Switching high-speed connector

A high-speed connector and rigid contact technology, which is applied in the direction of connection, contact parts, fixed/insulated contact components, etc., can solve the problems that cannot meet the requirements of use, and achieve the effect of easy short pile, reliable contact, and elimination of short pile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

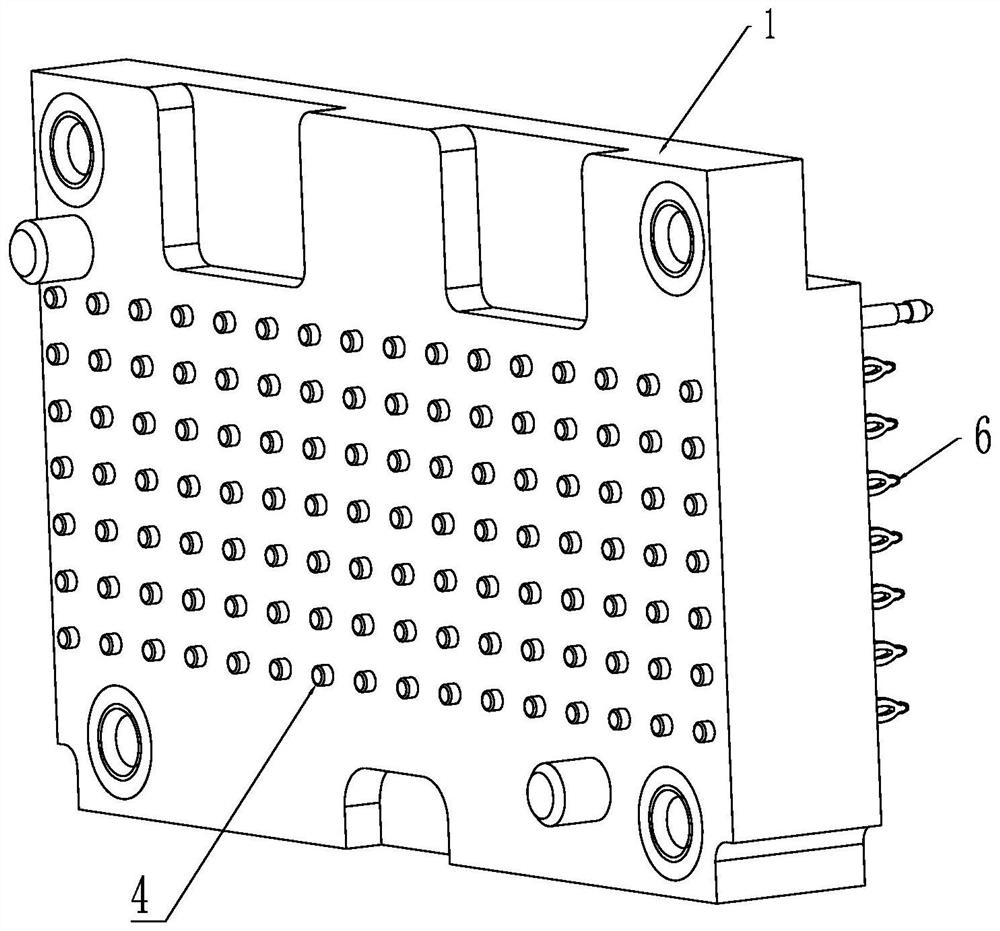

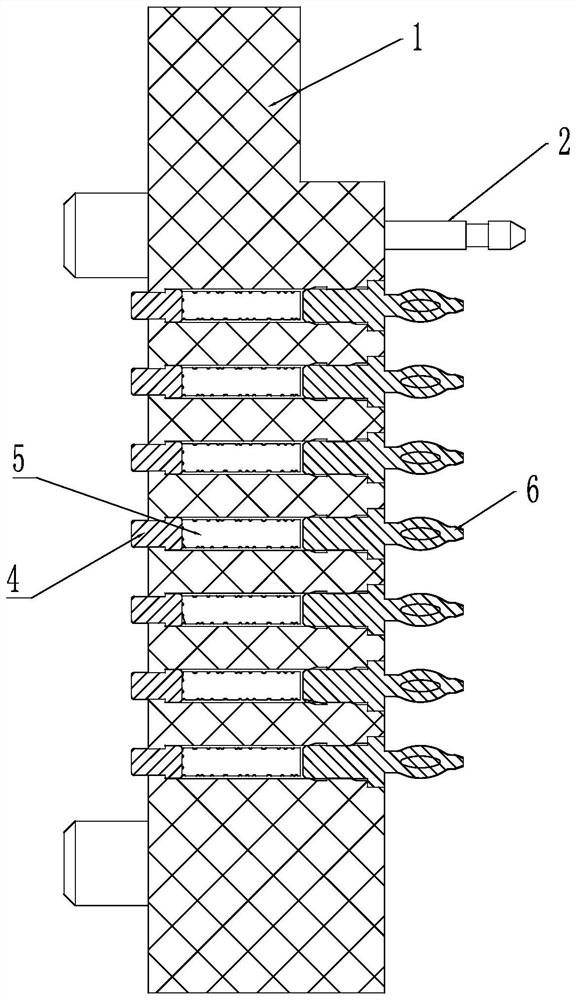

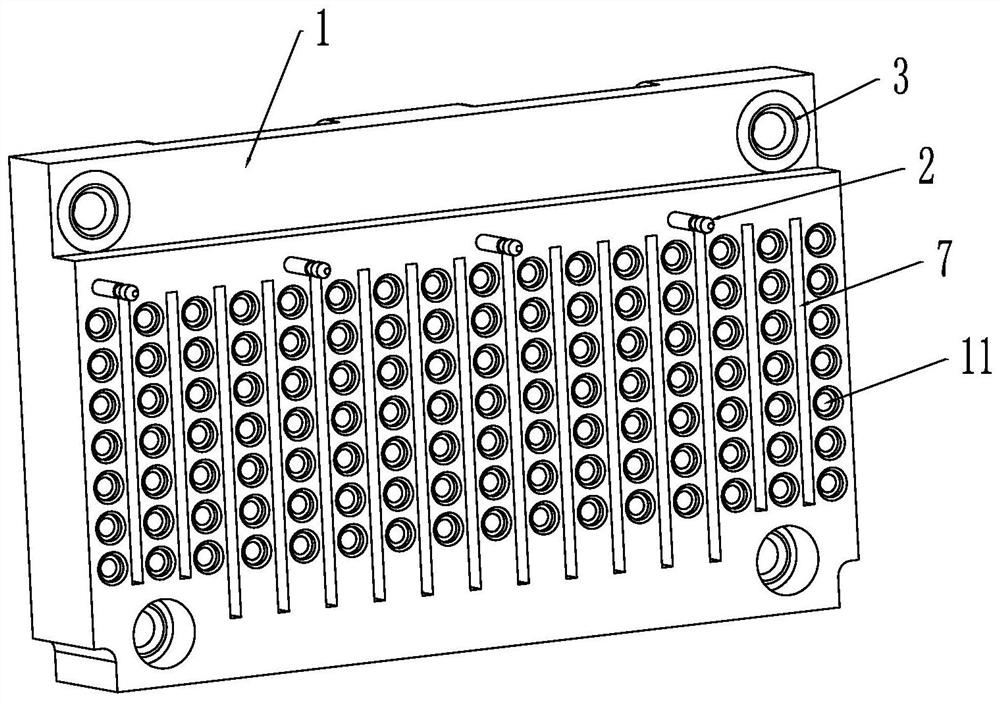

[0036] An embodiment of a transfer high-speed connector, such as Figure 1 to Figure 7 , used to achieve a reliable transfer between the optical active module and the printed board, the transfer high-speed connector includes an insulator part and a contact part, the insulator part includes an insulator 1, a guide pin 2 and a nut 3, and an installation The hole 11, the contact part is installed in the corresponding installation hole, and the contact part adopts a sequential series structure of the rigid contact head 4, the button contact part 5 and the fisheye needle 6. The fisheye pin 6 is a fisheye structure, which protrudes from one end of the mounting hole 11 and is used for welding-free crimping with the printed board. The rigid contact head 4 and the button contact piece 5 form an elastic contact stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com