Nail-embedded snow tire

A snow tire, tire technology, applied in tire parts, tire tread/tread pattern, transportation and packaging, etc., can solve problems such as lack of maneuverability, poor pattern design, cleat shedding, etc., to strengthen snow pressure and snow removal ability, enhance the sidewall anti-skid ability, increase the effect of anti-skid ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

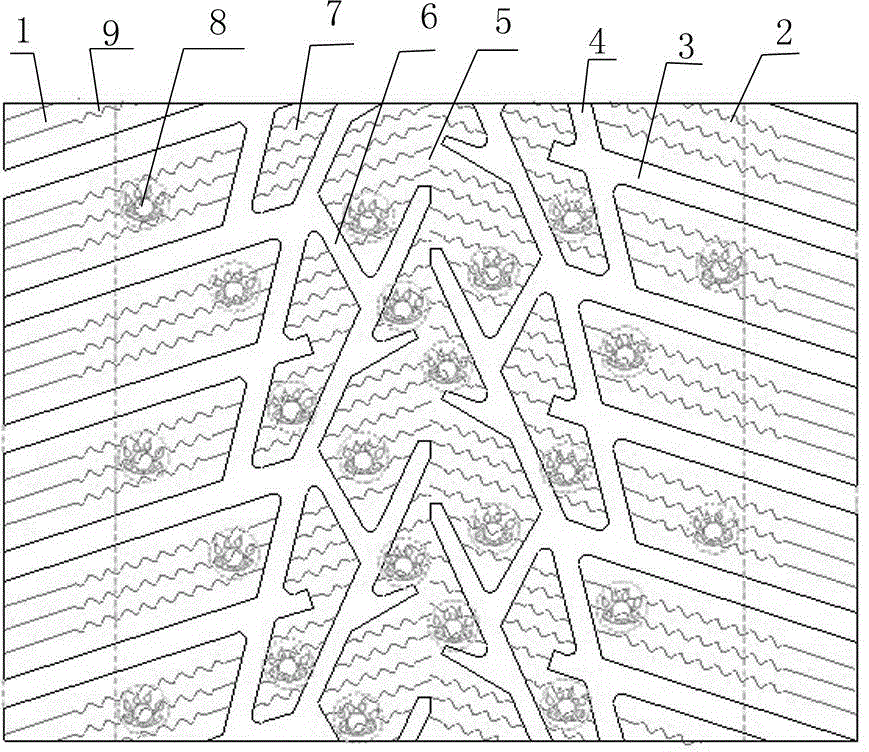

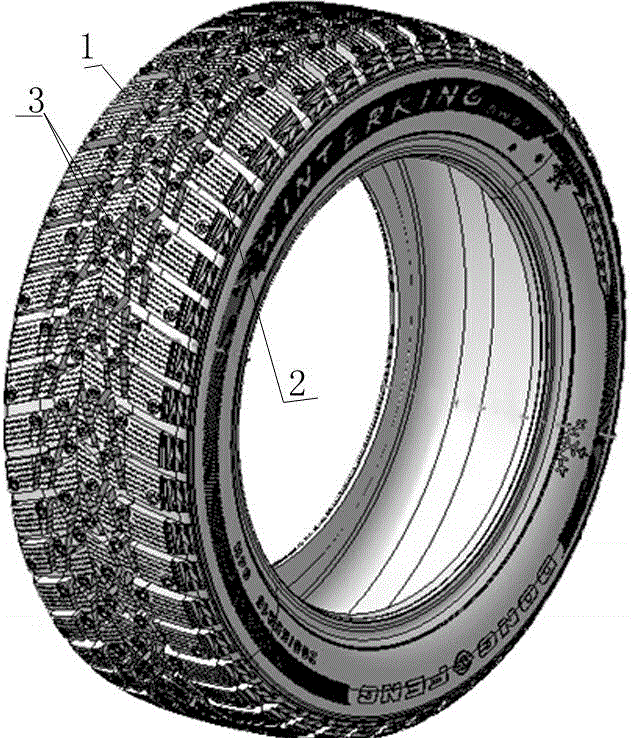

[0023] The present invention as figure 1 , 2 shown.

[0024] Studded snow tires, including the tire body, sidewalls, and tread, the tread is evenly divided into single-guide grooves with multiple "Λ"-shaped main grooves 3 and "Λ"-shaped auxiliary grooves 4 in the same direction. tread, wherein the tread adjacent to the sidewall is tread one 1, 2; the middle tread is tread two 5; "Λ"-shaped main groove and auxiliary groove 3, 4 are on both sides of tread two 5 respectively through.

[0025] The width of the "Λ"-shaped main groove 3 is greater than the width of the "Λ"-shaped auxiliary groove 4.

[0026] Tread two 5 is divided into tread three 7 by the reverse groove 6 of " Λ " font auxiliary groove from the middle thereof.

[0027] Tread one 1, 2, tread 5 and tread three 7 are provided with anti-skid studs 8, and are linearly arranged respectively.

[0028] On tread one 1, 2, tread 5, tread three 7, be provided with evenly distributed horizontal wavy pattern 9.

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com