110kv and above prefabricated dry cable terminal accessories

A cable termination, prefabricated technology used in cable termination and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

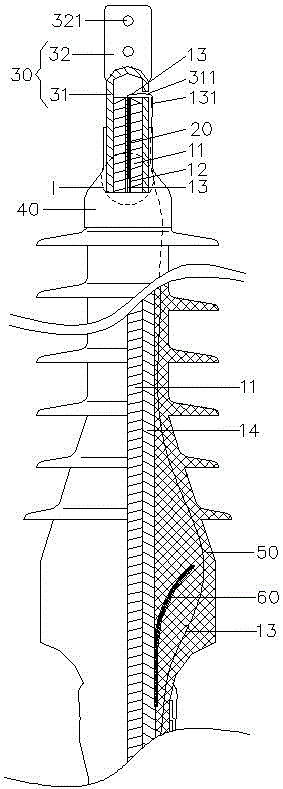

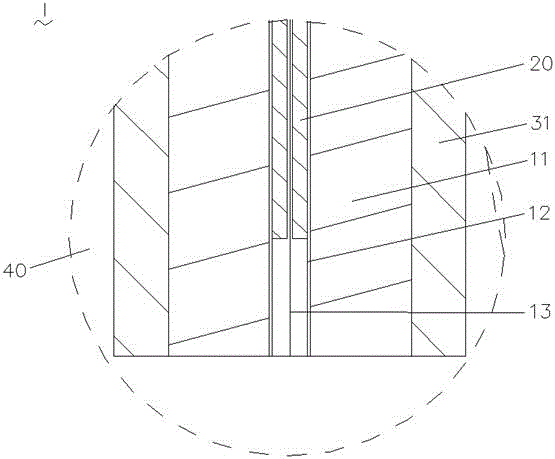

[0024] see figure 1 and figure 2 , the 110KV and above prefabricated dry-type cable terminal accessories of the present invention are used to connect the cable 10 to electrical equipment (not shown in the figure), including at least one crimping liner 20, terminal 30, sealing tube 40, and terminal insulator 50 and stress control body 60.

[0025] The cable 10 includes a cable conductor 11 , an optical fiber sheath 12 disposed in the cable conductor 11 , at least one optical fiber 13 sheathed in the optical fiber sheath 12 , and a cladding layer 14 outside the cable conductor 11 .

[0026] The crimped liner 20 may consist of one segment or several segments.

[0027] Preferably, the crimping liner 20 is made of a hard metal crimping liner, or a hard polymer material.

[0028] In this embodiment, the crimping liner 20 is disposed in the optical fiber sheath 12 of the cable 10 and sleeved outside the optical fiber 13 , and the crimping liner 20 is directly sleeved outside the ...

Embodiment 2

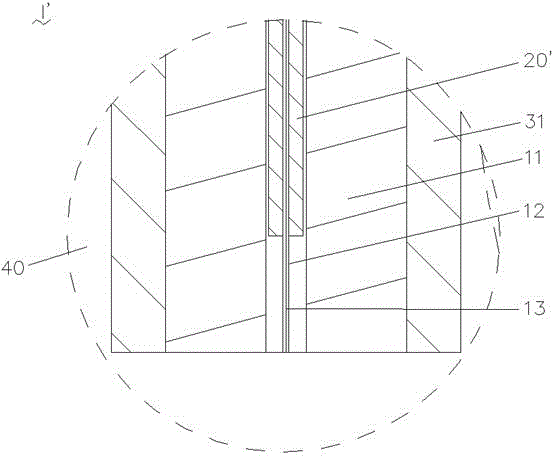

[0035] see image 3 , image 3 is the enlarged schematic diagram of I', where the position of I' is the same as figure 1 The position at I is the same, which discloses an embodiment in which the crimping liner is arranged inside the cable conductor and outside the fiber sheath. This embodiment is similar to Example 1, the difference being that the crimping liner 20' is set on The cable conductor 11 of the cable 10 is located outside the optical fiber sheath 12 , and the crimping liner 20 ′ is indirectly located outside the optical fiber 13 . The optical fiber 13 of the cable 10 is led out from one end of the optical fiber sheath 12 .

[0036] The 110KV and above prefabricated dry-type cable terminal accessories of the present invention are provided with a crimping liner 20' outside the optical fiber sheath 12 of the cable conductor 11. When the cable conductor 11 is crimped and connected, the crimping liner 20' bears the crimping force, which prevents the optical fiber 13 i...

Embodiment 3

[0038] see Figure 4 , Figure 4 It is the enlarged schematic diagram of I'', where the position of I'' is the same as figure 1 The position of I is the same, which discloses Embodiment 3 of the 110KV and above prefabricated dry-type cable terminal accessories of the present invention. This embodiment is similar to Embodiment 1, and the difference is that: the cable conductor 11 of the cable 10 is located in the optical fiber A crimping liner 20 ″ is further provided outside the sheath 12 , and the crimping liner 20 ″ is indirectly located outside the optical fiber 13 .

[0039] The 110KV and above prefabricated dry-type cable terminal accessories of the present invention are provided with a crimping liner 20 inside the optical fiber sheath 12 of the cable conductor 11, and a crimping liner 20'' outside the optical fiber sheath 12, and between the crimping tube 31 and the cable When the conductor 11 is crimped and connected, the crimping liner 20 / 20'' bears the crimping forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com