All-steel radial truck tyre carcass size composition and mixing method thereof

A radial tire and carcass rubber technology, which is applied in the field of all-steel radial tire carcass rubber composition and its mixing, can solve the problem of low rubber hardness and tensile strength, high price of anti-aging agent 4020, and the impact on tires. Use performance and other issues to achieve the effect of improving rubber performance, improving processing safety and elasticity, and good adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The active agent is nano-zinc oxide, and the particle size of the nano-zinc oxide is 20-80nm.

[0027] The anti-aging agent TMQ is 2,2,4-trimethyl-1,2-dihydroquinoline polymer.

[0028] The mixing method of the above-mentioned carcass compound composition comprises the following steps:

[0029] 1. One-stage mixing: control the temperature of the internal mixing chamber of the internal mixer to 35°C, and the rotor speed to 80r.min -1 , then add 100 parts of natural rubber, 1 minute later, add 8 parts of nano zinc oxide, 1 part of anti-aging agent 4020, 0.9 parts of anti-aging agent TMQ, 20 parts of adhesive GLR, after 1.5 minutes, add 56 parts of carbon black N326, 3 Deglue after minutes;

[0030] 2. Two-stage mixing: Add the above-mentioned degumming, 70204.5 parts of insoluble sulfur, 1.25 parts of accelerator DZ, 0.2 parts of anti-scorch agent CTP, 5 parts of adhesive RA65 in the open mixer, thin pass 5 times, and the next film .

[0031] Example 2, an all-steel r...

Embodiment 2

[0032] The active agent is nano-zinc oxide, and the particle size of the nano-zinc oxide is 20-80nm.

[0033] The mixing method of the above-mentioned carcass compound composition comprises the following steps:

[0034] 1. One-stage mixing: control the temperature of the internal mixing chamber of the internal mixer to 35°C, and the rotor speed to 80r.min -1 , then add 100 parts of natural rubber, 1 minute later, add 8 parts of nano-zinc oxide, 1 part of anti-aging agent 4020, 1.05 parts of anti-aging agent TMQ, 3 parts of adhesive GLR20, after 1.5 minutes, add 56 parts of carbon black N326, 3 Deglue after minutes;

[0035] 2. Two-stage mixing: Add the above-mentioned degumming, 4.5 parts of insoluble sulfur 7020, 1.25 parts of accelerator DZ, 0.2 parts of anti-scorch agent CTP, 5 parts of adhesive RA65 into the open mill in sequence, thin pass 5 times, and lower piece.

[0036] The anti-aging agent TMQ is 2,2,4-trimethyl-1,2-dihydroquinoline polymer.

[0037] Example 3, a...

Embodiment 3

[0038] The mixing method of the above-mentioned carcass compound composition comprises the following steps:

[0039] 1. One-stage mixing: control the temperature of the internal mixing chamber of the internal mixer to 35°C, and the rotor speed to 80r.min -1 , then add 100 parts of natural rubber, 1 minute later, add 8 parts of nano zinc oxide, 1 part of anti-aging agent 4020, 1.5 parts of anti-aging agent TMQ, 3 parts of adhesive GLR20, after 1.5 minutes, add 56 parts of carbon black N326, 3 Deglue after minutes;

[0040] 2. Two-stage mixing: Add the above-mentioned degumming, 4.5 parts of insoluble sulfur 7020, 1.25 parts of accelerator DZ, 0.2 parts of anti-scorch agent CTP, 5 parts of adhesive RA65 into the open mill in sequence, thin pass 5 times, and lower piece.

[0041] The active agent is nano-zinc oxide, and the particle size of the nano-zinc oxide is 20-80nm.

[0042] The anti-aging agent TMQ is 2,2,4-trimethyl-1,2-dihydroquinoline polymer.

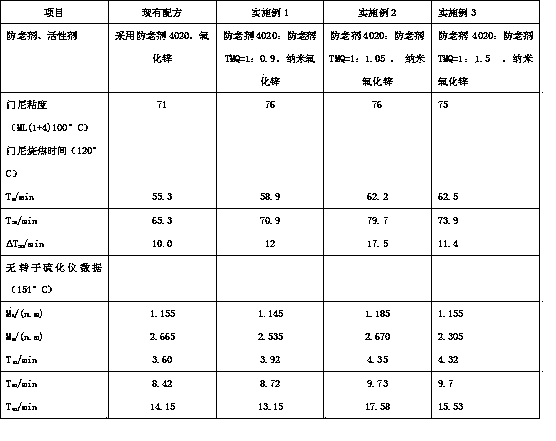

[0043] The performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com