Industrial vehicle with power steering apparatus and steering wheel angle correction device

A technology of industrial vehicles and steering equipment, applied in the direction of motor vehicles, automatic steering control components, lifting devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

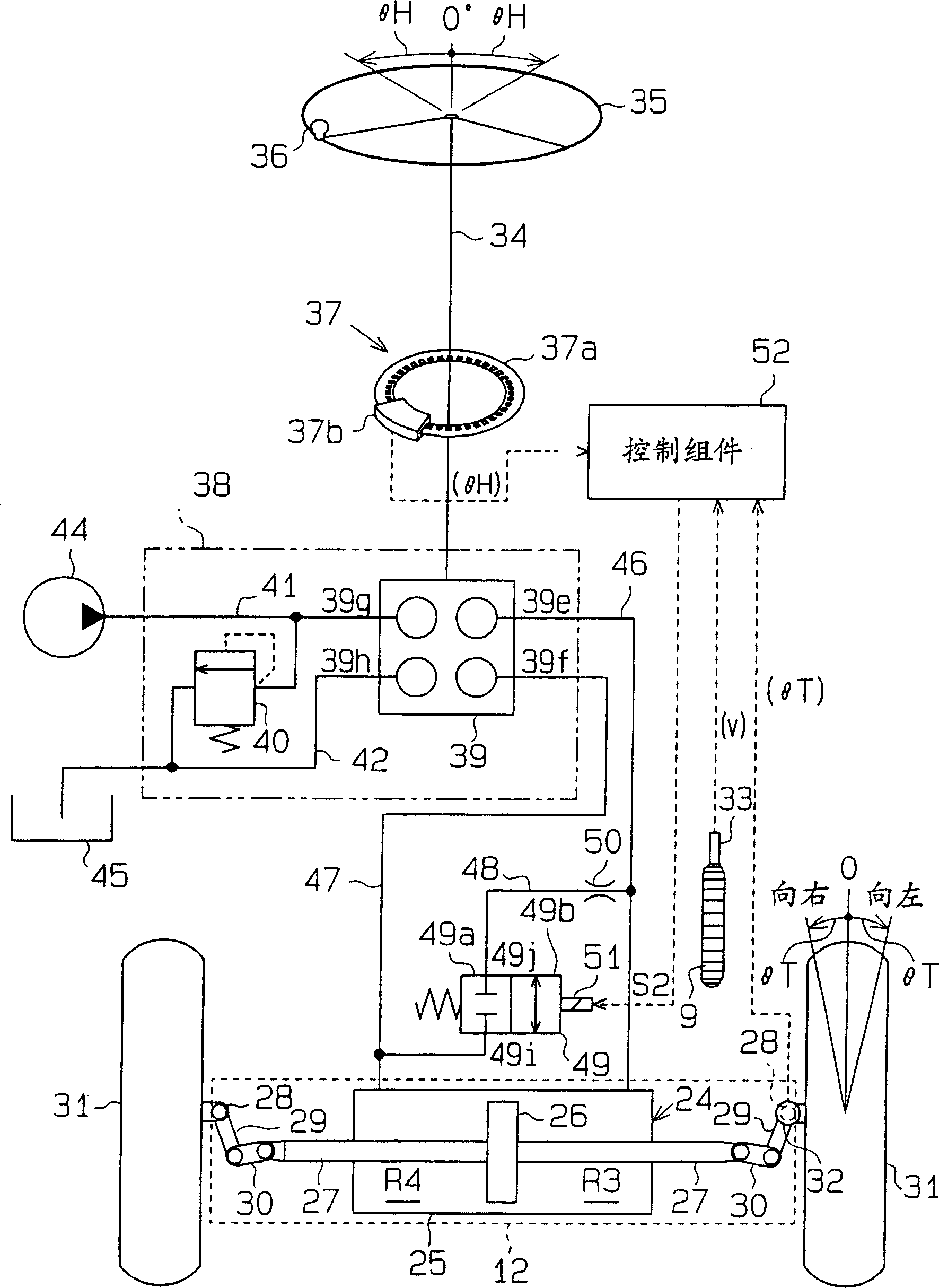

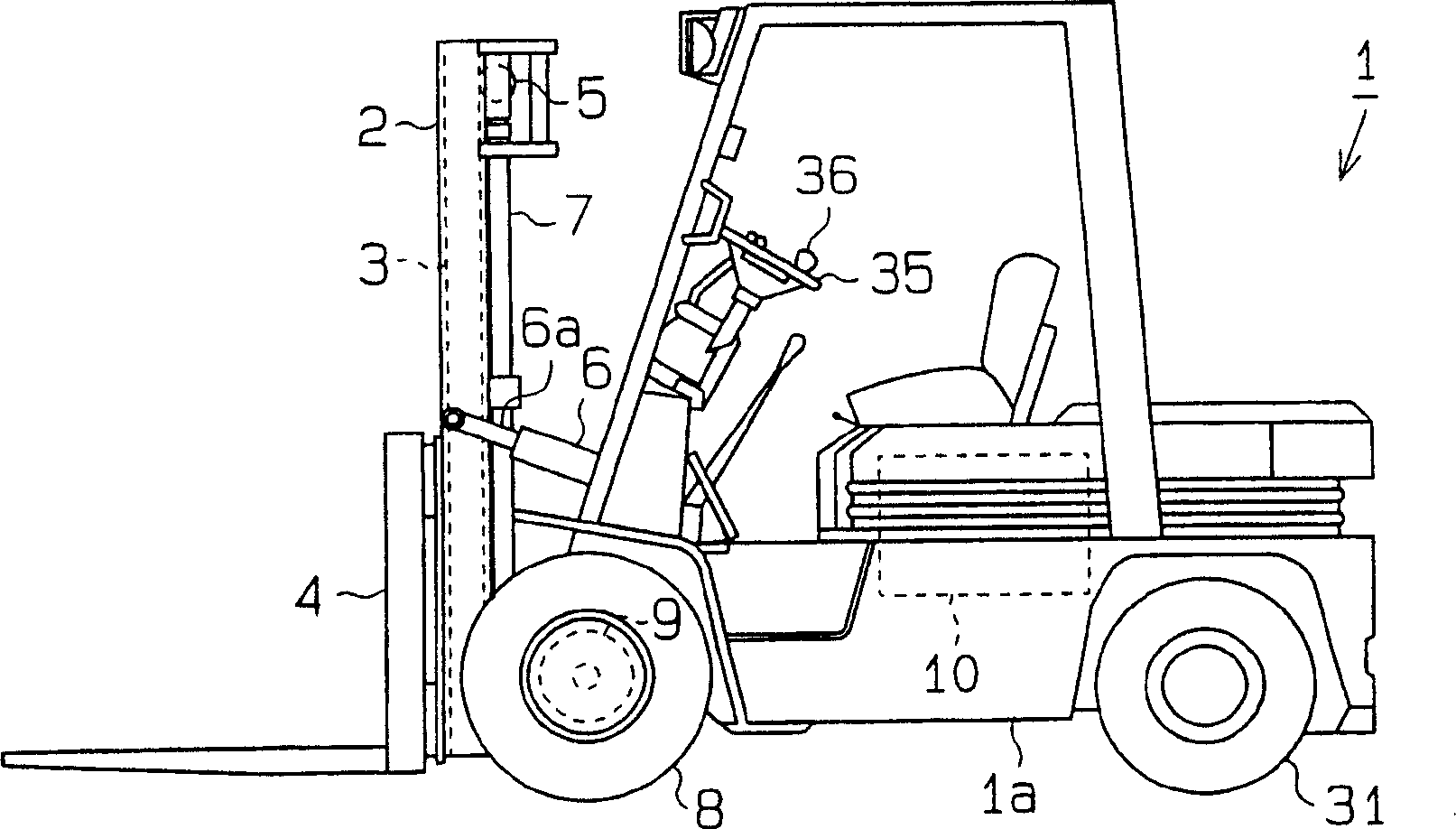

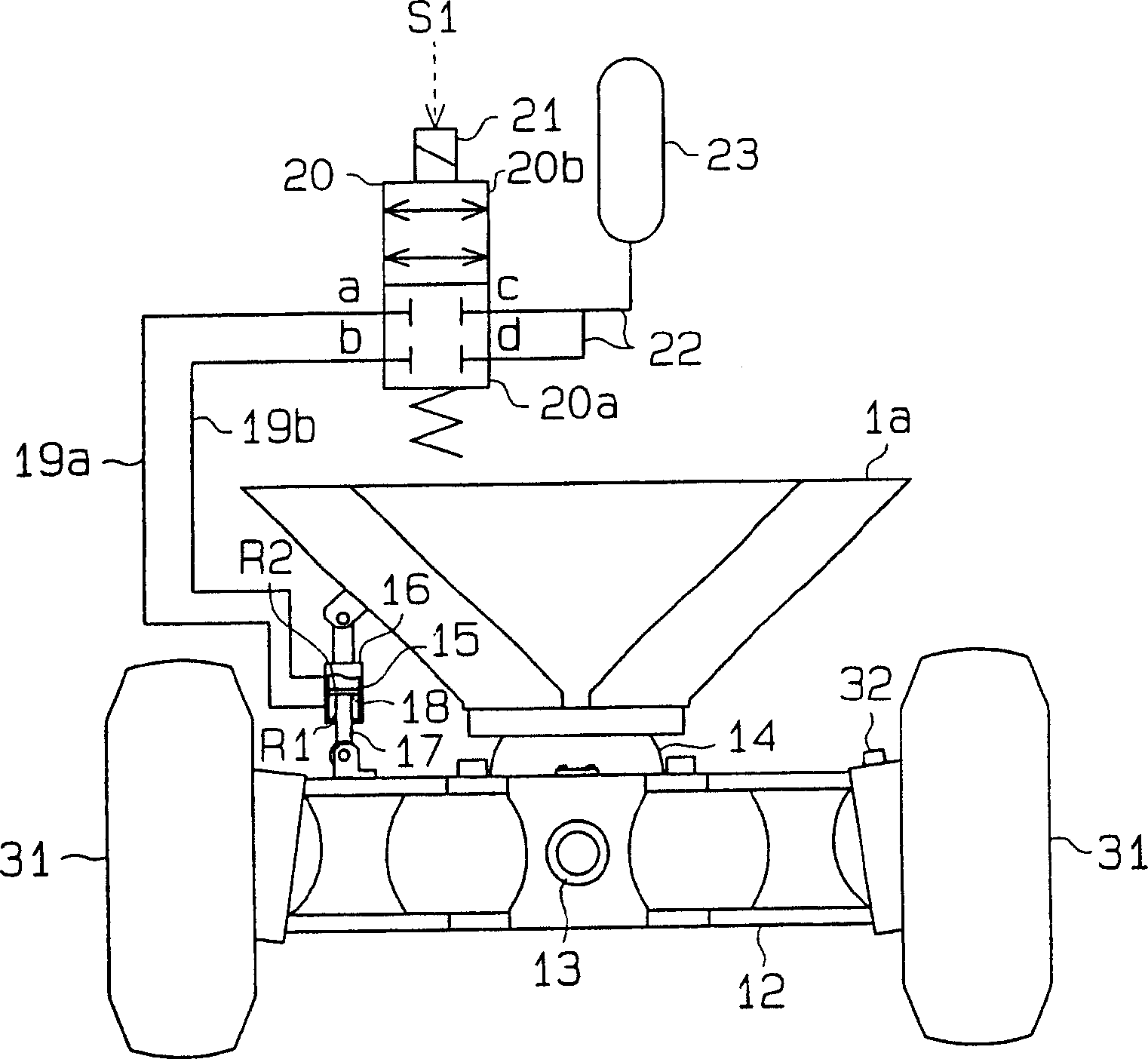

[0048] Combining the embodiment of a hydraulic steering device of the present invention Figure 1 to Figure 10 The introduction is as follows. This power steering equipment is used in forklifts or other industrial vehicles.

[0049] displayed on figure 2Forklift 1 in has driven front wheels and controlled steering rear wheels. The forklift 1 also has a body frame 1a. A pair of outer masts 2 are supported on the front of the vehicle body frame 1a in a tiltable manner. A pair of inner jibs 3 is arranged between the outer jibs 2 and a fork 4 is mounted on each inner jib 3 . The fork 4 is lifted and lowered in one piece along the outer mast 2 together with the cooperating inner mast 3 . A sprocket 5 is placed on top of each inner mast 3 . The top of each external jib is connected to the corresponding fork 4 via a chain (not shown), and the chain is connected to the corresponding sprocket 5 in turn. A pair of tilting cylinders 6 are arranged in front of the vehicle body fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com