Avalanche photodiode with three-mesa structure and manufacturing method thereof

A technology of avalanche optoelectronics and mesa structure, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as edge breakdown, lower reliability, and affect the normal operation of devices, so as to reduce parasitic capacitance, improve reliability, and suppress The effect of the fringe electric field breakdown phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

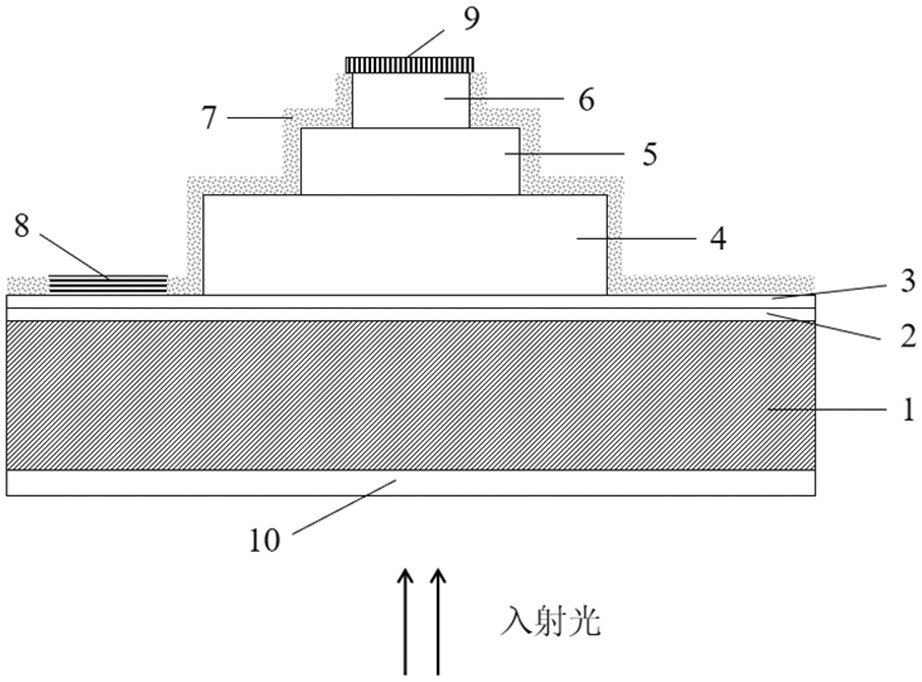

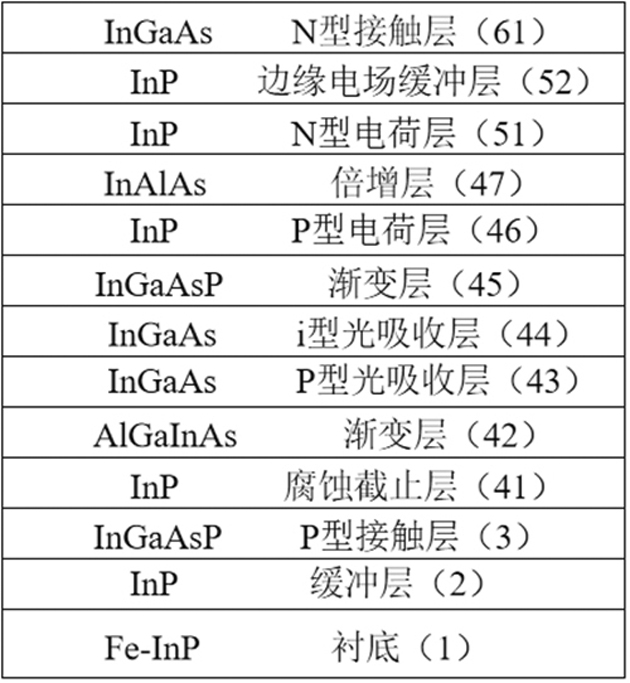

[0038] Such as figure 1 As shown, the present invention provides an avalanche photodiode with a three-mesa structure, comprising a Fe-InP substrate 1, an InP buffer layer 2, a P-type InGaAsP contact layer 3, a third mesa 4, a second Mesa 5 and first mesa 6. A P electrode 8 and an N electrode 9 are arranged above the P-type InGaAsP contact layer and the N-type InGaAs contact layer respectively. SiO is provided on the top and sidewalls of the three-mesa structure 2 Passivation layer 7. An anti-reflection film 10 is provided on the back of the Fe-InP substrate. When the avalanche photodiode is working, light is incident from the back of the substrate.

[0039] Since there is a large band step between the light-absorbing layer InGaAs and InP, the discontinuity of the energy band will generate a potential barrier, hinder the movement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com