Device for transporting bundles for a strapping machine

A technology of strapping machines and conveying equipment, applied in the direction of mechanical conveyors, conveyors, transportation and packaging, etc., can solve the problems of difficult adjustment of assembly areas, poor performance of conveyor belts, difficult synchronization of conveyor belts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

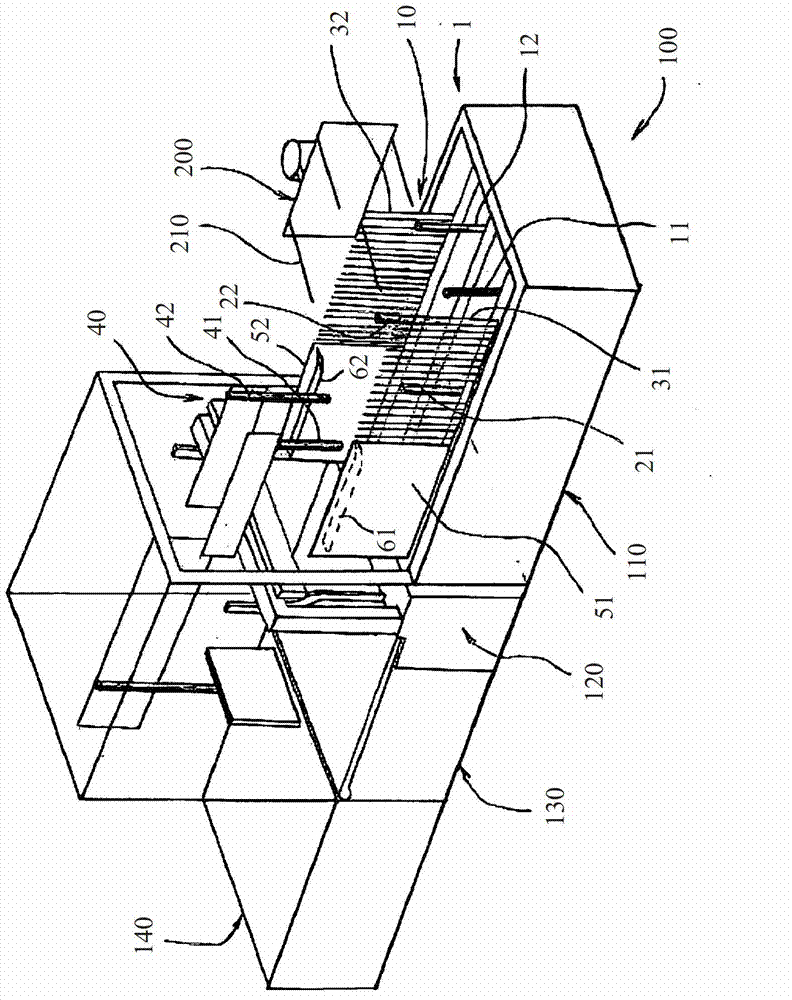

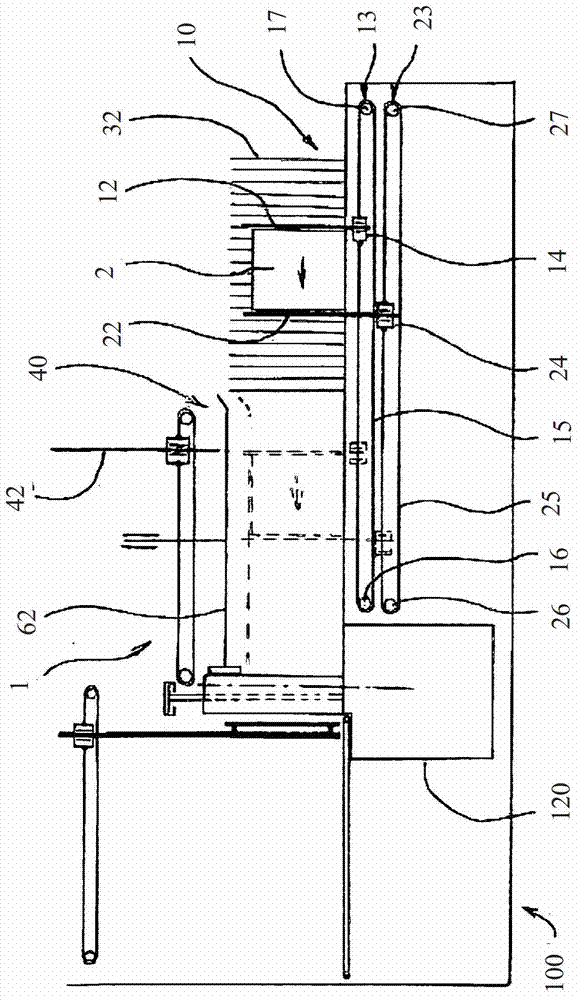

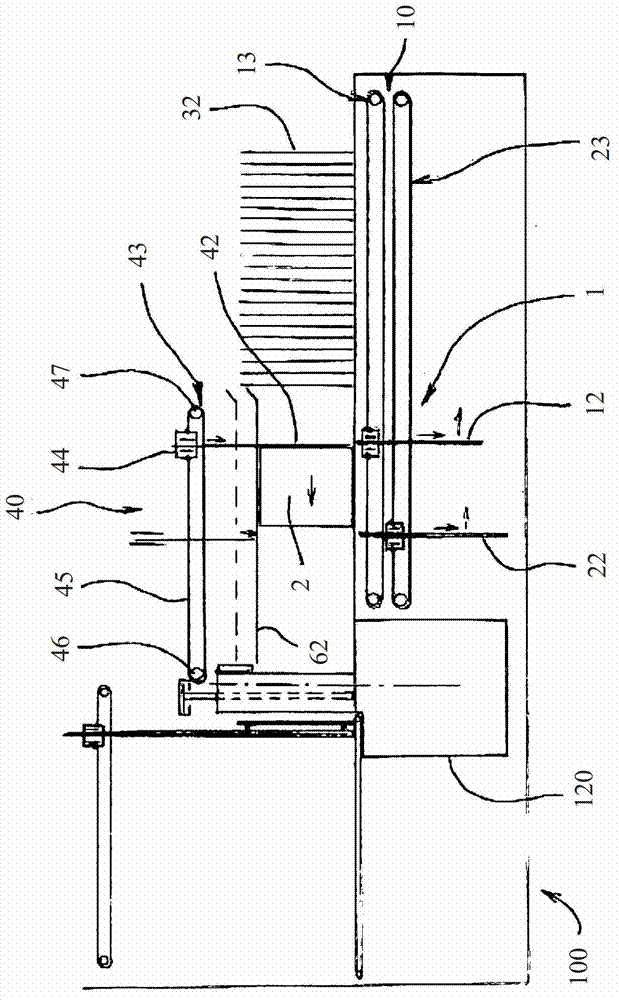

[0024] Figure 1 to Figure 6 A strapping machine 100 is described which is designed to be incorporated within a packaging machine as a module designed to transform a continuous flow of folding boxes coming out of a folder-gluer into a continuous flow of folding boxes ready for processing and / or storage. Bundled bundles.

[0025] As its name suggests, the strapping machine 100 is more particularly intended for strapping a stack of folding boxes, forming bundles 2, 3 formed all upstream of said machine 100, in this example on an equipment table 110 . To fulfill its function, the strapping machine 100 has a strapping unit 120 capable of joining together the planar objects of each bundle 2 , 3 , said strapping unit 120 being permanently arranged at the outlet of the assembly station 110 housing 130. Once bundled, the bundles 2 , 3 are placed at a transfer table 140 located directly downstream of the housing 130 .

[0026] As can be seen in all figures, the bundles 2 , 3 of fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com