Bearing retainer

A technology of bearing cage and axial direction, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems affecting the matching accuracy of the concave part of the annular body and the ball, processing and assembly errors, complex shape of the concave part, etc., and achieve structural The effect of simplicity, easy processing, and small assembly errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Description with reference to the accompanying drawings.

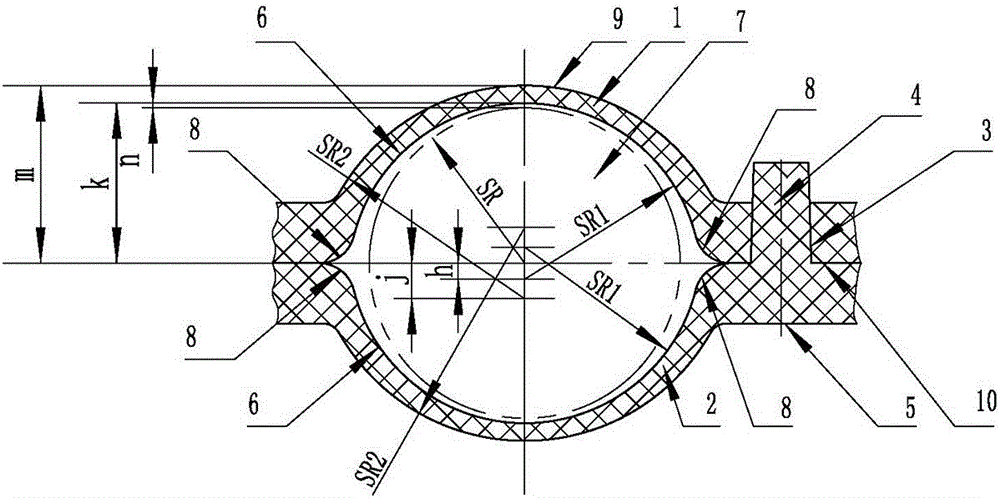

[0019] The cage of this embodiment is a corrugated ball bearing cage made of carbon fiber reinforced polyamide nylon PA66, and glass fiber is often used for reinforcement in practical applications. There is a shoulder taper hole 3 on the wavy annular body A1, a shoulder conical cylinder 4 is provided on the wavy annular body B2, a recess and a shoulder 5 on the wavy annular body A1 and the wavy annular body B2 Arranged alternately, the recesses on the two wavy annular bodies face each other to form pockets. Except that the tapered shoulder hole 3 is different from the tapered shoulder cylinder 4, the wave-shaped annular body A1 and the wave-shaped annular body B2 are identical. The shoulder joint surfaces 10 of the shoulders 5 of the two wavy annular bodies cooperate, and the shoulder conical cylinder 4 cooperates with the shoulder conical small hole 3. In the figure, the shoulder conical cylinder 4 is higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com