A synchronous feeding manipulator for machine tools

A technology of manipulator and machine tool, applied in the field of synchronous refueling manipulator for machine tools, can solve the problems of prolonging single-piece processing cycle, increasing refueling time, reducing processing efficiency, etc., to speed up processing cycle, increase refueling time, and reduce refueling effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

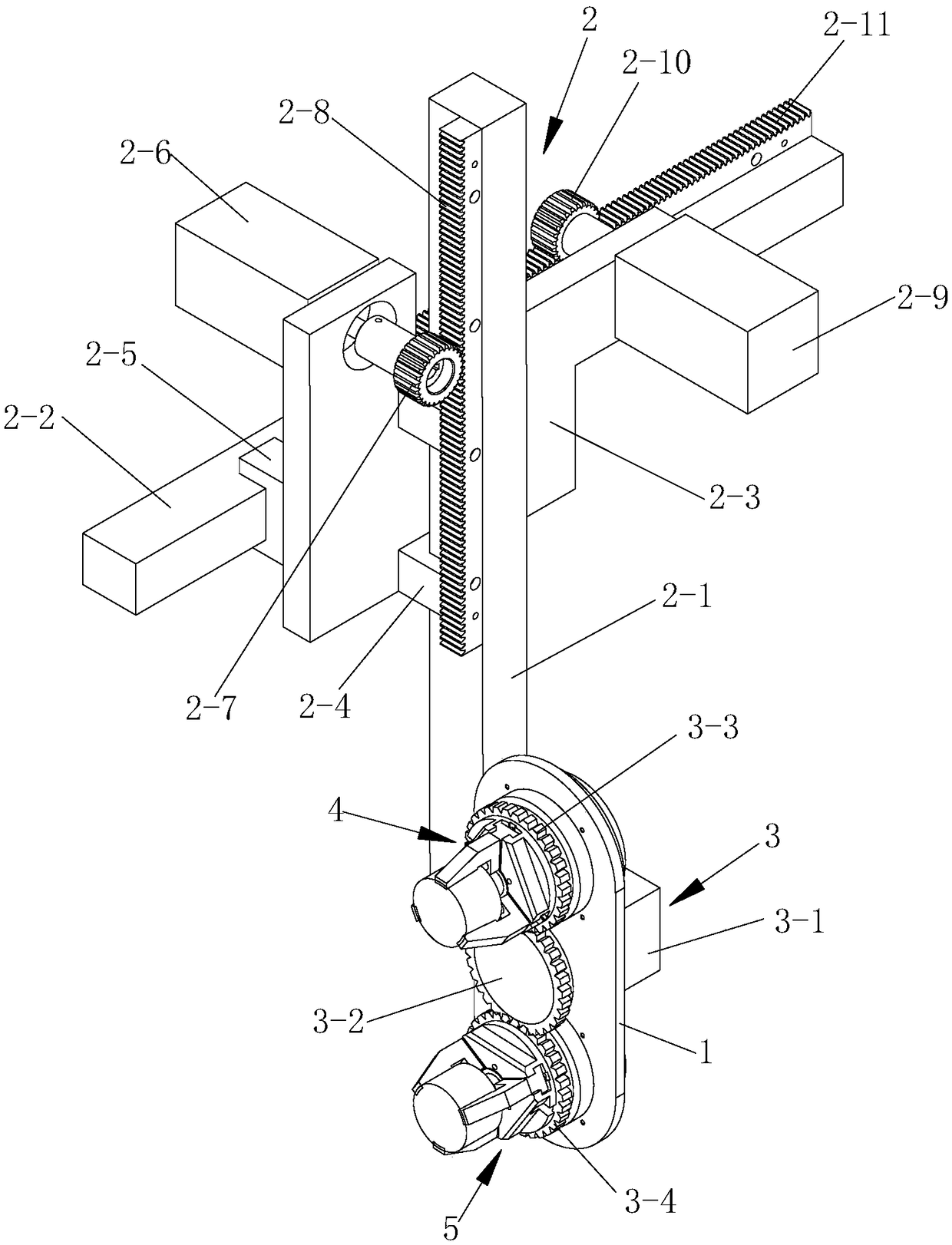

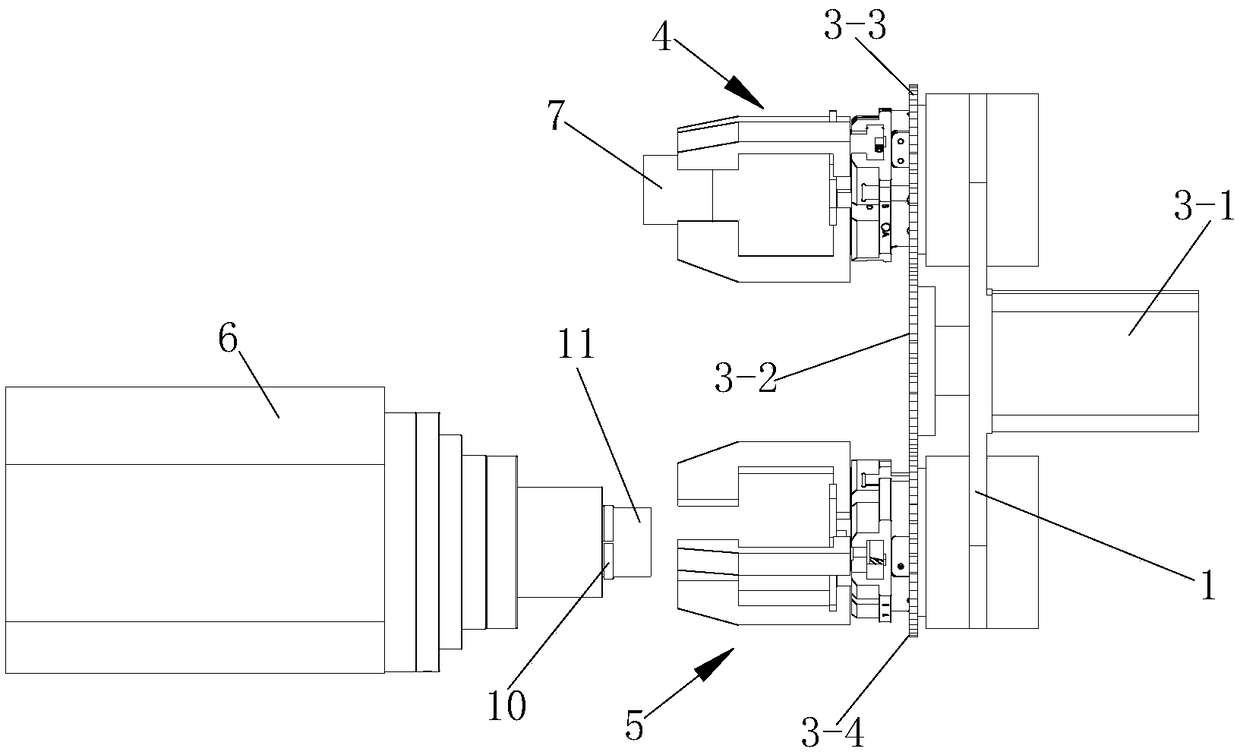

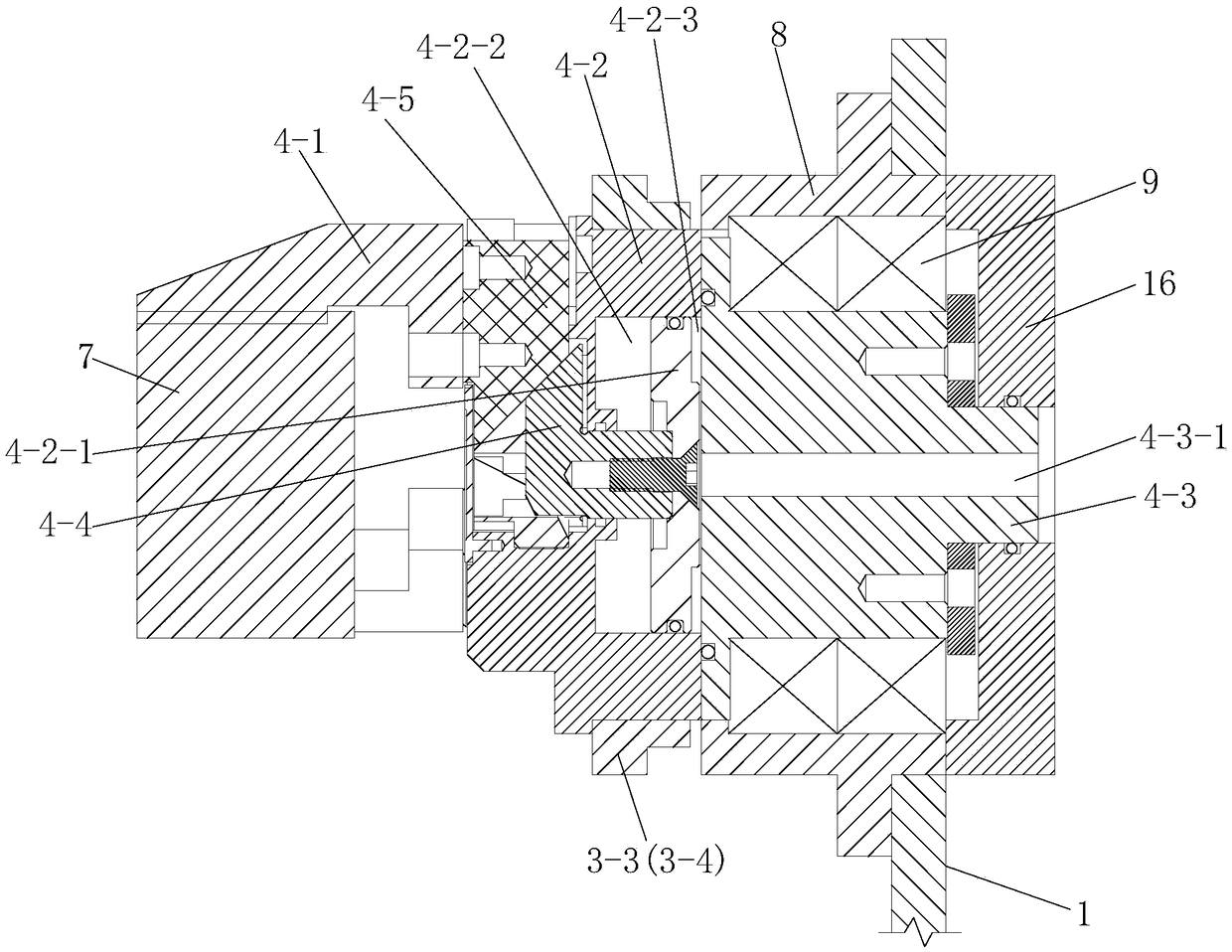

[0064] Such as figure 1 , figure 2 and image 3 A synchronous refueling manipulator for a machine tool is shown, including a jaw fixing plate 1, and a moving mechanism 2 for driving the jaw fixing plate 1 to move up and down and left and right; the jaw fixing plate 1 is provided with a useful It is used to install the blank 7 on the machine tool chuck 10, the blank 7 is used to unload the workpiece 11 processed from the blank 7 from the machine tool chuck 10, and it is used to drive the upper jaw 5. The power device 3 for synchronously rotating the material claw 4 and the blanking claw 5 with the machine tool spindle 6; the loading claw 4 and the blanking claw 5 both include a plurality of claw fingers 4-1 and are used to drive a plurality of the claws The drive means for the fingers 4-1 to move away from each other or to approach each other simultaneously.

[0065] In this embodiment, when the synchronous refueling manipulator for the machine tool is in use, that is, afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com