Device and method for fabricating forming fabric with rapid dehydration property

A rapid dehydration and manufacturing device technology, applied in papermaking, paper machines, textiles and papermaking, etc., can solve problems affecting production efficiency, reduced retention of fine fibers and fillers, and slow dehydration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

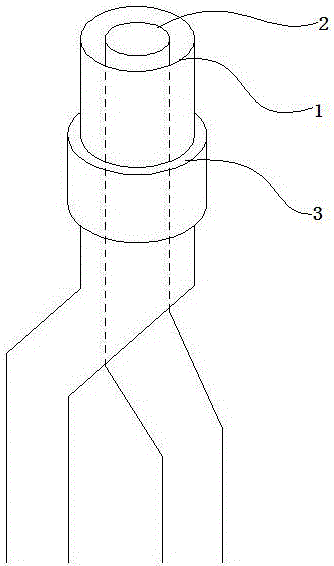

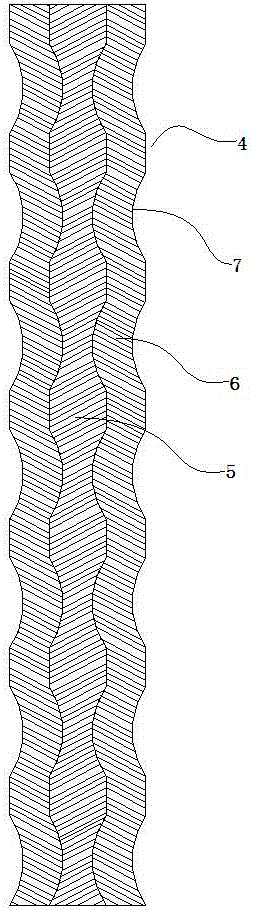

[0023] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0024] like figure 1 As shown, a manufacturing device for rapid dehydration forming mesh, including: a spinning device and a high-frequency electromagnetic heating coil, the spinning device includes a cortical tube and a concentric core tube that is inserted into the cortical tube, and the cortical tube Both the tube and the core tube are connected to their respective pressure supply devices, and a ring-shaped intermittent vibration device is sleeved close to the outer peripheral surface of the cortex tube, and the vibration frequency of the intermittent vibration device is adjustable.

[0025] The free ends of the cortical tube and the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com