A tissue-engineered artificial nerve and its preparation method

A tissue engineering and nerve technology, applied in the field of biomedical engineering, can solve the problems of difficult production and complex microfabrication technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

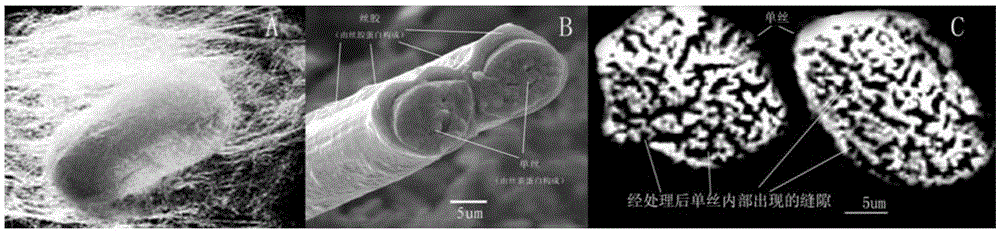

[0043] The preparation of embodiment 1 silk monofilament

[0044] Silk monofilament is the main material used in this study. The quality of the prepared monofilament is directly related to the quality of the artificial nerve. Because the silk is relatively slender, it is more difficult in the experimental operation. In order to facilitate the experimental operation, in this embodiment, first n (100-500) silks are bundled into tows, cut into a certain length, and the ephrinB2 / After the monofilament slow-release carrier is successfully prepared, it is further cut. Follow the steps below:

[0045] 1) Degumming

[0046]First, 100-500 silks are bundled into tows with surgical sutures, and cut into 10-15cm lengths. Place in a beaker, add sodium carbonate aqueous solution (concentration of sodium carbonate aqueous solution is shown in Table 1), place in an autoclave for degumming (degumming treatment pressure, temperature and degumming treatment time parameters are shown in Tabl...

Embodiment 2

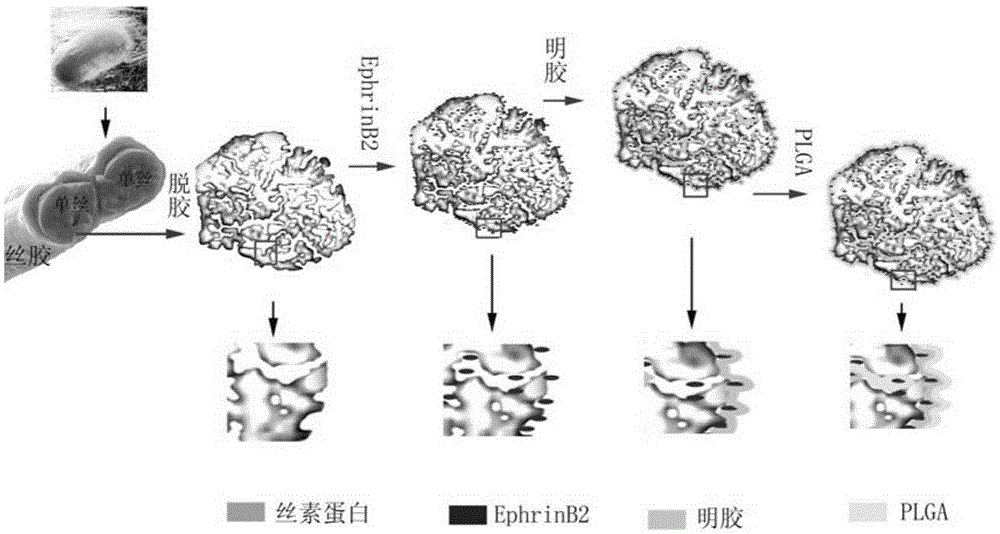

[0053] The preparation of embodiment 2 ephrinB2 monofilament sustained-release carrier

[0054] The ephrinB2 silk monofilament slow-release carrier was prepared from the obtained degummed silk monofilament prepared under the experimental conditions of No. 2 group in Example 1. The specific operation is carried out according to the following steps:

[0055] 1) Soak the degummed silk monofilament tow in ephrinB2 aqueous solution, and freeze-dry;

[0056] 2) soaking the tow after freeze-drying in step 1) in an aqueous gelatin solution, and freeze-drying;

[0057] 3) Soak the tow after freeze-drying in step 2) in PLGA-chloroform solution, and dry it under low pressure. The experimental parameters of steps 1), 2), and 3) are shown in Table 2. The production process of EphrinB2 monofilament (filament) sustained-release carrier is as follows: image 3 shown.

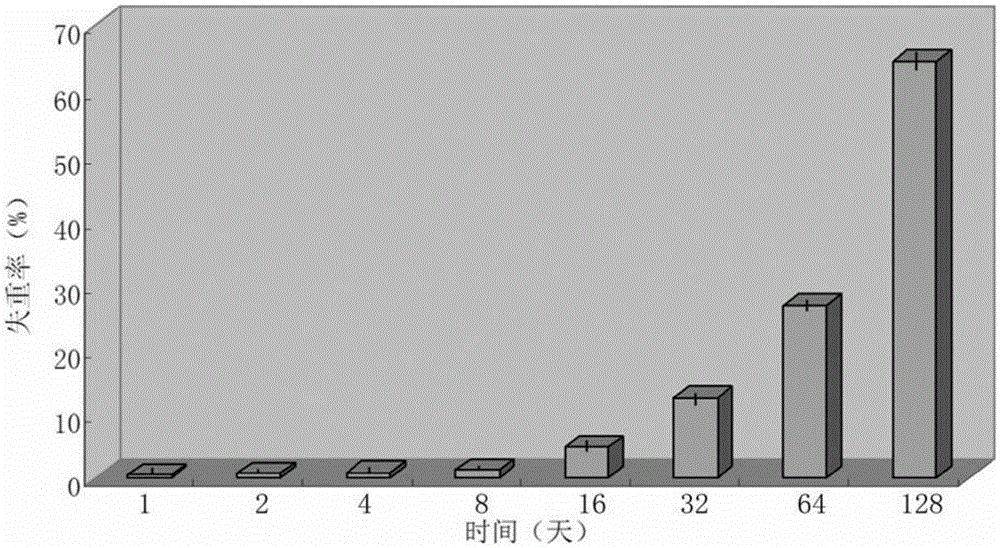

[0058] A certain weight of ephrinB2 monofilament slow-release carrier was taken, crushed, placed in triple distilled wat...

Embodiment 3

[0063] The assembly of embodiment 3 artificial nerves

[0064] The ephrinB2 silk monofilament slow-release carrier obtained in Example 2 was assembled according to the following two schemes respectively:

[0065] Scheme 1 (artificial nerve composed of a single channel): n ten thousand ephrinB2 silk monofilament slow-release carriers 2 are directly placed in the PLGA hollow catheter 1 as the artificial nerve (such as Figure 5 shown in A);

[0066] Scheme 2 (artificial nerve composed of wide-channel units): first insert n pieces of ephrinB2 silk monofilament slow-release carriers 2 into the PLGA hollow microcatheter 3 to form a wide-channel unit, and the wide-channel unit is then used as the structural unit of the artificial nerve. These wide-channel units are then assembled into PLGA hollow conduits 1 as artificial nerves (such as Figure 5 shown in B).

[0067] During the process of arranging the filamentous carriers in the PLGA hollow conduit or in the PLGA hollow microcond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com