Single mold opening mechanism of bottle blowing machine

A bottle blowing machine, mold opening and closing technology, which is applied to household components, household appliances, other household appliances, etc., can solve the problems of difficult installation and positioning of cams, easy wear and tear of convex profile surfaces, and high requirements for processing accuracy, and achieves enhanced smooth movement. High performance and reliability, good mold clamping dynamic performance, good for vibration reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

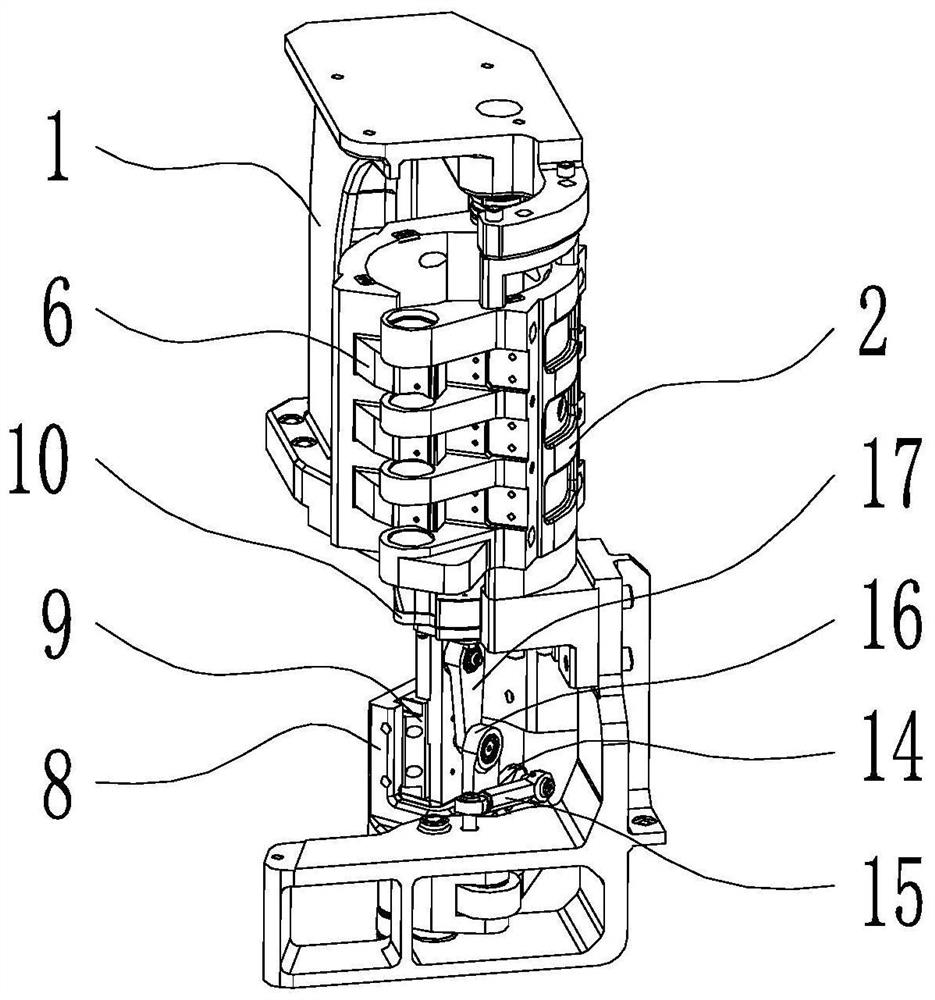

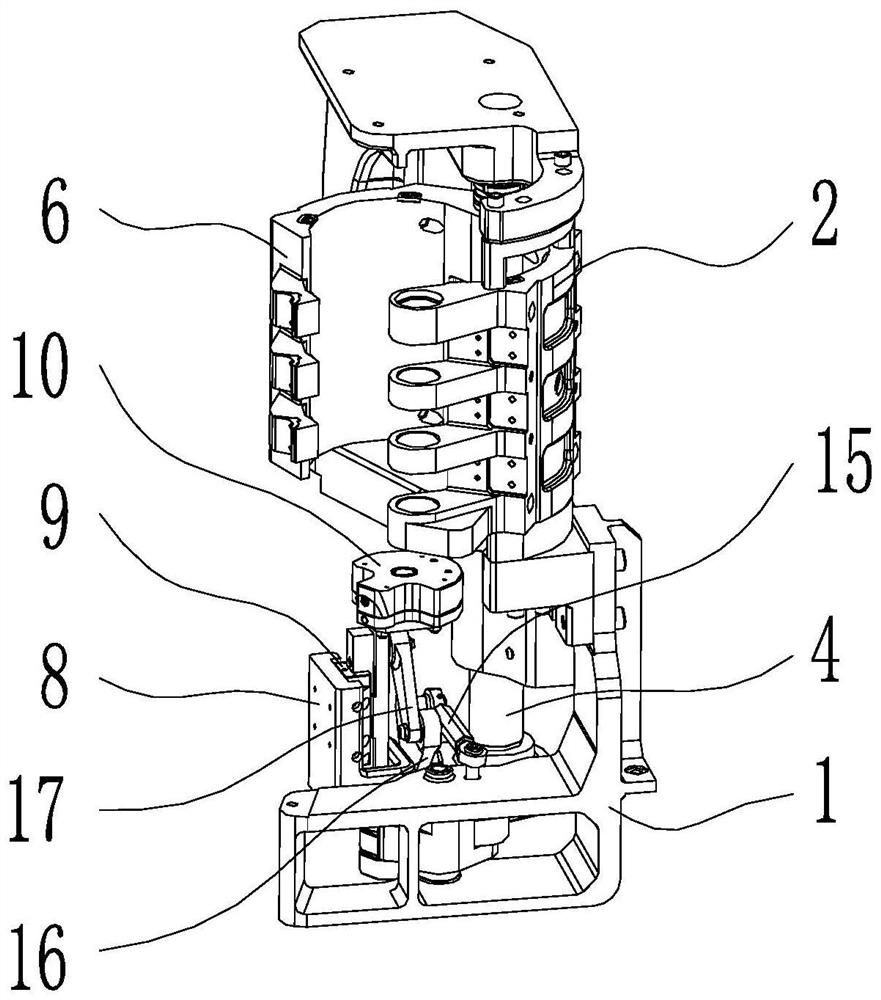

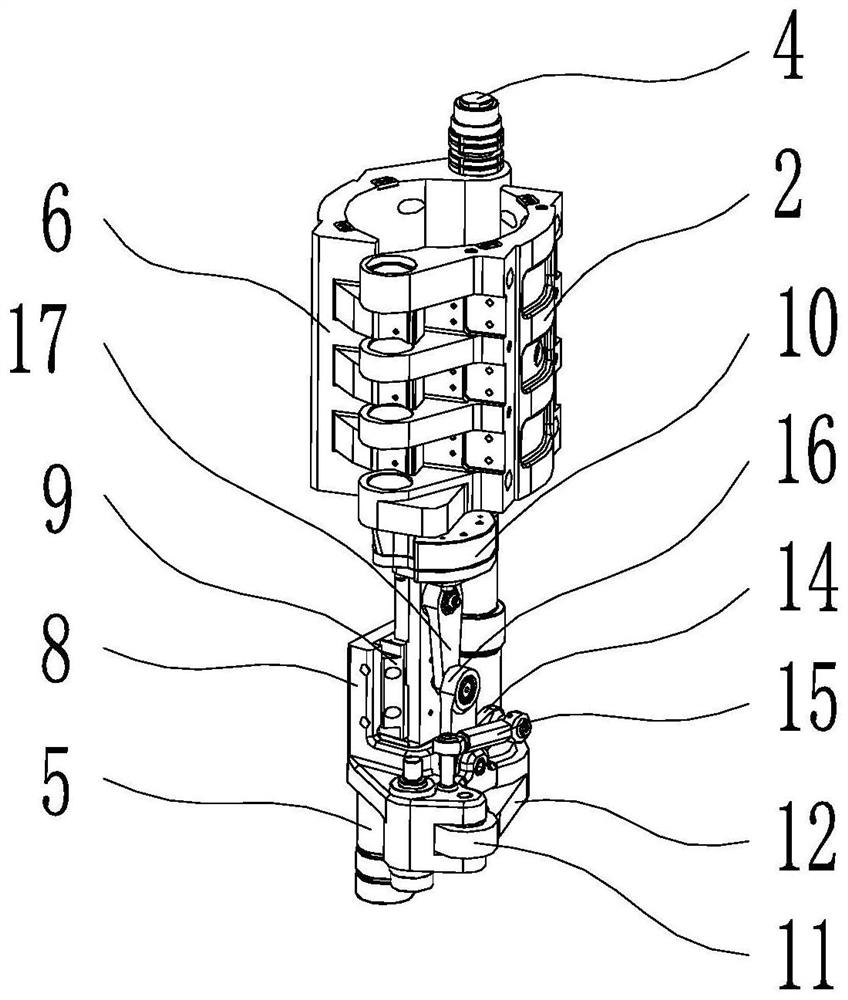

[0036] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] see Figure 1-8 As shown, the above-mentioned single mold opening mechanism of a bottle blowing machine includes a mold frame bracket 1, a fixed side mold 2 fixed on the mold frame bracket 1, and a mold frame bracket 1 that can rotate around the first axis line 3. The mold opening and closing shaft 4 on the top, the mold opening and closing rotor arm 5 that is fixedly connected to the mold opening and closing shaft 4 and used to be driven by the mold opening and closing cam, and the movable side mold 6 that is fixedly connected to the mold opening and closing shaft 4 , the bottom mold support 8 on the formwork support 1 that can rotate around the second axis 7, the bottom mold guide rail 9 fixed on the bottom mold support 8, and the bottom mold guide rail 9 that can be lifted and lowered. Die 10. The mold opening and closing cam (not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com