Patents

Literature

34results about How to "Realize the leading role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

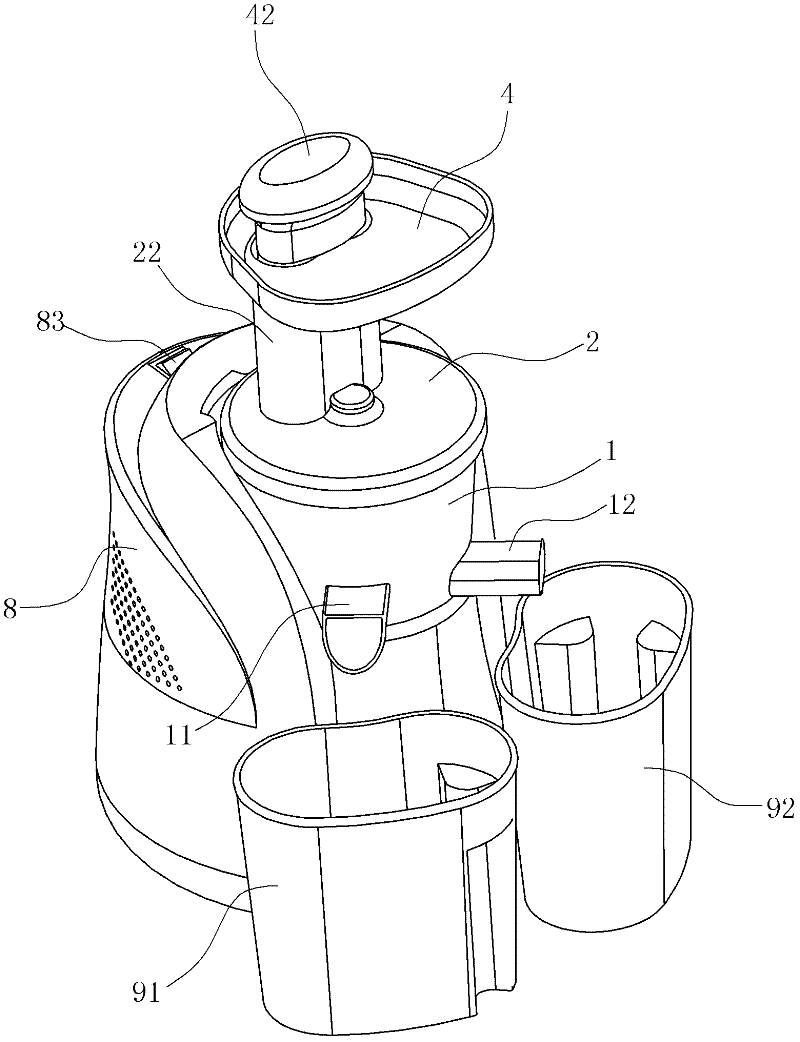

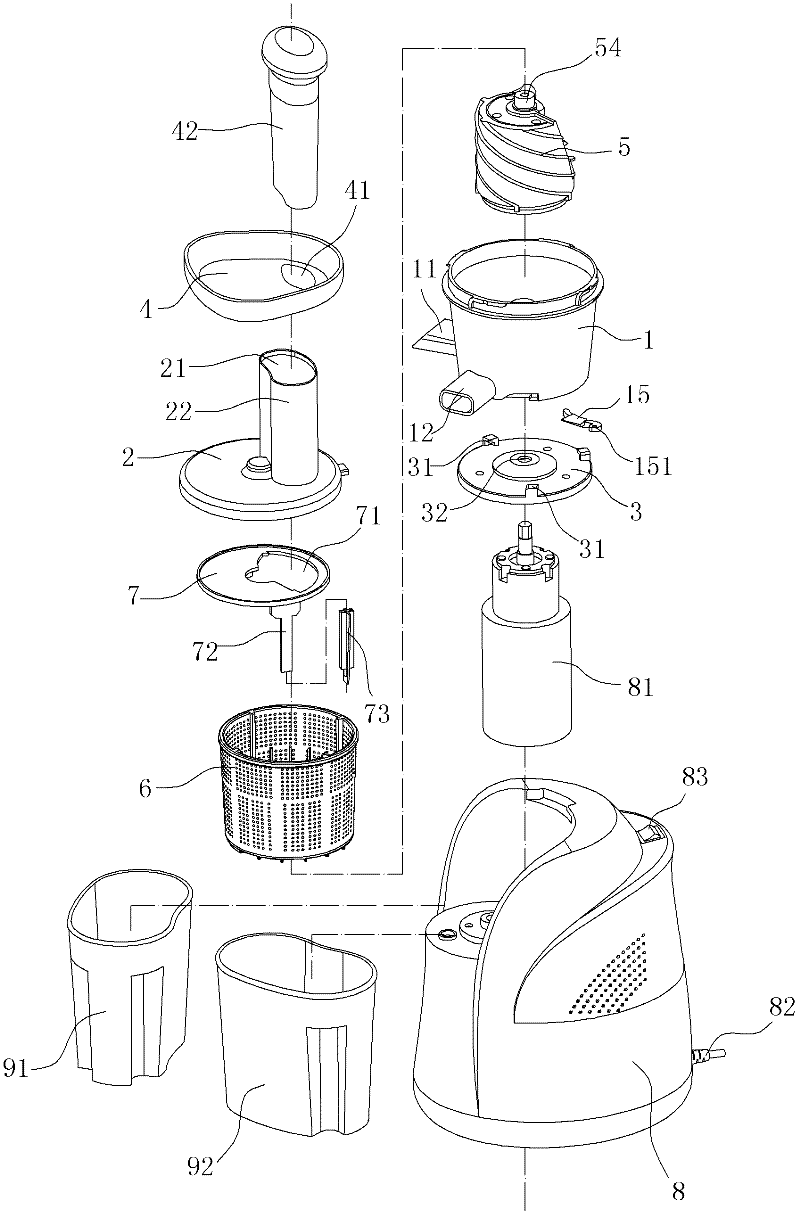

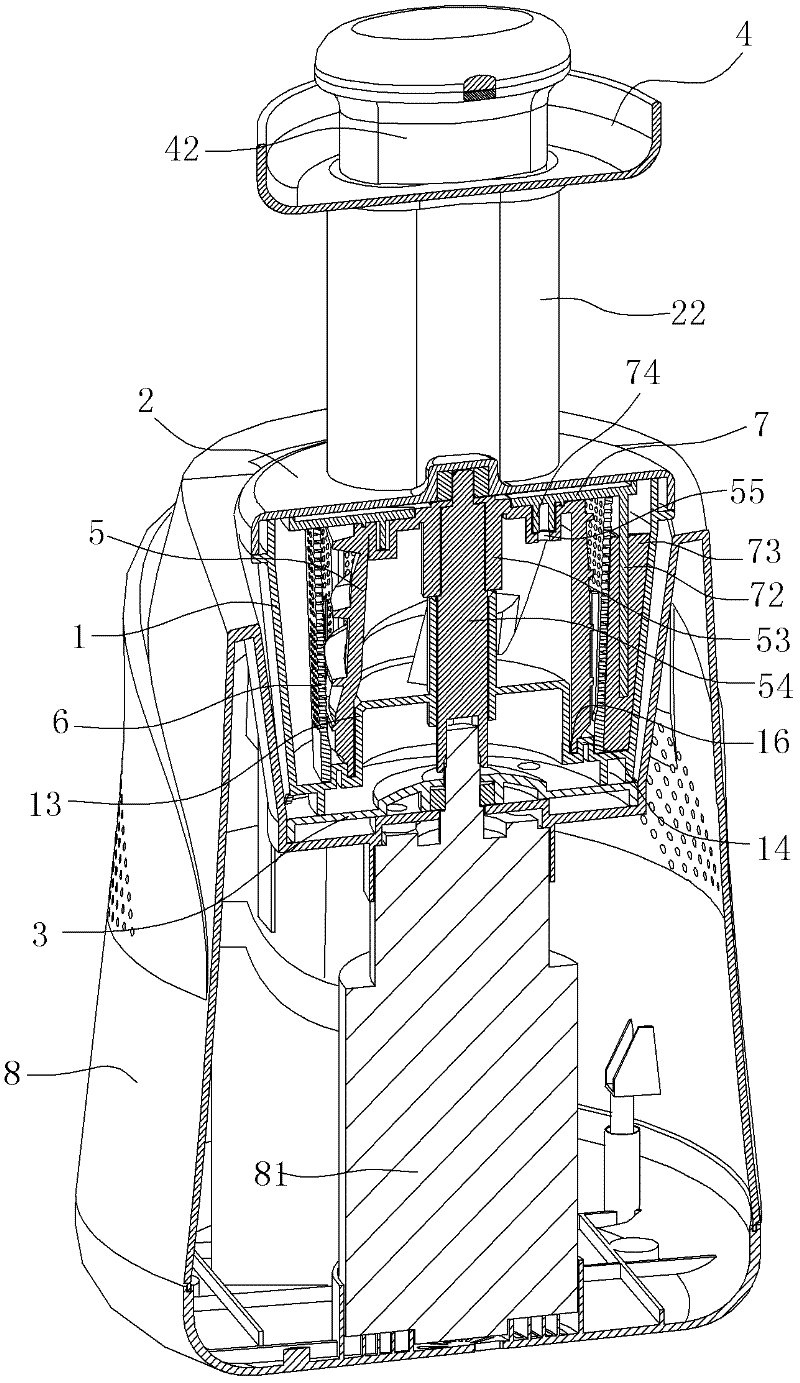

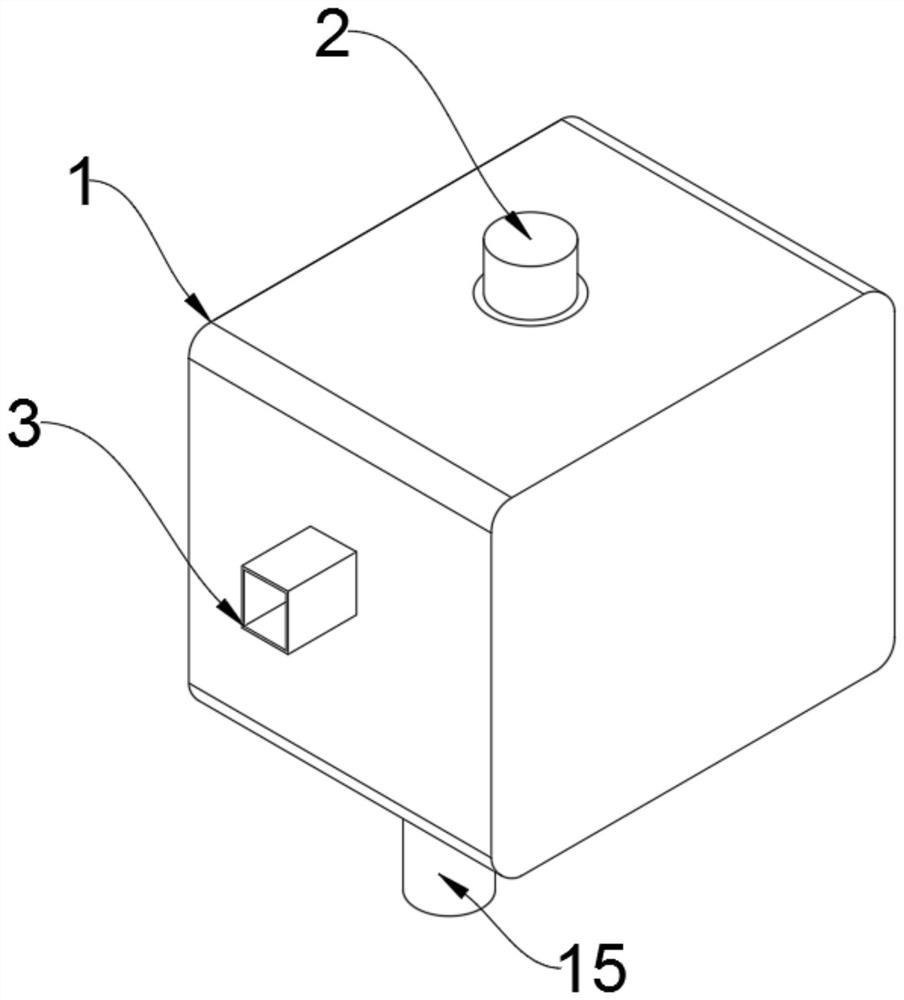

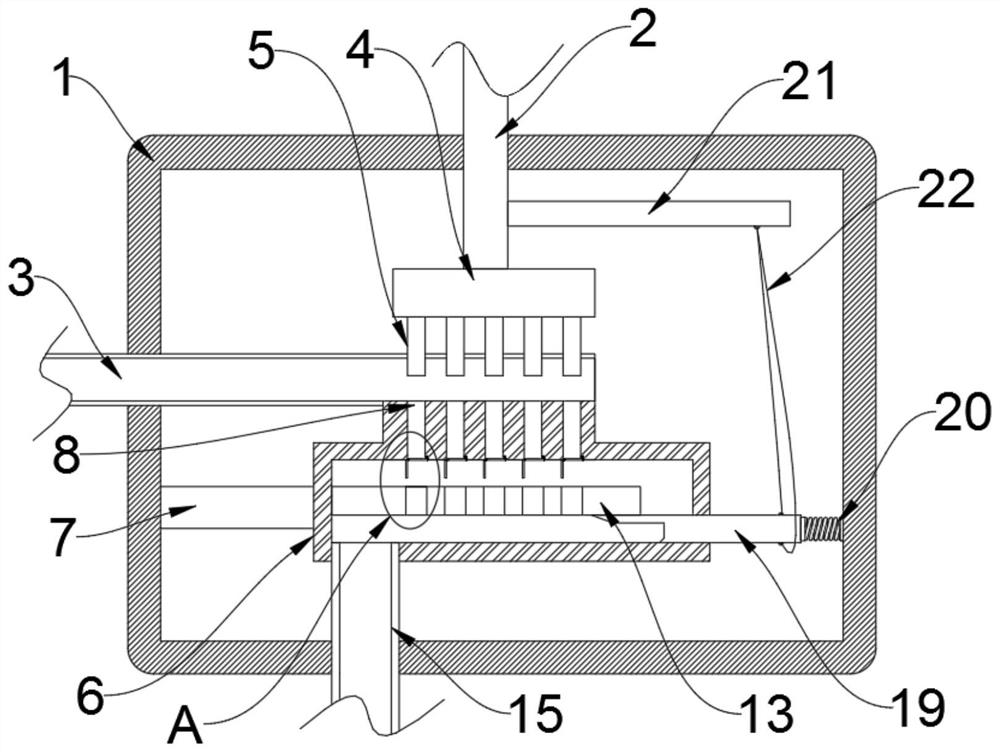

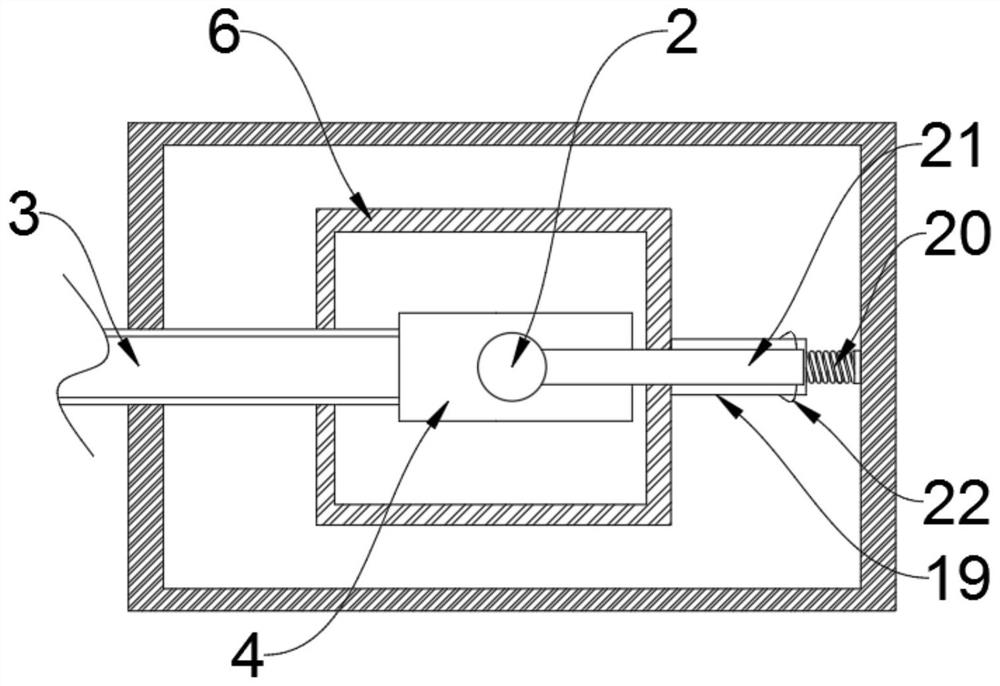

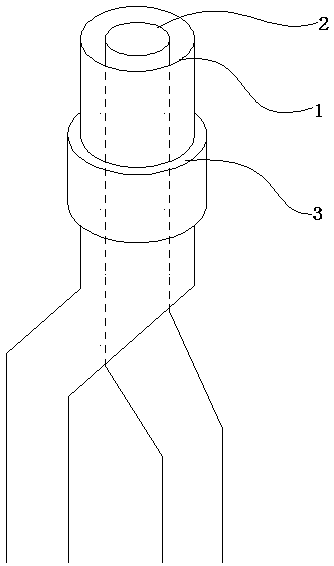

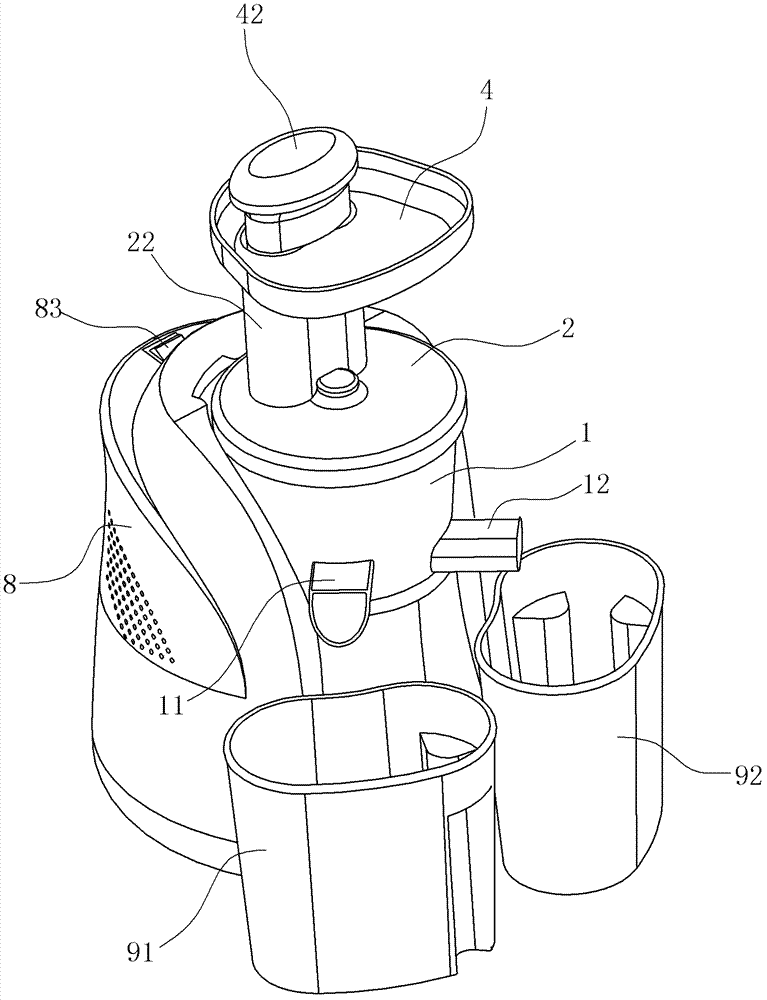

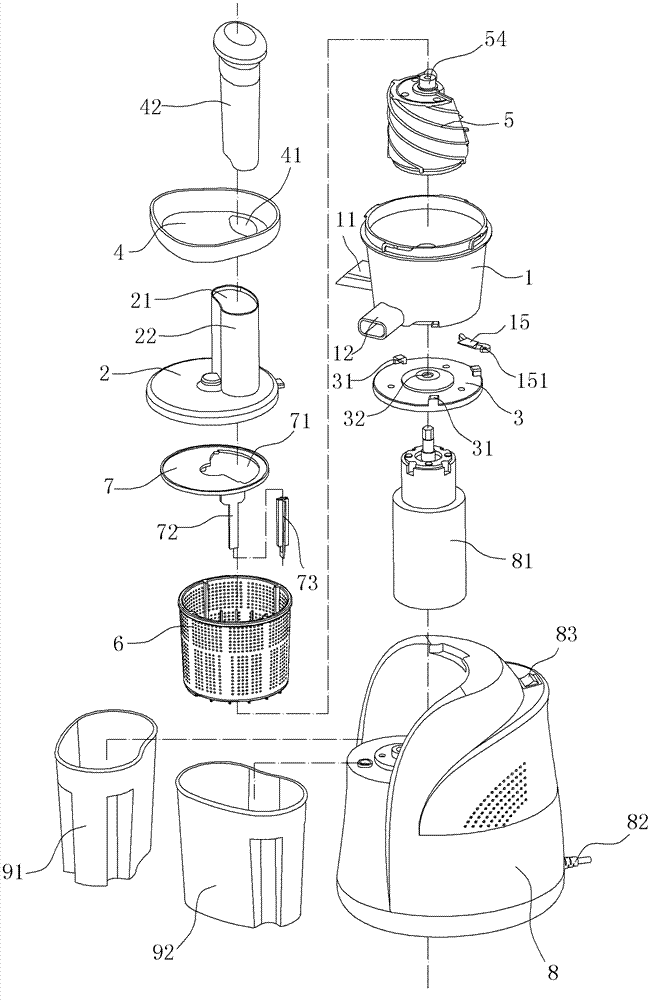

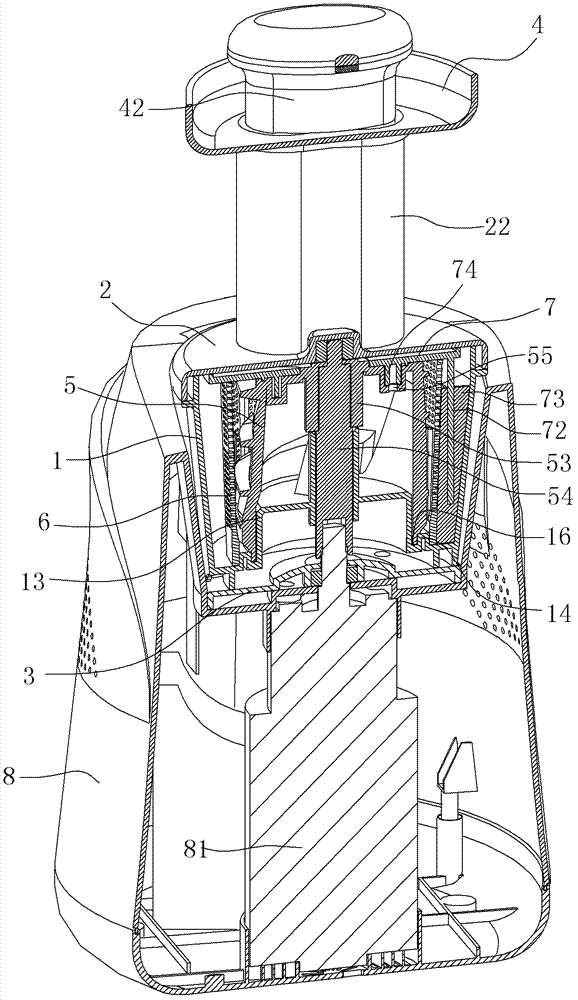

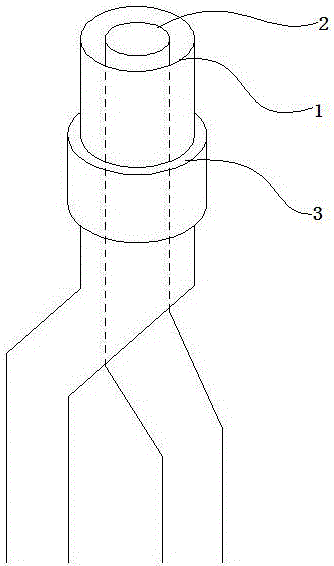

Juice extractor

The invention relates to a juice extractor. The juice extractor comprises a shell, a juice extracting component and a driving component, wherein a feed inlet, a juice outlet and a dreg outlet are formed in the shell; the juice extracting component is arranged in the shell; and the driving component is used for driving the juice extracting component to work and arranged below the shell. The juice extractor is characterized in that: the juice extracting component comprises a juice extracting body and a filtering screen; the juice extracting body is a columnar rotor which can be driven to rotate by the driving component; a notch which can be correspondingly communicated with the feed inlet of the shell is formed on the upper half part of the juice extracting body; spiral teeth are formed on the juice extracting body along an outer circumferential surface; the juice extracting body is arranged in the filtering screen in a rotatable way; and the filtering screen is fixedly arranged in the shell. The juice extractor has a more simple overall structure, a small number of parts, low production cost and high juice extracting efficiency and is safely used; automatic blanking can be realized in the rotating process of the juice extracting body; and the two ends of the juice extracting body are not required to be fixed, so that the juice extracting body can be directly connected with the driving component, and the juice extractor is more convenient to mount.

Owner:张建民

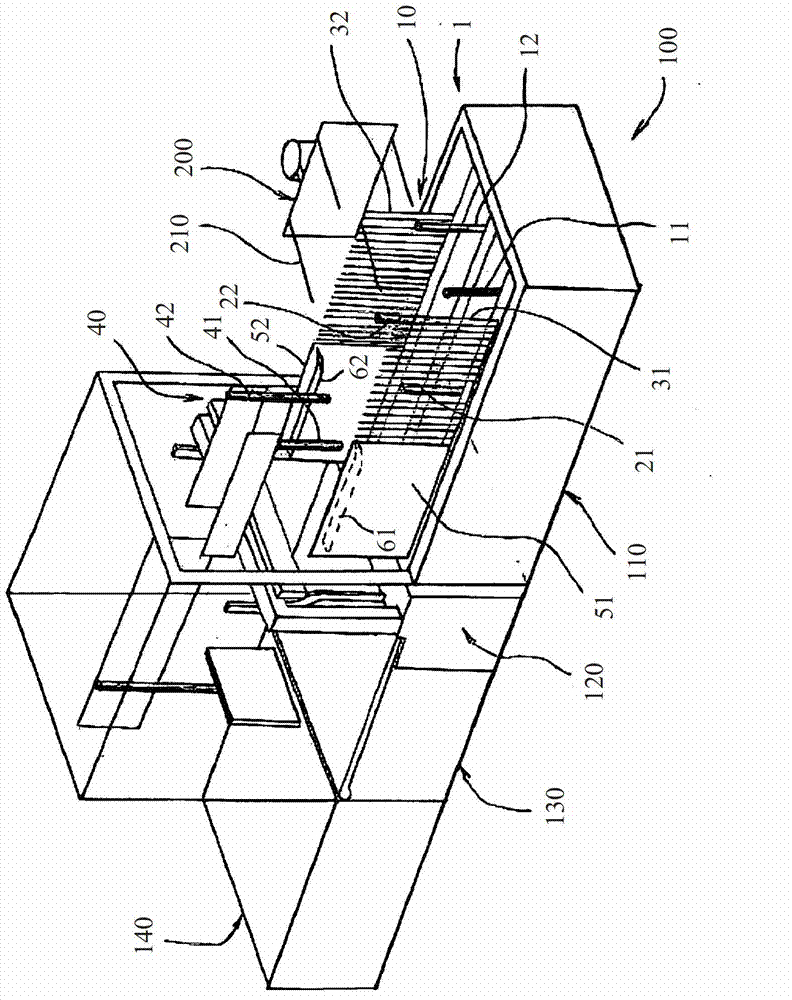

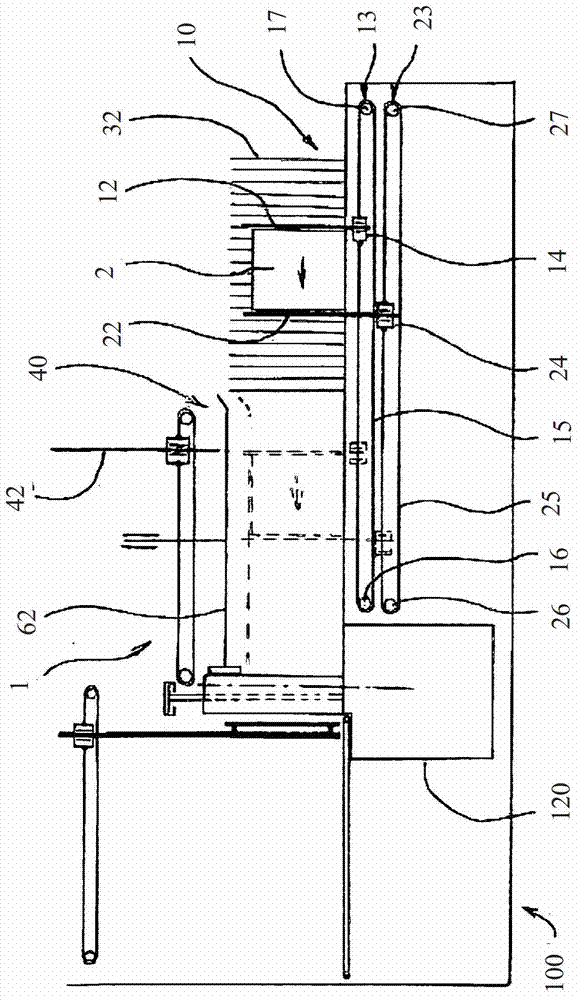

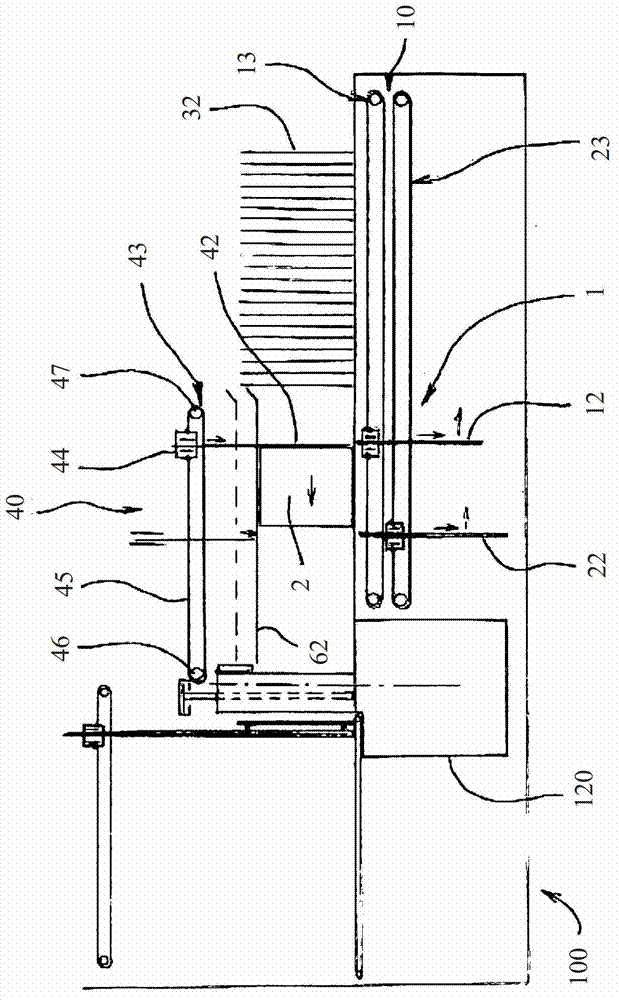

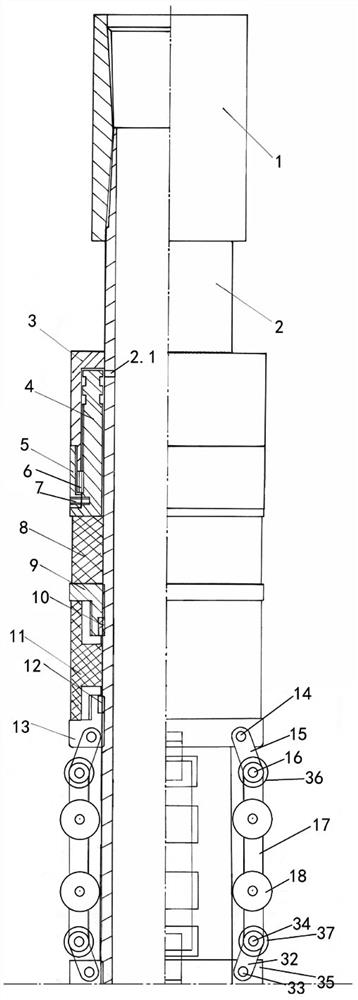

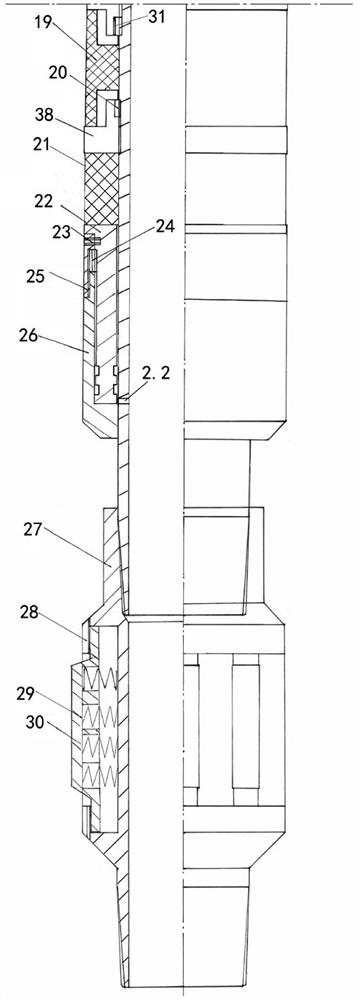

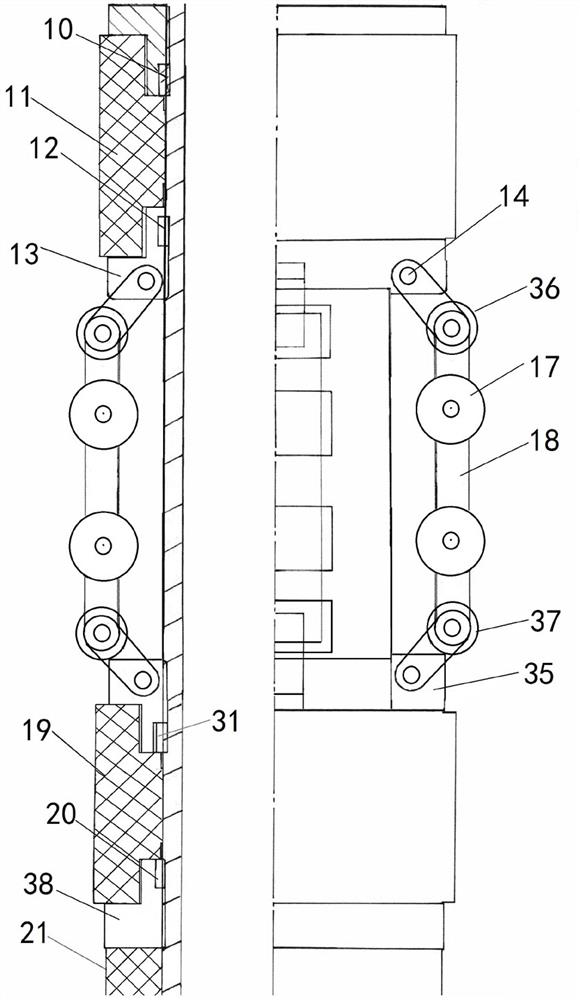

Device for transporting bundles for a strapping machine

ActiveCN103079976AMove preciselyRealize the leading rolePile receiversMechanical conveyorsEngineeringMechanical engineering

The present invention relates to a transporting device (1) for moving, within a strapping machine (100), a succession of bundles (2), comprising first transporting means (10) which are able to move each bundle (2) from an assembly zone to a transfer zone, and second transporting means (40) which are able to move each bundle (2) from the transfer zone to a strapping zone. The invention is notable in that the first transporting means (10) are also able to guide the stack of flat objects longitudinally during the formation of each bundle (2) in the assembly zone, and to hold said bundle (2) longitudinally during its movement from the assembly zone to the transfer zone.

Owner:BOBST MEX SA

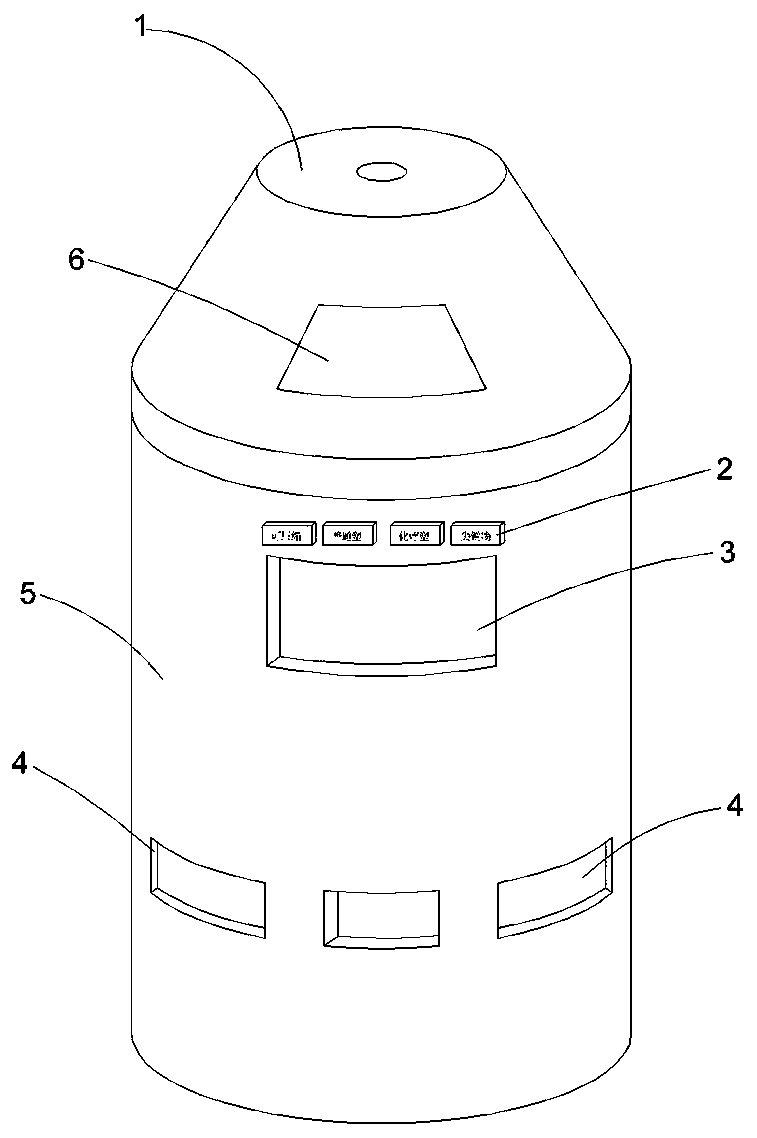

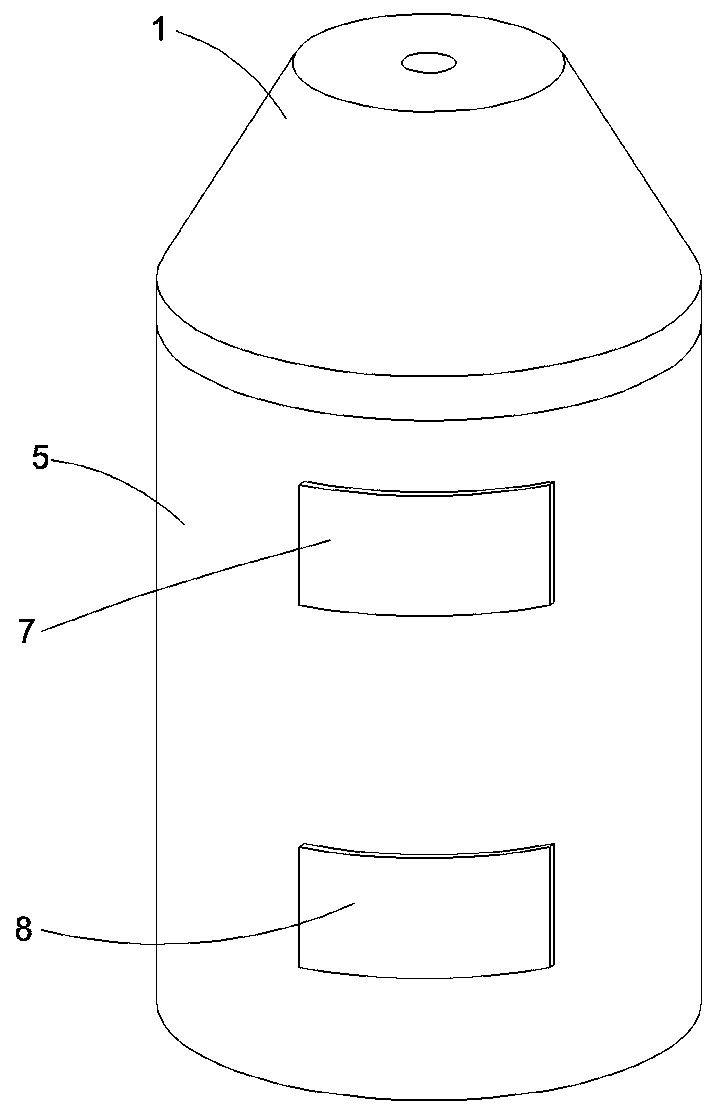

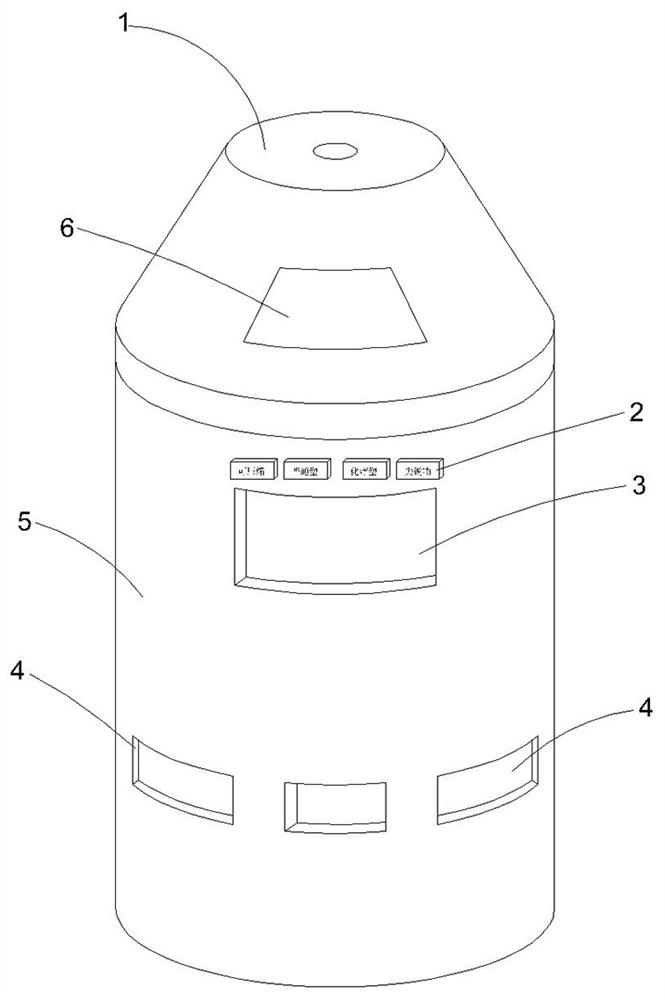

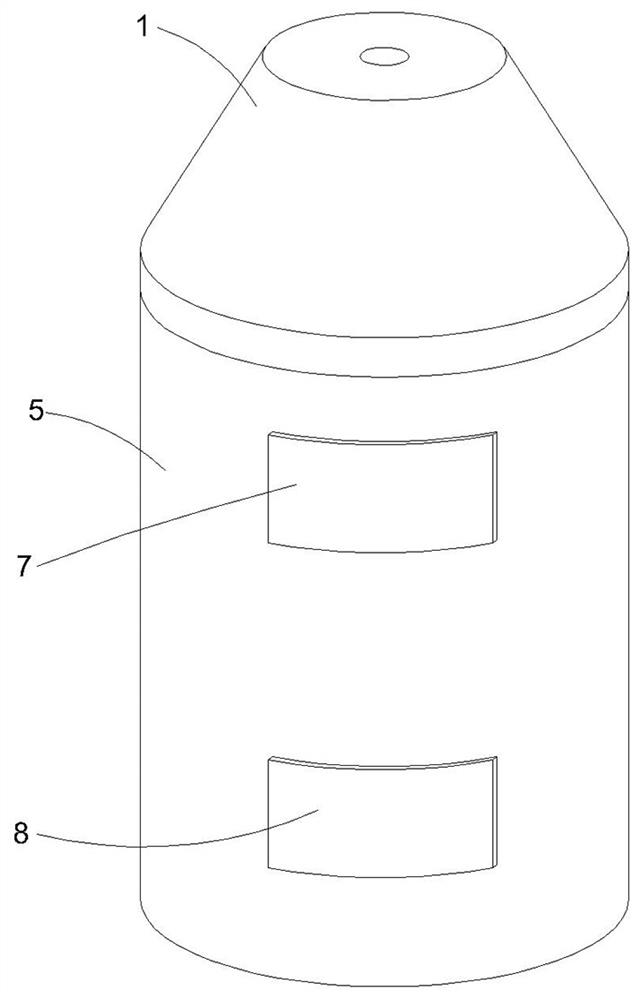

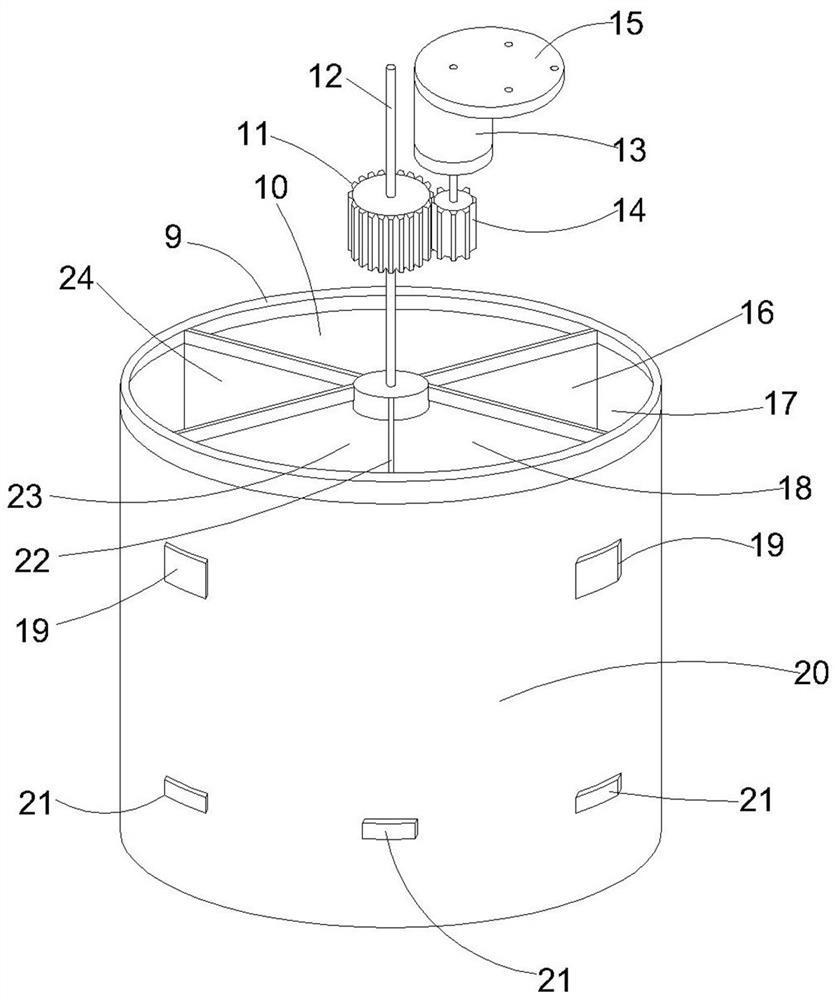

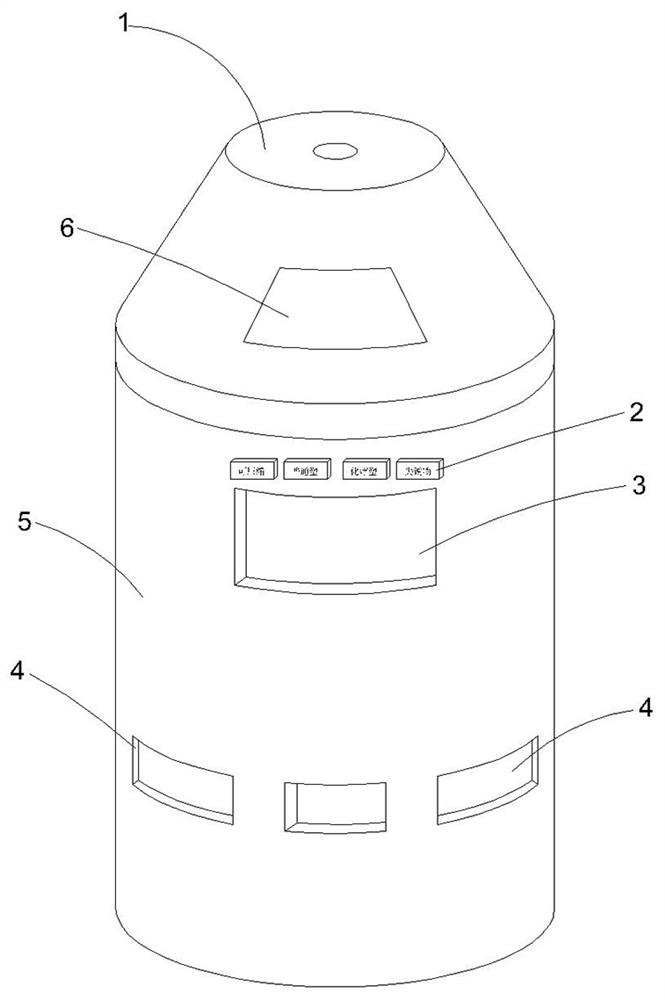

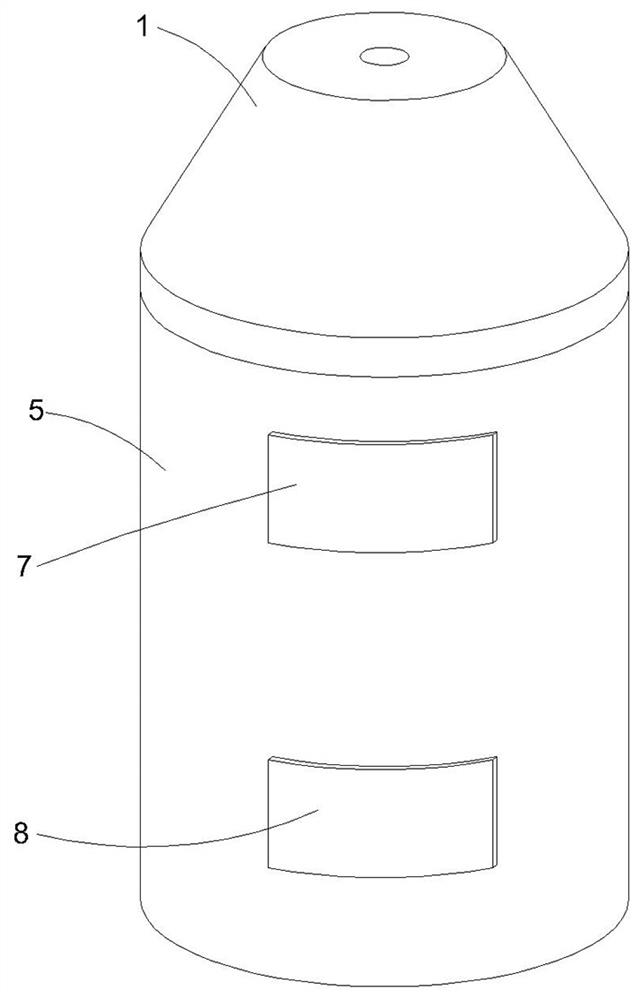

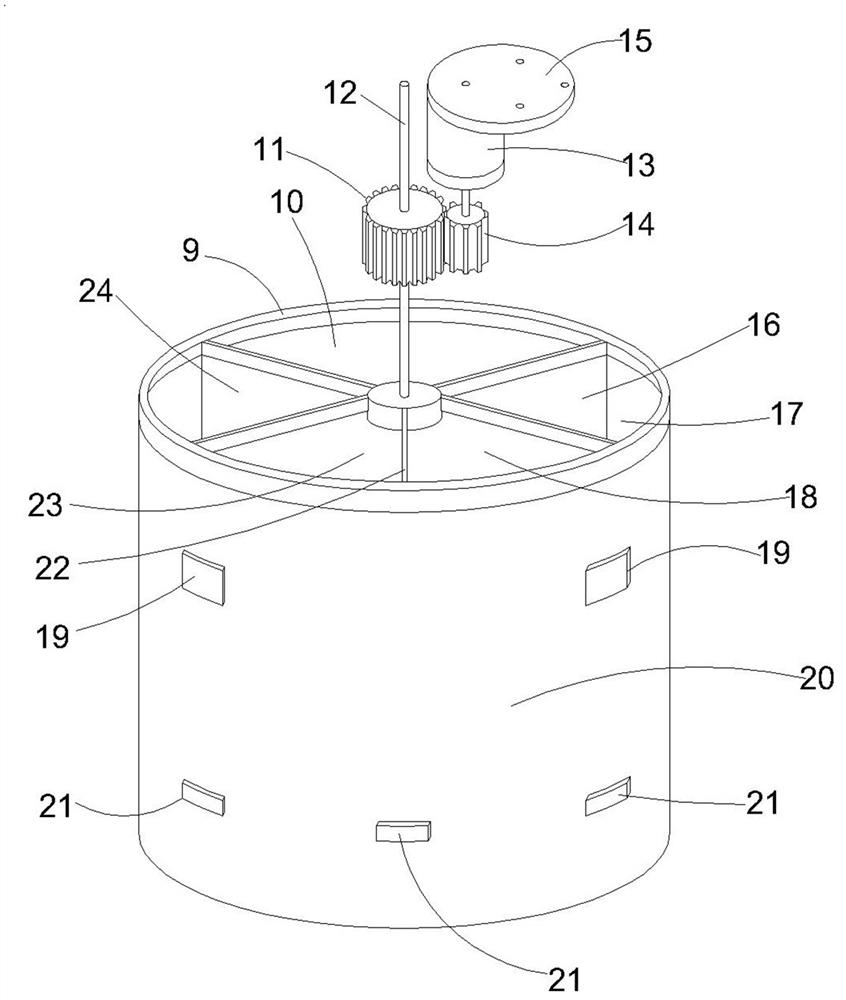

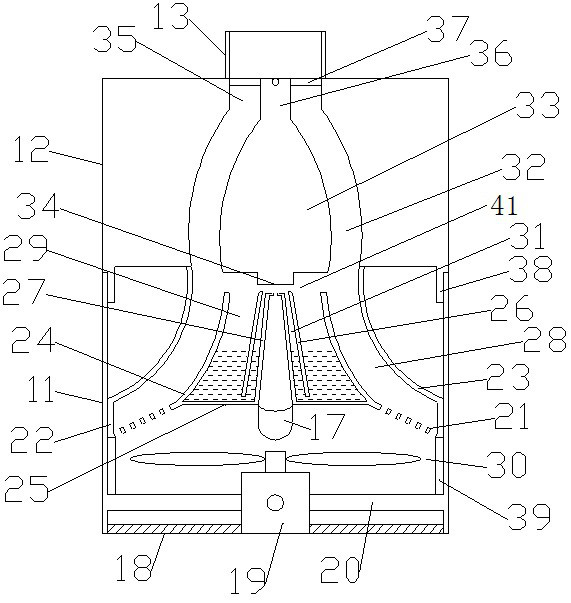

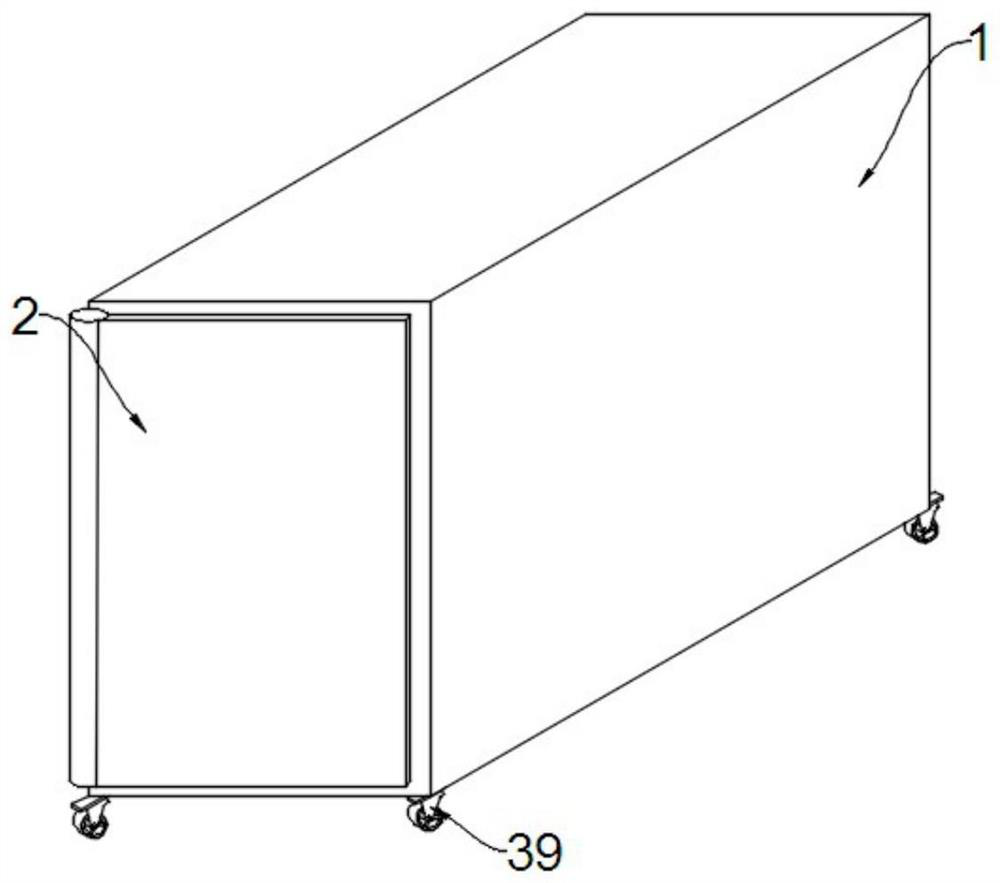

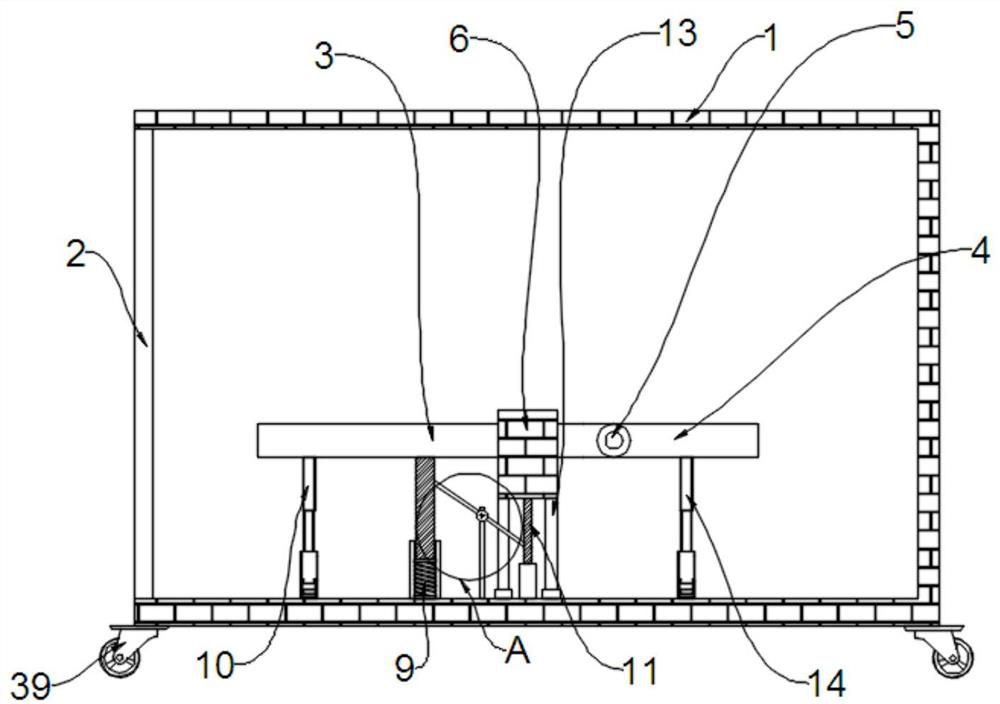

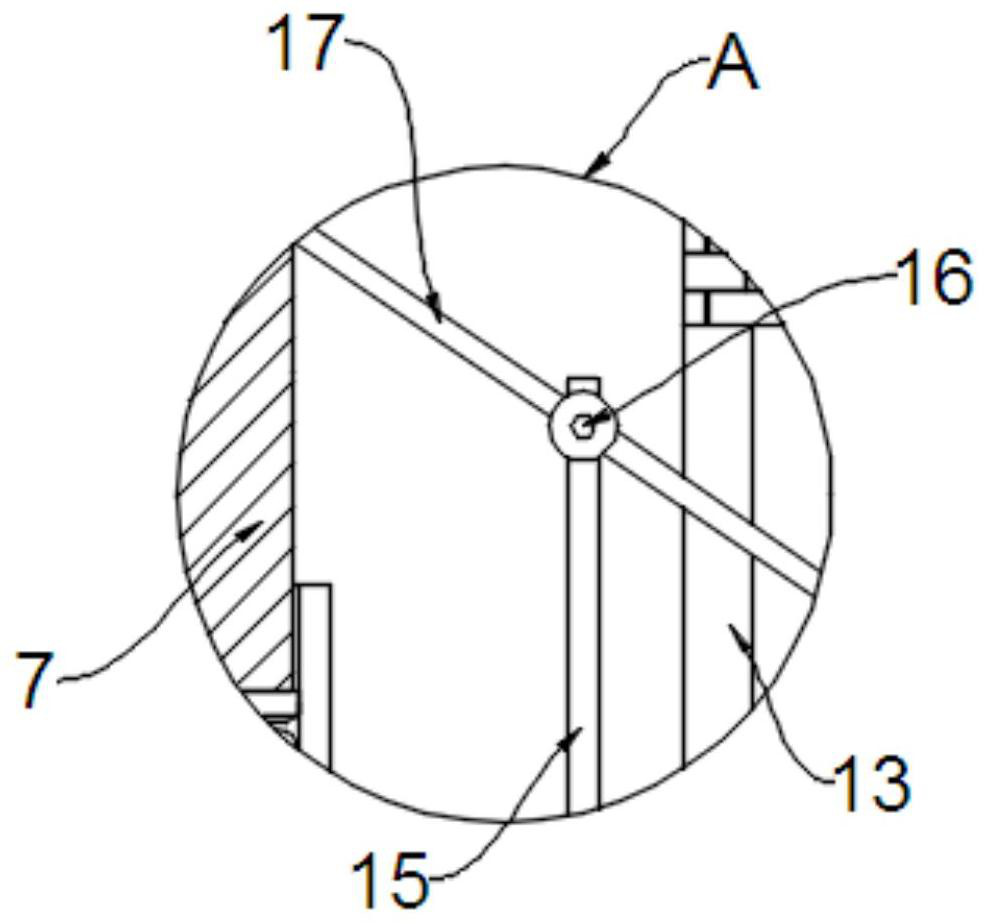

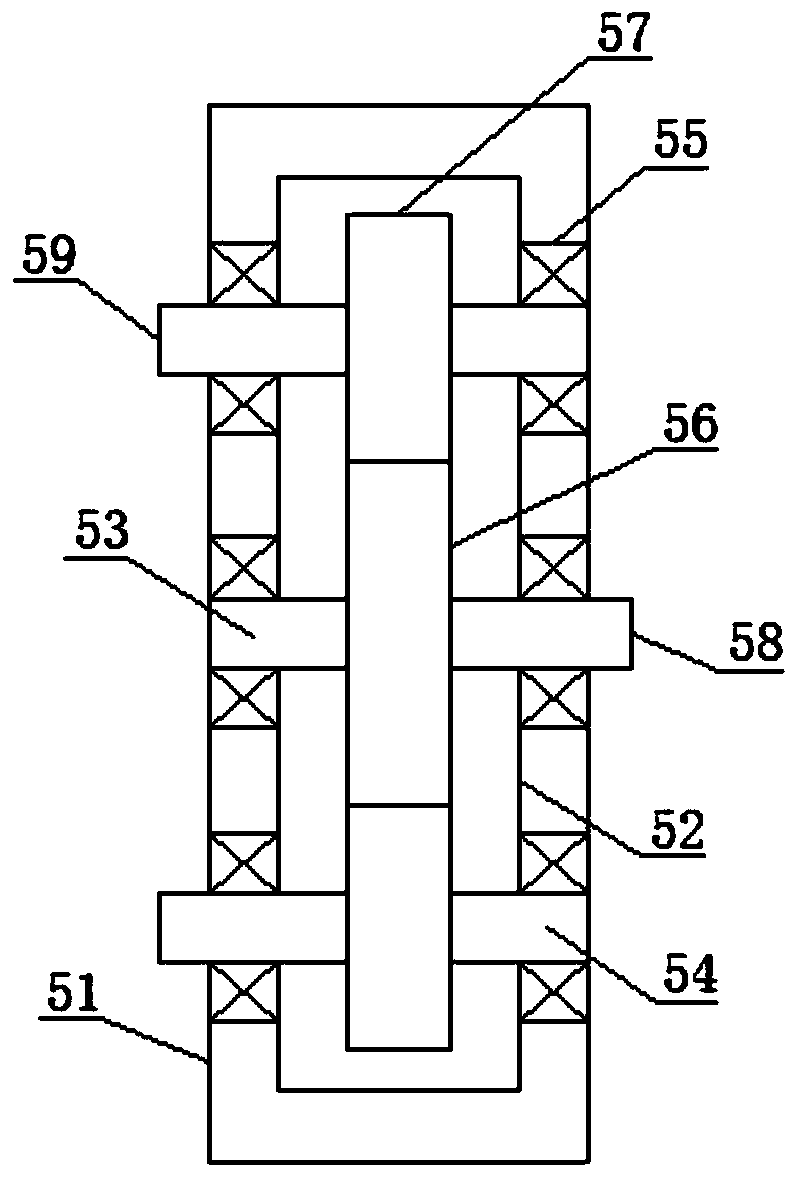

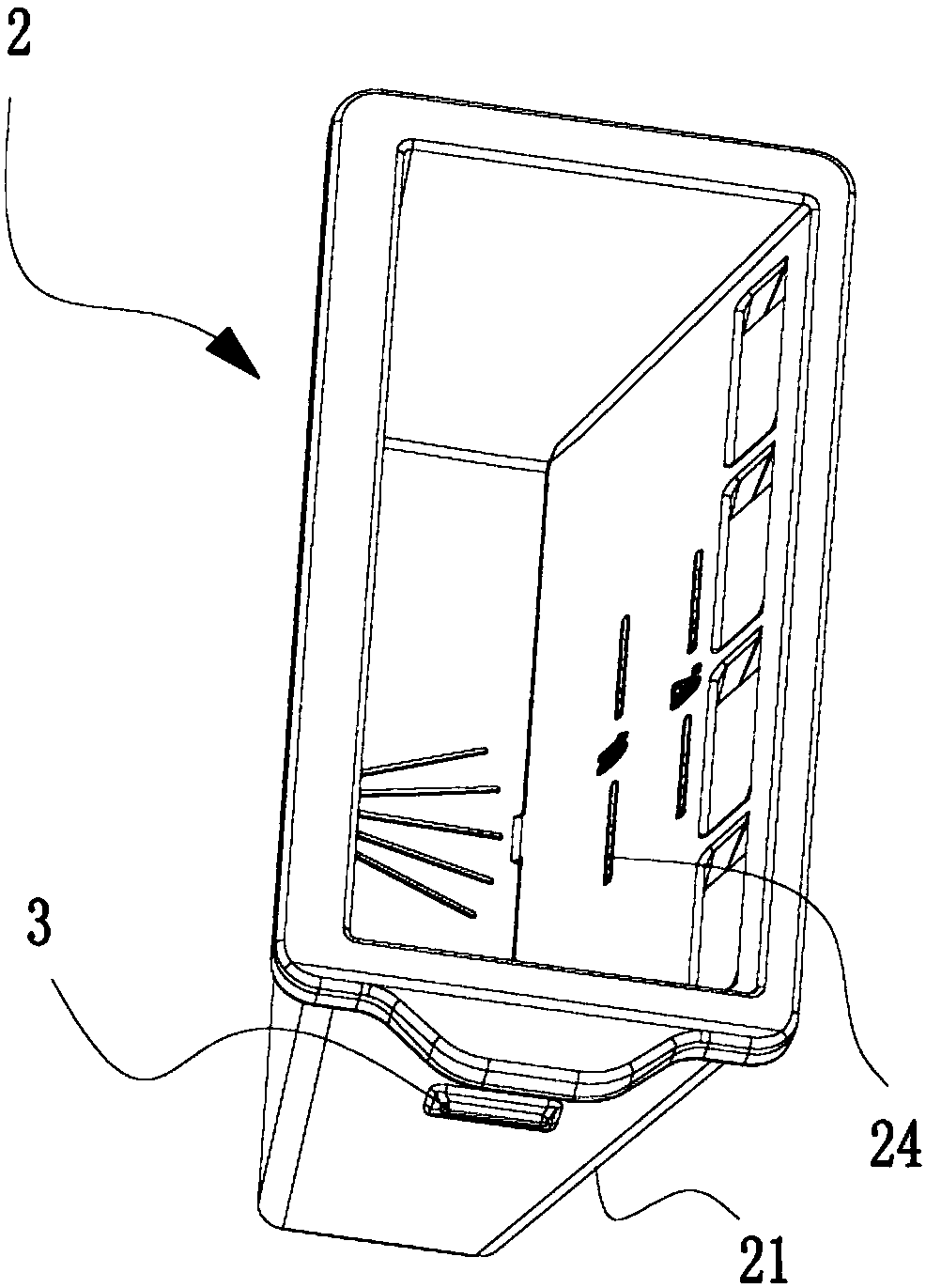

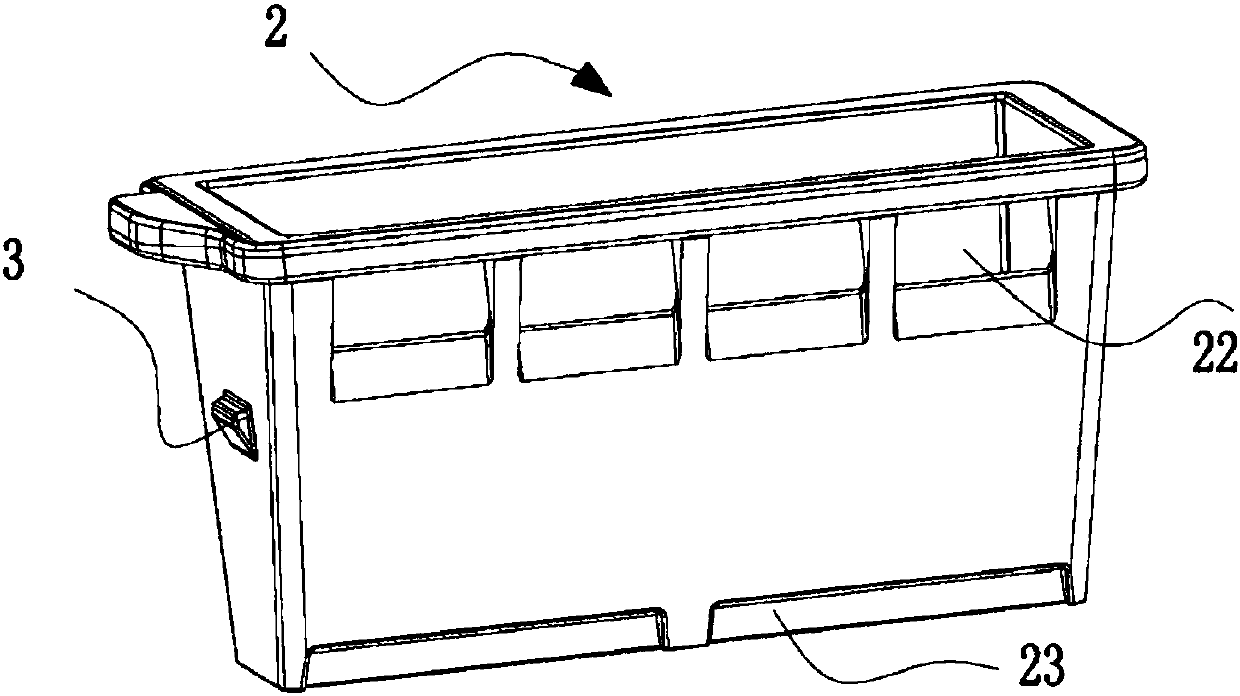

Medical waste temporary storage system for inpatient area and using method

ActiveCN111301893ASmooth rotationEasy to put inGlass recyclingWaste collection and transferMedical wasteEnvironmental engineering

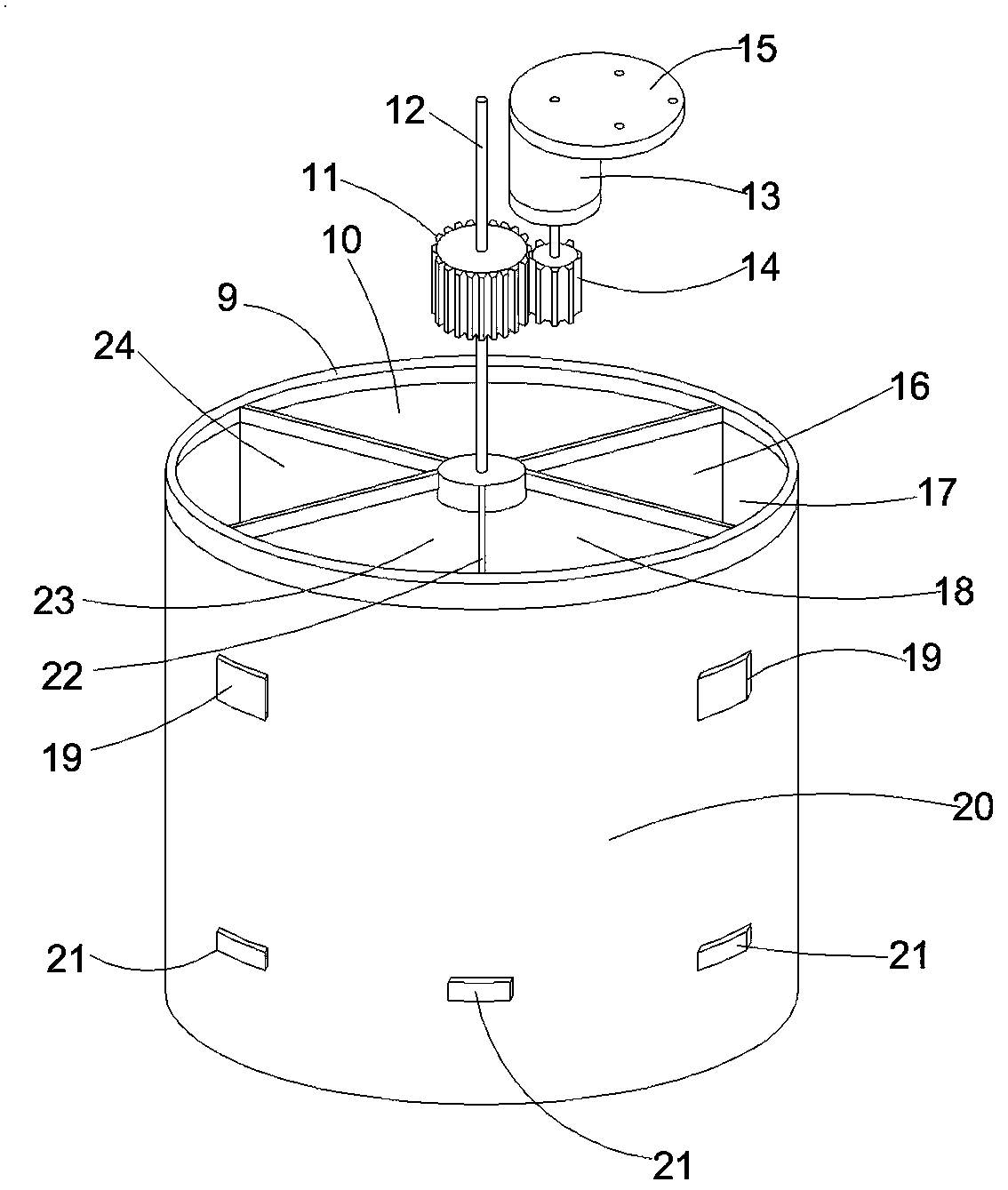

The invention belongs to the technical field of medical waste treatment and particularly discloses a medical waste temporary storage system for an inpatient area. The medical waste temporary storage system comprises an outer shell, an upper storage area and a lower storage area are arranged in the outer shell, and the upper storage area and the lower storage area are separated through a supportingplate. The upper storage area is cylindrical and is partitioned into at least four upper partition storage chambers through partition plates, a rotating shaft is arranged in the center of the upper storage area, and the upper partition storage chambers rotate along with the rotating shaft. A body fluid storage chamber, a blood bag storage chamber and a glass storage chamber are arranged in the lower storage area. An upper input port corresponding to the upper storage area is formed in the outer shell, and three lower input ports corresponding to the lower storage area are formed in the outershell and correspond to the body fluid storage chamber, the blood bag storage chamber and the glass storage chamber respectively. An upper fetching port is formed in the top end of the outer shell, alower fetching port is formed in the side wall of the lower portion of the outer shell, an upper fetching port cover is arranged in the upper fetching port, and a lower fetching port cover is arrangedin the fetching port of the lower storage area.

Owner:HENAN CANCER HOSPITAL

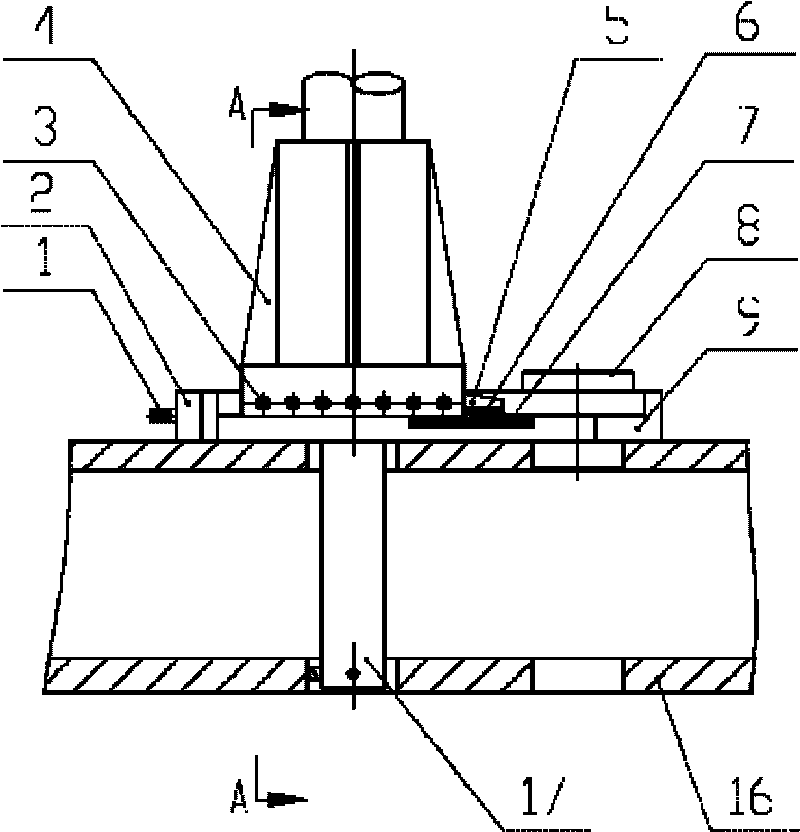

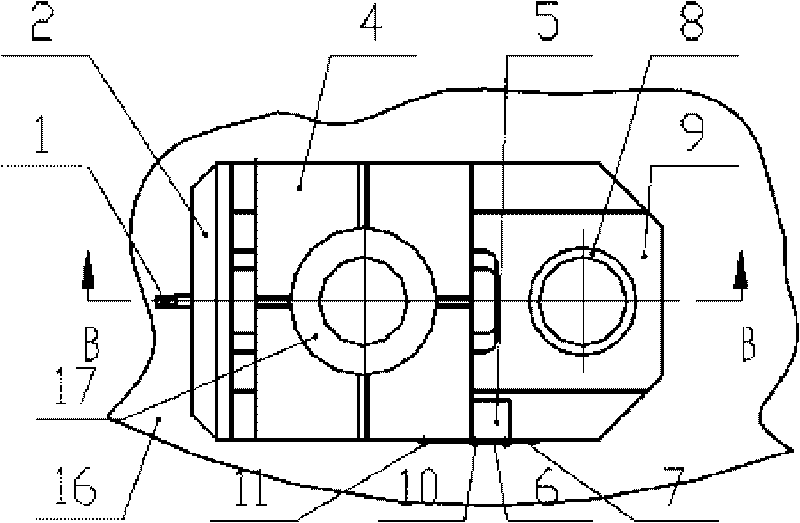

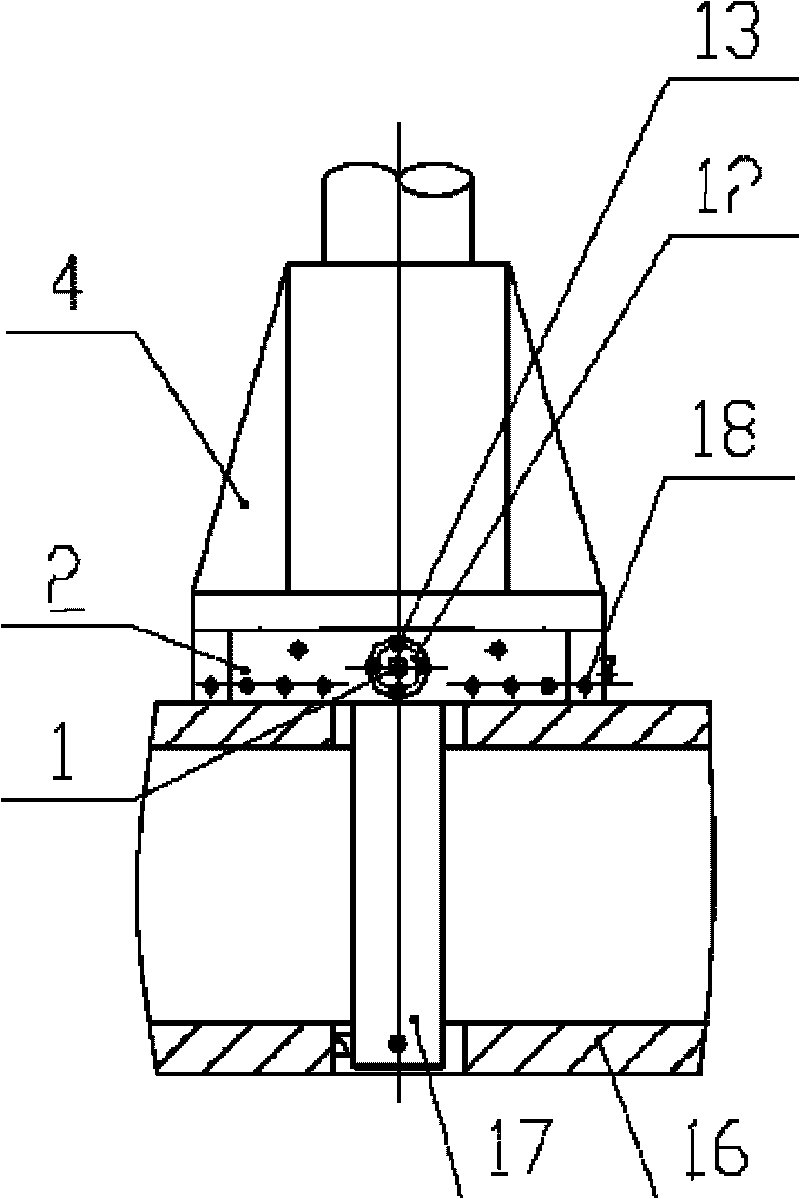

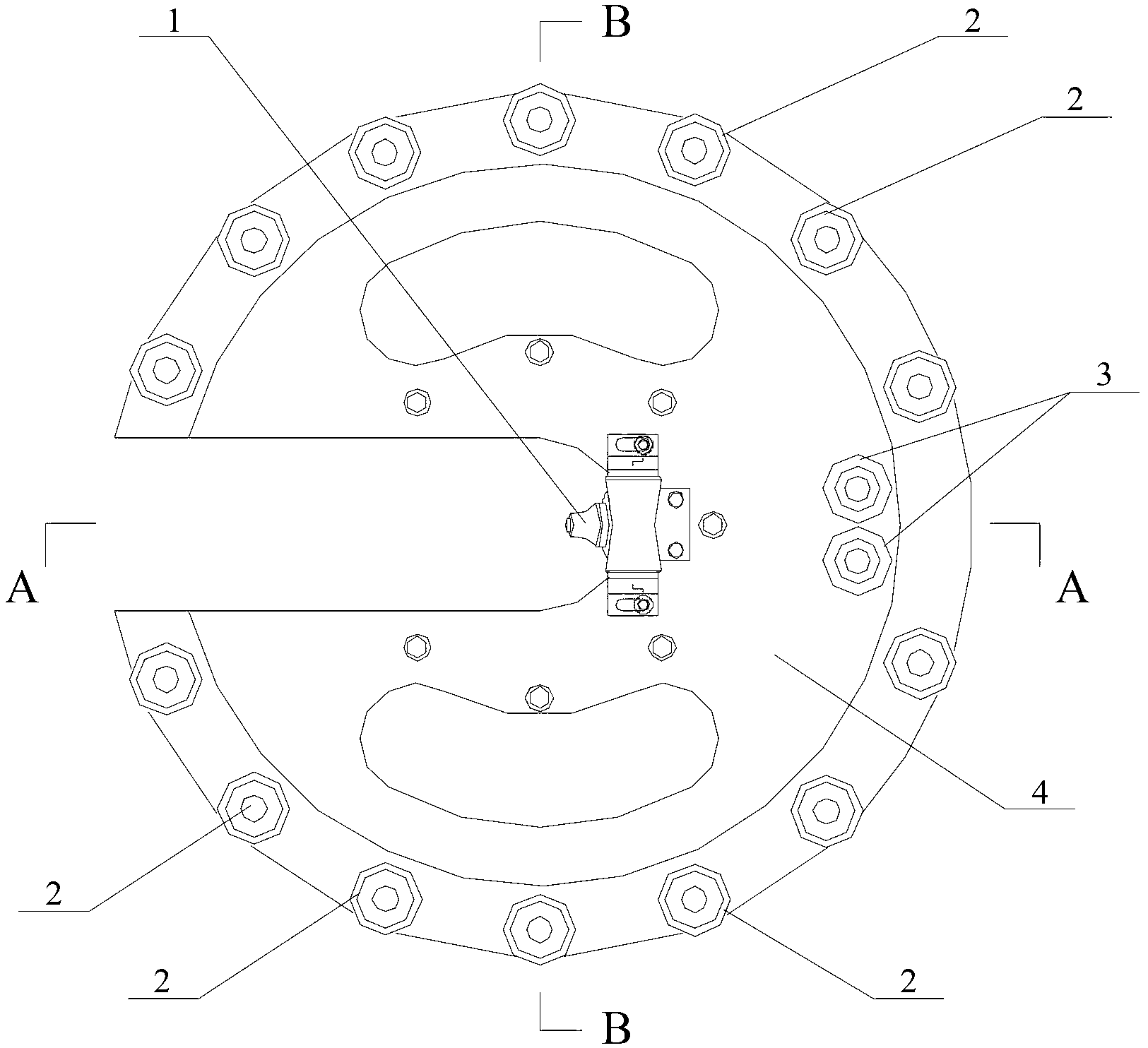

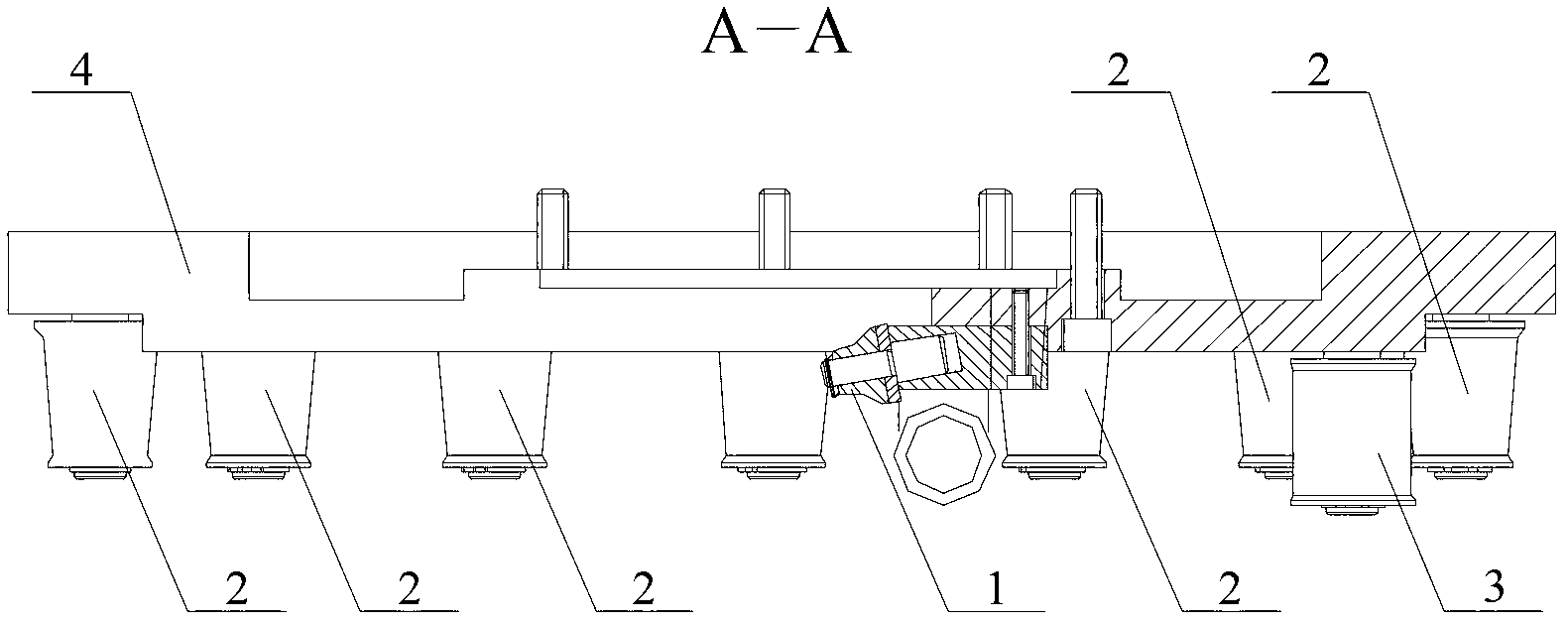

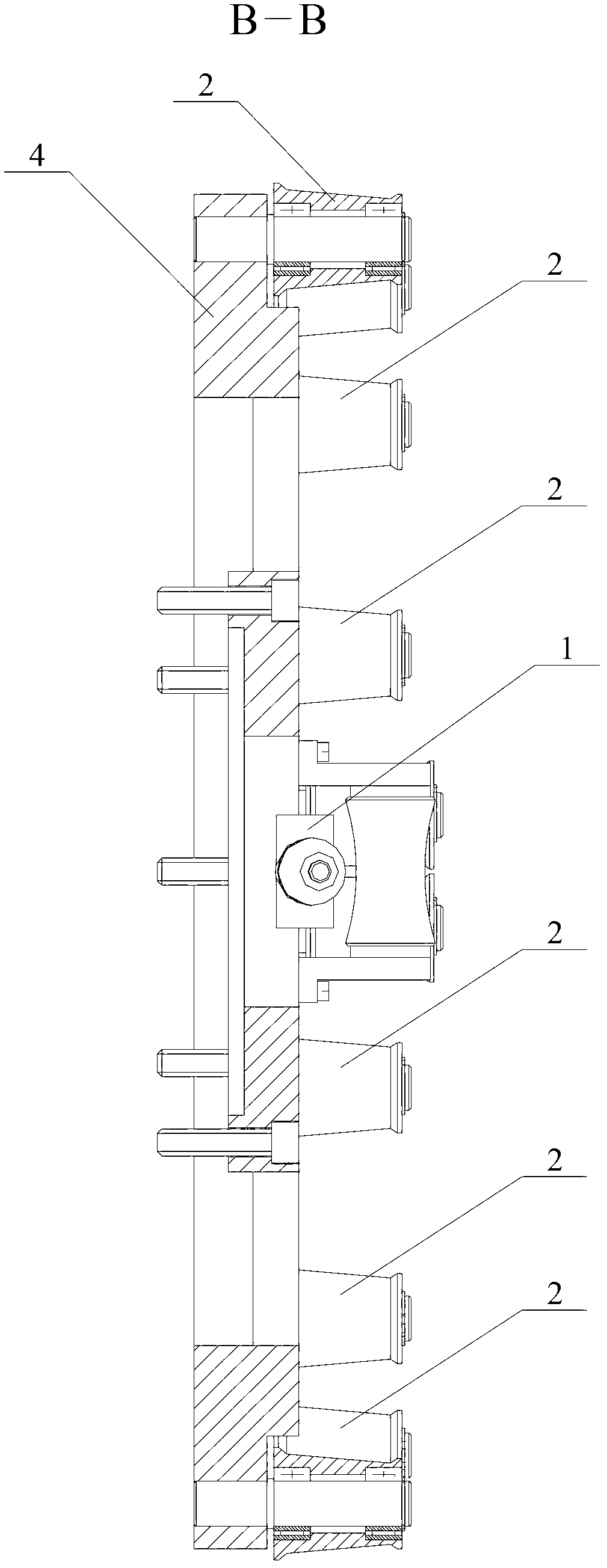

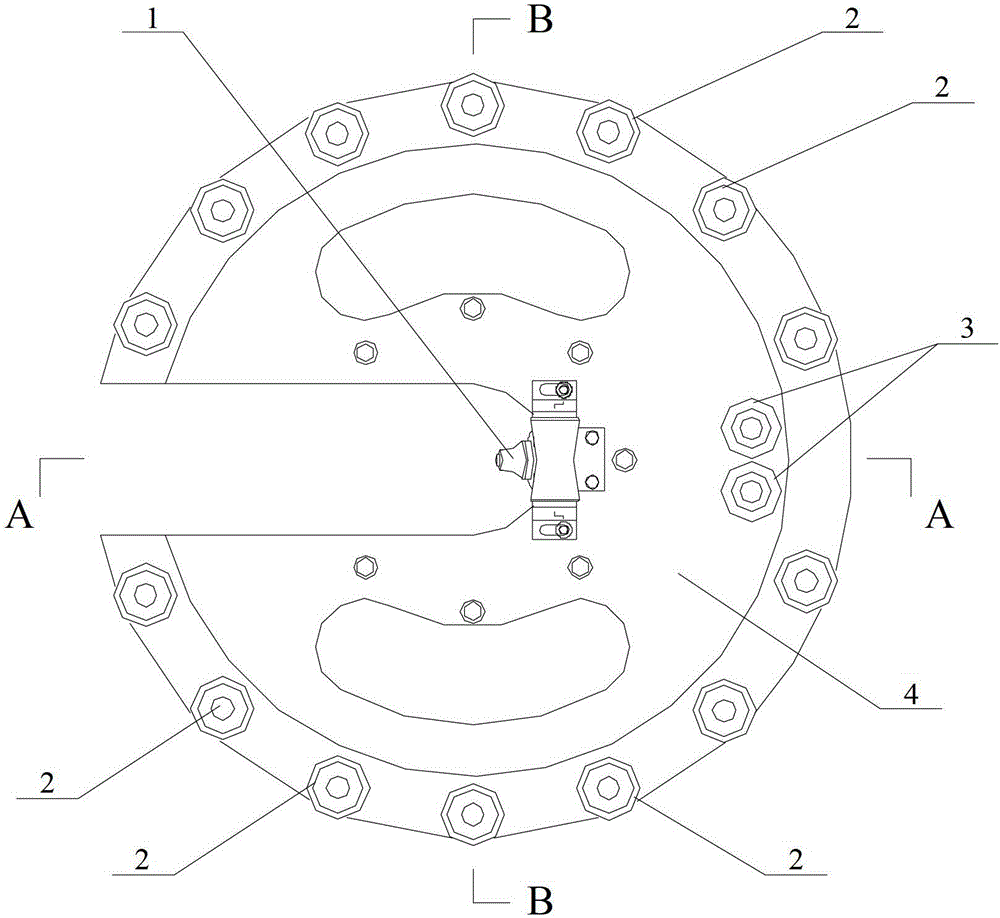

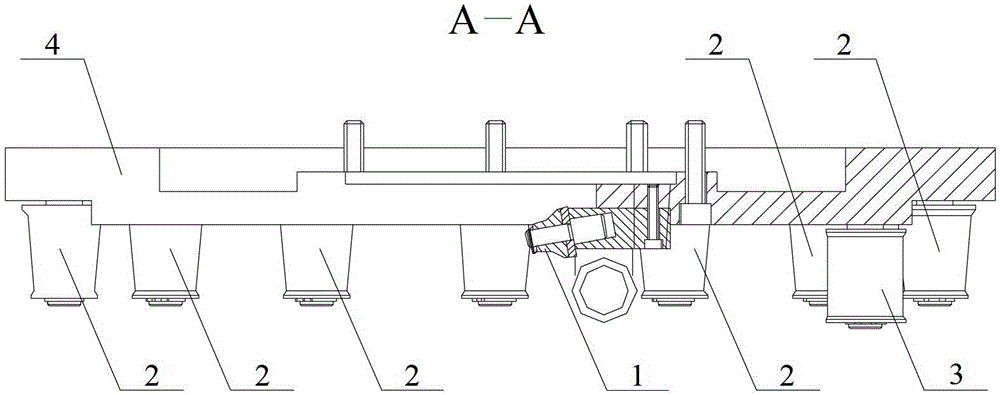

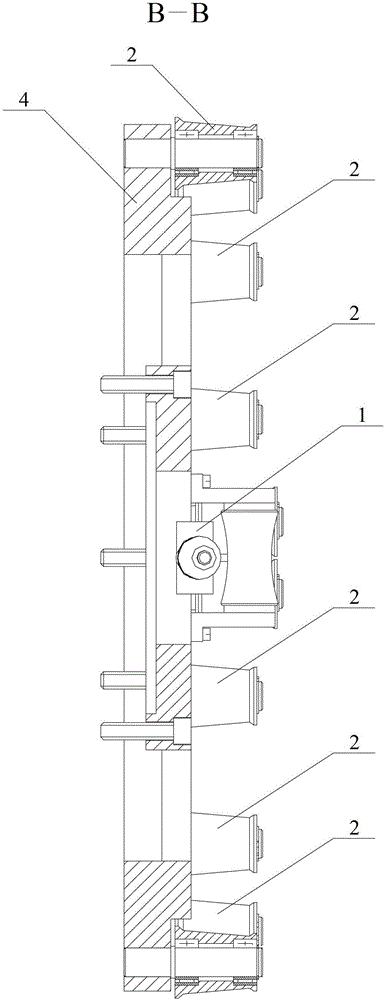

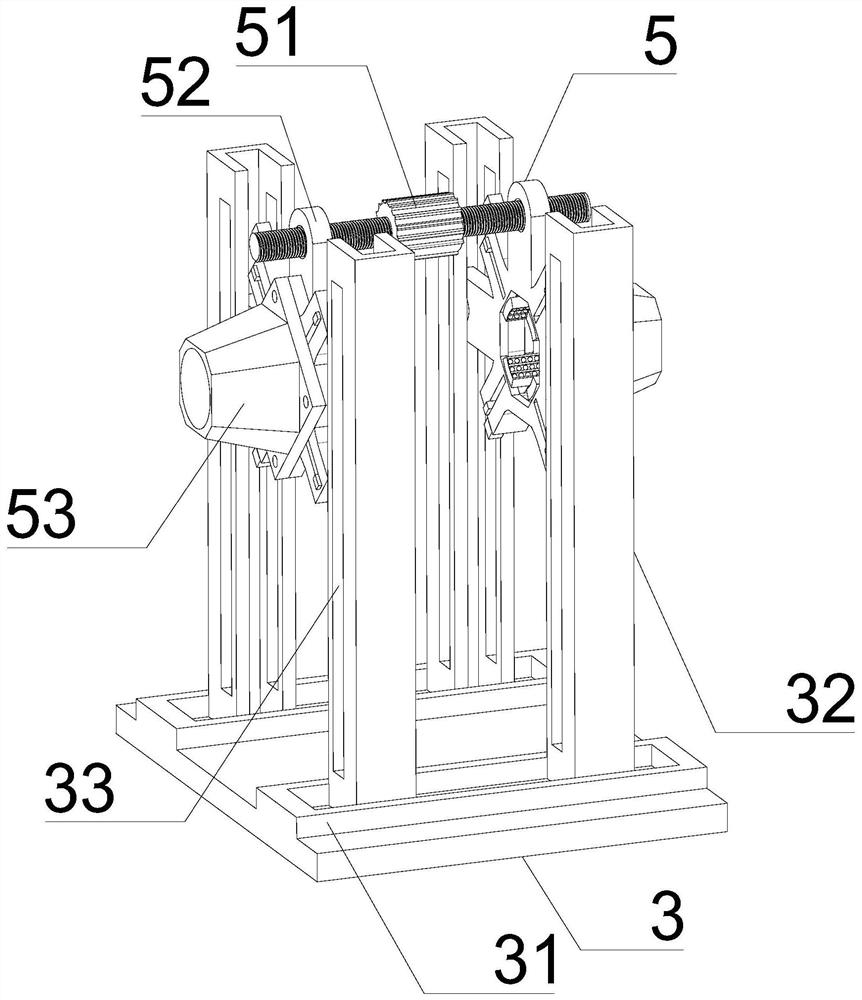

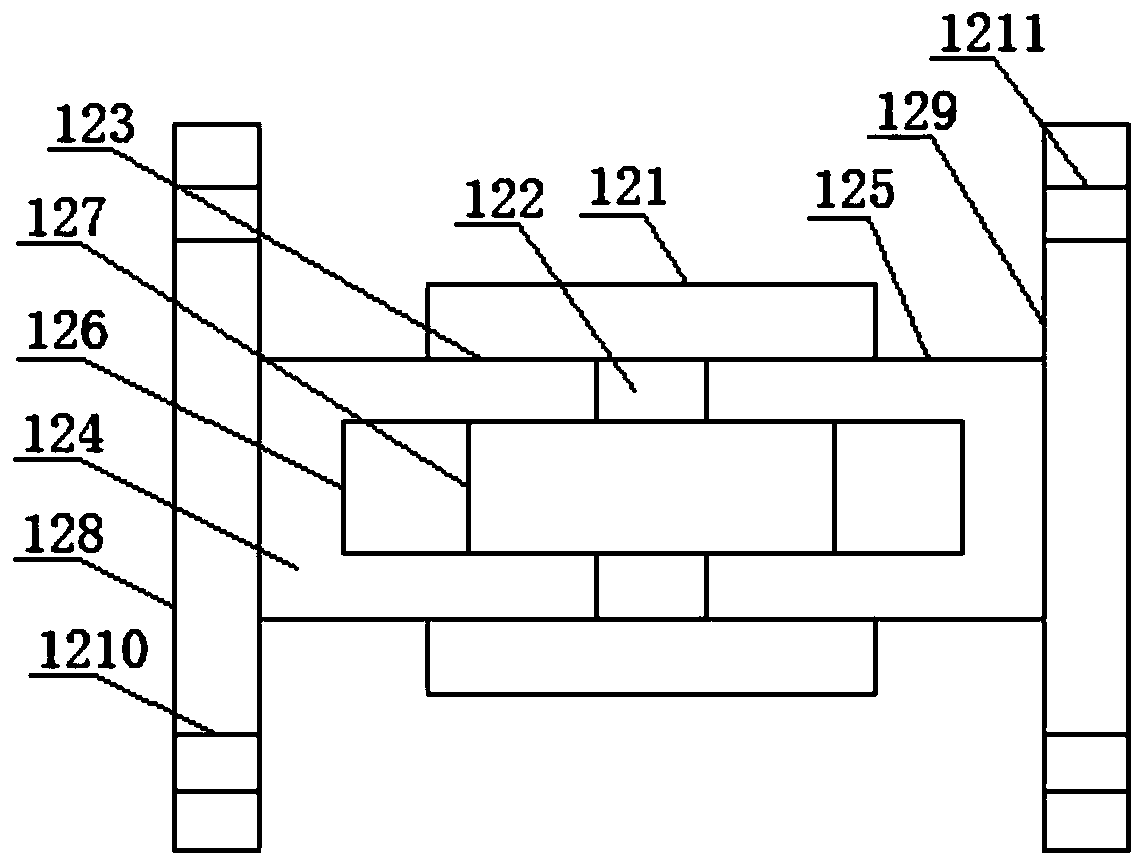

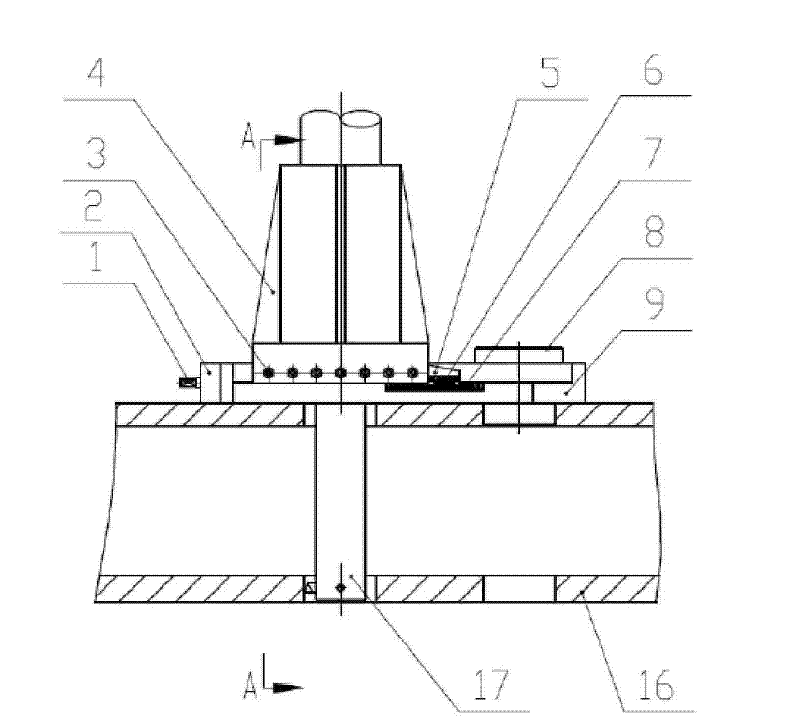

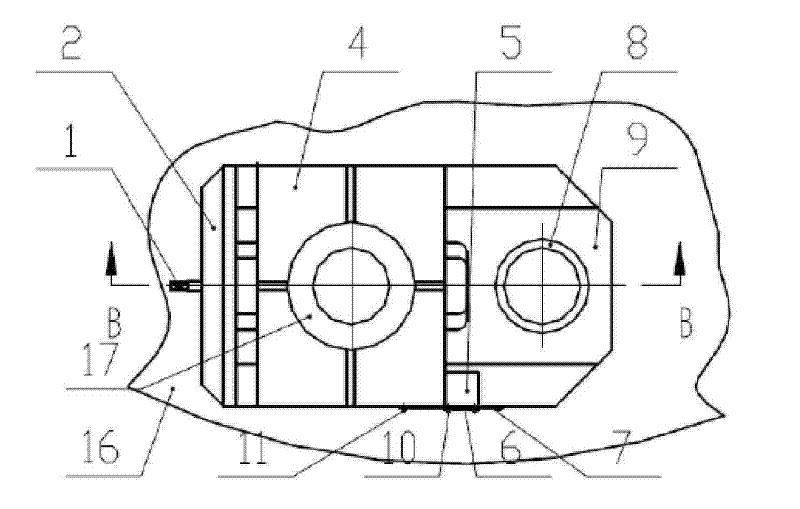

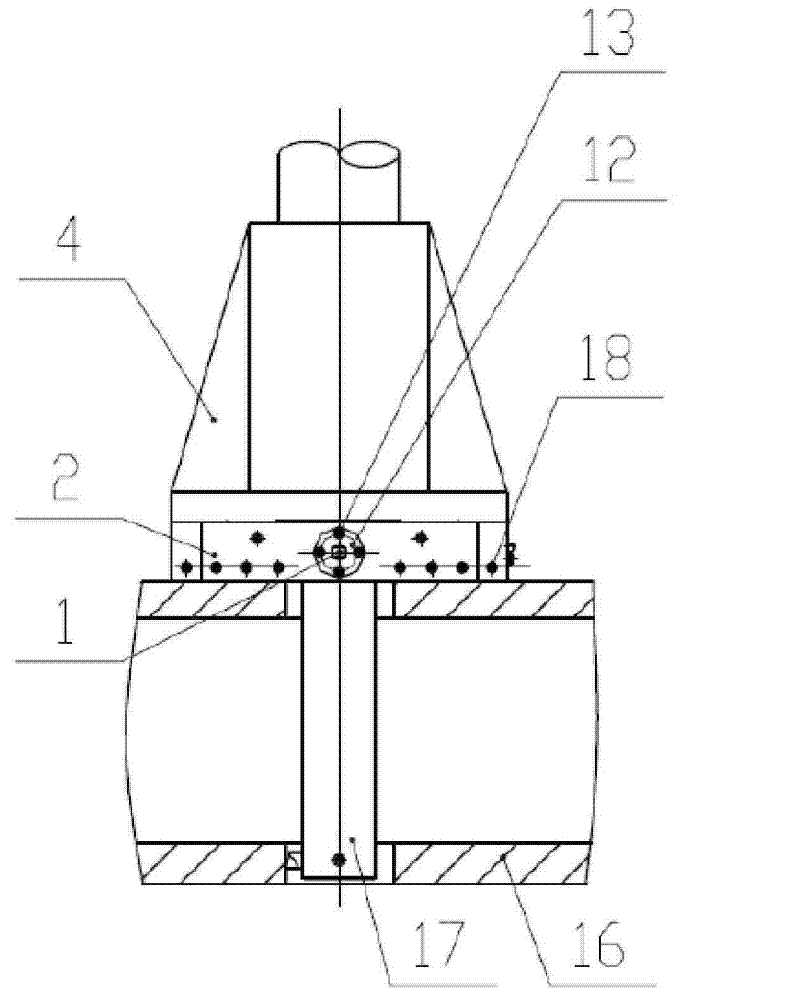

Processing device of rotational platform hole

InactiveCN101704119AHigh positioning accuracyMeet the process requirementsTool holdersBoring/drilling machinesBiochemical engineeringMachining

The invention discloses a processing device of a rotational platform hole, belonging to the technical field of machining. The processing device comprises a clamp body, a handle screw rod, a moving staff, a fixed staff, a compression screw, a changeable cutter rod sleeve and a changeable positioning pin; wherein the changeable positioning pin is fixedly arranged on the clamp body; one end of the handle screw rod is rotatably connected with the changeable cutter rod sleeve and the other end is rotatably arranged on the clamp body; the moving staff is fixedly arranged on the changeable cutter rod sleeve; and the fixed staff is fixedly arranged on the clamp body. The invention can regulate out a required pitch-row according to requirements and then carry out processing, wherein compared with the traditional fitter method of positioning by marking on hole sites, the pitch-rows of all holes are consistent in processing, thereby improving hole positional accuracy; meanwhile, the function of cutter guiding during processing is realized. The invention has the advantages of light weight, compact structure, and convenient operation, and can realize higher processing efficiency and better meet the technical requirements on processing holes on the rotational platform.

Owner:SHANGHAI JIAO TONG UNIV

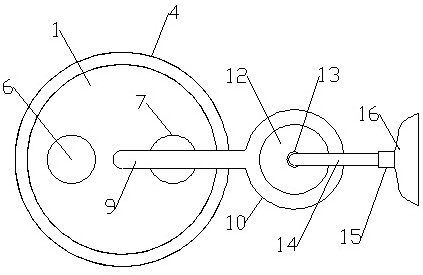

Wire winding disk of aviation tire bead ring winding machine

The invention provides a wire winding disk of an aviation tire bead ring winding machine, belonging to the technical field of bead ring winding disks. The wire winding disk comprises a wire nozzle, winding displacement rolls, two wire guide rolls and a wire winding disk, wherein the wire nozzle is fixed on the center of the wire winding disk, the winding displacement rolls are fixed on the periphery of the wire winding disk, and the two wire guide rolls are fixed on the wire winding disk. The wire winding disk has the beneficial effects that 1, the winding of a large-diameter steel wire can be ensured, the process difficulty of the large-diameter steel wire is overcome; 2, the bending of the large-diameter steel wire is reduced, the plastic deformation of the steel wire is avoided, and thus the guarantee is provided for realizing the high-efficiency winding; and 3, due to the reasonable winding displacement rolls design and the reasonable wire guide roll layout, the process difficulties of few fed wires, multiple supplied wires and large passive pulling tensile force in the process of winding the steel wire are solved, and due to the reasonable design of the wire nozzle, the guide function of spirally winding the steel wire is skillfully realized, and the reverse guide function in the process of winding the steel wire is realized with the positive rotation and the negative rotation of the wire winding disk.

Owner:哈尔滨工大宏图橡塑科技有限公司

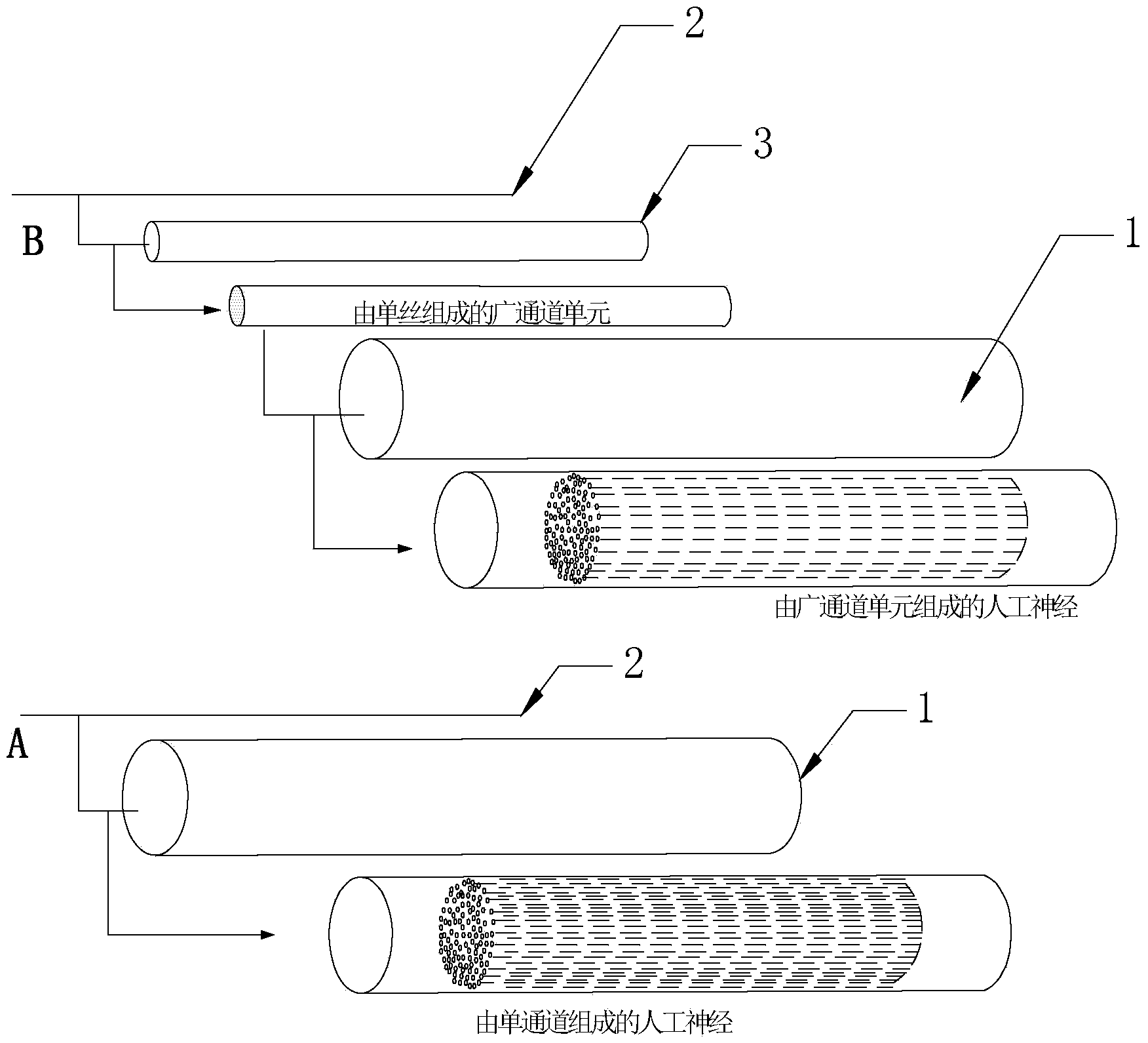

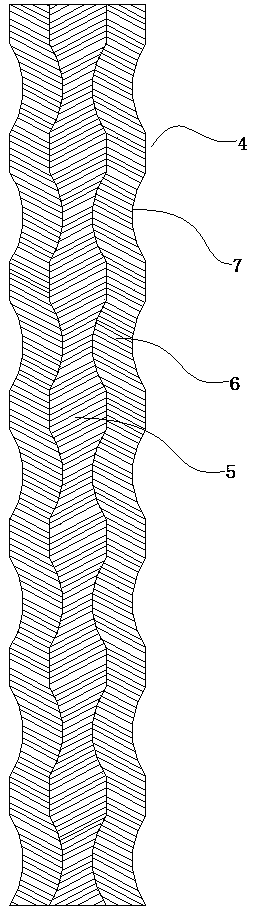

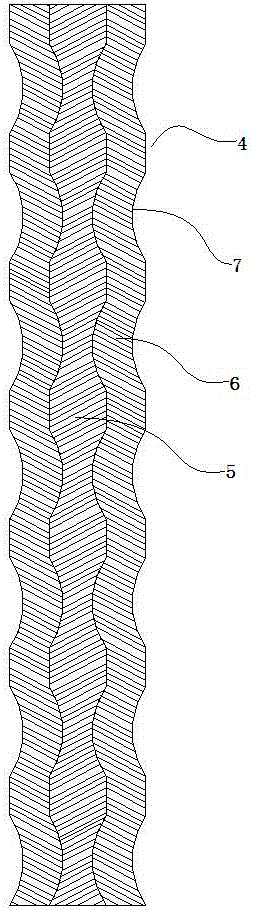

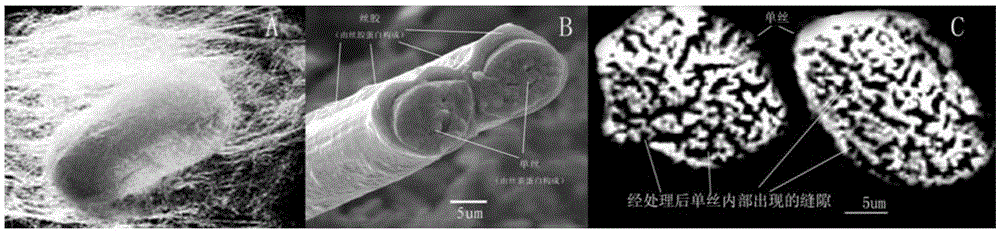

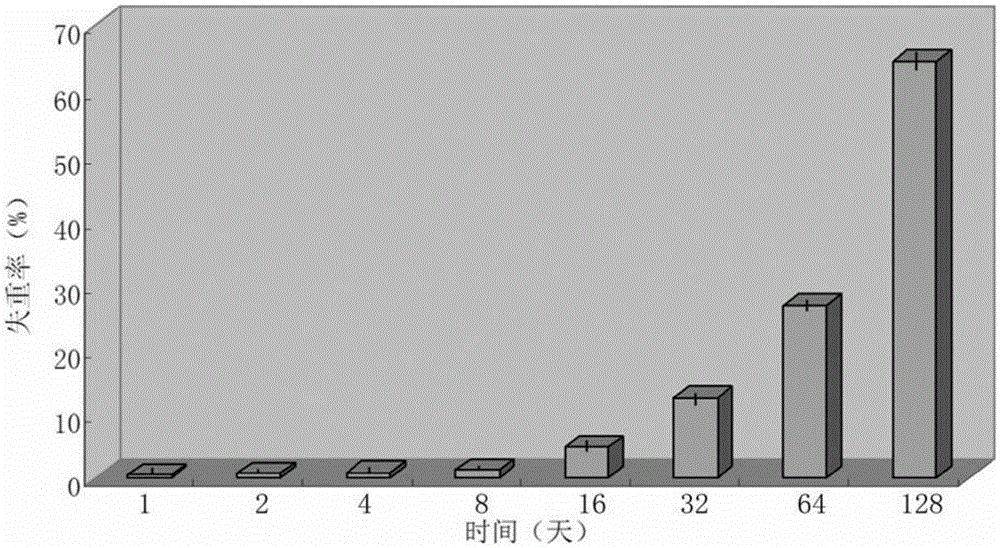

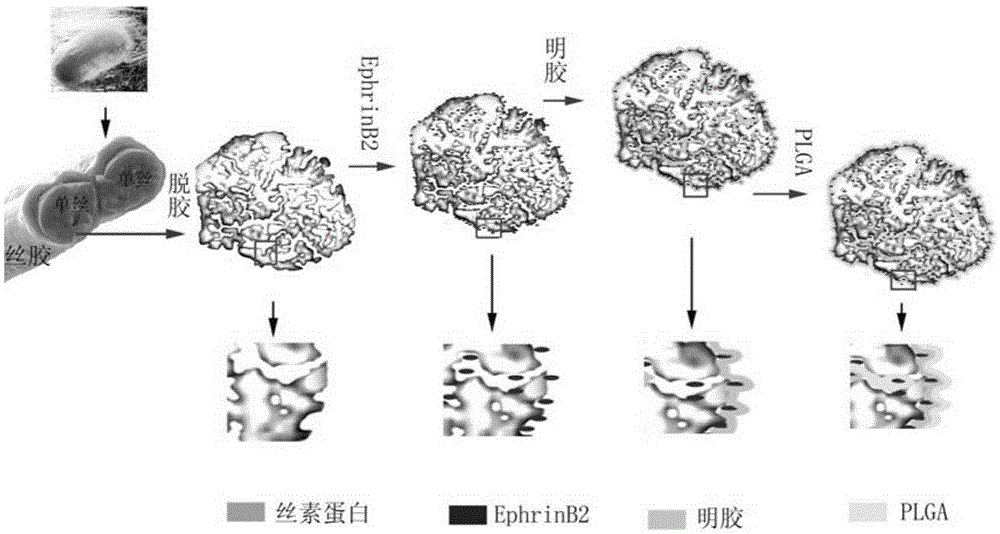

Tissue engineered artificial nerve and preparation method thereof

InactiveCN103877623AAchieve inductionRealize the leading roleProsthesisPeripheral nerveTissue engineer

The invention relates to a tissue engineered artificial nerve and a preparation method thereof. The tissue engineered artificial nerve comprises a PLGA (poly lactic-co-glycolic acid) hollow duct, degummed silk monofilaments and cell factors EphrinB2, wherein the degummed silk monofilaments and the cell factors EphrinB2 form controlled-release carriers which are regularly arranged in the PLGA hollow duct in parallel along a long axis. The preparation method comprises the steps of firstly degumming silks so as to prepare the monofilaments; by using the monofilaments as materials for preparing EphrinB2 filiform controlled-release carriers, then assembling the filiform controlled-release carriers in the PLGA hollow duct so as to obtain the artificial nerve. The artificial nerve has the advantages that the filiform controlled-release carriers are piled up in the artificial nerve so as to form a series of micro-channels among the filiform controlled-release carriers, and the micro-channels compel the ordered growth of axons along the long axis of the tissue engineered artificial nerve in a peripheral nerve defect repair process through the sustained release of the cell factors EphrinB2; the preparation method of the tissue engineered artificial nerve is free of special requirements of a micro-preparation technology for equipment and processes, and has the advantages of being simple, practicable, low in cost and high in quality.

Owner:SOUTHWEST UNIVERSITY

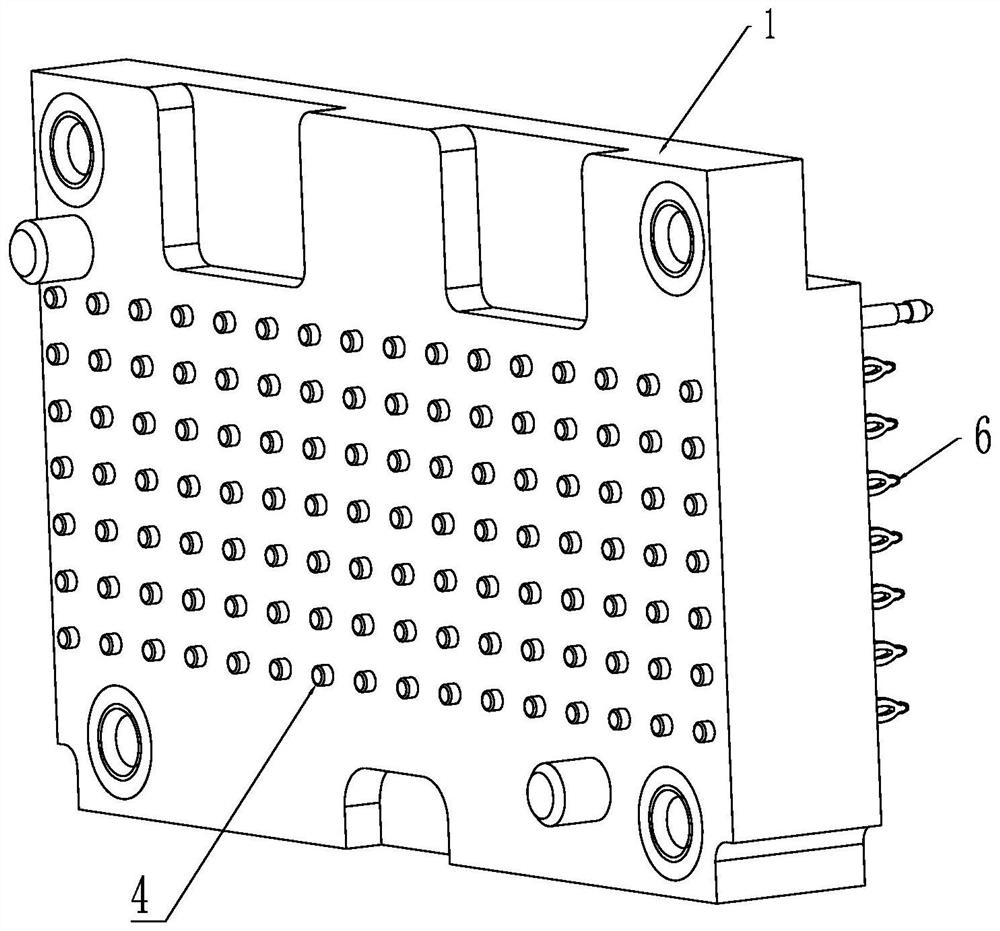

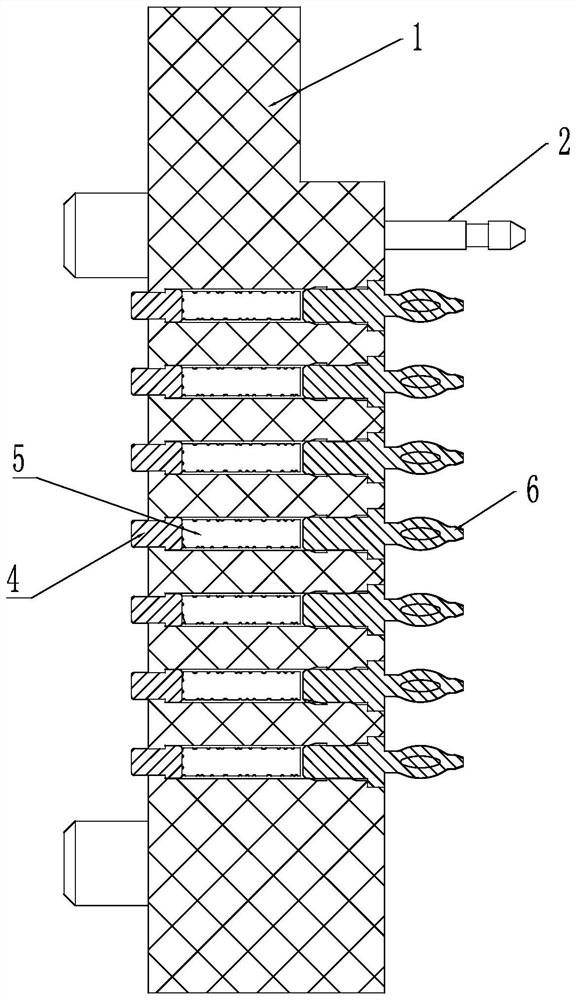

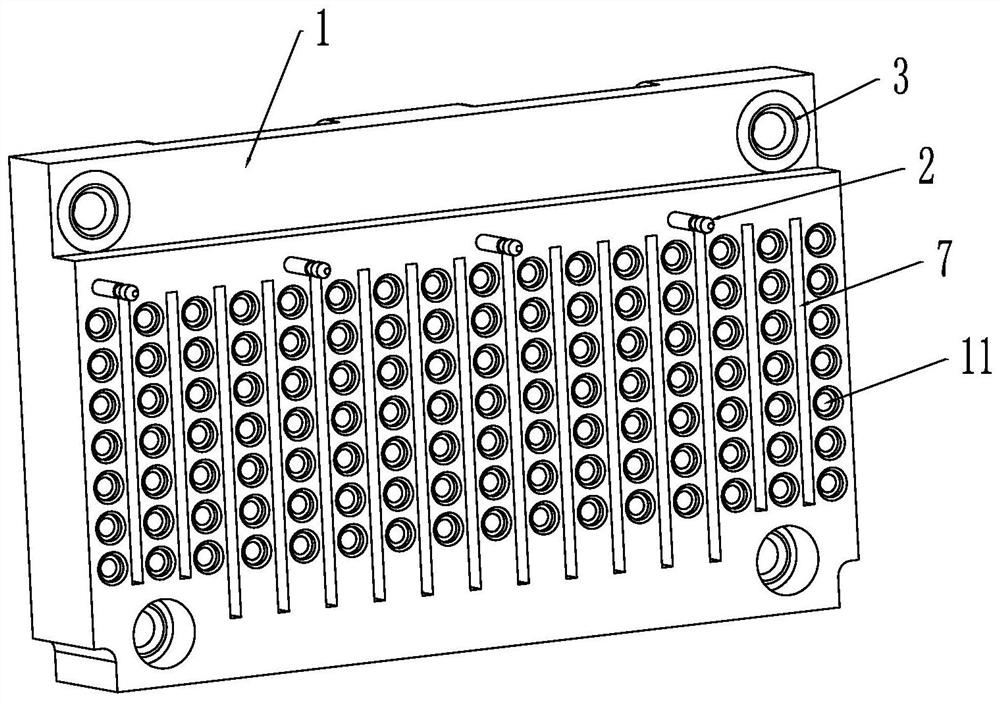

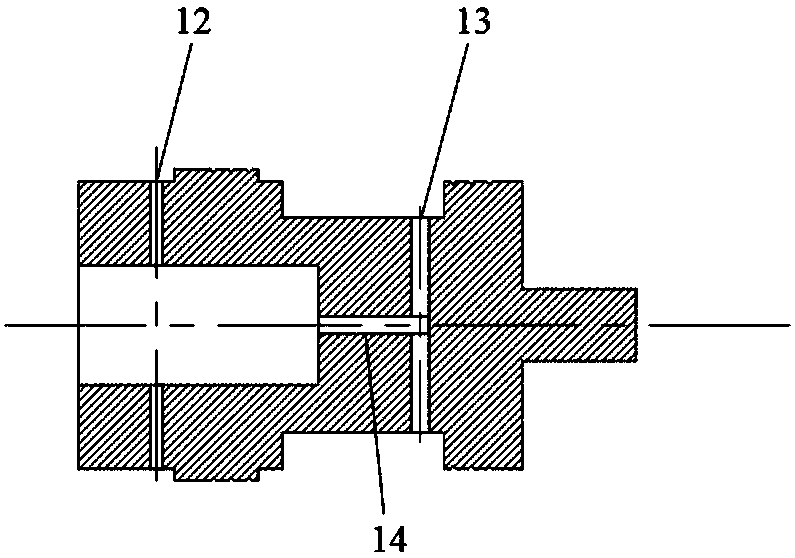

Switching high-speed connector

PendingCN114122782AAchieve lossless connectionEnables press-fit connections without solderingSecuring/insulating coupling contact membersCoupling contact membersPhotoelectric conversionData transmission

The invention relates to a switching high-speed connector, which is used for realizing a switching connection effect between an optical active module and a printed board, and comprises an insulator component which comprises an insulator provided with a mounting hole; the contact part is installed in the installation hole, one end of the contact part is provided with a fisheye structure extending out of one end of the installation hole, the fisheye structure is used for being in compression joint with the printed board, the other end of the contact part is provided with an elastic contact structure extending out of the other end of the installation hole, and the elastic contact structure is used for being elastically attached to the photoelectric conversion module to achieve lossless connection. By means of the technical scheme, the two faces of the switching connector are designed in two different terminating modes, one end of the connector is designed to be of a fisheye structure to achieve welding-free press-fit connection with a printed board, the other end of the connector is designed to be of an end face elastic contact structure, and lossless connection of a photoelectric conversion module is achieved; meanwhile, the structure is easy to eliminate short piles and is suitable for high-speed data transmission scenes.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Winding reel of a wire coil winding machine for aviation tires

The invention provides a wire winding disk of an aviation tire bead ring winding machine, belonging to the technical field of bead ring winding disks. The wire winding disk comprises a wire nozzle, winding displacement rolls, two wire guide rolls and a wire winding disk, wherein the wire nozzle is fixed on the center of the wire winding disk, the winding displacement rolls are fixed on the periphery of the wire winding disk, and the two wire guide rolls are fixed on the wire winding disk. The wire winding disk has the beneficial effects that 1, the winding of a large-diameter steel wire can be ensured, the process difficulty of the large-diameter steel wire is overcome; 2, the bending of the large-diameter steel wire is reduced, the plastic deformation of the steel wire is avoided, and thus the guarantee is provided for realizing the high-efficiency winding; and 3, due to the reasonable winding displacement rolls design and the reasonable wire guide roll layout, the process difficulties of few fed wires, multiple supplied wires and large passive pulling tensile force in the process of winding the steel wire are solved, and due to the reasonable design of the wire nozzle, the guide function of spirally winding the steel wire is skillfully realized, and the reverse guide function in the process of winding the steel wire is realized with the positive rotation and the negative rotation of the wire winding disk.

Owner:哈尔滨工大宏图橡塑科技有限公司

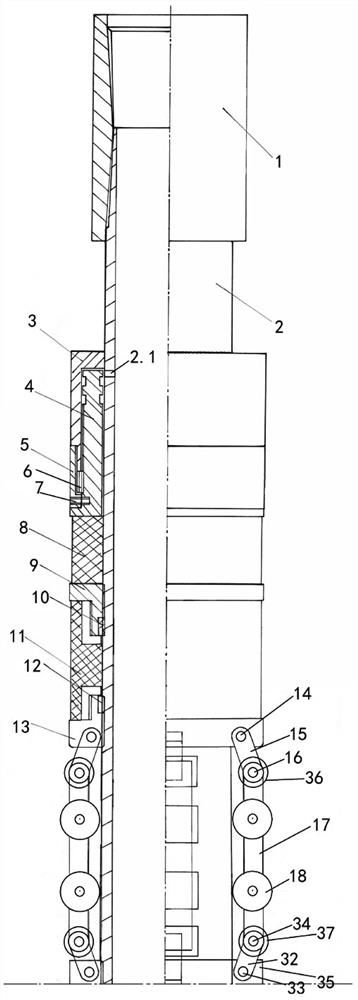

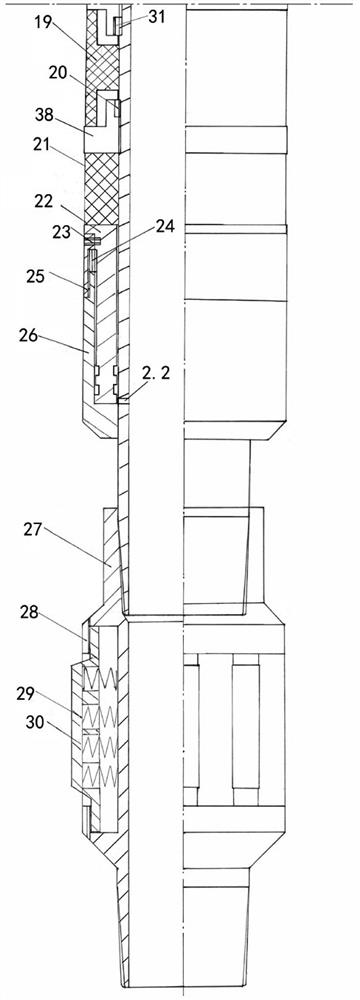

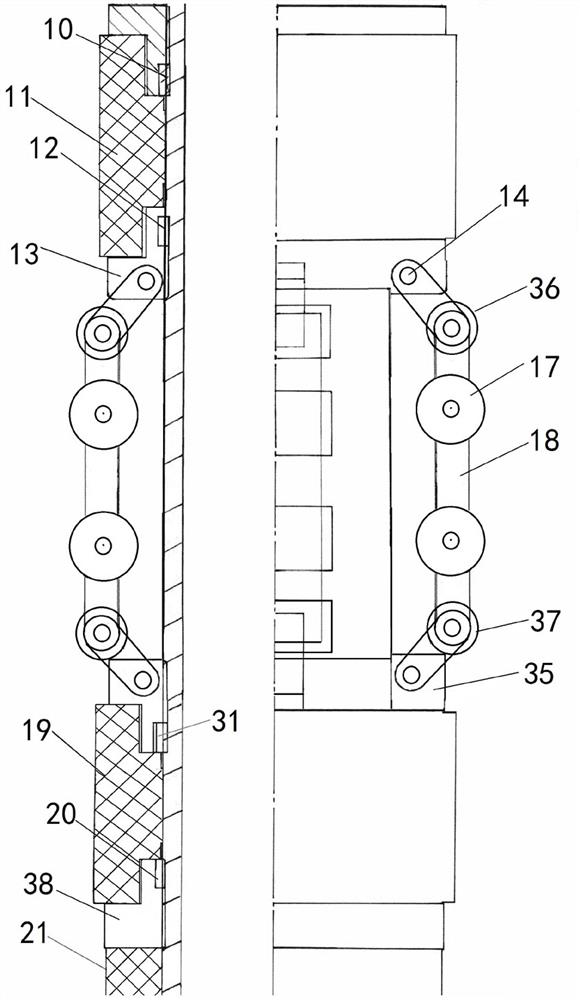

Casing centralizer for well cementation construction and method

ActiveCN114086898AAdjust the righting functionRealize the leading roleDrilling rodsSealing/packingClassical mechanicsWell cementing

The invention relates to the field of oil exploitation equipment, in particular to a casing centralizer for well cementation construction and a method. According to the technical scheme, a second centralizing device is arranged in the middle of a base pipe, an upper sealing device and a lower sealing device are arranged on the two sides of the second centralizing device respectively, an upper sealing cylinder sleeve of the upper sealing device is fixed to the outer wall of the base pipe, an upper sealing piston is arranged in an inner cavity of the upper sealing cylinder sleeve, and the lower end of the upper sealing piston is matched with an upper hydraulic sealing rubber cylinder arranged on the outer wall of the base pipe; a lower sealing cylinder sleeve of the lower sealing device is fixed to the outer wall of the base pipe, a lower sealing piston is installed in an inner cavity of the lower sealing cylinder sleeve, the second centralizing device adopts a four-connecting-rod adjusting centralizer, and when a water-swelling rubber block or oil-swelling rubber swells, the four-connecting-rod adjusting centralizer can be pushed to deform and adjust, so that centering and centralizing of a casing pipe are achieved; the mechanical four-connecting-rod adjusting centralizer is adopted to achieve large-amplitude deformation adjustment, and the centering and centralizing effects are better achieved when a casing pipe, a packer and the like are tripped into a shaft.

Owner:DONGYING JIANYUAN TRADE & IND

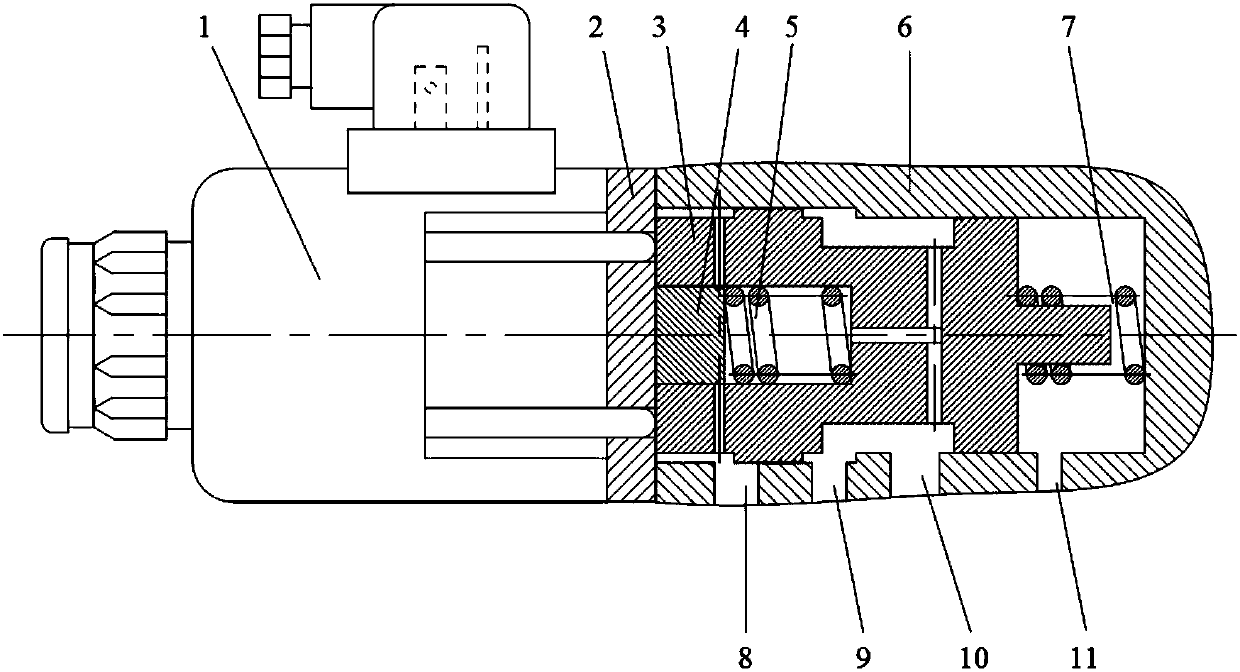

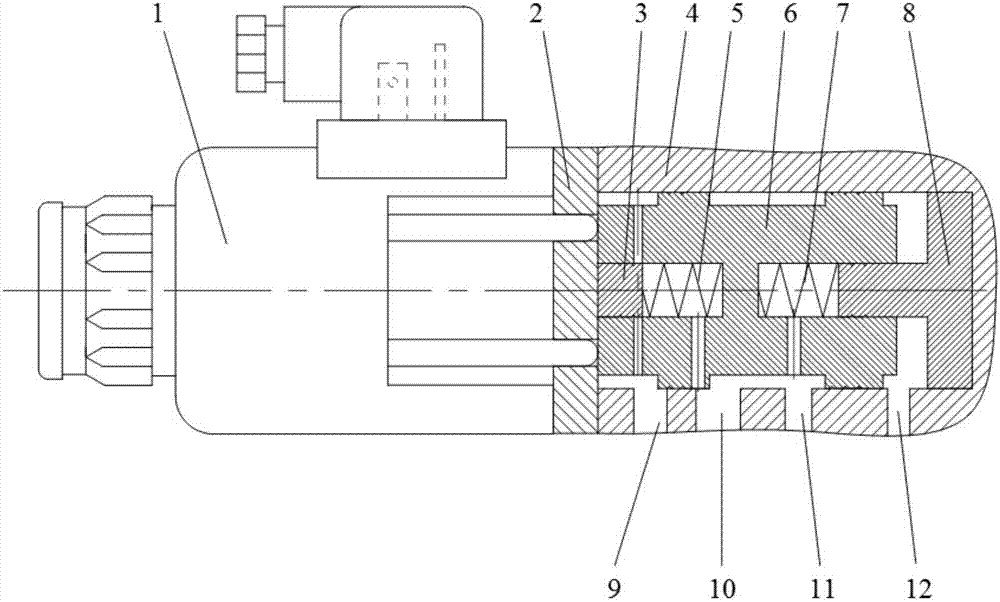

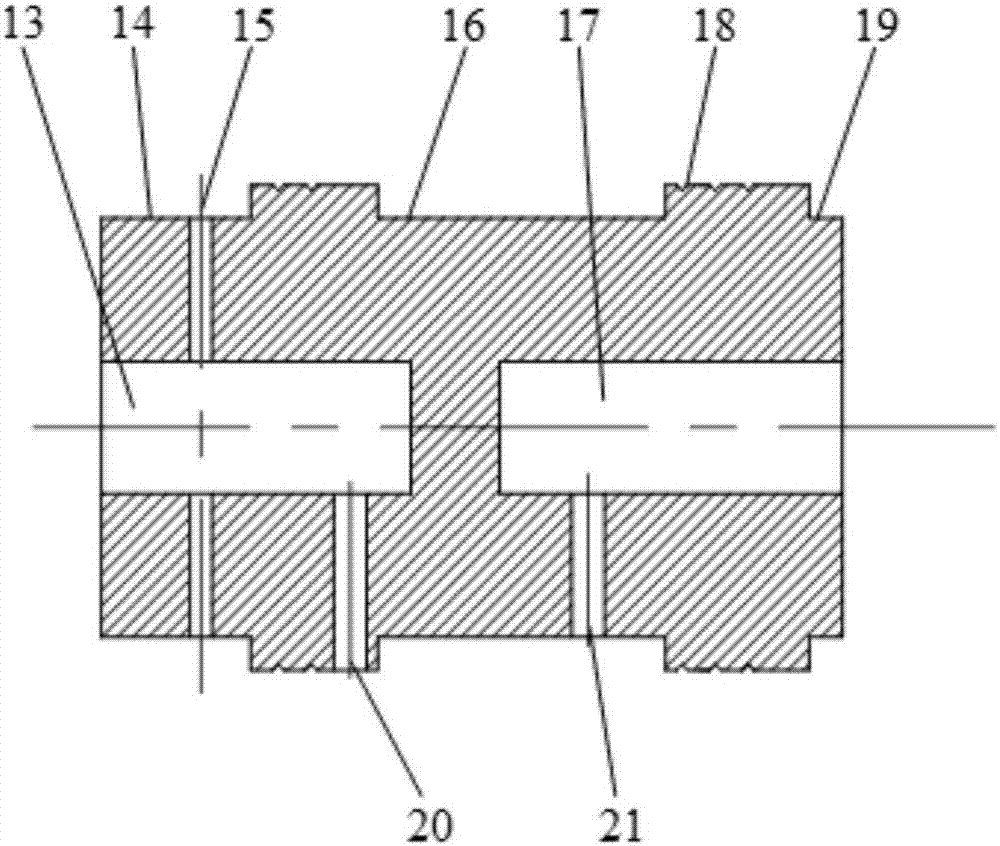

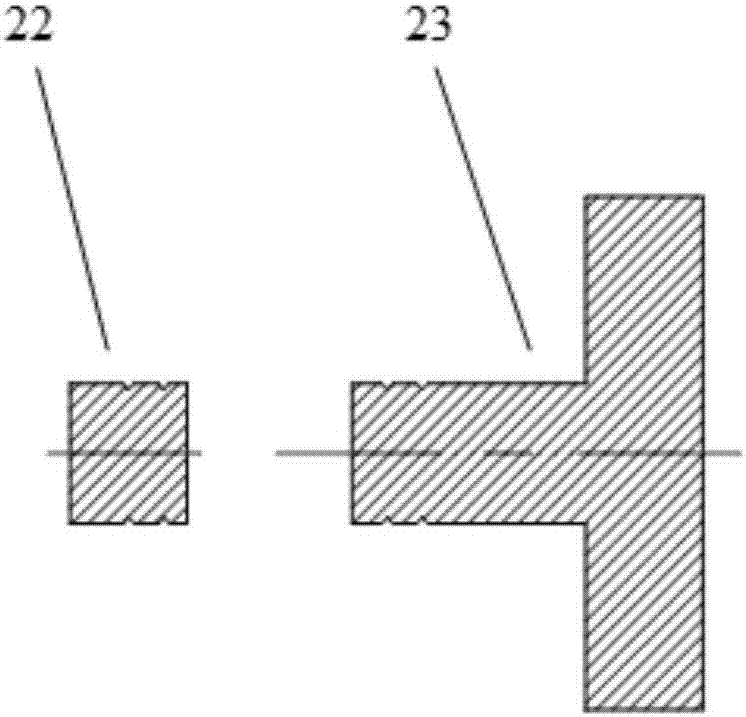

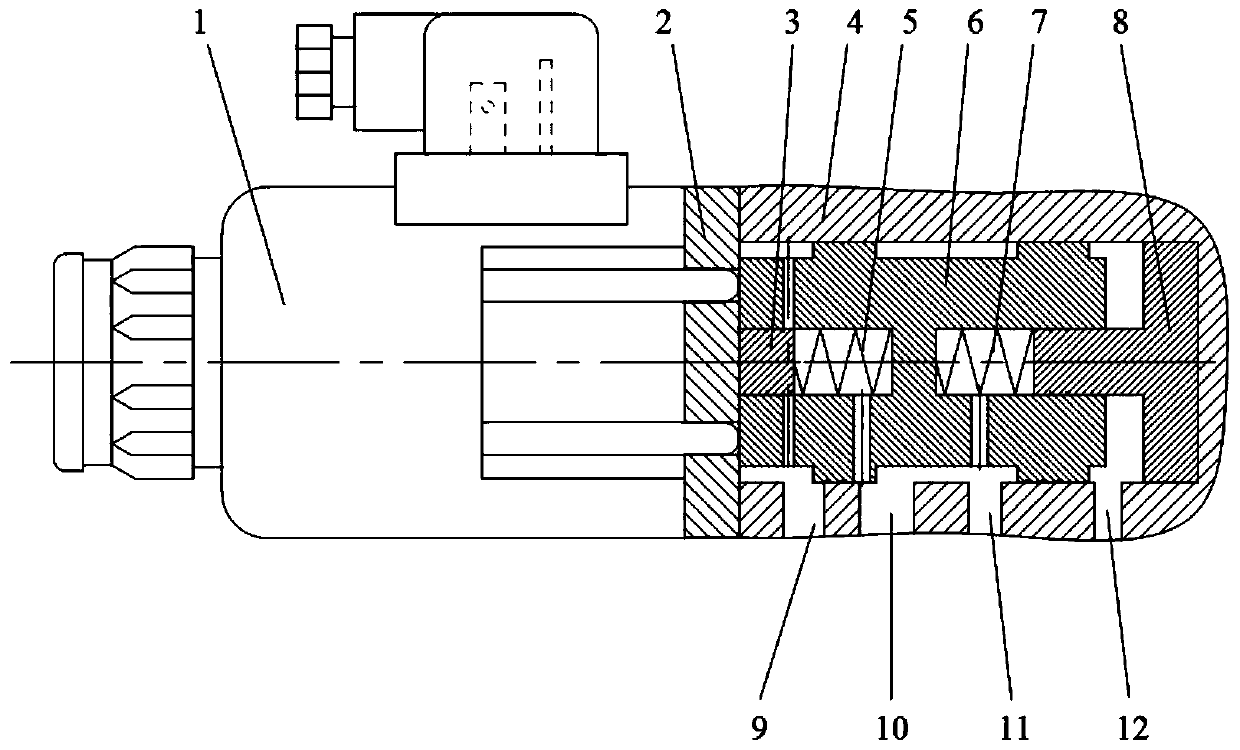

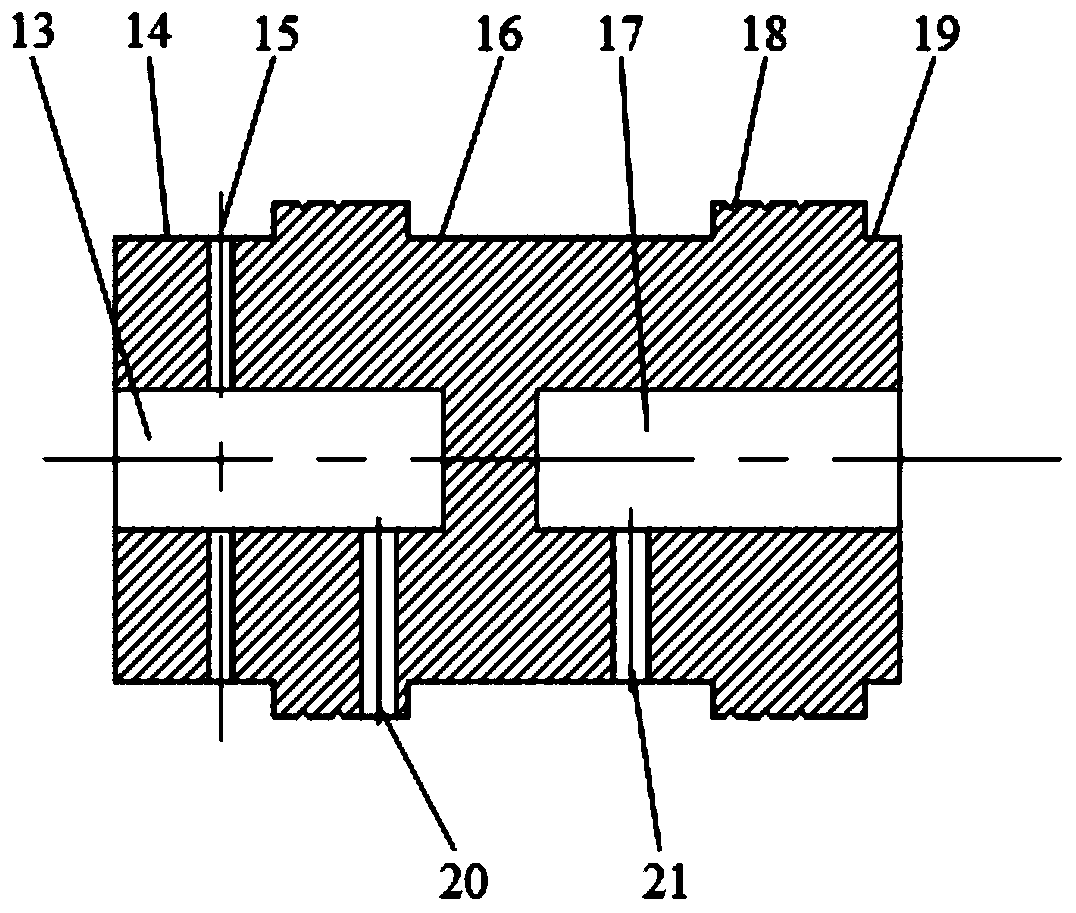

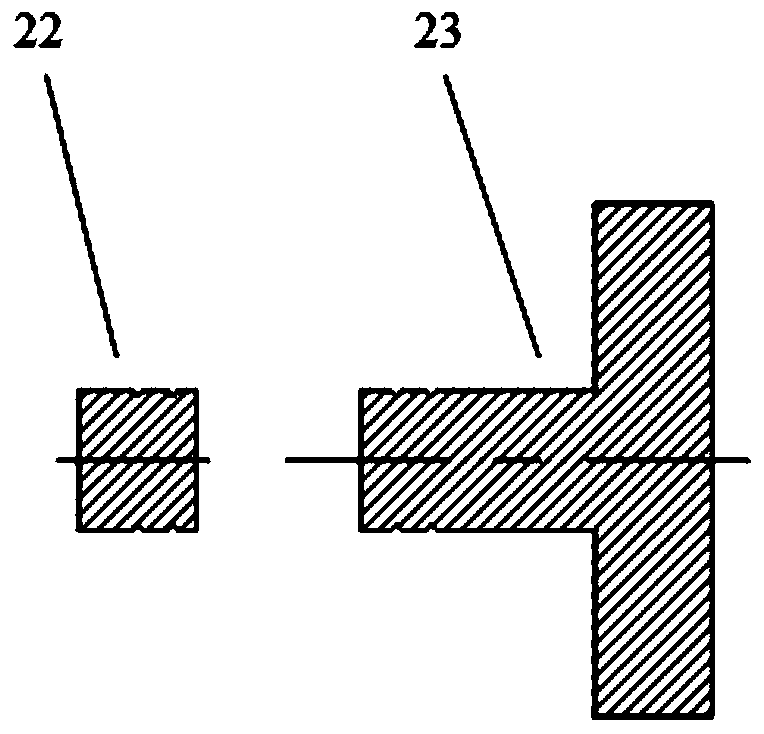

Electrohydraulic inverse proportion pressure reducing valve

ActiveCN107830006AReduce work stressAchieve pressure regulationOperating means/releasing devices for valvesServomotor componentsWorking pressureSpring force

The invention relates to an electrohydraulic inverse proportion pressure reducing valve and belongs to the field of hydraulic control. The proportion pressure reducing valve comprises a valve body, avalve element, a cylinder plug, a first resetting spring, a second resetting spring, a proportion electromagnet and a baffle. A stepped valve cavity is adopted, when the electromagnet does not work, the work pressure output by the pressure reducing valve is maximum, along with increasing of current, the electromagnetic pushing force output by the electromagnet increases, the work pressure of the pressure reducing valve is gradually reduced, the hydraulic force in a work cavity of the valve element is balanced with the spring force and the electromagnetic force, and pressure adjusting of a hydraulic oil way is achieved. The structure of the pressure reducing valve is greatly simplified, and the production cost is reduced. The inverse proportion pressure reducing valve can improve the stability and the control precision of work of the system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Metal powder continuous extrusion forming device

InactiveCN112536441ARealize the effect of automatic replyHigh densityMetal working apparatusStructural engineeringMetal powder

The invention discloses a metal powder continuous extrusion forming device. The metal powder continuous extrusion forming device comprises a box body and a pressing rod, a feeding pipe opening is fixedly formed in the left side wall of the box body, the pressing rod is slidably connected to the upper side wall of the box body, an extrusion disc is fixedly connected to the lower side wall of the pressing rod, a plurality of extrusion rods are fixedly connected to the lower side wall of the extrusion disc, the extrusion rods are slidably connected with the side wall of the upper end of the feeding pipe opening, the lower end of the feeding pipe opening is fixedly connected with an extrusion collecting box, the extrusion collecting box is connected with the left side wall of the box body through a supporting rod, a plurality of extrusion notches are formed in the upper side wall of the extrusion collecting box, and a rotary plate cavity is formed in the right side wall of the extrusion notches. Through the cooperation of the extrusion rods, a cutting mechanism, a blocking mechanism, a rotary baffle, springs and traction ropes, equal-density extrusion and automatic discharging operation on metal powder are achieved, and meanwhile the equal-length cutting and pushing effects on the metal powder after the metal powder is blocked are achieved through the driving effect.

Owner:沈超

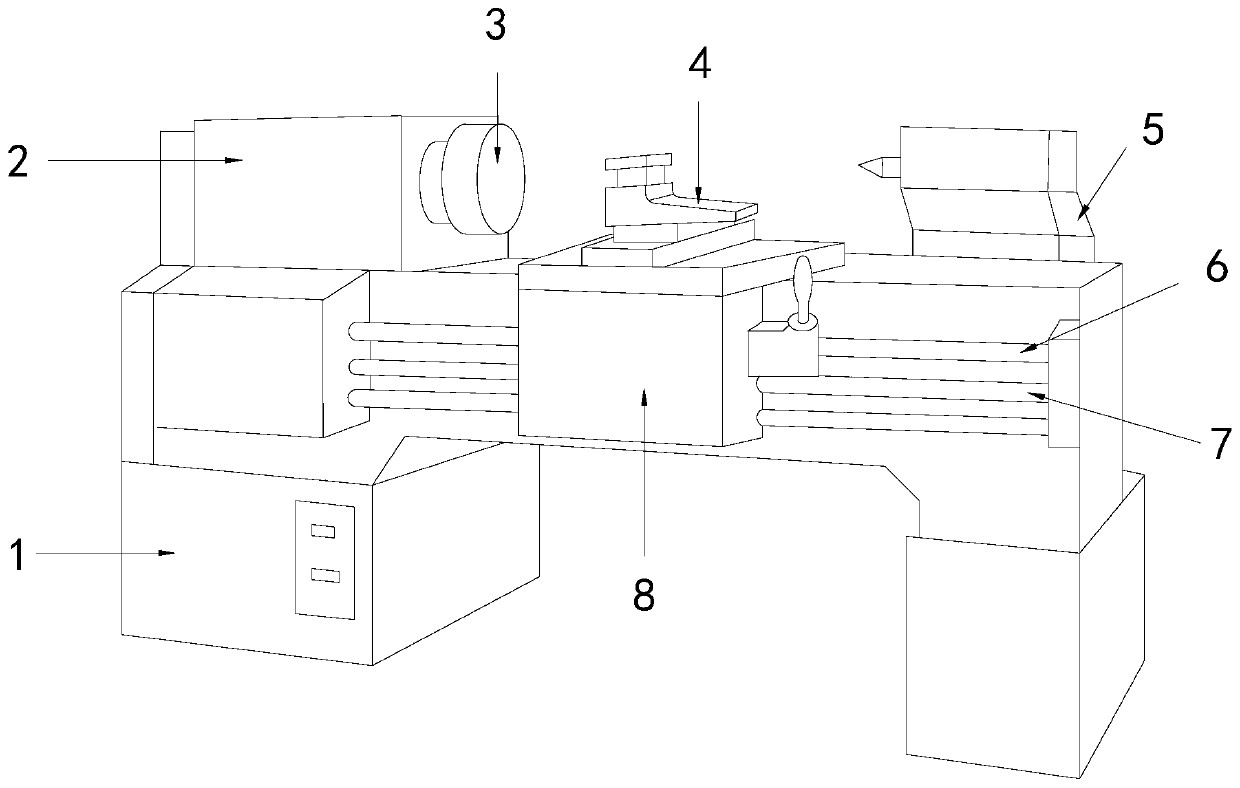

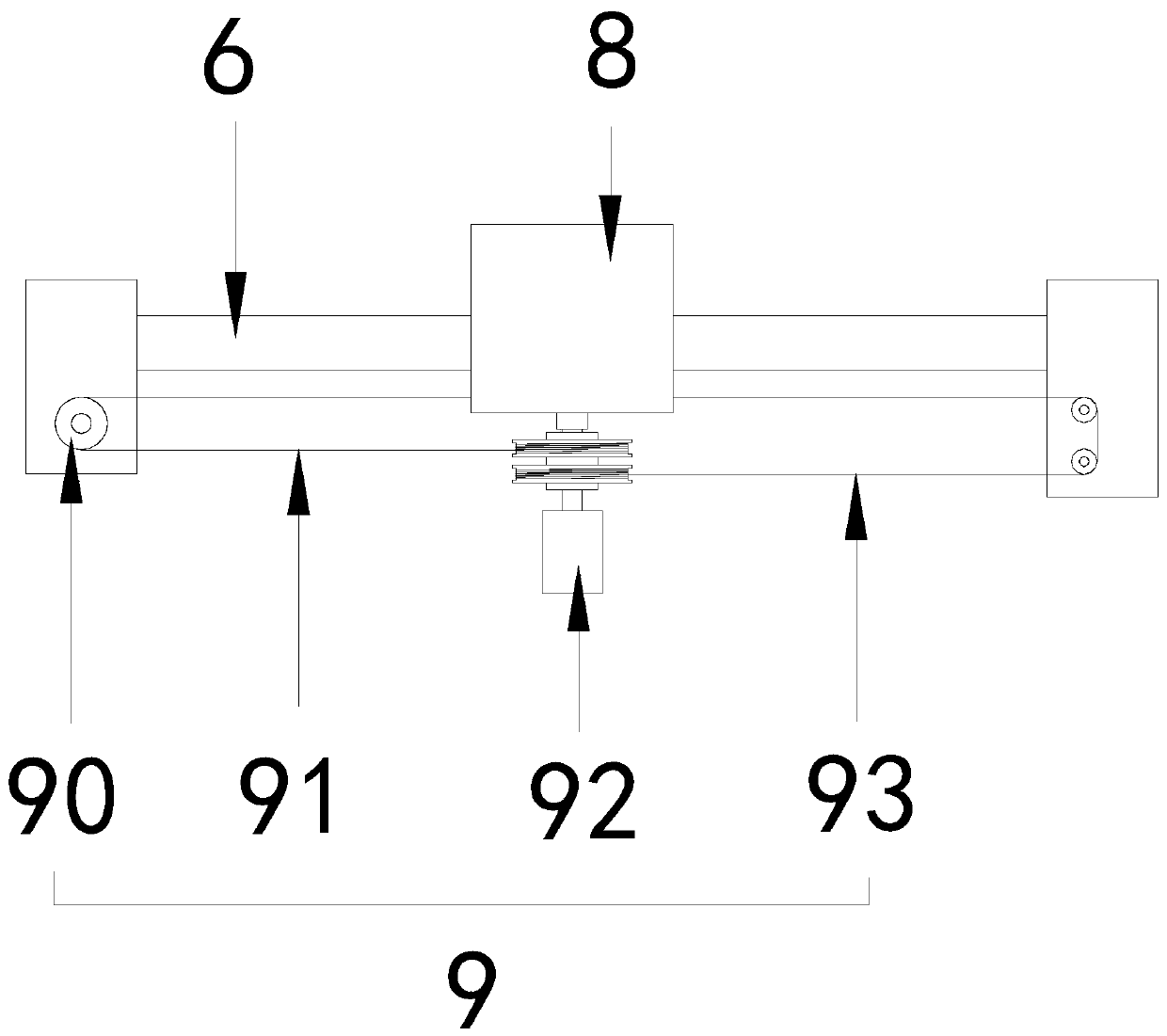

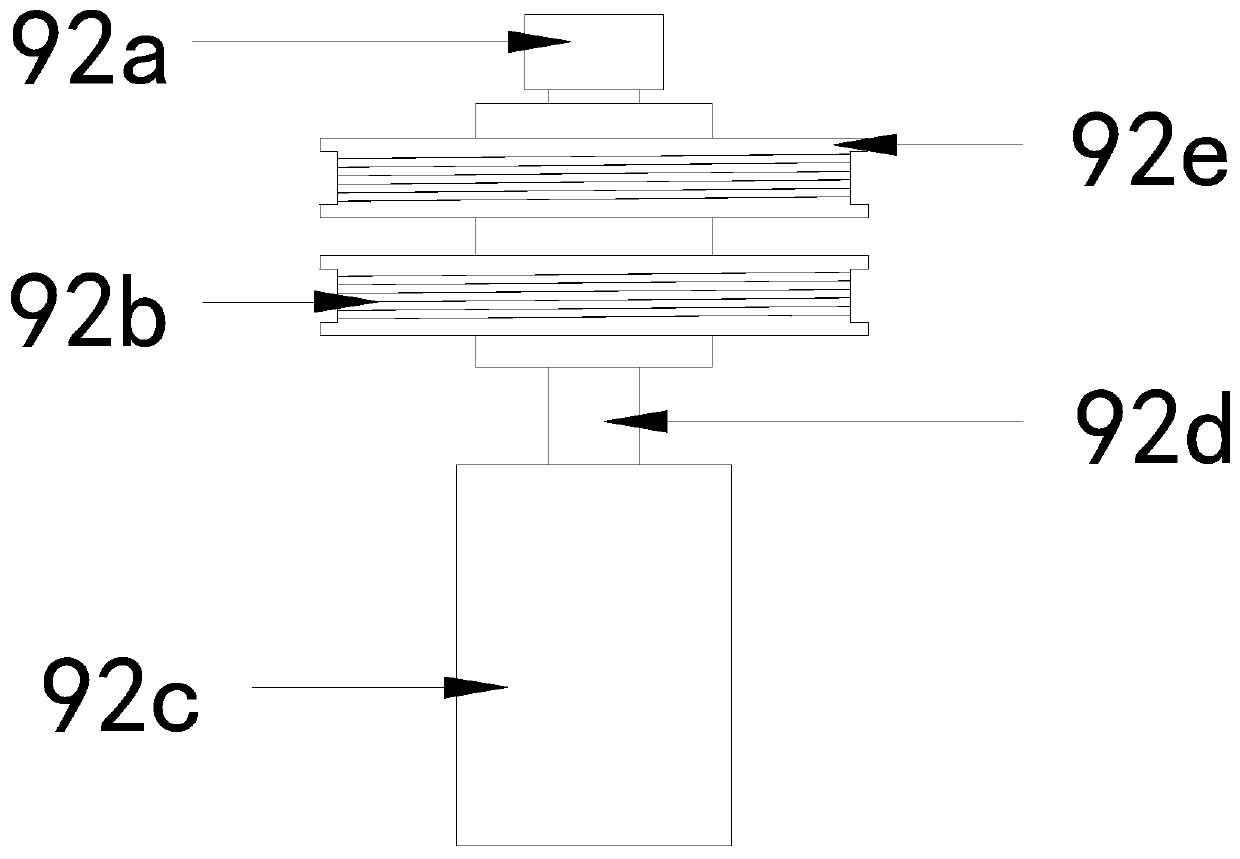

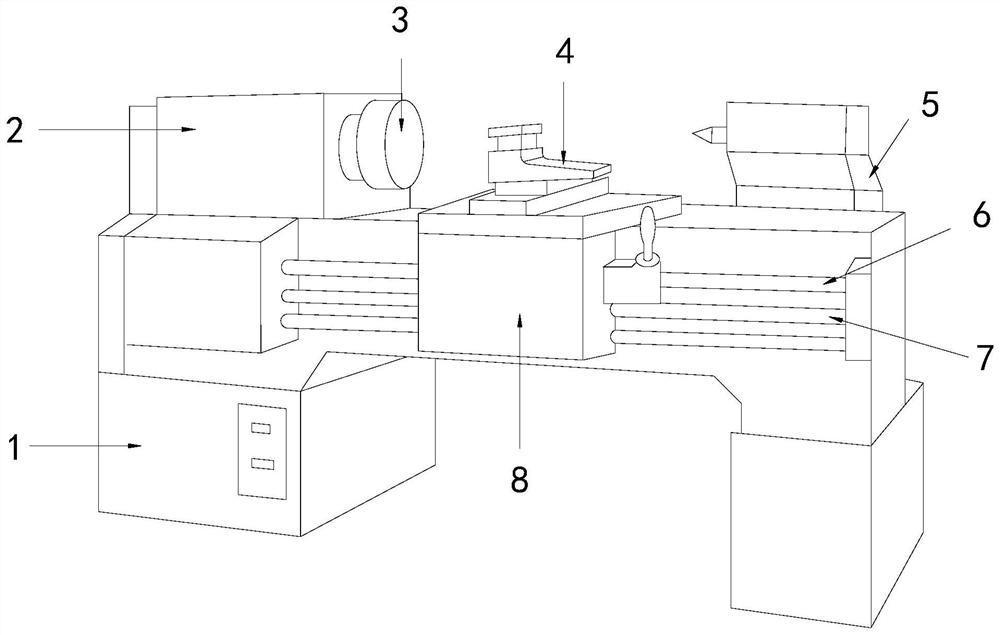

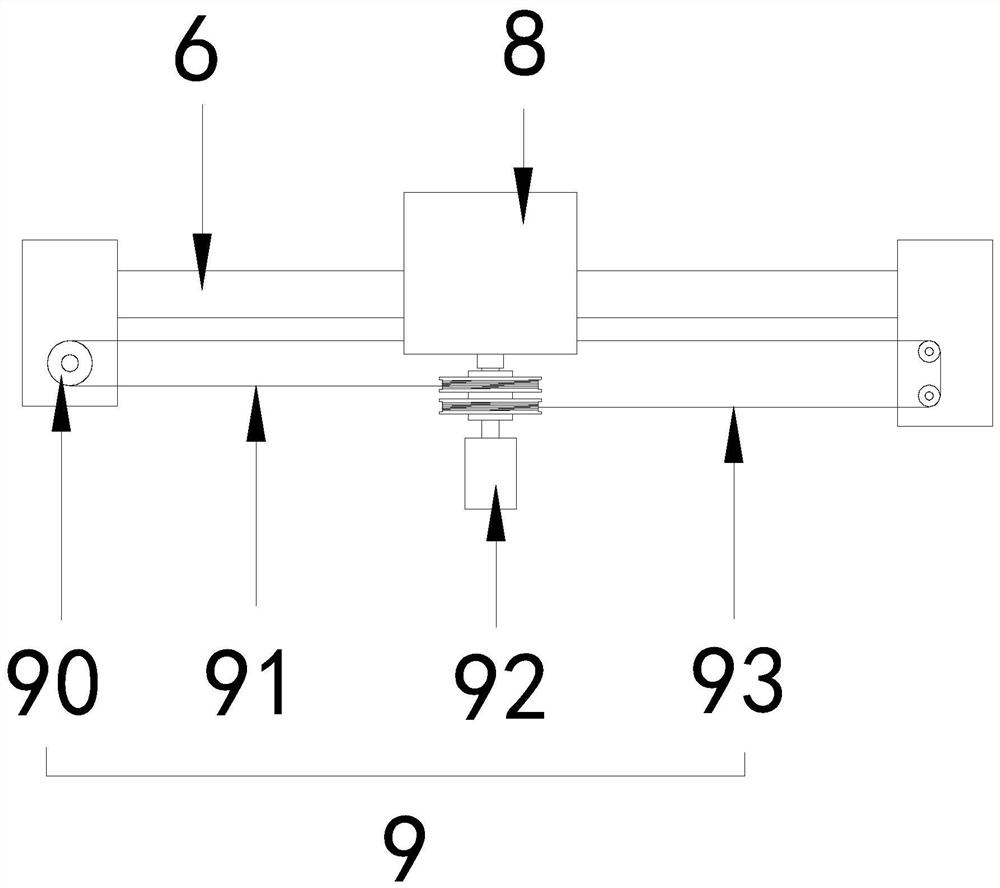

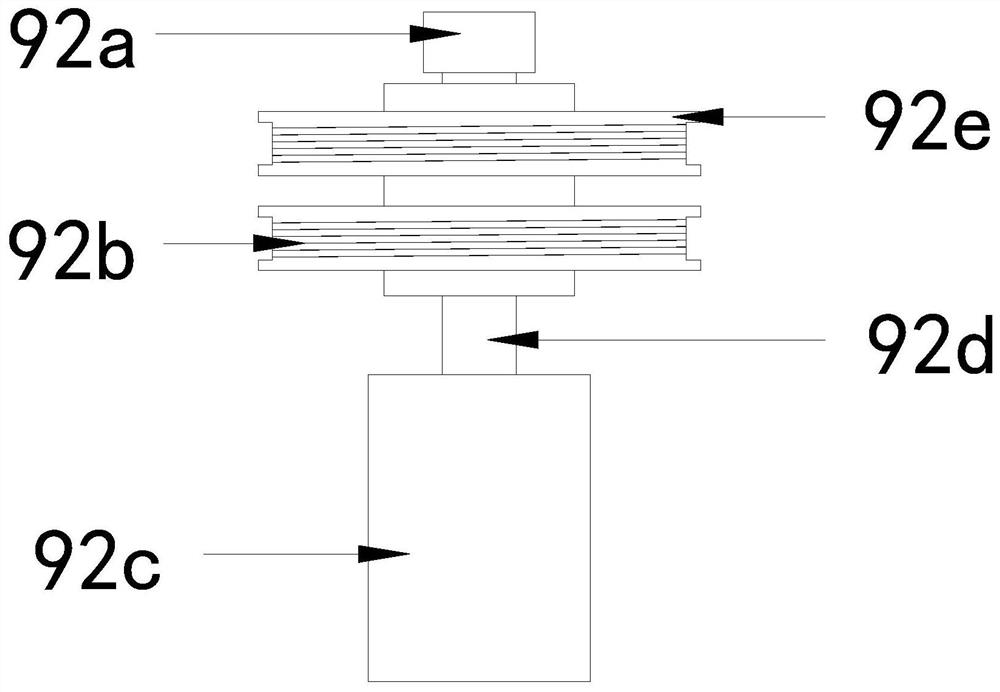

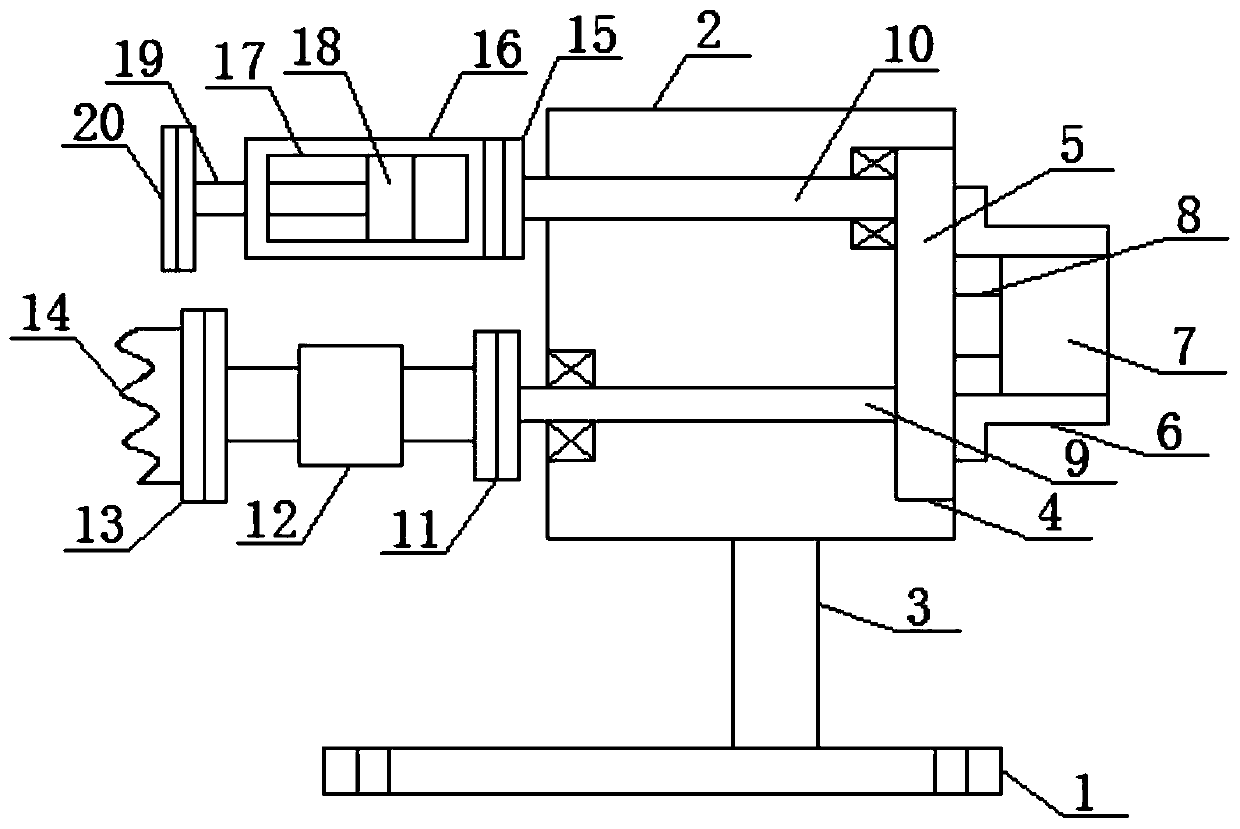

Numerical control horizontal lathe equipment

ActiveCN111230148AReduce frictionReduce resistanceAutomatic/semiautomatic turning machinesFeeding apparatusNumerical controlControl engineering

The invention discloses numerical control horizontal lathe equipment. The numerical control horizontal lathe equipment structurally comprises a lathe bed, a power box, a main shaft, a tool rest, a tailstock, a lead screw, a polish rod, a tool rest feeding system and a power assisting device, wherein the lead screw and the polish rod are installed on the lathe bed, the tool rest feeding system is movably connected with the lead screw and the polish rod, the tool rest is arranged on the top of the tool rest feeding system, the main shaft is arranged on the left side of the tool rest and is connected with the power box, the power box is fixed on the lathe bed, the tailstock is arranged on the right side of the lathe bed, the power assisting device is connected with the tool rest feeding system and arranged inside the lathe bed, and the power assisting device comprises a pulley, a first pull rope, a winding structure and a second pull rope. The numerical control horizontal lathe equipmenthas the beneficial effects that the moving tool rest feeding system can be assisted by the power assisting device, so that the resistance is reduced, in addition, friction between a nut and the lead screw is reduced, the service life of the nut and the lead screw is prolonged, two movable claws opposite in direction match with a first winding wheel and a second winding wheel so that respective work can be carried out when the two movable claws move in the left direction and the right direction, and mutual interference is avoided.

Owner:嘉兴市中法天线实业有限公司 +1

A temporary storage system for medical waste in wards

ActiveCN111301893BSmooth rotationEasy to put inGlass recyclingWaste collection and transferMedical wasteEnvironmental engineering

The invention belongs to the technical field of medical waste treatment, and specifically discloses a short-term storage system for medical waste in wards. The upper storage area is set in a cylindrical shape and divided into at least four upper sub-storage rooms by a partition plate. A rotating shaft is arranged in the center of the upper storage area, and each sub-storage room rotates with the rotating shaft; the lower storage area is provided with a body fluid storage room, Blood bag storage room and glass storage room; the outer casing is provided with an upper inlet corresponding to the upper storage area, and the outer casing is provided with three lower inlets corresponding to the lower storage area, and each lower inlet is respectively connected to the body fluid The storage room, the blood bag storage room and the glass storage room correspond; the top of the outer casing is provided with an upper outlet, the lower side wall of the outer casing is provided with a lower outlet, the upper outlet is provided with an upper outlet cover, and the lower storage area is taken out. The outlet is provided with a lower removal outlet cover.

Owner:HENAN CANCER HOSPITAL

Manufacturing apparatus and manufacturing method of rapidly dewatering fiber for forming web

The invention relates to a device and a method for preparing rapid dehydration fibers for forming fabric. The device comprises a surface layer tube and a core layer tube arranged in the surface layer tube concentrically in a sleeving manner, and the surface layer tube and the core layer tube are both connected with respective pressure supply devices. The device is characterized in that an annular intermittent vibration device is arranged on the peripheral surface of the surface layer tube in a sleeving manner, and the vibration frequency of the intermittent vibration device is adjustable. The method for preparing the dehydration fibers comprises the following steps: (1) the surface layer tube and the core layer tube are used for performing spinning towards a spinning liquid simultaneously, the intermittent vibration device transmits own vibration into the surface layer tube and the core layer tube during spinning, and the radial size of the core layer increases with decrease of the radial size of the surface layer in the axial direction of the fibers due to vibration; (2) a high-frequency electromagnetic heating coil is further used for heating surface and core fibers prepared in the step (1), the conductive core layer is enabled to produce heat, and a dehydration groove surrounding each fiber is formed in the outer surface of the fiber.

Owner:JIANGSU LEE & MAN PAPER MFG

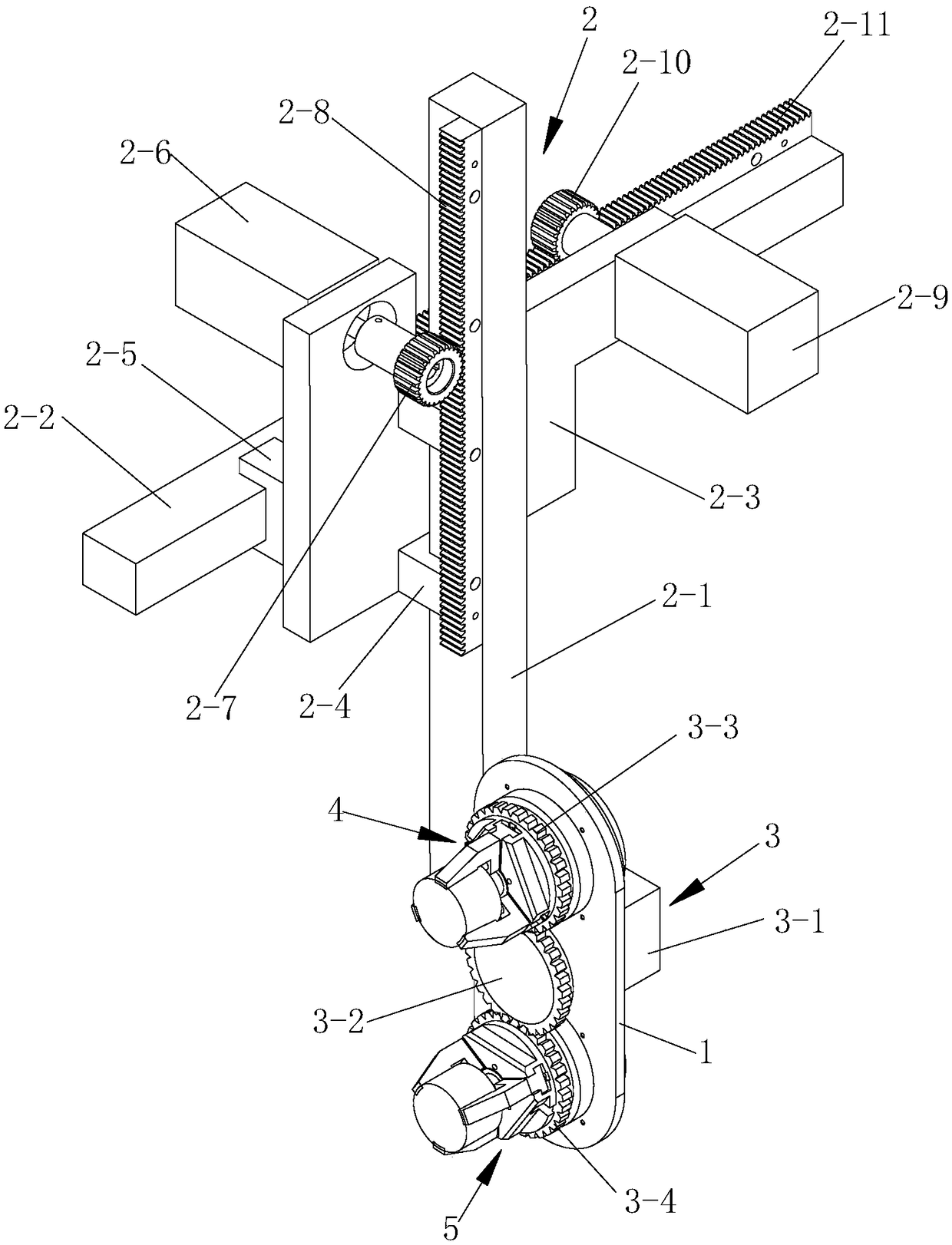

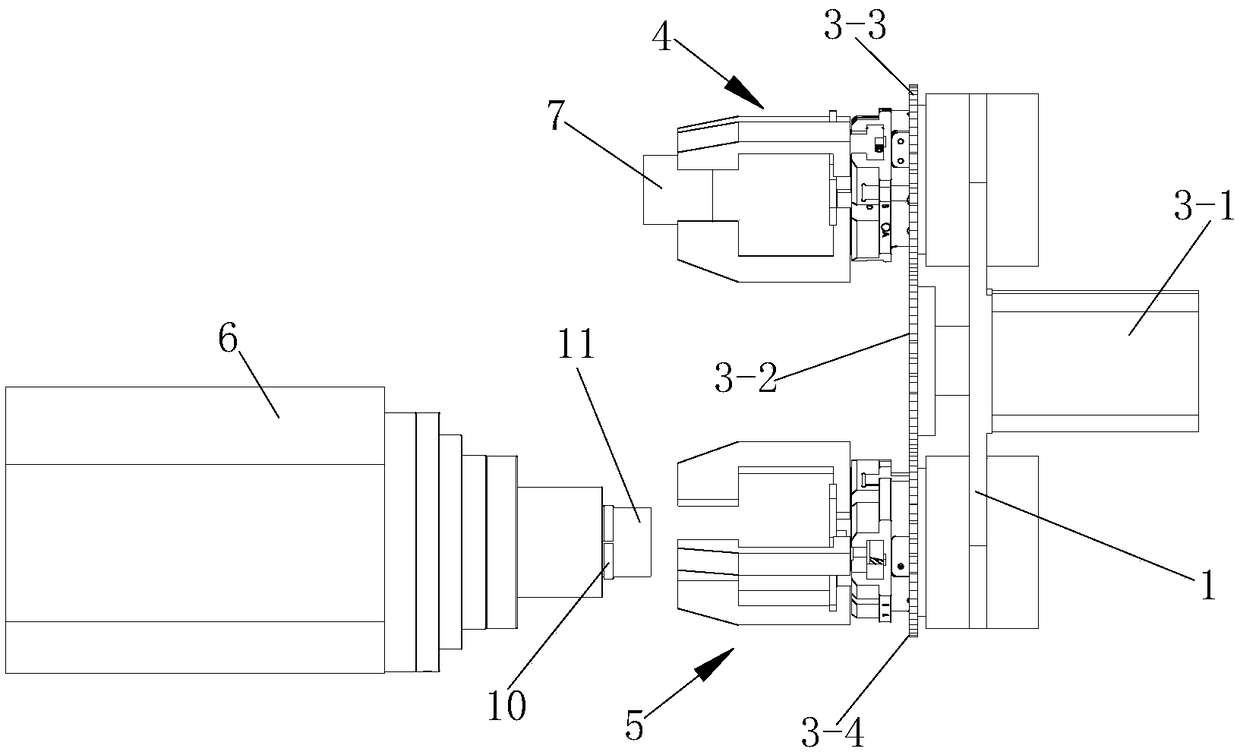

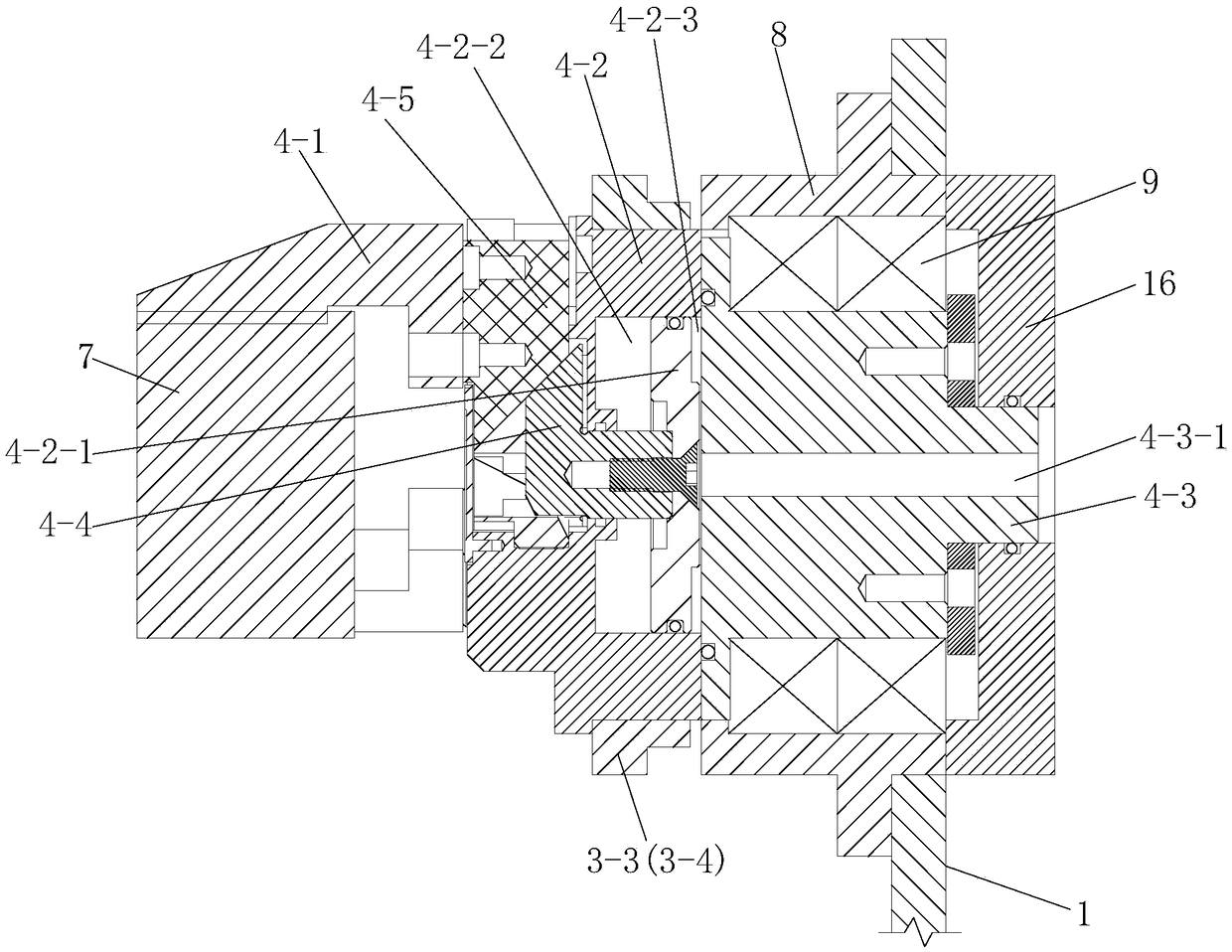

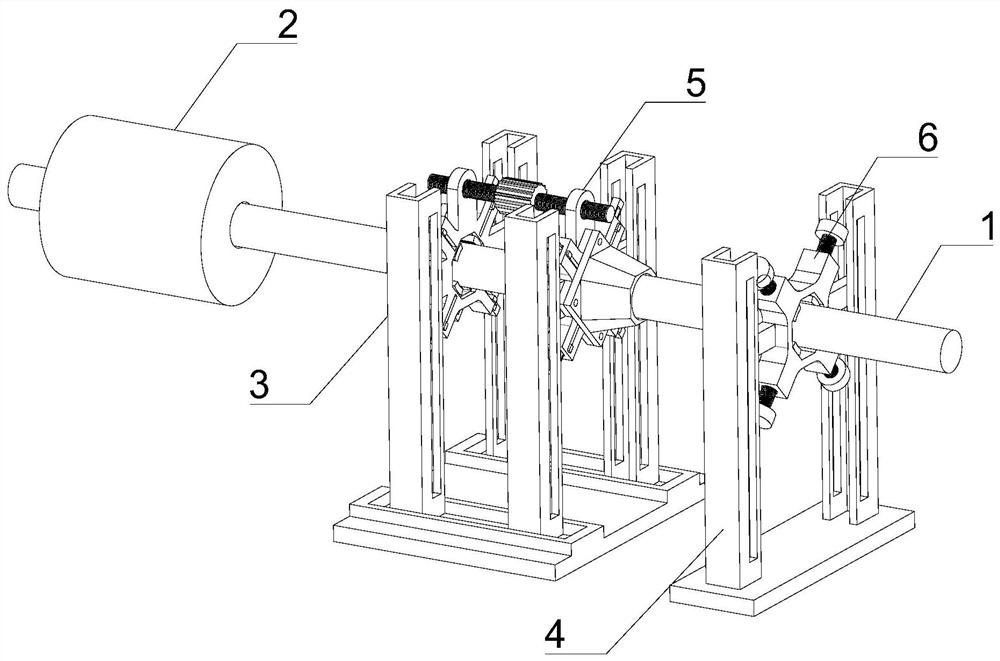

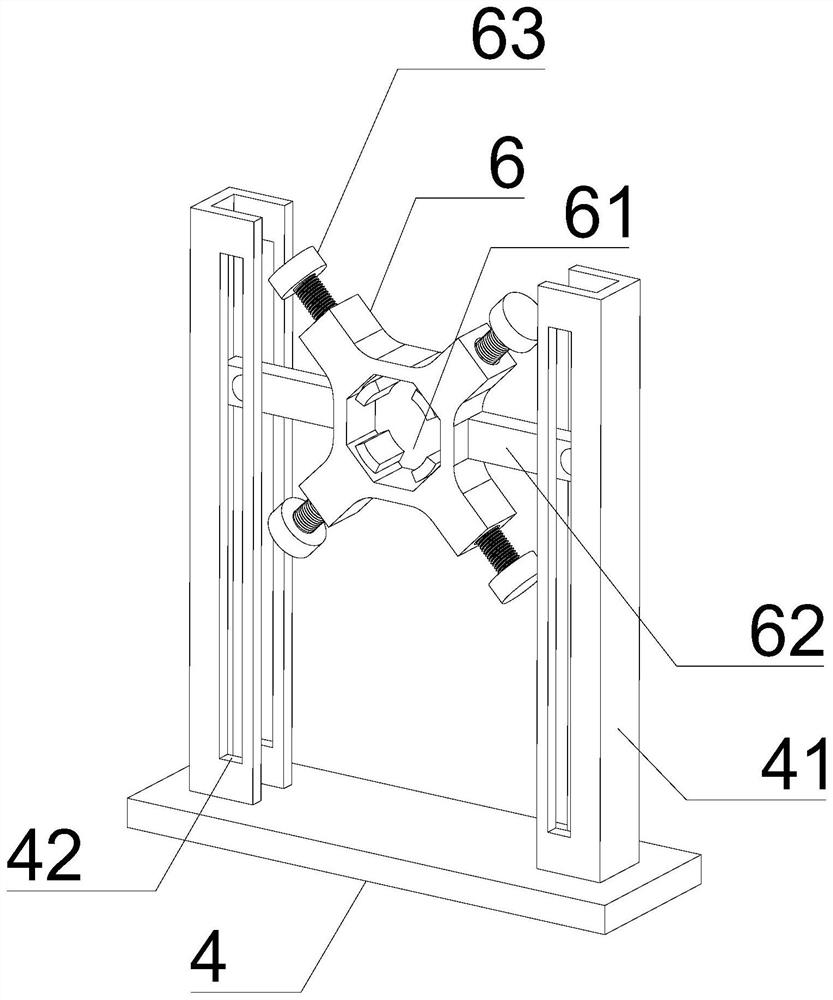

A synchronous feeding manipulator for machine tools

InactiveCN106514411BImprove processing efficiencyImprove processing timeMetal working apparatusEngineeringPower apparatus

The invention discloses a synchronous material change mechanical hand for a machine tool. The synchronous material change mechanical hand comprises a material paw fixed plate, and a moving mechanism used for driving the material paw fixed plate to move up and down and move left and right, wherein a feeding paw used for mounting a blank on a machine tool chuck, a discharge paw used for discharging a workpiece processed through the blank from the machine tool chuck, and a power device used for driving the feeding paw and the discharge paw to synchronously rotate along with a machine tool spindle; and the feeding paw and the discharge paw comprise a plurality of material paw fingers and driving devices used for driving the plurality of material paw fingers to be away from each other at the same time or to be close to each other at the same time. According to the synchronous material change mechanical hand for the machine tool, feeding and discharge actions can be carried out during the high-speed operation process of the machine tool spindle, so that the material change time is effectively shortened, and the processing efficiency of the workpiece is improved.

Owner:XIAN AERONAUTICAL POLYTECHNIC INST

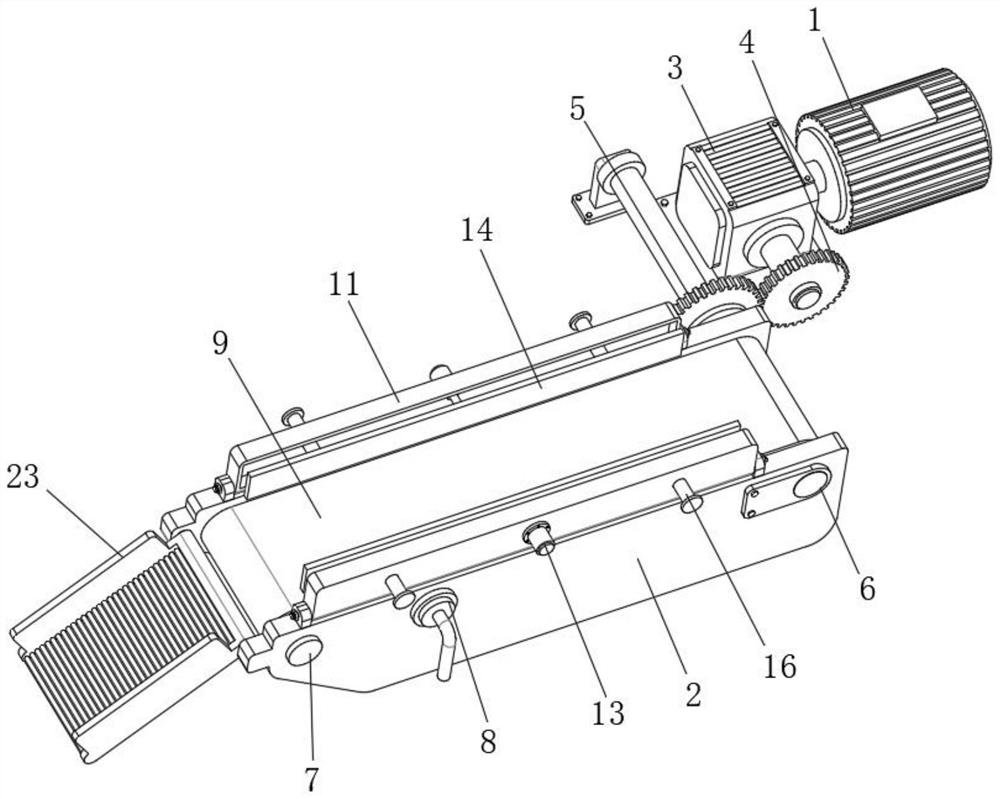

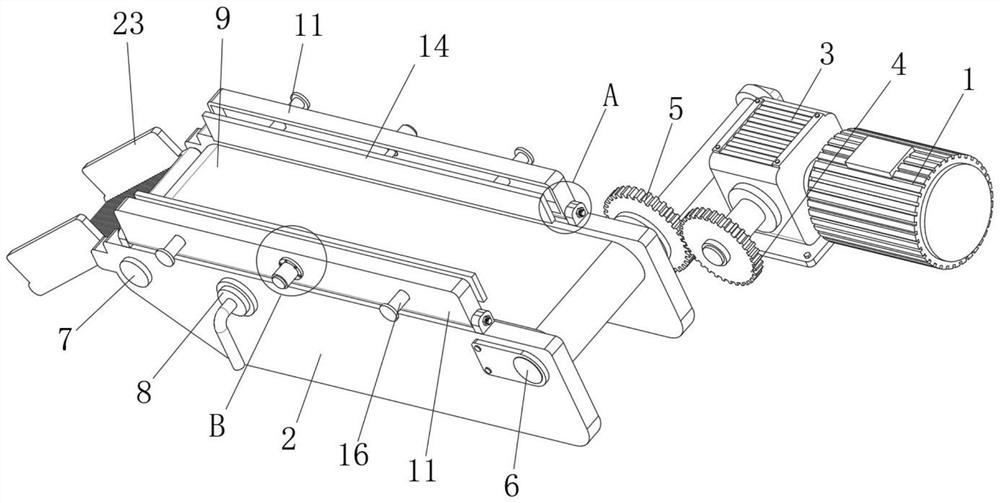

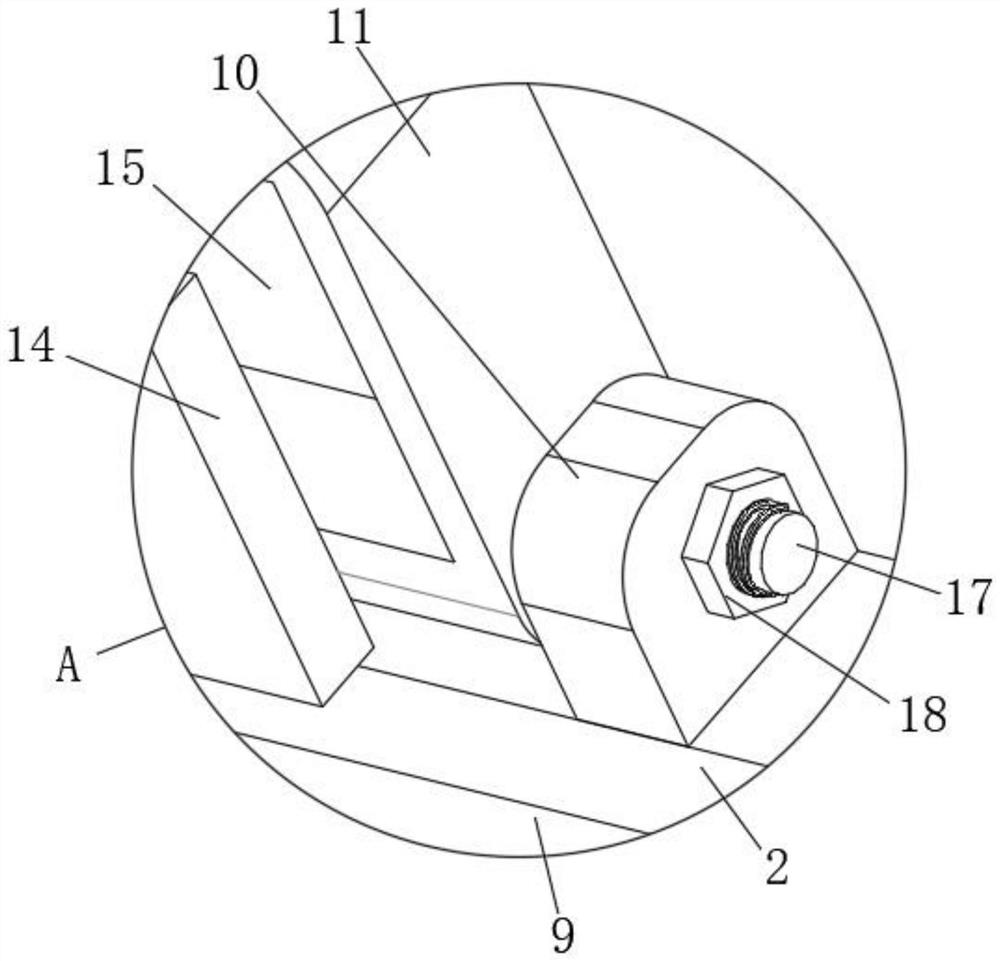

Novel vegetable cutter feeding mechanism

InactiveCN114180274AGuaranteed normal feedingTo achieve a limiting effectConveyorsPackagingElectric machineryAgricultural engineering

The invention relates to the technical field of vegetable cutter feeding, in particular to a novel vegetable cutter feeding mechanism which comprises a motor and mounting plates, a speed reducer is fixedly mounted at the output end of the motor, a driving gear is fixedly mounted at the output end of the speed reducer, and a driving roller and an auxiliary roller are symmetrically arranged between the mounting plates. The end, close to the driving gear, of the driving roller is sleeved with a driven gear, a tightening roller is arranged in the mounting plate, a belt is wound around the outer surfaces of the driving roller, the auxiliary roller and the tightening roller, and bases are symmetrically and fixedly mounted on the upper surface of the mounting plate. According to the potato and carrot conveying device, by arranging the base, the rotating plate, the mounting disc, the electric push rod, limiting plates and other related mechanisms, when potatoes, carrots and other similar spherical or cylindrical vegetables are conveyed through a belt, the distance between the two sets of limiting plates can be adjusted through the pushing effect of the electric push rod, and then the limiting effect on the potatoes and the carrots is achieved; therefore, the subsequent vegetable cutting process can be smoothly carried out.

Owner:刘佑红

Application method of medical waste temporary storage system for inpatient area

ActiveCN112357392ASmooth rotationEasy to put inGlass recyclingWaste collection and transferMedical wasteEnvironmental engineering

Owner:HENAN CANCER HOSPITAL

Juice extractor

The invention relates to a juice extractor. The juice extractor comprises a shell, a juice extracting component and a driving component, wherein a feed inlet, a juice outlet and a dreg outlet are formed in the shell; the juice extracting component is arranged in the shell; and the driving component is used for driving the juice extracting component to work and arranged below the shell. The juice extractor is characterized in that: the juice extracting component comprises a juice extracting body and a filtering screen; the juice extracting body is a columnar rotor which can be driven to rotate by the driving component; a notch which can be correspondingly communicated with the feed inlet of the shell is formed on the upper half part of the juice extracting body; spiral teeth are formed on the juice extracting body along an outer circumferential surface; the juice extracting body is arranged in the filtering screen in a rotatable way; and the filtering screen is fixedly arranged in the shell. The juice extractor has a more simple overall structure, a small number of parts, low production cost and high juice extracting efficiency and is safely used; automatic blanking can be realized in the rotating process of the juice extracting body; and the two ends of the juice extracting body are not required to be fixed, so that the juice extracting body can be directly connected with the driving component, and the juice extractor is more convenient to mount.

Owner:张建民

Casing centralizer and method for cementing construction

ActiveCN114086898BAdjust the righting functionRealize the leading roleDrilling rodsSealing/packingThermodynamicsWell cementing

The invention relates to the field of oil exploitation equipment, in particular to a casing centralizer and method for well cementing construction. The technical solution is: a second centralizing device is provided in the middle of the base pipe, an upper sealing device and a lower sealing device are respectively installed on both sides of the second centralizing device, the upper sealing cylinder liner of the upper sealing device is fixed on the outer wall of the base pipe, The upper sealing piston is installed in the inner cavity of the upper sealing cylinder liner, and the lower end of the upper sealing piston cooperates with the upper hydraulic sealing rubber cylinder provided on the outer wall of the base pipe; the lower sealing cylinder liner of the lower sealing device is fixed on the outer wall of the base pipe, and the lower sealing piston Installed in the inner cavity of the lower sealing cylinder liner, the second centralizing device adopts a four-link adjusting centralizer, which will push the four-link adjusting centralizer to deform and adjust when encountering water-swelling rubber block or oil-expanding rubber to realize casing Centering and centralizing; the beneficial effect is that a mechanical four-link adjusting centralizer is used to realize large-scale deformation adjustment, and the centering and centralizing effect of the casing and packer when running into the wellbore is better realized.

Owner:DONGYING JIANYUAN TRADE & IND

Sliding valve type inverse proportion pressure reduction valve

ActiveCN107990024ARealize the leading roleRegulating pressureOperating means/releasing devices for valvesMultiple way valvesSpring forceEngineering

The invention relates to a sliding valve type inverse proportion pressure reduction valve, and belongs to the field of hydraulic control. The valve comprises a proportion electromagnet, a baffle, a cylindrical plug, a valve body, a first reset spring, a valve element, a second reset spring and a piston; valve cavity equal-diameter machining is adopted, when the electromagnet does not work, work pressure output by the pressure reduction valve is maximum, along with current increase, electromagnetic thrust output by the electromagnet is increased, work pressure of the pressure reduction valve isgradually reduced, hydraulic pressure in a valve element work cavity, spring force and electromagnetic force are balanced, and hydraulic oil path pressure adjusting is achieved. The proportion pressure reduction valve is high in control precision, system work stability can be improved, the structure is simple and easy to machine, the manufacturing cost is low, and assembling complexity is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Device for reducing conductor vibration and improving insulation concentricity

ActiveCN113707393AImprove adaptabilityRealize the clamping effectInsulating conductors/cablesWire rodElectrical conductor

The invention discloses a device for reducing conductor vibration and improving insulation concentricity. The device comprises a first support assembly, a second support assembly, a limiting assembly and an adjusting assembly. Through the limiting assemblies, when the wire rod penetrates through the limiting assemblies, the wire rod penetrating through the middle of the fixing block is guided and clamped through the connecting rod, balls are arranged at the bottom of the connecting rod, and advancing of the wire rod can be facilitated to a certain degree. Through the spring arranged in the connecting rod, the limiting assemblies can clamp and guide wires of different sizes through self-adaptive adjustment of the connecting rods, so that the adaptability of the limiting assemblies is enhanced, the two limiting assemblies can be moved bidirectionally through the bidirectional threaded rod under the manual action, and therefore by adjusting the distance between the two limiting assemblies, the large-range clamping and guiding effects on the wire are achieved, and the concentricity change situation generated in the wire extrusion machining process is advantageously solved.

Owner:东莞市领亚数字通讯科技有限公司

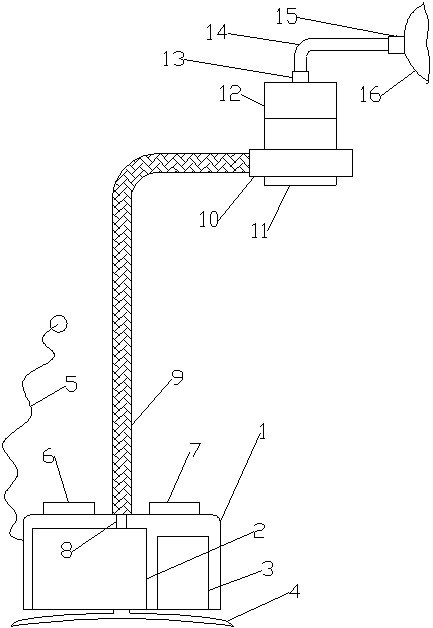

Airflow distribution continuous driving medical nebulizer and airflow distribution continuous driving method

The invention relates to a medical nebulizer continuously driven by airflow distribution and a method for continuously driving airflow distribution. The center position of the bottom of the liquid medicine storage box is connected to the air supply connecting pipe installed inside the universal adjustment pipe through the bottom bend pipe. The top airflow distribution cover is installed on the upper part of the continuous drive sleeve through screw connection, and the top airflow distribution chamber corresponding to the bottom airflow distribution chamber is set at the bottom center of the top airflow distribution chamber, and the top airflow distribution chamber is set at the center There is an atomization stopper, and an airflow distribution outlet connected to the top of the top airflow distribution cavity is set at the top center of the top airflow distribution cover, and an atomization generation stopper is set at the center of the airflow distribution outlet to connect and fix The top of the air distribution air outlet is fixedly connected with the mouth and nose mask connection joint; the external air is pressed into the bottom air distribution cavity and the top air distribution cavity, which further realizes the driving effect on the atomized molecules, and can be customized according to the needs of patients. Implement the speed regulation operation of the induced draft fan.

Owner:XINXIANG YATAI MEDICAL PROD CO LTD

A kind of CNC horizontal lathe equipment

ActiveCN111230148BReduce weight burdenRealize the leading roleAutomatic/semiautomatic turning machinesFeeding apparatusNumerical controlTailstock

Owner:黑玛智能科技(阳春)有限公司

Device and method for fabricating forming fabric with rapid dehydration property

The invention relates to a device and a method for fabricating forming fabric with a rapid dehydration property. The device comprises a spinning device and a high-frequency electromagnetic heating coil, wherein the spinning device comprises a surface layer tube and a core layer tube arranged in the surface layer tube concentrically in a sleeving manner, and the surface layer tube and the core layer tube are both connected with respective pressure supply devices; an annular intermittent vibration device is attached to the peripheral surface of the surface layer tube in a sleeving manner, and the vibration frequency of the intermittent vibration device is adjustable. The method for preparing the forming fabric with the rapid dehydration property comprises the following steps: (1) the surface layer tube and the core layer tube are used for performing spinning towards a spinning liquid simultaneously, the intermittent vibration device transmits own vibration into the surface layer tube and the core layer tube, and the radial size of the core layer increases with decrease of the radial size of the surface layer in the axial direction of the fibers due to vibration; (2) the fibers prepared in the step (1) are combined to fabricate yarn, and the forming fabric is woven with the yarn; (3) the high-frequency electromagnetic heating coil is used for heating the forming fabric, and the fiber conductive core layer is enabled to produce heat.

Owner:JIANGSU LEE & MAN PAPER MFG

Emergency diagnosis and treatment device for dangerous critically ill patient

ActiveCN112641583AImprove disinfection effectAchieving tightnessBreathing protectionSurgical furnitureCritically illHead of bed

The invention discloses an emergency diagnosis and treatment device for a dangerous critically ill patient. The emergency diagnosis and treatment device comprises a diagnosis and treatment outer frame; the bottom part of the inner side wall of the diagnosis and treatment outer frame is fixedly connected with an automatic telescopic rod, a telescopic rod sliding groove, a disinfection rod sliding groove, a fixing support and a bed head telescopic rod; the other end of the automatic telescopic rod is fixedly connected with a sickbed; one side of a bed head is fixedly connected with a starting box; a disinfection sliding rod is slidably connected with one side of the bottom part of the starting box; the disinfection sliding rod penetrate through the starting box and extend into the starting box; the end, extending into the starting box, of the disinfection sliding rod is fixedly connected with a high-temperature disinfection box; and a heating bin, two heaters and two high-temperature disinfection bins are arranged in the disinfection box. The emergency diagnosis and treatment device achieves the high-temperature disinfection effect on related emergency diagnosis and treatment tools, and achieves the sealing effect on the high-temperature disinfection box, and accordingly, the disinfection effect in the high-temperature disinfection box is enhanced, and a patient can breathe better in the sickbed.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

Integrated type paint spraying drive device

InactiveCN111473099AAchieve stirring and mixingRealize the conveying effectGearingSpraying apparatusGear wheelMixing effect

The invention discloses an integrated type paint spraying drive device. The integrated type paint spraying drive device comprises a bottom mounting base plate. The integrated type paint spraying drivedevice is matched with an integrated type paint spraying stirring feeding device for use, so that stirring and mixing effect on the raw materials can be realized, and conveying effect on the mixed raw materials also can be realized; moreover, conveying has certain kinetic energy, the device is the drive device, a kinetic energy utilization rate is high, and cost is relatively low; moreover, the device is provided with a length regulating mechanism while a reverse threaded structure rotates, so that length regulation can be realized, and therefore, a distance relationship between a ring-shapedconnecting plate mounting type wavy rotary resisting mechanism and a rotary part is controlled, and linkage effect is controlled; besides, the device is provided with a gear group engaged type rotarystate differential mechanism, and can realize drive effect of a rotation state, so that one machine serves multiple purposes. Besides, the device is provided with a ring-shaped connecting plate mounting type wavy rotary resisting mechanism, and can realize drive effect during rotation if structure spatial positions are different.

Owner:王俊霞

A slide valve type inverse proportional pressure reducing valve

ActiveCN107990024BRealize the leading roleRegulating pressureOperating means/releasing devices for valvesMultiple way valvesPower flowSpring force

The invention relates to a sliding valve type inverse proportion pressure reduction valve, and belongs to the field of hydraulic control. The valve comprises a proportion electromagnet, a baffle, a cylindrical plug, a valve body, a first reset spring, a valve element, a second reset spring and a piston; valve cavity equal-diameter machining is adopted, when the electromagnet does not work, work pressure output by the pressure reduction valve is maximum, along with current increase, electromagnetic thrust output by the electromagnet is increased, work pressure of the pressure reduction valve isgradually reduced, hydraulic pressure in a valve element work cavity, spring force and electromagnetic force are balanced, and hydraulic oil path pressure adjusting is achieved. The proportion pressure reduction valve is high in control precision, system work stability can be improved, the structure is simple and easy to machine, the manufacturing cost is low, and assembling complexity is reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

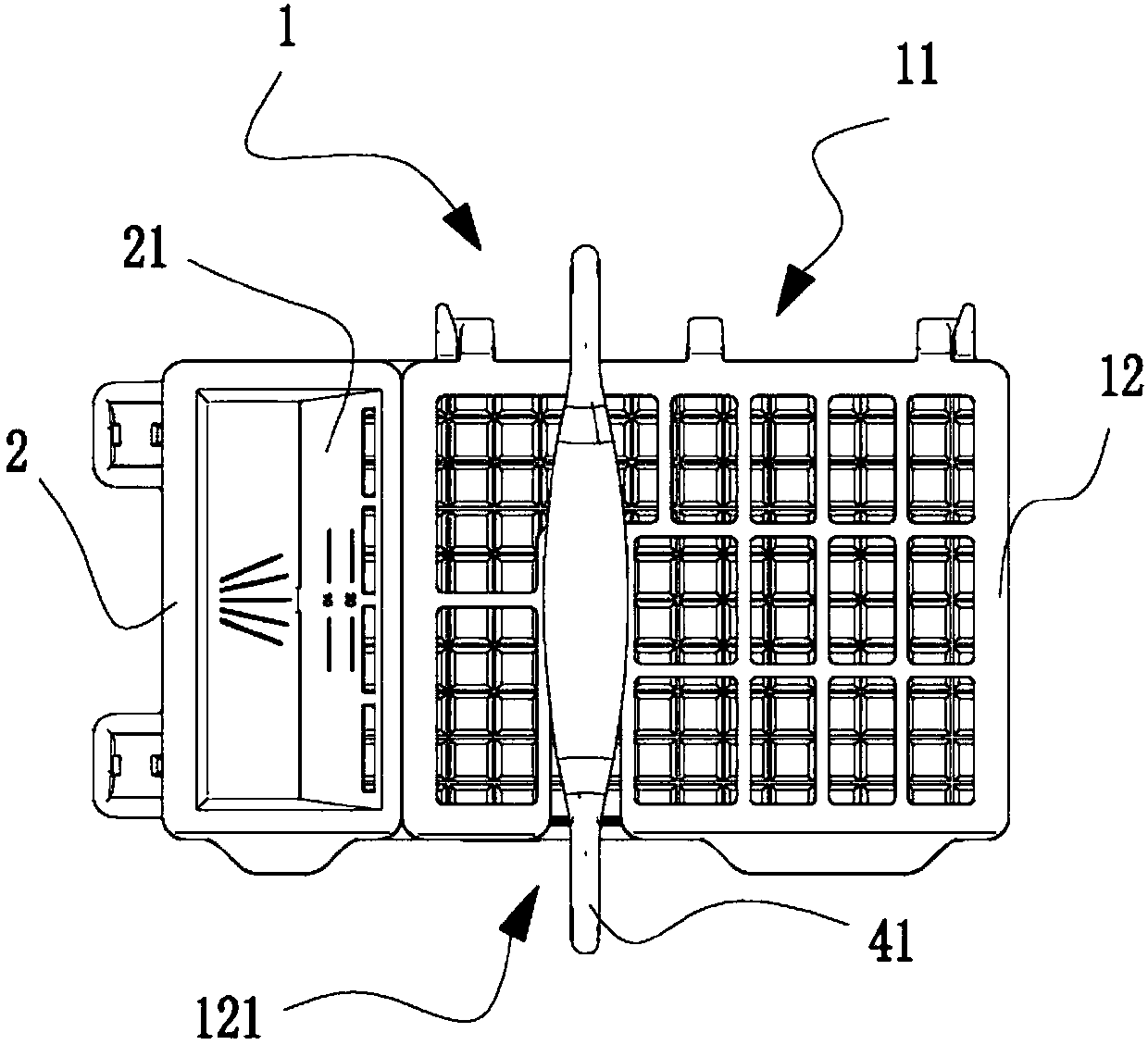

Dishwasher

PendingCN110236468AWill not affect performanceReduce the burden of coordinationTableware washing/rinsing machine detailsEngineering

Owner:QINGDAO HAIER DISHWASHER

Processing device of rotational platform hole

InactiveCN101704119BHigh positioning accuracyMeet the process requirementsTool holdersBoring/drilling machinesBiochemical engineeringMachining

Owner:SHANGHAI JIAOTONG UNIV

A tissue-engineered artificial nerve and its preparation method

InactiveCN103877623BAchieve inductionRealize the leading roleProsthesisGlycolic acidPeripheral neuron

Owner:SOUTHWEST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com