Numerical control horizontal lathe equipment

A horizontal lathe and equipment technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of speeding up loosening, increasing the friction between the nut and the screw, increasing the weight of the nut, etc. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

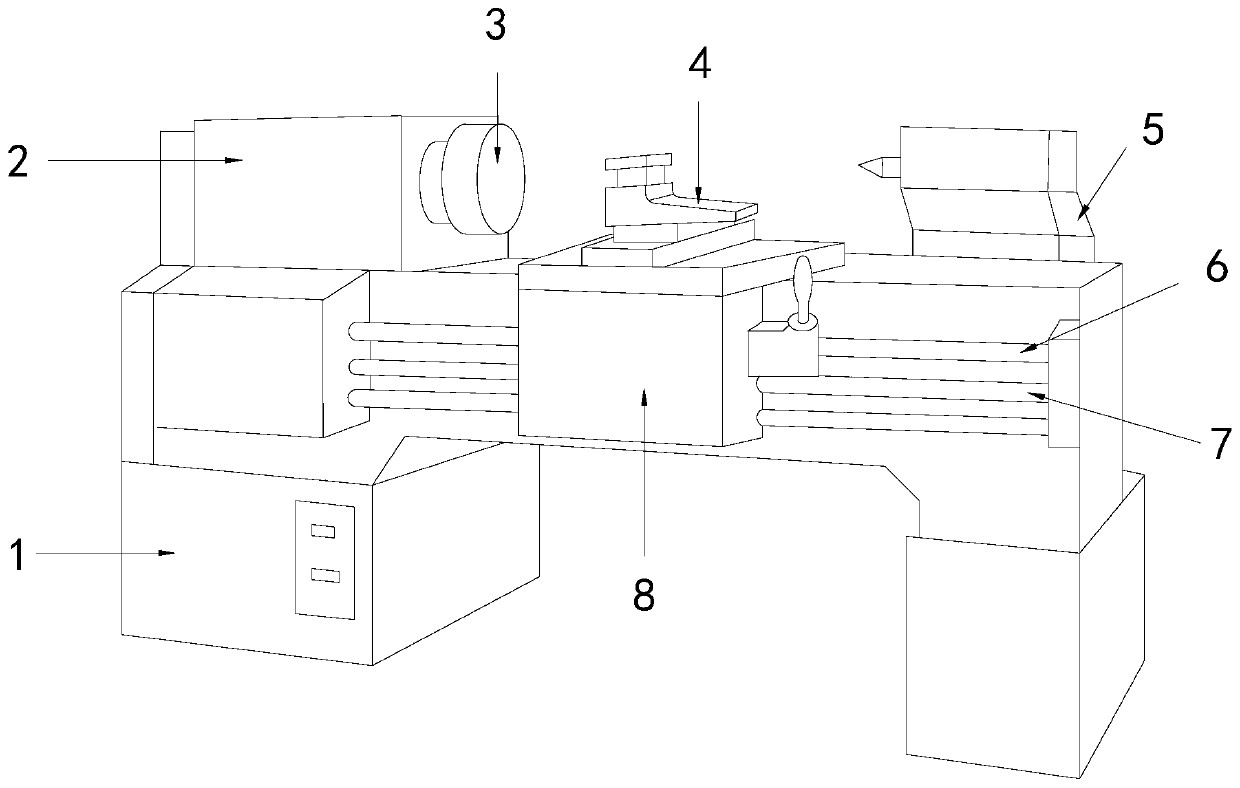

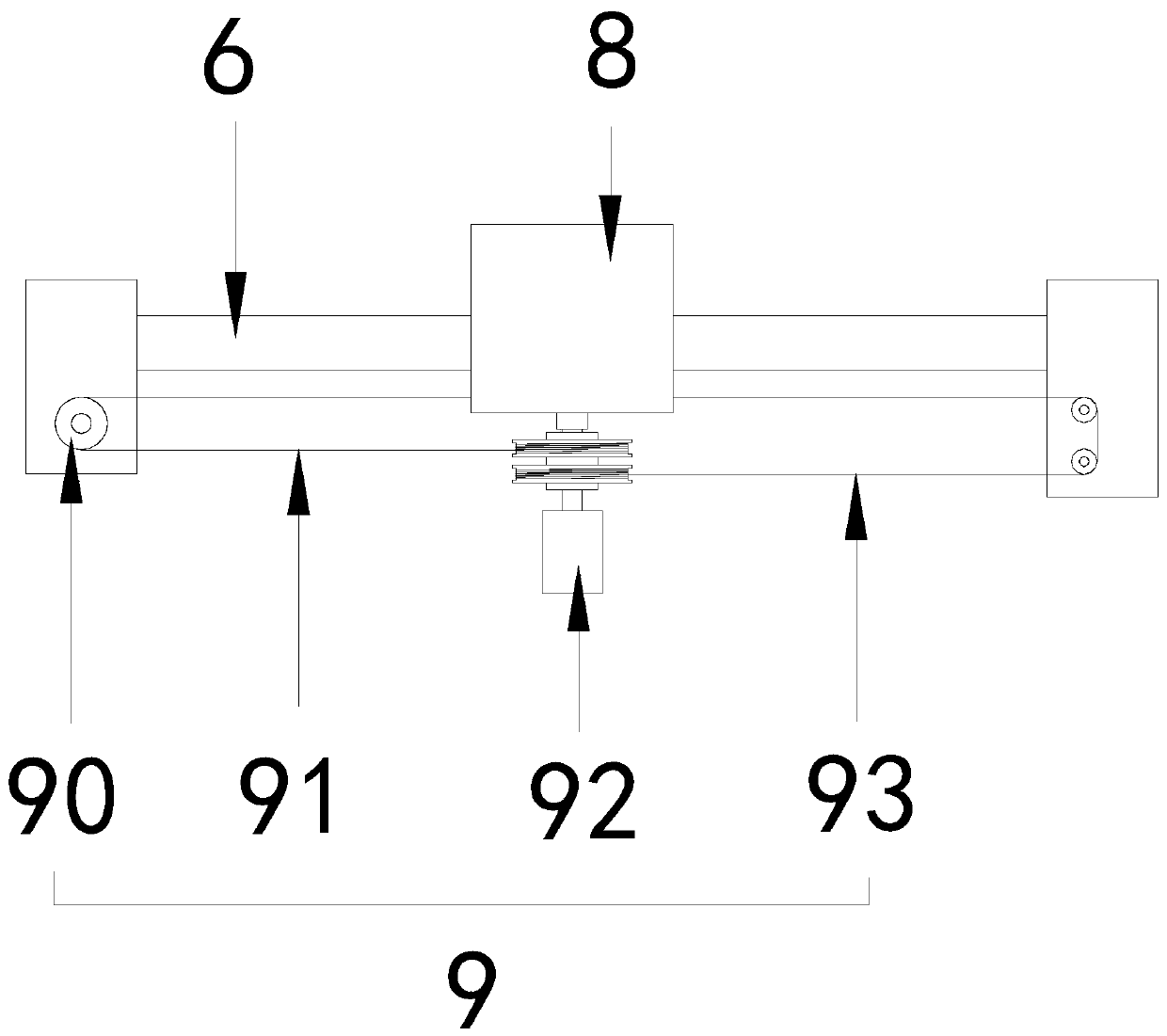

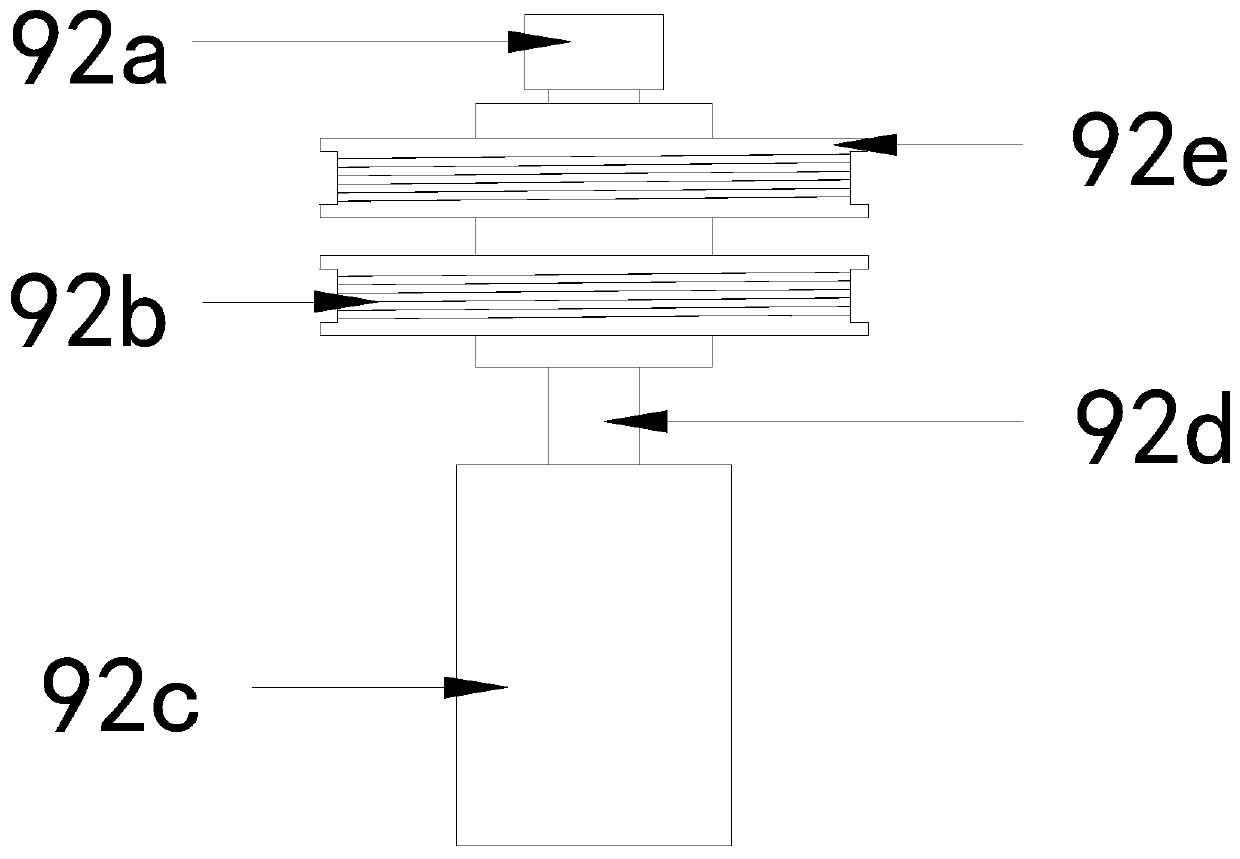

[0027] see Figure 1-3 , the present invention provides a technical solution for CNC horizontal lathe equipment: its structure includes a bed 1, a power box 2, a spindle 3, a tool rest 4, a tailstock 5, a lead screw 6, a feed rod 7, and a tool rest feed system 8 , booster device 9, lead screw 6, feed rod 7 are installed on described bed 1, described tool rest feed system 8 is connected with lead screw 6, feed rod 7 movably, described tool rest feed system 8 tops are arranged There is a tool rest 4, the main shaft 3 is located on the left side of the tool rest 4 and is connected with the power box 2, the power box 2 is fixed on the bed 1, and the right side of the bed 1 is provided with a tailstock 5, so The booster device 9 is connected with the tool post feeding system 8 and is arranged inside the bed 1. The booster device 9 includes a pulley 90, a first stay cord 91, a winding structure 92, and a second stay cord 93. The two sides of the roll structure 92 are respectively c...

Embodiment 2

[0030] see Figure 1-4, the present invention provides a technical solution for CNC horizontal lathe equipment: its structure includes a bed 1, a power box 2, a spindle 3, a tool rest 4, a tailstock 5, a lead screw 6, a feed rod 7, and a tool rest feed system 8 , booster device 9, lead screw 6, feed rod 7 are installed on described bed 1, described tool rest feed system 8 is connected with lead screw 6, feed rod 7 movably, described tool rest feed system 8 tops are arranged There is a tool rest 4, the main shaft 3 is located on the left side of the tool rest 4 and is connected with the power box 2, the power box 2 is fixed on the bed 1, and the right side of the bed 1 is provided with a tailstock 5, so The booster device 9 is connected with the tool post feeding system 8 and is arranged inside the bed 1. The booster device 9 includes a pulley 90, a first stay cord 91, a winding structure 92, and a second stay cord 93. The two sides of the roll structure 92 are respectively co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com