Wide-temperature-range high-speed fluid dynamic oil seal

A high-speed fluid and power oil technology, applied in the field of rubber parts production, can solve the problems that cannot meet the actual use conditions of high temperature, high speed and high wear resistance, etc., achieve good product advantages and cost performance, simplify the production process, and seal the effect good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

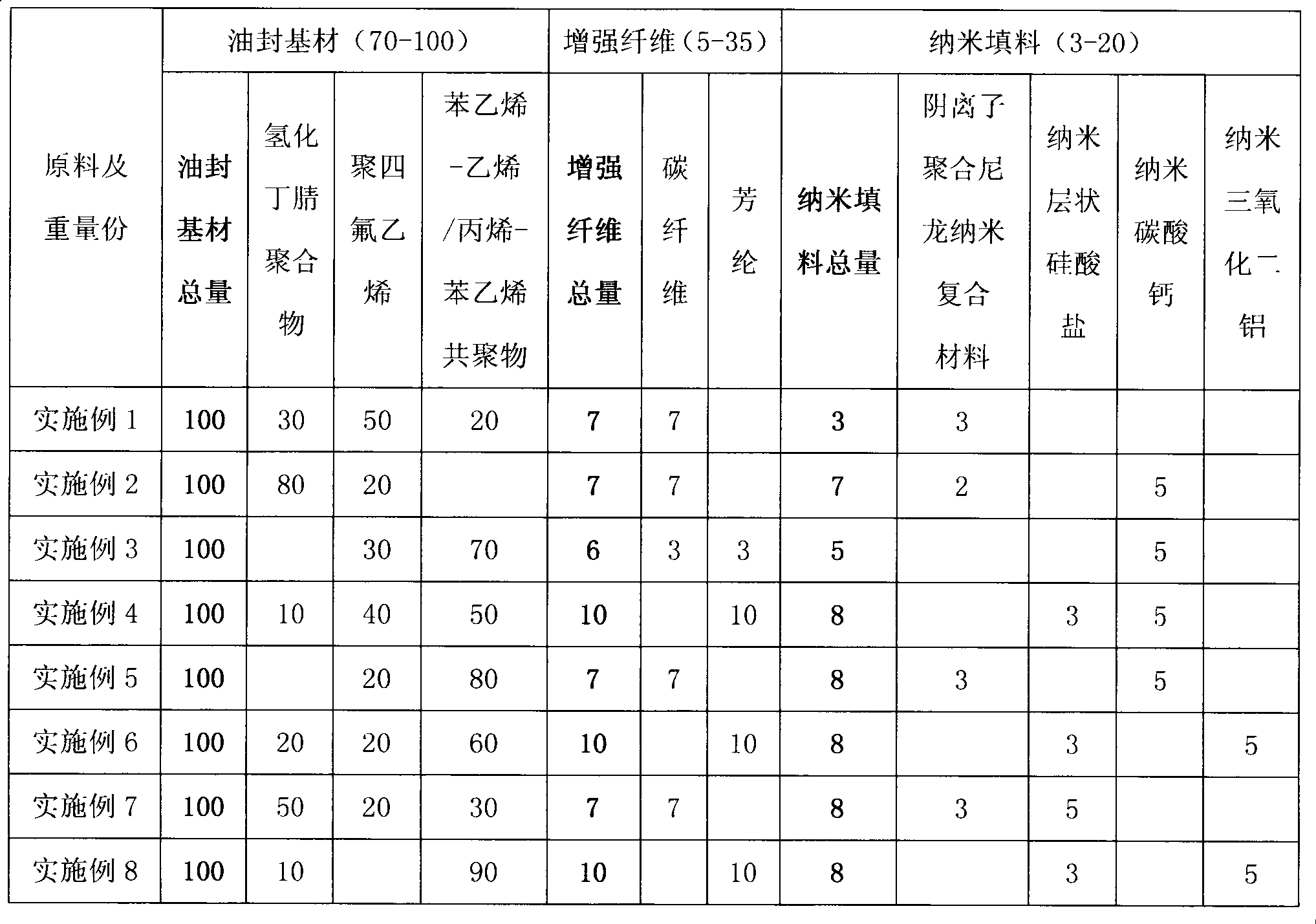

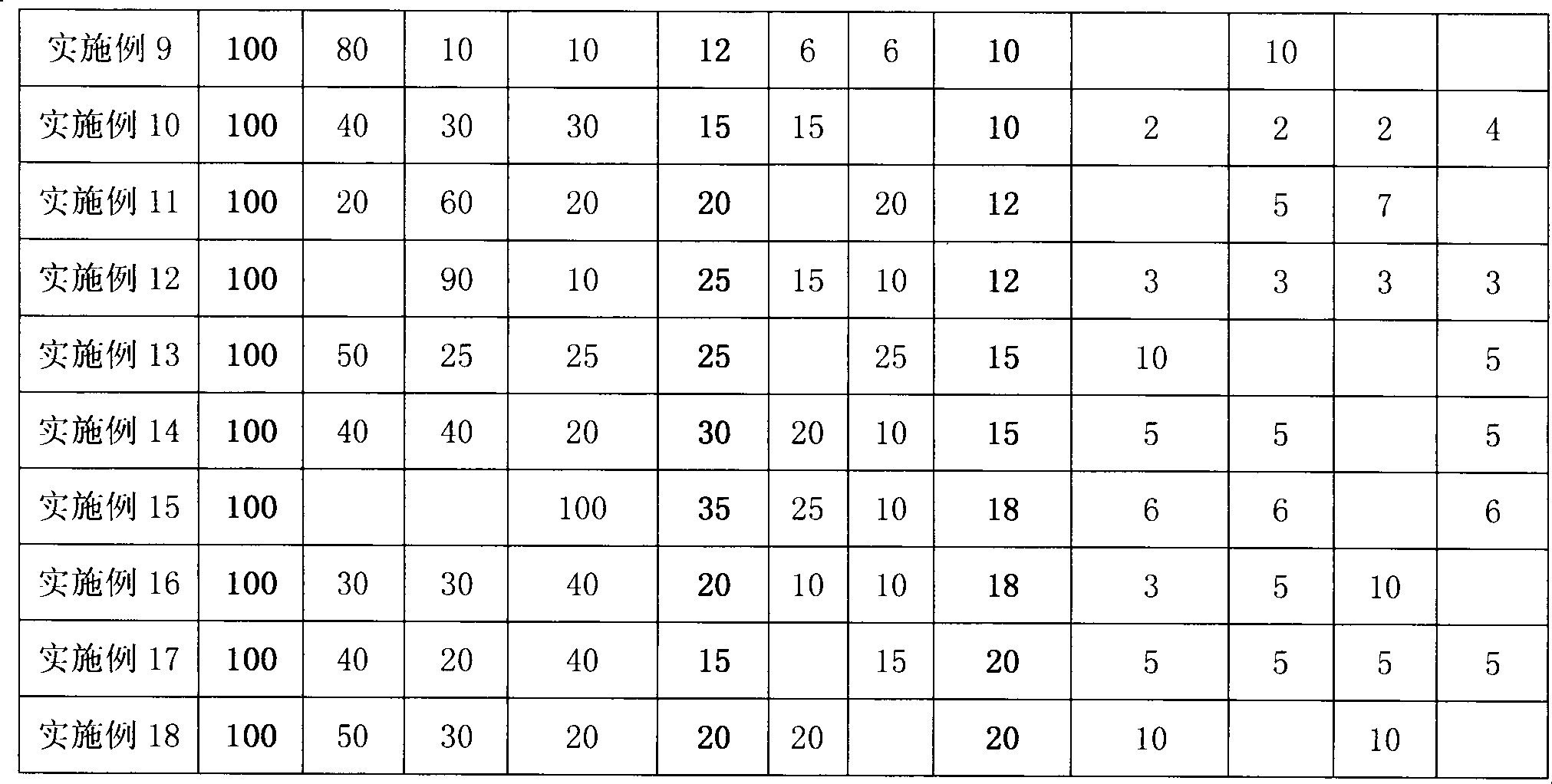

[0019]

[0020]

[0021] The above raw materials can be purchased from the market.

[0022] Among them: oil seal base material, as the basic raw material for oil seal manufacturing, its selection must consider the compatibility of the material with the working medium, the adaptability to the working temperature range and the ability of the lip to follow the rotating shaft at high speed. The present invention uses one or several of hydrogenated nitrile polymer, polytetrafluoroethylene, and styrene copolymer, and the relative ratio is arbitrary. Among them, styrene-based copolymers are selected as styrene-ethylene / propylene-styrene copolymers.

[0023] Reinforcing fiber refers to a fibrous substance that can improve the mechanical strength of the polymer and the dimensional stability of the product, reduce the shrinkage rate or reduce the thermal deformation after being compounded with the resin (polymer). In the present invention, it is recommended to use inorganic fibers and / or or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com