Device for reducing conductor vibration and improving insulation concentricity

A concentricity, conductor technology, applied in the direction of conductor/cable insulation, cable/conductor manufacturing, electrical components, etc., can solve problems affecting factory efficiency, large changes in wire insulation concentricity, and reduced quality of extruded wire products. The effect of avoiding changes in concentricity, improving concentricity, and enhancing adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

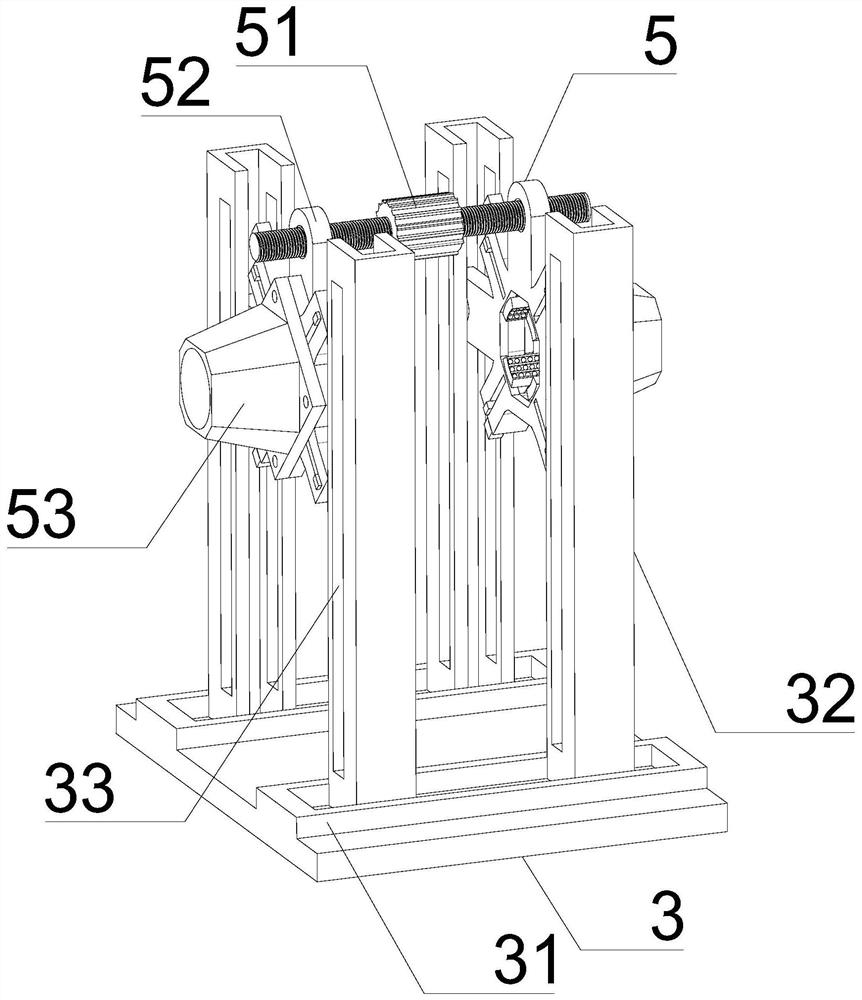

[0029] As an embodiment of the present invention, the top end of the fixed block 5 is fixedly connected with an internal thread seat 52 , and the front end of the fixed block 5 is fixedly connected with a protective sleeve 53 .

[0030] When working, the protective sleeve 53 can guide and protect the wire 1 passing through the limit assembly to a certain extent, and wherein, the internal thread seats 52 provided on the upper ends of the two sets of limit assemblies are provided with the same thread.

[0031]As an embodiment of the present invention, the connecting rod 55 is provided with a movable groove 551, and the limiting block 56 is slidably connected in the movable groove 551; the other end of the spring 58 is fixedly connected to the movable groove 551 On the side wall of one end away from the limit block 56 .

[0032] During work, when the connecting rod 55 is pressed by the wire rod 1 passing through the fixed block 5, it will move outwards. At this time, the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com