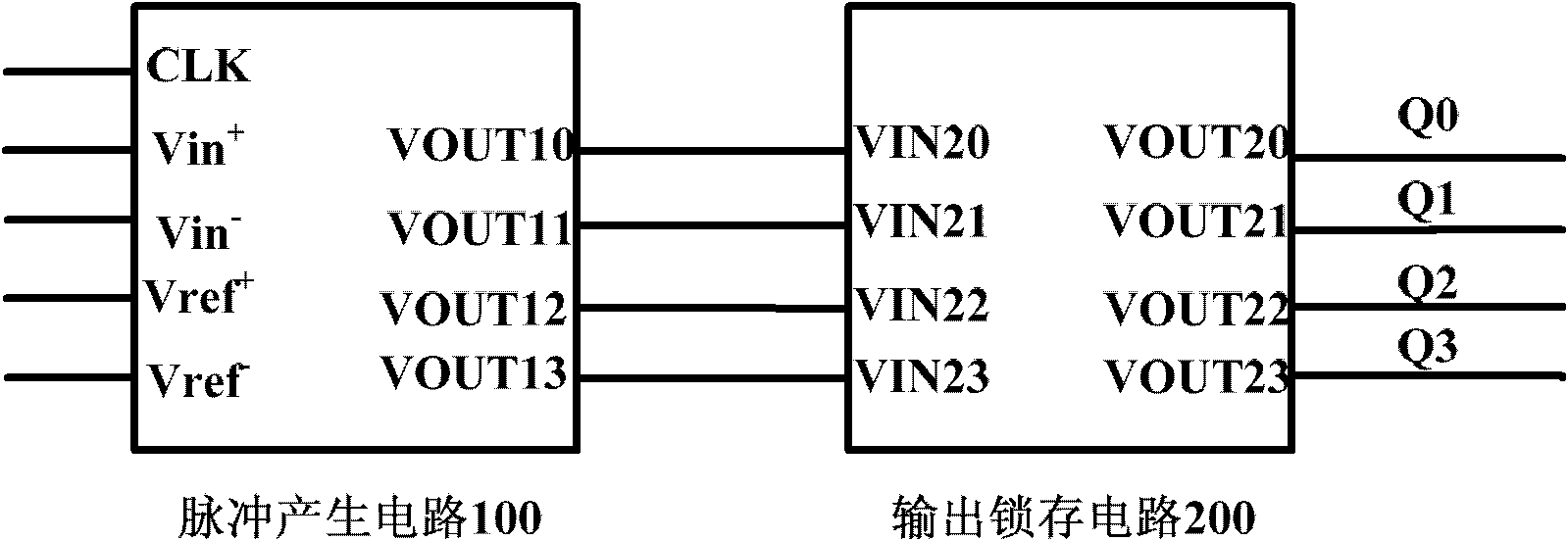

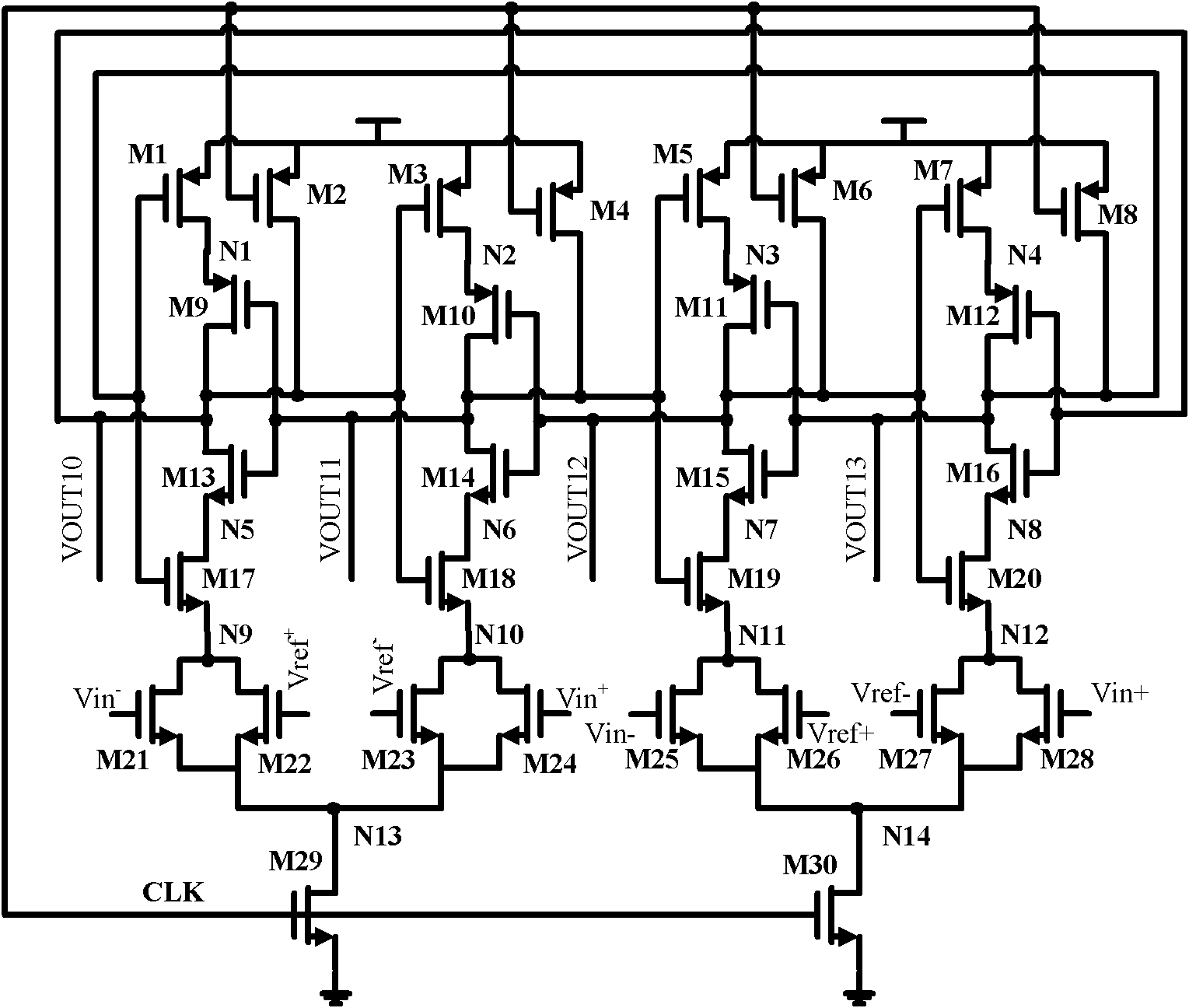

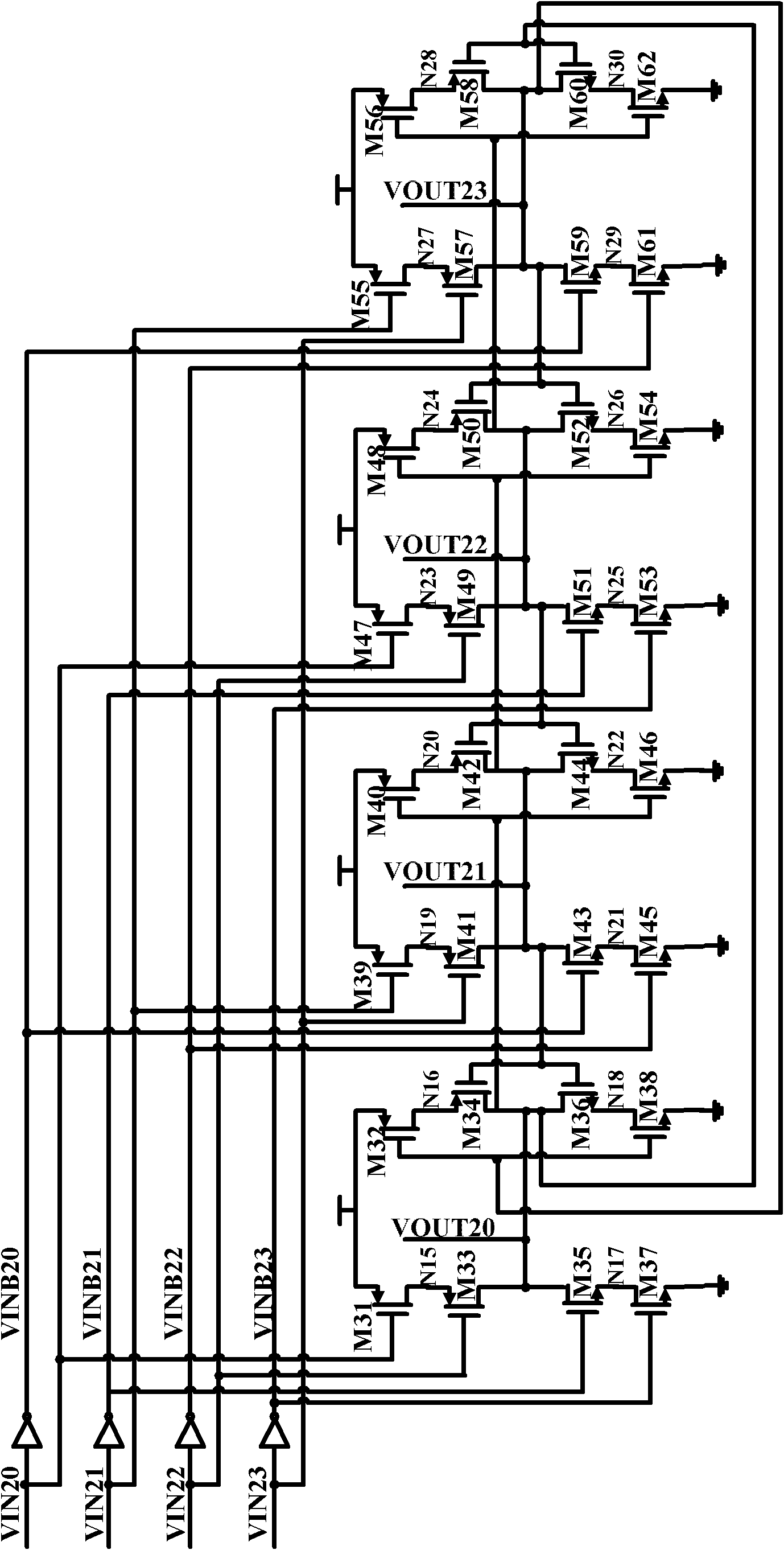

SEU (single event upset)/SET (single event transient)-resistant dynamic comparator

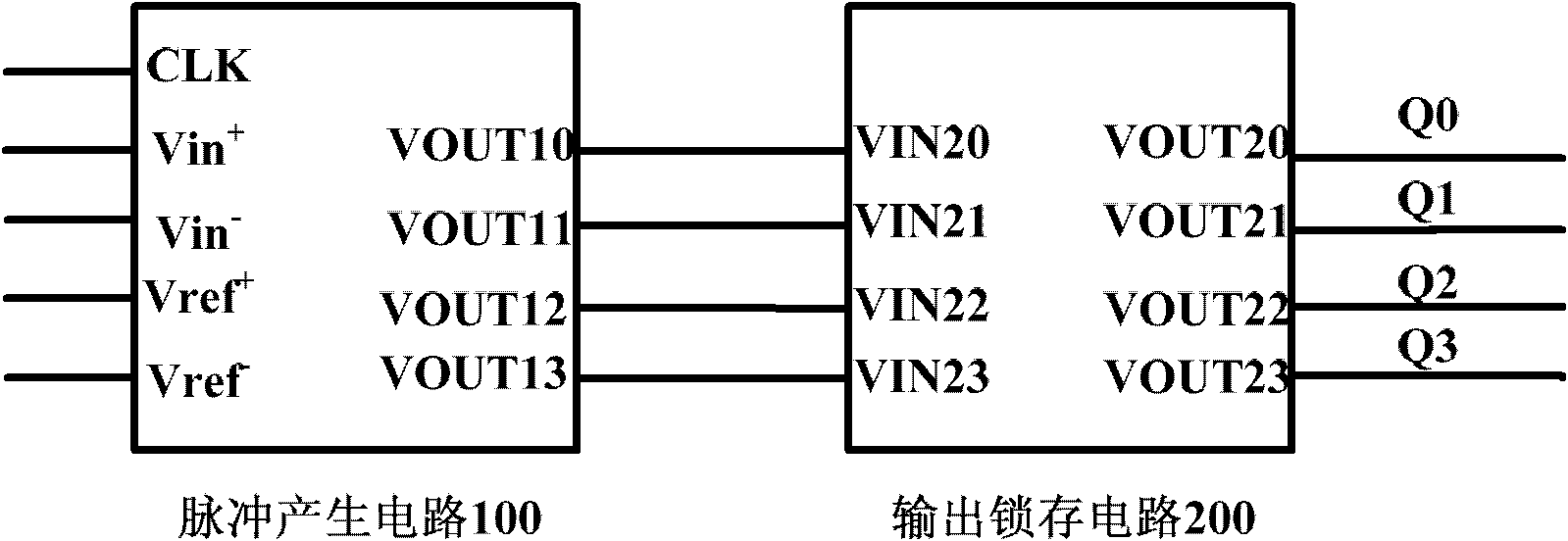

InactiveCN102025351AReduce power consumptionReduced power consumption performance,Multiple input and output pulse circuitsAudio power amplifierClock network

The invention discloses an SEU (single event upset) / SET (single event transient)-resistant dynamic comparator, which comprises a pulse generating circuit based on a sensitive amplifier structure and an output latch circuit; the top of the whole comparator is provided with five input ports and four output ports outwards, the five input ports are respectively connected with clock signals, input signals and reference voltage signals, and the output ports are connected with data output signals; the pulse generating circuit is connected with the clock signals, the input signals, the reference voltage signals and the output latch circuit; and the output latch circuit is connected with the pulse generating circuit and the data output signals. The dynamic comparator has the advantages that the upset threshold LETth is greater than 500MeV / (mg.cm2); the time delay is reduced while the high-speed low power consumption of the SEU / SET-resistant dynamic comparator same as that of a traditional dynamic comparator is achieved; the symmetrical arrangement, equal time delay and same drive capacity of complementary output terminals Q and QB are realized; by adopting the sensitive amplifier structure, the clock network is simple, reliable and small in load; and by adopting the minor clock swing technology, the power consumption is obviously reduced.

Owner:XI AN JIAOTONG UNIV

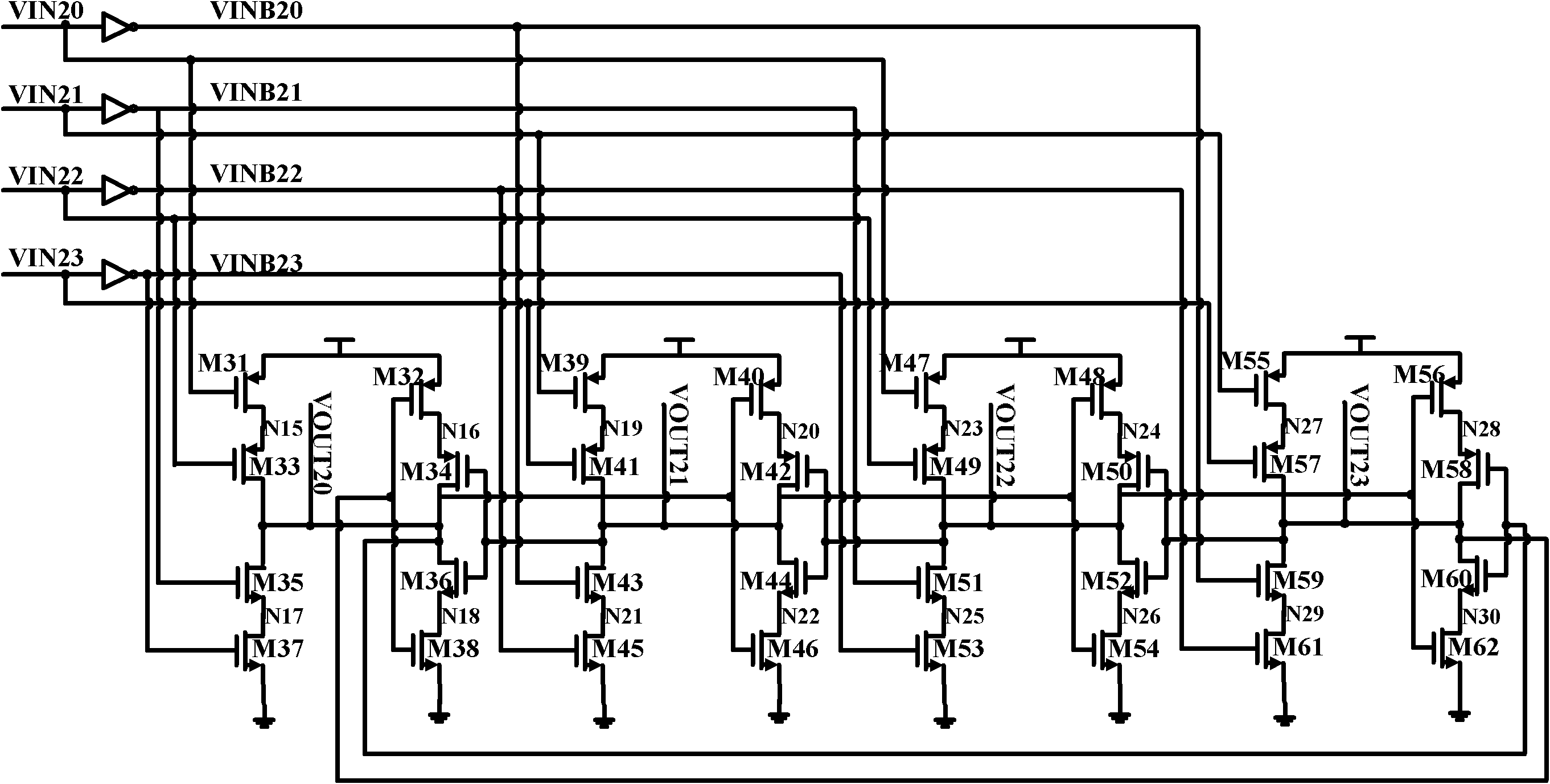

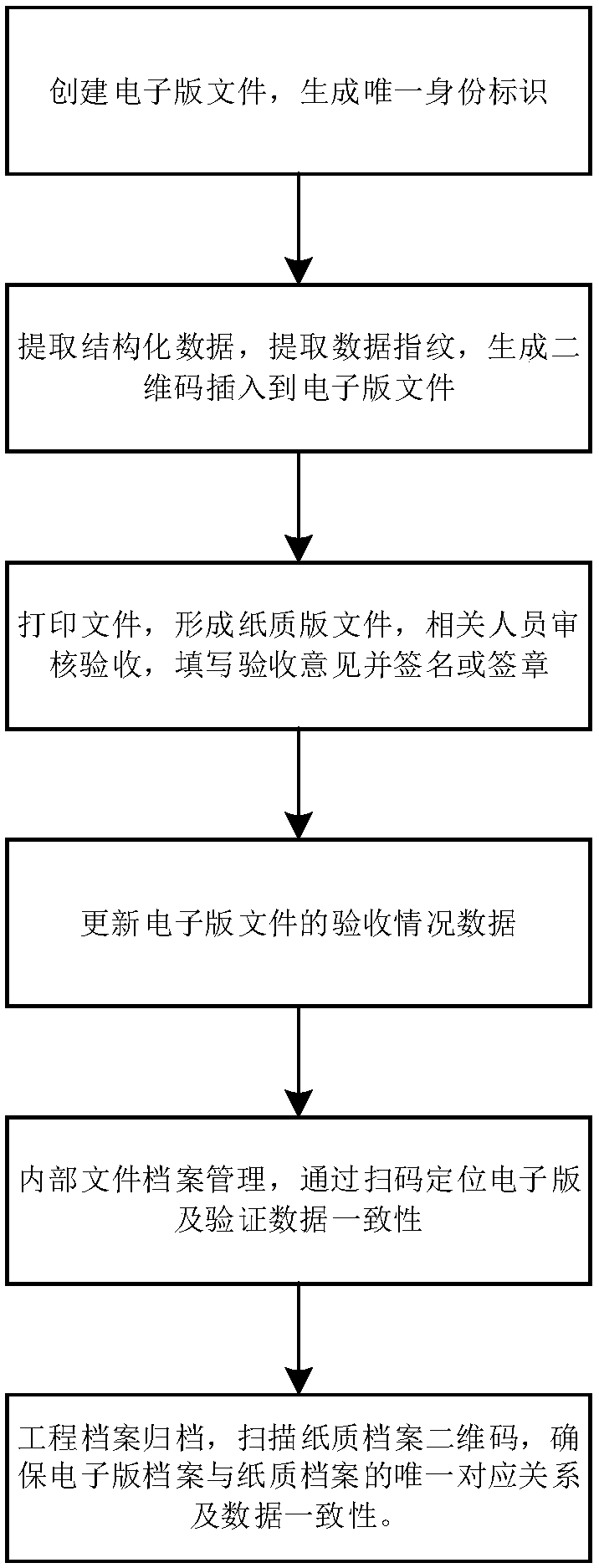

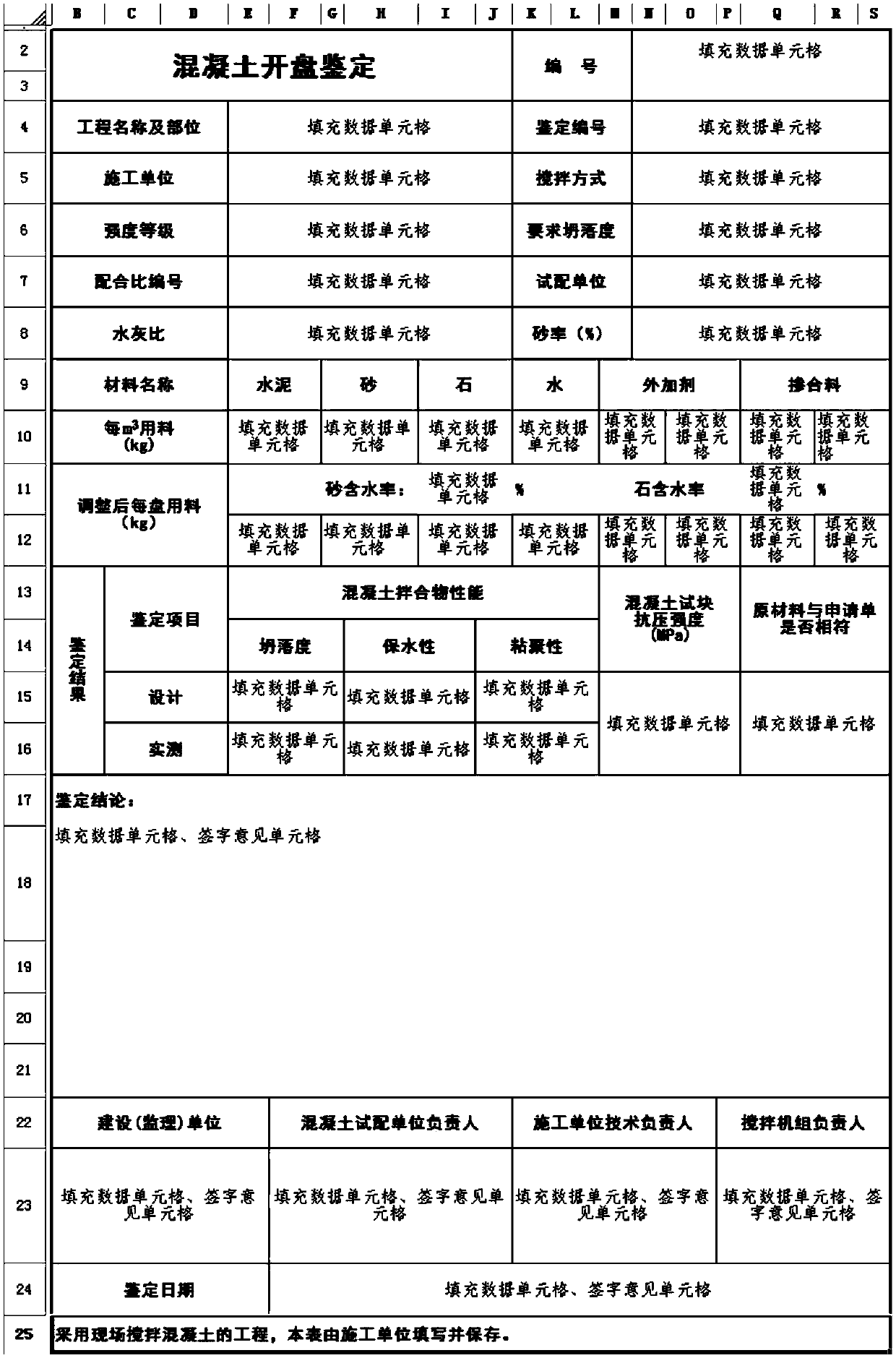

File management method and system

InactiveCN107729576APrecise positioningGood for high speedOffice automationSpecial data processing applicationsData ingestionElectronic document

The invention relates to a file management method and system. The file management method comprises the following steps that electronic documents of files are created, electric document identifiers uniquely corresponding to the electronic documents are automatically generated by the system and are used for conducting identity identification on the electronic documents; electronic document content is filled, the electronic documents are stored, data filled in the electronic documents are extracted as structural data through an electronic document structural data extracting algorithm; the secondary data in the extracted structural data are removed, main data in the documents is retained, and data fingerprints are generated through a fingerprint extracting algorithm; the data fingerprints andthe electric document identifiers are utilized to generate standard identification codes, and the standard identification codes are inserted into the electronic documents; the structural data and theelectronic documents are synchronously stored in a background database. The high speed and accuracy of matching with electric documents of paper documents can be improved, the integrity, accuracy andconsistency with paper documents of data are ensured.

Owner:北京筑业志远软件开发有限公司

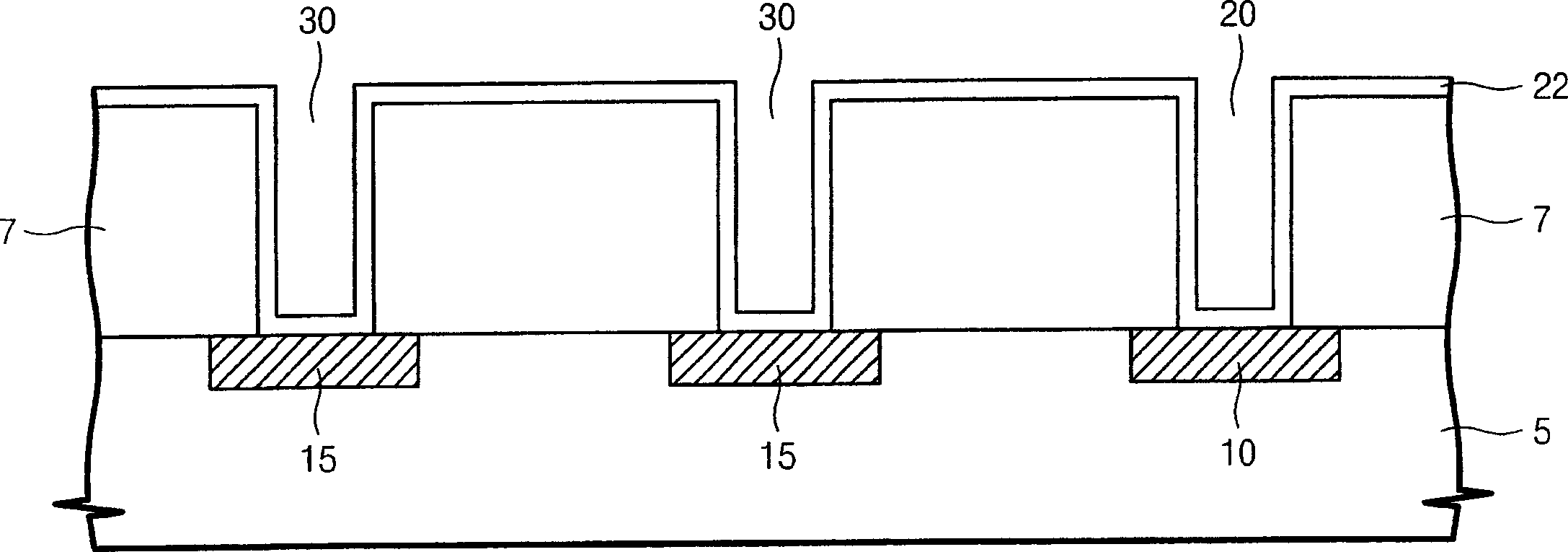

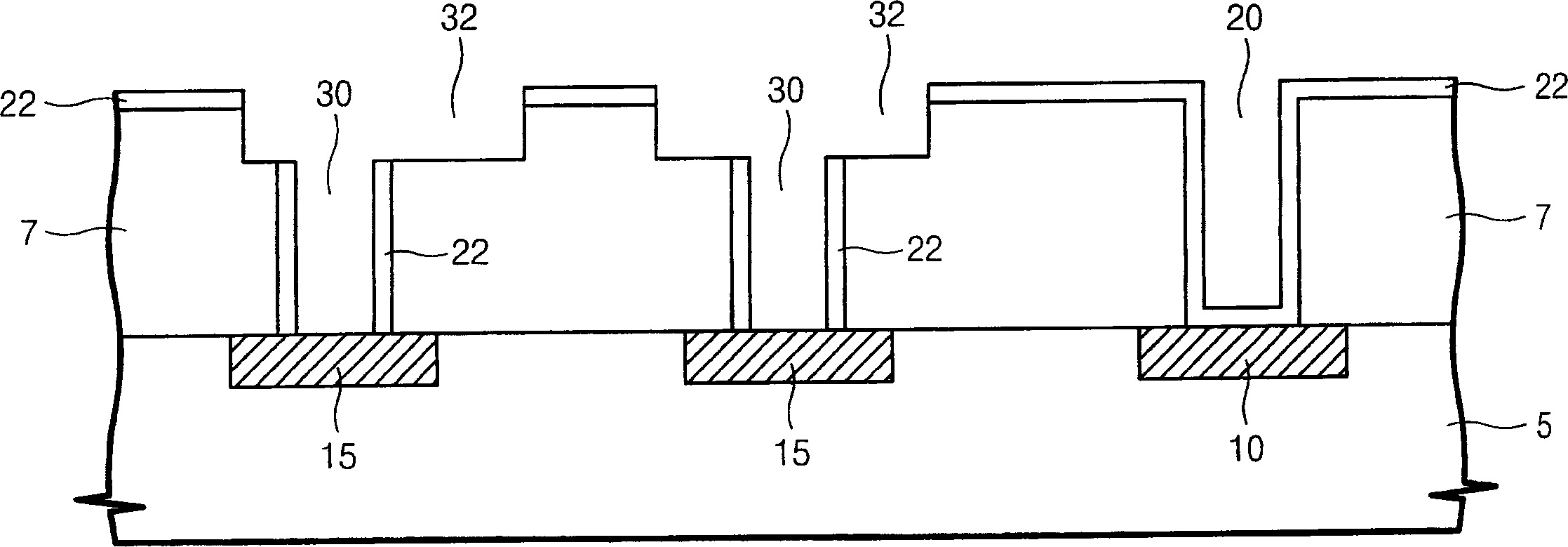

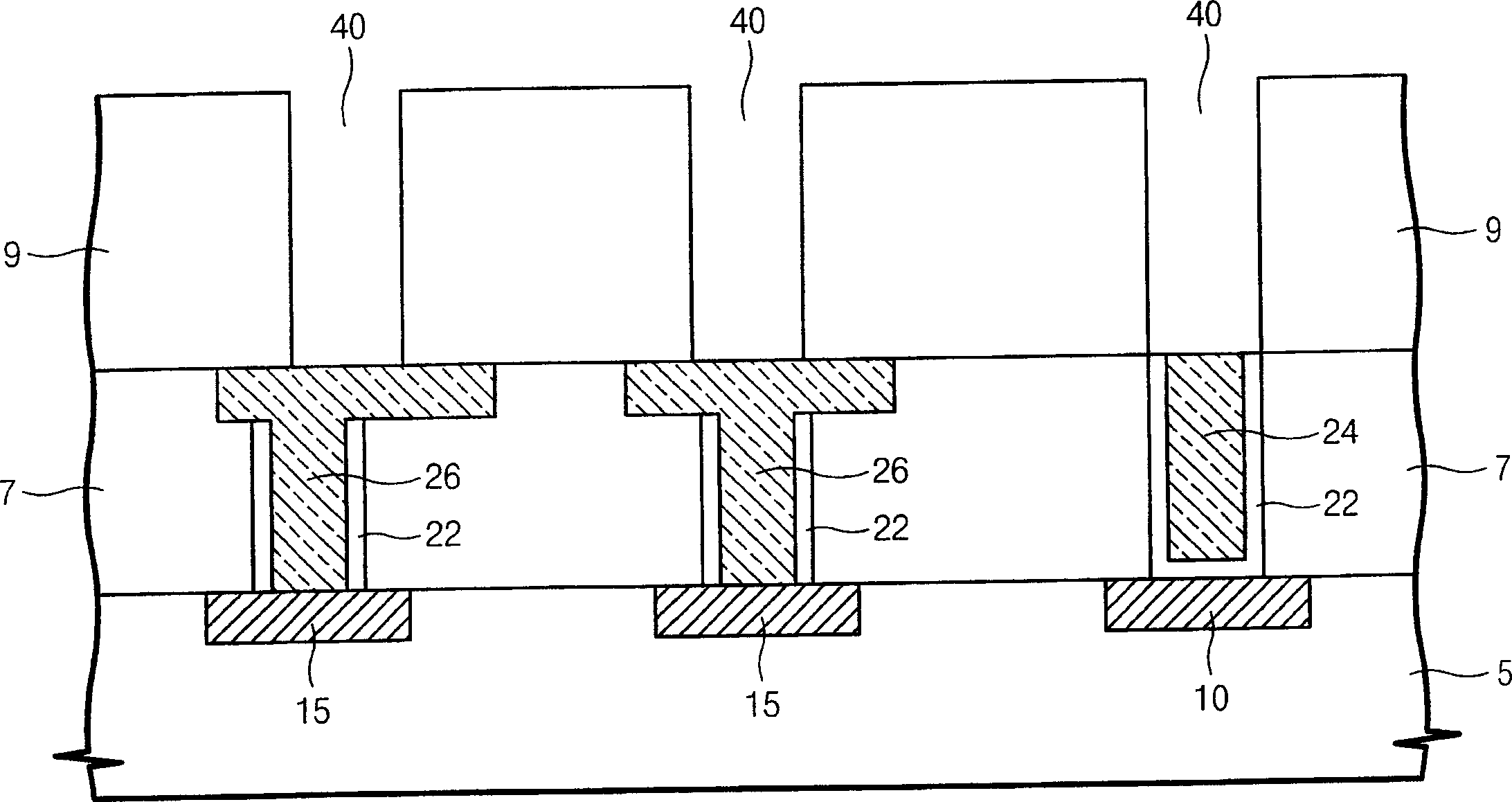

Semiconductor device with analog capacitor

InactiveCN1453875AGood for high speedImprove high frequency performanceTransistorSemiconductor/solid-state device detailsEngineeringDielectric layer

The invention discloses a semiconductor device with an analog capacitor and a manufacturing method thereof. A semiconductor device includes a bottom plate electrode formed on a predetermined region of a semiconductor substrate, and an upper plate electrode having a region overlapped by the bottom plate electrode thereon. Metal compounds are used to form the top and bottom plate electrodes. A capacitor dielectric layer is sandwiched between the bottom and top plate electrodes. The bottom and upper electrode plugs are connected to the bottom and upper plate electrodes through an interlayer dielectric layer. According to the method of the present invention, a bottom plate electrode is formed in a predetermined region of a semiconductor substrate. The upper plate electrode is formed to have a region overlapped by the bottom plate electrode, and a capacitor dielectric layer sandwiched between the bottom and upper plate electrodes is formed. An interlayer dielectric layer is formed on the entire surface of the semiconductor substrate on which the upper plate electrode is formed. Bottom and upper electrode plugs connected to the bottom and upper plate electrodes through the interlayer dielectric layer are formed. Metal compounds are used to form bottom and top plate electrodes.

Owner:SAMSUNG ELECTRONICS CO LTD

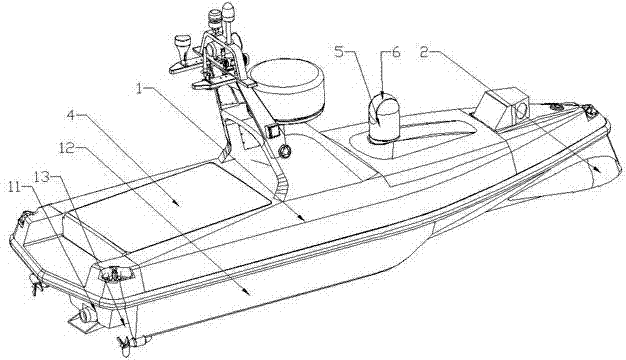

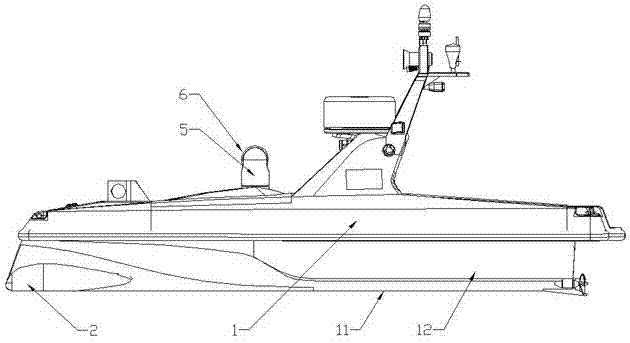

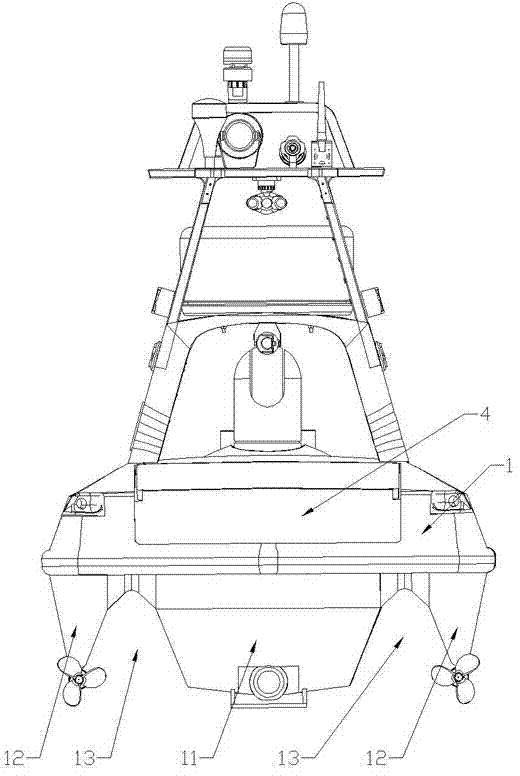

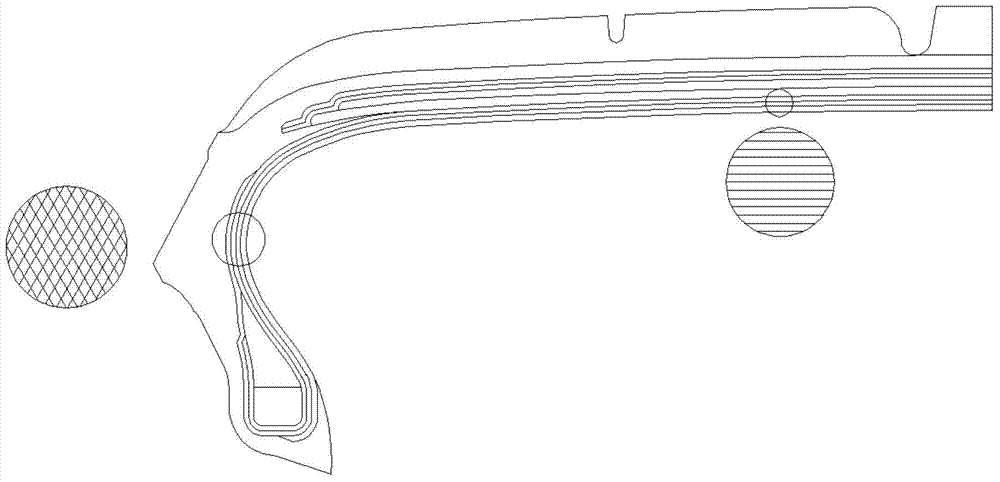

High speed shallow draft triple-hulled vessel with bulbous bow and system with the same

ActiveCN104494776AReduce bow waveSlow down the slapHull stemsHydrodynamic/hydrostatic featuresBreaking waveMain vessel

The invention provides a high speed shallow draft triple-hulled vessel with a bulbous bow which is low in powder, small in wave making resistance, good in navigability, high in stability and not has the bow diving phenomenon when breaking wave, and an unmanned vehicle system containing the triple-hulled vessel. The triple-hulled vessel comprises a vessel body, the vessel body comprises a main vessel and two symmetrical auxiliary vessels which are arranged on the two sides of the main vessel, a vertically perforated wave damping gas passage is arranged between the two auxiliary vessels and the main vessel, the bulbous bow is arranged on the bow part of the main vessel; and an instrument chamber is arranged on a water glider main body and provided with a communication system, a control system and a sampling system. The system also comprises a ground base station, the control system communicates with the ground base station by the communication system, and the control system controls the sampling system to sample and upload the sample data to the ground base station and performs the communication control on the communication system. The invention can be applied to the technical field of vessels.

Owner:ZHUHAI YUNZHOU INTELLIGENCE TECH COMPANY

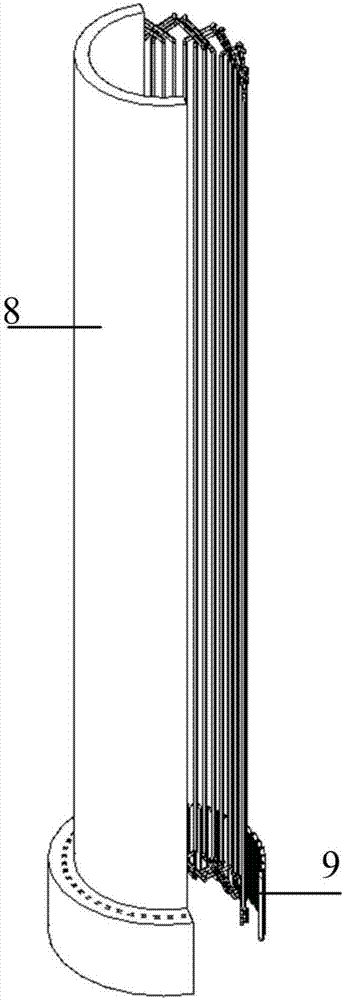

Low-loss and high-speed integrated flywheel energy storage motor

ActiveCN107482841AReduce lossHarmonic reductionMechanical energy handlingSpiral groove bearingFlywheel energy storage

The present invention discloses a low-loss and high-speed integrated flywheel energy storage motor. The motor comprises a flywheel outer rotor, an excitation permanent magnet, an inner rotor, a motor bearing and a hollow core stator. The flywheel outer rotor is configured to store energy when rotation, the excitation permanent magnet is pasted at the surface of the inner side of the flywheel outer rotor to supply an excitation field for a motor; the hollow core stator is arranged between the inner rotor and the flywheel outer rotor, the air-gap winding in the hollow core stator is arranged along the direction of a rotation shaft, the motor bearing comprises a magnetic suspension bearing and a spiral groove bearing, the bottom of the inner rotor is connected with the rotation portion of the spiral groove bearing, and the upper portion of the boss of the inner rotor is connected with the rotation portion of the magnetic suspension bearing. The low-loss and high-speed integrated flywheel energy storage motor employs a mode of combination of an outer rotor structure, the excitation permanent magnet, the air-gap winding, the passive magnetic suspension bearing and the spiral groove bearing to allow the motor to reach low loss while high-speed operation and zero load energy storage maintenance.

Owner:中能(深圳)能源科技发展有限公司

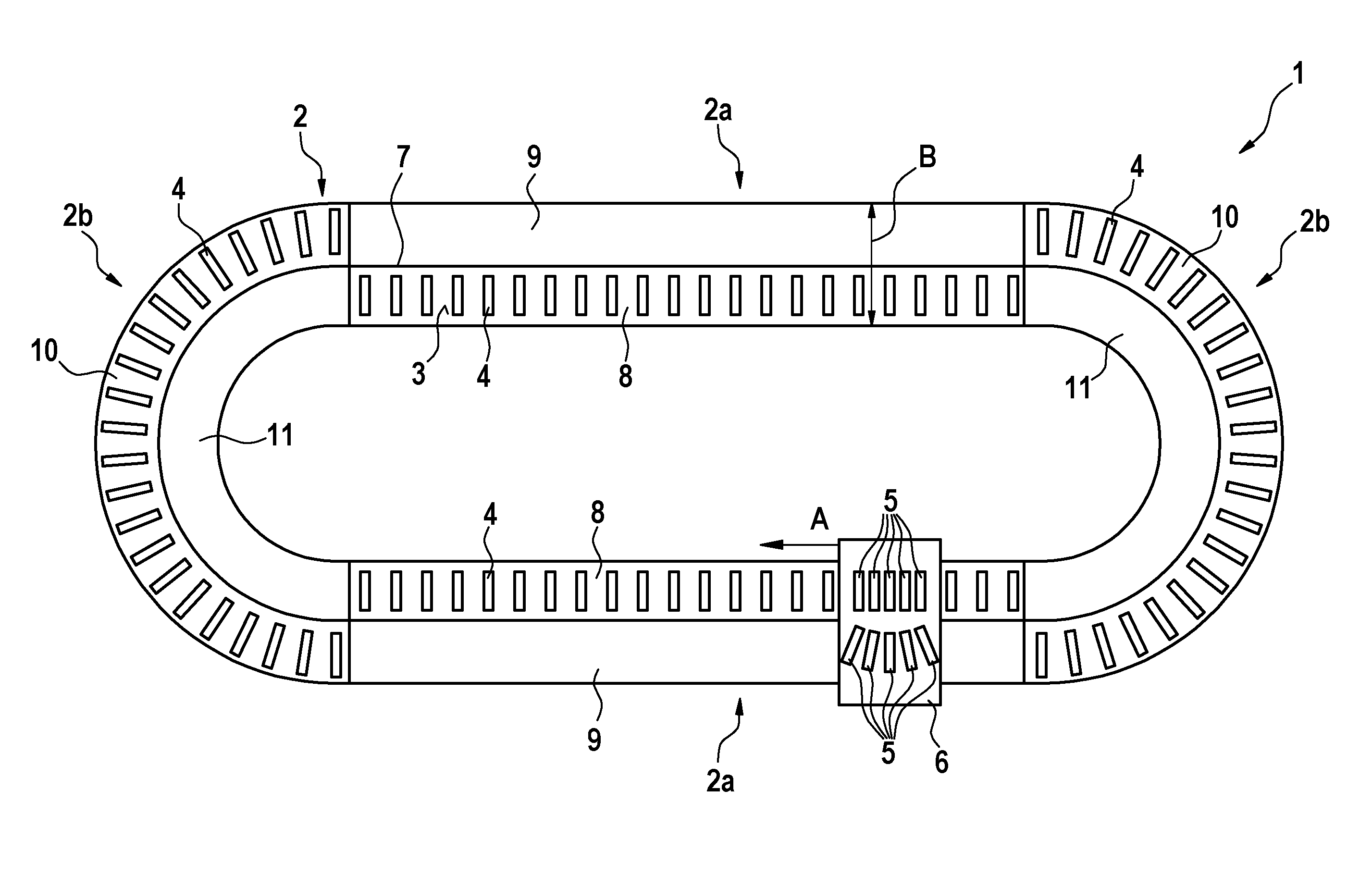

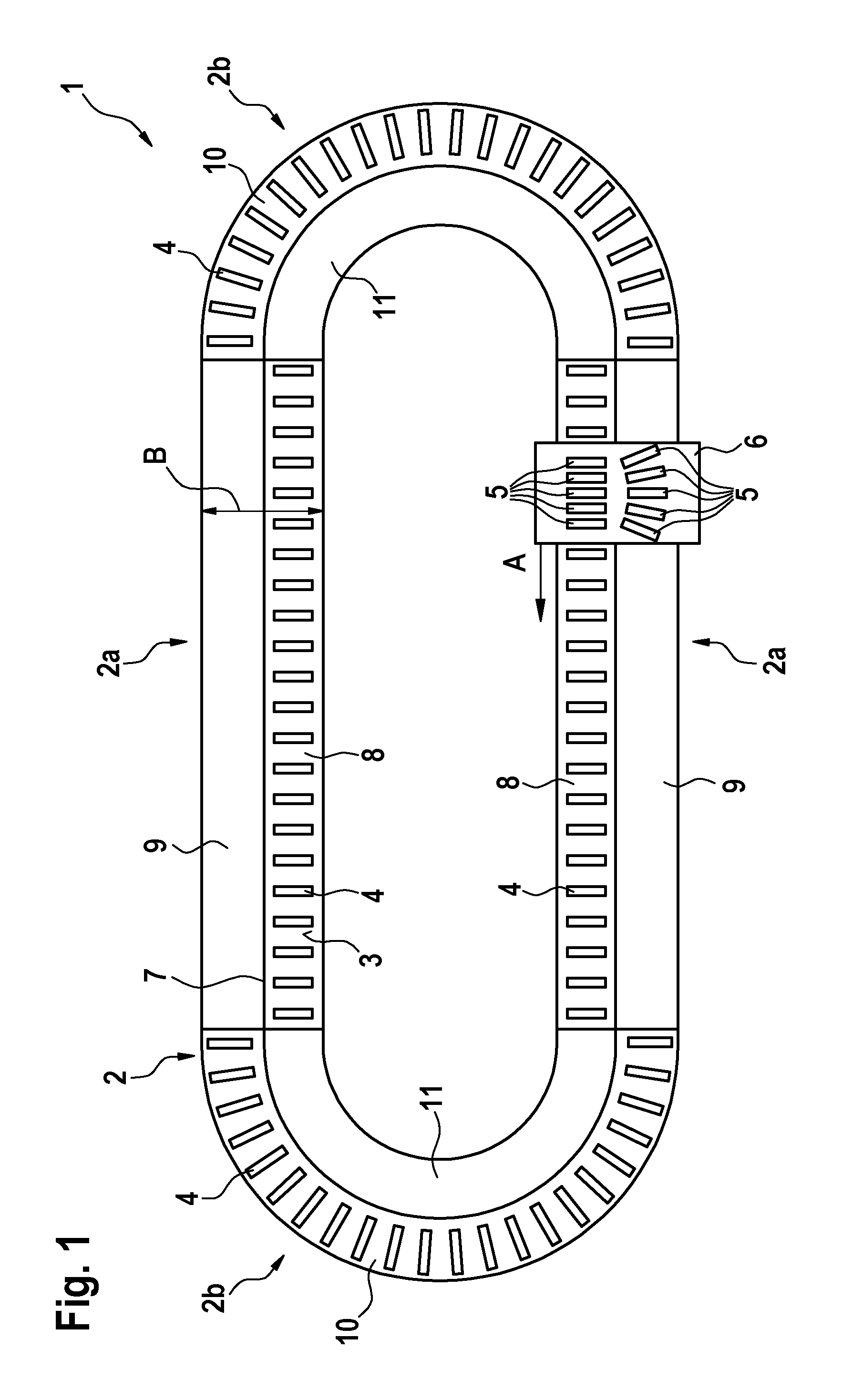

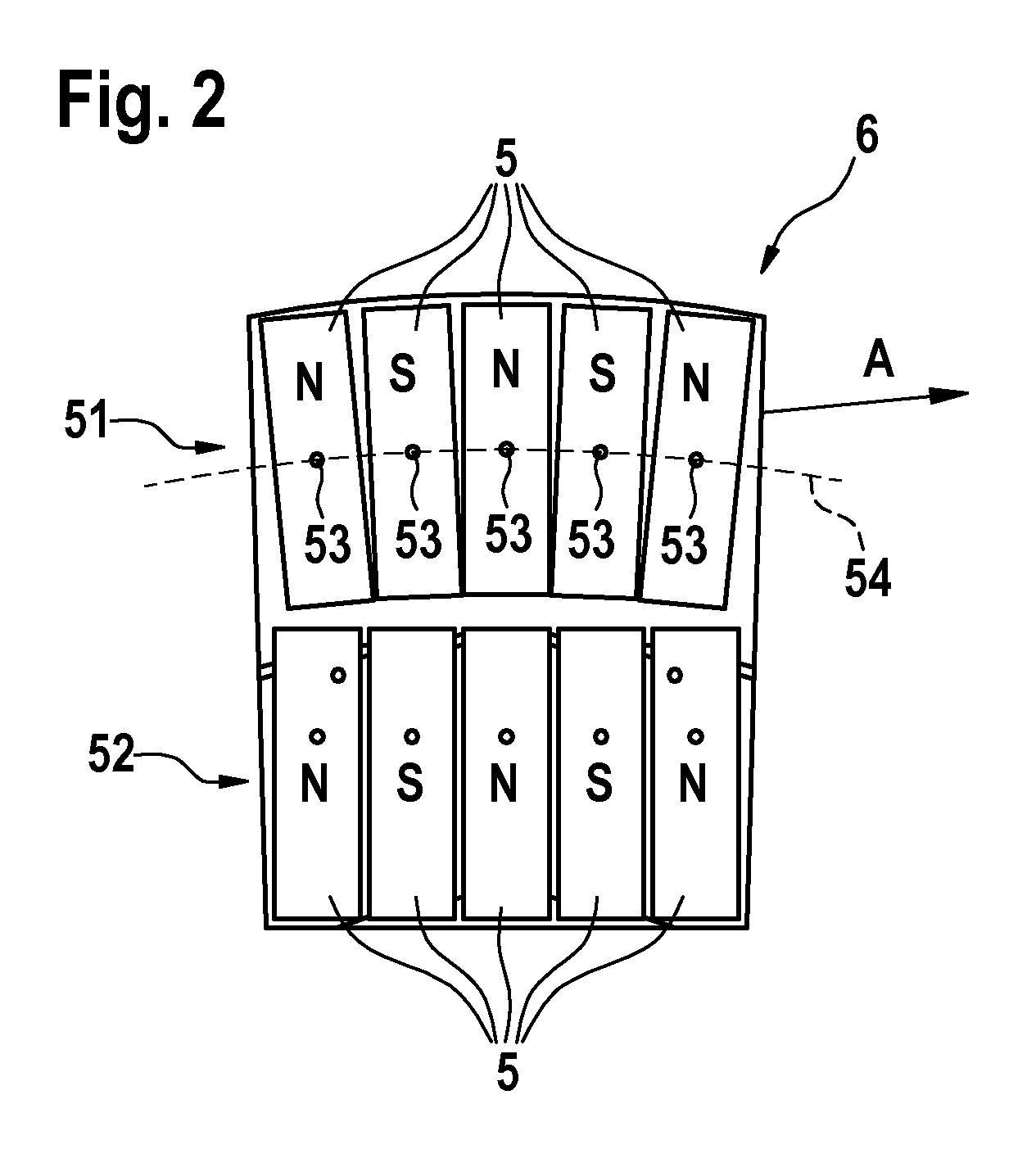

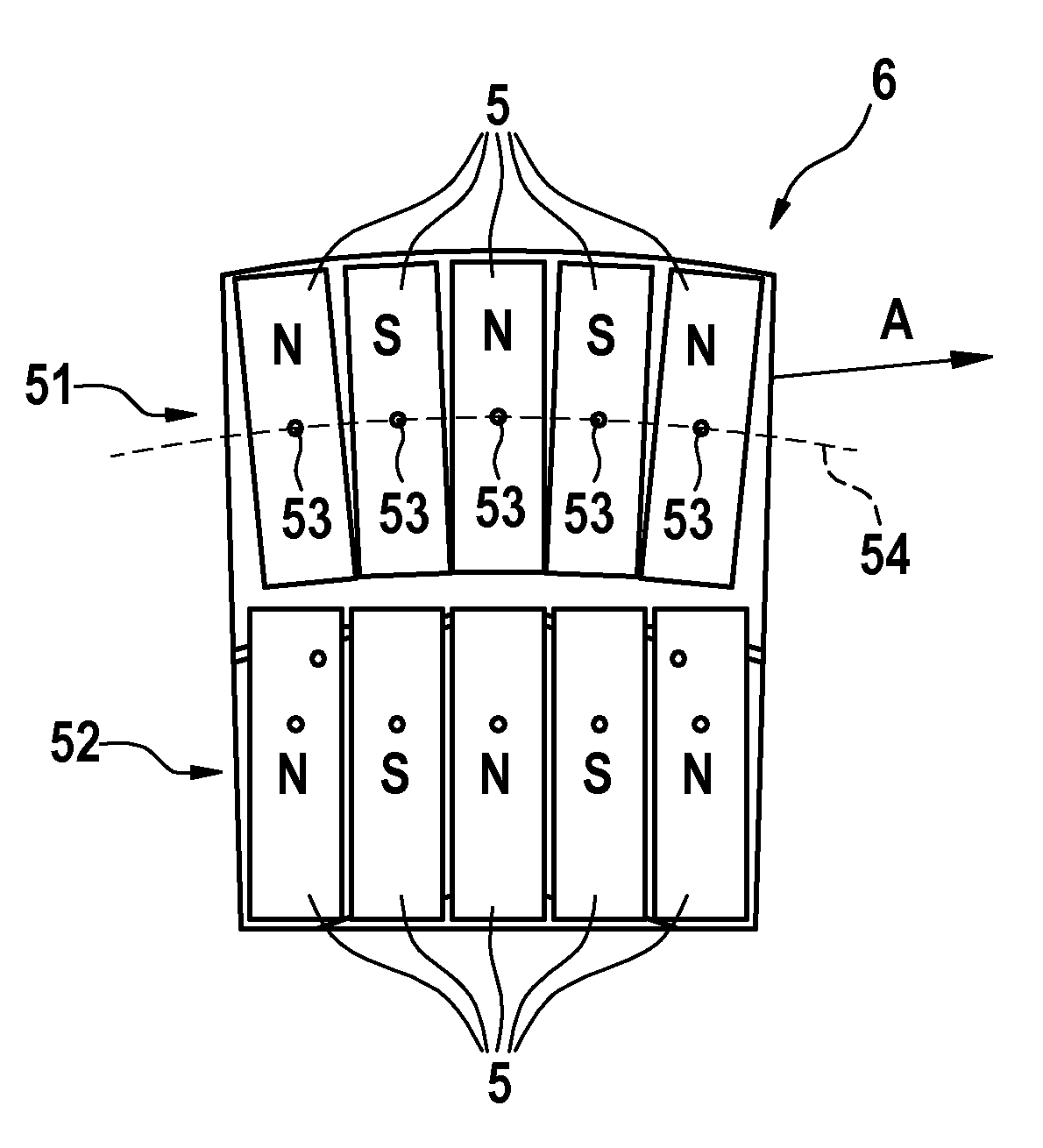

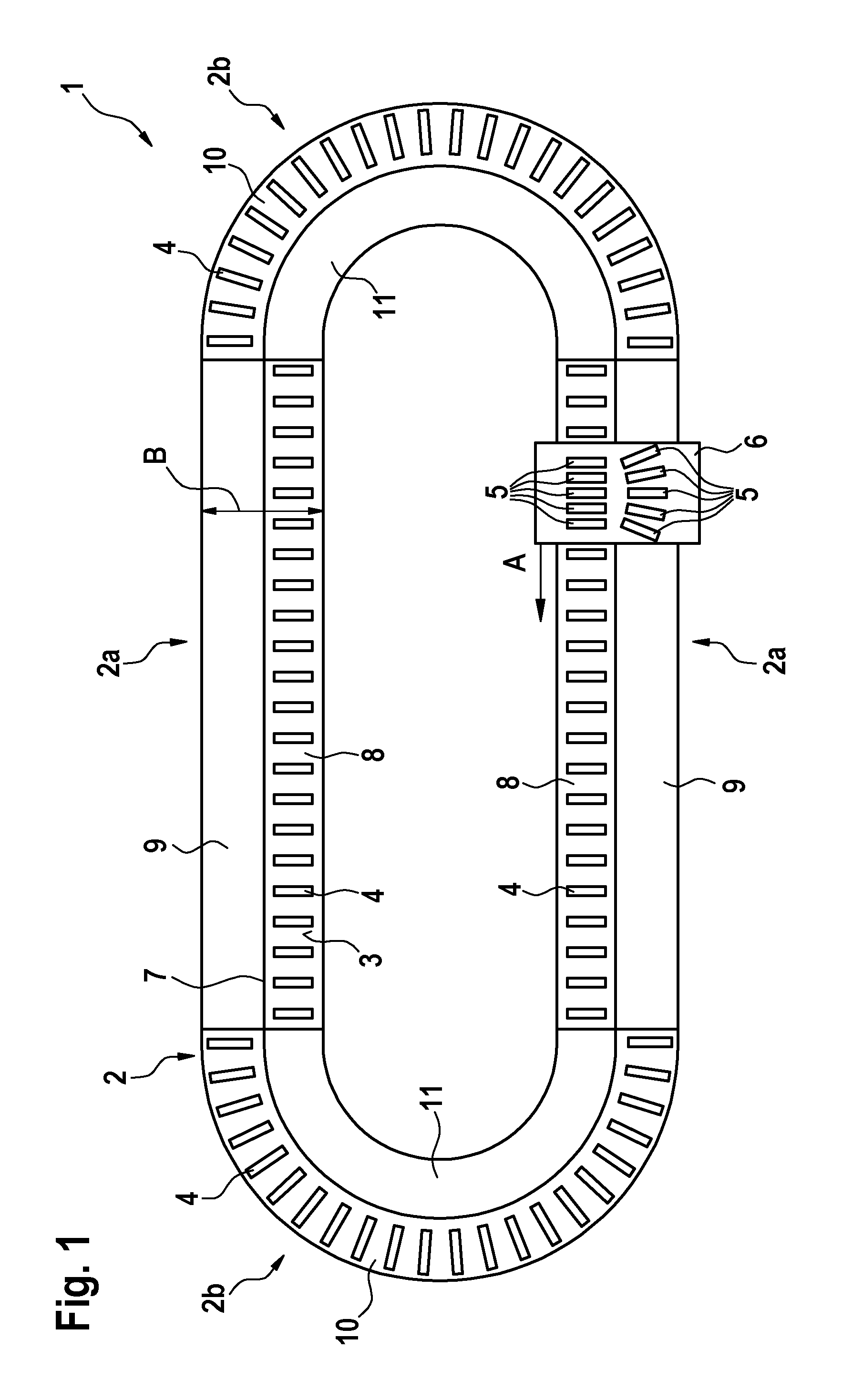

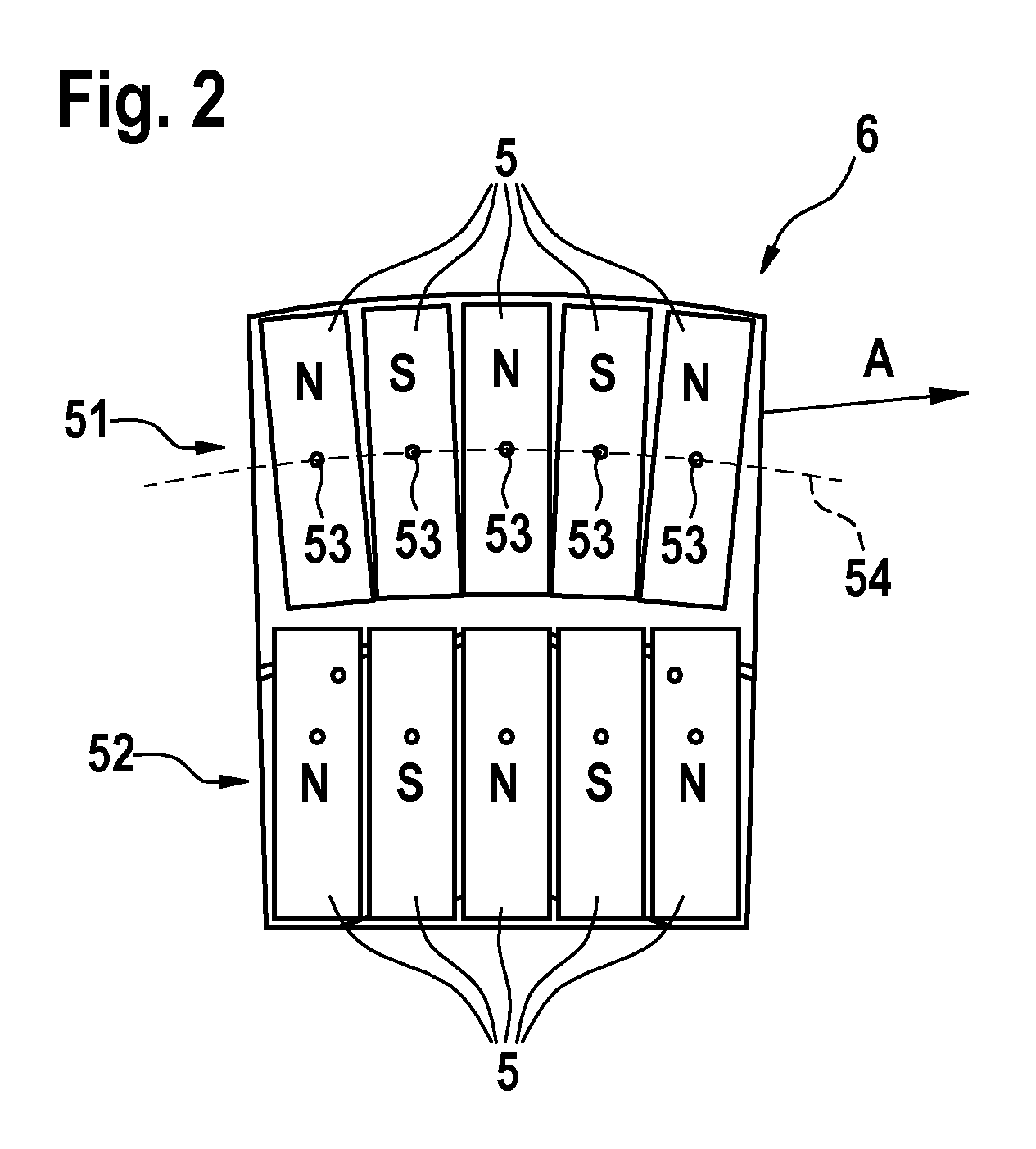

Revolving transport device having an improved drive concept

InactiveUS8733541B2Good for high speedSmall radiusNon-mechanical conveyorsPropulsion systemsLinear regionElectromagnetic drive

The invention relates to a transport device that includes a revolving transport section having a linear region (2a) and a curve region (2b), an electromagnetic drive having a plurality of stationary coil elements (4) and a plurality of permanent magnets (5), wherein the stationary coil elements (4) are arranged on the transport section (2), and at least one mover (6), which is movably arranged on the revolving transport section (2) and can be moved by way of electromagnetic forces. A first row (51) of permanent magnets (5) and a second row (52) of permanent magnets (5) are arranged on the mover (6). The revolving transport section (2) has first coil regions (10), which are exclusively operatively connected to the first row (51) of permanent magnets (5), and second coil regions (8), which are exclusively operatively connected to the second row (52) of permanent magnets (5).

Owner:SYNTEGON TECHNOLOGY GMBH

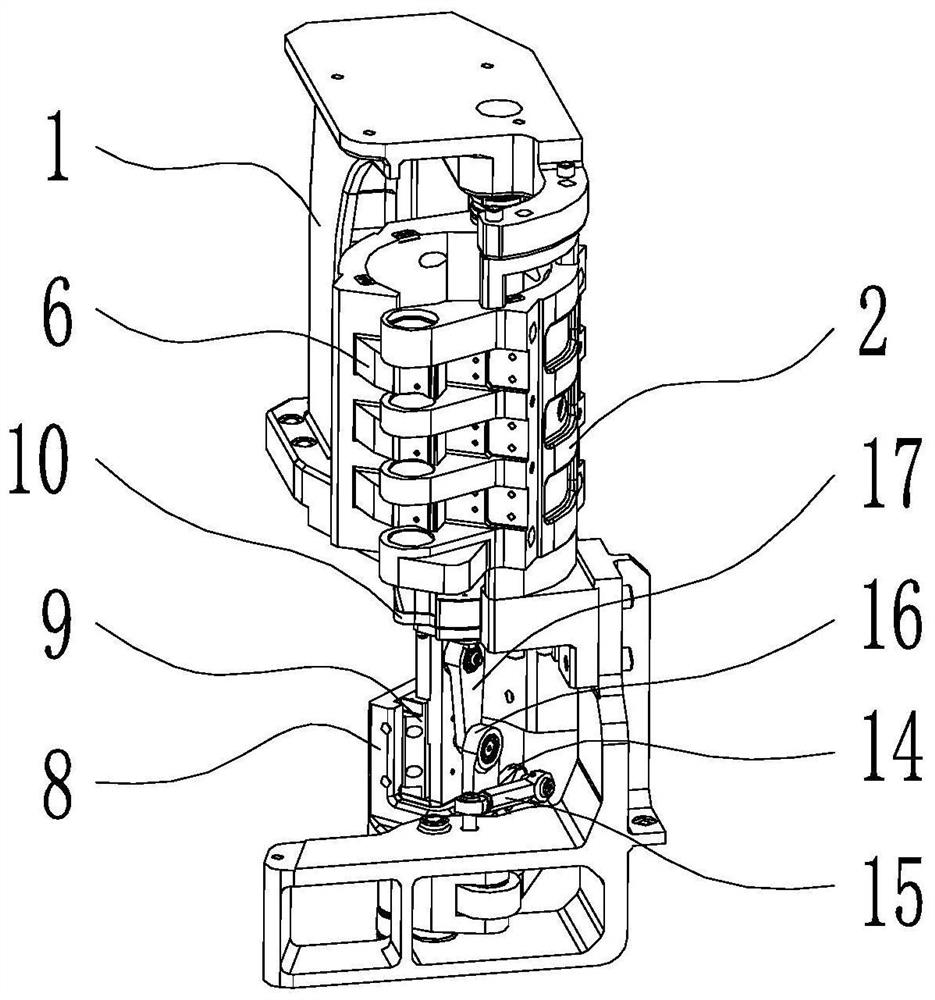

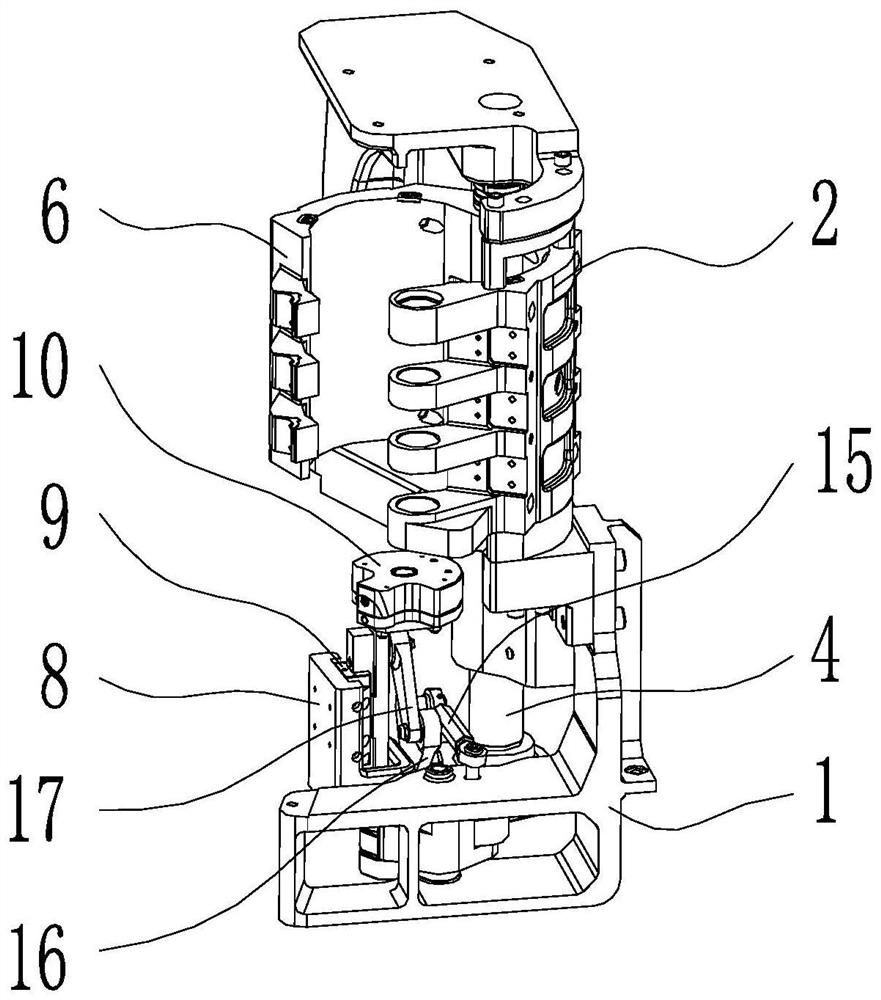

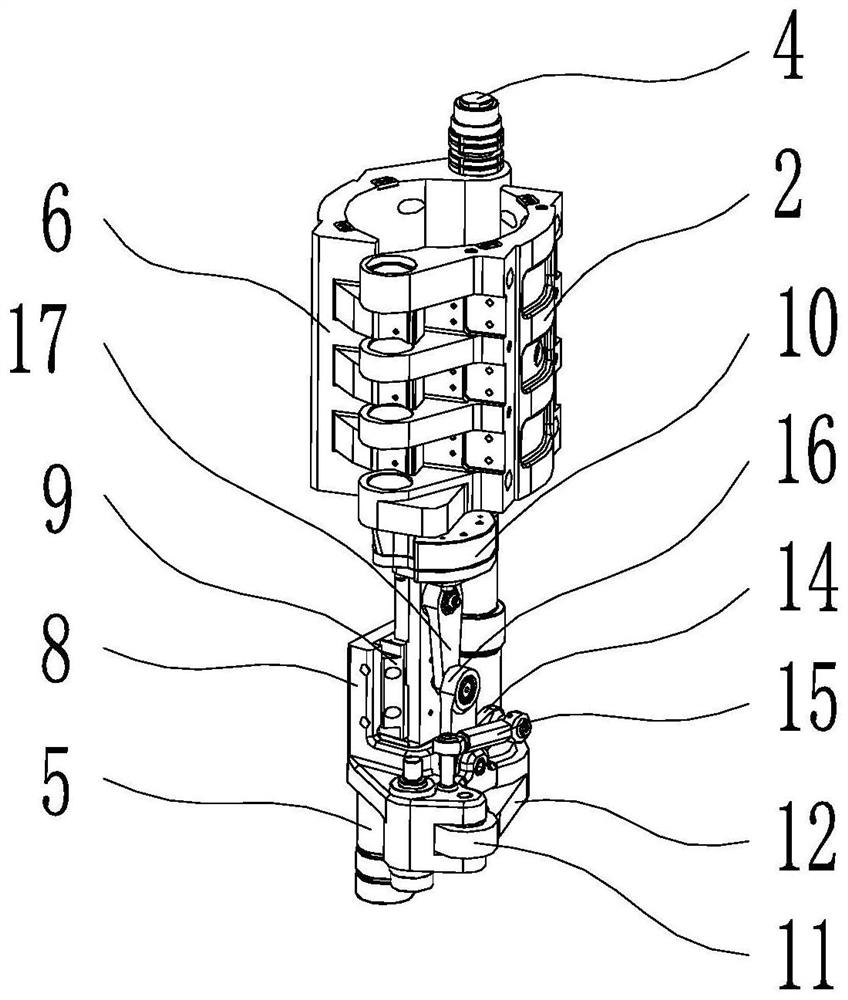

Motor main shaft

InactiveCN109412325AGood for high speedImprove stabilityMechanical energy handlingStructural associationPistonFront cover

The invention discloses a motor main shaft. The motor main shaft comprises a waterproof ring, a front cover, an angular contact bearing, a front bearing pedestal, a sleeve, a disc spring, a pull rod,a motor stator, a motor rotor, a core shaft, an encoder mounting plate, an encoder, an oil cylinder sleeve, a piston, an oil cylinder cover, a cutter block, an encoding wheel, a rear cover and a rearbearing pedestal; the motor rotor is integrated with the core shaft, and the motor stator is fixedly connected with the sleeve; the front bearing pedestal and the rear cover are arranged at the two ends of the sleeve; the sleeve is in rotation connection with the core shaft through the front bearing pedestal, the rear bearing pedestal and the angular contact bearing; the front cover is arranged atthe front end of the front bearing pedestal; the oil cylinder sleeve is arranged at the rear end of the rear cover; the piston is arranged in the oil cylinder sleeve; the oil cylinder cover is arranged at the rear end of the oil cylinder sleeve; the piston is located at the rear end of the pull rod, and the cutter block is arranged at the tail end of the pull rod; the encoder mounting plate is installed on the rear cover; the encoder is installed on the encoder mounting plate; the encoding wheel is installed at the tail end of the core shaft; and the pull rod and the disc spring are arrangedin a central hole of the core shaft. According to the motor main shaft, the rotating speed, stability and rigidity of the main shaft are improved, and the space is saved.

Owner:SWIFT NANTONG PRECISION MACHINERY

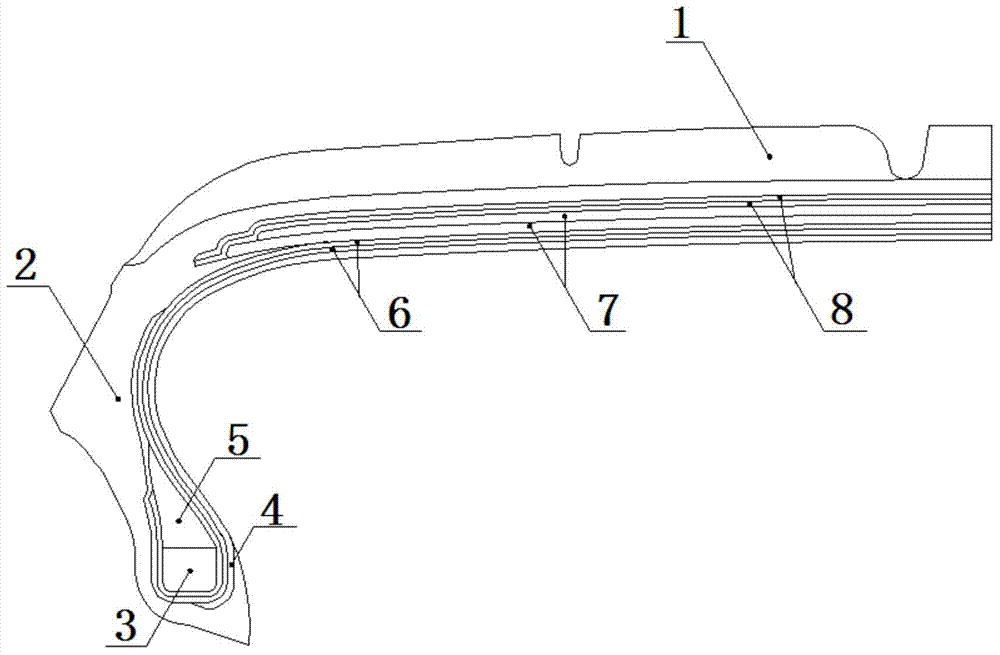

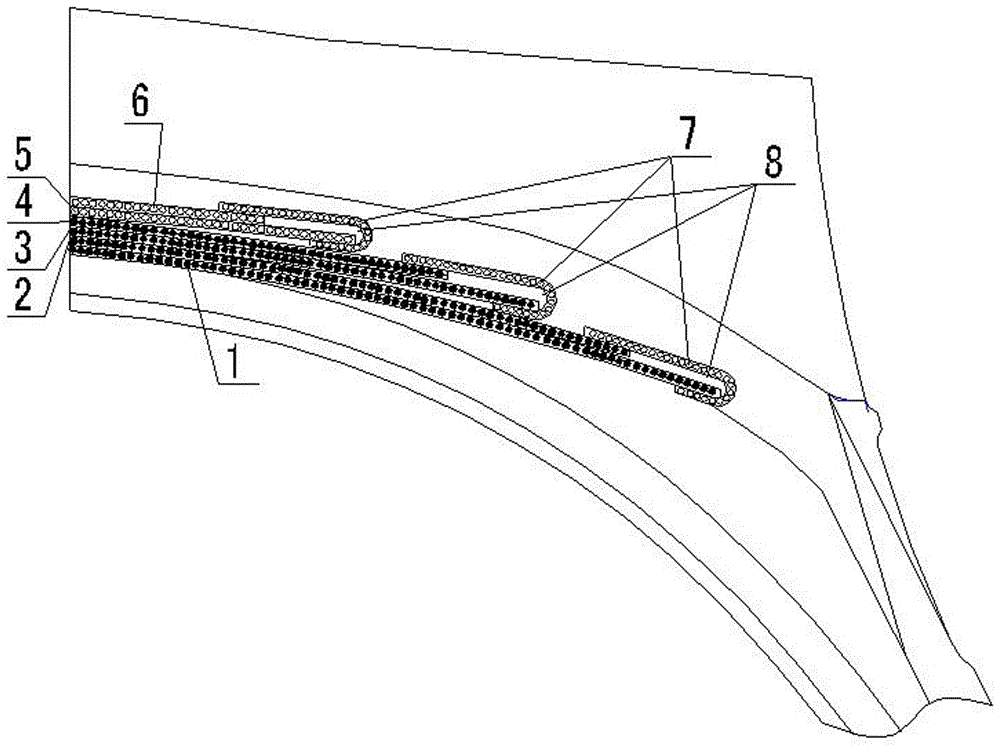

Meridianal bias tire with low flatness ratio

InactiveCN103568731APrevent repeated flexing and deformationAvoid burnsPneumatic tyre reinforcementsTire beadRolling resistance

The invention discloses a meridianal bias tire with low flatness ratio. The meridianal bias tire mainly comprises tread rubber, sidewall rubber, a tire bead, an air-tight layer, bead filler, tire body layers, a belt ply and a cap ply, wherein the laying direction of cord threads of the two tire body layers in a tread rubber area is along a meridian direction, and a tire body structure is a double-layer parallel stacked structure; compared with the bias tire, the high-speed performance of the tire is improved, the tire is easy to realize low flatness ratio, and the control stability of the tire is improved; the laying direction of the cord threads of the two tire body layers in a sidewall rubber area forms an included angle with the meridian direction, and the included angles of two tire body layers are equal in size and opposite in direction; the tire body structure is a reticular double-layer intersected stacked structure; as the tire body structure in the sidewall rubber area is a reticular intersected structure, the rigidity of the sidewall rubber is enhanced, the sidewall rubber is difficult to damage, the steering and braking performances and other performances of the meridianal bias tire are improved, the footprint area of the tire is reduced, the tire footprint shape is rationalized and the tire rolling resistance is reduced.

Owner:BEIJING UNIV OF CHEM TECH

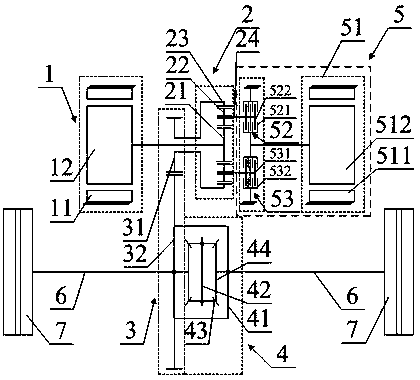

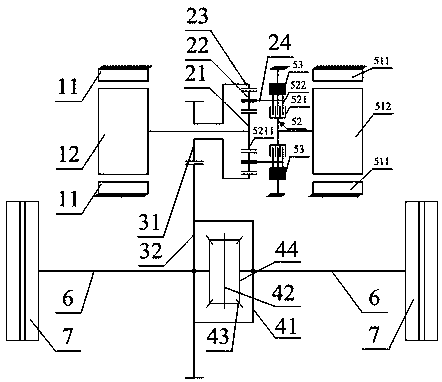

Electric bridge system

InactiveCN108327497AIncrease speedSpeed adjustmentElectric propulsion mountingControl devicesTransmitted powerEngineering

The invention provides an electric bridge system, comprising: a first driving motor for driving vehicle hubs to rotate; a planet gear mechanism, wherein an input shaft of the planet gear mechanism isconnected with an output shaft of the first driving motor, and the planet gear mechanism is used for driving the hubs to rotate; a driving mechanism connected with the planet gear mechanism and used for selectively driving the planet gear mechanism to rotate so as to adjust the speed of the hubs. The first driving motor cooperates with the planet gear mechanism to transmit power; the driving mechanism selectively drives the planet gear mechanism to rotate so as to selectively increase the output speed of the planet gear mechanism; the first driving motor and the driving mechanism cooperate with the planet gear mechanism so that the output speed of the planet gear mechanism is adjusted under fixed tooth ratio to adjust vehicle speed; therefore, the requirement on highest speed of the motoris lowered.

Owner:CH AUTO TECH CORP CO LTD

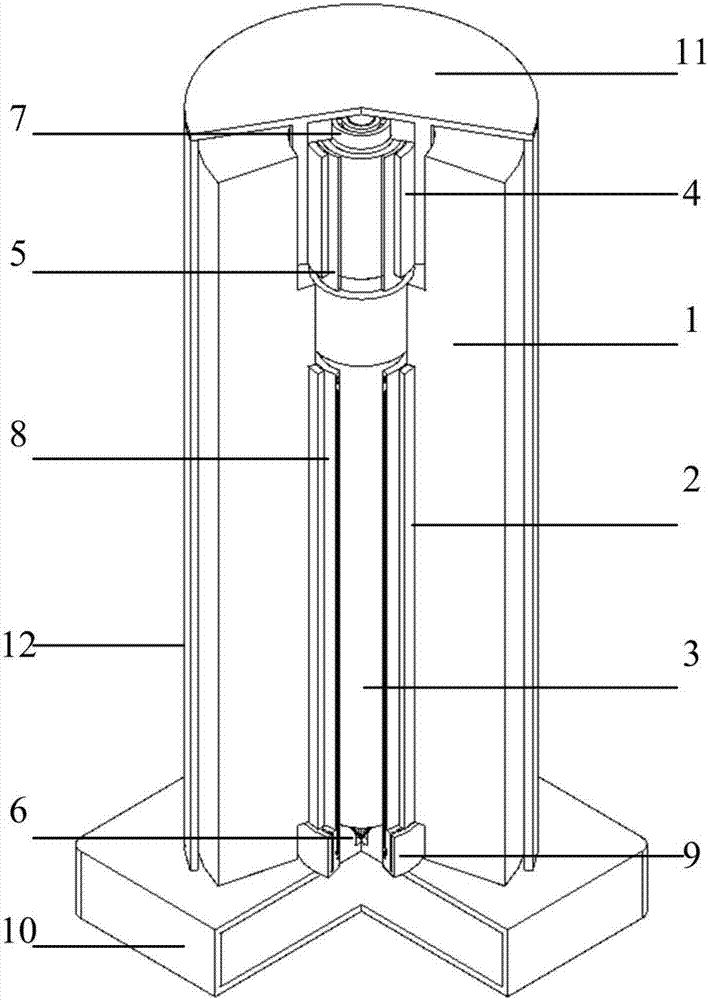

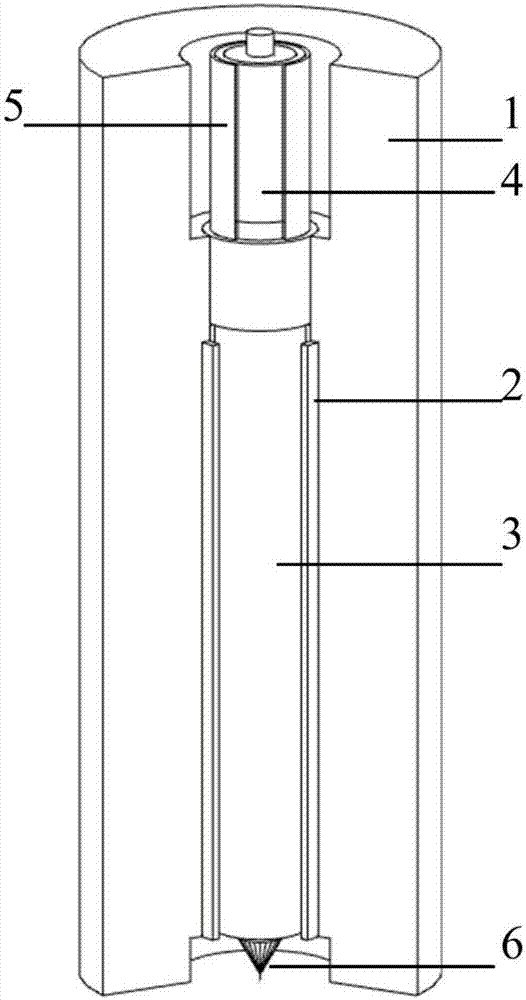

Built-in variable throttler

A built-in variable throttler comprises a throttler seat, a throttling post and a spring. A stair-step centre hole is arranged on the throttler seat and composed of a big diameter hole, a middle diameter hole and a small diameter hole, the big diameter hole is communicated with the small diameter hole through the middle diameter hole, the throttling post is formed by connecting a big diameter post, a middle diameter post and a small diameter post, the throttling post is installed in the throttler seat, the big diameter post is tightly matched with the big diameter hole, an oil storage chamber is defined by the top end of the big diameter post and the inner wall of the big diameter hole, an oil inlet chamber is formed between the middle diameter post and the big diameter hole, an oil inlet channel for communicating the oil storage chamber and the oil inlet chamber is arranged on the throttling post, a throttling gap communicated with the oil inlet channel is formed between the middle diameter post and the middle diameter hole, an oil collecting chamber is formed between the small diameter post and the middle diameter hole, the small diameter post is tightly matched with the small diameter hole, an output channel communicated with the oil collecting chamber is arranged on the small diameter post, and a spring abuts against and is arranged between the bottom end of the middle diameter post and the bottom end of the middle diameter hole. The built-in variable throttler is simple and compact in structure, and rapid in changing dynamic response of external loads.

Owner:HUNAN UNIV

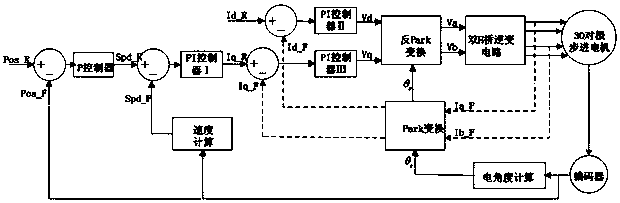

High speed high torque realization method of hybrid stepping motor

InactiveCN107154760ALarge torqueGreat tractionElectronic commutation motor controlVector control systemsClosed loopMotor control

The invention provides a high speed high torque realization method of a hybrid stepping motor, and belongs to the motor control field. A closed loop control way is adopted for control of a 30-pair pole hybrid stepping motor. Position overshoot and oscillation are not expected by a stepping servo system, and then position precision decreasing is prevented. A position control normally adopts a proportional regulator, and the stepping servo is corrected to be an I type system. Under the above mentioned condition, in order to guarantee control precision and reduce deviation during steady state operation, the system adopts feedforward compound controller to compensate following errors of speed control.

Owner:深圳市杰美康机电有限公司

Revolving transport device having an improved drive concept

InactiveUS20120090963A1Avoid collisionGood for high speedNon-mechanical conveyorsPropulsion systemsLinear regionElectromagnetic drive

The invention relates to a transport device, in particular for charging packaging machines, comprising a revolving transport section having a linear region (2a) and a curve region (2b), an electromagnetic drive having a plurality of stationary coil elements (4) and a plurality of permanent magnets (5), wherein the stationary coil elements (4) are arranged on the transport section (2), and at least one mover (6), which is movably arranged on the revolving transport section (2) and can be moved by way of electromagnetic forces. The permanent magnets (5) are arranged on the mover (6), wherein a first row (51) of permanent magnets (5) and a second row (52) of permanent magnets (5) are arranged on the mover (6), wherein the first row (51) and the second row (52) of the permanent magnets are successively arranged in a miming direction (A) of the mover (6), and wherein the revolving transport section (2) has first coil regions (10), which are exclusively operatively connected to the first row (51) of permanent magnets (5) on the mover (6), and second coil regions (8), which are exclusively operatively connected to the second row (52) of permanent magnets (5) on the mover (6).

Owner:SYNTEGON TECHNOLOGY GMBH

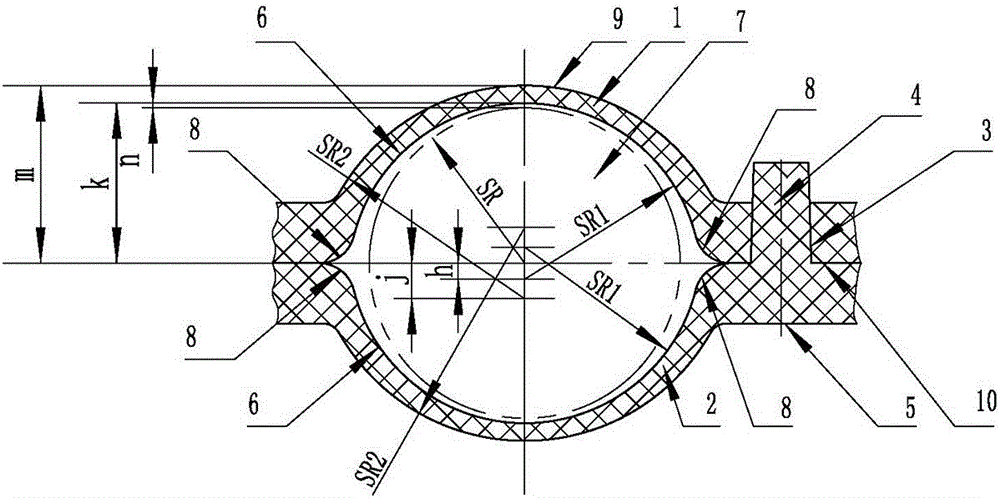

Bearing retainer

The invention provides a bearing retainer, and belongs to the technical field of bearing retainers. The bearing retainer is used for corrugated bearings made of synthetic resin. Concave parts and shoulders on a corrugated annular body A and on a corrugated annular body B are distributed in an alternate mode. The concave parts and the shoulders are connected through matching of small conical holes of the shoulders and conical columns of the shoulders. The inner surfaces of the concave parts are concave spherical faces. The ratio of the radius SR1 of the concave spherical faces and the radius SR of a sphere 7 ranges from 1.08 to 1.20. The spherical center of the sphere and the spherical centers of the concave spherical faces are located in the radial direction, and the spherical center of the sphere is in the intersection point of the radial direction and the axial direction. The spherical centers of the concave spherical faces deviate from the concave spherical faces. The deviation distance of the spherical centers of the concave spherical faces and the spherical center of the sphere is (0.02-0.07) SR1. The combination faces of the concave spherical faces and the shoulders are in rounded corner connection, and round corners are R0.3-R2.0. According to the technical scheme, the technical problems that a connection structure between annular bodies of an existing retainer made of synthetic resin is complex, concave parts are complex in shape, implementation is difficult, machining and assembling errors are likely to occur, and matching precision of the concave parts of the annular bodies and the sphere is affected are solved.

Owner:QINGDAO TAIDE AUTOMOBILE BEARING

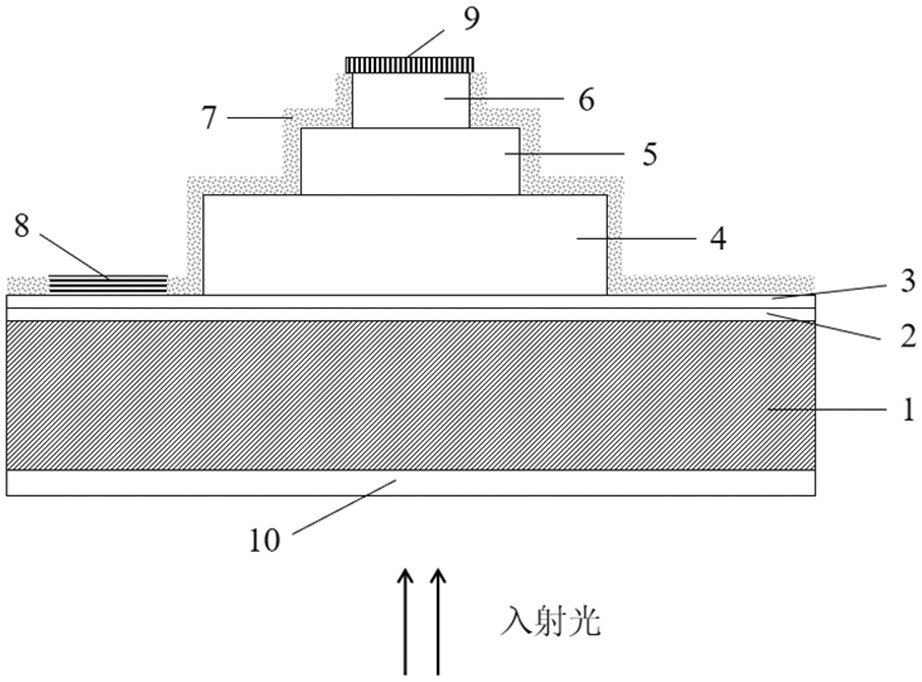

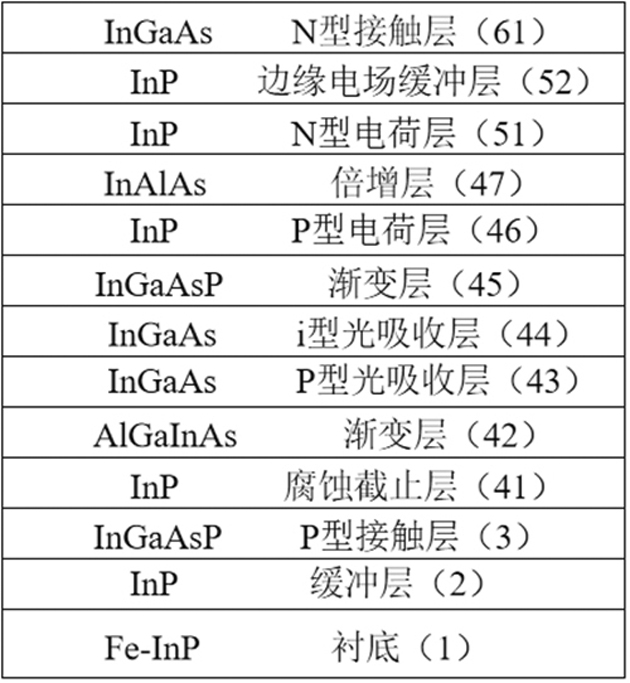

Avalanche photodiode with three-mesa structure and manufacturing method thereof

PendingCN111739975AImprove reliabilityReduce parasitic capacitanceSemiconductor devicesCharge layerEngineering

The invention relates to an avalanche photodiode with a three-mesa structure and a manufacturing method thereof. The avalanche photodiode comprises a Fe-InP substrate, an InP buffer layer, a P-type InGaAsP contact layer, a third mesa, a second mesa and a first mesa which are arranged from bottom to top, wherein the third mesa comprises a P-type InP corrosion cut-off layer, a P-type InGaAsP gradient layer, a P-type InGaAs light absorption layer, an i-type InGaAs light absorption layer, a P-type AlGaInAs gradient layer, a P-type InP charge layer and an i-type InAlAs multiplication layer which are arranged from bottom to top; the second mesa comprises an N-type InP charge layer and an N-type InP edge electric field buffer layer which are arranged from bottom to top; the first mesa comprises an N-type InGaAs contact layer. According to the avalanche photodiode and the manufacturing method thereof, the reliability, high speed and high bandwidth performance of the avalanche photodiode can beimproved.

Owner:FUJIAN Z K LITECORE LTD

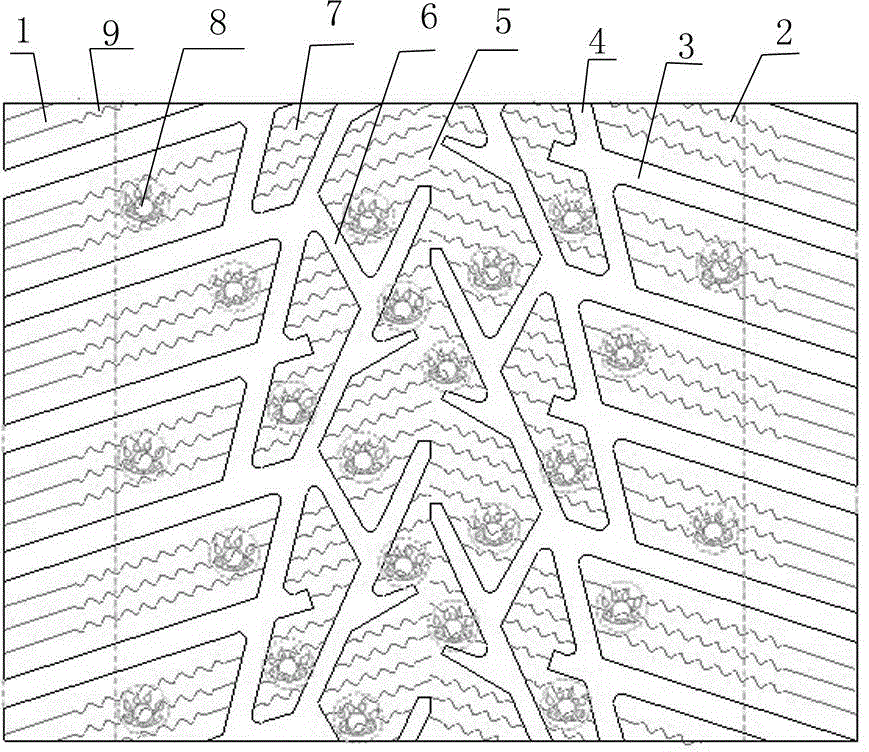

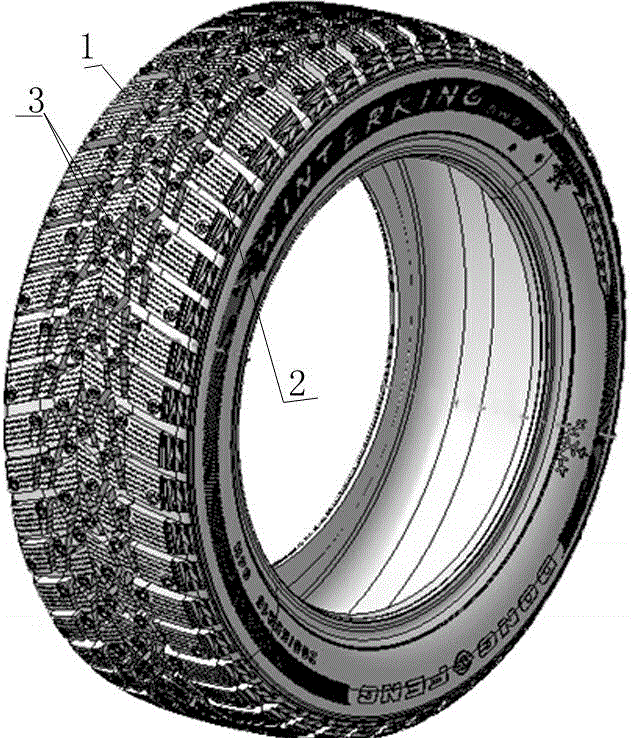

Nail-embedded snow tire

InactiveCN104385857AImprove straight line stabilityGood for high speedTyre tread bands/patternsEngineeringVehicle driving

The invention discloses a nail-embedded snow tire which comprises a tire body, a tire sidewall and a tread, wherein the tread is uniformly segmented into single-guide treads by using multiple inverted-V-shaped primary grooves and inverted-V-shaped secondary grooves in the same direction in the primary grooves; the tread adjacent to the tire sidewall is a tread I; the middle tread is a tread II; the inverted-V-shaped primary grooves and the inverted-V-shaped secondary grooves respectively run through one another in two sides of the tread II; and non-slip nails are arranged on the tread I, the tread II and the tread III and are respectively and linearly arranged. According to the nail-embedded snow tire disclosed by the invention, patterns are in the unique inverted-V-shaped single-guide design, and the linear stability and high speed performances of the tire are improved; and moreover, the inverted-V-shaped primary grooves and the inverted-V-shaped secondary grooves respectively run through one another in two sides of the tread, so that the water suction capacity and road holding force of the tire in the vehicle driving process are improved, a water film on an ice surface is easily broken, and the driving is relatively safe.

Owner:双星东风轮胎有限公司

Coaxial package structure and optical transmission assembly

PendingCN108732690AReduce sensibilityImproving impedanceCoupling light guidesElectromagnetic receiversHigh rateTube socket

The present invention discloses a coaxial package structure and an optical transmission assembly. The coaxial package structure comprises a flexible board and a tube socket electrically connected withthe flexible board; and the flexible board comprises a dielectric material layer, a signal transmission layer on the dielectric material layer, and a grounding layer under the dielectric material layer, wherein the grounding layer on the flexible board is electrically connected with the tube socket directly. According to the coaxial package structure and the optical transmission assembly of the invention, a cover film under the flexible board and a reinforcing board under the cover film are omitted; and the signal transmission layer of the flexible board is electrically connected with the tube socket directly; and therefore, the inductiveness of a loop path can be decreased, the impedance of a signal link is decreased, and the high-speed performance of a product can be improved. The coaxial package structure and the optical transmission assembly can be used for ultra-high-rate transmission.

Owner:INNOLIGHT TECHNOLOGY (SUZHOU) LTD

Rubber composition and design for snap-in tire valve

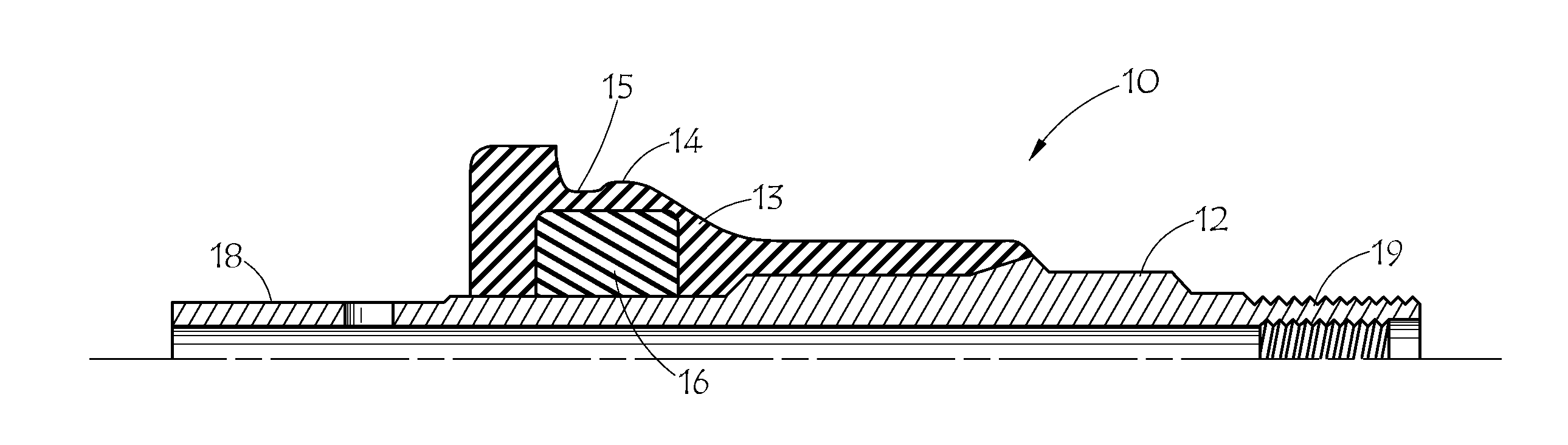

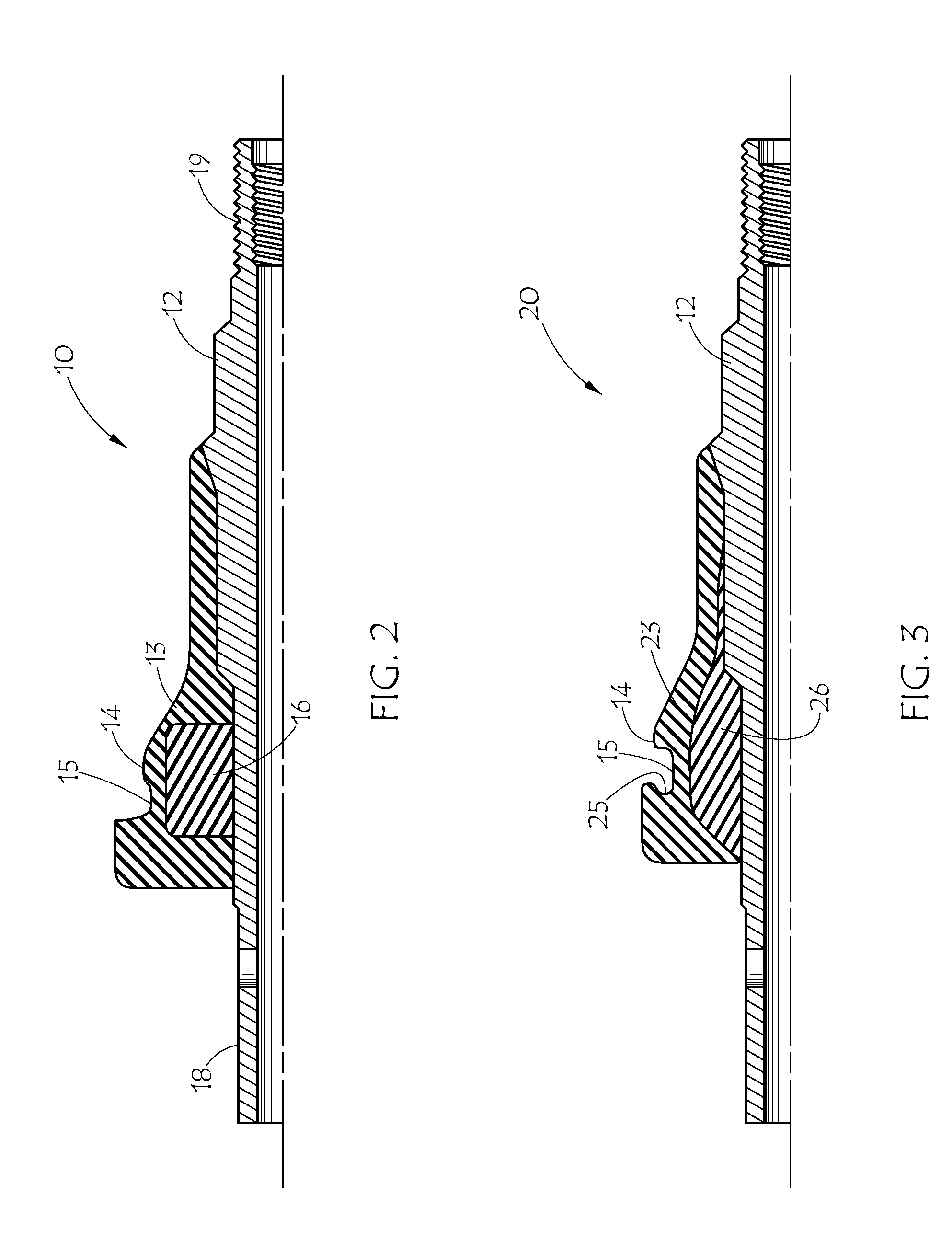

ActiveUS20140261753A1Good for high speedImprove high temperature performanceEngine sealsCheck valvesEthylene propylene copolymerOxide

A snap-in tire valve for mounting in a valve hole in a wheel rim, having a valve body and a resilient member having an overall shape including a groove and a rib adapted to snap into and be retained in the hole. The resilient member may include a rubber that is the reaction product of ethylene-propylene copolymer elastomer, a peroxide curative, zinc diacrylate or zinc dimethacrylate, and a high-density inert filler, such as barium sulfate. The resilient member may include a first and second rubber members of different compositions from each other and defining two layers under the groove. The thickness of the layer of the first rubber member is preferably greater than the thickness of the layer of the second rubber member.

Owner:THE GATES CORP

Molding method of high-speed-resisting belted layer of off-road vehicle tire

The invention discloses a molding method of a high-speed-resisting belted layer of an off-road vehicle tire. Aramid cord fabrics are used as #1 to #4 belted layers; #5 to #6 belted layers are made of nylon cord fabrics; the nylon cord fabric with the width of 30mm to 50mm is used, and each two layers of the nylon cord fabrics cover two end parts of the belted layers; the end parts are filled through adopting edge covering rubber strips with the width of 10mm to 20mm. Ultrahigh-strength aramid cord threads are used as #1 to #4 belted layers of a stressing main body for bearing driving stress of the tire; the number of layers of the belted layers is reduced and the heat generated by the tire is reduced. The #5 to #6 belted layers are made of the nylon cord fabrics with relatively sparse linear density so that the bonding of the cord threads and rubber is good; meanwhile, a cutting-off angle of the #5 to #6 belted layers is 80 degrees or more, so that the hooping effect of the middle part of a crown of the tire is enhanced and the strain caused by the fact that the tire rolls is reduced; the two end parts of each two layers of belted layers are covered with the large-angle nylon cord fabrics and the rubber strips with low heat generation are filled, so that the rigidity of the end parts of the belted layers can be enhanced; high-frequency deformation and heat generation in a high-speed driving process are reduced, so that high-speed performance of the off-road vehicle tire is improved.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

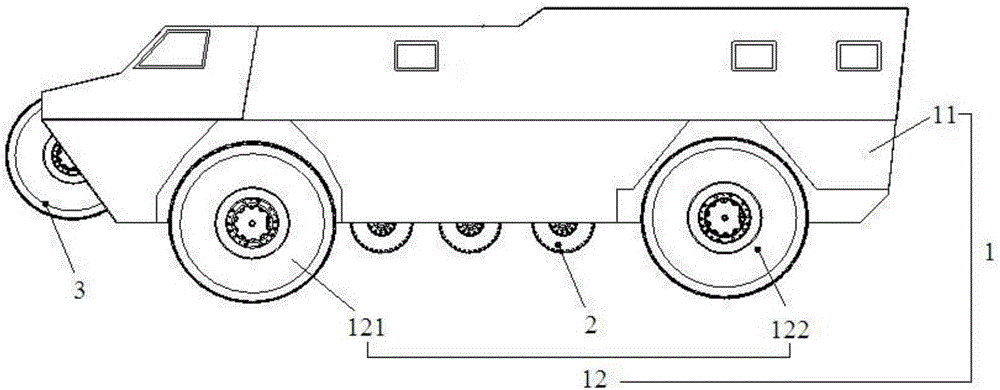

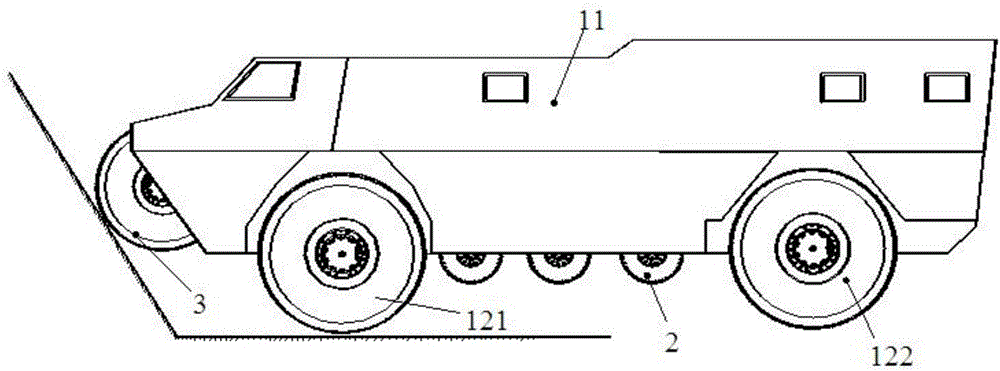

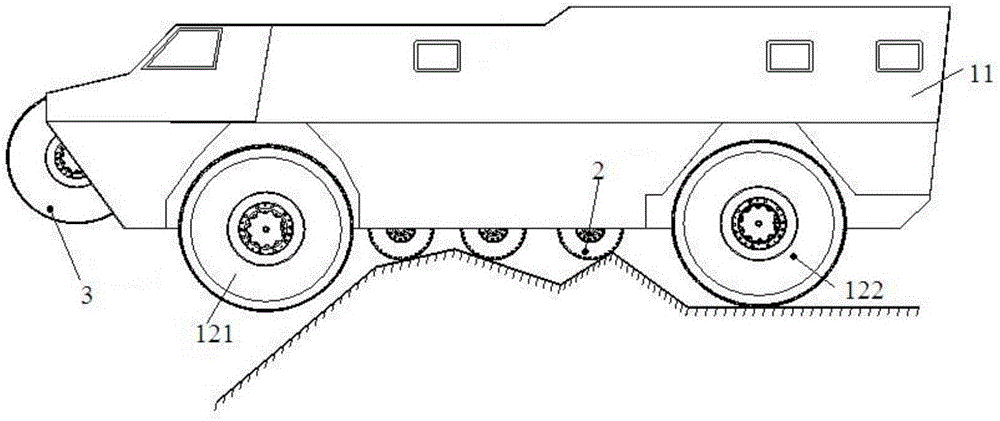

Wheeled off-road vehicle

The invention relates to the technical field of vehicles, in particular to a wheeled off-road vehicle. The wheeled off-road vehicle comprises a vehicle body. A plurality of first auxiliary wheels are arranged on the vehicle body bottom surface of the vehicle body. The rotating direction of the first auxiliary wheels is the same as the rotating direction of wheels of the vehicle body, and the diameter of the first auxiliary wheels is smaller than the diameter of the wheels of the vehicle body. According to the wheeled off-road vehicle, on the basis of a traditional all-wheel drive off-road vehicle, the auxiliary wheels are additionally arranged at the vehicle body bottom surface, so that the off-road performance is remarkably improved on the premise that the high speed of the off-road vehicle is not decreased, in other words, when the vehicle travels on a soft road surface, the ground contact area of the vehicle can be enlarged through the first auxiliary wheels at the bottom of the vehicle; and when the off-road vehicle passes through a single bump, bellying can be prevented, the vehicle can pass through a low-bearing-capacity road surface, and the high-speed performance on a pavement road surface is kept. The wheeled off-road vehicle has the high-speed traveling capacity on ordinary road surfaces of traditional vehicles and can cross large obstacles.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

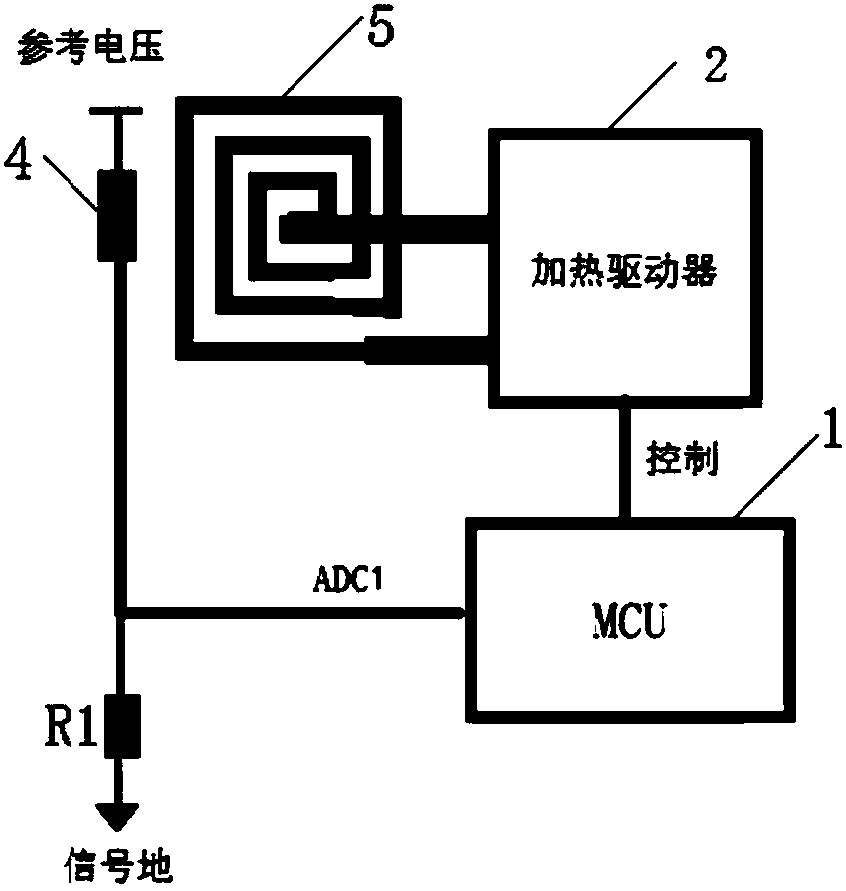

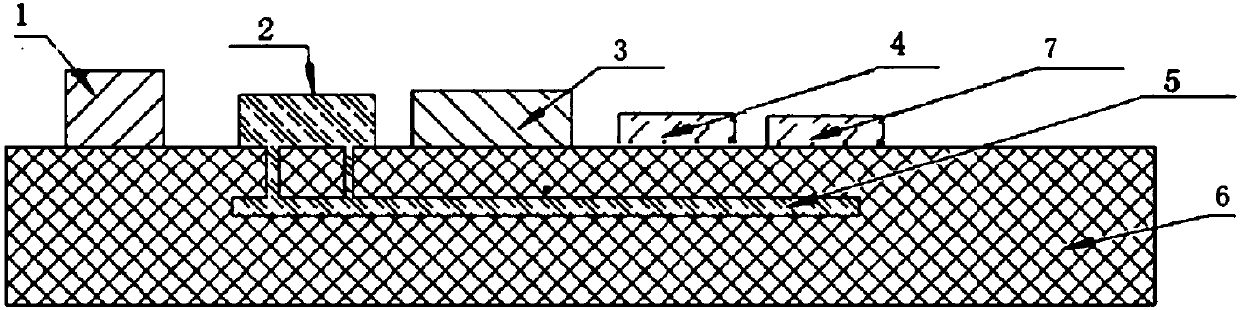

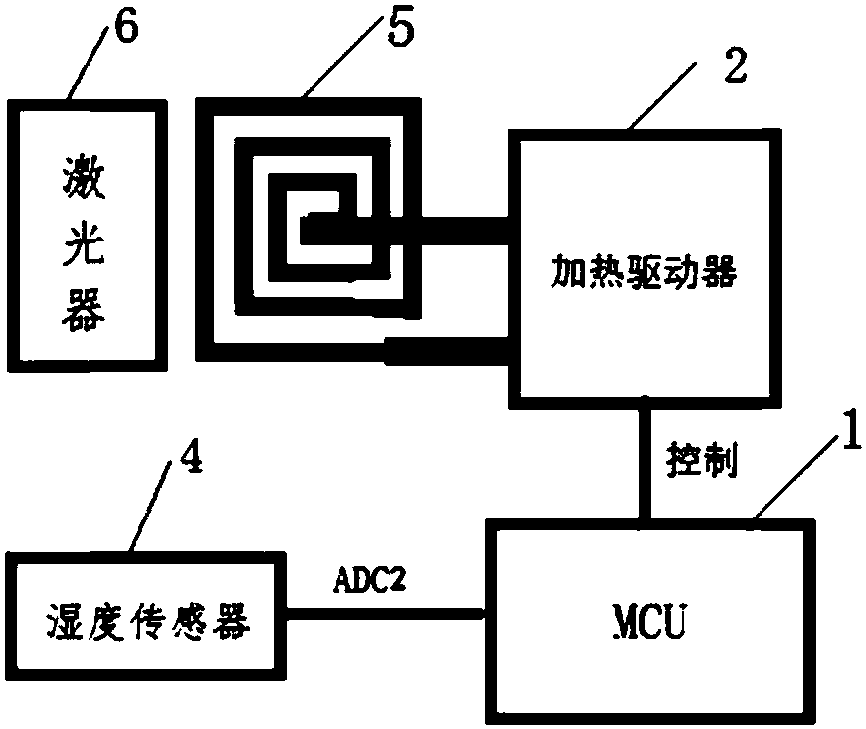

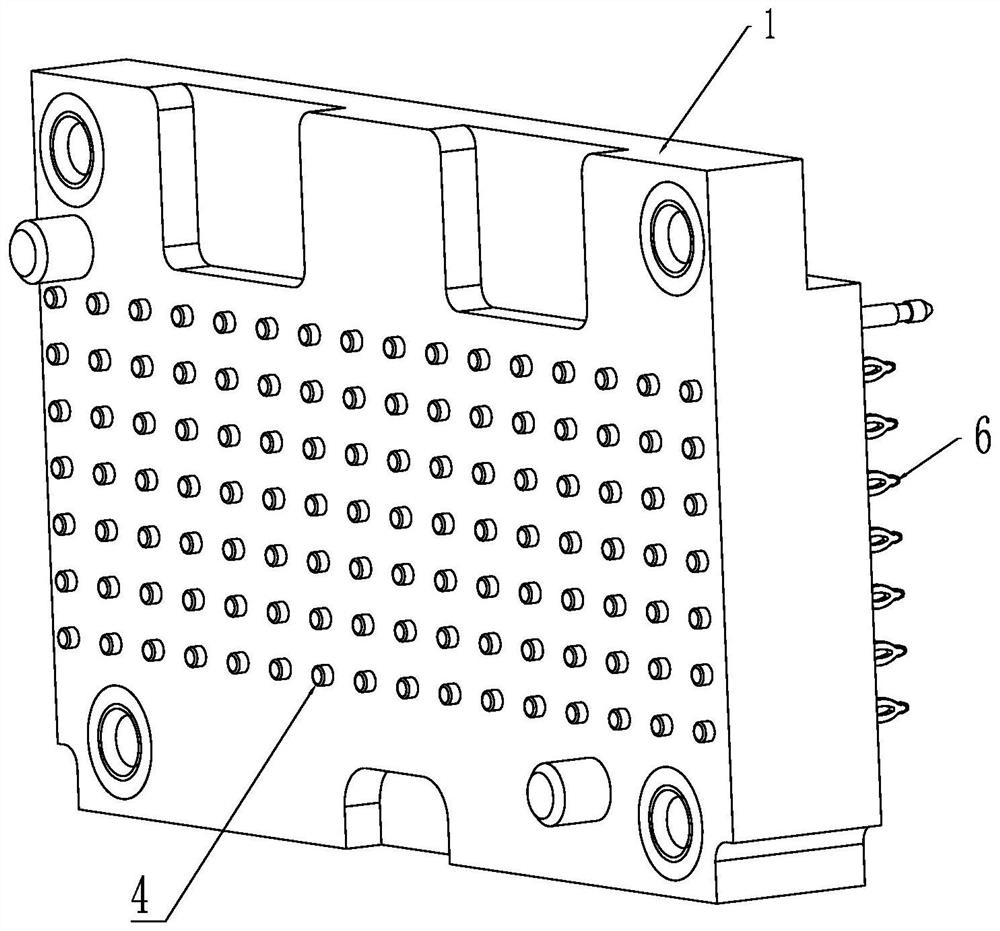

Automatic control system for humidity and temperature of working environment of non-airtight-sealing laser device

PendingCN107632654AGood for high speedWide Temperature Operating RangeLaser constructional detailsSemiconductor lasersAutomatic controlWorking temperature

The invention discloses an automatic control system for the humidity and the temperature of a working environment of the non-airtight-sealing laser device, which is applied to the field of photoelectric devices. A thermistor which is arranged beside the laser device and is used for inducing the working temperature of the laser device is used for obtaining the current working temperature of the laser device; when the temperature of the laser device is lower than a certain pre-set value, a coil heating driver is started up to heat so that the temperature of the laser device is raised; when the temperature of the laser device exceeds a certain pre-set value, the coil heating driver is switched off to control the fluctuation of the temperature, so that a working temperature range of the laserdevice is expanded when compared with that of an original product; the working temperature range of the similar laser device can be expanded to -40 DEG C to 85 DEG C from 0 to 85 DEG C; the working humidity of the laser device is obtained through a humidity sensor; when the working humidity is too great, a heating coil is controlled to work; when the working humidity returns to a normal range, theheating coil is cut off, so that the laser device is controlled to work in the normal humidity range, and the working reliability and the service life of the laser device are ensured.

Owner:成都光创联科技有限公司

Switching high-speed connector

PendingCN114122782AAchieve lossless connectionEnables press-fit connections without solderingSecuring/insulating coupling contact membersCoupling contact membersPhotoelectric conversionData transmission

The invention relates to a switching high-speed connector, which is used for realizing a switching connection effect between an optical active module and a printed board, and comprises an insulator component which comprises an insulator provided with a mounting hole; the contact part is installed in the installation hole, one end of the contact part is provided with a fisheye structure extending out of one end of the installation hole, the fisheye structure is used for being in compression joint with the printed board, the other end of the contact part is provided with an elastic contact structure extending out of the other end of the installation hole, and the elastic contact structure is used for being elastically attached to the photoelectric conversion module to achieve lossless connection. By means of the technical scheme, the two faces of the switching connector are designed in two different terminating modes, one end of the connector is designed to be of a fisheye structure to achieve welding-free press-fit connection with a printed board, the other end of the connector is designed to be of an end face elastic contact structure, and lossless connection of a photoelectric conversion module is achieved; meanwhile, the structure is easy to eliminate short piles and is suitable for high-speed data transmission scenes.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

SEU (single event upset)/SET (single event transient)-resistant dynamic comparator

InactiveCN102025351BReduce power consumptionLower latencyMultiple input and output pulse circuitsAudio power amplifierVoltage reference

The invention discloses an SEU (single event upset) / SET (single event transient)-resistant dynamic comparator, which comprises a pulse generating circuit based on a sensitive amplifier structure and an output latch circuit; the top of the whole comparator is provided with five input ports and four output ports outwards, the five input ports are respectively connected with clock signals, input signals and reference voltage signals, and the output ports are connected with data output signals; the pulse generating circuit is connected with the clock signals, the input signals, the reference voltage signals and the output latch circuit; and the output latch circuit is connected with the pulse generating circuit and the data output signals. The dynamic comparator has the advantages that the upset threshold LETth is greater than 500MeV / (mg.cm2); the time delay is reduced while the high-speed low power consumption of the SEU / SET-resistant dynamic comparator same as that of a traditional dynamic comparator is achieved; the symmetrical arrangement, equal time delay and same drive capacity of complementary output terminals Q and QB are realized; by adopting the sensitive amplifier structure, the clock network is simple, reliable and small in load; and by adopting the minor clock swing technology, the power consumption is obviously reduced.

Owner:XI AN JIAOTONG UNIV

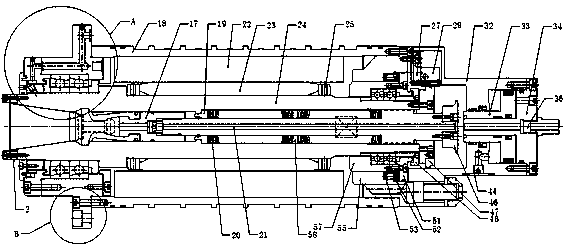

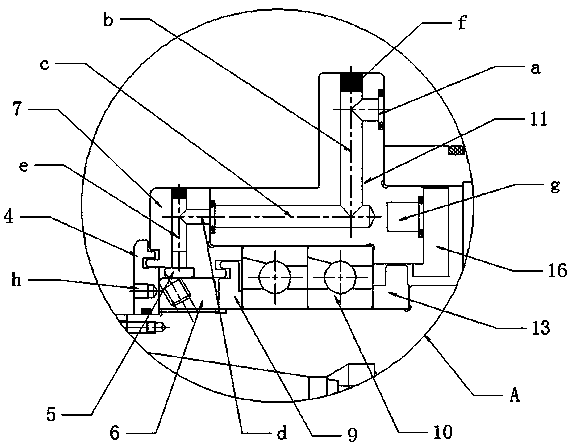

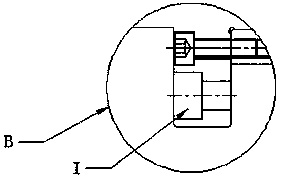

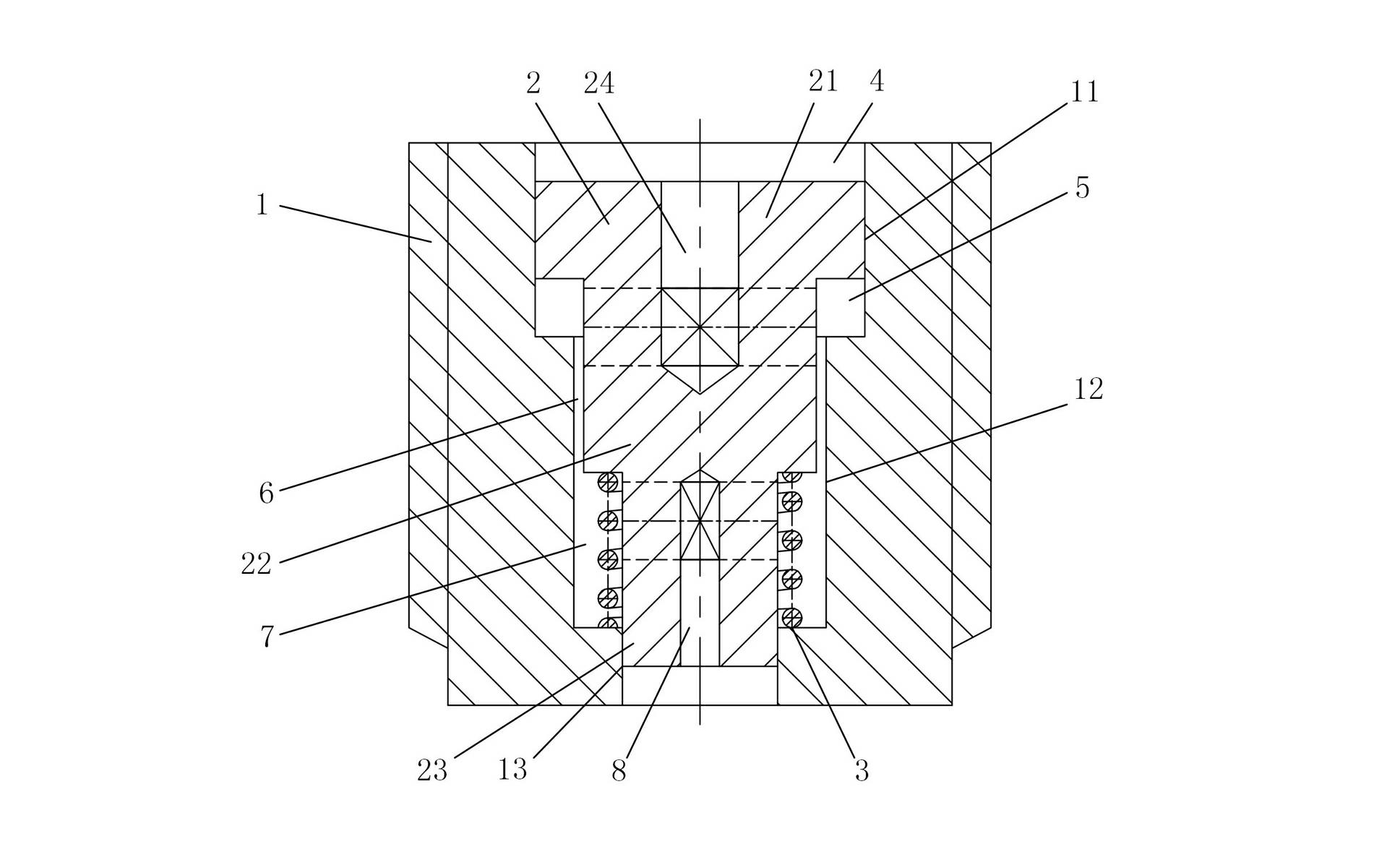

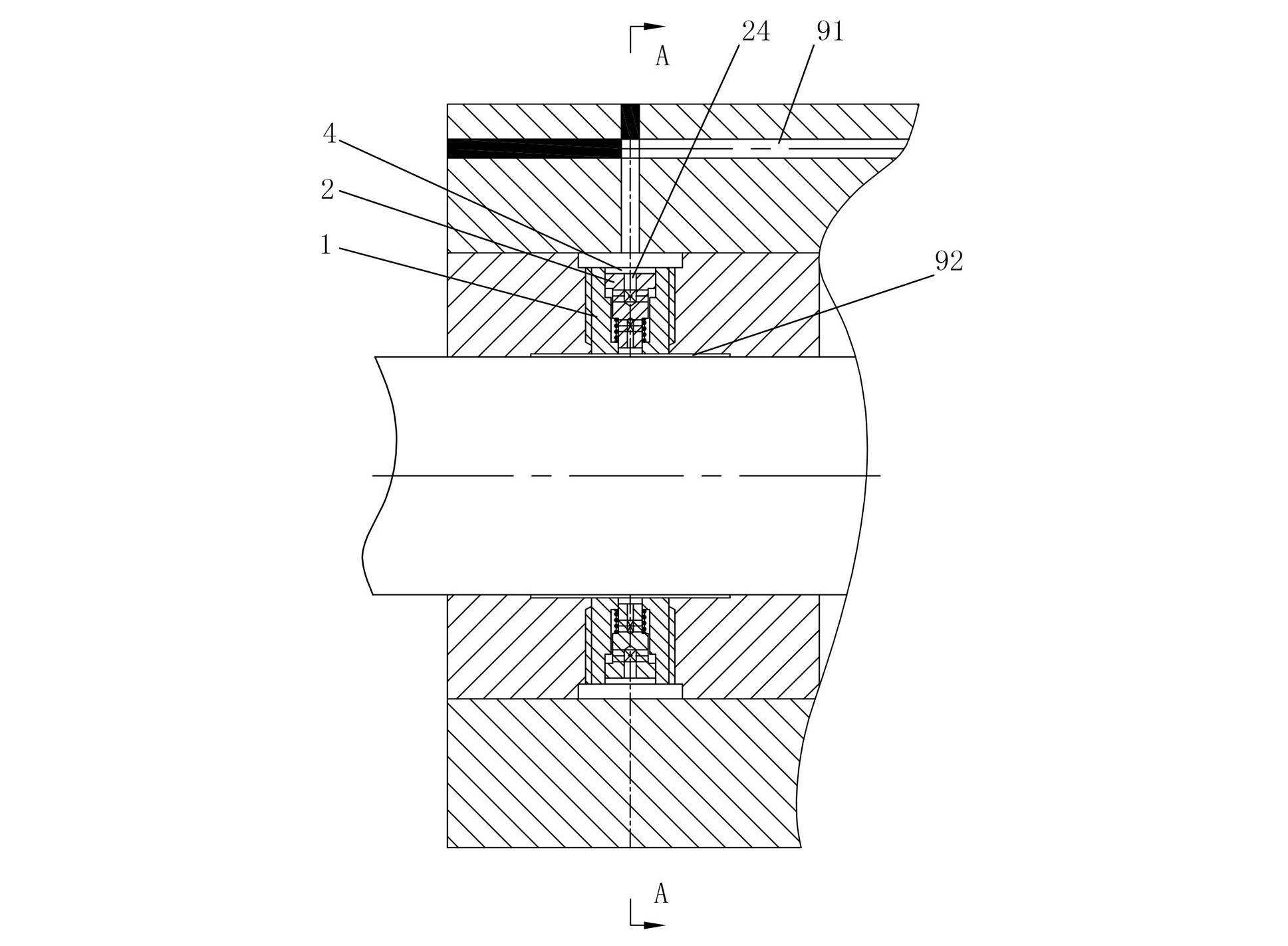

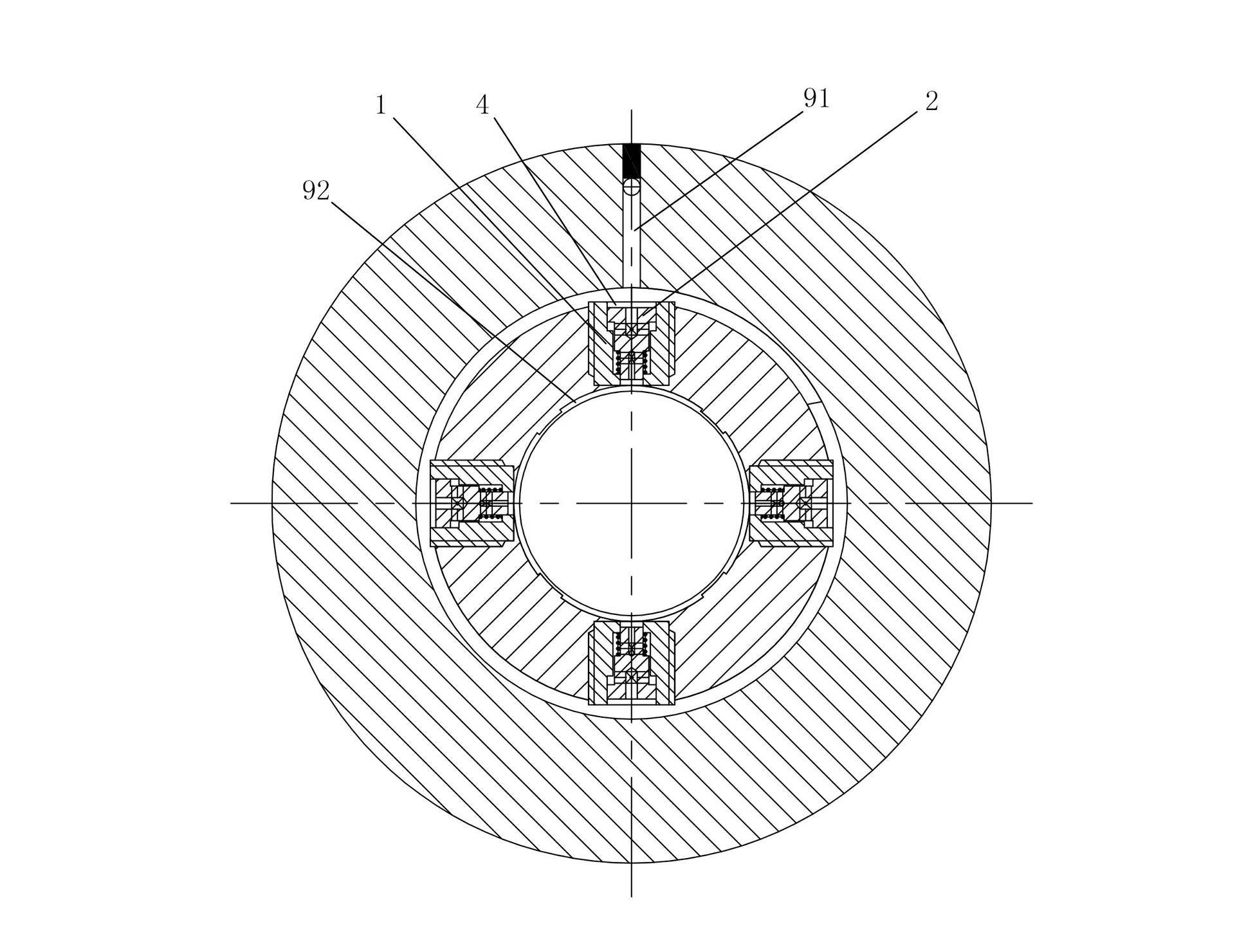

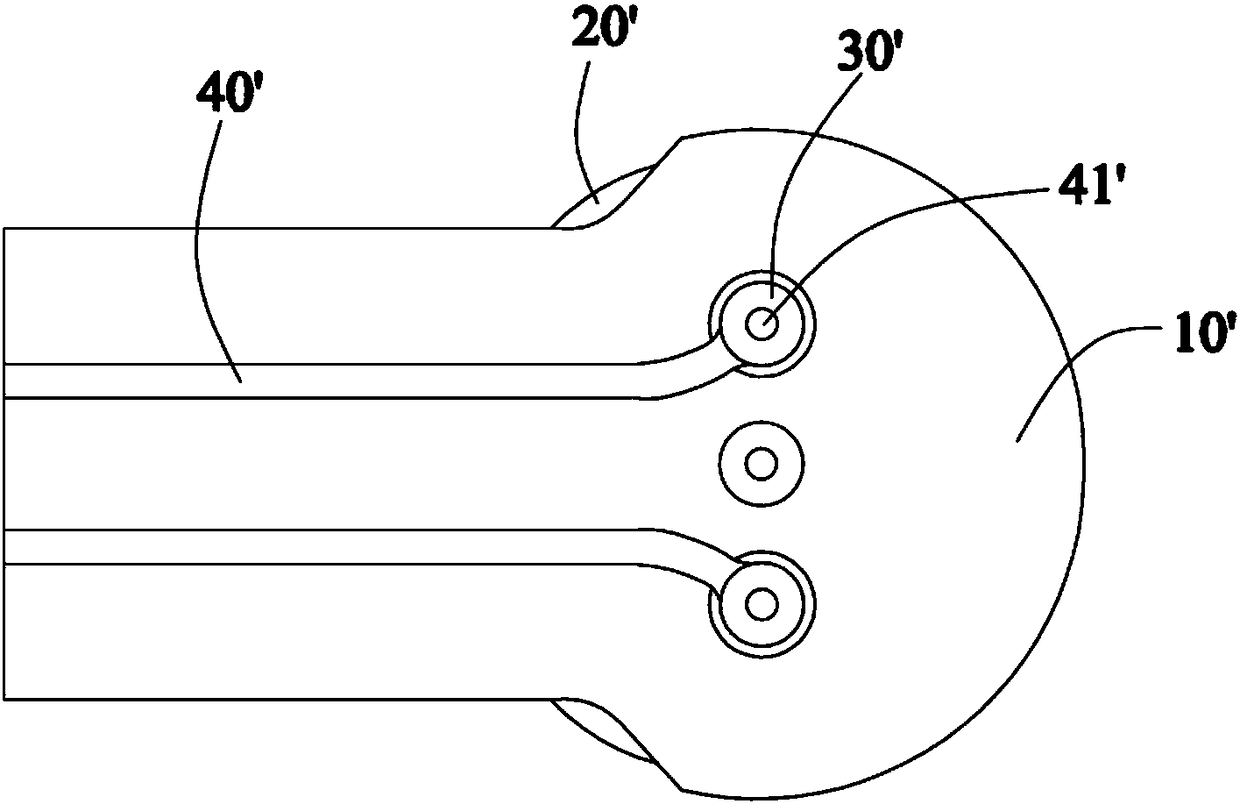

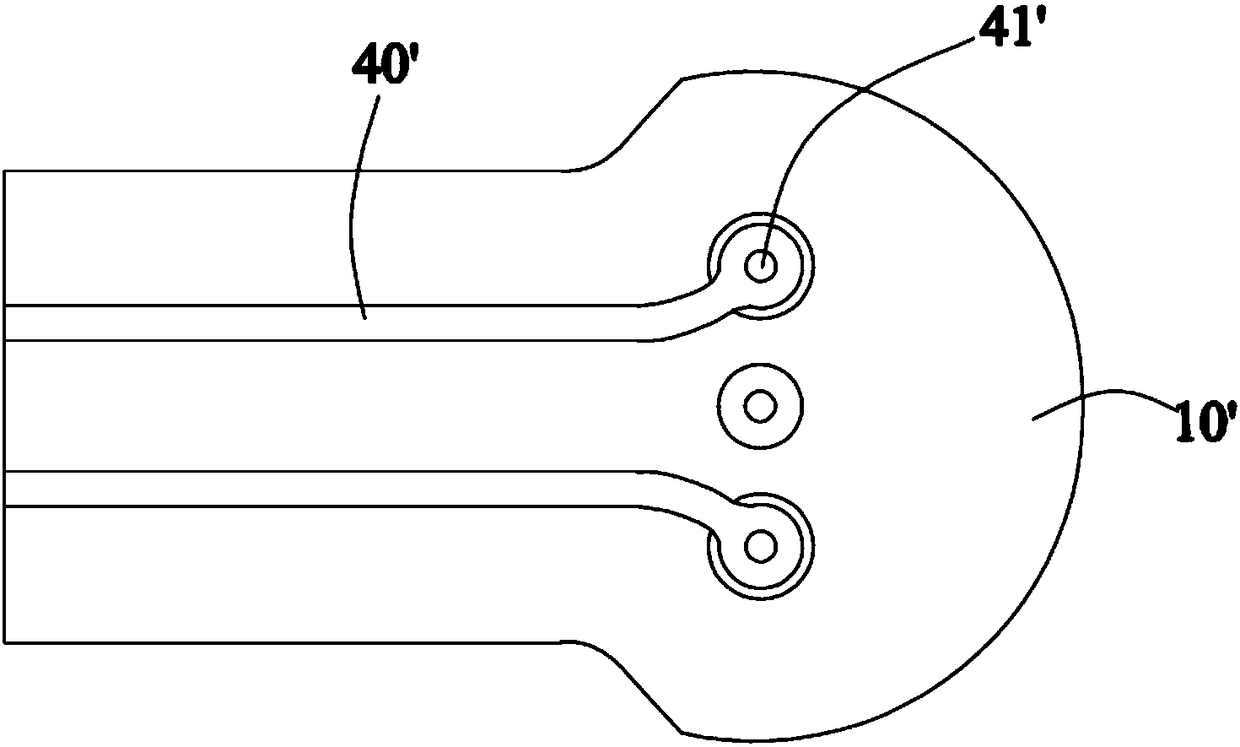

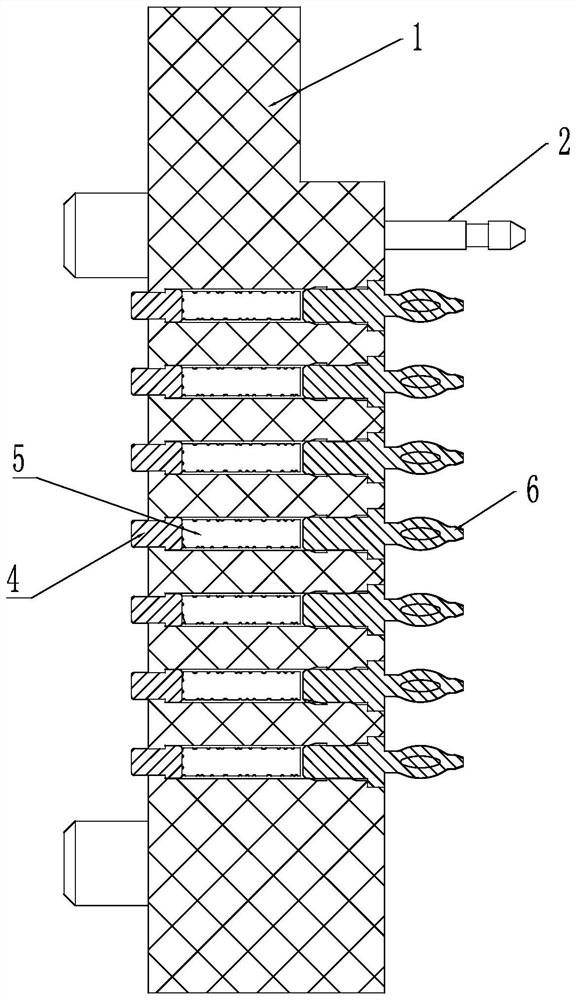

Single mold opening mechanism of bottle blowing machine

The invention discloses a single mold opening mechanism of a bottle blowing machine. The single mold opening mechanism comprises a formwork bracket, a fixed-edge mold, a mold opening and closing rotating shaft capable of being rotatably arranged on the formwork bracket around the first shaft axis, a mold opening and closing rotor arm, a movable-edge mold, a bottom mold bracket capable of being rotatably arranged on the formwork bracket around the second shaft axis, a bottom mold guide rail, a bottom mold, a bottom mold connecting rod, a bottom mold swing arm, a bottom mold swing rod, a space connecting rod, a bottom mold crank and a bottom mold pull rod; the first shaft axis and the second shaft axis are correspondingly located on the two sides of a mold assembly center line; when the bottle blowing machine opens the mold, the mold opening and closing rotating shaft is used for driving the movable-edge mold to rotate away from the fixed-edge mold and driving the bottom mold bracket tomove towards the mold opening; and the bottom mold bracket is used for driving the bottom mold to descend. According to the single mold opening mechanism of the bottle blowing machine, the movement rule of the movable-edge mold and the bottom mold can be accurately controlled, the structure is simple, the dynamic load is small, vibration and impact of the mechanism can be effectively reduced, partabrasion is reduced, the movement stability and reliability of the bottle blowing machine are enhanced, and the high-speed performance of the whole machine is improved.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

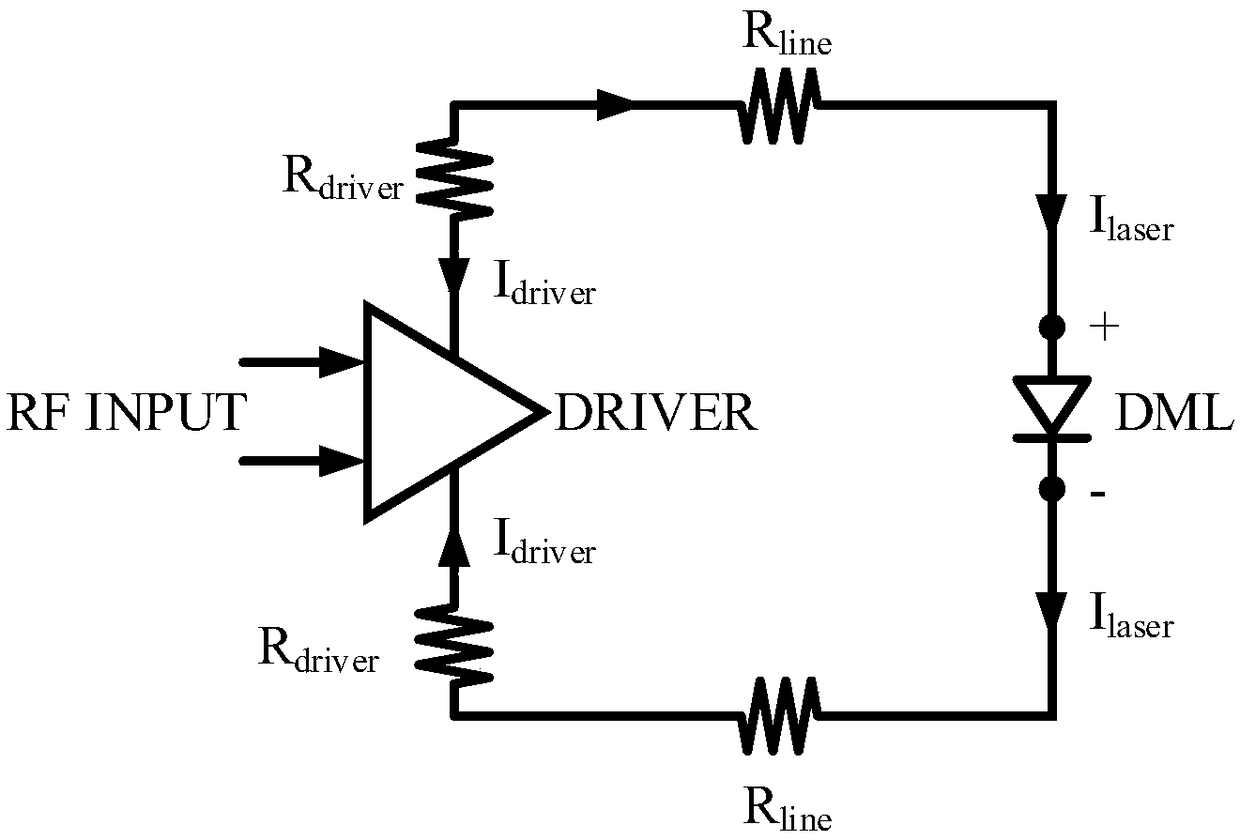

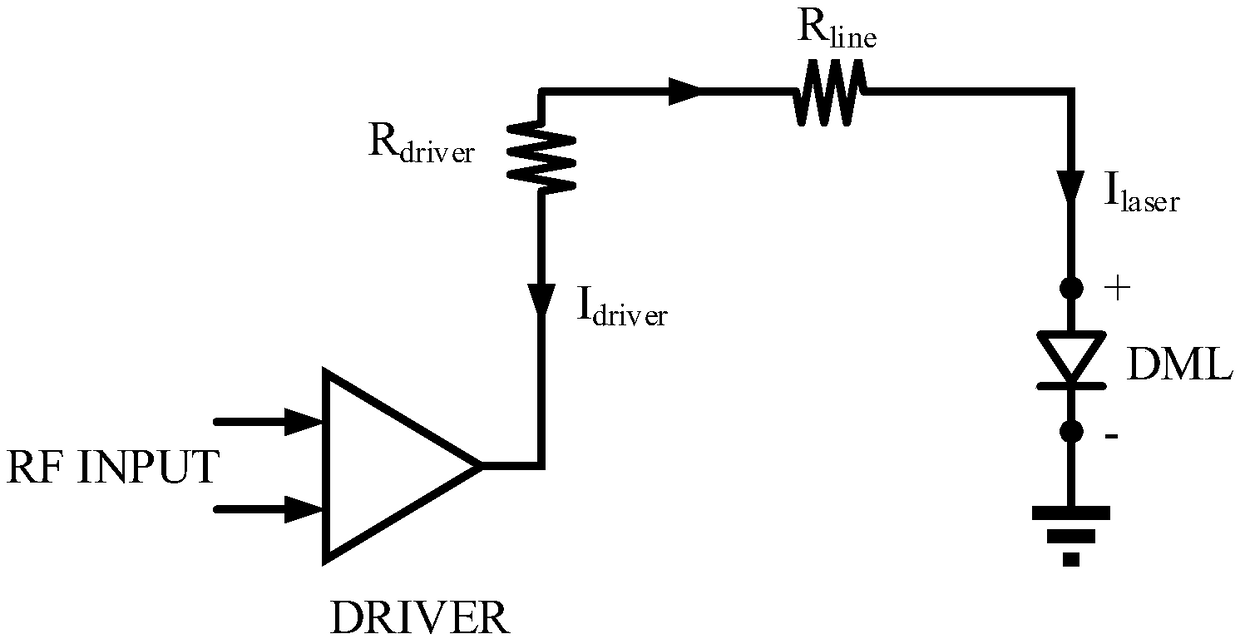

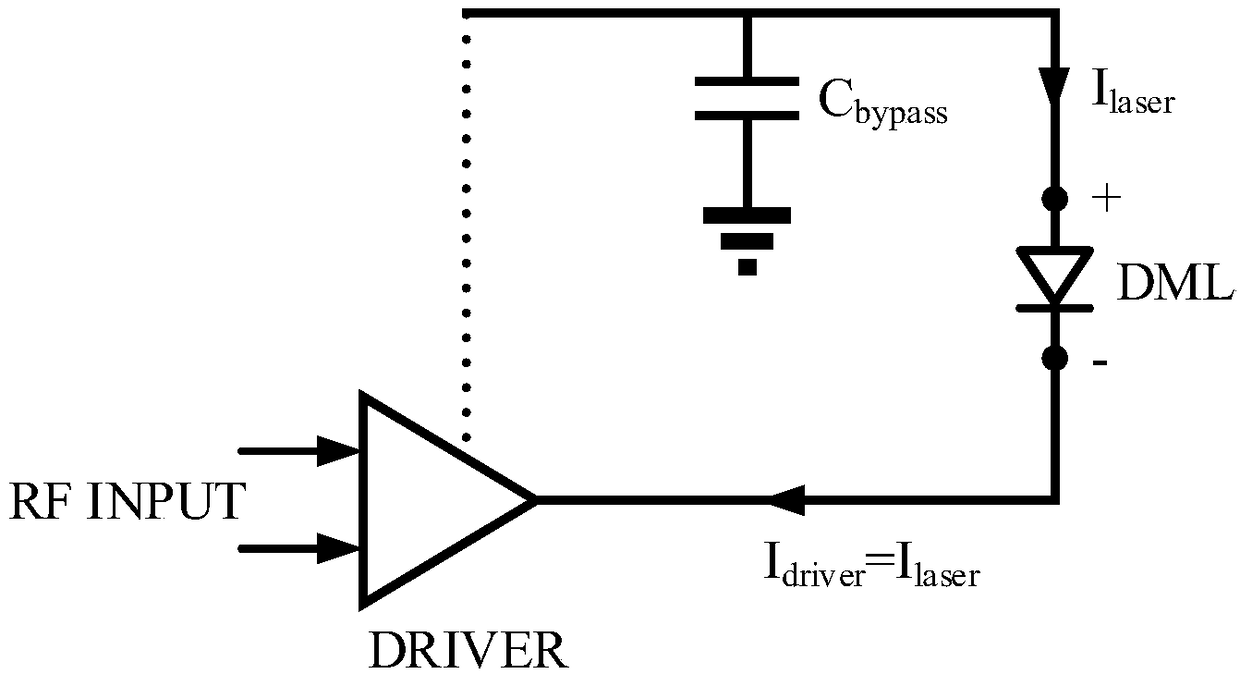

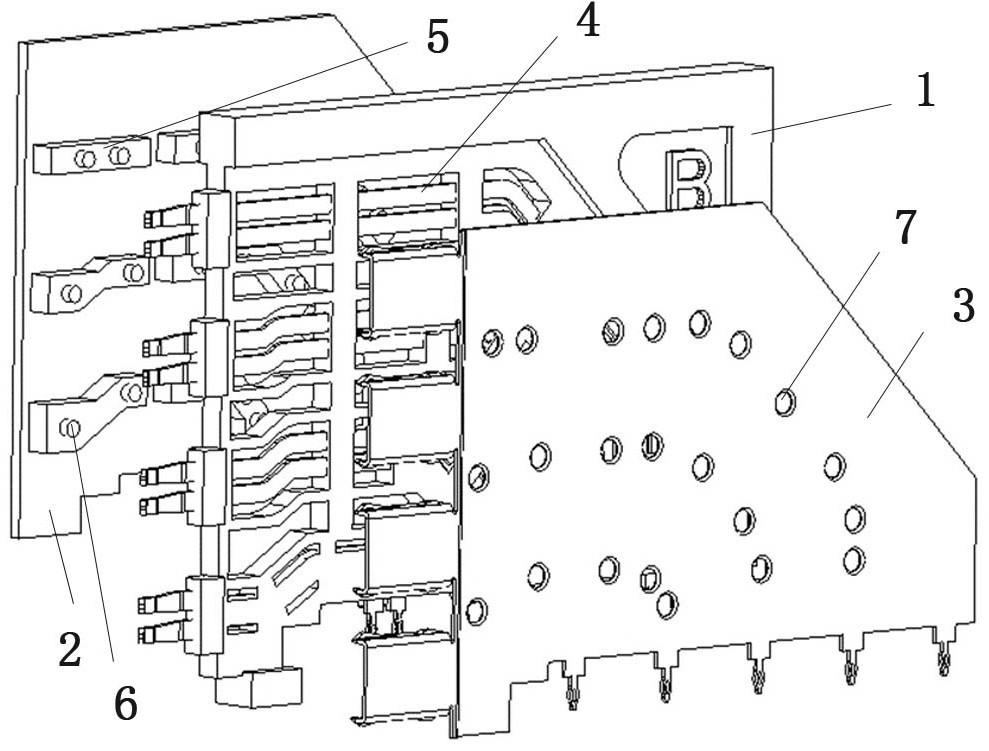

Structure and application of sunk type direct modulation laser and driver

ActiveCN108923248AEasy to produceImprove performanceLaser detailsSemiconductor lasersRadio frequencyEngineering

The invention discloses a structure and application of a sunk type direct modulation laser and a driver, which can reduce the power consumption of the driver and improve the high-speed performance ofthe driver; the integration is high; and the volume is small. In the structure, the DML is connected with the driver in series, wherein the anode of the DML is grounded as a radio frequency, and the cathode of the DML is connected with a radio frequency connection node of the driver; the radio frequency input signal is converted into a driver current by the driver to modulate the DML current; theDML current is completely sunk, flows into, or is drawn into the driver; and the drive current is equal to the DML current.

Owner:成都英思嘉半导体技术有限公司

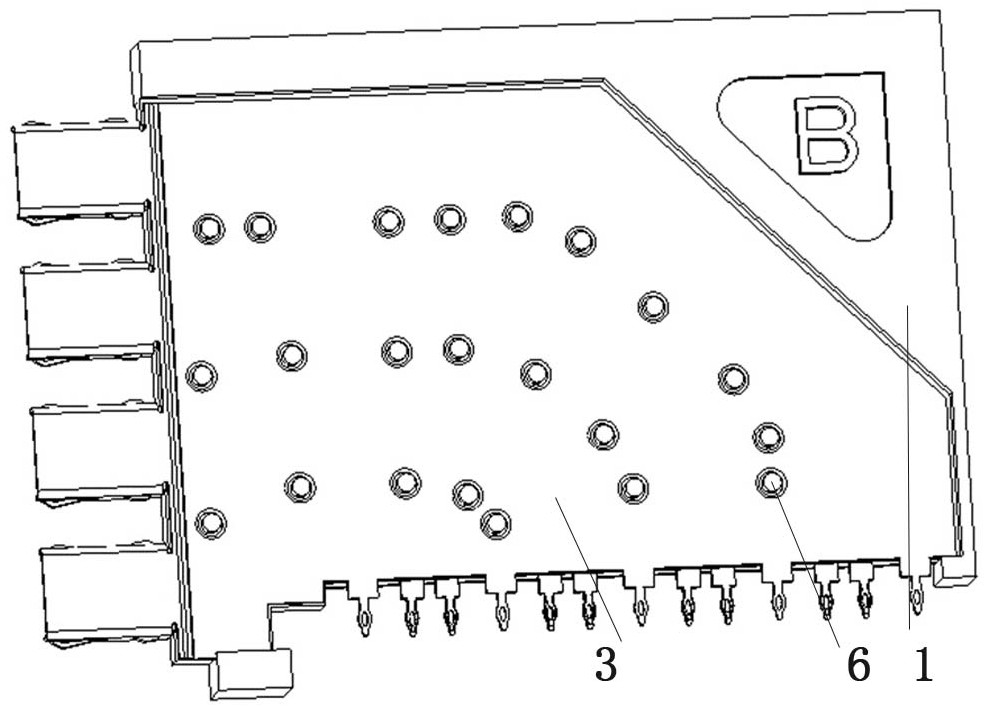

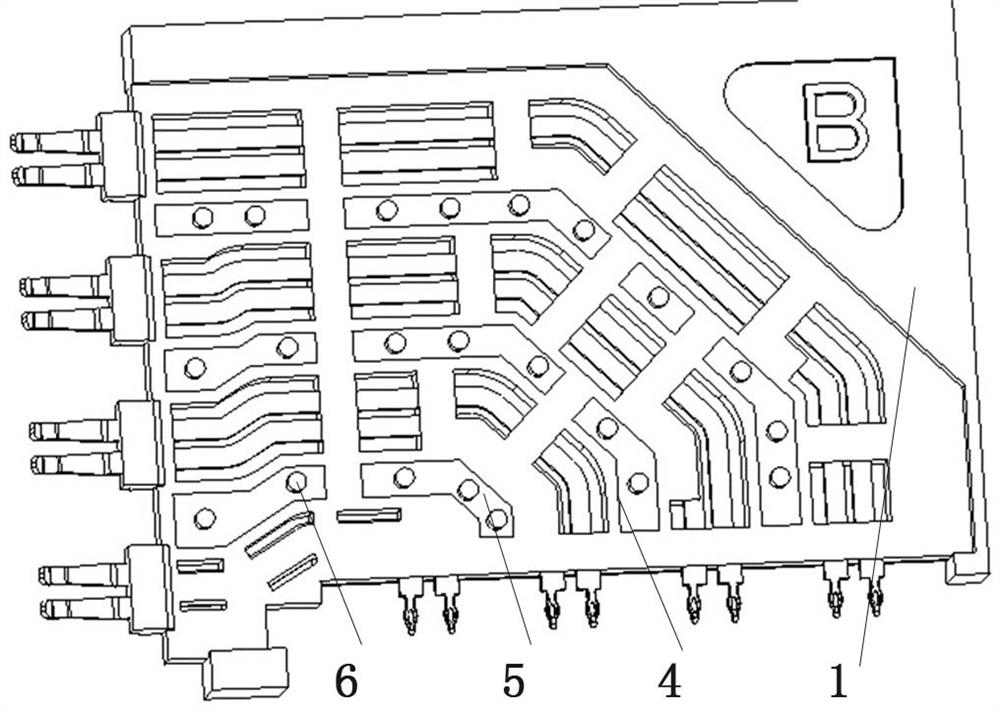

Terminal module and high-speed connector using same

PendingCN113571973ALow costGood for high speedCoupling device detailsPlastic materialsStructural engineering

The invention provides a terminal module and a high-speed connector using the terminal module; the terminal module comprises a connector transmission frame body, two sides of the connector transmission frame body are respectively provided with a conductive plastic plate and a conductive metal sheet, two sides of different differential wires on the connector transmission frame body are provided with at least one air slot hole. A connecting contact part is arranged on the end face of one side, close to the connector transmission frame body, of the conductive plastic plate, a matched contact part corresponding to the connecting contact part is arranged on the conductive metal sheet, and the connecting contact part penetrates through the air slot hole and then is correspondingly connected with the matched contact part arranged on the conductive metal sheet. Through the use of the conductive plastic material, the cost of the material adopting metal shielding on both sides is reduced; meanwhile, the conductive plastic plate is arranged on one side of the connector transmission frame body, and the conductive metal sheet is arranged on the other side of the connector transmission frame body, so that the electrical shielding of the two sides of the connector transmission frame body is realized, and meanwhile, the high-speed performance is also greatly improved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

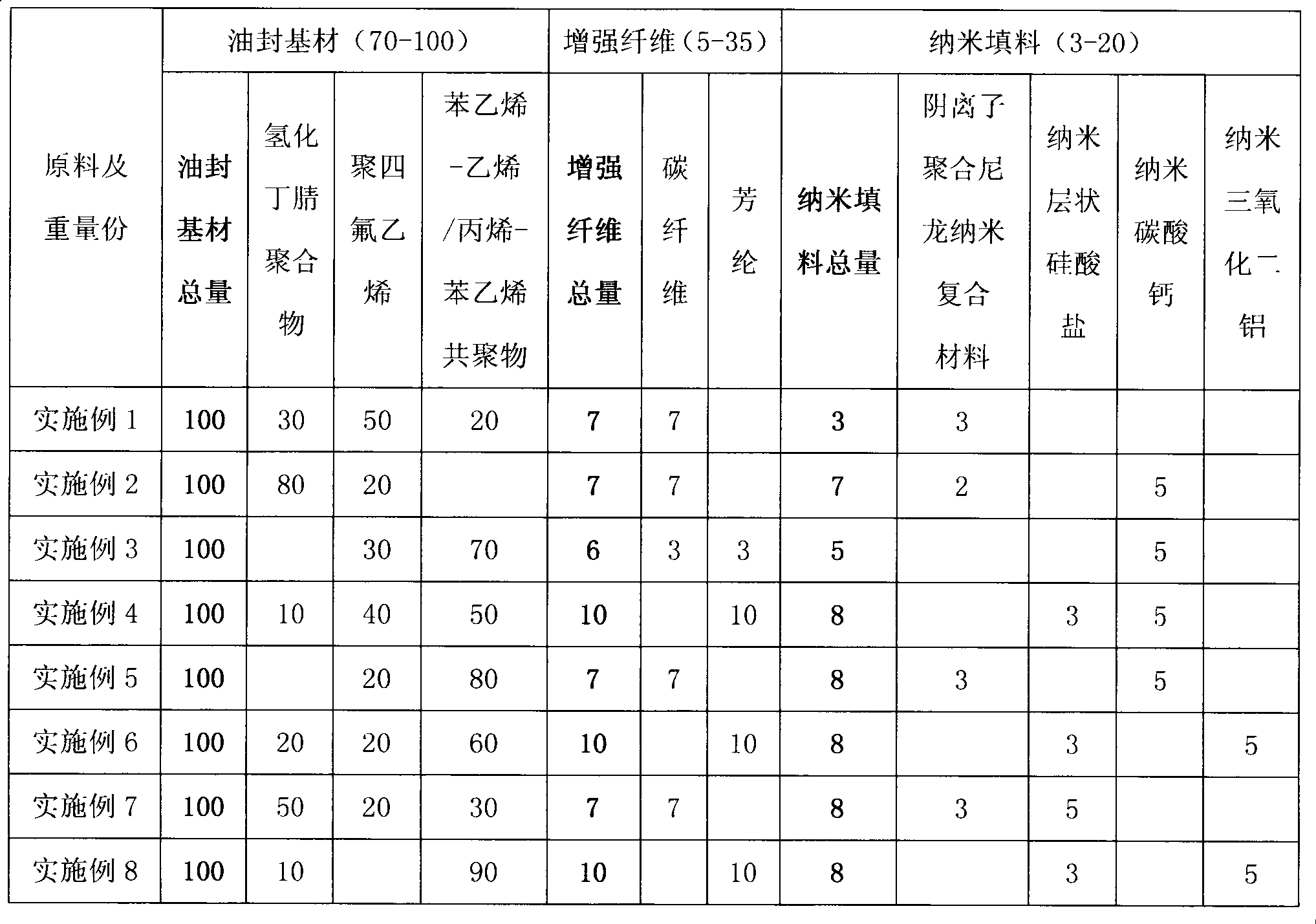

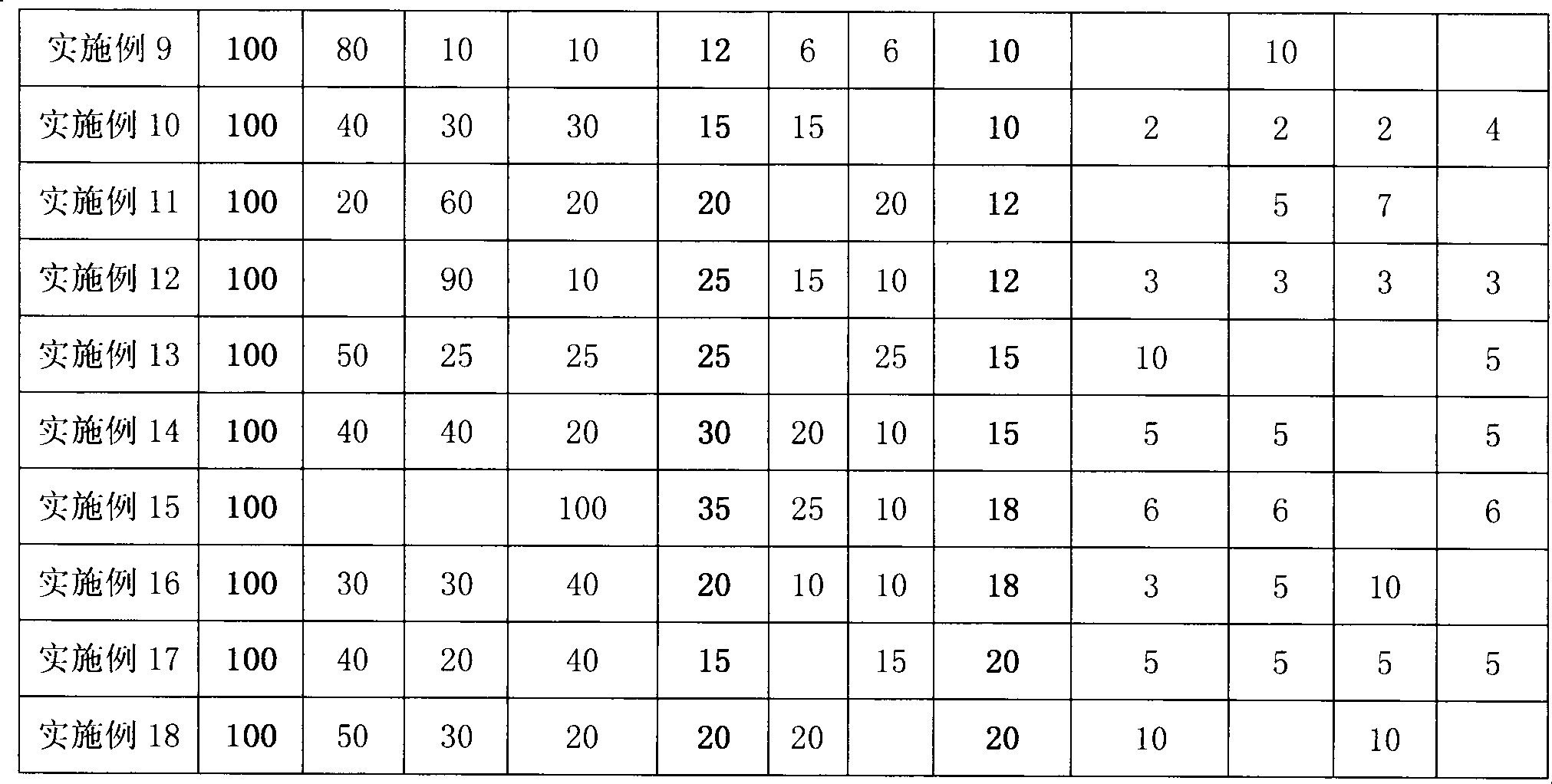

Wide-temperature-range high-speed fluid dynamic oil seal

The invention provides a wide-temperature-range high-speed fluid dynamic oil seal. The wide-temperature-range high-speed fluid dynamic oil seal comprises the following raw material components in parts by weight: 100 parts of an oil seal base material, 5 to 35 parts of reinforced fibers and 3 to 20 parts of a nano-filler. The wide-temperature-range high-speed fluid dynamic oil seal with an interpenetrating polymer network (IPN) structure is prepared from the oil seal base material serving as a base and the reinforced fibers and the nano-filler serving as auxiliary materials; expensive fluoropolymer and an acrylate adhesive with low process tolerance are replaced by a common base material, so that the production cost is effectively reduced; the prepared oil seal has appropriate oil expansibility and a good sealing effect, and by adopting the formed IPN structure, the adaptability of a finished product to high rotating speed, high and low temperatures and oil resistance working conditions, and the use reliability of the finished product are improved, the temperature resistance grade is between 35 DEG C below zero and 200 DEG C, and the transient temperature can reach 300 DEG C; and the linear speed of fluid at a sealing part reaches 20m / s, so that the soil seal product is good in product superiority and high in cost performance.

Owner:HUANGSHAN SHANGYI RUBBER & PLASTIC PRODS

Prescription of low-heat generation tire casing bottom layer glue of pneumatic tyre

The invention provides a formulation for low-heat tread bottom rubber of pneumatic tire. The formulation mainly contains the components with the following weight portions: 85 to 110 portions of raw rubber, 5 to 15 portions of white carbon black, 30 to 40 portions of carbon black N375, 0.8 to 2.0 portions of promoter, 2.0 to 4.0 portions of anti-aging system, 2.0 to 5.0 portions of zinc oxide, 1.5 to 3.0 portions of stearic acid, 0.8 to 2.0 portions of sulfur and 8.0 to 10.0 portions of other components. The invention improves the tire high-speed performance, increases the tire loading capacity and prolongs the tire service life.

Owner:万达集团股份有限公司

All-steel radial truck tyre carcass size composition and mixing method thereof

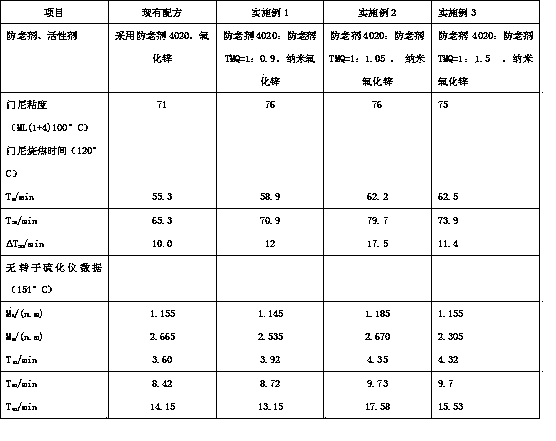

The invention discloses an all-steel radial truck tyre carcass size composition which comprises the following components by weight: 100 parts of natural rubber, 56 parts of carbon black N326, 1 part of an antiager 4020, 0.9-1.5 parts of an antiager TMQ, 4.5 parts of insoluble sulfur 7020, 1.25 parts of an accelerator DZ, 0.2 part of a scorch retarder CTP, 5 parts of an adhesive RA65, 3 parts of an adhesive GLR, and 8 parts of an active agent. Through the adoption of the technical scheme, the antiager 4020 and the antiager TMQ are combined for use to enable the mooney viscosity of the size to be increased, the scorch time of the size is prolonged, the adhesion property is enhanced, and when the ratio of the antiager 4020 to the antiager TMQ is 1:1.05, the adhesion property and the coating quality are better.

Owner:WEIFANG YUELONG RUBBER

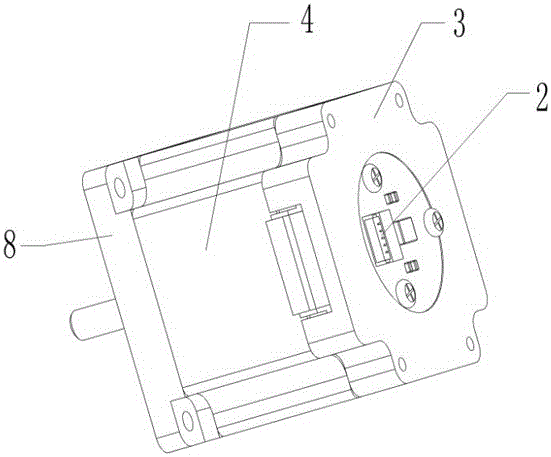

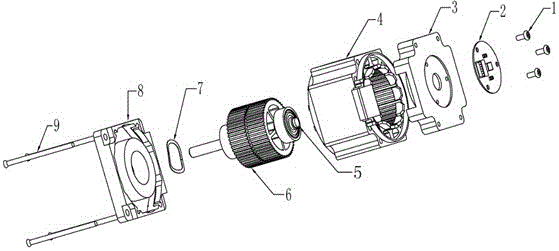

High-speed rotary motor capable of being positioned accurately

PendingCN106787315APrecise positioningGood for high speedAssociation with control/drive circuitsMagnetic circuit rotating partsMoment of inertiaEngineering

The invention discloses a high-speed rotary motor capable of being positioned accurately. The high-speed rotary motor comprises a circuit board, a back end cover, high-performance magnetic steel, a rotor assembly and a front end cover, wherein the circuit board is fixedly connected with the back end cover through first screws; the high-performance magnetic steel is mounted at one end of the rotor assembly, and the high-performance magnetic steel is mounted in the back end cover; the rotor assembly is mounted in a stator assembly; and the rotor assembly is connected with the front end cover through a wave gasket. According to the high-speed rotary motor capable of being positioned accurately, the center of a rotor iron core of the rotor assembly is hollowed out, so that rotational inertia can be lowered and high-speed performance of the motor can be improved; in addition, the high-performance magnetic steel is mounted on the motor shaft of the rotor assembly, so that signal induction can be performed conveniently and the motor can be positioned accurately; and therefore, the high-speed rotary motor is reasonable in design, capable of solving the problem of inaccurate positioning of the existing motor rotor and avoiding a phenomenon of low rotary speed of the rotor caused by unreasonable design, and quite bright in application market.

Owner:中山市胜洋电机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com